jacking FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1355 of 2057

too close to the fluid level indicator assembly,

or float assembly damage.

Bypass Condition Test

1. Check the fluid in the brake master cylinderreservoir. Fill the brake master cylinder reservoir

if low or empty.

2. Observe the fluid level in the brake master cylinder reservoir. If after several brake

applications, the fluid level remains the same,

measure the wheel turning torque required to

rotate the wheels with the brakes applied as

follows:

Place the transaxle in the NEUTRAL position.

Raise and support the vehicle. REFER to: (100-02

Jacking and Lifting) Jacking (Description and Operation),

Lifting (Description and Operation).

Apply the brakes with a minimum of 445 N (100

lb) and hold for approximately 15 seconds. With

the brakes still applied, exert a torque on the front

wheels of 10.1 Nm (75 lb ft). If either wheel rotates,

install a new brake master cylinder.

REFER to: Brake Master Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06 Hydraulic Brake

Actuation, Removal and Installation).

Non-Pressure Leaks

Any empty brake master cylinder reservoir

condition may be caused by two types of

non-pressure external leaks.

Type 1: An external leak may occur at the brake

master cylinder reservoir cap because of incorrect

positioning of the gasket and cap. Reposition the

cap and gasket.

Type 2: An external leak may occur at the brake

master cylinder reservoir mounting seals. Service

such a leak by installing new seals.

G1058975en2008.50 Kuga8/2011

206-00- 19

Brake System - General Information

206-00- 19

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1368 of 2057

Brake System Draining and Filling(12 154 0; 12 154 4)

General EquipmentFluid Container

Draining

15. Refer to: Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

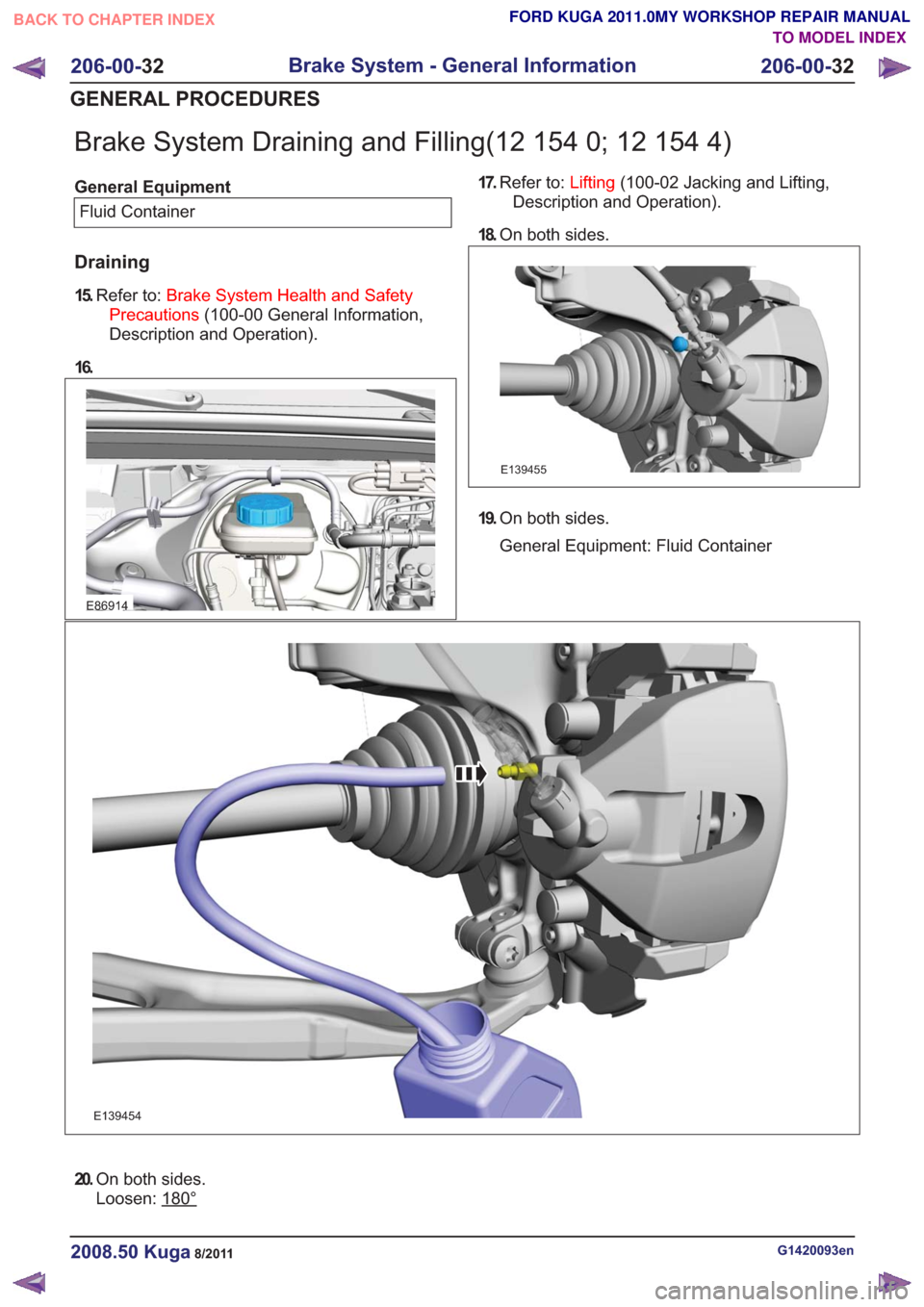

16.

E86914

17. Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

18. On both sides.

E139455

19.On both sides.

General Equipment: Fluid Container

E139454

20.On both sides.

Loosen: 180°

G1420093en2008.50 Kuga8/2011

206-00- 32

Brake System - General Information

206-00- 32

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1388 of 2057

Pinpoint Tests

PINPOINT TEST A : THE PARKING BRAKE WILL NOT APPLY

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

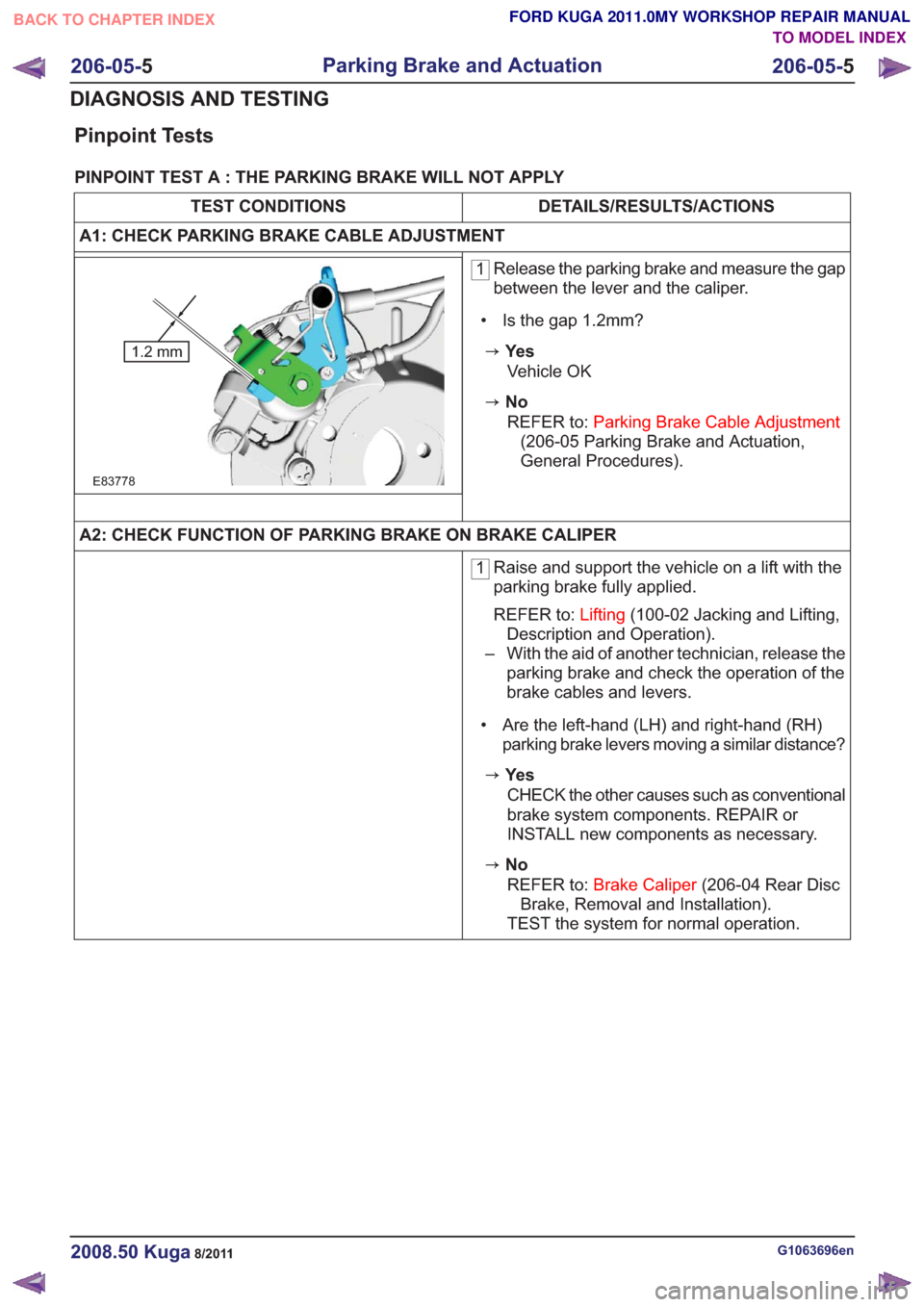

A1: CHECK PARKING BRAKE CABLE ADJUSTMENT

1 Release the parking brake and measure the gap

between the lever and the caliper.

• Is the gap 1.2mm?

zYe s

E83778

1.2 mm

Vehicle OK

zNo REFER to: Parking Brake Cable Adjustment

(206-05 Parking Brake and Actuation,

General Procedures).

A2: CHECK FUNCTION OF PARKING BRAKE ON BRAKE CALIPER

1 Raise and support the vehicle on a lift with the

parking brake fully applied.

REFER to:

Lifting(100-02 Jacking and Lifting,

Description and Operation).

– With the aid of another technician, release the parking brake and check the operation of the

brake cables and levers.

• Are the left-hand (LH) and right-hand (RH) parking brake levers moving a similar distance?

zYe s

CHECK the other causes such as conventional

brake system components. REPAIR or

INSTALL new components as necessary.

zNoREFER to: Brake Caliper (206-04 Rear Disc

Brake, Removal and Installation).

TEST the system for normal operation.

G1063696en2008.50 Kuga8/2011

206-05- 5

Parking Brake and Actuation

206-05- 5

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1393 of 2057

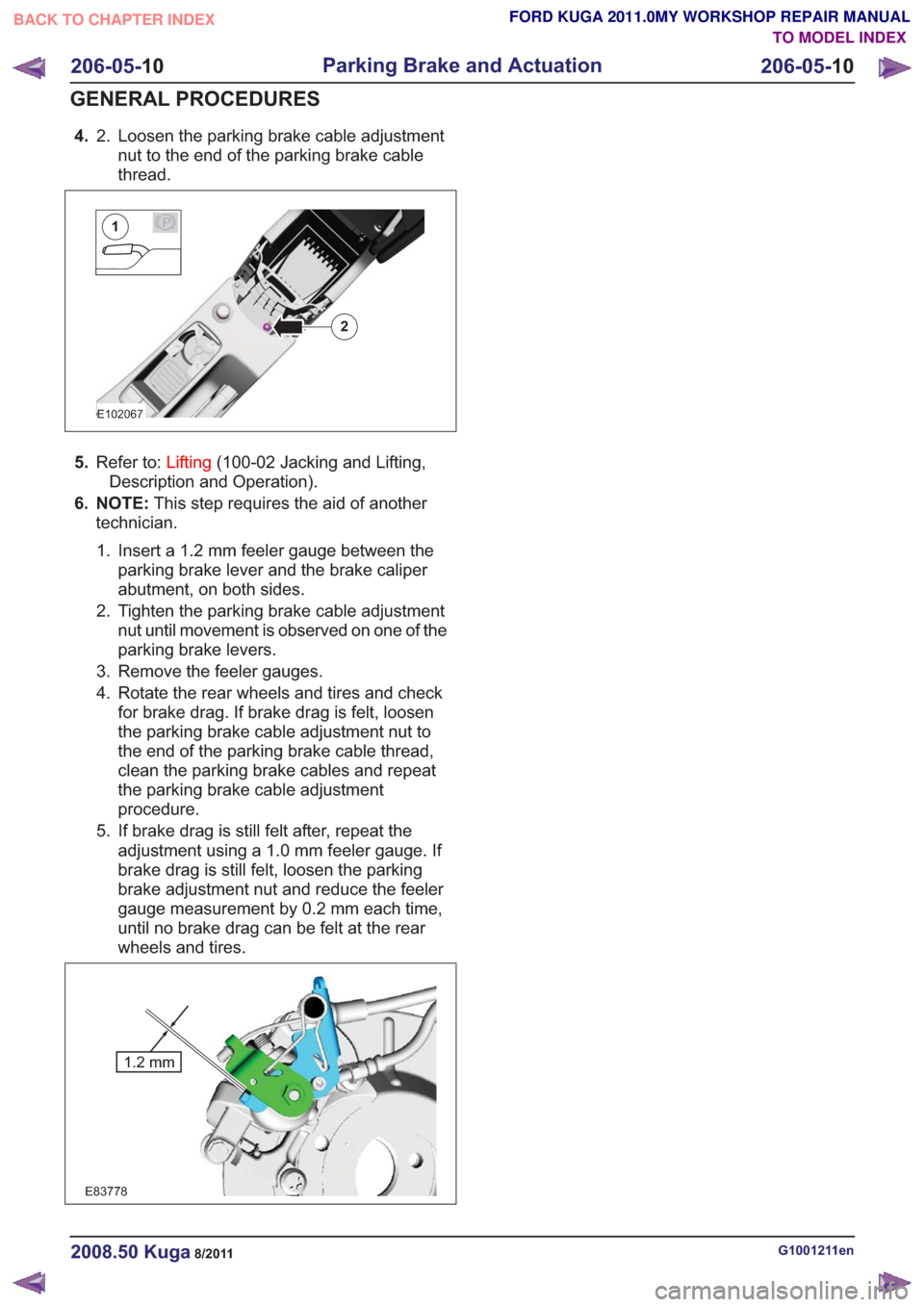

4.Loosen the parking brake cable adjustment

nut to the end of the parking brake cable

thread.

2.

E102067

2

P1

5.

Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

6. NOTE: This step requires the aid of another

technician.

1. Insert a 1.2 mm feeler gauge between the parking brake lever and the brake caliper

abutment, on both sides.

2. Tighten the parking brake cable adjustment nut until movement is observed on one of the

parking brake levers.

3. Remove the feeler gauges.

4. Rotate the rear wheels and tires and check for brake drag. If brake drag is felt, loosen

the parking brake cable adjustment nut to

the end of the parking brake cable thread,

clean the parking brake cables and repeat

the parking brake cable adjustment

procedure.

5. If brake drag is still felt after, repeat the adjustment using a 1.0 mm feeler gauge. If

brake drag is still felt, loosen the parking

brake adjustment nut and reduce the feeler

gauge measurement by 0.2 mm each time,

until no brake drag can be felt at the rear

wheels and tires.

E83778

1.2 mm

G1001211en2008.50 Kuga8/2011

206-05- 10

Parking Brake and Actuation

206-05- 10

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1406 of 2057

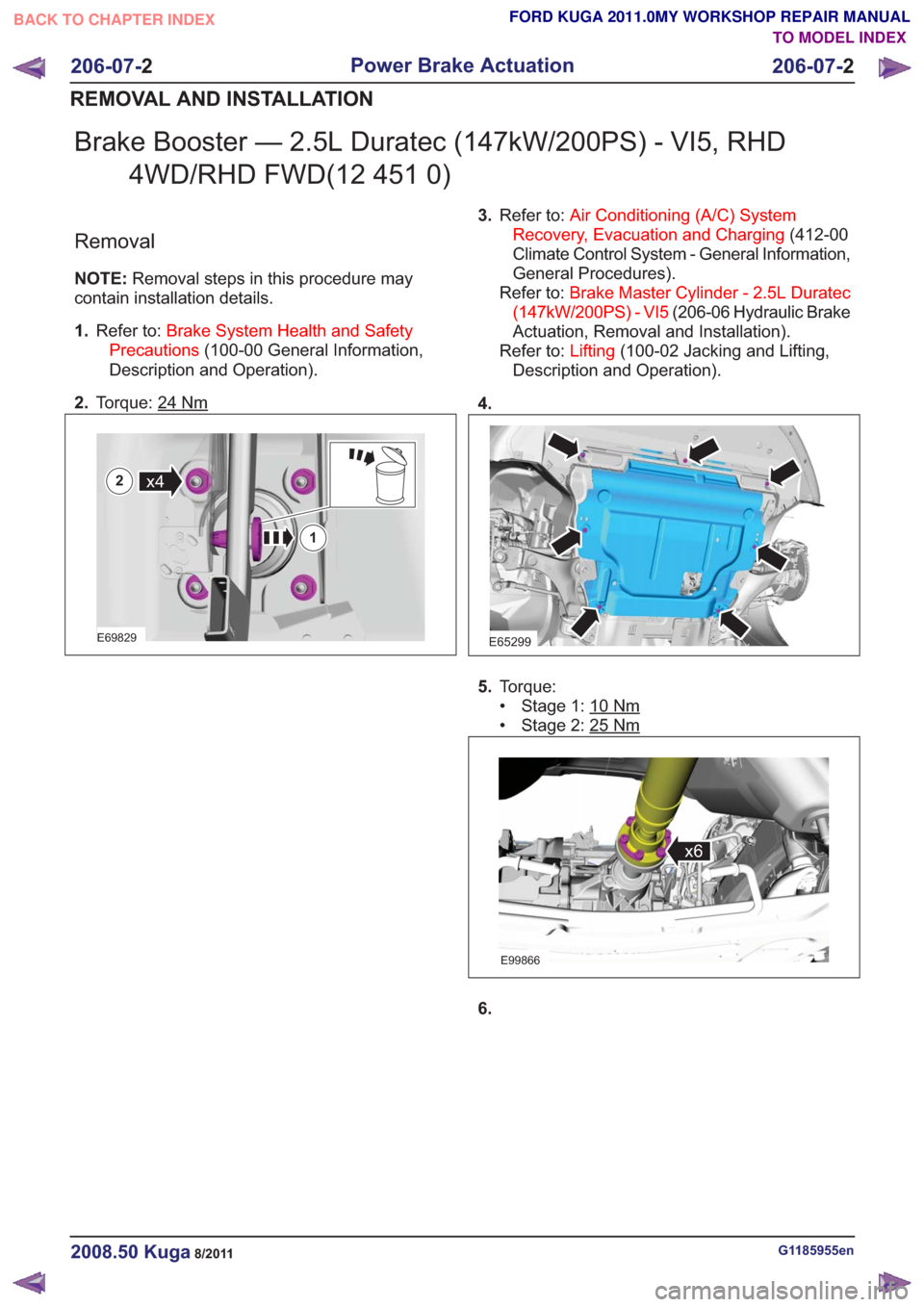

Brake Booster — 2.5L Duratec (147kW/200PS) - VI5, RHD4WD/RHD FWD(12 451 0)

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Brake System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

2. Torque: 24

Nm

E69829

x4

1

2

3.Refer to: Air Conditioning (A/C) System

Recovery, Evacuation and Charging (412-00

Climate Control System - General Information,

General Procedures).

Refer to: Brake Master Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06 Hydraulic Brake

Actuation, Removal and Installation).

Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

4.

E65299

5. Torque:

• Stage 1: 10

Nm

• Stage 2: 25Nm

E99866

x6

6.

G1185955en2008.50 Kuga8/2011

206-07- 2

Power Brake Actuation

206-07- 2

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1444 of 2057

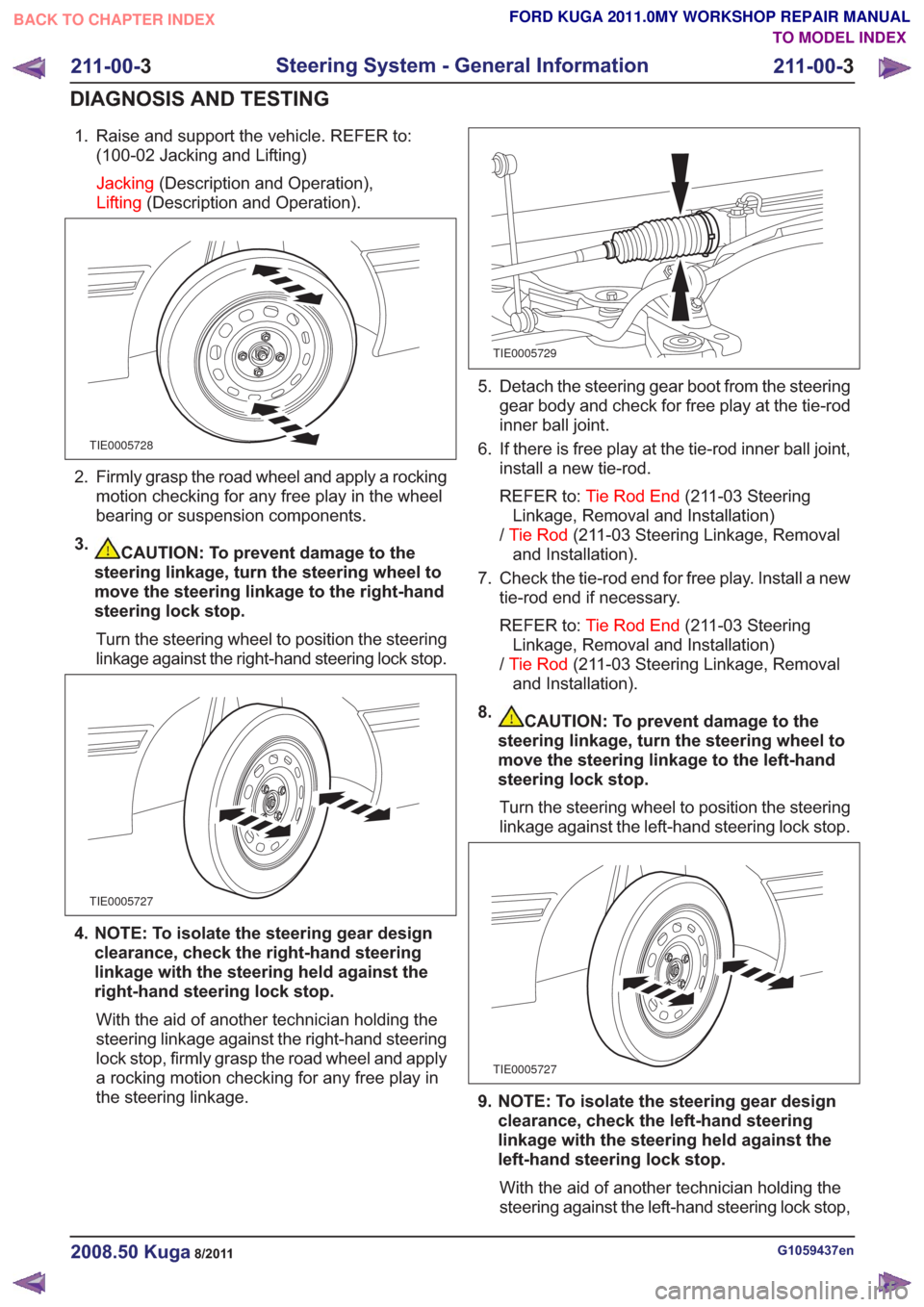

1. Raise and support the vehicle. REFER to:(100-02 Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

TIE0005728

2. Firmly grasp the road wheel and apply a rocking

motion checking for any free play in the wheel

bearing or suspension components.

3.

CAUTION: To prevent damage to the

steering linkage, turn the steering wheel to

move the steering linkage to the right-hand

steering lock stop.

Turn the steering wheel to position the steering

linkage against the right-hand steering lock stop.

TIE0005727

4. NOTE: To isolate the steering gear design clearance, check the right-hand steering

linkage with the steering held against the

right-hand steering lock stop.

With the aid of another technician holding the

steering linkage against the right-hand steering

lock stop, firmly grasp the road wheel and apply

a rocking motion checking for any free play in

the steering linkage.

TIE0005729

5. Detach the steering gear boot from the steering gear body and check for free play at the tie-rod

inner ball joint.

6. If there is free play at the tie-rod inner ball joint, install a new tie-rod.

REFER to: Tie Rod End (211-03 Steering

Linkage, Removal and Installation)

/ Tie Rod (211-03 Steering Linkage, Removal

and Installation).

7. Check the tie-rod end for free play. Install a new tie-rod end if necessary.

REFER to: Tie Rod End (211-03 Steering

Linkage, Removal and Installation)

/ Tie Rod (211-03 Steering Linkage, Removal

and Installation).

8.

CAUTION: To prevent damage to the

steering linkage, turn the steering wheel to

move the steering linkage to the left-hand

steering lock stop.

Turn the steering wheel to position the steering

linkage against the left-hand steering lock stop.

TIE0005727

9. NOTE: To isolate the steering gear design clearance, check the left-hand steering

linkage with the steering held against the

left-hand steering lock stop.

With the aid of another technician holding the

steering against the left-hand steering lock stop,

G1059437en2008.50 Kuga8/2011

211-00- 3

Steering System - General Information

211-00- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1447 of 2057

Steering Gear Checks After a Collision

General EquipmentFeeler gauge

Straight edge

Items to be observed when checking the steering

system

The following list of steering gear conditions and

the methods of testing should be taken into account

when carrying out checks to the steering system:

• If the steering gear has no faults after completing the following checks, do not install

a new steering gear.

• Surface corrosion and marks on the tie-rod are acceptable.

• When checking for turning effort torque peaks in the steering gear, turn the steering wheel from

steering lock stop to steering lock stop in

approximately 15 seconds.

• A steady increase of turning effort torque from steering center to steering lock stop is

acceptable.

• When checking for power steering fluid leaks, turn the steering wheel to the steering lock stop

in approximately 10 seconds.

• Noises from the power steering, for example the power steering pump relief valve, are

acceptable.

STEERING GEAR HOUSING

1. Raise and support the vehicle. REFER to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

2. Visually inspect the steering gear housing for cracks and damage. If the steering gear housing

is cracked or damaged, install a new steering

gear.

REFER to: Steering Gear (211-02 Power

Steering, Removal and Installation).

TIE-RODS

1. Using a straight edge and feeler gauge, check the tie-rods to see if they are straight. If the

distance between the tie-rod and straight edge is greater than 0.5 mm, install a new steering

gear.

REFER to:

Steering Gear (211-02 Power

Steering, Removal and Installation).

2. Check the tightening torque of the tie-rod end to wheel knuckle nut.

REFER to: Tie Rod End (211-03 Steering

Linkage, Removal and Installation).

3. Check the tightening torque of the tie-rod end locking nut.

REFER to: Tie Rod End (211-03 Steering

Linkage, Removal and Installation).

CHECK FOR TURNING EFFORT TORQUE

PEAKS IN THE STEERING GEAR

1. Lower and support the vehicle making sure that the road wheels are just clear of the floor.

2. With the ignition switch in position I, slowly turn the steering wheel from steering lock stop to

steering lock stop. If a turning effort torque peak

or judder is felt while turning the steering wheel,

detach the tie-rods from the wheel knuckles.

3. Slowly turn the steering wheel from steering lock stop to steering lock stop. If a turning effort

torque peak or judder is felt while turning the

steering wheel, install a new steering gear.

REFER to: Steering Gear (211-02 Power

Steering, Removal and Installation).

CHECK FOR POWER STEERING FLUID LEAKS

1. Lower the vehicle.

2. Run the engine at a fast idle and slowly turn the steering wheel to the left-hand steering lock

stop. Hold the steering wheel in this position for

5 seconds with a turning effort torque of 15 Nm

at the steering wheel rim.

3. Turn the steering wheel away from the left-hand steering lock stop for 30 seconds.

4. Run the engine at a fast idle and slowly turn the steering wheel to the right-hand steering lock

stop. Hold the steering wheel in this position for

5 seconds with a turning effort torque of 15 Nm

at the steering wheel rim.

5. Turn the steering wheel away from the right-hand steering lock stop.

6. Check for power steering fluid leaks at the steering gear housing and the power steering

line connections to the steering gear. If there is

G538091en2008.50 Kuga8/2011

211-00- 6

Steering System - General Information

211-00- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1449 of 2057

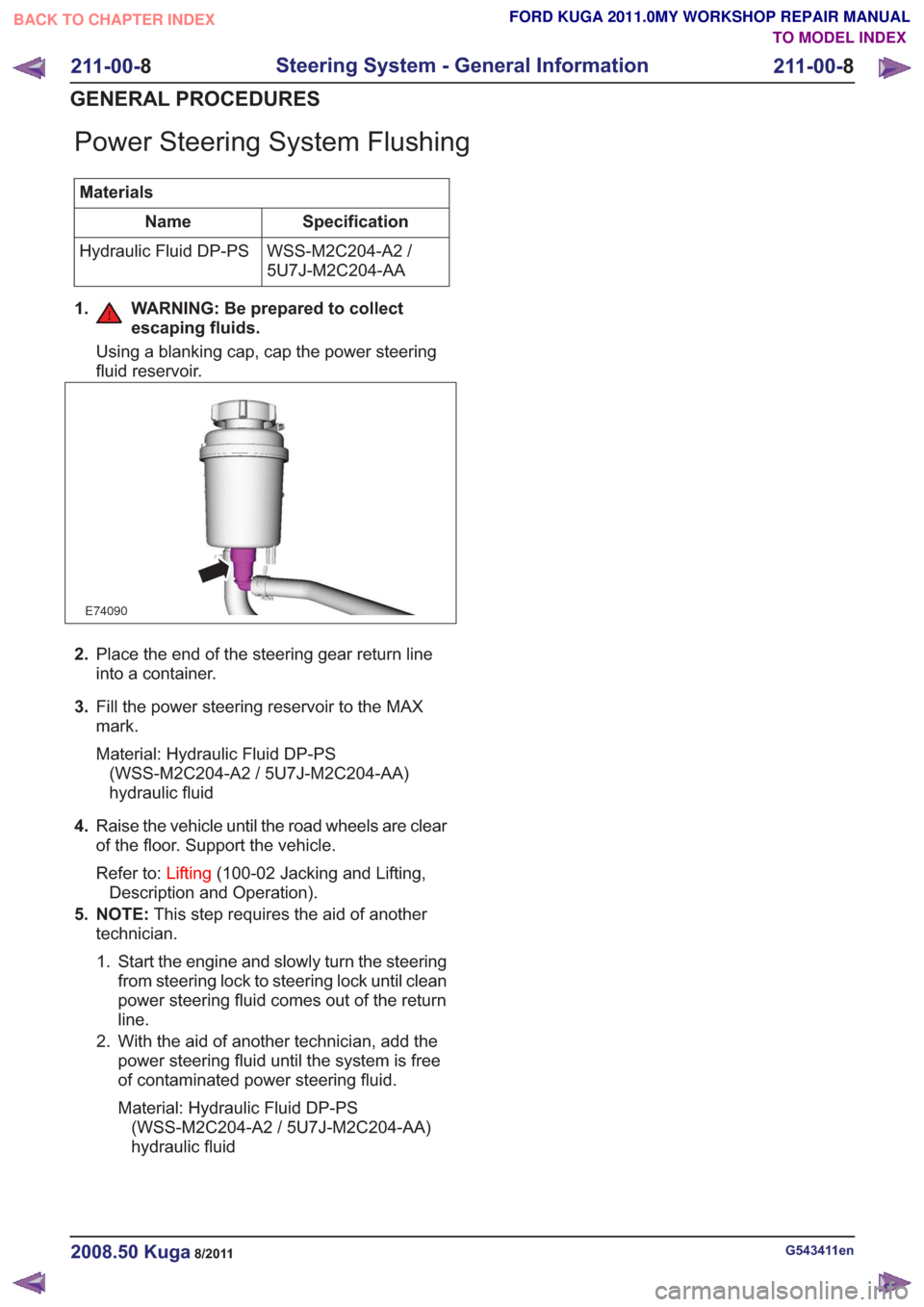

Power Steering System Flushing

MaterialsSpecification

Name

WSS-M2C204-A2 /

5U7J-M2C204-AA

Hydraulic Fluid DP-PS

1. WARNING: Be prepared to collect escaping fluids.

Using a blanking cap, cap the power steering

fluid reservoir.

E74090

2.Place the end of the steering gear return line

into a container.

3. Fill the power steering reservoir to the MAX

mark.

Material: Hydraulic Fluid DP-PS

(WSS-M2C204-A2 / 5U7J-M2C204-AA)

hydraulic fluid

4. Raise the vehicle until the road wheels are clear

of the floor. Support the vehicle.

Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

5. NOTE: This step requires the aid of another

technician.

1. Start the engine and slowly turn the steering from steering lock to steering lock until clean

power steering fluid comes out of the return

line.

2. With the aid of another technician, add the power steering fluid until the system is free

of contaminated power steering fluid.

Material: Hydraulic Fluid DP-PS(WSS-M2C204-A2 / 5U7J-M2C204-AA)

hydraulic fluid

G543411en2008.50 Kuga8/2011

211-00- 8

Steering System - General Information

211-00- 8

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1450 of 2057

Power Steering System Filling

Special Tool(s)211-189

Adapter, Power Steering

Bleeding

13016

416-D001

Hand Vacuum

Pump/Pressure Pump

23036A

Materials

Specification

Name

WSS-M2C204-A2 /

5U7J-M2C204-AA

Hydraulic Fluid DP-PS

1. Fill the power steering fluid reservoir to the MAX

mark.

Material: Hydraulic Fluid DP-PS

(WSS-M2C204-A2 / 5U7J-M2C204-AA)

hydraulic fluid

2. Raise the vehicle until the road wheels are clear

of the floor. Support the vehicle.

Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

3. Slowly turn the steering wheel from lock to lock

and add power steering fluid until the power

steering fluid in the power steering fluid reservoir

stops dropping.

4. Start the engine and slowly turn the steering

wheel from lock to lock and add power steering

fluid until the power steering fluid in the power

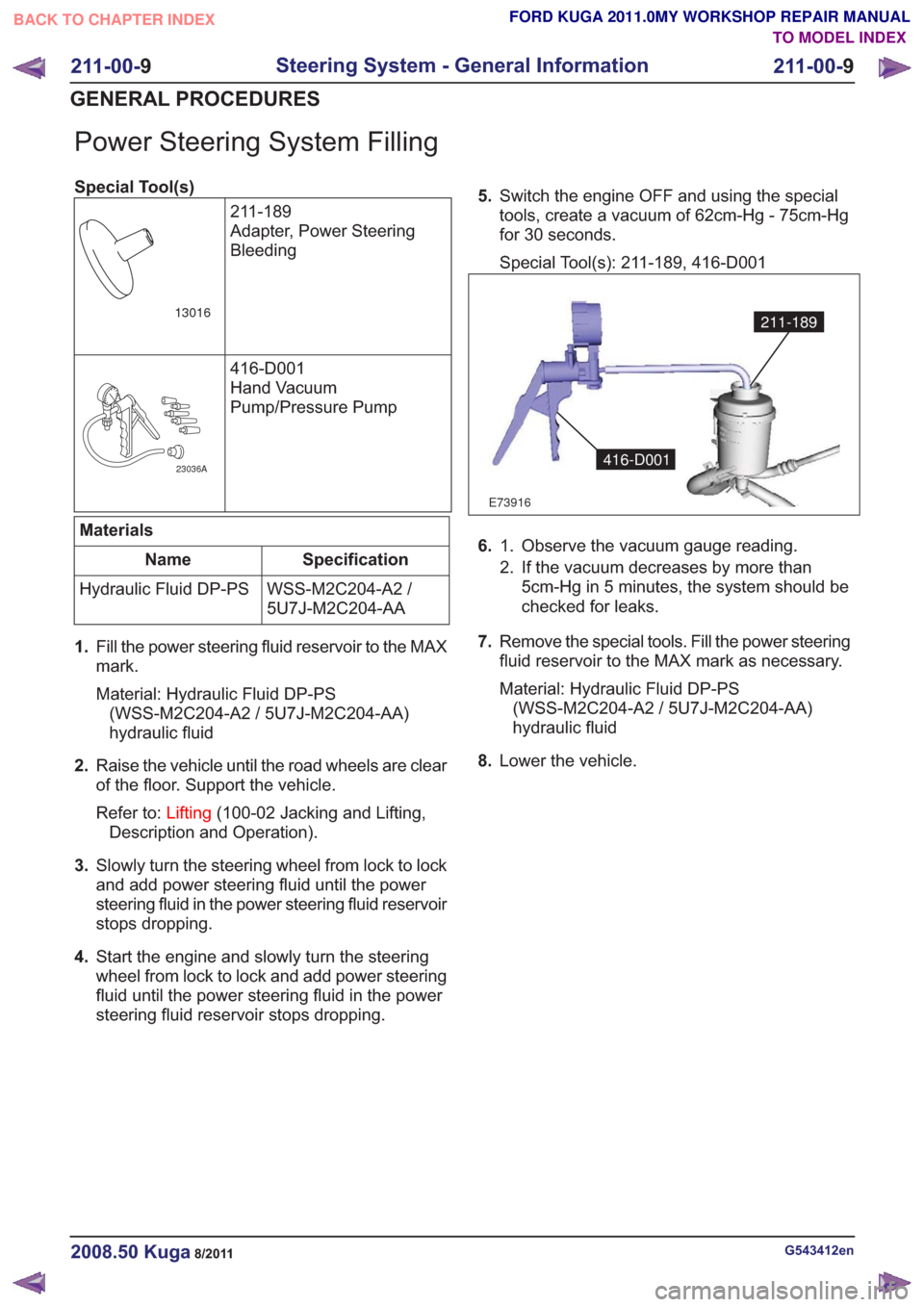

steering fluid reservoir stops dropping. 5.

Switch the engine OFF and using the special

tools, create a vacuum of 62cm-Hg - 75cm-Hg

for 30 seconds.

Special Tool(s): 211-189, 416-D001

E73916

211-189

416-D001

6. Observe the vacuum gauge reading.

1.

2. If the vacuum decreases by more than

5cm-Hg in 5 minutes, the system should be

checked for leaks.

7. Remove the special tools. Fill the power steering

fluid reservoir to the MAX mark as necessary.

Material: Hydraulic Fluid DP-PS

(WSS-M2C204-A2 / 5U7J-M2C204-AA)

hydraulic fluid

8. Lower the vehicle.

G543412en2008.50 Kuga8/2011

211-00- 9

Steering System - General Information

211-00- 9

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1527 of 2057

9. Install the ignition coil-on-plug.REFER to: Ignition Coil-On-Plug (303-07 Engine

Ignition - 2.5L Duratec (147kW/200PS) - VI5,

Removal and Installation).

TIE44609

10. Install the fuel pump relay and close the CJB.

TIE44608

11. Install the CJB cover.

Measure the compression pressure

(Engine - 2.0L Duratorq-TDCi (DW)

Diesel)

WARNINGS:

Do not smoke or carry lighted tobacco or

open flame of any type when working on or near any fuel related components.

Highly flammable vapors are always

present and can ignite. Failure to follow

these instructions may result in personal

injury.

Do not carry out any repairs to the fuel

injection system without checking that the

fuel pressure has dropped to zero and that

the fuel temperature has either reached

ambient temperature or is below 30°C,

whichever is the greater. Failure to follow

these instructions may result in personal

injury.

1. Using datalogger in the Ford diagnostic

equipment , check that the fuel pressure has

dropped to zero and that the fuel temperature

has either reached ambient temperature or is

below 30°C, whichever is the greater.

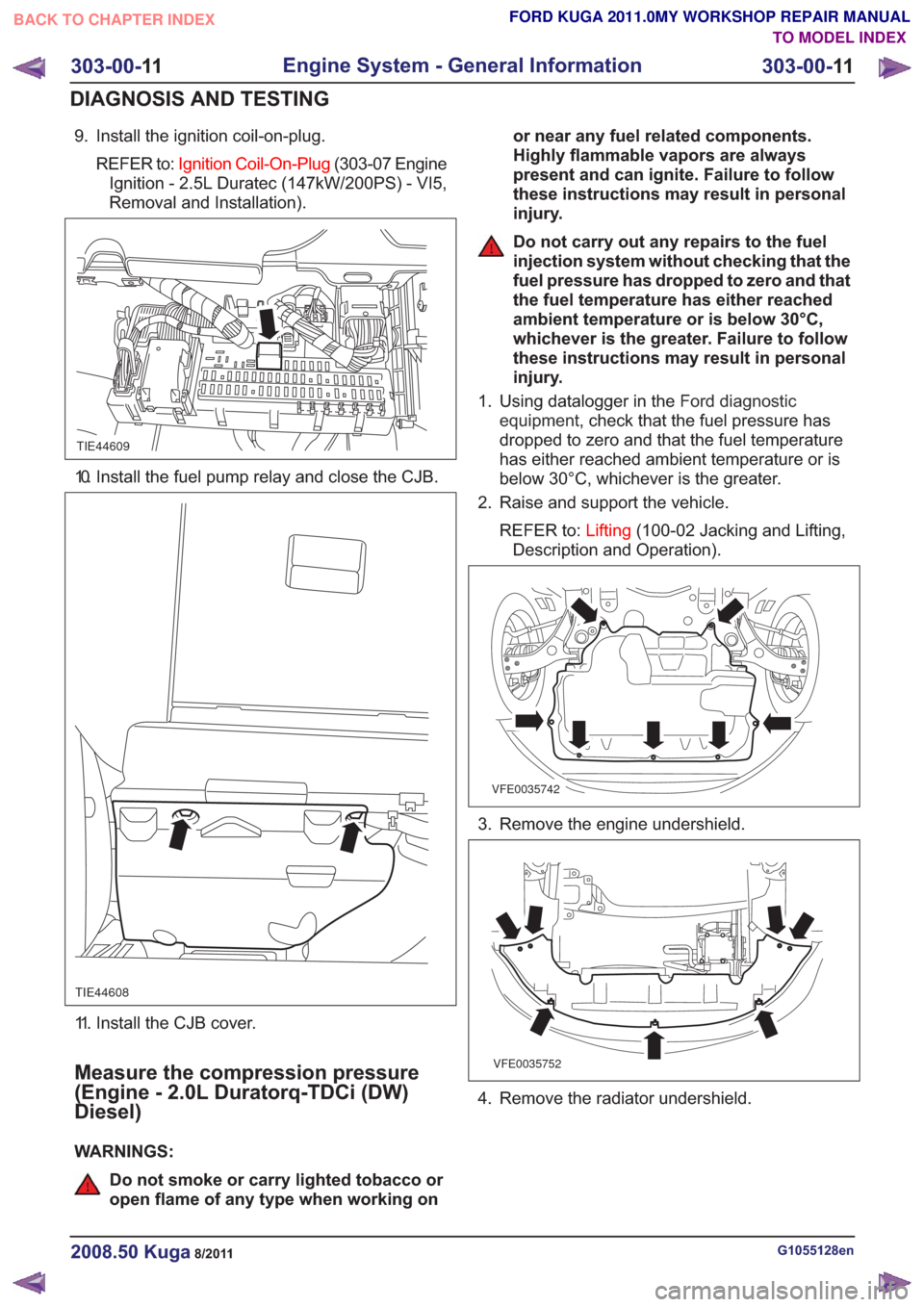

2. Raise and support the vehicle.

REFER to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

VFE0035742

3. Remove the engine undershield.

VFE0035752

4. Remove the radiator undershield.

G1055128en2008.50 Kuga8/2011

303-00- 11

Engine System - General Information

303-00- 11

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL