light FORD FIESTA 2007 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 192 of 1226

206-00-20 Brake System - General Information 206=00-20

DIAGNOSIS AND TESTING

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

F4: BLEED THE BRAKE SYSTEM

rn Check for air in the brake system. Bleed the

brake system. REFER to: (206-00 Brake System

- General lnformation)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Procedures)

.

Is the condition still present?

+ Yes

GO to F5.

+ No

Vehicle OK.

F5: CHECK FRONT WHEEL HUB RETAINING NUT

Check the front wheel hub retaining nut for

looseness.

Is the front wheel hub retaining nut loose?

+ Yes

INSTALL a new front wheel hub retaining nut.

REFER to: Specifications (204-01 Front

Suspension, Specifications).

Do not reuse the

frontwheel hub retaining nut.

TEST the system for normal operation.

+ No

CHECK the parking bake adjustment. REFER

to: (206-05 Parking Brake and Actuation)

Parking Brake Cable Adjustment

- Vehicles With:

Rear Drum Brakes (General Procedures),

Parking Brake Cable Adjustment

- Vehicles With:

Rear Disc Brakes (General Procedures).

PINPOINT TEST G

: BRAKE LOCK UP DURING LIGHT BRAKE PEDAL FORCE

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

I GI : ROAD TEST-THE VEHICLE I

Road test the vehicle and apply the brake pedal

lightly.

Do the rear brakes lock up?

+ Yes

GO to G2. GO to Pinpoint Test G.

+ No

Vehicle OK.

2006.0 Fiesta 12/2006 G28494en

procarmanuals.com

Page 196 of 1226

206-00-24 Brake System - General Information 206-00-24

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

12: ROAD TEST THE VEHICLE

rn Road test the vehicle and apply the brakes.

Are the brakes functioning correctly?

-+ Yes

Vehicle OK.

+ No

INSPECT individual wheel cylinders or

calipers for binding or sticking components.

INSTALL new components as necessary.

BLEED the brake system. REFER to: (206-00

Brake System

- General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General Procedures).

TEST the system for normal operation.

PINPOINT TEST J

: EXCESSIVE BRAKE PEDAL EFFORT

TEST CONDITIONS

DETAILSIRESULTSIACTIONS

J1: CHECK BRAKE APPLICATION

With the engine off, apply and release the brake

pedal five times to deplete all vacuum from the

brake booster. Apply the brake pedal, hold with

light pressure. Start the engine.

Does the brake pedal hold?

+ Yes

GO to J2.

+ No

GO to J6.

52: CHECK BRAKE BOOSTER FOR LEAKS

rn Run the engine at medium idle, release the

accelerator pedal and turn the engine off. Wait

90 seconds and apply the brakes. Two or more

brake applications should be power assisted.

Does the brake booster work?

+ Yes

Vehicle OK.

-+ No

GO to

J3.

2006.0 Fiesta 1212006 G28494en

procarmanuals.com

Page 201 of 1226

206-00-29 Brake System - General Information 206-00-29

DIAGNOSIS AND TESTING

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in

NEUTRAL.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for vacuum to replenish the

brake booster.

N0TE:This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving

downward or an increased resistance to the

pedal travel occurs.

5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

N0TE:The additional movement of the brake pedal

is the result of the increased engine intake manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that

the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

lnspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed 2.

With the transaxle in NEUTRAL, stop the engine

and apply the parking brake. Apply the brake

pedal several times to exhaust all vacuum in

the system.

3. With the engine turned off and all vacuum in the

system exhausted, apply the brake pedal and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

4. Remove the vacuum hose from the brake

booster.

Intake manifold vacuum should be

available at the brake booster end of the hose

with the engine at idle speed and the transaxle

in NEUTRAL. Make sure that all unused vacuum

outlets are correctly capped, hose connectors

are correctly secured and vacuum hoses are in

good condition. When it is established that

manifold vacuum is available to the brake

booster, connector the vacuum hose to the

brake booster and repeat Step

3. If no

downward movement of the brake pedal is felt,

install a new brake booster. REFER to: (206-07

Power Brake Actuation)

Brake Booster

- LHD (Removal and lnstallation),

Brake Booster

- RHD (Removal and lnstallation).

5. Operate the engine a minimum of 10 seconds

at fast idle. Stop the engine and let the vehicle

stand for

10 minutes. Then, apply the brake

pedal with approximately 89

N (20 lb) force. The

pedal feel (brake application) should be the

same as that noted with the engine operating.

If the brake pedal feels hard (no power assist),

install a new vacuum check valve and then

repeat the test. If the brake pedal still feels hard,

install a new brake booster. REFER to: (206-07

Power Brake Actuation)

Brake Booster

- LHD (Removal and Installation),

Brake Booster

- RHD e em oval and installation).

If the brake pedal movement feels spongy, bleed

the brake system. REFER to: (206-00 Brake

System

- General Information)

areas. Inspect the check valve on the brake booster Brake System Bleeding (General Procedures),

for damage. Brake

System Pressure Bleeding (General

Procedures).

Brake Booster Operation Check

Brake Master Cylinder

1. Check the hydraulic brake system for leaks or

low fluid. Usually,

the first and strongest indicator of anything

wrong with the braking system is a feeling through

the brake pedal. In diagnosing the condition of the

brake master cylinder, check pedal feel as

2006.0 Fiesta 1212006 G28494en I

i

procarmanuals.com

Page 202 of 1226

Brake System - General Information

DIAGNOSIS AND TESTING

evidence of a brake concern. Check for the brake

warning indicator illumination and the fluid level in

the master cylinder reservoir.

Normal Conditions

The following conditions are considered normal

and are not indications that the brake master

cylinder is in need of service.

- Modern brake systems are not designed to

produce as hard a pedal effort as in the past.

Complaints of light pedal efforts should be

compared to pedal efforts of another vehicle, of

the same model and year.

- During normal operation of the brake the fluid

level in the reservoir will rise during brake

application and fall during release. The net fluid

level

(i.e., after brake application and release)

will remain unchanged.

- A trace of brake fluid will exists on the brake

booster shell below the master cylinder

mounting flange. This results from the normal

lubricating action of the master cylinder bore

end seal.

- The fluid level will fall with brake shoe and lining

wear.

Abnormal Conditions

N0TE:Prior to performing any diagnosis, make

sure the brake system warning indicator is

functional.

Changes in brake pedal feel or travel are indicators

that something could be wrong with the braking system. The diagnostic procedure and techniques

use brake pedal feel, warning indicator illumination

and low brake fluid level as indicators in diagnosing

braking system concerns. The following conditions

are considered abnormal and indicate that the

brake master cylinder is in need of service.

- The brake pedal effort is excessive. This may

be caused by a bind or obstruction in the pedal

.

or linkage, clogged fluid control valve or ( ' insufficient booster vacuum.

- The rear brakes lock up during light pedal force.

This may be caused by incorrect tire pressures,

grease or fluid on the brake shoes and linings,

damaged brake shoes and linings, incorrectly

adjusted parking brake, or damaged or

contaminated brake pressure control valves.

- The brake pedal effort is erratic. This condition

could be caused by a brake booster malfunction,

extreme caliper piston knock back or incorrectly

installed brake shoes and linings.

- The brake warning indicator is ON. This may

be caused by low fluid level, ignition wire routing

too close to the fluid level indicator assembly,

or float assembly damage.

Bypass Condition Test

1. Check the fluid in brake master cylinder. Fill the

brake master cylinder reservoir if low or empty.

2. Observe the fluid level in the brake master

cylinder reservoir. If after several brake

applications, the fluid level remains the same,

measure the wheel turning torque required to

rotate the wheels with the brakes applied as

follows:

Place the transaxle in NEUTRAL and raise and

support the vehicle. REFER to: (1 00-02 Jacking

and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

Apply the brakes with a minimum of 445 N (100

Ib) and hold for approximately 15 seconds. With

the brakes still applied, exert a torque on the front

wheels of 10.1 Nm (75

1b.R). If either wheel rotates,

install a new brake master cylinder. REFER to:

(206-06 Hydraulic Brake Actuation)

- The brake pedal goes down fast. This could be Brake Master Cylinder - RHD (Removal and

caused by an external or internal leak. Installation),

- The brake

pedal eases down slowly. This could Brake Master Cylinder - LHD

(Removal and

be caused by an external or internal leak. Installation).

- The

brake pedal is low and or feels spongy. This

condition may be caused by no fluid in the brake

Non-Pressure Leaks master cylinder reservoir, reservoir cap vent

holes clogged or air in the hydraulic system.

Any empty brake master cylinder reservoir

condition may be caused by two types of

non-pressure external leaks.

2006.0 Fiesta 1212006

procarmanuals.com

Page 358 of 1226

21 1-02-1 0 Power Steering 21 1-02-1 0

REMOVAL AND INSTALLATION

Power Steering Pump - 2.OL Duratec-HE (M14)

f

I I Remover, Power Steering I

1 I Installer, Camshaft Pulley 1

7 I Removerllnstaller, Cooling I

1. Remove the right-hand headlamp assembly.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation).

2. Remove the accessory drive belt.

For additional information, refer to:

Accessory Drive Belt

- 2.OL Duratec-HE

(M14) (303-05 Accessory Drive, Removal

and Installation).

I

3. Detach the power steering pump to steering

, gear pressure line from the intake manifold. I

1 4. Lower the vehicle.

5. Remove the components in the order

indicated in the following

illustration(s) and

table(s).

2006.0 Fiesta 1212006 G428496en

procarmanuals.com

Page 368 of 1226

21 1-02-20 Power Steering 211 -02-20

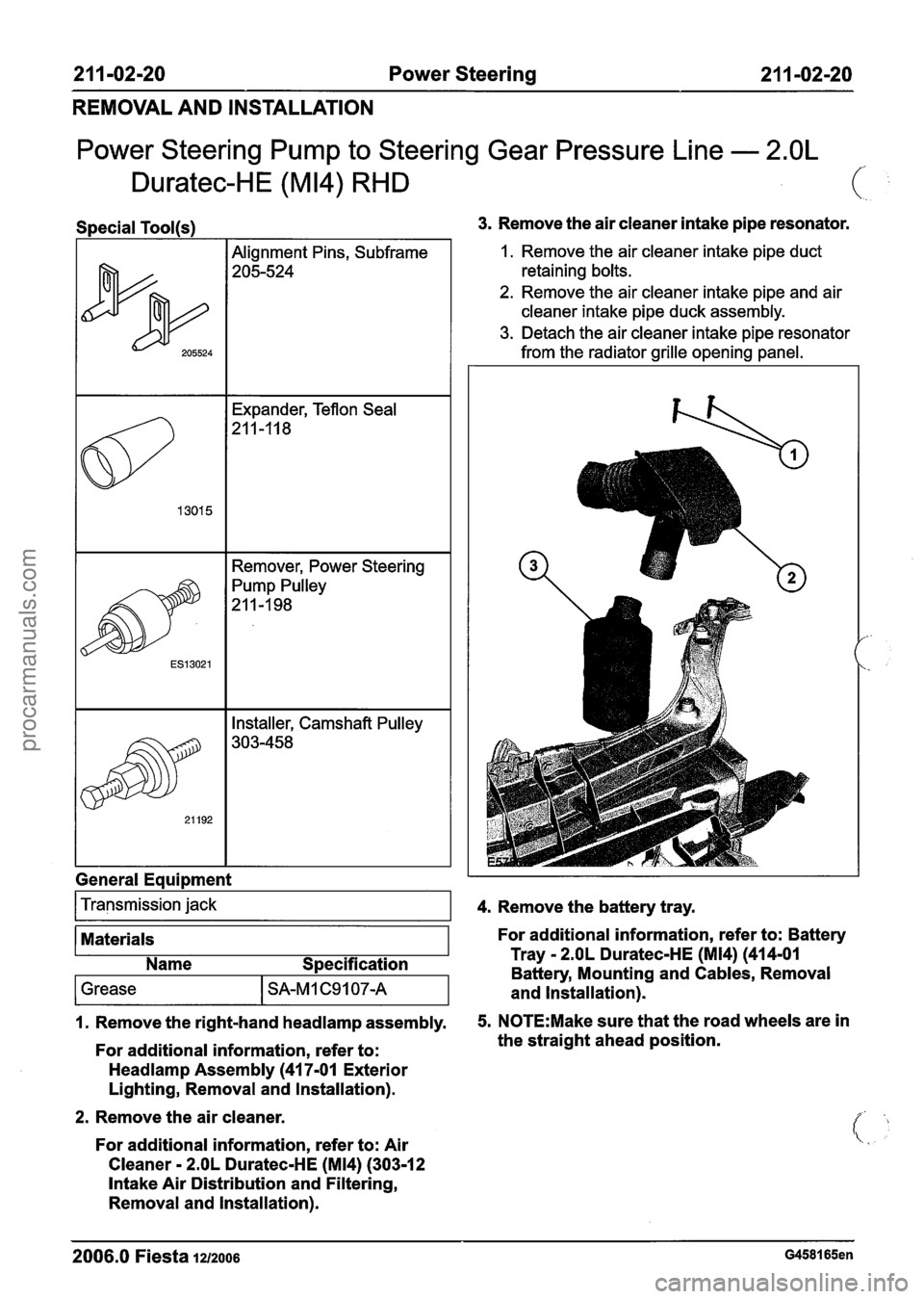

REMOVAL AND INSTALLATION

Power Steering Pump to Steering Gear Pressure Line - 2.OL

Duratec-HE (M14) RHD

Special Tool(s)

I

- -

I Remover, Power Steering I

General Equipment 3.

Remove the air cleaner intake pipe resonator.

1. Remove the air cleaner intake pipe duct

retaining bolts.

2. Remove the air cleaner intake pipe and air

cleaner intake pipe duck assembly.

3. Detach the air cleaner intake pipe resonator

from the radiator grille opening panel.

Transmission jack

1. Remove the right-hand headlamp assembly. 5. N0TE:Make sure that the road wheels are in

For additional information, refer to: the

straight ahead position.

4.

Remove the battery tray.

Materials

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation). For additional information, refer

to: Battery

2. Remove the air cleaner.

For additional information, refer to: Air

Cleaner

- 2.OL Duratec-HE (M14) (303-1 2

Intake Air Distribution and Filtering,

Removal and Installation).

Name

Specification Tray

- 2.OL Duratec-HE (M14) (414-01

Battery, Mounting and Cables, Removal

2006.0 Fiesta 1212006 G458165en

1 Grease I SA-M 1 C9 1 07-A and Installation).

procarmanuals.com

Page 439 of 1226

303-00-1 7 Engine System - General Information 303-00-1 7

DIAGNOSIS AND TESTING

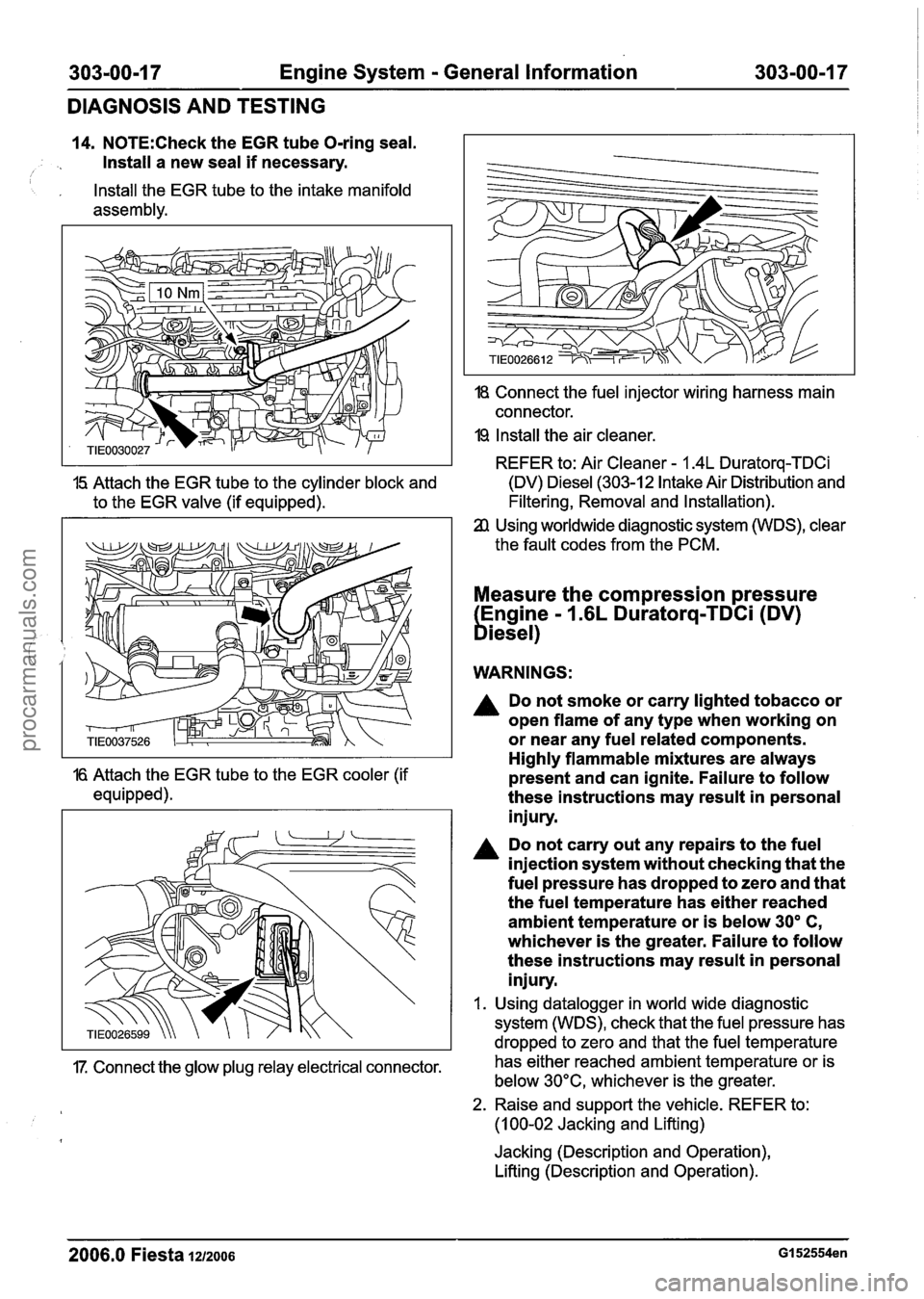

14. N0TE:Check the EGR tube O-ring seal.

Install a new seal

if necessary. I

, Install the EGR tube to the intake manifold

assembly.

18 Connect the fuel injector wiring harness main

connector.

19 Install the air cleaner.

REFER to: Air Cleaner

- 1.4L Duratorq-TDCi

15 Attach the EGR tube to the cylinder block and (DV) Diesel (303-12 Intake Air Distribution

and

to the EGR valve (if equipped). Filtering, Removal

and Installation).

Using worldwide diagnostic system (WDS), clear

the fault codes from the PCM.

Measure the compression pressure

Engine

- 1.6L Duratorq-TDCi (DV)

biesel)

WARNINGS:

A Do not smoke or carry lighted tobacco or

open flame of any type when working on

or near any fuel related components.

Highly flammable mixtures are always

16 Attach the EGR tube to the EGR cooler (if present and can ignite. Failure to follow

equipped). these instructions may result in personal

injury.

Do not carry out any repairs to the fuel

injection system without checking that the

fuel pressure has dropped to zero and that

the fuel temperature has either reached

ambient temperature or is below

30' C,

whichever is the greater. Failure to follow

these instructions may result in personal

injury.

I. Using datalogger in world wide diagnostic

system (WDS), check that the fuel pressure has

dropped to zero and that the fuel temperature

17. Connect the glow plug relay electrical connector. has

either reached ambient temperature or is

below 30°C, whichever is the greater.

2. Raise and support the vehicle. REFER to:

(1 00-02 Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 443 of 1226

303-00-21 Engine System - General Information 303-00-21

DIAGNOSIS AND TESTING

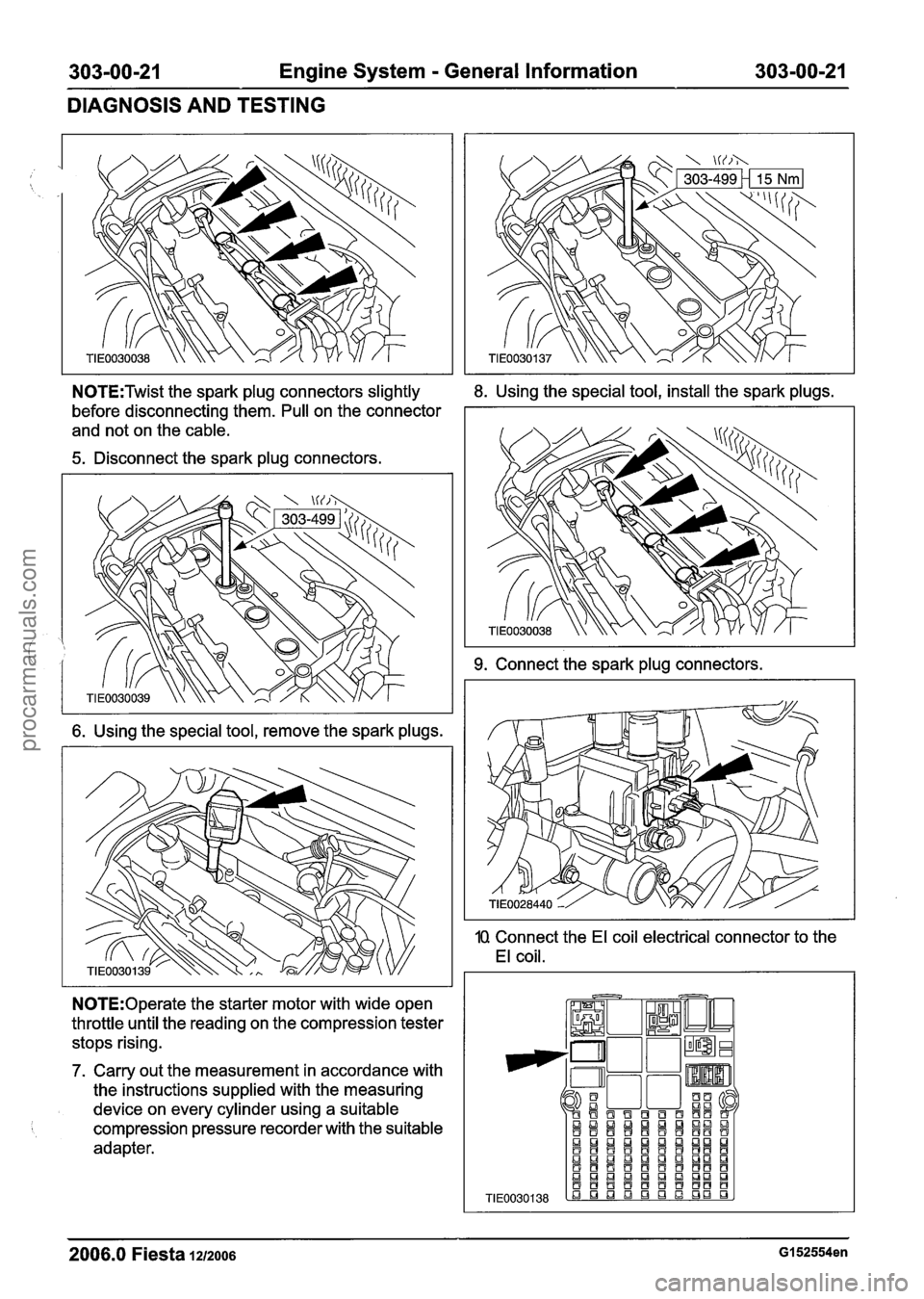

N0TE:Twist the spark plug connectors slightly 8. Using the special tool, install the spark plugs.

before disconnecting them. Pull on the connector

and not on the cable.

5. Disconnect the spark plug connectors.

6. Using the special tool, remove the spark plugs.

N0TE:Operate the starter motor with wide open

throttle until the reading on the compression tester

stops rising.

7. Carry out the measurement in accordance with

the instructions supplied with the measuring

device on every cylinder using a suitable

compression pressure recorder with the suitable

adapter.

9. Connect the spark plug connectors.

10 Connect the El coil electrical connector to the

El coil.

2006.0 Fiesta 1212006 GI 52554en

TIE0030138

QI!J!J!J~QUQI!J!J aaaaaaaaaa aBQnQIamman aBBaaaBBt3B a!JQ!JaLlnQma aaaaaaBBaf3 aaQaaQmQDa ~a~f3~B~~~B .a q q q L! q gD

procarmanuals.com

Page 444 of 1226

303-00-22 Engine System - General Information 303-00-22

DIAGNOSIS AND TESTING

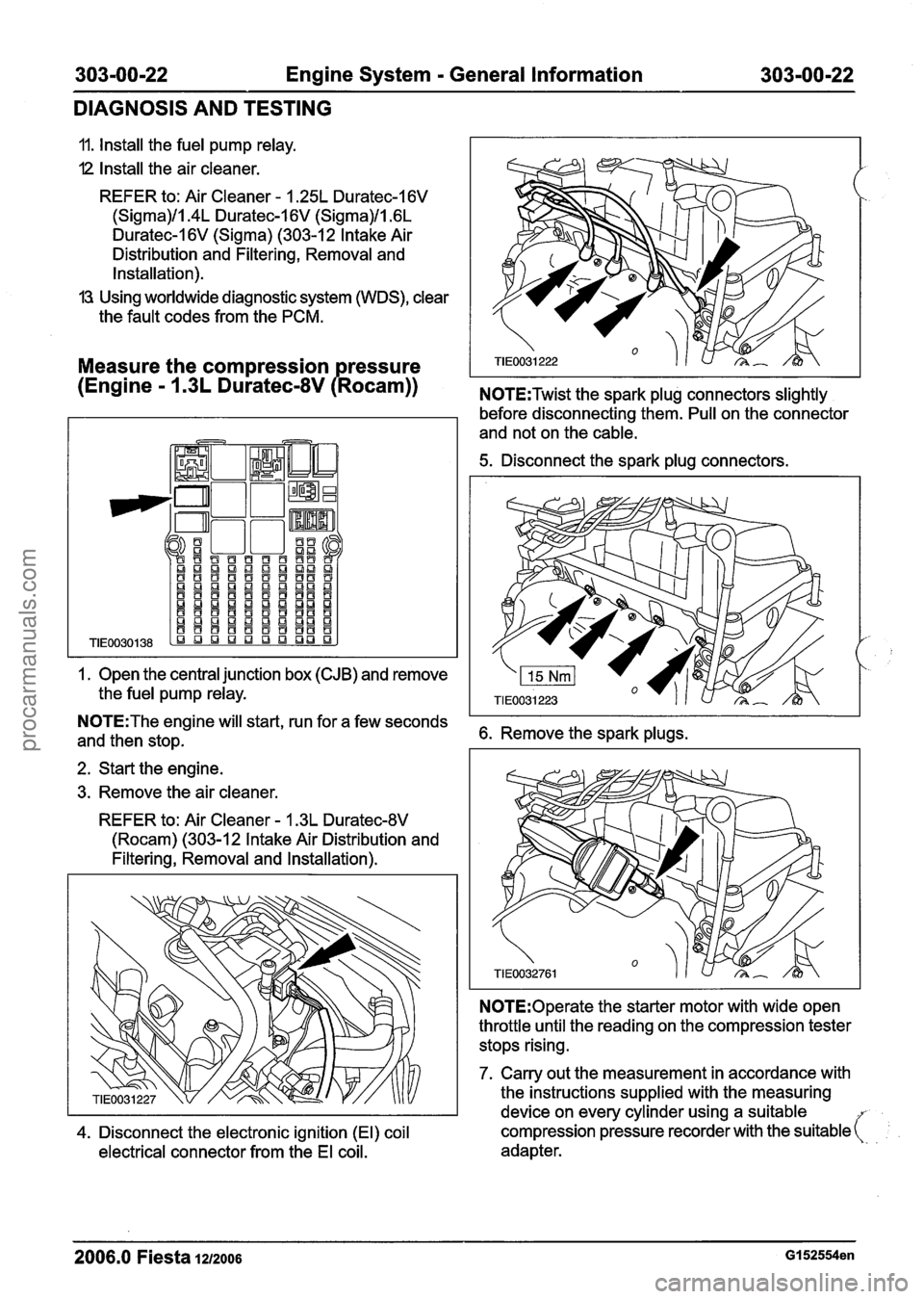

11. Install the fuel pump relay.

I2 Install the air cleaner.

REFER to: Air Cleaner - 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-16V (Sigma)/l .6L

Duratec-I 6V (Sigma) (303-1 2 Intake Air

Distribution and

Filtering, Removal and

Installation).

13 Using worldwide diagnostic system (WDS), clear

the fault codes from the PCM.

Measure the compression ressure

(Engine

- 1 .3L Duratec-8V P Rocam)) N0TE:Twist the spark plug connectors slightly

1. Open the

central junction box (CJB) and remove

the

fuel pump relay.

before disconnecting them. Pull on the connector

and not on the

cable.

5. Disconnect the spark plug connectors.

N0TE:The engine will start, run for a few seconds

and then stop. 6. Remove the spark plugs.

2. Start the engine.

3. Remove the air

cleaner.

REFER to: Air Cleaner - 1.3L Duratec-8V

(Rocam) (303-12 Intake Air Distribution and

Filtering, Removal and Installation).

N0TE:Operate the starter motor with wide open

throttle until the reading on the compression tester

stops rising.

7. Carry out the measurement in accordance with

the instructions

supplied with the measuring

device on every

cylinder using a suitable

4. Disconnect the electronic ignition (El) coil compression pressure recorder

with the suitable (:

electrical connector from the El coil. adapter.

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com

Page 446 of 1226

303-00-24 Engine System - General Information 303-00-24

DIAGNOSIS AND TESTING

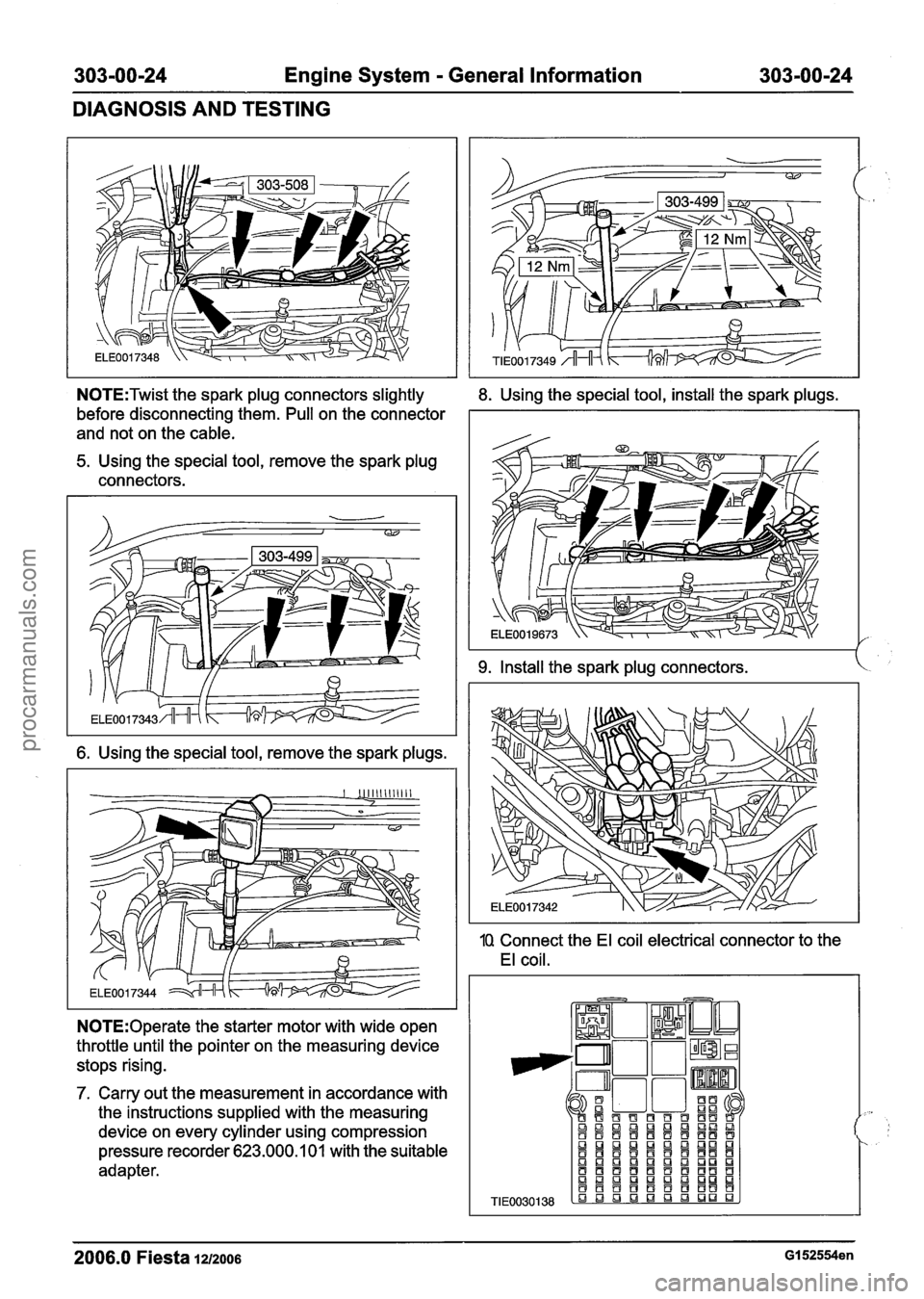

N0TE:Twist the spark plug connectors slightly

before disconnecting them. Pull on the connector

and not on the cable.

5. Using the special tool, remove the spark plug

connectors.

6. Using the special tool, remove the spark plugs.

N0TE:Operate the starter motor with wide open

throttle until the pointer on the measuring device stops rising.

7. Carry out the measurement in accordance with

the instructions supplied with the measuring

device on every cylinder using compression

pressure recorder 623.000.1 01 with the suitable

adapter.

8. Using the special tool, install the spark plugs.

9. Install the spark plug connectors. k

1Q Connect the El coil electrical connector to the

El coil.

TIE

2006.0 Fiesta 1212006 GI 52554en

procarmanuals.com