battery FORD FIESTA 2007 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 871 of 1226

303-06-7 Starting System 303-06-7

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

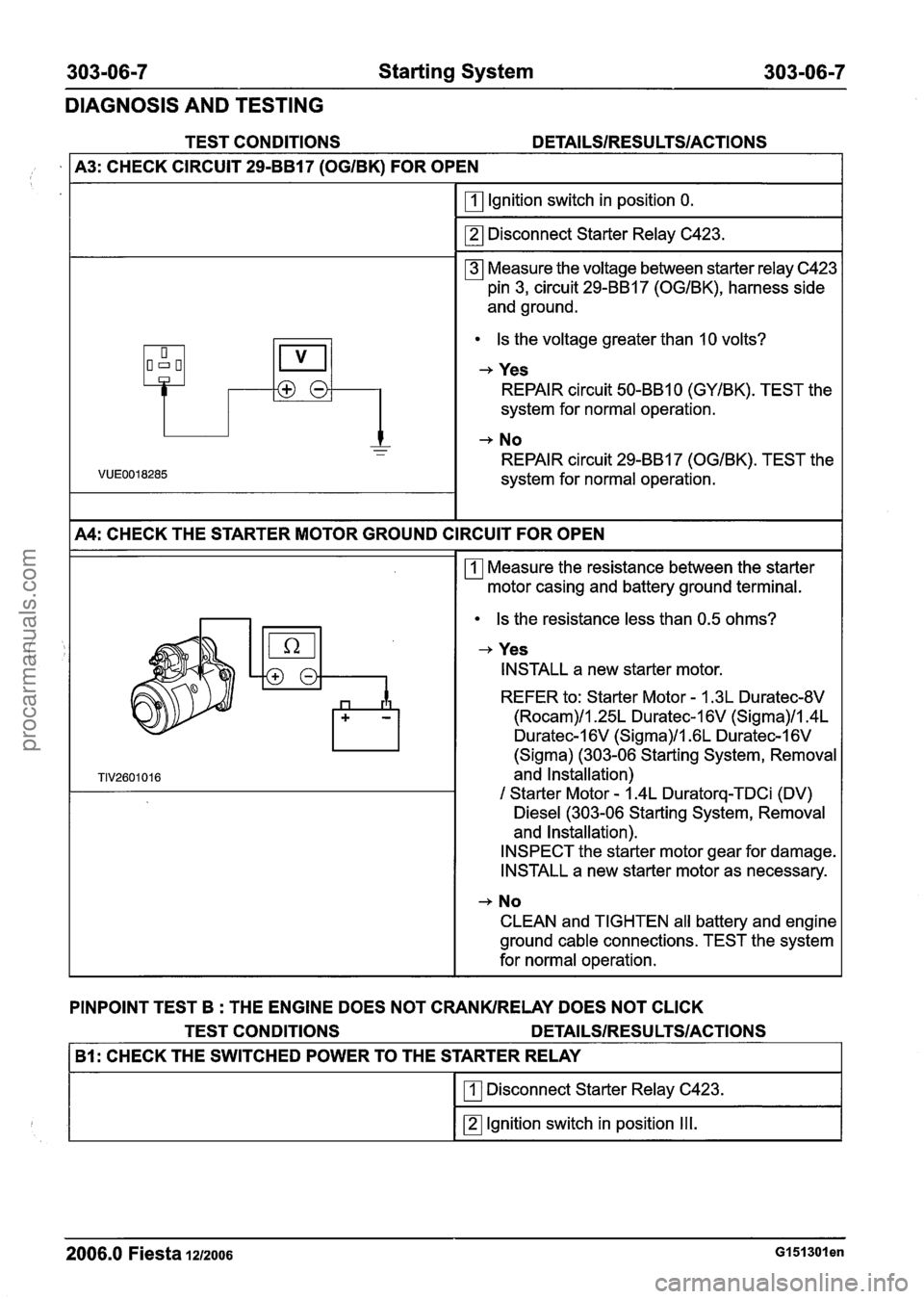

I A3: CHECK CIRCUIT 29-BB17 (OGIBK) FOR OPEN I

I Ignition switch in position 0. I

I rn Disconnect Starter Relay C423. I

Measure the voltage between starter relay C423

pin 3, circuit

29-8817 (OGIBK), harness side

Is the voltage greater than 10 volts?

+ Yes

REPAIR circuit 50-BB10 (GYIBK). TEST the

system for normal operation.

+ No

REPAIR circuit 29-BB17 (OGIBK). TEST the

system for normal operation.

I A4: CHECK THE STARTER MOTOR GROUND CIRCUIT FOR OPEN I - - --

Measure the resistance between the starter

motor casing and battery

1 ground terminal.

Is the resistance less than 0.5 ohms?

+ Yes

INSTALL a new starter motor.

REFER to: Starter Motor

- 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (303-06 Starting System, Removal

and Installation)

I Starter Motor - 1.4L Duratorq-TDCi (DV)

Diesel (303-06 Starting System, Removal

and

Installation).

INSPECT the starter motor gear for damage.

INSTALL a new starter motor as necessary.

+ No

CLEAN and TIGHTEN all battery and engine

ground cable connections. TEST the system

for normal operation.

PINPOINT TEST B : THE ENGINE DOES NOT CRANKIRELAY DOES NOT CLICK

TEST CONDITIONS

DETAILSIRESU LTSIACTIONS

B1: CHECK THE SWITCHED POWER TO THE STARTER RELAY

Disconnect Starter Relay C423.

rn lgnition switch in position Ill.

2006.0 Fiesta 1212006 GI 51 301 en

procarmanuals.com

Page 874 of 1226

303-06-1 0 Starting System 303-06-1 0

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESULTSIACTIONS

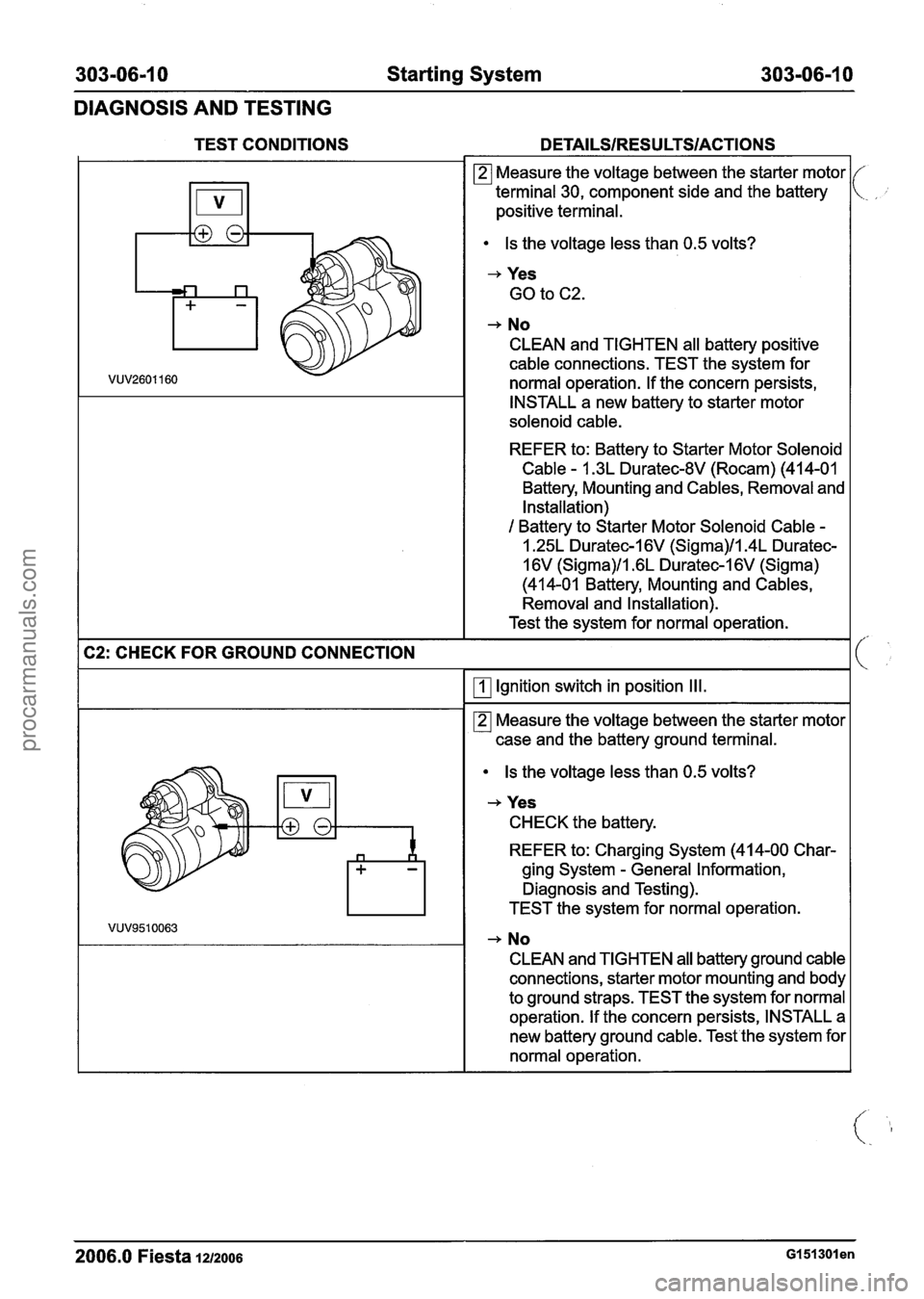

Measure the voltage between the starter motor

terminal 30, component side and the battery

positive

terminal.

Is the voltage less than 0.5 volts?

+ Yes

GO to C2.

+ No

CLEAN and TIGHTEN all battery positive

cable connections. TEST the system for

normal operation. If the concern persists,

INSTALL a new battery to starter motor

solenoid cable.

REFER to: Battery to Starter Motor Solenoid

Cable - 1.3L Duratec-8V (Rocam) (41 4-01

Battery, Mounting and

Cables, Removal and

Installation)

1 Battery to Starter Motor Solenoid Cable -

1.25L Duratec-1 6V (Sigma)/l.4L Duratec-

16V (Sigma)/l.6L Duratec-1 6V (Sigma)

(414-01 Battery, Mounting and

Cables,

Removal and Installation).

Test the system for normal operation. - - ---

I C2: CHECK FOR GROUND CONNECTION

-

I f

Ignition switch in position Ill.

Is the voltage less than 0.5 volts?

-, Yes

CHECK the battery.

REFER to: Charging System (414-00 Char-

ging System

- General Information,

Diagnosis and Testing).

TEST the system for

normal operation.

+ No

CLEAN and TIGHTEN all battery ground cable

connections, starter motor mounting and body

to ground straps. TEST the system for

normal

operation. If the concern persists, INSTALL a

new battery ground

cable. Testlhe system for

normal operation.

2006.0 Fiesta 1212006 GI 51 301 en

procarmanuals.com

Page 875 of 1226

303-06-1 I Starting System 303-06-1 1

REMOVAL AND INSTALLATION

Starter Motor - 1.3L Duratec-8V (Rocam)/l.25L Duratec-I 6V

I \, (Sigma)/l.4L Duratec-1 6V (Sigma)/l .6L Duratec-1 6V

(Sigma)(26 204 0)

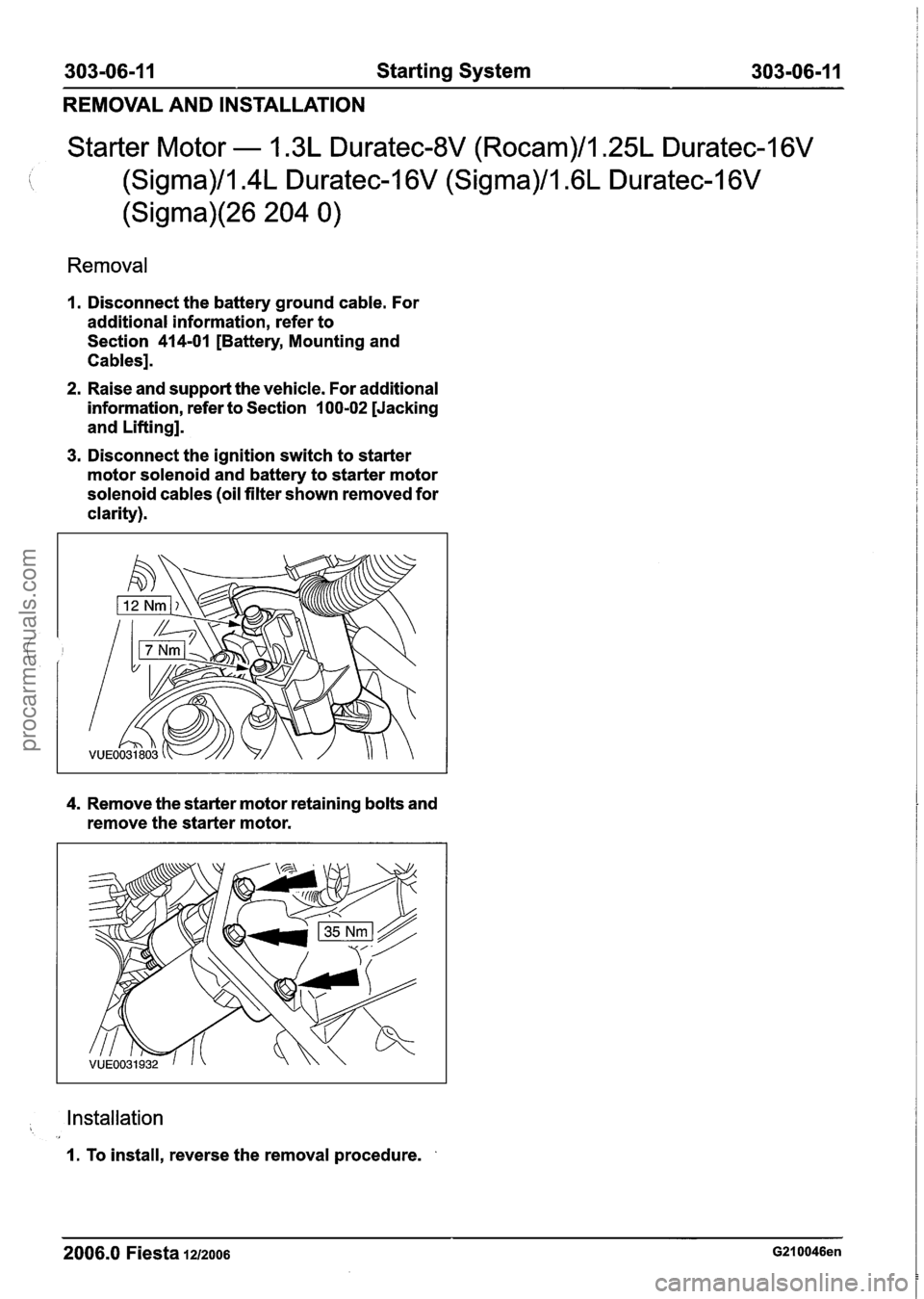

Removal

I. Disconnect the battery ground cable. For

additional information, refer to

Section

414-01 [Battery, Mounting and

Cables].

2. Raise and support the vehicle. For additional

information, refer to Section

100-02 [Jacking

and Lifting].

3. Disconnect the ignition switch to starter

motor solenoid and battery to starter motor

solenoid cables (oil filter shown removed for

clarity).

4. Remove the starter motor retaining bolts and

remove the starter motor.

, Installation

I. To install, reverse the removal procedure.

2006.0 Fiesta 1212006 G210046en

procarmanuals.com

Page 876 of 1226

303-06-1 2 Starting System 303-06-1 2

REMOVAL AND INSTALLATION

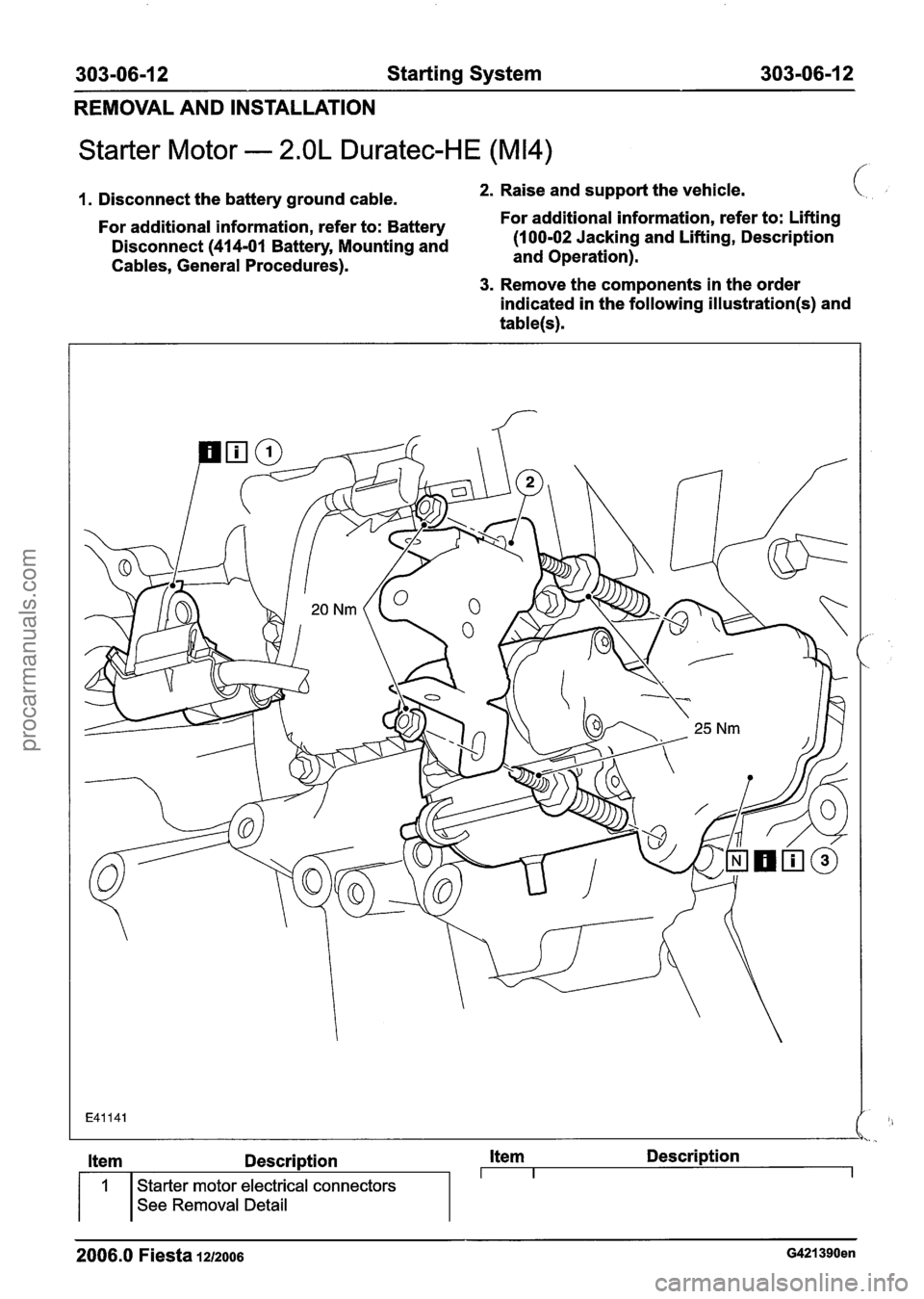

Starter Motor - 2.OL Duratec-HE (M14)

/'

I. Disconnect the battery ground cable. 2. Raise and support the vehicle. (.. . ,,

For additional information, refer to: Battery For additional

information, refer to: Lifting

Disconnect

(414-01 Battery, Mounting and (1 00-02 Jacking and Lifting, Description

Cables, General Procedures). and

Operation).

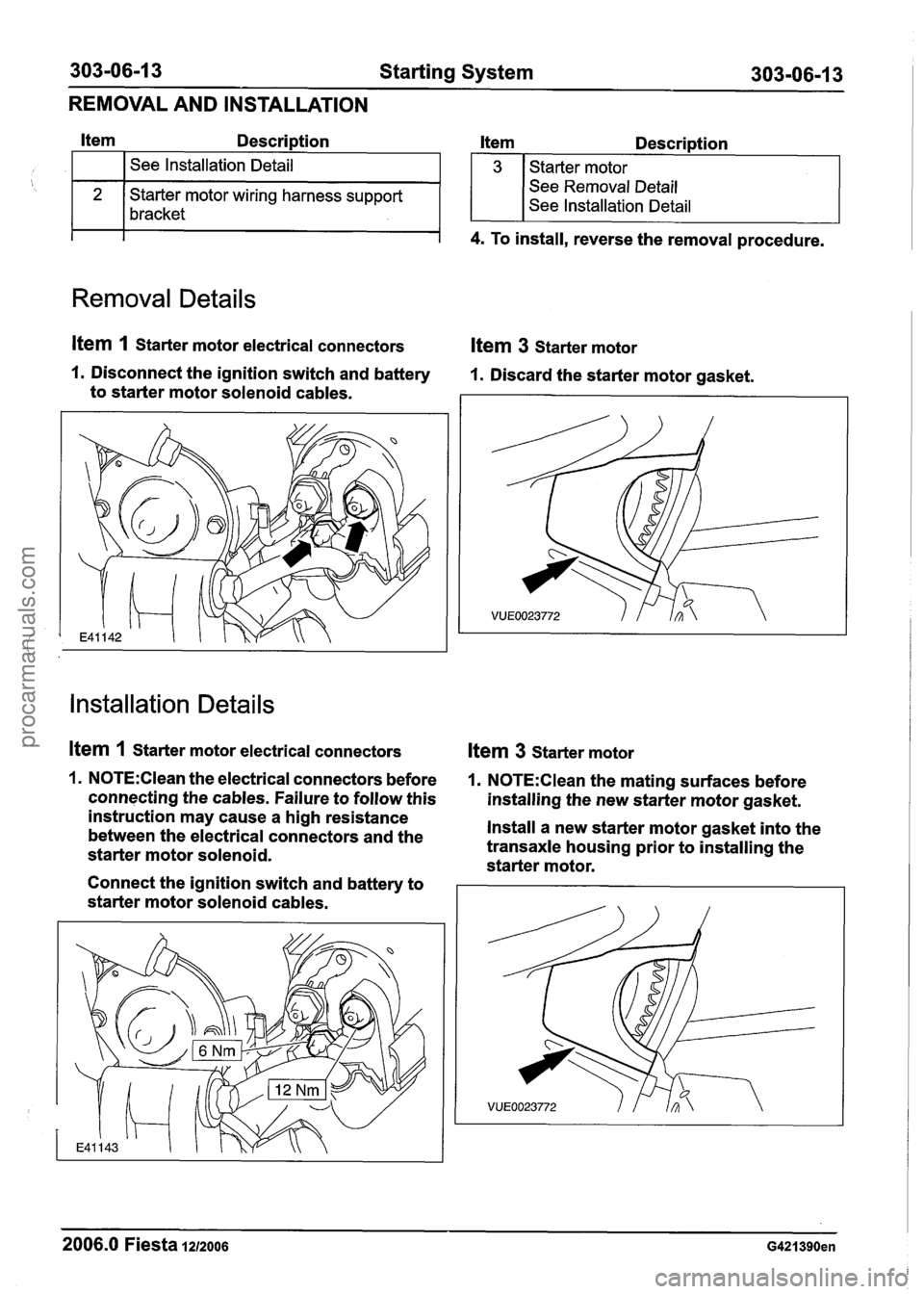

3. Remove the components in the order

indicated in the following

illustration(s) and

table(s).

2006.0 Fiesta 1212006 G421390en

Item Description Item Description I I I 1 Starter motor electrical connectors

See Removal Detail

procarmanuals.com

Page 877 of 1226

303-06-1 3 Starting System 303-06-1 3

REMOVAL AND INSTALLATION

Item Description Item Description

I I 4. To install, reverse the removal procedure.

I See Installation Detail

2

Removal Details

1 3 1 Starter motor

Item 1 starter motor electrical connectors Item 3 Starter motor

Starter motor wiring harness support

bracket

1. Disconnect the ignition switch and battery 1. Discard the starter motor gasket.

to starter motor solenoid cables.

See Removal Detail

See Installation Detail

Installation Details

Item 1 Starter motor electrical connectors Item 3 Starter motor

1. N0TE:Clean the electrical connectors before 1. N0TE:Clean the mating surfaces before

connecting the cables. Failure to follow this

installing the new starter motor

gasket. - - instruction may cause a high resistance

between the electrical connectors and the Install

a new starter motor gasket into the

starter motor solenoid. transaxle

housing prior to installing the

starter motor.

Connect the ignition switch and battery to

starter motor solenoid cables.

2006.0 Fiesta 1212006 G421390en

procarmanuals.com

Page 930 of 1226

303-1 4-6 Electronic Engine Controls 303-1 4-6

DESCRIPTION

AND OPERATION

Item Descri~tion

1 5 1 Crankshaft Position (CKP) sensor 1

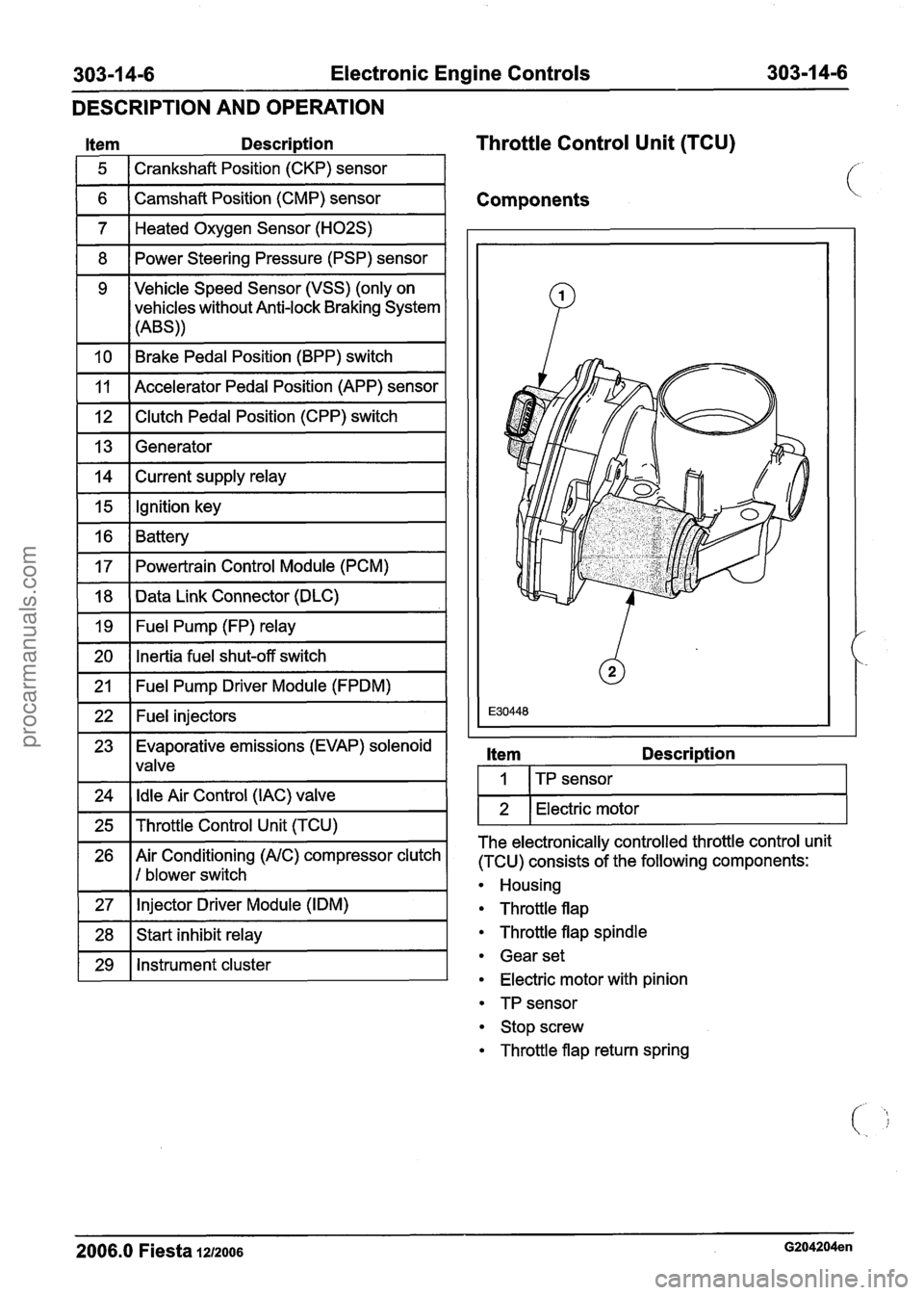

Throttle Control Unit (TCU)

1 6 ( Camshaft Position (CMP) sensor I Components

1 7 1 Heated Oxygen Sensor (H02S) I

1 8 1 Power Steering Pressure (PSP) sensor I

1 10 1 Brake Pedal Position (BPP) switch I

9 Vehicle Speed Sensor (VSS)

(only on

vehicles without Anti-lock Braking System

(ABS))

1 12 1 Clutch Pedal Position (CPP) switch I

11

1 13 1 Generator I

Accelerator Pedal Position (APP) sensor

1 14 1 Current supply relay I

1 15 1 Ignition key I -

16

17

1 20 1 Inertia fuel shut-off switch I

Battery

Powertrain Control Module (PCM)

-

18

19

1 21 1 Fuel Pump Driver Module (FPDM) I

Data Link Connector (DLC)

Fuel Pump (FP) relay

1 22 1 Fuel injectors I

23 Evaporative emissions (EVAP) solenoid

1 lvalve

1 24 1 Idle Air Control (IAC) valve 1

1 25 1 Throttle Control Unit (TCU) I

26 Air Conditioning (AIC) compressor clutch

1 I 1 blower switch

1 27 1 Injector Driver

Module (IDM) I

1 28 1 Start inhibit relay I

1 29 1 Instrument cluster I

Item Descri~tion

I I ITP sensor I

1 2 1 Electric motor I

The electronically controlled throttle control unit

(TCU) consists of the following components:

Housing

Throttle flap

Throttle flap spindle

Gear set

Electric motor with pinion

TP sensor

Stop screw

Throttle flap return spring

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 933 of 1226

303-1 4-9 Electronic Engine Controls 303-1 4-9

DESCRIPTION AND OPERATION

If one potentiometer fails, the engine will run with

reduced power (maximum torque

80 Nm), if both

potentiometers fail, the engine will run with reduced

power (maximum torque

55 Nm).

This warning may also be indicated if the engine

does not start. The cause may be a poor state of

charge of the battery.

The warning indication normally disappears once

the battery is re-charged.

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 935 of 1226

303-1 4-1 1 Electronic Engine Controls 303-1 4-1 I

DESCRIPTION AND OPERATION

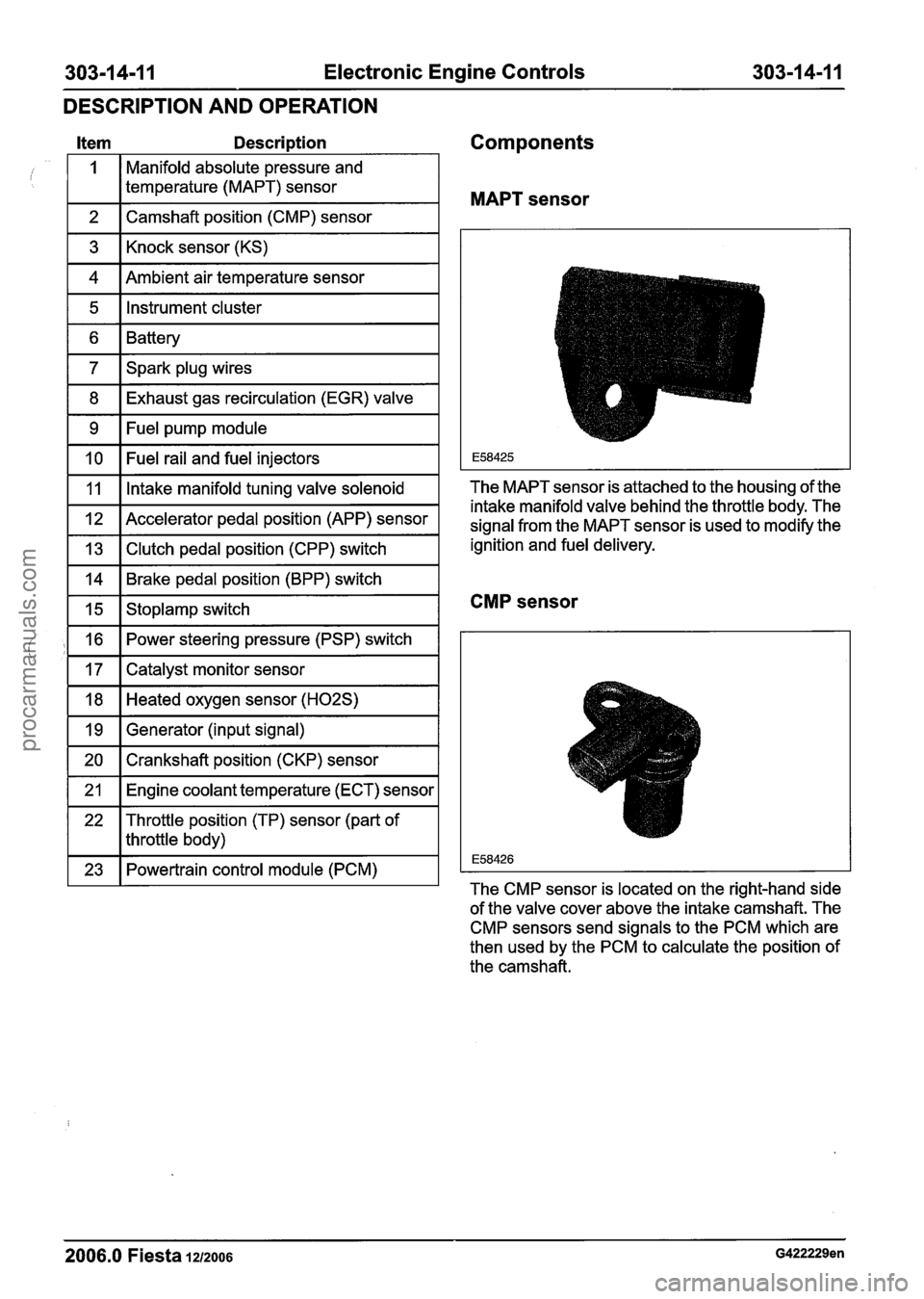

Item Description Components

MAPT sensor

Manifold absolute pressure and

temperature (MAPT) sensor

1 2 1 Camshaft position (CMP) sensor I

1 3 1 Knock sensor (KS) I

vl~Ame%air temperature sensor I

1 5 1 Instrument cluster I

1 6 1 Battery I

1 7 1 Spark plug wires I

1 8 1 Exhaust gas recirculation (EGR) valve I

1 9 1 Fuel pump module I

1 10 1 Fuel rail and fuel injectors I

I 11 I Intake manifold tuning valve solenoid The

MAPT sensor is attached to the housing of the

intake manifold valve behind the throttle body. The

signal from the MAPT sensor is used to modify the

ignition and fuel delivery.

1 12 1 Accelerator pedal position (APP) sensor

1 13 1 Clutch pedal position (CPP) switch

1 14 1 Brake pedal position (BPP) switch

CMP sensor 1 15 1 Stoplamp switch

1 16 1 Power steering pressure (PSP) switch I

1 17 1 Catalyst monitor sensor I

FIGted oxygen sensor (H02S) I

1 19 1 Generator (input signal) I

1 20 1 Crankshaft position (CKP) sensor I

1 21 1 Engine coolant temperature (ECT) sensor I

22 Throttle position

(TP) sensor (part of

I I throttle body)

1 23 1 Powertrain control module (PCM) I The CMP sensor is located on the right-hand side

of the valve cover above the intake camshaft. The

CMP sensors send signals to the PCM which are

then used by the PCM to calculate the position of

the camshaft.

2006.0 Fiesta 1212006 G422229en

procarmanuals.com

Page 936 of 1226

303-1 4-1 2 Electronic Engine Controls 303-1 4-1 2

DESCRIPTION AND OPERATION

Powertrain control module (PCM) The KS detects engine vibrations caused by knock

and produces an output voltage signal in proportion

, to the knock. The PCM uses the voltage signal to(

control knock by retarding the ignition timing.

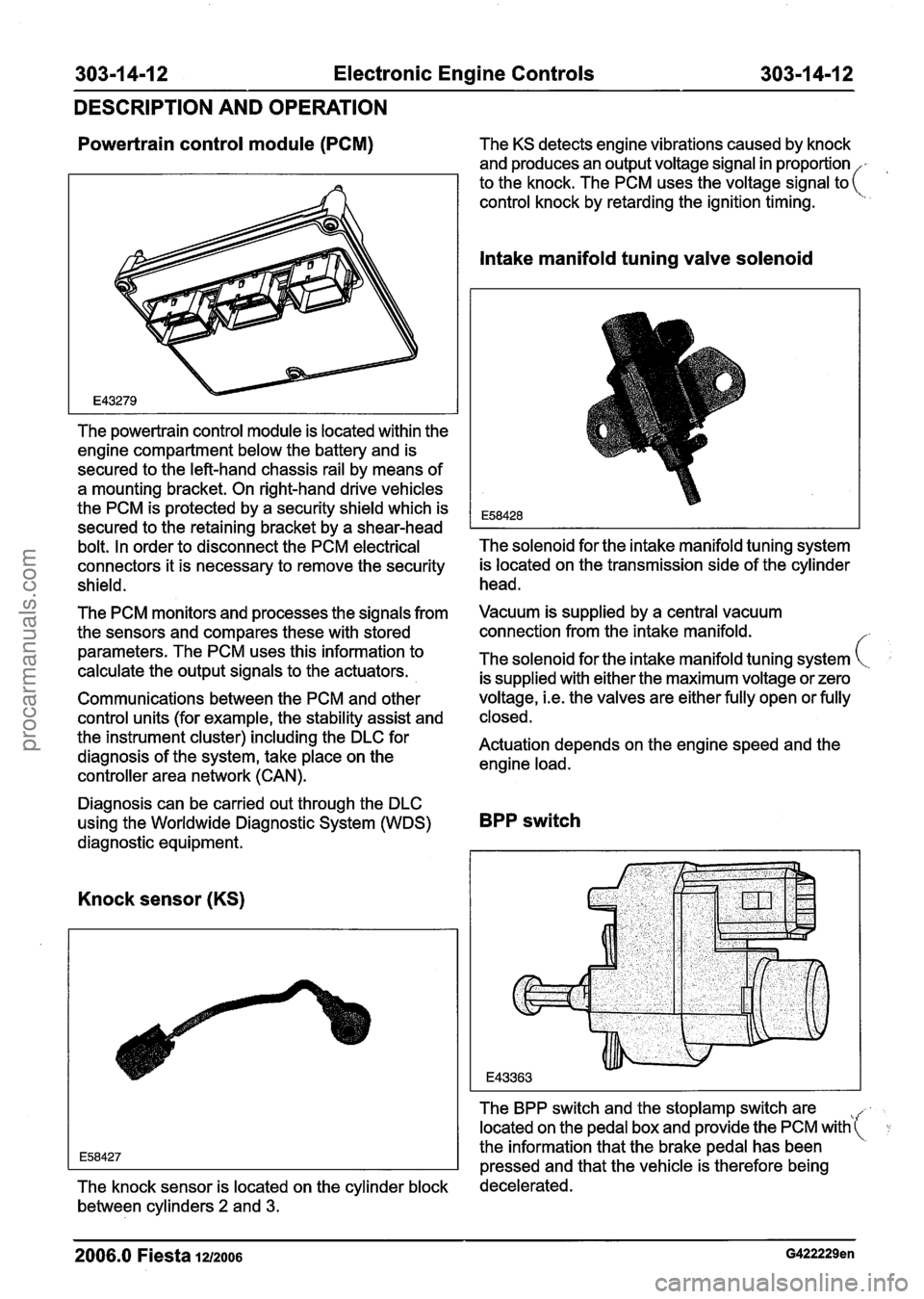

The powertrain control module is located within the

engine compartment below the battery and is

secured to the left-hand chassis rail by means of

a mounting bracket. On right-hand drive vehicles

the PCM is protected by a security shield which is

secured to the retaining bracket by a shear-head

bolt. In order to disconnect the PCM electrical

connectors it is necessary to remove the security

shield.

The PCM monitors and processes the signals from

the sensors and compares these with stored

parameters. The PCM uses this information to

calculate the output signals to the actuators.

Communications between the PCM and other

control units (for example, the stability assist and

the instrument cluster) including the DLC for

diagnosis of the system, take place on the

controller area network (CAN).

Intake manifold tuning valve solenoid

The solenoid for the intake manifold tuning system

is located on the transmission side of the cylinder

head.

Vacuum is supplied by a central vacuum

connection from the intake manifold.

The solenoid for the intake manifold tuning system

is supplied with either the maximum voltage or zero

voltage,

i.e. the valves are either fully open or fully

closed.

Actuation depends on the engine speed and the

engine load.

Diagnosis can be carried out through the DLC

using the Worldwide Diagnostic System (WDS)

BPP switch

diagnostic equipment.

Knock sensor (KS)

The BPP switch and the stoplamp switch are tt(r located on the pedal box and provide the PCM with

the information that the brake pedal has been

pressed and that the vehicle is therefore being

The knock sensor is located on the cylinder block decelerated.

between cylinders

2 and 3.

2006.0 Fiesta 1212006 G422229en

procarmanuals.com

Page 943 of 1226

Electronic Engine Controls

DIAGNOSIS AND TESTING

I PO304 I Cylinder No. 4 misfire detected I

/ I

KS implausible signal I

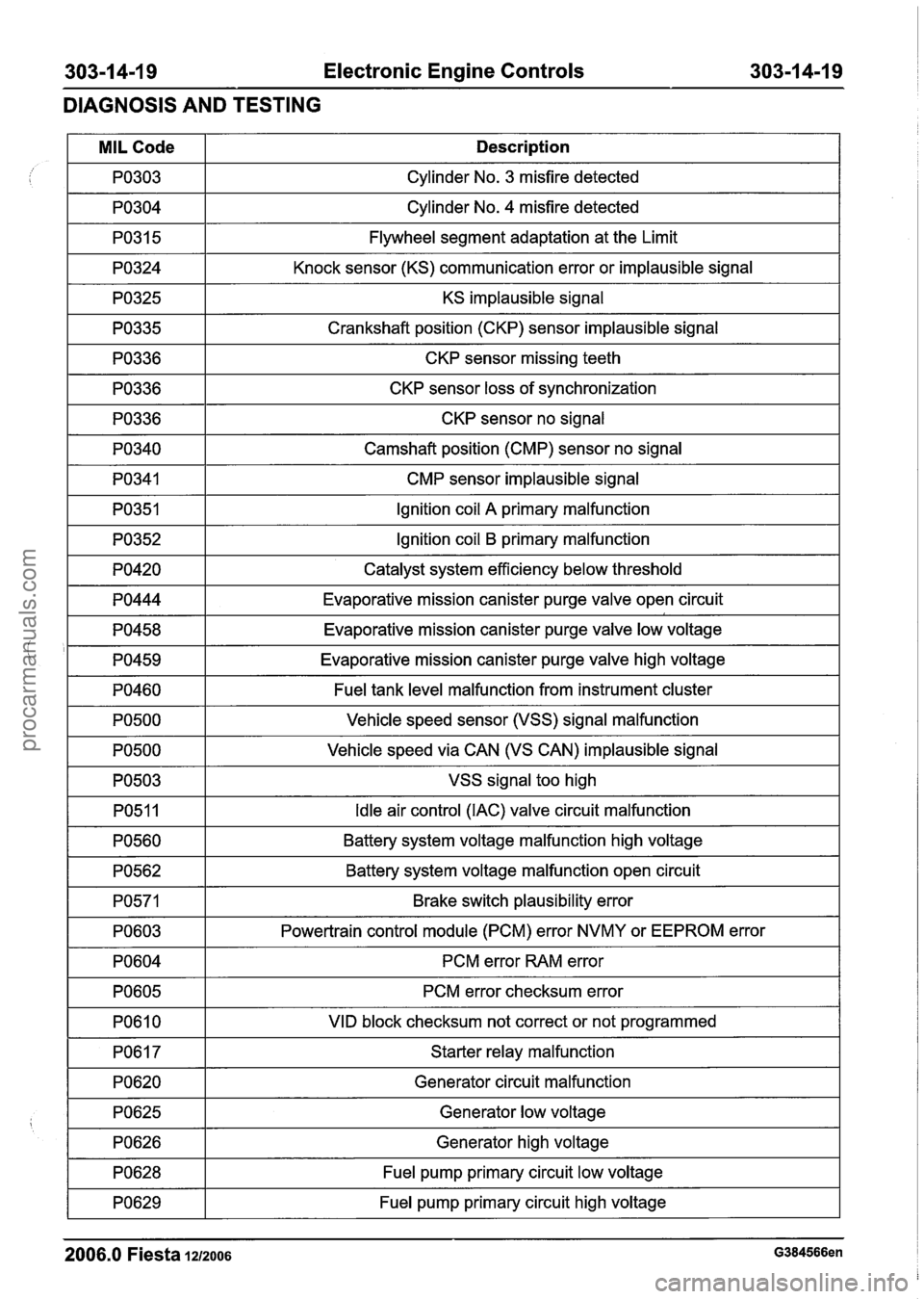

MIL Code

PO303

PO31 5

PO324

1 PO335 1 Crankshaft position (CKP) sensor implausible signal I

Description

Cylinder No. 3 misfire detected

Flywheel segment adaptation at the Limit

Knock sensor (KS) communication error or implausible signal

1 PO336 1 CKP sensor missing teeth I

1 PO336 1 CKP sensor loss of synchronization I

1 PO336 1 CKP sensor no signal I

I PO340 I Camshaft position (CMP) sensor no signal I

I PO341 I CMP sensor implausible signal I

I PO351 I Ignition coil A primary malfunction I

1 PO352 1 Ignition coil B primary malfunction I

I PO420 I Catalyst system efficiency below threshold I

1 PO444 1 Evaporative mission canister purge valve open circuit I

1 PO458 1 Evaporative mission canister purge valve low voltage I

I '1 PO459 1 Evaporative mission canister purge valve high voltage I

I PO460 I Fuel tank level malfunction from instrument cluster I

-3 I VSS signal too high I

PO500

PO500

Vehicle speed sensor (VSS) signal malfunction

Vehicle speed via CAN (VS CAN) implausible signal

PO51 1

PO560

I PO603 I Powertrain control module (PCM) error NVMY or EEPROM error 1

Idle air control (IAC) valve circuit malfunction

Battery system voltage malfunction high voltage

PO562

PO571

I PO604 I PCM error RAM error I

Battery system voltage malfunction open circuit

Brake switch plausibility error

PO605 I PCM error checksum error I

I PO610 I VID block checksum not correct or not programmed I

I PO617 I Starter relay malfunction I

I PO620 I Generator circuit malfunction I

1 PO628 1 Fuel pump primary circuit low voltage I

I

7 1 Fuel pump primary circuit high voltage I

2006.0 Fiesta 1212006 G384566en

PO625

PO626

Generator low voltage

Generator high voltage

procarmanuals.com