light FORD FIESTA 2007 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 931 of 1226

303-1 4-7 Electronic Engine Controls 303-1 4-7

DESCRIPTION AND OPERATION

Function The throttle flap position is adjusted and monitored

in a closed control loop. The TP sensor provides

I A CAUTI0N:The throttle control unit (TCU)

the PCM with the information on the actual position

must not be dismantled. No adjustments

of the throttle flap.

or repairs can be made to the TCU.

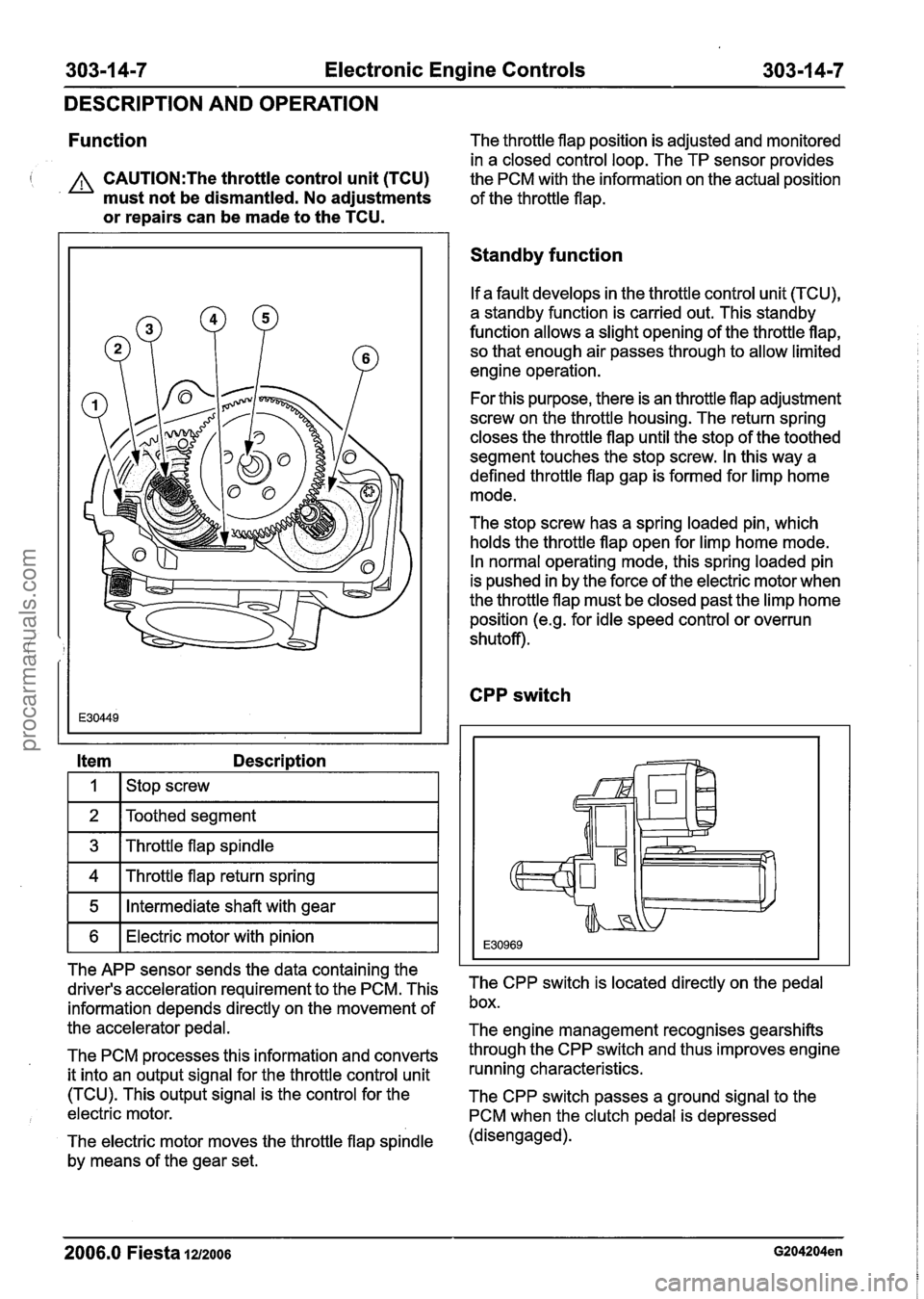

Item Description

I I I stop screw I

1 2 IToothed segment I

1 3 1 Throttle flap spindle I

1 4 1 Throttle flap return spring I

1 5 1 Intermediate shaft with gear I

1 6 1 Electric motor with pinion I

The APP sensor sends the data containing the

driver's acceleration requirement to the PCM. This

information depends directly on the movement of

the accelerator pedal.

The PCM processes this information and converts

it into an output signal for the throttle control unit

(TCU). This output signal is the control for the

electric motor.

The electric motor moves the throttle flap spindle

by means of the gear set.

Standby function

If a fault develops in the throttle control unit (TCU),

a standby function is carried out. This standby

function allows a slight opening of the throttle flap, so that enough air passes through to allow limited

engine operation.

For this purpose, there is an throttle flap adjustment

screw on the throttle housing. The return spring

closes the throttle flap until the stop of the toothed

segment touches the stop screw. In this way a

defined throttle flap gap is formed for limp home

mode.

The stop screw has a spring loaded pin, which

holds the throttle flap open for limp home mode.

In normal operating mode, this spring loaded pin

is pushed in by the force of the electric motor when

the throttle flap must be closed past the limp home

position

(e.g. for idle speed control or overrun

shutoff).

CPP switch

The CPP switch is located directly on the pedal

box.

The engine management recognises gearshifts

through the CPP switch and thus improves engine

running characteristics.

The CPP switch passes a ground signal to the

PCM when the clutch pedal is depressed

(disengaged).

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 990 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -30 Transmission (AW81-40) 307-01 -30

DESCRIPTION AND OPERATION

The transmission control unit can be diagnosed

with WDS via the DLC.

Gearshift strategies

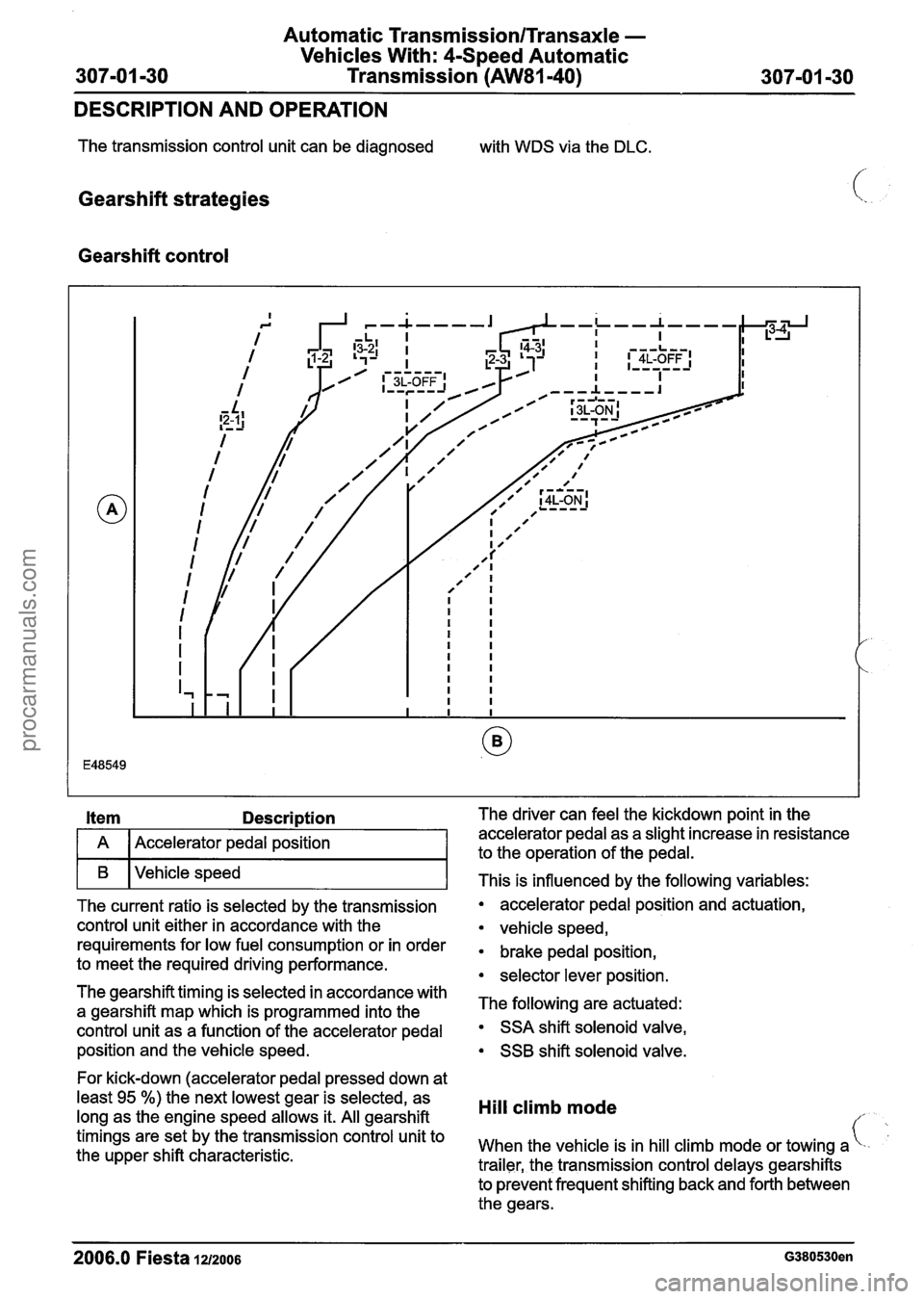

Gearshift control

I A I Accelerator pedal position I

I B I vehicle speed 1

The current ratio is selected by the transmission

control unit either in accordance with the

requirements for low fuel consumption or in order

to meet the required driving performance.

The gearshift timing is selected in accordance with

a gearshift map which is programmed into the

control unit as a function of the accelerator pedal

position and the vehicle speed.

For kick-down (accelerator pedal pressed down at

least

95 %) the next lowest gear is selected, as

long as the engine speed allows it. All gearshift

timings are set by the transmission control unit to

the upper shift characteristic. The driver can feel the

kickdown point

in the

accelerator pedal as a slight increase in resistance

to the operation of the pedal.

This is influenced by the following variables:

accelerator pedal position and actuation,

vehicle speed,

brake pedal position,

selector lever position.

The following are actuated:

SSA shift solenoid valve,

SSB shift solenoid valve.

Hill climb mode

When the vehicle is in hill climb mode or towing a

trailer, the transmission control delays gearshifts

to prevent frequent shifting back and forth between

the gears.

2006.0 Fiesta 1u2oos

procarmanuals.com

Page 1020 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -60 Transmission

(AW81-40) 307-01 -60

IN-VEHICLE REPAIR

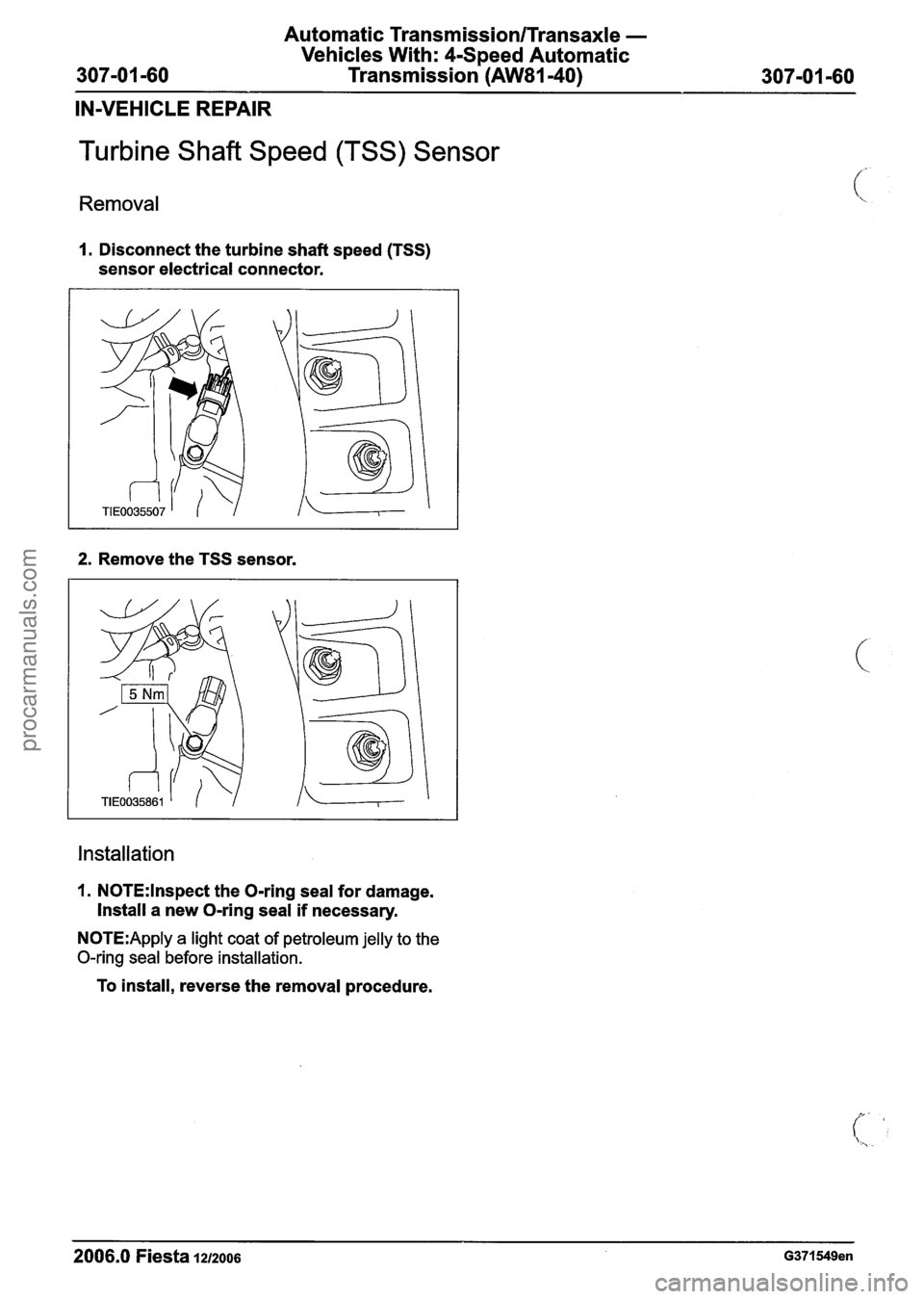

Turbine Shaft Speed (TSS) Sensor

Removal

1. Disconnect the turbine shaft speed (TSS)

sensor electrical connector.

2. Remove the TSS sensor.

Installation

1. N0TE:lnspect the O-ring seal for damage.

Install

a new O-ring seal if necessary.

N0TE:Apply a light coat of petroleum jelly to the

O-ring seal before installation.

To install, reverse the removal procedure.

2006.0 Fiesta 1212006 G371549en

procarmanuals.com

Page 1021 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -61 Transmission (AW81-40) 307-01 -61 --

IN-VEHICLE REPAIR

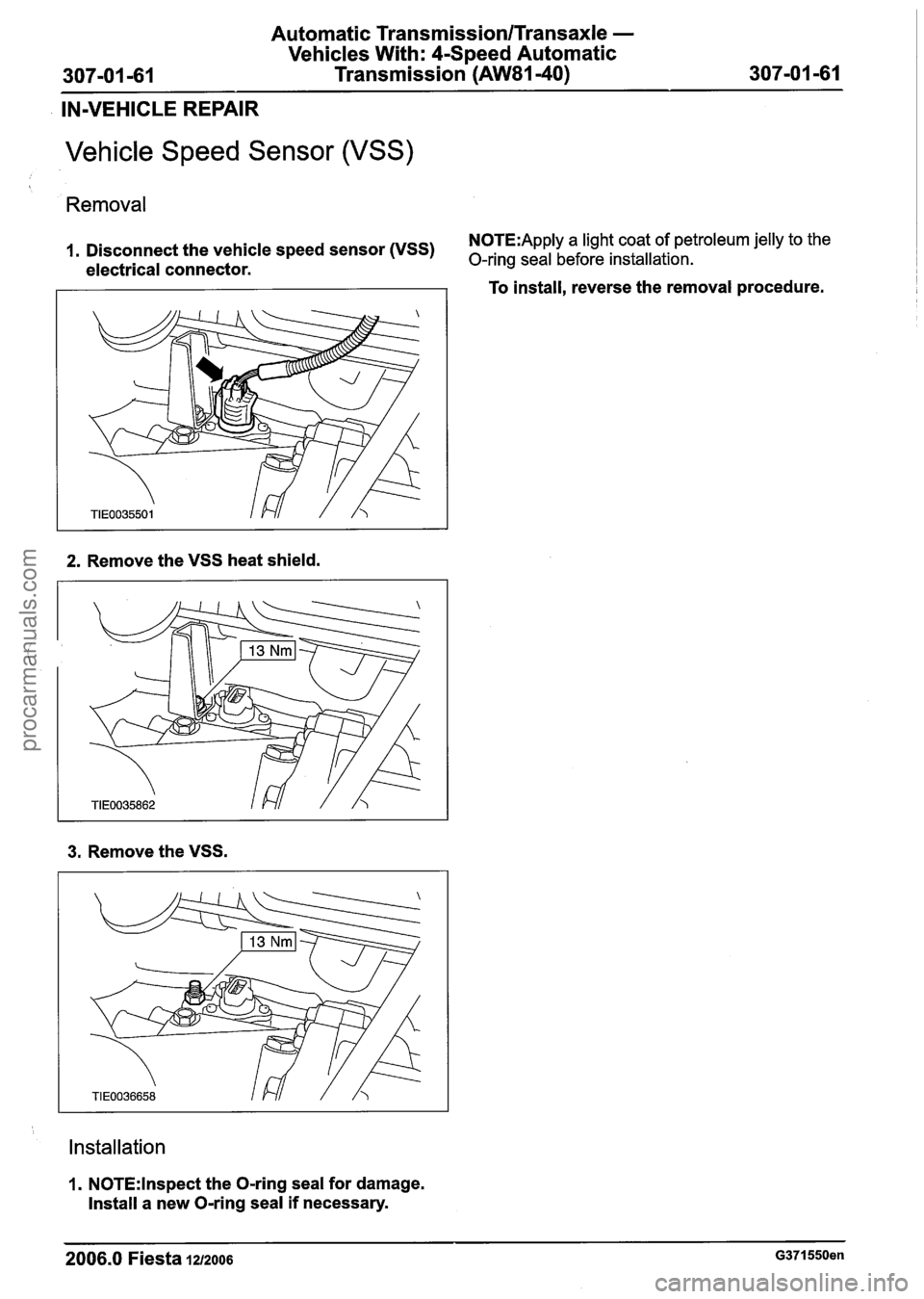

Vehicle Speed Sensor (VSS)

Removal

N0TE:Apply a light coat of petroleum jelly to the 1. Disconnect the vehicle speed sensor (VSS) O-ring seal before installation. electrical connector.

2. Remove the VSS heat shield.

3. Remove the VSS.

Installation

1. N0TE:lnspect the O-ring seal for damage.

Install a new O-ring seal if necessary. To

install, reverse the removal procedure.

2006.0 Fiesta 1212006 G371550en

procarmanuals.com

Page 1076 of 1226

308-01 4 Clutch 308-01 -4

DESCRIPTION AND OPERATION

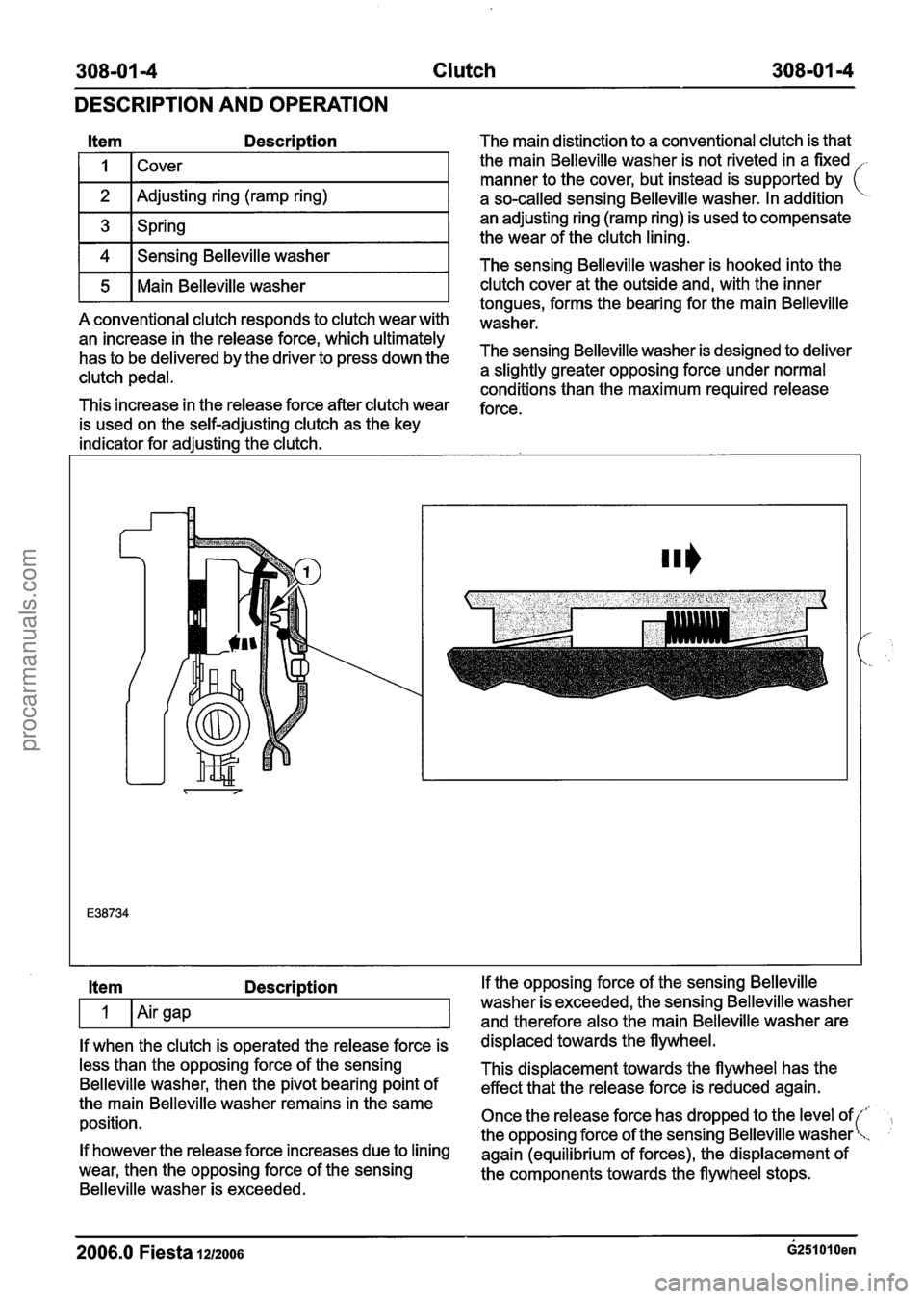

Item Description

I I 1 Cover I

1 2 I Adjusting ring (ramp ring) I

1 3 1 Spring I

1 4 1 Sensing Belleville washer I

r5 1 Main Belleville washer I

A conventional clutch responds to clutch wear with

an increase in the release force, which ultimately

has to be delivered by the driver to press down the

clutch pedal.

This increase in the release force after clutch wear

is used on the self-adjusting clutch as the key

indicator for adjusting the clutch. The main

distinction to a conventional clutch is that

the main Belleville washer is not riveted in a fixed

-

manner to the cover, but instead is supported by (

a so-called sensing Belleville washer. In addition

an adjusting ring (ramp ring) is used to compensate

the wear of the clutch lining.

The sensing Belleville washer is hooked into the

clutch cover at the outside and, with the inner

tongues, forms the bearing for the main Belleville

washer.

The sensing Belleville washer is designed to deliver

a slightly greater opposing force under normal

conditions than the maximum required release

force.

Item Description

If when the clutch is operated the release force is

less than the opposing force of the sensing

Belleville washer, then the pivot bearing point of

the main Belleville washer remains in the same

position.

If however the release force increases due to lining

wear, then the opposing force of the sensing

Belleville washer is exceeded. If the

opposing force of the sensing Belleville

washer is exceeded, the sensing Belleville washer

and therefore also the main Belleville washer are

displaced towards the flywheel.

This displacement towards the flywheel has the

effect that the release force is reduced again.

Once the release force has dropped to the level of

the opposing force of the sensing Belleville washer

again (equilibrium of forces), the displacement of

the components towards the flywheel stops.

2006.0 Fiesta lazoos ~251010en

procarmanuals.com

Page 1144 of 1226

308-03-54 Manual Transmission/Transaxle 308-0344

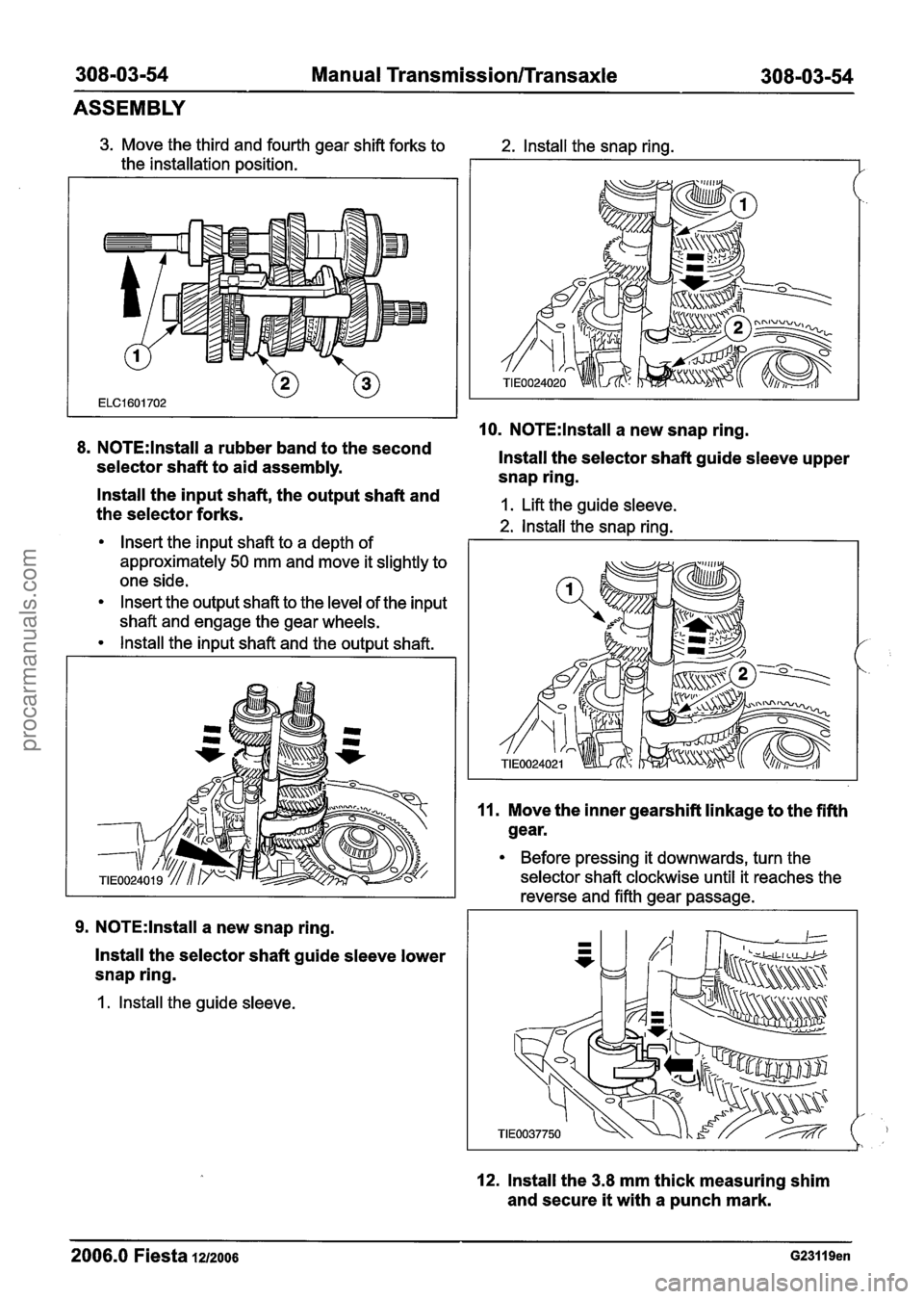

ASSEMBLY

3. Move the third and fourth gear shift forks to

the installation position.

8. N0TE:lnstall a rubber band to the second

selector shaft to aid assembly.

2. lnstall the snap ring.

10. N0TE:lnstall a new snap ring.

lnstall the selector shaft guide sleeve upper

snap ring.

- lnstall the input shaft, the output shaft and

the selector forks. 1. Lift the guide sleeve.

2. lnstall the snap rina.

Insert the input shaft to a depth of I

approximately 50 mm and move it slightly to

one side.

Insert the output shaft to the level of the input

shaft and engage the gear wheels.

lnstall the input shaft and the output shaft.

9. N0TE:lnstall a new snap ring.

lnstall the selector shaft guide sleeve lower

snap ring.

1. lnstall the guide sleeve.

11. Move the inner gearshift linkage to the fifth

gear.

Before pressing it downwards, turn the

selector shaft clockwise until it reaches the

reverse and fifth gear passage.

12. lnstall the 3.8 mm thick measuring shim

and secure

it with a punch mark.

2006.0 Fiesta 1212006 G23119en

procarmanuals.com

Page 1147 of 1226

308-03-57 Manual Transmission/Transaxle 308-03-57 I I

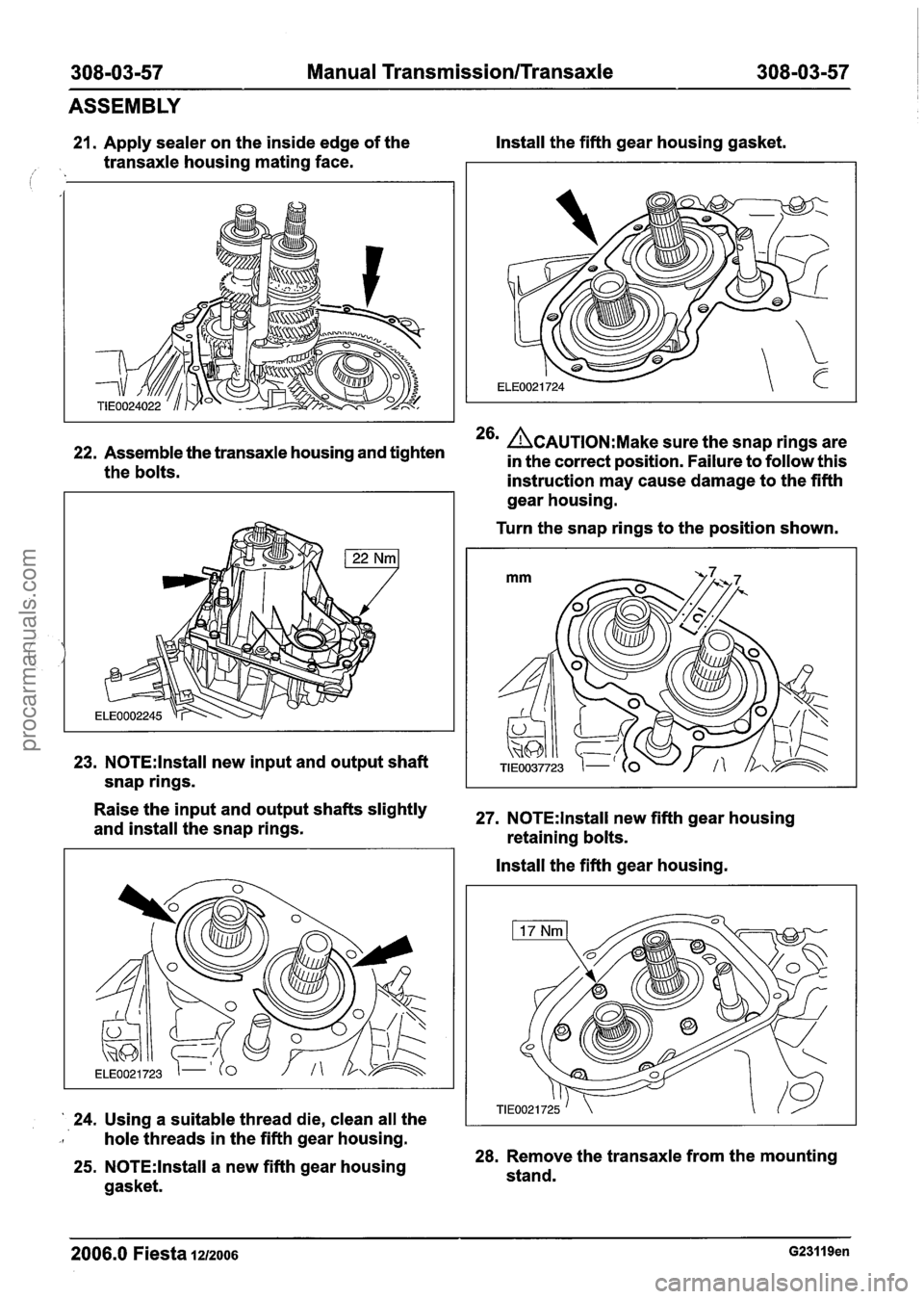

ASSEMBLY

21. Apply sealer on the inside edge of the Install

the fifth gear housing gasket.

1. transaxle housing mating face.

22. Assemble the transaxle housing and tighten 26m ACAUTION:M~~~ sure the snap rings are

in the correct position. Failure to follow this

the bolts.

instruction may cause damage to the fifth

23. N0TE:lnstall new input and output shaft

snap rings. gear

housing.

Turn the snap rings to the position shown.

Raise the and shafts 'lightly 27. NOTE:lnstall new fifth gear housing

and install the snap rings.

retaining bolts.

' 24. Using a suitable thread die, clean all the Install

the fifth gear housing.

-I hole threads in the fifth gear housing.

25. N0TE:lnstall a new fifth gear housing 28. Remove the transaxle from the mounting

stand.

gasket.

2006.0 Fiesta 1212006 G23119en

procarmanuals.com

Page 1171 of 1226

Manual Transmission/Transaxle External

Controls

REMOVAL AND INSTALLATION

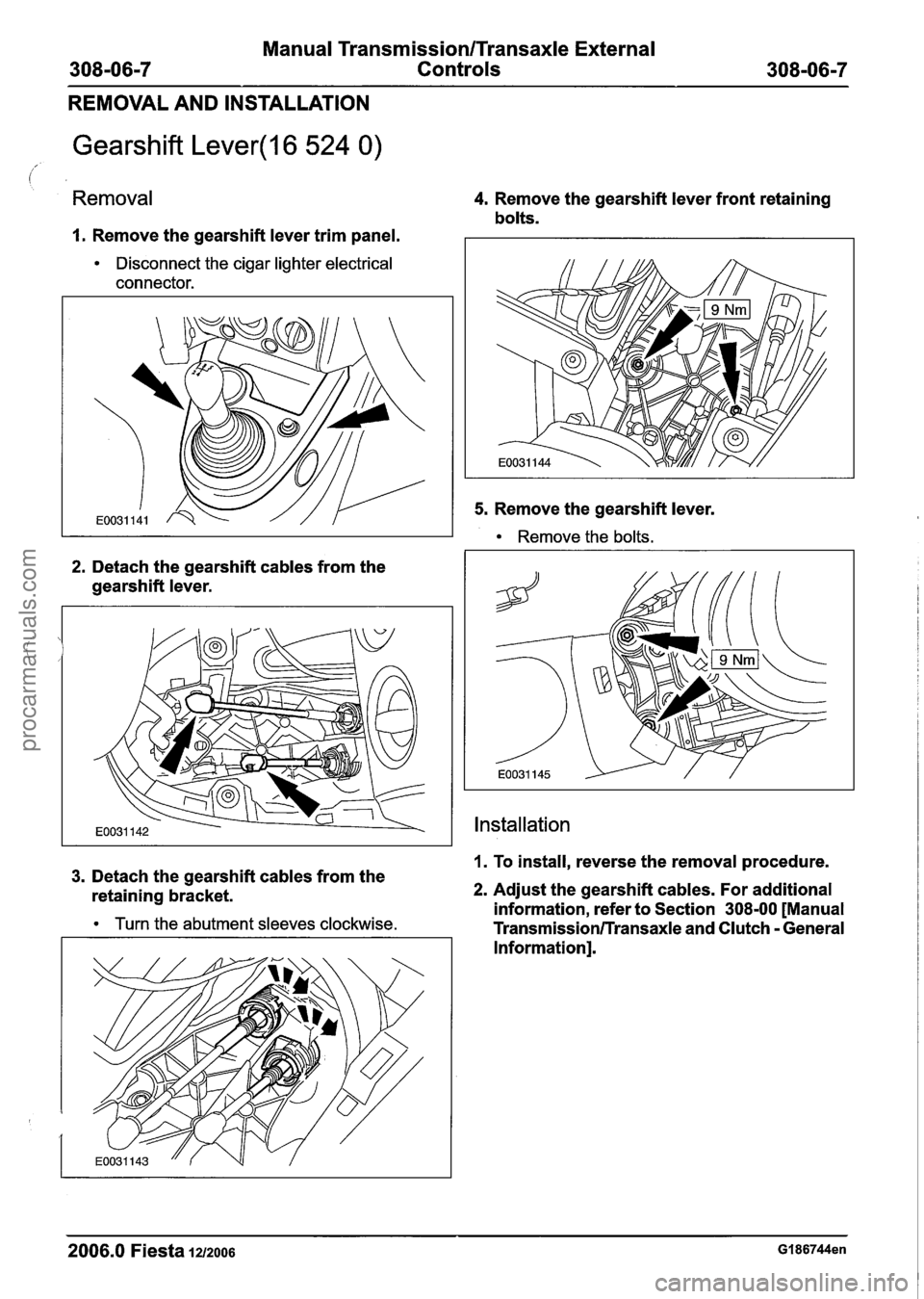

Gearshift Lever(l6 524 0)

Removal

I. Remove the gearshift lever trim panel.

Disconnect the cigar lighter electrical

connector.

2. Detach the gearshift cables from the

gearshift lever.

4. Remove the gearshift lever front retaining

bolts.

5. Remove the gearshift lever.

Remove the bolts.

Installation

1. To install, reverse the removal procedure. 3. Detach the gearshift cables from the

retaining bracket. 2. Adjust the gearshift cables. For additional

information, refer to Section

308-00 [Manual Turn the abutment sleeves clockwise. Transmission/Transaxle and Clutch - General

Information].

2006.0 Fiesta 1212006 GI 86744en

procarmanuals.com

Page 1189 of 1226

31 0-00-3 Fuel System - General Information 31 0-00-3

GENERAL PROCEDURES

/'

Fuel System Pressure Release(23 420 0)

i

Release

I. WARNINGS:

ADO not smoke or carry lighted tobacco or

open flame of any type when working on or

near any fuel related components. Highly

flammable vapors are always present and

may ignite. Failure to follow these

instructions may result in personal injury.

A~he fuel system remains pressurized for

a long time after the ignition is switched off.

The fuel pressure must be released before

attempting any repairs. Failure to follow this

instruction may result in personal injury.

Remove the fuel pump fuse.

2. Start the engine and allow to idle until the

engine stalls.

3. Crank the engine for approximately five

seconds to make sure the fuel injection

supply manifold pressure has been released.

,1 4. Install the fuel pump fuse.

2006.0 Fiesta 1212006 GI 81 91 en

procarmanuals.com

Page 1190 of 1226

31 0-00-4 Fuel System - General Information 31 0-00-4

GENERAL PROCEDURES

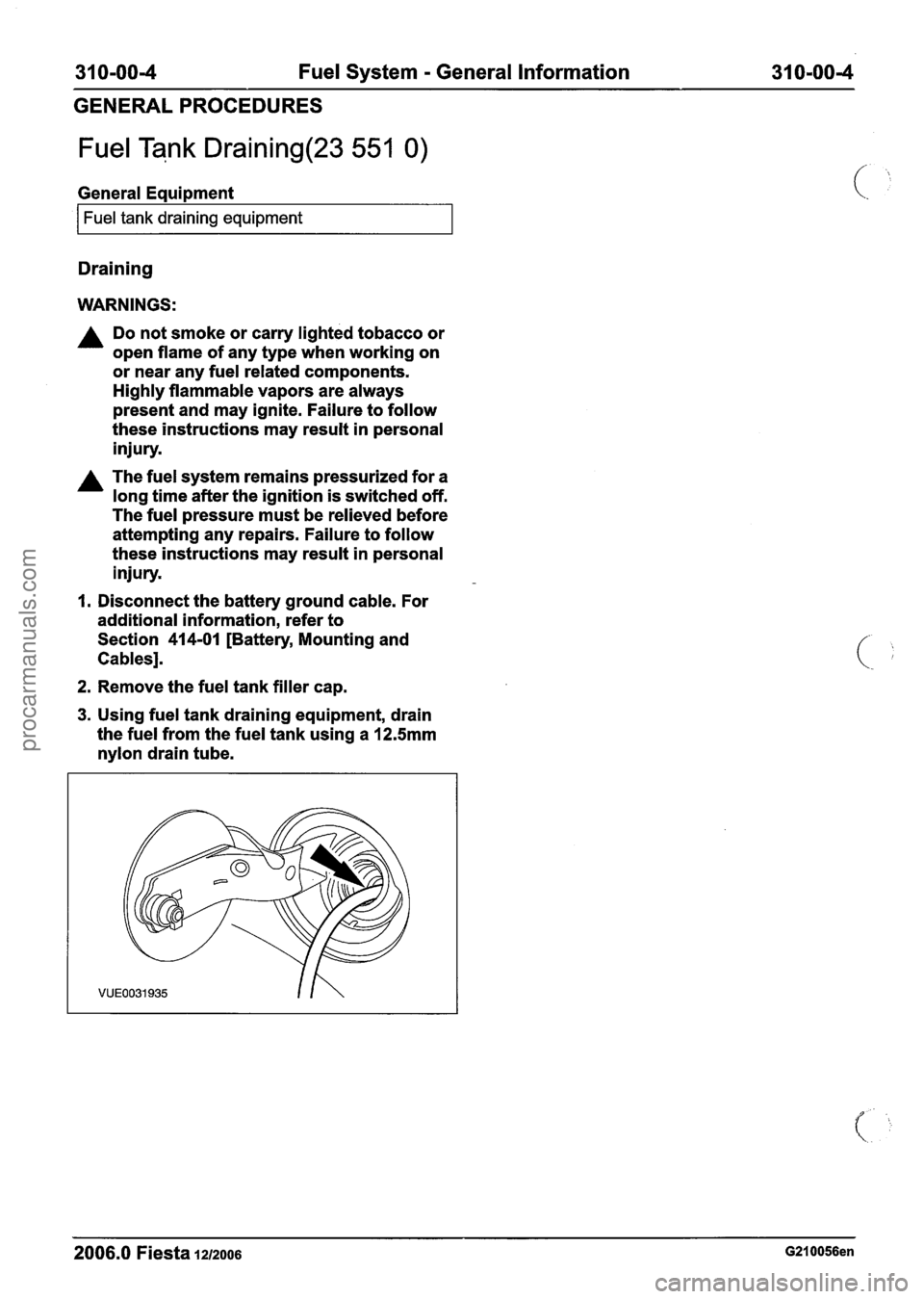

Fuel Tank Draining(23 551 0)

General Eaui~ment

I Fuel tank draining equipment I

Draining

WARNINGS:

A Do not smoke or carry lighted tobacco or

open flame of any type when working on

or near any fuel related components.

Highly flammable vapors are always

present and may ignite. Failure to follow

these instructions may result in personal

injury.

A The fuel system remains pressurized for a

long time after the ignition is switched off.

The fuel pressure must be relieved before

attempting any repairs. Failure to follow

these instructions may result in personal

injury.

I. Disconnect the battery ground cable. For

additional information, refer to

Section

414-01 [Battery, Mounting and

Cables].

2. Remove the fuel tank filler cap.

3. Using fuel tank draining equipment, drain

the fuel from the fuel tank using a

12.5mm

nylon drain tube.

2006.0 Fiesta 1212006 G210056en

procarmanuals.com