FORD MONDEO 1993 Service Owners Manual

Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 91 of 279

4If a hose proves stubborn, try to release it

by rotating it on its unions before attempting

to work it off. Gently prise the end of the hose

with a blunt instrument (such as a flat-bladed

screwdriver), but do not apply too much force,

and take care not to damage the pipe stubs or

hoses. Note in particular that the radiator hose

unions are fragile; do not use excessive force

when attempting to remove the hoses. If all

else fails, cut the hose with a sharp knife, then

slit it so that it can be peeled off in two pieces.

While expensive, this is preferable to buying a

new radiator. Check first, however, that a new

hose is readily available.

5When refitting a hose, first slide the clampsonto the hose, then work the hose onto its

unions. If the hose is stiff, use soap (or

washing-up liquid) as a lubricant, or soften it

by soaking it in boiling water, but take care to

prevent scalding.

6Work each hose end fully onto its union,

then check that the hose is settled correctly

and is properly routed. Slide each clip along

the hose until it is behind the union flared end,

before tightening it securely.

7Refill the system with coolant (see Chap-

ter 1).

8Check carefully for leaks as soon as

possible after disturbing any part of the

cooling system.Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Removal

1Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).

2Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses, then swing the resonator up

clear of the thermostat housing (see Chap-

ter 4).

3Drain the cooling system (see Chapter 1). If

the coolant is relatively new or in good

condition, drain it into a clean container and

re-use it.

4Disconnect the expansion tank coolant

hose and the radiator top hose from the

thermostat housing’s water outlet.

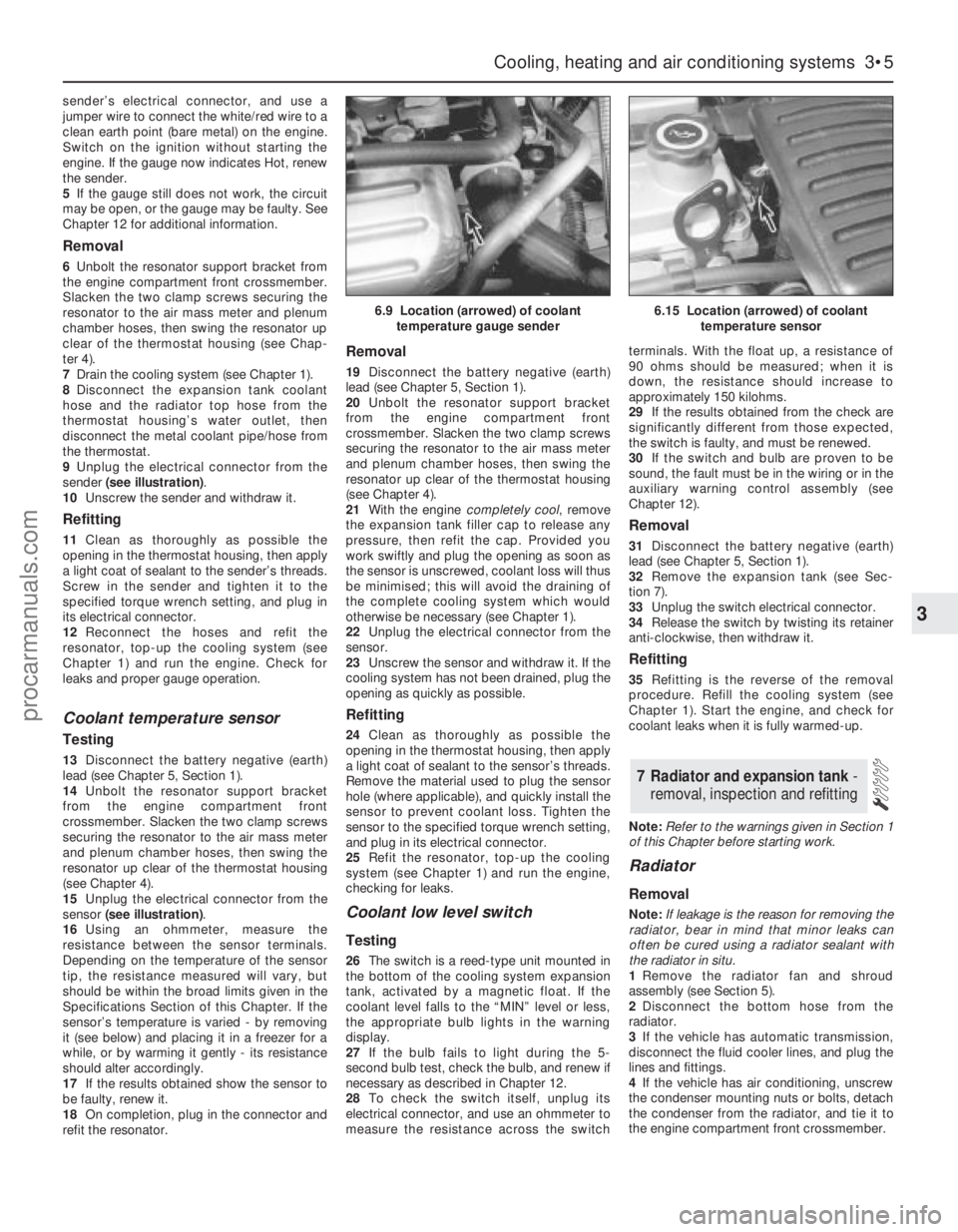

5Unbolt the water outlet and withdraw the

thermostat (see illustration). Note the

position of the air bleed valve, and how the

thermostat is installed (which end is facing

outwards).

Testing

General check

6Before assuming the thermostat is to blame

for a cooling system problem, check the

coolant level, auxiliary drivebelt tension and

condition (see Chapter 1) and temperature

gauge operation.

7If the engine seems to be taking a long time

to warm up (based on heater output or

temperature gauge operation), the thermostat

is probably stuck open. Renew the

thermostat.

8If the engine runs hot, use your hand to

check the temperature of the radiator top

hose. If the hose isn’t hot, but the engine is,

the thermostat is probably stuck closed,

preventing the coolant inside the engine from

escaping to the radiator - renew the

thermostat.

4 Thermostat -

removal, testing and refitting

Cooling, heating and air conditioning systems 3•3

3

4.5 Unbolt water outlet to withdraw

thermostat

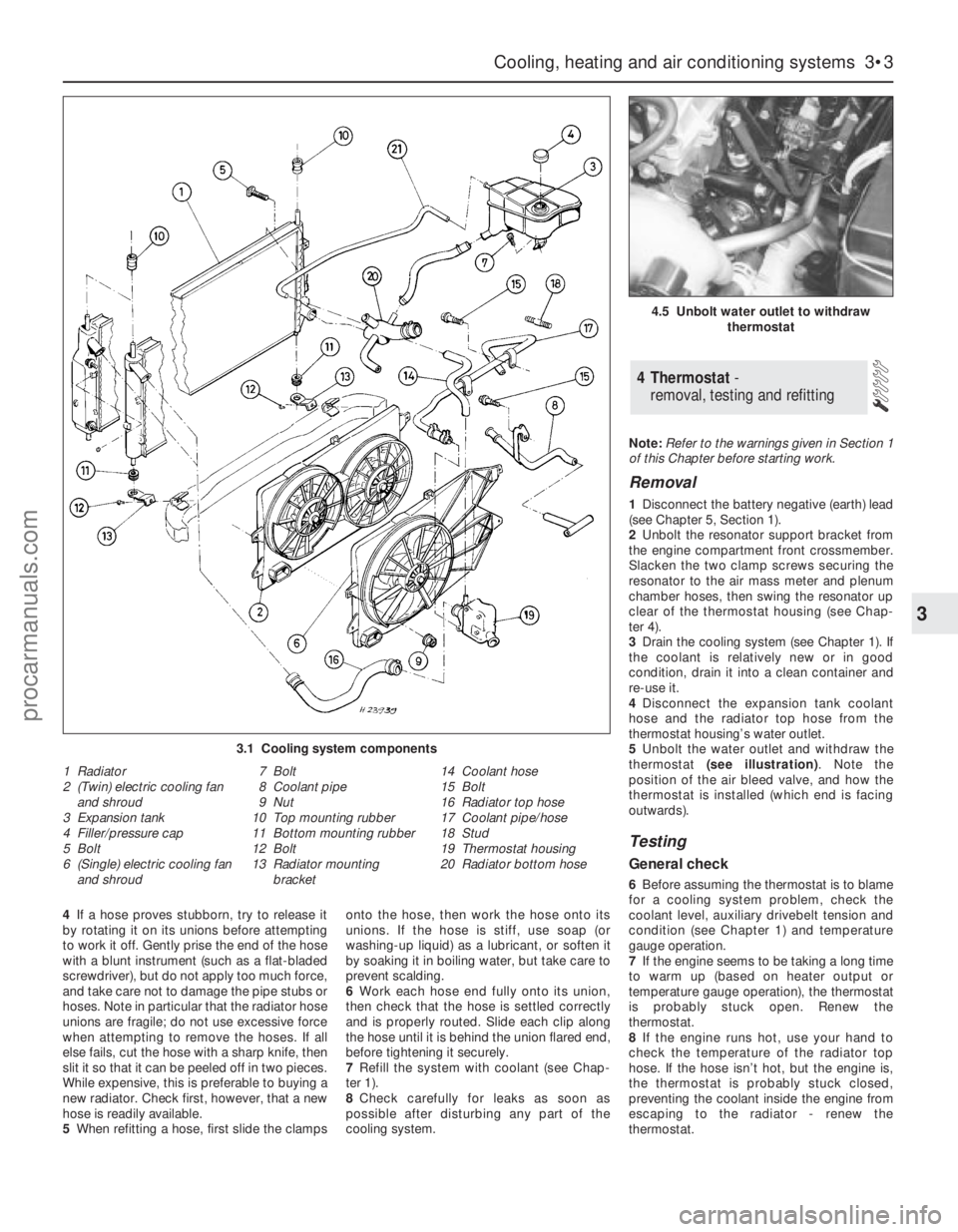

3.1 Cooling system components

1 Radiator

2 (Twin) electric cooling fan

and shroud

3 Expansion tank

4 Filler/pressure cap

5 Bolt

6 (Single) electric cooling fan

and shroud7 Bolt

8 Coolant pipe

9 Nut

10 Top mounting rubber

11 Bottom mounting rubber

12 Bolt

13 Radiator mounting

bracket14 Coolant hose

15 Bolt

16 Radiator top hose

17 Coolant pipe/hose

18 Stud

19 Thermostat housing

20 Radiator bottom hose

procarmanuals.com

Page 92 of 279

Caution: Don’t drive the vehicle

without a thermostat. The lack of

a thermostat will slow warm-up

time. The engine management system’s

ECU will then stay in warm-up mode for

longer than necessary, causing emissions

and fuel economy to suffer.

9If the radiator top hose is hot, it means that

the coolant is flowing and the thermostat is

open. Consult the “Fault diagnosis”section at

the front of this manual to assist in tracing

possible cooling system faults.

Thermostat test

10If the thermostat remains in the open

position at room temperature, it is faulty, and

must be renewed as a matter of course.

11To test it fully, suspend the (closed)

thermostat on a length of string in a container

of cold water, with a thermometer beside it;

ensure that neither touches the side of the

container.

12Heat the water, and check the

temperature at which the thermostat begins to

open; compare this value with that specified.

Continue to heat the water until the

thermostat is fully open; the temperature at

which this should happen is stamped in the

unit’s end. Remove the thermostat and allow

it to cool down; check that it closes fully.

13If the thermostat does not open and close

as described, if it sticks in either position, or if

it does not open at the specified temperature,

it must be renewed.

Refitting

14Refitting is the reverse of the removal

procedure. Clean the mating surfaces

carefully, renew the thermostat’s sealing ring

if it is worn or damaged, then refit the

thermostat with its air bleed valve uppermost

(see illustration). Tighten the water outlet

bolts to the specified torque wrench setting.

15Refill the cooling system (see Chapter 1).

16Start the engine and allow it to reach

normal operating temperature, then check for

leaks and proper thermostat operation.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Testing

1The radiator cooling fan is controlled by the

engine management system’s ECU, acting on

the information received from the coolant

temperature sensor. Where twin fans or two-

speed fans are fitted, control is through a

resistor assembly, secured to the bottom left-

hand corner of the fan shroud - this can be

renewed separately if faulty.

2First, check the relevant fuses and relays

(see Chapter 12).

3To test the fan motor, unplug the electrical

connector, and use fused jumper wires to

connect the fan directly to the battery. If the

fan still does not work, renew the motor.

4If the motor proved sound, the fault lies in

the coolant temperature sensor (see Section 6

for testing details), in the wiring loom (see

Chapter 12 for testing details) or in the engine

management system (see Chapter 6).

Removal and refitting

5Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).

6Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses, then swing the resonator up

clear of the thermostat housing (see Chapter 4).7Drain the cooling system (see Chapter 1).

8Remove the radiator top hose completely.

Disconnect the metal coolant pipe/hose from

the thermostat, and unbolt the coolant pipe

from the exhaust manifold heat shield.

9Unplug the cooling fan electrical

connector(s), then release all wiring and hoses

from the fan shroud.

10Unscrew the two nuts securing the fan

shroud, then lift the assembly to disengage it

from its bottom mountings and from the

radiator top edge (see illustrations).

11Withdraw the fan and shroud as an

assembly (see illustration).

12At the time of writing, the fan, motor and

shroud are available only as a complete

assembly, and must be renewed together if

faulty.

13Refitting is the reverse of the removal

procedure. Ensure that the shroud is settled

correctly at all four mounting points before

refitting and tightening the nuts.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Coolant temperature gauge

sender

Testing

1If the coolant temperature gauge is inopera-

tive, check the fuses first (see Chapter 12).

2If the gauge indicates Hot at any time,

consult the “Fault finding”section at the end

of this manual, to assist in tracing possible

cooling system faults.

3If the gauge indicates Hot shortly after the

engine is started from cold, unplug the

coolant temperature sender’s electrical

connector. If the gauge reading now drops,

renew the sender. If the reading remains high,

the wire to the gauge may be shorted to earth,

or the gauge is faulty.

4If the gauge fails to indicate after the engine

has been warmed up (approximately

10 minutes) and the fuses are known to be

sound, switch off the engine. Unplug the

6 Cooling system electrical

switches and sensors-

testing, removal and refitting

5 Radiator electric cooling

fan(s)- testing,

removal and refitting

3•4 Cooling, heating and air conditioning systems

4.14 Ensure thermostat is refitted as

shown

5.10A Fan shroud is secured at top by

mounting nut (A), at bottom by clip (B) . . .5.10B . . . and is hooked over radiator top

edge (one point arrowed)5.11 Removing radiator electric cooling

fan and shroud assembly

procarmanuals.com

Page 93 of 279

sender’s electrical connector, and use a

jumper wire to connect the white/red wire to a

clean earth point (bare metal) on the engine.

Switch on the ignition without starting the

engine. If the gauge now indicates Hot, renew

the sender.

5If the gauge still does not work, the circuit

may be open, or the gauge may be faulty. See

Chapter 12 for additional information.

Removal

6Unbolt the resonator support bracket from

the engine compartment front crossmember.

Slacken the two clamp screws securing the

resonator to the air mass meter and plenum

chamber hoses, then swing the resonator up

clear of the thermostat housing (see Chap-

ter 4).

7Drain the cooling system (see Chapter 1).

8Disconnect the expansion tank coolant

hose and the radiator top hose from the

thermostat housing’s water outlet, then

disconnect the metal coolant pipe/hose from

the thermostat.

9Unplug the electrical connector from the

sender (see illustration).

10Unscrew the sender and withdraw it.

Refitting

11Clean as thoroughly as possible the

opening in the thermostat housing, then apply

a light coat of sealant to the sender’s threads.

Screw in the sender and tighten it to the

specified torque wrench setting, and plug in

its electrical connector.

12Reconnect the hoses and refit the

resonator, top-up the cooling system (see

Chapter 1) and run the engine. Check for

leaks and proper gauge operation.

Coolant temperature sensor

Testing

13Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

14Unbolt the resonator support bracket

from the engine compartment front

crossmember. Slacken the two clamp screws

securing the resonator to the air mass meter

and plenum chamber hoses, then swing the

resonator up clear of the thermostat housing

(see Chapter 4).

15Unplug the electrical connector from the

sensor (see illustration).

16Using an ohmmeter, measure the

resistance between the sensor terminals.

Depending on the temperature of the sensor

tip, the resistance measured will vary, but

should be within the broad limits given in the

Specifications Section of this Chapter. If the

sensor’s temperature is varied - by removing

it (see below) and placing it in a freezer for a

while, or by warming it gently - its resistance

should alter accordingly.

17If the results obtained show the sensor to

be faulty, renew it.

18On completion, plug in the connector and

refit the resonator.

Removal

19Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

20Unbolt the resonator support bracket

from the engine compartment front

crossmember. Slacken the two clamp screws

securing the resonator to the air mass meter

and plenum chamber hoses, then swing the

resonator up clear of the thermostat housing

(see Chapter 4).

21With the engine completely cool, remove

the expansion tank filler cap to release any

pressure, then refit the cap. Provided you

work swiftly and plug the opening as soon as

the sensor is unscrewed, coolant loss will thus

be minimised; this will avoid the draining of

the complete cooling system which would

otherwise be necessary (see Chapter 1).

22Unplug the electrical connector from the

sensor.

23Unscrew the sensor and withdraw it. If the

cooling system has not been drained, plug the

opening as quickly as possible.

Refitting

24Clean as thoroughly as possible the

opening in the thermostat housing, then apply

a light coat of sealant to the sensor’s threads.

Remove the material used to plug the sensor

hole (where applicable), and quickly install the

sensor to prevent coolant loss. Tighten the

sensor to the specified torque wrench setting,

and plug in its electrical connector.

25Refit the resonator, top-up the cooling

system (see Chapter 1) and run the engine,

checking for leaks.

Coolant low level switch

Testing

26The switch is a reed-type unit mounted in

the bottom of the cooling system expansion

tank, activated by a magnetic float. If the

coolant level falls to the “MIN” level or less,

the appropriate bulb lights in the warning

display.

27If the bulb fails to light during the 5-

second bulb test, check the bulb, and renew if

necessary as described in Chapter 12.

28To check the switch itself, unplug its

electrical connector, and use an ohmmeter to

measure the resistance across the switchterminals. With the float up, a resistance of

90 ohms should be measured; when it is

down, the resistance should increase to

approximately 150 kilohms.

29If the results obtained from the check are

significantly different from those expected,

the switch is faulty, and must be renewed.

30If the switch and bulb are proven to be

sound, the fault must be in the wiring or in the

auxiliary warning control assembly (see

Chapter 12).

Removal

31Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

32Remove the expansion tank (see Sec-

tion 7).

33Unplug the switch electrical connector.

34Release the switch by twisting its retainer

anti-clockwise, then withdraw it.

Refitting

35Refitting is the reverse of the removal

procedure. Refill the cooling system (see

Chapter 1). Start the engine, and check for

coolant leaks when it is fully warmed-up.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Radiator

Removal

Note:If leakage is the reason for removing the

radiator, bear in mind that minor leaks can

often be cured using a radiator sealant with

the radiator in situ.

1Remove the radiator fan and shroud

assembly (see Section 5).

2Disconnect the bottom hose from the

radiator.

3If the vehicle has automatic transmission,

disconnect the fluid cooler lines, and plug the

lines and fittings.

4If the vehicle has air conditioning, unscrew

the condenser mounting nuts or bolts, detach

the condenser from the radiator, and tie it to

the engine compartment front crossmember.

7 Radiator and expansion tank -

removal, inspection and refitting

Cooling, heating and air conditioning systems 3•5

3

6.9 Location (arrowed) of coolant

temperature gauge sender6.15 Location (arrowed) of coolant

temperature sensor

procarmanuals.com

Page 94 of 279

Warning: Do not disconnect any

of the refrigerant hoses.

5Unbolt the radiator mounting brackets from

the subframe; note that they are handed, and

are marked to ensure correct refitting (see

illustration). Collect the bottom mounting

rubbers, noting which way up they are fitted,

and store them carefully.

6Carefully lower the radiator from the

vehicle, and withdraw it.

7With the radiator removed, it can be

inspected for leaks and damage. If it needs

repair, have a radiator specialist or dealer

service department perform the work, as

special techniques are required.

8Insects and dirt can be removed from the

radiator with a garden hose or a soft brush.

Don’t bend the cooling fins as this is done.

Refitting

9Refitting is the reverse of the removal

procedure. Be sure the mounting rubbers are

seated properly at the base of the radiator.

10After refitting, refill the cooling system

with the proper mixture of antifreeze and

water (see Chapter 1).

11Start the engine, and check for leaks.

Allow the engine to reach normal operating

temperature, indicated by the radiator top

hose becoming hot. Recheck the coolant

level, and add more if required.12If working on an vehicle with automatic

transmission, check and add transmission

fluid as needed (see Chapter 1).

Expansion tank

13With the engine completely cool, remove

the expansion tank filler cap to release any

pressure, then refit the cap.

14Disconnect the hoses from the tank,

upper hose first. As each hose is

disconnected, drain the tank’s contents into a

clean container. If the antifreeze is not due for

renewal, the drained coolant may be re-used,

if it is kept clean.

15Unscrew the tank’s two mounting bolts

and withdraw it, unplugging the coolant low

level switch electrical connector (where fitted).

16Wash out the tank, and inspect it for

cracks and chafing - renew it if damaged.

17Refitting is the reverse of the removal

procedure. Refill the cooling system with the

proper mixture of antifreeze and water (see

Chapter 1), then start the engine and allow it

to reach normal operating temperature,

indicated by the radiator top hose becoming

hot. Recheck the coolant level and add more

if required, then check for leaks.

Note:Refer to the warnings given in Section 1

of this Chapter before starting work.

Check

1A failure in the water pump can cause

serious engine damage due to overheating.

2There are three ways to check the operation

of the water pump while it’s installed on the

engine. If the pump is defective, it should be

replaced with a new or rebuilt unit.

3With the engine running at normal operating

temperature, squeeze the radiator top hose. If

the water pump is working properly, a

pressure surge should be felt as the hose is

released. Warning: Keep your hands away

from the radiator electric

cooling fan blades!

4Remove the timing belt covers (see Chap-

ter 2, Part A). Water pumps are equipped with

weep or vent holes. If a failure occurs in the

pump seal, coolant will leak from the hole. In

most cases you’ll need an electric torch to

find the hole on the water pump from

underneath to check for leaks.

5If the water pump shaft bearings fail, there

may be a howling sound at the drivebelt end

of the engine while it’s running. Shaft wear

can be felt if the water pump pulley is rocked

up and down. Don’t mistake drivebelt

slippage, which causes a squealing sound, for

water pump bearing failure.

Removal and refitting

6Remove the timing belt and tensioner (see

Chapter 2, Part A). As noted in Chapter 2, if

the belt is fouled with coolant, it must be

renewed as a matter of course.

7Drain the cooling system (see Chapter 1).

8Disconnect the radiator bottom hose from

the pump union. It is easier to reach this union

if the power steering pump is unbolted and

moved aside as described in Chapter 10 (see

illustration). There is no need to disconnect

any of the power steering system hoses.

9Unbolt and remove the water pump (see

illustration). If the pump is to be renewed,

unbolt the timing belt guide pulleys, and

transfer them to the new pump.

10Clean the mating surfaces carefully; the

gasket must be renewed whenever it is

disturbed (see illustration).

11On refitting, use grease to stick the new

gasket in place, refit the pump, and tighten

the pump bolts to the specified torque wrench

setting.

12The remainder of the reassembly

procedure is the reverse of dismantling. Note

that a new tensioner spring and retaining pin

must be fitted if the timing belt has been

removed for the first time. Tighten all

fasteners to the specified torque wrench

settings, and refill the system with coolant as

described in Chapter 1.

8 Water pump -

check, removal and refitting

3•6 Cooling, heating and air conditioning systems

7.5 Radiator mounting bracket-to-

subframe bolts (A), air conditioning system

condenser mounting bolt (B)

8.8 Power steering system pump should

be removed to reach water pump hose

union (arrowed)8.9 Unscrew bolts (arrowed) . . .8.10 . . . to remove water pump - always

renew gasket and clean all mating

surfaces carefully

procarmanuals.com

Page 95 of 279

Heater blower motor

Removal

1Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).

2Release the four clips (by pulling them out)

securing the passenger side footwell upper

trim panel, then withdraw the panel.

3Unplug the motor’s electrical connector.

4Lift the motor’s retaining lug slightly, twist

the motor anti-clockwise (seen from beneath)

through approximately 30°, then withdraw the

assembly.

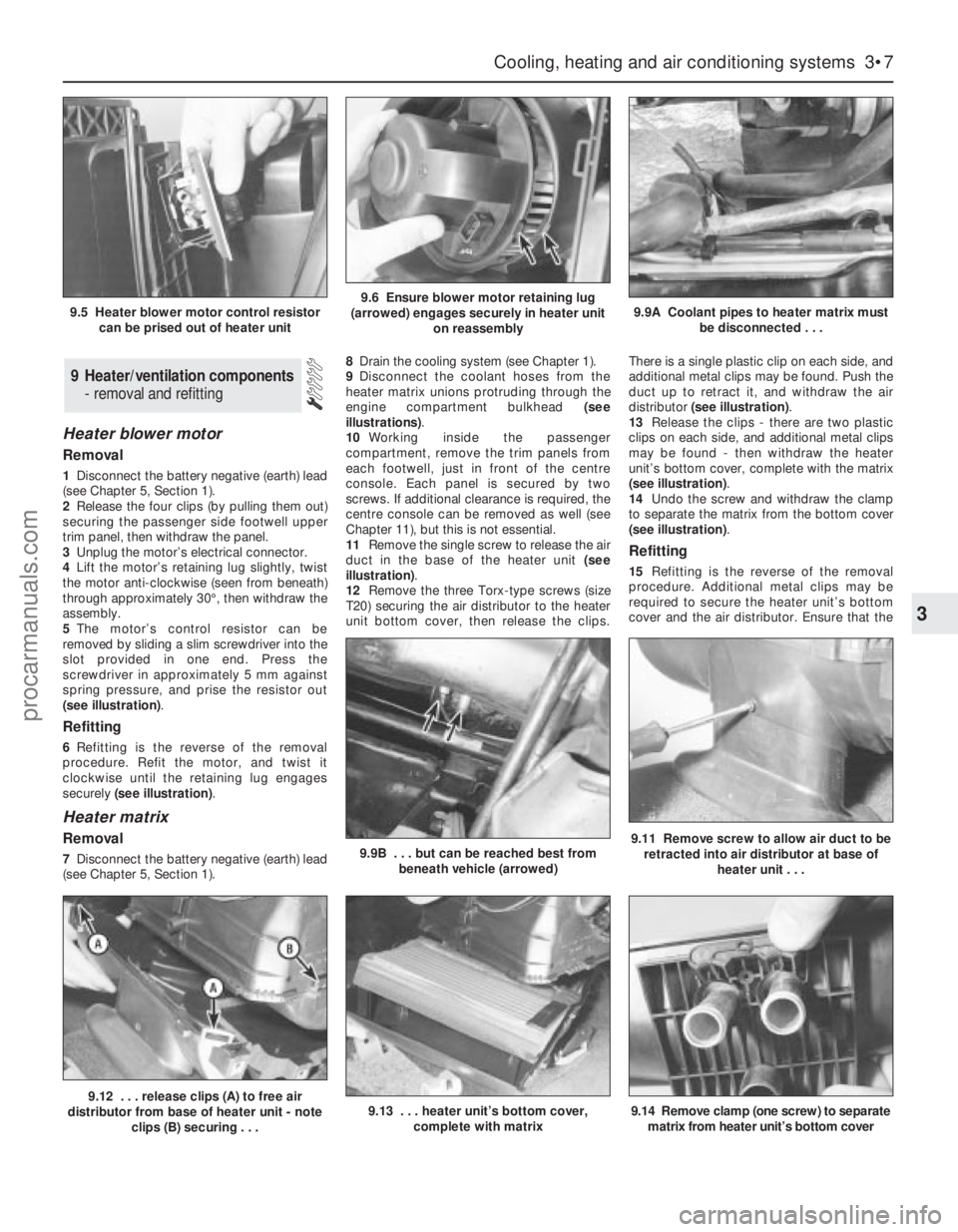

5The motor’s control resistor can be

removed by sliding a slim screwdriver into the

slot provided in one end. Press the

screwdriver in approximately 5 mm against

spring pressure, and prise the resistor out

(see illustration).

Refitting

6Refitting is the reverse of the removal

procedure. Refit the motor, and twist it

clockwise until the retaining lug engages

securely (see illustration).

Heater matrix

Removal

7Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).8Drain the cooling system (see Chapter 1).

9Disconnect the coolant hoses from the

heater matrix unions protruding through the

engine compartment bulkhead (see

illustrations).

10Working inside the passenger

compartment, remove the trim panels from

each footwell, just in front of the centre

console. Each panel is secured by two

screws. If additional clearance is required, the

centre console can be removed as well (see

Chapter 11), but this is not essential.

11Remove the single screw to release the air

duct in the base of the heater unit (see

illustration).

12Remove the three Torx-type screws (size

T20) securing the air distributor to the heater

unit bottom cover, then release the clips.There is a single plastic clip on each side, and

additional metal clips may be found. Push the

duct up to retract it, and withdraw the air

distributor (see illustration).

13Release the clips - there are two plastic

clips on each side, and additional metal clips

may be found - then withdraw the heater

unit’s bottom cover, complete with the matrix

(see illustration).

14Undo the screw and withdraw the clamp

to separate the matrix from the bottom cover

(see illustration).

Refitting

15Refitting is the reverse of the removal

procedure. Additional metal clips may be

required to secure the heater unit’s bottom

cover and the air distributor. Ensure that the

9 Heater/ventilation components

- removal and refitting

Cooling, heating and air conditioning systems 3•7

3

9.12 . . . release clips (A) to free air

distributor from base of heater unit - note

clips (B) securing . . .9.13 . . . heater unit’s bottom cover,

complete with matrix9.14 Remove clamp (one screw) to separate

matrix from heater unit’s bottom cover

9.5 Heater blower motor control resistor

can be prised out of heater unit9.6 Ensure blower motor retaining lug

(arrowed) engages securely in heater unit

on reassembly9.9A Coolant pipes to heater matrix must

be disconnected . . .

9.9B . . . but can be reached best from

beneath vehicle (arrowed)9.11 Remove screw to allow air duct to be

retracted into air distributor at base of

heater unit . . .

procarmanuals.com

Page 96 of 279

duct is lowered from the air distributor and

secured with its screw.

16Refill the cooling system with the proper

mixture of antifreeze and water (see Chapter

1). Start the engine and allow it to reach

normal operating temperature, indicated by

the radiator top hose becoming hot. Recheck

the coolant level and add more if required,

then check for leaks. Check the operation of

the heater.

Pollen filter

17Refer to Chapter 1.

Blower/air conditioning control

Removal

1Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).

2Remove the ashtray. Referring to the

relevant Sections of Chapter 11, undo the two

upper screws from the centre console and

pull out the cassette storage compartment,

then remove the radio/cassette player.

3Pull the heater control/radio bezel out of the

three clips securing its top edge, pull it

forwards and unplug the switch electrical

connector (where fitted).

4Pull off the heater control knobs, and

remove the screw securing each end of the

heater control unit (see illustration). Pull the

control unit out of the facia.

5Unplug the two electrical connectors from

the blower/air conditioning control. Remove

the retaining screw and withdraw the control,

twisting it to release it from the panel.

Refitting

6Refitting is the reverse of the removal

procedure. Check the operation of the control

on completion.

Temperature control

Removal

7Remove the heater control unit as

described in paragraphs 1 to 4 above.

8On vehicles without air conditioning,unhook the operating cable from the

temperature control (see illustration); where

air conditioning is fitted, unplug the control’s

electrical connector. Undo the retaining

screw, and withdraw the control.

Refitting

9Refitting is the reverse of the removal

procedure; check the operation of the control

on completion.

Air distribution control

Removal

10Remove the heater control unit as

described in paragraphs 1 to 4 above. Unplug

the electrical connectors, and unhook the

operating cable (where fitted) to withdraw the

unit (see illustration).

11Use a pair of slim screwdrivers to release

the clips on each side of the control, then

withdraw the control from the unit.

Refitting

12Refitting is the reverse of the removalprocedure. Check the operation of the

controls on completion.

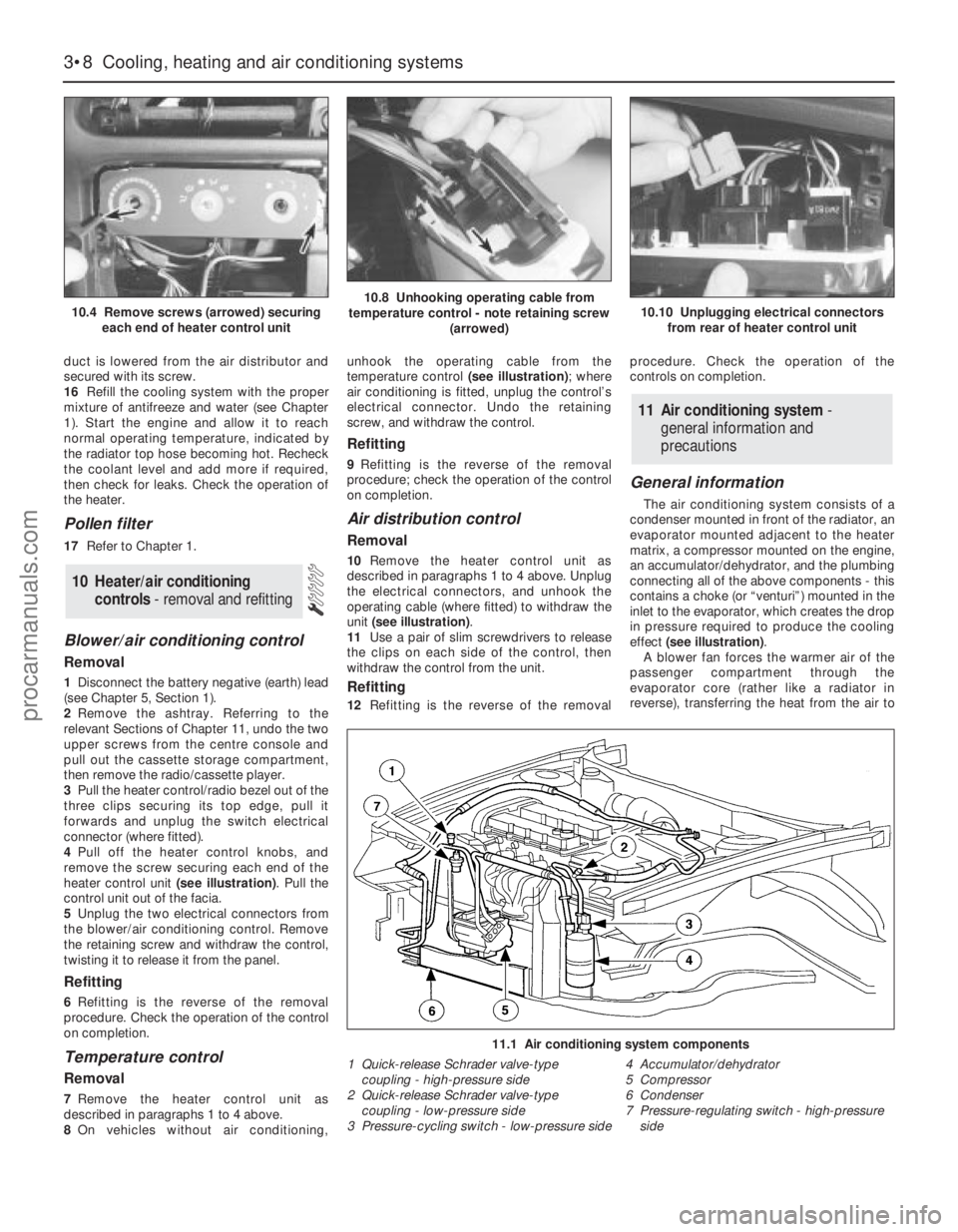

General information

The air conditioning system consists of a

condenser mounted in front of the radiator, an

evaporator mounted adjacent to the heater

matrix, a compressor mounted on the engine,

an accumulator/dehydrator, and the plumbing

connecting all of the above components - this

contains a choke (or “venturi”) mounted in the

inlet to the evaporator, which creates the drop

in pressure required to produce the cooling

effect (see illustration).

A blower fan forces the warmer air of the

passenger compartment through the

evaporator core (rather like a radiator in

reverse), transferring the heat from the air to

11 Air conditioning system -

general information and

precautions

10 Heater/air conditioning

controls- removal and refitting

3•8 Cooling, heating and air conditioning systems

10.4 Remove screws (arrowed) securing

each end of heater control unit10.8 Unhooking operating cable from

temperature control - note retaining screw

(arrowed)10.10 Unplugging electrical connectors

from rear of heater control unit

11.1 Air conditioning system components

1 Quick-release Schrader valve-type

coupling - high-pressure side

2 Quick-release Schrader valve-type

coupling - low-pressure side

3 Pressure-cycling switch - low-pressure side4 Accumulator/dehydrator

5 Compressor

6 Condenser

7 Pressure-regulating switch - high-pressure

side

procarmanuals.com

Page 97 of 279

the refrigerant. The liquid refrigerant boils off

into low-pressure vapour, taking the heat with

it when it leaves the evaporator.

Precautions

Warning: The air conditioning

system is under high pressure.

Do not loosen any fittings or

remove any components until

after the system has been discharged. Air

conditioning refrigerant should be properly

discharged into an approved type of

container, at a dealer service department

or an automotive air conditioning repair

facility capable of handling R134a

refrigerant. Always wear eye protection

when disconnecting air conditioning

system fittings.

When an air conditioning system is fitted, it

is necessary to observe the following special

precautions whenever dealing with any part of

the system, its associated components, and

any items which necessitate disconnection of

the system:

(a) While the refrigerant used - R134a - is

less damaging to the environment than

the previously-used R12, it is still a very

dangerous substance. It must not be

allowed into contact with the skin or eyes,

or there is a risk of frostbite. It must also

not be discharged in an enclosed space -

while it is not toxic, there is a risk of

suffocation. The refrigerant is heavier than

air, and so must never be discharged over

a pit.

(b) The refrigerant must not be allowed to

come in contact with a naked flame,

otherwise a poisonous gas will be created

- under certain circumstances, this can

form an explosive mixture with air. For

similar reasons, smoking in the presence

of refrigerant is highly dangerous,

particularly if the vapour is inhaled

through a lighted cigarette.

(c) Never discharge the system to the

atmosphere - R134a is not an ozone-

depleting ChloroFluoroCarbon (CFC) as is

R12, but is instead a hydrofluorocarbon,

which causes environmental damage by

contributing to the “greenhouse effect” if

released into the atmosphere.

(d) R134a refrigerant must notbe mixed with

R12; the system uses different seals (now

green-coloured, previously black) and has

different fittings requiring different tools,

so that there is no chance of the two

types of refrigerant becoming mixed

accidentally.

(e) If for any reason the system must be

disconnected, entrust this task to your

Ford dealer or a refrigeration engineer.

(f) It is essential that the system be

professionally discharged prior to using

any form of heat - welding, soldering,

brazing, etc - in the vicinity of the system,

before having the vehicle oven-dried at a

temperature exceeding 70°C after

repainting, and before disconnecting any

part of the system.Warning: The air conditioning

system is under high pressure.

Do not loosen any fittings or

remove any components until after the

system has been discharged. Air

conditioning refrigerant should be properly

discharged into an approved type of

container, at a dealer service department

or an automotive air conditioning repair

facility capable of handling R134a

refrigerant. Cap or plug the pipe lines as

soon as they are disconnected, to prevent

the entry of moisture. Always wear eye

protection when disconnecting air

conditioning system fittings.

Note: This Section refers to the components

of the air conditioning system itself - refer to

Sections 9 and 10 for details of components

common to the heating/ventilation system.

Condenser

1Have the refrigerant discharged at a dealer

service department or an automotive air

conditioning repair facility.

2Disconnect the battery negative (earth) lead

(see Chapter 5, Section 1).

3Remove the radiator undershield (see

Chapter 1).

4Using the Ford service tool 34-001,

disconnect the refrigerant lines from the

condenser. Immediately cap the open fittings,

to prevent the entry of dirt and moisture.

5Unbolt the condenser (see illustration 7.5)

and lift it out of the vehicle. Store it upright, to

prevent oil loss.

6Refitting is the reverse of removal.

7If a new condenser was installed, add 20 cc

of refrigerant oil to the system.

8Have the system evacuated, charged and

leak-tested by the specialist who discharged

it.

Evaporator

9The evaporator is mounted with the heater

matrix. Apart from the need to have the

refrigerant discharged, and to use Ford

service tools 34-001 and 34-003 to

disconnect the lines, the procedure is as

described in Section 9 of this Chapter.

10On reassembly, if a new evaporator was

installed, add 20 cc of refrigerant oil to the

system.

11Have the system evacuated, charged and

leak-tested by the specialist who discharged

it.

Compressor

12Have the refrigerant discharged at a

dealer service department or an automotive

air conditioning repair facility.

13Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

14Remove the radiator undershield (see

Chapter 1).15Remove the auxiliary drivebelt (see

Chapter 1).

16Unbolt the compressor from the cylinder

block/crankcase, press it to one side, and

unscrew the clamping bolt to disconnect the

refrigerant lines. Plug the line connections,

swing the compressor upright, unplug its

electrical connector, then withdraw the

compressor from the vehicle. Note:Keep the

compressor level during handling and storage.

If the compressor has seized, or if you find

metal particles in the refrigerant lines, the

system must be flushed out by an air

conditioning technician, and the

accumulator/dehydrator must be renewed.

17Prior to installation, turn the compressor

clutch centre six times, to disperse any oil that

has collected in the head.

18Refit the compressor in the reverse order

of removal; renew all seals disturbed.

19If you are installing a new compressor,

refer to the compressor manufacturer’s

instructions for adding refrigerant oil to the

system.

20Have the system evacuated, charged and

leak-tested by the specialist that discharged

it.

Accumulator/dehydrator

21Have the refrigerant discharged at a

dealer service department or an automotive

air conditioning repair facility.

22Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

23The accumulator/dehydrator, which acts

as a reservoir and filter for the refrigerant, is

located in the left-hand front corner of the

engine compartment. Using the Ford service

tool 34-003, disconnect the refrigerant line

next to the accumulator/dehydrator from the

compressor. Immediately cap the open

fittings, to prevent the entry of dirt and

moisture, then unplug the pressure-cycling

switch electrical connector (see illustration).

24Remove the radiator undershield (see

Chapter 1).

25Unbolt the accumulator/dehydrator from

the front suspension subframe.

26Using the Ford service tool 34-003,

disconnect the lower refrigerant line from the

accumulator/dehydrator. It may be necessary

12 Air conditioning system

components -

removal and refitting

Cooling, heating and air conditioning systems 3•9

3

12.23 Unplug pressure-cycling switch

electrical connector (arrowed)

procarmanuals.com

Page 98 of 279

to unscrew the pressure-cycling switch to

allow the use of the tool. Immediately cap the

open fittings, to prevent the entry of dirt and

moisture.

27Withdraw the accumulator/dehydrator.

28Refit the accumulator/dehydrator in the

reverse order of removal; renew all seals

disturbed.

29If you are installing a new accumulator/

dehydrator, refer to the manufacturer’s

instructions for adding refrigerant oil to the

system.

30Have the system evacuated, charged and

leak-tested by the specialist that discharged

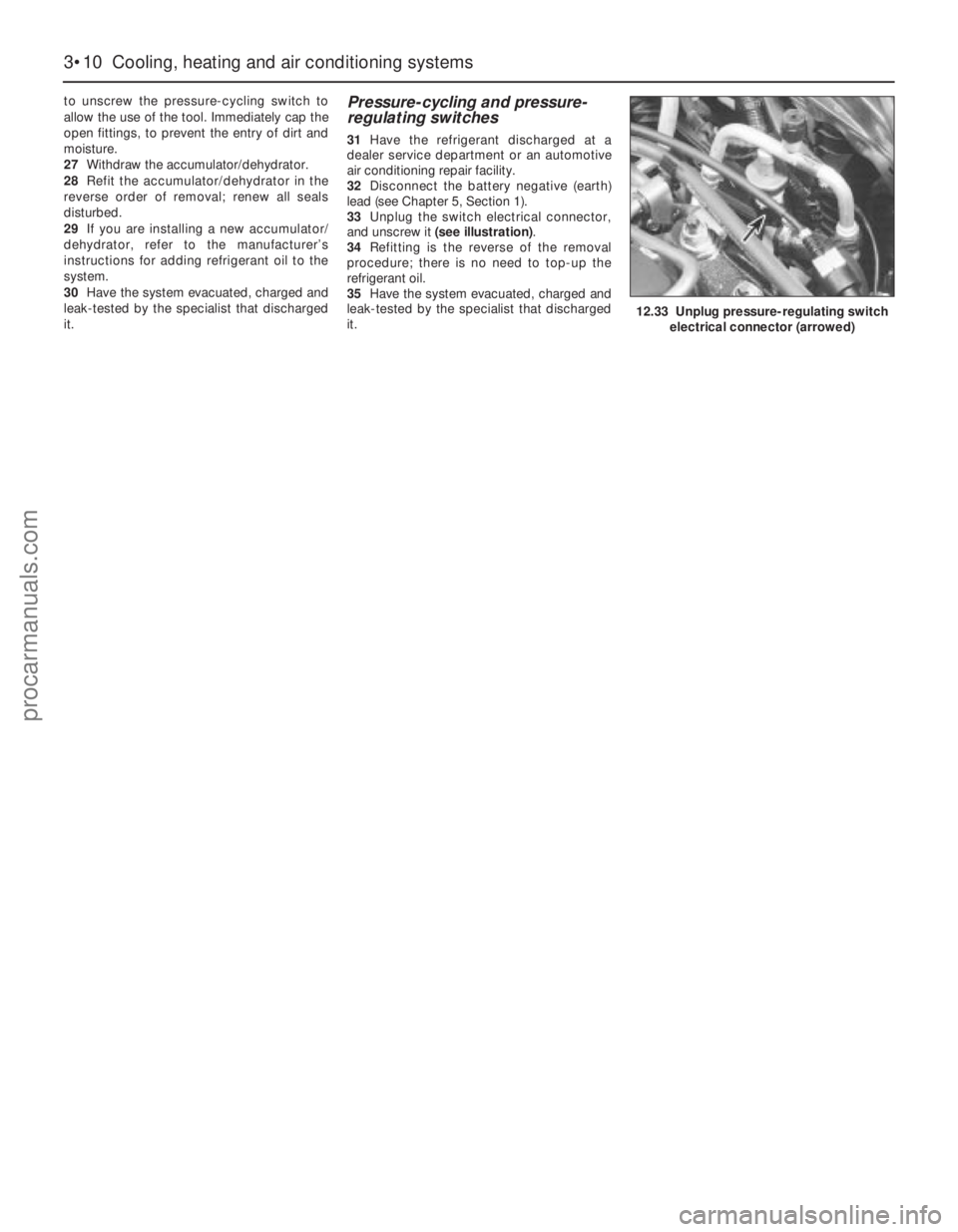

it.Pressure-cycling and pressure-

regulating switches

31Have the refrigerant discharged at a

dealer service department or an automotive

air conditioning repair facility.

32Disconnect the battery negative (earth)

lead (see Chapter 5, Section 1).

33Unplug the switch electrical connector,

and unscrew it (see illustration).

34Refitting is the reverse of the removal

procedure; there is no need to top-up the

refrigerant oil.

35Have the system evacuated, charged and

leak-tested by the specialist that discharged

it.

3•10 Cooling, heating and air conditioning systems

12.33 Unplug pressure-regulating switch

electrical connector (arrowed)

procarmanuals.com

Page 99 of 279

Chapter 4 Fuel and exhaust systems

Accelerator cable (models with traction control) -

removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accelerator cable (models without traction control) -

removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 5

Accelerator pedal - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Air cleaner assembly/air intake components - removal and refitting . 4

Air filter element renewal . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

Exhaust manifold - removal and refitting . . . . . . . . . . . See Chapter 2A

Exhaust system - general information and component renewal . . . . 17

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel cut-off switch - removal and refitting . . . . . . . . . . . . . . . . . . . . 13

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel injection system/engine management system - check . . . . . . . 15

Fuel injection system/engine management system - general . . . . . 14Fuel lines and fittings - general information . . . . . . . . . . . . . . . . . . . 3

Fuel pump/fuel gauge sender unit - removal and refitting . . . . . . . . 9

Fuel pump/fuel pressure - check . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fuel system - depressurisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Fuel system components - check and renewal . . . . . . . . . . . . . . . . 16

Fuel tank - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fuel tank cleaning and repair - general information . . . . . . . . . . . . . 11

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . 1

Idle speed and mixture check and adjustment . . . . . . See Section 14

Inlet manifold - removal and refitting . . . . . . . . . . . . . . See Chapter 2A

Oxygen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

Roll-over valves - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 12

Underbody fuel/brake line check . . . . . . . . . . . . . . . . . See Chapter 1

Underbonnet hose check . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

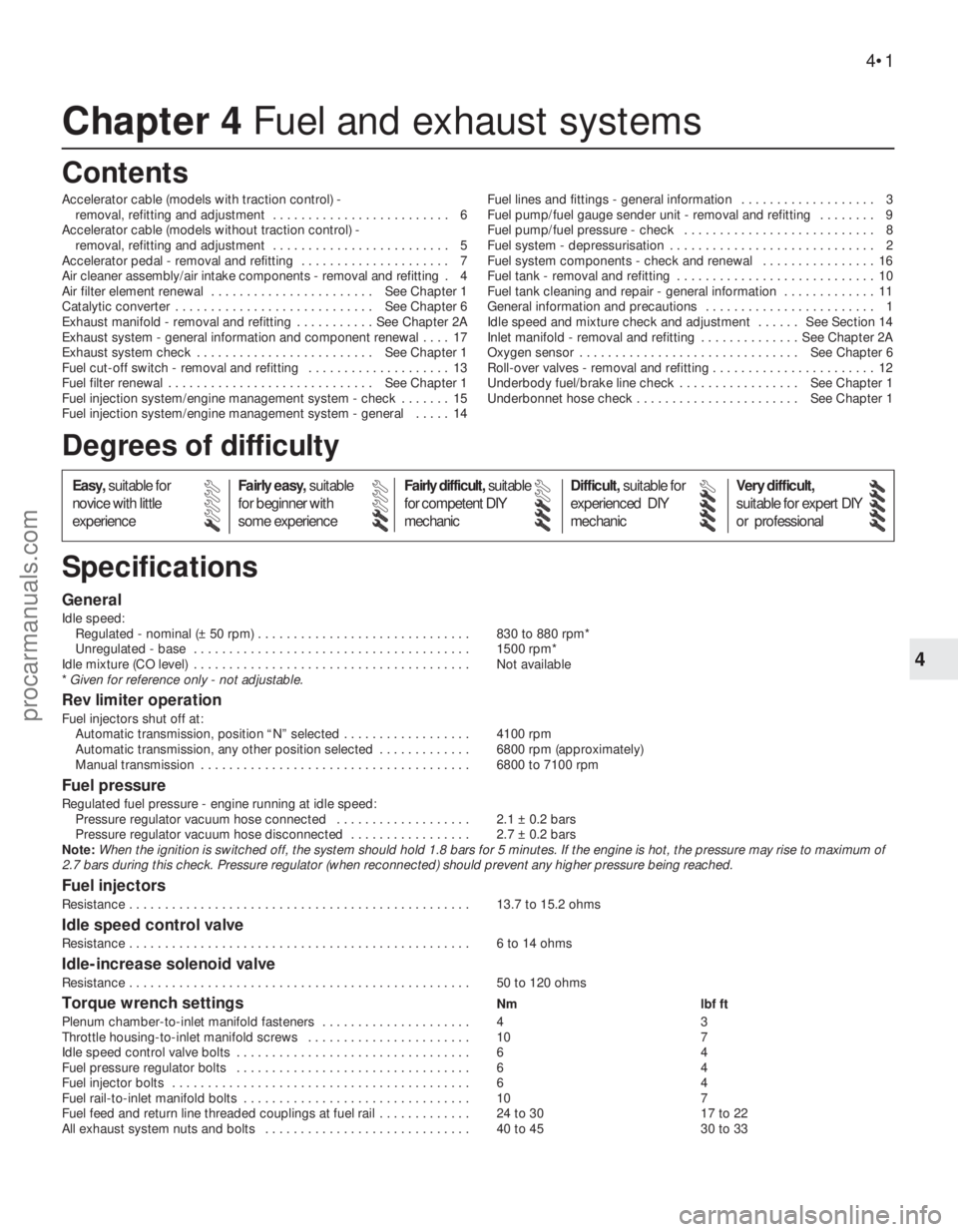

General

Idle speed:

Regulated - nominal (± 50 rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 830 to 880 rpm*

Unregulated - base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500 rpm*

Idle mixture (CO level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not available

* Given for reference only - not adjustable.

Rev limiter operation

Fuel injectors shut off at:

Automatic transmission, position “N” selected . . . . . . . . . . . . . . . . . . 4100 rpm

Automatic transmission, any other position selected . . . . . . . . . . . . . 6800 rpm (approximately)

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6800 to 7100 rpm

Fuel pressure

Regulated fuel pressure - engine running at idle speed:

Pressure regulator vacuum hose connected . . . . . . . . . . . . . . . . . . . 2.1 ± 0.2 bars

Pressure regulator vacuum hose disconnected . . . . . . . . . . . . . . . . . 2.7 ± 0.2 bars

Note:When the ignition is switched off, the system should hold 1.8 bars for 5 minutes. If the engine is hot, the pressure may rise to maximum of

2.7 bars during this check. Pressure regulator (when reconnected) should prevent any higher pressure being reached.

Fuel injectors

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.7 to 15.2 ohms

Idle speed control valve

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 to 14 ohms

Idle-increase solenoid valve

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 to 120 ohms

Torque wrench settingsNm lbf ft

Plenum chamber-to-inlet manifold fasteners . . . . . . . . . . . . . . . . . . . . . 4 3

Throttle housing-to-inlet manifold screws . . . . . . . . . . . . . . . . . . . . . . . 10 7

Idle speed control valve bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4

Fuel pressure regulator bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4

Fuel injector bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4

Fuel rail-to-inlet manifold bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Fuel feed and return line threaded couplings at fuel rail . . . . . . . . . . . . . 24 to 30 17 to 22

All exhaust system nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 to 45 30 to 33

4•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

4

procarmanuals.com

Page 100 of 279

This Chapter is concerned with those

features of the engine management system

that supply clean fuel and air to the engine,

meter it in the required proportions, and

dispose of the results. Since the emission

control sub-systems modify the functions of

both the fuel and exhaust sub-systems, all of

which are integral parts of the whole engine

management system, there are many cross-

references to Chapters 5 and 6. Information

on the electronic control system, its fault

diagnosis, sensors and actuators, is given in

Chapter 6.

The air intake system consists of several

plastics components designed to eliminate

induction roar as much as possible. The air

intake tube (opening behind the direction

indicator/headlight assembly) is connected,

via small and large resonators located under

the front left-hand wing, to the air cleaner

assembly in the engine compartment. Once it

has passed through the filter element and the

air mass meter, the air enters the plenum

chamber mounted above the throttle housing

and inlet manifold; the resonator mounted in

the engine compartment further reduces noise

levels.

The fuel system consists of a plastic tank

(mounted under the body, beneath the rear

seats), combined metal and plastic fuel hoses,

an electric fuel pump mounted in the fuel tank,

and an electronic fuel injection system.

The exhaust system consists of an exhaust

manifold, the front downpipe and catalytic

converter and, on production-fit systems, a

rear section incorporating two or three

silencers and the tailpipe assembly. The

service replacement exhaust system consists

of three or four sections: the front

downpipe/catalytic converter, the

intermediate pipe and front silencer, and the

tailpipe and rear silencer. On some versions,

the tailpipe is in two pieces, with two rear

silencers. The system is suspended

throughout its entire length by rubber

mountings.

Extreme caution should be exercised when

dealing with either the fuel or exhaust

systems. Fuel is a primary element for

combustion. Be very careful! The exhaust

system is an area for exercising caution, as it

operates at very high temperatures. Serious

burns can result from even momentary

contact with any part of the exhaust system,

and the fire risk is ever-present. The catalytic

converter in particular runs at very high

temperatures - refer to the information in

Chapter 6.

Warning: Many of the procedures

in this Chapter require the

removal of fuel lines and

connections, which may result in

some fuel spillage. Petrol is extremely

flammable, so take extra precautionswhen you work on any part of the fuel

system. Don’t smoke, or allow open flames

or bare light bulbs, near the work area.

Don’t work in a garage where a natural

gas-type appliance (such as a water

heater or clothes dryer) with a pilot light is

present. If you spill any fuel on your skin,

rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand. Before carrying out any operation

on the fuel system, refer also to the

precautions given in “Safety first!” at the

beginning of this manual, and follow them

implicitly. Petrol is a highly-dangerous and

volatile liquid, and the precautions

necessary when handling it cannot be

overstressed.

Warning: The fuel system will

remain pressurised for long

periods of time after the engine is

switched off - this pressure must

be released before any part of the system

is disturbed. Petrol is extremely

flammable, so take extra precautions

when you work on any part of the fuel

system. Don’t smoke, or allow open flames

or bare light bulbs, near the work area.

Don’t work in a garage where a natural

gas-type appliance (such as a water

heater or clothes dryer) with a pilot light is

present. If you spill any fuel on your skin,

rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand.

1The fuel system referred to in this Chapter

is defined as the fuel tank and tank-mounted

fuel pump/fuel gauge sender unit, the fuel

filter, the fuel injectors and the pressure

regulator in the injector rail, and the metal

pipes and flexible hoses of the fuel lines

between these components. All these contain

fuel, which will be under pressure while the

engine is running and/or while the ignition is

switched on.

2The pressure will remain for some time after

the ignition has been switched off, and must

be relieved before any of these components is

disturbed for servicing work.

3The simplest method is simply to

disconnect the fuel pump’s electrical supply

while the engine is running - either by

removing the fuel pump fuse (number 14), or

by lifting the red button on the fuel cut-off

switch (see Section 13) - and to allow the

engine to idle until it dies through lack of fuel

pressure. Turn the engine over once or twice

on the starter to ensure that all pressure is

released, then switch off the ignition; do not

forget to refit the fuse (or depress the redbutton, as appropriate) when work is

complete.

4The Ford method of depressurisation is to

use service tool 29-033 fitted to the fuel rail

pressure test/release fitting - a Schrader-type

valve with a blue plastic cap, located on the

union of the fuel feed line and the fuel rail - to

release the pressure, using a suitable

container and wads of rag to catch the spilt

fuel. Do notsimply depress the valve core to

release fuel pressure - droplets of fuel will

spray out, with a consequent risk of fire, and

of personal injury through fuel getting into

your eyes.

Warning: Either procedure will

merely relieve the increased

pressure necessary for the

engine to run. Remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

5Note that, once the fuel system has been

depressurised and drained (even partially), it

will take significantly longer to restart the

engine - perhaps several seconds of cranking

- before the system is refilled and pressure

restored.

Warning: The fuel system

pressure must be released before

any part of the system is

disturbed - see Section 2. Petrol

is extremely flammable, so take extra

precautions when you work on any part of

the fuel system. Don’t smoke, or allow

open flames or bare light bulbs, near the

work area. Don’t work in a garage where a

natural gas-type appliance (such as a

water heater or clothes dryer) with a pilot

light is present. If you spill any fuel on your

skin, rinse it off immediately with soap and

water. When you perform any kind of work

on the fuel system, wear safety glasses,

and have a Class B type fire extinguisher

on hand.

Disconnecting and connecting

quick-release couplings

1Quick-release couplings are employed at all

unions in the fuel feed and return lines.

2Before disconnecting any fuel system

component, relieve the residual pressure in

the system (see Section 2), and equalise tank

pressure by removing the fuel filler cap.

Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

3 Fuel lines and fittings-

general information

2 Fuel system - depressurisation

1 General information and

precautions

4•2 Fuel and exhaust systems

procarmanuals.com