exhaust System FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 6 of 2057

SECTION 100-00 General Information

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

100-00-3

About This Manual ........................................................................\

......................................

100-00-3

Introduction ........................................................................\

.................................................

100-00-4

How to use Repair Procedures ........................................................................\

...................

100-00-4

Global Authoring Standards (GAS) Repair Procedures ..................................................

100-00-18

How to use Diagnosis and Testing procedures ..................................................................

100-00-19

Symbols Glossary ........................................................................\

.......................................

100-00-41

Steering System Health and Safety Precautions ................................................................

100-00-42

Health and Safety Precautions ........................................................................\

...................

100-00-42

Introduction ........................................................................\

.................................................

100-00-42

Acids and Alkalis ........................................................................\

........................................

100-00-42

Air Bags ........................................................................\

......................................................

100-00-42

Air Conditioning Refrigerant ........................................................................\

.......................

100-00-42

Adhesives and Sealers ........................................................................\

...............................

100-00-43

Antifreeze ........................................................................\

...................................................

100-00-43

Asbestos ........................................................................\

.....................................................

100-00-44

Battery Acids ........................................................................\

..............................................

100-00-44

Brake and Clutch Linings and Pads ........................................................................\

...........

100-00-44

Brake Fluids (Polyalkylene Glycols) ........................................................................\

...........

100-00-44

Brazing ........................................................................\

.......................................................

100-00-44

Chemical Materials ........................................................................\

.....................................

100-00-45

Chlorofluorocarbons (CFC) ........................................................................\

........................

100-00-45

Clutch Fluids ........................................................................\

...............................................

100-00-45

Clutch Linings and Pads ........................................................................\

.............................

100-00-45

Corrosion Protection Materials ........................................................................\

...................

100-00-45

Cutting ........................................................................\

....................................................... .

100-00-45

Dewaxing ........................................................................\

....................................................

100-00-45

Dusts ........................................................................\

..........................................................

100-00-45

Electric Shock ........................................................................\

.............................................

100-00-45

Engine Oils ........................................................................\

.................................................

100-00-46

Exhaust Fumes ........................................................................\

...........................................

100-00-46

Fibre Insulation ........................................................................\

...........................................

100-00-46

Fire ........................................................................\

.............................................................

100-00-46

First Aid

........................................................................\

......................................................

100-00-46

Fluoroelastomer ........................................................................\

..........................................

100-00-46

Foams

- Polyurethane ........................................................................\

................................

100-00-47

Freon ........................................................................\

..........................................................

100-00-47

Fuels ........................................................................\

...........................................................

100-00-47

Gas Cylinders ........................................................................\

.............................................

100-00-47

Gases ........................................................................\

.........................................................

100-00-47

Gaskets (Fluoroelastomer) ........................................................................\

.........................

100-00-47

General Workshop Tools and Equipment ........................................................................\

...

100-00-48

High Pressure Air, Lubrication and Oil Test Equipment ......................................................

100-00-48

Halon ........................................................................\

..........................................................

100-00-48

Legal Aspects ........................................................................\

.............................................

100-00-1

General Information

100-00- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 1 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 48 of 2057

Health and Safety Precautions

Introduction

Many of the procedures associated with vehicle

maintenance and repair involve physical hazards

or other risks to health. This subsection lists,

alphabetically, some of these hazardous operations

and the materials and equipment associated with

them. Precautions necessary to avoid these

hazards are identified.

The list is not exhaustive and all operations and

procedures, and the handling of materials, should

be carried out with health and safety in mind.

Before using any product the Materials Safety Data

Sheet supplied by the manufacturer or supplier

should be consulted.

Acids and Alkalis

See alsoBattery Acids.

For example caustic soda, sulphuric acid.

Used in batteries and cleaning materials.

Irritant and corrosive to the skin, eyes, nose and

throat. Cause burns. Can destroy ordinary

protective clothing.

Avoid splashes to the skin, eyes and clothing. Wear

suitable protective impervious apron, gloves and

goggles. Do not breath mists.

Make sure access to eye wash bottles, shower and

soap are readily available for splashing accidents.

Display Eye Hazard sign.

Air Bags

See also Fire, Chemical Materials.

Highly flammable, explosive – observe No Smoking

policy.

Used as a safety restraint system mounted in the

steering wheel and passenger side of the

instrument panel.

The inflator contains a high-energetic propellant

which, when ignited, produces a VERY HOT GAS

(2500°C).

The gas generant used in air bags is Sodium Azide.

This material is hermetically sealed in the module

and is completely consumed during deployment.

No attempt should be made to open an air bag inflator as this will lead to the risk of exposure to

Sodium Azide. If a gas generator is ruptured, full

protective clothing should be worn when dealing

with the spillage.

After normal deployment, gloves and safety

goggles must be worn during the handling process.

Deployed air bags should be disposed of in a

plastic bag in accordance with local regulations at

an approved chemical waste site.

For additional information, refer to:

Supplemental

Restraint System (SRS) Health and Safety

Precautions (100-00 General Information,

Description and Operation).

Air Conditioning Refrigerant

See also Chlorofluorocarbon, Chemical Materials

Highly flammable, combustible – observe No

Smoking policy.

Skin contact may result in frostbite.

Instructions given by the manufacturer must be

followed. Avoid naked lights, wear suitable

protective gloves and goggles.

If refrigerant comes into contact with the skin or

eyes, immediately rinse the affected areas with

water. Eyes should also be rinsed with an

appropriate irrigation solution and should not be

rubbed. SEEK MEDICAL ASSISTANCE IF

NECESSARY.

For additional information, refer to: Air Conditioning

(A/C) System Health and Safety Precautions

(100-00 General Information, Description and

Operation).

Adhesives and Sealers

See also Fire, Chemical Materials.

Highly flammable, flammable, combustible –

observe No Smoking policy.

Generally should be stored in No Smoking areas.

Cleanliness and tidiness in use should be

observed, for example disposable paper covering

benches; should be dispensed from applicators

where possible; containers, including secondary

containers, should be labeled appropriately.

G566527en2008.50 Kuga8/2011

100-00- 42

General Information

100-00- 42

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 49 of 2057

Solvent-based Adhesives/Sealers - See

Solvents

Follow manufacturers instructions.

Water-based Adhesives/Sealers

Those based on polymer emulsions and rubber

latexes may contain small amounts of volatile toxic

and harmful chemicals. Skin and eye contact

should be avoided and adequate ventilation

provided during use.

Hot Melt Adhesives

In the solid state, they are safe. In the molten state

they may cause burns and health hazards may

arise from the inhalation of toxic fumes.

Use appropriate protective clothing and a

thermostatically controlled heater with a thermal

cut-out and adequate extraction.

Resin-based Adhesives/Sealers, for

example Epoxide and Formaldehyde

Resin-based

Mixing should be carried out in well ventilated

areas, as harmful or toxic volatile chemicals may

be released.

Skin contact with uncured resins and hardeners

can result in irritation, dermatitis, and absorption

of toxic or harmful chemicals through the skin.

Splashes can damage the eyes.

Provide adequate ventilation and avoid skin and

eye contact.

Anaerobic, Cyanoacrylate (super-glues)

and other Acrylic Adhesives

Many are irritant, sensitizing or harmful to the skin

and respiratory tract. Some are eye irritants.

Skin and eye contact should be avoided and the

manufacturers instructions followed.

Cyanoacrylate adhesives (super-glues) MUST NOT

contact the skin or eyes. If skin or eye tissue is

bonded, cover with a clean moist pad and SEEK

IMMEDIATE MEDICAL ATTENTION. Do not

attempt to pull tissue apart. Use in well ventilated

areas as vapors can cause irritation to the nose

and eyes.For two-pack systems see Resin-based and

Isocyanate Adhesives/Sealers.

Isocyanate (Polyurethane)

Adhesives/Sealers

See also

Resin-based Adhesives.

Individuals suffering from asthma or respiratory

allergies should not work with or near these

materials as sensitivity reactions can occur.

Over exposure is irritating to the eyes and

respiratory system. Excessive concentrations may

produce effects on the nervous system including

drowsiness. In extreme cases, loss of

consciousness may result. Long term exposure to

vapor concentrations may result in adverse health

effects.

Prolonged contact with the skin may have a

defatting effect which may lead to skin irritation

and in some cases, dermatitis.

Splashes entering the eye will cause discomfort

and possible damage.

Any spraying should preferably be carried out in

exhaust ventilated booths, removing vapors and

spray droplets from the breathing zone.

Wear appropriate gloves, eye and respiratory

protection.

Antifreeze

See also Fire, Solvents.

For example isopropanol, ethylene glycol,

methanol.

Highly flammable, flammable, combustible.

Used in vehicle coolant systems, brake air pressure

systems, screenwash solutions.

For additional information, refer to: Engine Cooling

System Health and Safety Precautions (100-00

General Information, Description and Operation).

Asbestos

See also Warning Symbols on Vehicles at the end

of this subsection.

Breathing asbestos dust may cause lung damage

or, in some cases, cancer.

Used in brake and clutch linings, transmission

brake bands and gaskets.

G566527en2008.50 Kuga8/2011

100-00- 43

General Information

100-00- 43

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 80 of 2057

Noise Conditions

• Gear noise is typically a howling or whining dueto gear damage or incorrect bearing preload. It

can occur at various speeds and driving

conditions, or it can be continuous.

• Chuckle is a particular rattling noise that sounds like a stick against the spokes of a spinning

bicycle wheel. It occurs while decelerating from

64 km/h (40 mph) and can usually be heard all

the way to a stop. The frequency varies with

vehicle speed.

• Knock is very similar to chuckle, though it may be louder and occurs on acceleration or

deceleration. The teardown will disclose what

has to be corrected.

Clicking, popping or grinding noises may be caused

by the following:

• worn, damaged or incorrectly installed wheel bearing, suspension or brake component.

Check and rule out tires, exhaust and trim items

before disassembling the transmission to diagnose

and correct gear noise.

The noises described under Road Test usually

have specific causes that can be diagnosed by

observation as the unit is disassembled. The initial

clues are the type of noise heard on the road test

and driving conditions.

Vibration Conditions

Vibration at highway speeds may be caused by

the following:

• out-of-balance front or rear wheels.

• out-of-round tires.

Shudder or vibration during acceleration may be

caused by the following:

• damaged powertrain/drivetrain mounts.

• excessively high constant velocity (CV) joint operating angles caused by incorrect ride height.

Check ride height, verify correct spring rate and

check items under inoperative conditions.

Road Test

A gear-driven unit will produce a certain amount

of noise. Some noise is acceptable and may be

audible at certain speeds or under various driving

conditions, as on a newly paved asphalt road. The slight noise is in no way detrimental and must be

considered normal.

The road test and customer interview (if available)

provide information needed to identify the condition

and give direction to the correct starting point for

diagnosis.

1. Make notes throughout the diagnosis routine.

Make sure to write down even the smallest bit

of information, because it may turn out to be the

most important.

2. Do not touch anything until a road test and a thorough visual inspection of the vehicle have

been carried out. Leave the tire pressures and

vehicle load just where they were when the

condition was first observed. Adjusting tire

pressures, vehicle load or making other

adjustments may reduce the condition(s)

intensity to a point where it cannot be identified

clearly. It may also inject something new into

the system, preventing correct diagnosis.

3. Make a visual inspection as part of the preliminary diagnosis routine, writing down

anything that does not look right. Note tire

pressures, but do not adjust them yet. Note

leaking fluids, loose nuts and bolts, or bright

spots where components may be rubbing

against each other. Check the load space for

unusual loads.

4. Road test the vehicle and define the condition by reproducing it several times during the road

test.

5. Carry out the Road Test Quick Checks as soon as the condition is reproduced. This will identify

the correct diagnostic procedure. Carry out the

Road Test Quick Checks more than once to

verify they are providing a valid result.

Remember, the Road Test Quick Checks may

not tell where the concern is, but they will tell

where it is not.

Road Test Quick Checks

1. 24-80 km/h (15-50 mph): with light acceleration,a moaning noise is heard and possibly a

vibration felt in the front floor panel. It is usually

worse at a particular engine speed and at a

particular throttle setting during acceleration at

that speed. It may also produce a moaning

sound, depending on what component is

causing it. REFER to Tip-in Moan in the

Driveline Noise and Vibration Symptom Chart.

2. Acceleration/Deceleration: With slow acceleration and deceleration, a shake is

G37349en2008.50 Kuga8/2011

100-04- 3

Noise, Vibration and Harshness

100-04- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 91 of 2057

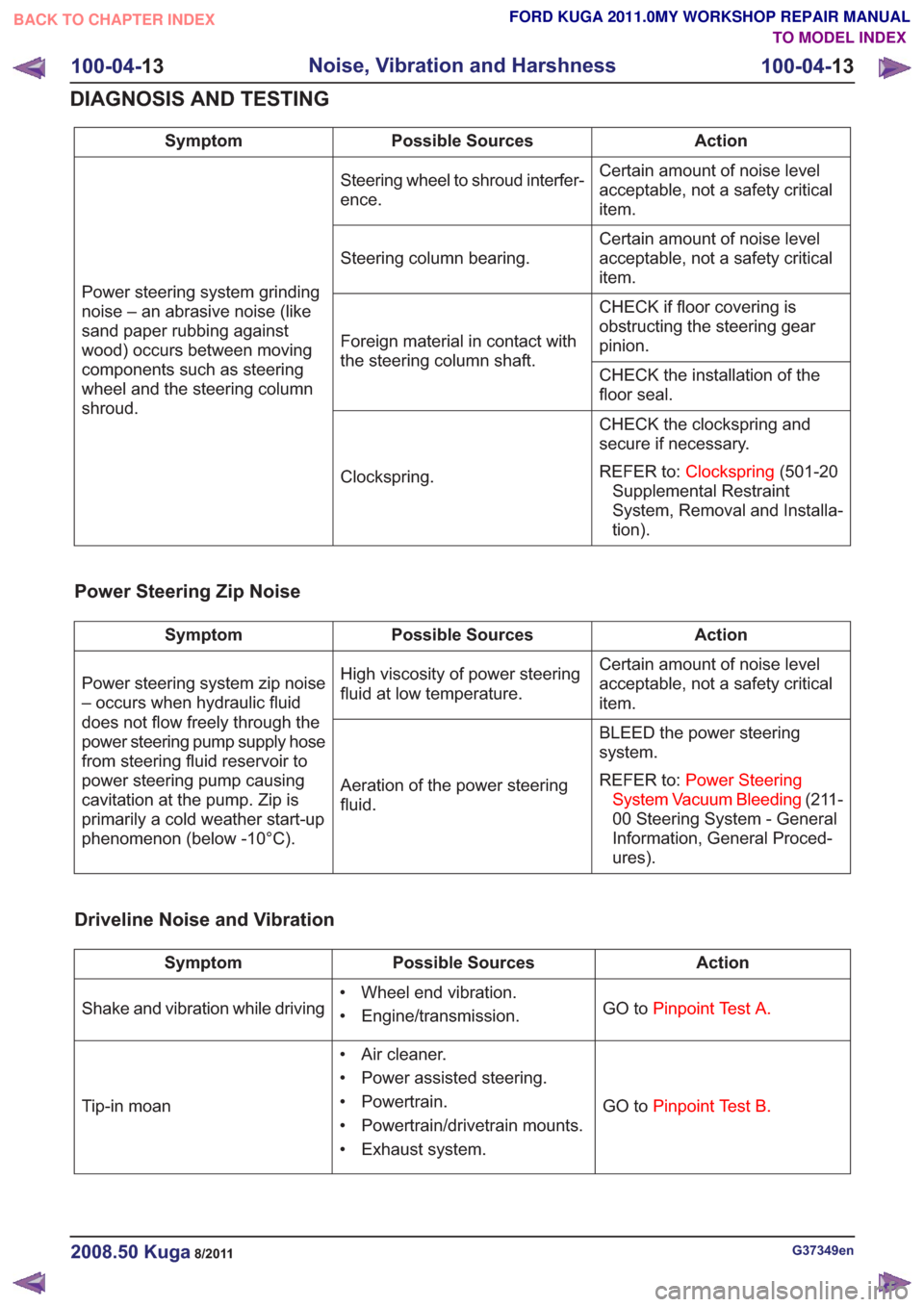

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

Steering wheel to shroud interfer-

ence.

Power steering system grinding

noise – an abrasive noise (like

sand paper rubbing against

wood) occurs between moving

components such as steering

wheel and the steering column

shroud. Certain amount of noise level

acceptable, not a safety critical

item.

Steering column bearing.

CHECK if floor covering is

obstructing the steering gear

pinion.

Foreign material in contact with

the steering column shaft.

CHECK the installation of the

floor seal.

CHECK the clockspring and

secure if necessary.

REFER to:Clockspring (501-20

Supplemental Restraint

System, Removal and Installa-

tion).

Clockspring.

Power Steering Zip Noise

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

High viscosity of power steering

fluid at low temperature.

Power steering system zip noise

– occurs when hydraulic fluid

does not flow freely through the

power steering pump supply hose

from steering fluid reservoir to

power steering pump causing

cavitation at the pump. Zip is

primarily a cold weather start-up

phenomenon (below -10°C). BLEED the power steering

system.

REFER to:

Power Steering

System Vacuum Bleeding (211-

00 Steering System - General

Information, General Proced-

ures).

Aeration of the power steering

fluid.

Driveline Noise and Vibration

Action

Possible Sources

Symptom

GO toPinpoint Test A.

• Wheel end vibration.

• Engine/transmission.

Shake and vibration while driving

GO toPinpoint Test B.

• Air cleaner.

• Power assisted steering.

• Powertrain.

• Powertrain/drivetrain mounts.

• Exhaust system.

Tip-in moan

G37349en2008.50 Kuga8/2011

100-04-

13

Noise, Vibration and Harshness

100-04- 13

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 92 of 2057

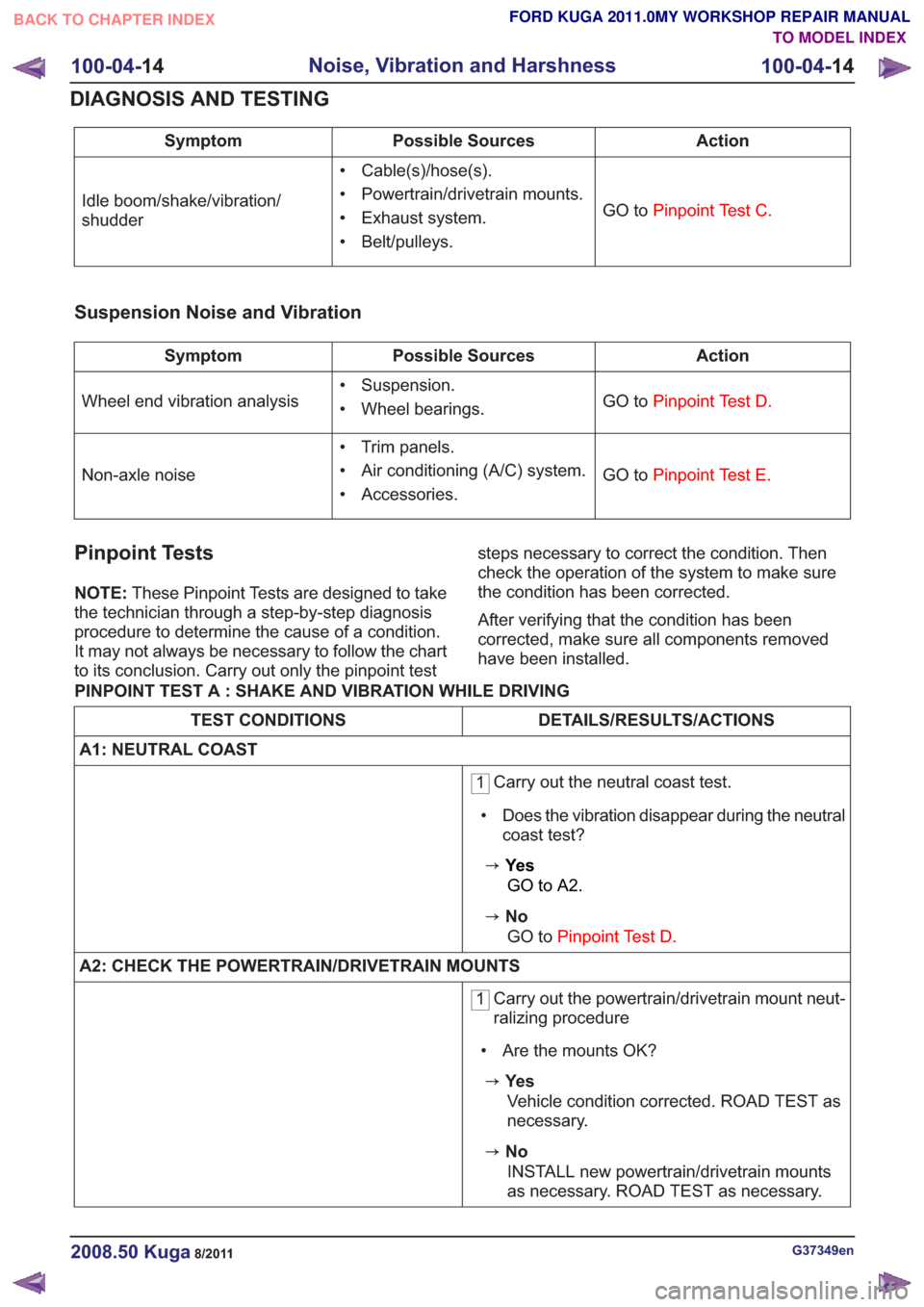

Action

Possible Sources

Symptom

GO toPinpoint Test C.

• Cable(s)/hose(s).

• Powertrain/drivetrain mounts.

• Exhaust system.

• Belt/pulleys.

Idle boom/shake/vibration/

shudder

Suspension Noise and Vibration

Action

Possible Sources

Symptom

GO toPinpoint Test D.

• Suspension.

• Wheel bearings.

Wheel end vibration analysis

GO toPinpoint Test E.

• Trim panels.

• Air conditioning (A/C) system.

• Accessories.

Non-axle noise

Pinpoint Tests

NOTE:

These Pinpoint Tests are designed to take

the technician through a step-by-step diagnosis

procedure to determine the cause of a condition.

It may not always be necessary to follow the chart

to its conclusion. Carry out only the pinpoint test steps necessary to correct the condition. Then

check the operation of the system to make sure

the condition has been corrected.

After verifying that the condition has been

corrected, make sure all components removed

have been installed.

PINPOINT TEST A : SHAKE AND VIBRATION WHILE DRIVING

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

A1: NEUTRAL COAST

1 Carry out the neutral coast test.

• Does the vibration disappear during the neutral coast test?

zYe s

GO to A2.

zNoGO to Pinpoint Test D.

A2: CHECK THE POWERTRAIN/DRIVETRAIN MOUNTS

1 Carry out the powertrain/drivetrain mount neut-

ralizing procedure

• Are the mounts OK?

zYe s Vehicle condition corrected. ROAD TEST as

necessary.

zNoINSTALL new powertrain/drivetrain mounts

as necessary. ROAD TEST as necessary.

G37349en2008.50 Kuga8/2011

100-04- 14

Noise, Vibration and Harshness

100-04- 14

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 93 of 2057

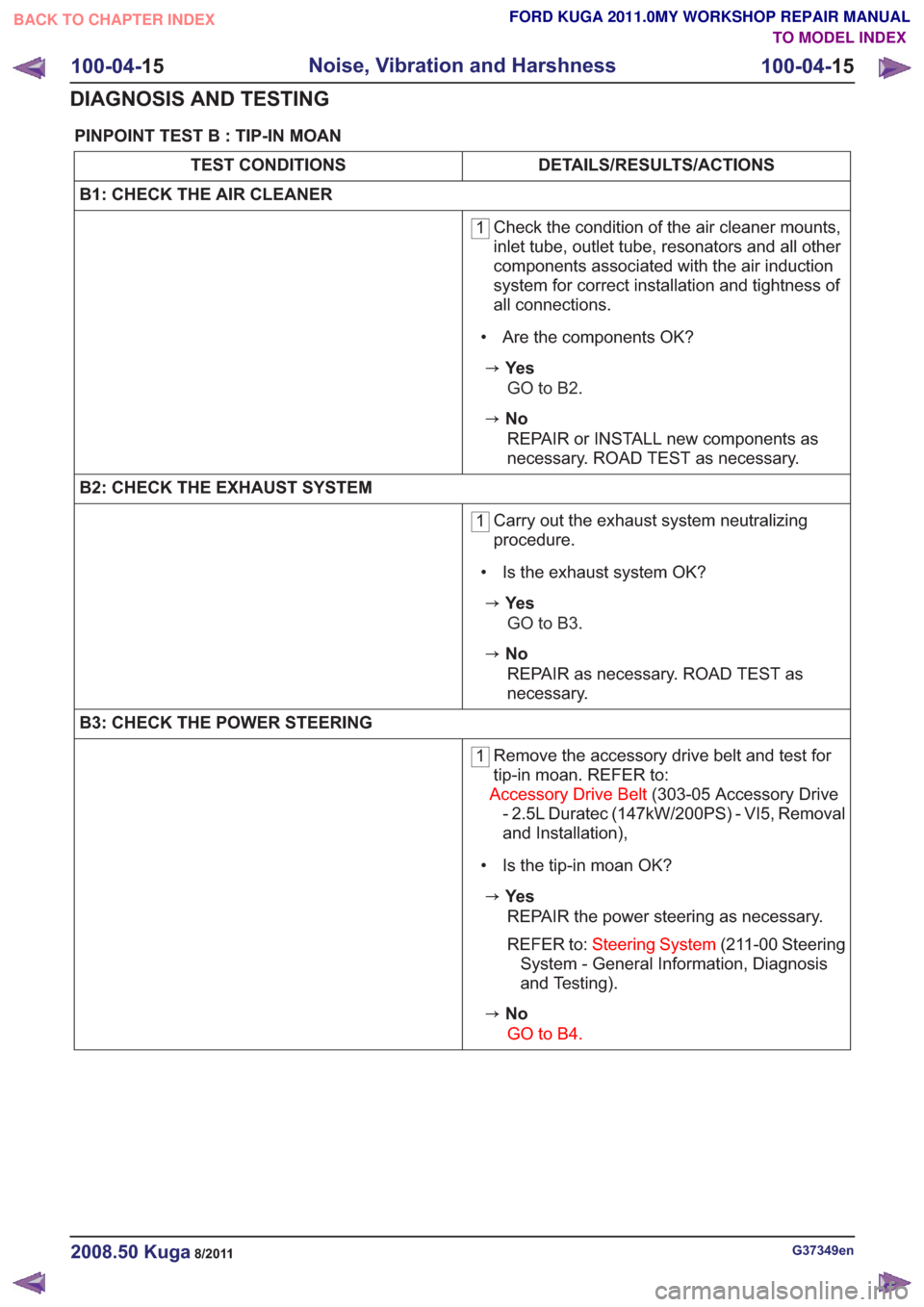

PINPOINT TEST B : TIP-IN MOAN

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B1: CHECK THE AIR CLEANER

1 Check the condition of the air cleaner mounts,

inlet tube, outlet tube, resonators and all other

components associated with the air induction

system for correct installation and tightness of

all connections.

• Are the components OK?

zYe s GO to B2.

zNoREPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

B2: CHECK THE EXHAUST SYSTEM

1 Carry out the exhaust system neutralizing

procedure.

• Is the exhaust system OK?

zYe s GO to B3.

zNoREPAIR as necessary. ROAD TEST as

necessary.

B3: CHECK THE POWER STEERING

1 Remove the accessory drive belt and test for

tip-in moan. REFER to:

Accessory Drive Belt (303-05 Accessory Drive

- 2.5L Duratec (147kW/200PS) - VI5, Removal

and Installation),

• Is the tip-in moan OK?

zYe s REPAIR the power steering as necessary.

REFER to: Steering System (211-00 Steering

System - General Information, Diagnosis

and Testing).

zNo

GO to B4.

G37349en2008.50 Kuga8/2011

100-04- 15

Noise, Vibration and Harshness

100-04- 15

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 95 of 2057

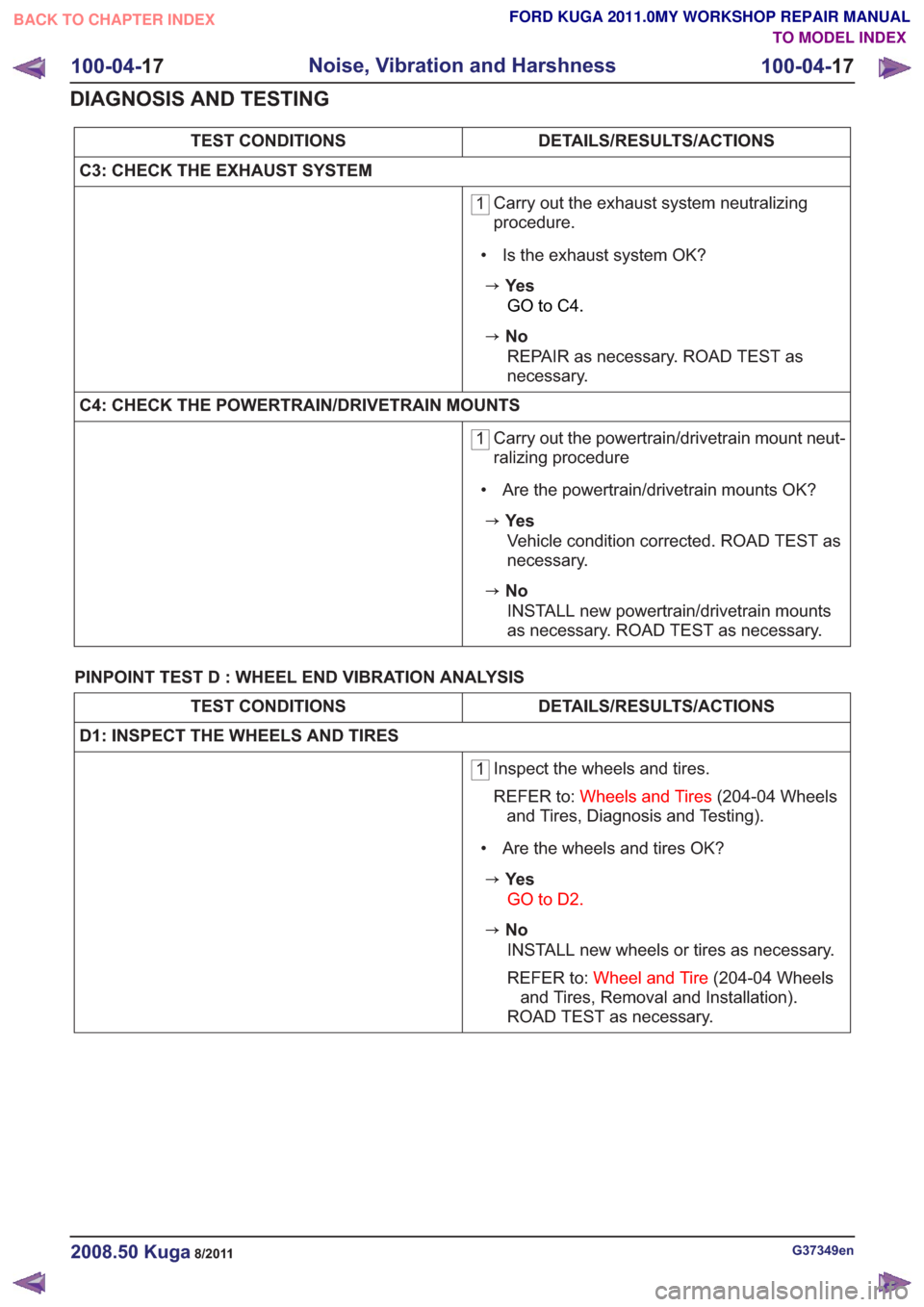

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

C3: CHECK THE EXHAUST SYSTEM

1 Carry out the exhaust system neutralizing

procedure.

• Is the exhaust system OK?

zYe s GO to C4 .

zNo

REPAIR as necessary. ROAD TEST as

necessary.

C4: CHECK THE POWERTRAIN/DRIVETRAIN MOUNTS

1 Carry out the powertrain/drivetrain mount neut-

ralizing procedure

• Are the powertrain/drivetrain mounts OK?

zYe s Vehicle condition corrected. ROAD TEST as

necessary.

zNoINSTALL new powertrain/drivetrain mounts

as necessary. ROAD TEST as necessary.

PINPOINT TEST D : WHEEL END VIBRATION ANALYSIS

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

D1: INSPECT THE WHEELS AND TIRES

1 Inspect the wheels and tires.

REFER to:

Wheels and Tires (204-04 Wheels

and Tires, Diagnosis and Testing).

• Are the wheels and tires OK?

zYe s GO to D2 .

zNo

INSTALL new wheels or tires as necessary.

REFER to: Wheel and Tire (204-04 Wheels

and Tires, Removal and Installation).

ROAD TEST as necessary.

G37349en2008.50 Kuga8/2011

100-04- 17

Noise, Vibration and Harshness

100-04- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 156 of 2057

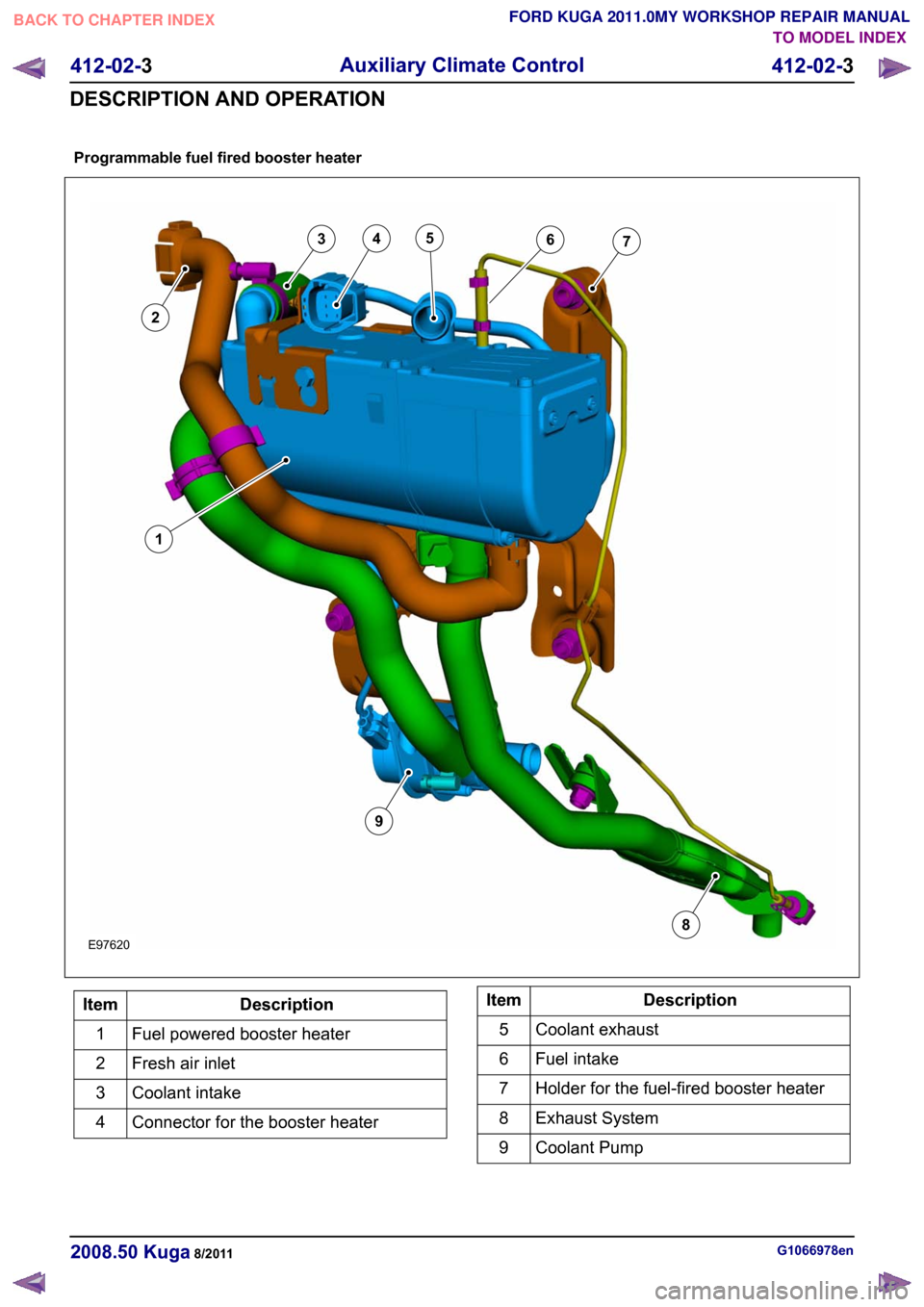

Programmable fuel fired booster heater

Description

Item

Fuel powered booster heater

1

Fresh air inlet

2

Coolant intake

3

Connector for the booster heater

4 Description

Item

Coolant exhaust

5

Fuel intake

6

Holder for the fuel-fired booster heater

7

Exhaust System

8

Coolant Pump

9 G1066978en

2008.50 Kuga 8/2011 412-02-3

Auxiliary Climate Control

412-02-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL269835471E97620

Page 1353 of 2057

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

F2: CHECK FOR BRAKE PEDAL BINDING

1 Check the brake pedal for free operation.

• Did the brake pedal operate freely?

zYe s INSTALL a new brake booster. TEST the

system for normal operation.

zNoINSTALL new brake pedal bushings. TEST

the system for normal operation.

Component Tests

Hydraulic Leak Check

NOTE: There is a common clutch and brake fluid

reservoir, therefore it is possible that a clutch leak

can lead to reduction in the reservoir level.

It is possible that all evidence of fluid leakage may

have washed off if the vehicle has been operated

in rain or snow, as brake fluid is water-soluble.

Refill the system, bleed then apply the brakes

several times. Examine the system to verify that

the reservoir fluid level is actually dropping. Locate

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in the NEUTRAL position.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for the vacuum to replenish the brake booster.

NOTE: This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving downward or an increased resistance to the

pedal travel occurs. 5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

NOTE: The additional movement of the brake pedal

is the result of the increased engine manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

Inspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed

areas. Inspect the check valve on the brake booster

for damage.

Brake Booster Operation Check

1. Check the hydraulic brake system for leaks orlow fluid.

2. With the transaxle in the NEUTRAL position, stop the engine and apply the parking brake.

Apply the brake pedal several times to exhaust

all the vacuum in the system.

3. With the engine turned off and the vacuum in the system exhausted, apply the brake pedal

and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

G1058975en2008.50 Kuga8/2011

206-00- 17

Brake System - General Information

206-00- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL