FORD MONDEO 1993 Service Manual PDF

Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 71 of 279

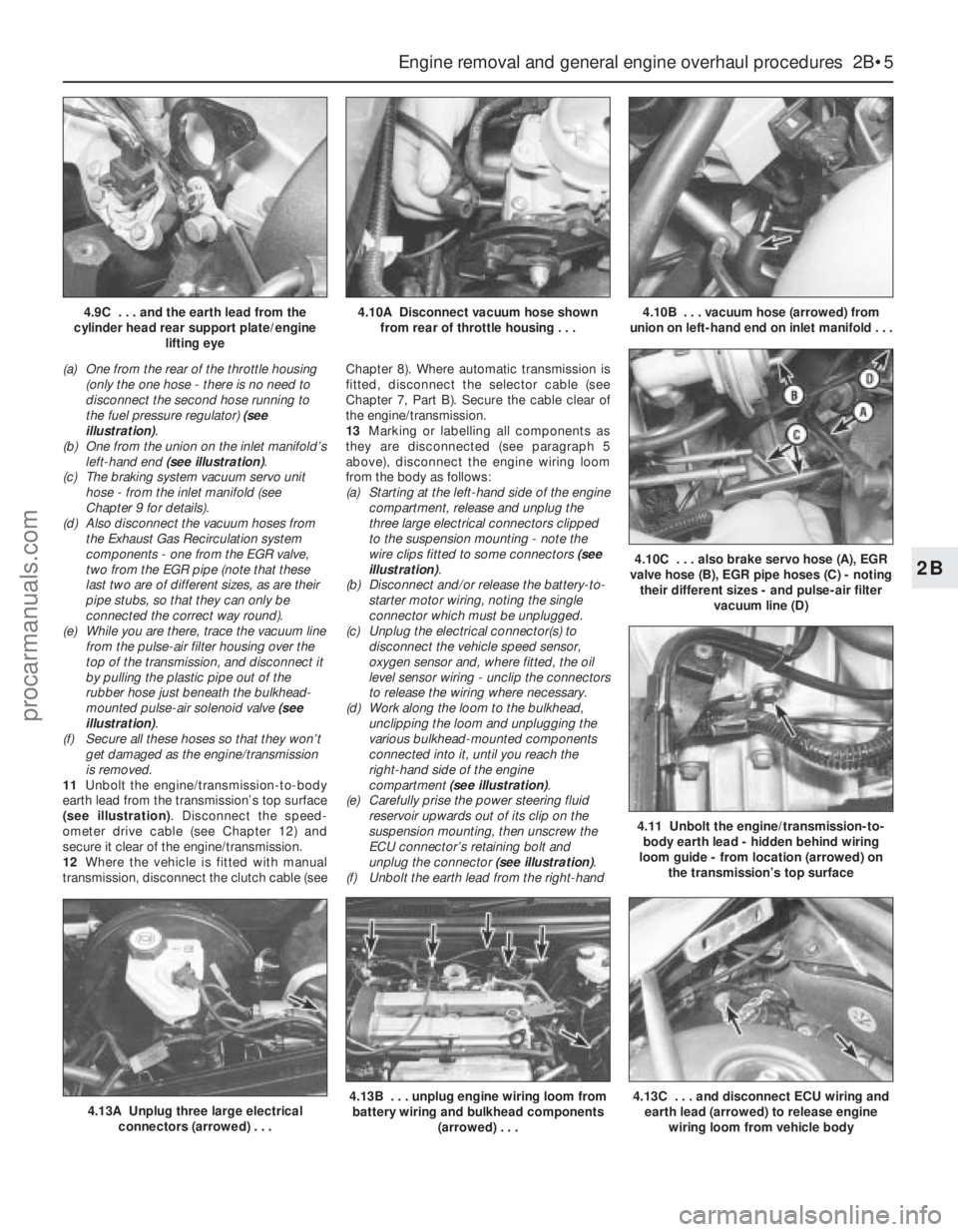

(a) One from the rear of the throttle housing

(only the one hose - there is no need to

disconnect the second hose running to

the fuel pressure regulator) (see

illustration).

(b) One from the union on the inlet manifold’s

left-hand end (see illustration).

(c) The braking system vacuum servo unit

hose - from the inlet manifold (see

Chapter 9 for details).

(d) Also disconnect the vacuum hoses from

the Exhaust Gas Recirculation system

components - one from the EGR valve,

two from the EGR pipe (note that these

last two are of different sizes, as are their

pipe stubs, so that they can only be

connected the correct way round).

(e) While you are there, trace the vacuum line

from the pulse-air filter housing over the

top of the transmission, and disconnect it

by pulling the plastic pipe out of the

rubber hose just beneath the bulkhead-

mounted pulse-air solenoid valve (see

illustration).

(f) Secure all these hoses so that they won’t

get damaged as the engine/transmission

is removed.

11Unbolt the engine/transmission-to-body

earth lead from the transmission’s top surface

(see illustration). Disconnect the speed-

ometer drive cable (see Chapter 12) and

secure it clear of the engine/transmission.

12Where the vehicle is fitted with manual

transmission, disconnect the clutch cable (seeChapter 8). Where automatic transmission is

fitted, disconnect the selector cable (see

Chapter 7, Part B). Secure the cable clear of

the engine/transmission.

13Marking or labelling all components as

they are disconnected (see paragraph 5

above), disconnect the engine wiring loom

from the body as follows:

(a) Starting at the left-hand side of the engine

compartment, release and unplug the

three large electrical connectors clipped

to the suspension mounting - note the

wire clips fitted to some connectors (see

illustration).

(b) Disconnect and/or release the battery-to-

starter motor wiring, noting the single

connector which must be unplugged.

(c) Unplug the electrical connector(s) to

disconnect the vehicle speed sensor,

oxygen sensor and, where fitted, the oil

level sensor wiring - unclip the connectors

to release the wiring where necessary.

(d) Work along the loom to the bulkhead,

unclipping the loom and unplugging the

various bulkhead-mounted components

connected into it, until you reach the

right-hand side of the engine

compartment (see illustration).

(e) Carefully prise the power steering fluid

reservoir upwards out of its clip on the

suspension mounting, then unscrew the

ECU connector’s retaining bolt and

unplug the connector (see illustration).

(f) Unbolt the earth lead from the right-hand

Engine removal and general engine overhaul procedures 2B•5

2B

4.13A Unplug three large electrical

connectors (arrowed) . . .4.13B . . . unplug engine wiring loom from

battery wiring and bulkhead components

(arrowed) . . .4.13C . . . and disconnect ECU wiring and

earth lead (arrowed) to release engine

wiring loom from vehicle body

4.9C . . . and the earth lead from the

cylinder head rear support plate/engine

lifting eye4.10A Disconnect vacuum hose shown

from rear of throttle housing . . .4.10B . . . vacuum hose (arrowed) from

union on left-hand end on inlet manifold . . .

4.10C . . . also brake servo hose (A), EGR

valve hose (B), EGR pipe hoses (C) - noting

their different sizes - and pulse-air filter

vacuum line (D)

4.11 Unbolt the engine/transmission-to-

body earth lead - hidden behind wiring

loom guide - from location (arrowed) on

the transmission’s top surface

procarmanuals.com

Page 72 of 279

inner wing panel, release the engine

wiring loom and refit the power steering

fluid reservoir.

(g) Secure the engine wiring loom neatly to

the engine/transmission so that it cannot

be damaged as the unit is removed from

the vehicle.

14Unbolt both parts of the exhaust manifold

heat shield; unclip the coolant hose to allow

the upper part to be withdrawn.

15Remove the auxiliary drivebelt (see

Chapter 1).

16Unbolt the power steering pump (see

Chapter 10); secure it as far as possible

(without disconnecting the system’s hoses)

clear of the engine/transmission.

17Raise the vehicle and support it securely

on axle stands, then remove the front

roadwheels. Drain the cooling system and (if

the engine is to be dismantled) drain the

engine oil and remove the oil filter (see

Chapter 1). Also drain the transmission as

described in the relevant Part of Chapter 7.

18Withdraw the lower part of the exhaust

manifold heat shield.

19Unscrew the nuts to disconnect the

exhaust system front downpipe from the

manifold, then unhook all the system’s rubber

mountings and withdraw the complete

exhaust system from under the vehicle (see

Chapter 4 for details).

20Where the vehicle is fitted with manual

transmission, mark their positions, then

disconnect the gearchange linkage and

transmission support rods from the rear of the

transmission. Unscrew the retaining nuts, and

withdraw the gear linkage heat shield from the

underbody. Unbolt the rear end of the linkage

from the underbody, swivel the linkage around

to the rear, and tie it to the underbody (see

Chapter 7, Part A, for details).

21Disconnect both anti-roll bar links from

their respective suspension strut - note the

flexible brake hose bracket attached to each

link stud - and both track rod ends from their

steering knuckles. Unfasten the clamp bolt

securing each front suspension lower arm

balljoint to its steering knuckle (see Chap-

ter 10 for details). Check that both balljoints

can be released from the knuckle assemblies

when required, but leave them in place for thetime being, secured by the clamp bolts if

necessary.

22Where the vehicle is fitted with air

conditioning, unbolt the accumulator/

dehydrator from the subframe; secure it as far

as possible (without disconnecting the

system’s hoses) clear of the engine/

transmission.

Warning: Do not disconnect the

refrigerant hoses.

23Unbolt the steering gear from the

subframe; if the bolts are not accessible from

above, a Ford service tool will be required to

reach them from underneath the vehicle (see

Chapter 10 for details).

24Unscrew the two bolts securing the power

steering system pipes to the right-hand side

of the subframe.

25Hold the radiator in its raised position, by

inserting split pins through the holes in the

rear of the engine compartment front

crossmember and into the radiator’s upper

mounting extensions. Unbolt the radiator

mounting brackets from the subframe; note

that they are handed, and are marked to

ensure correct refitting (see illustrations).

Collect and store the bottom mounting

rubbers for safekeeping, noting which way up

they are fitted.

26Unbolt the engine/transmission rear

mounting from the subframe - where the

vehicle is fitted with automatic transmission, a

separate damper may be fitted beneath the

subframe, which must be unbolted to reach

the mounting’s fasteners. Where the vehicle is

fitted with manual transmission, also unscrew

the mounting centre bolt, and unbolt the

mounting bracket from the transmission.

27Unscrew the engine/transmission front

mounting centre bolt, and unbolt the

mounting from the subframe, noting the

location of the wiring connector bracket.

28Use white paint or similar (do not use a

sharp-pointed scriber, which might break the

underbody protective coating and cause

rusting) to mark the exact relationship of the

subframe to the underbody. Unscrew the four

mounting bolts from the subframe (note their

different-sized washers - see also illus-tration 4.47A) and allow the subframe to hang

down on the suspension lower arm balljoints.

Disconnect the balljoints one at a time from

the steering knuckle assemblies (see Chap-

ter 10) and lower the subframe to the ground;

withdraw the subframe from under the

vehicle.

29Marking or labelling all components as

they are disconnected (see paragraph 5

above) and catching as much as possible of

the escaping coolant in the drain tray,

disconnect the cooling system hoses and

pipes as follows - refer to Chapter 3 for further

details, if required:

(a) Remove the radiator top hose.

(b) Remove the (heater) hose running from

the thermostat to the engine

compartment bulkhead union.

(c) Disconnect from the thermostat the hose

running to the expansion tank - secure the

hose clear of the working area.

(d) Disconnect from the thermostat the

coolant hose/pipe which runs to the

radiator bottom hose.

(e) Disconnect the radiator bottom hose from

the radiator union, from the (sump) heater

coolant pipe and from the water pump

union - secure the hose clear of the

working area.

(f) Unbolt the (heater) coolant pipe from the

sump, trace the pipe/hose round to the

engine compartment bulkhead union,

disconnecting (where fitted) the oil cooler

hoses from the cooler unions, then

remove it.

(g) Unless the vehicle has air conditioning

fitted, secure the radiator as far forwards

as possible while it is in its raised position;

if air conditioning is fitted, remove the

radiator completely (see Chapter 3).

30Where the vehicle is fitted with air

conditioning, unplug the compressor’s

electrical connector, and unbolt the

compressor from the engine (see

illustration). Secure it as far as possible

(without disconnecting the system’s hoses)

clear of the engine/transmission.

Warning: Do not disconnect the

refrigerant hoses.

2B•6 Engine removal and general engine overhaul procedures

4.25A Use split pins as shown to secure

radiator in its raised position . . .

4.25B . . . while you unbolt the bottom

mountings (arrowed) - note that the

mountings are handed, and do not lose the

mounting rubbers

4.30 Unscrew bolts (arrowed) to release

air conditioning compressor from engine

procarmanuals.com

Page 73 of 279

31Where the vehicle is fitted with manual

transmission, disconnect the driveshafts from

the transmission as follows, referring to

Chapter 8 for further details when required:

(a) Unscrew the nuts securing the right-hand

driveshaft support bearing, and withdraw

the heat shield.

(b) Pull the right-hand driveshaft out of the

transmission; be prepared to catch any

spilt oil.

(c) Secure the driveshaft clear of the

engine/transmission - remember that the

unit is to be lowered out of the vehicle -

and ensure that the inner joint is not

turned through more than 18°.

(d) Prise the left-hand driveshaft out of the

transmission - again, be prepared for oil

spillage. Secure the driveshaft clear of the

engine/transmission, and ensure that its

inner joint is not turned through more than

18°.

32Where the vehicle is fitted with automatic

transmission, proceed as follows, referring to

Chapter 7, Part B and to Chapter 8 for further

details when required:

(a) Unscrew its centre bolt, then unbolt the

engine/transmission rear mounting

bracket from the transmission.

(b) Disconnect the fluid cooler pipe from the

rear of the transmission, and secure it

clear of the unit.

(c) Prise the left-hand driveshaft out of the

transmission; be prepared to catch any

spilt oil.

(d) Secure the driveshaft clear of the

engine/transmission - remember that the

unit is to be lowered out of the vehicle -

and ensure that the inner joint is not

turned through more than 18°.

(e) Unscrew the nuts securing the right-hand

driveshaft support bearing, and withdraw

the heat shield.

(f) Pull the right-hand driveshaft out of the

transmission - again, be prepared for oil

spillage. Secure the driveshaft clear of the

engine/transmission, and ensure that its

inner joint is not turned through more than

18°.

(g) Disconnect the fluid cooler pipe from the

front of the transmission, and secure it

clear of the unit.

33The engine/transmission unit should now

be hanging on the right- and left-hand

mountings only, with all components which

connect it to the rest of the vehicle

disconnected or removed and secured well

clear of the unit. Make a final check that this is

the case, then ensure that the body is

securely supported, high enough to permit the

withdrawal of the engine/transmission unit

from underneath; allow for the height of the

engine dolly, if used.

34Take the weight of the engine/

transmission unit, using the lifting eyes

provided on the cylinder head. Unscrew the

six nuts securing the right-hand mounting

bracket, then the three nuts securing the left-

hand bracket. Warning: Do not put any part of

your body under the vehicle, or

under the engine/transmission

unit, when they are supported only by a

hoist or other lifting equipment.

35Lower the engine/transmission to the

ground, and withdraw it from under the

vehicle (see illustration).

36Referring to the relevant part of Chapter 7,

separate the transmission from the engine.

37While the engine/transmission is removed,

check the mountings; renew them if they are

worn or damaged. Similarly, check the

condition of all coolant and vacuum hoses

and pipes (see Chapter 1); components that

are normally hidden can now be checked

properly, and should be renewed if there is

any doubt at all about their condition. Where

the vehicle is fitted with manual transmission,

take the opportunity to overhaul the clutch

components (see Chapter 8). It is regarded by

many as good working practice to renew the

clutch assembly as a matter of course,

whenever major engine overhaul work is

carried out. Check also the condition of all

components (such as the transmission oil

seals) disturbed on removal, and renew any

that are damaged or worn.

Refitting

38Refitting is the reverse of the removal

procedure, noting the following points.

Tighten all fasteners to the torque wrench

settings given; where settings are not quoted

in the Specifications Sections of the two Parts

of this Chapter, refer to the Specifications

Section of the relevant Chapter of this manual.

39In addition to the points noted in

paragraph 37 above, always renew any

circlips and self-locking nuts disturbed on

removal.

40Where wiring, etc, was secured by cable

ties which had to be cut on removal, ensure

that it is secured with new ties on refitting.

41With all overhaul operations completed,

refit the transmission to the engine as

described in Chapter 7.

42Manoeuvre the engine/transmission unit

under the vehicle, attach the hoist, and lift the

unit into position until the right- and left-hand

mountings can be reassembled; tighten the

(new) nuts only lightly at this stage. Do not yet

release the hoist; the weight of the

engine/transmission unit must not be taken by

the mountings until all are correctly aligned.

43Using new circlips, and ensuring that the

inner joints are not twisted through too great

an angle (see Chapter 8), refit the driveshafts.

Where the vehicle is fitted with manual

transmission, the procedure is the reverse of

that outlined in paragraph 31 above. Where

the vehicle is fitted with automatic

transmission, proceed as follows, referring to

Chapter 7, Part B and to Chapter 8 for further

details when required:

(a) Refit the left-hand driveshaft.

(b) Using the clips provided to ensure that

they are correctly routed, and tighteningthe couplings to the specified torque

wrench setting where possible, reconnect

the fluid cooler pipes, first to the rear,

then to the front, of the transmission.

(c) Refit the right-hand driveshaft to the

transmission, refit the heat shield, and

tighten the support bearing nuts to the

specified torque wrench setting.

(d) Refit the engine/transmission rear

mounting bracket to the transmission,

tightening the bolts to the torque wrench

setting specified, then refit the mounting,

tightening the centre bolt only lightly at

this stage.

44Where the vehicle is fitted with air

conditioning, do not forget to refit the

compressor; tighten the bolts to the specified

torque wrench setting, and plug in its

electrical connector.

45Using the marks and notes made on

removal, refit the cooling system hoses.

Where they are left disconnected or unclipped

for the time being, do not forget to secure

them at the appropriate moment during the

reassembly procedure. Refit the radiator (if

removed), using split pins to secure it in the

raised position.

46Offer up the subframe one side at a time,

and hold it by securing the suspension lower

arm balljoints to the steering knuckle

assemblies. Refit the subframe bolts, ensuring

that the washers are refitted correctly, and

tightening the bolts only lightly at this stage.

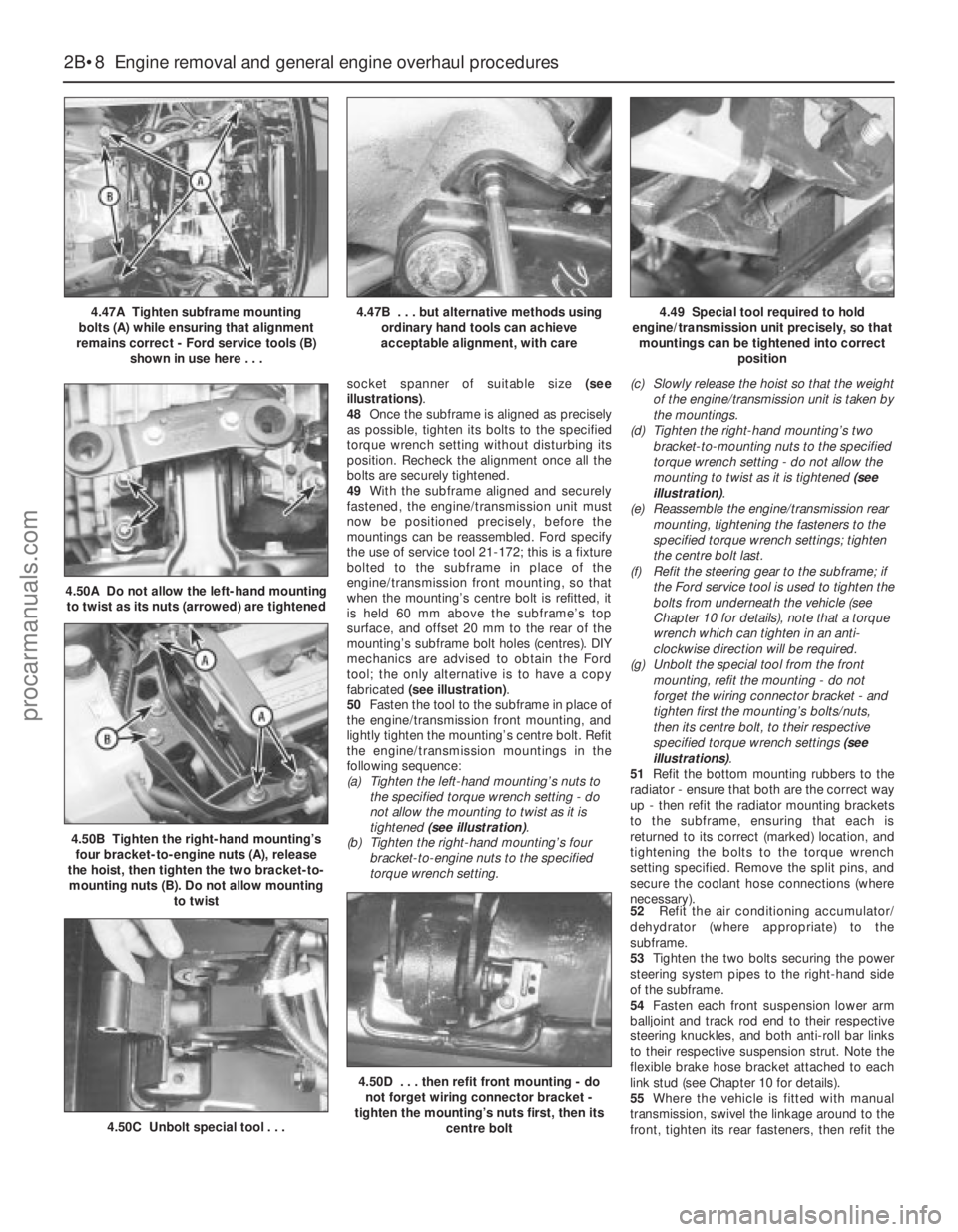

47The subframe must now be aligned on the

underbody. Ford specify the use of service

tool 15-097, which is a pair of tapered guides,

with attachments to hold them in the

subframe as it is refitted. However, since the

working diameter of these tools is 20.4 mm,

and since the corresponding aligning holes in

the subframe and underbody are respectively

21 mm and 22 mm in diameter, there is a

significant in-built tolerance possible in the

subframe’s alignment, even if the correct tools

are used. If these tools are not available, you

can align the subframe by eye, centring the

subframe aligning holes on those of the

underbody, and using the marks made on

removal for assistance. Alternatively, you can

align the subframe using a tapered drift (such

as a clutch-aligning tool), or even a deep

Engine removal and general engine overhaul procedures 2B•7

2B

4.35 Lowering the engine/transmission

unit out of the vehicle

procarmanuals.com

Page 74 of 279

socket spanner of suitable size (see

illustrations).

48Once the subframe is aligned as precisely

as possible, tighten its bolts to the specified

torque wrench setting without disturbing its

position. Recheck the alignment once all the

bolts are securely tightened.

49With the subframe aligned and securely

fastened, the engine/transmission unit must

now be positioned precisely, before the

mountings can be reassembled. Ford specify

the use of service tool 21-172; this is a fixture

bolted to the subframe in place of the

engine/transmission front mounting, so that

when the mounting’s centre bolt is refitted, it

is held 60 mm above the subframe’s top

surface, and offset 20 mm to the rear of the

mounting’s subframe bolt holes (centres). DIY

mechanics are advised to obtain the Ford

tool; the only alternative is to have a copy

fabricated (see illustration).

50Fasten the tool to the subframe in place of

the engine/transmission front mounting, and

lightly tighten the mounting’s centre bolt. Refit

the engine/transmission mountings in the

following sequence:

(a) Tighten the left-hand mounting’s nuts to

the specified torque wrench setting - do

not allow the mounting to twist as it is

tightened (see illustration).

(b) Tighten the right-hand mounting’s four

bracket-to-engine nuts to the specified

torque wrench setting.(c) Slowly release the hoist so that the weight

of the engine/transmission unit is taken by

the mountings.

(d) Tighten the right-hand mounting’s two

bracket-to-mounting nuts to the specified

torque wrench setting - do not allow the

mounting to twist as it is tightened (see

illustration).

(e) Reassemble the engine/transmission rear

mounting, tightening the fasteners to the

specified torque wrench settings; tighten

the centre bolt last.

(f) Refit the steering gear to the subframe; if

the Ford service tool is used to tighten the

bolts from underneath the vehicle (see

Chapter 10 for details), note that a torque

wrench which can tighten in an anti-

clockwise direction will be required.

(g) Unbolt the special tool from the front

mounting, refit the mounting - do not

forget the wiring connector bracket - and

tighten first the mounting’s bolts/nuts,

then its centre bolt, to their respective

specified torque wrench settings (see

illustrations).

51Refit the bottom mounting rubbers to the

radiator - ensure that both are the correct way

up - then refit the radiator mounting brackets

to the subframe, ensuring that each is

returned to its correct (marked) location, and

tightening the bolts to the torque wrench

setting specified. Remove the split pins, and

secure the coolant hose connections (where

necessary).

52Refit the air conditioning accumulator/

dehydrator (where appropriate) to the

subframe.

53Tighten the two bolts securing the power

steering system pipes to the right-hand side

of the subframe.

54Fasten each front suspension lower arm

balljoint and track rod end to their respective

steering knuckles, and both anti-roll bar links

to their respective suspension strut. Note the

flexible brake hose bracket attached to each

link stud (see Chapter 10 for details).

55Where the vehicle is fitted with manual

transmission, swivel the linkage around to the

front, tighten its rear fasteners, then refit the

2B•8 Engine removal and general engine overhaul procedures

4.47A Tighten subframe mounting

bolts (A) while ensuring that alignment

remains correct - Ford service tools (B)

shown in use here . . .4.47B . . . but alternative methods using

ordinary hand tools can achieve

acceptable alignment, with care4.49 Special tool required to hold

engine/transmission unit precisely, so that

mountings can be tightened into correct

position

4.50B Tighten the right-hand mounting’s

four bracket-to-engine nuts (A), release

the hoist, then tighten the two bracket-to-

mounting nuts (B). Do not allow mounting

to twist

4.50A Do not allow the left-hand mounting

to twist as its nuts (arrowed) are tightened

4.50C Unbolt special tool . . .

4.50D . . . then refit front mounting - do

not forget wiring connector bracket -

tighten the mounting’s nuts first, then its

centre bolt

procarmanuals.com

Page 75 of 279

gear linkage heat shield. Reconnect the

gearchange linkage and transmission support

rods to the transmission, adjusting the linkage

using the marks made on removal (see

Chapter 7, Part A, for details).

56Re-install the remaining components and

fasteners in the reverse order of removal.

57Add coolant, engine oil and transmission

fluids as needed (see Chapter 1).

58Run the engine, and check for proper

operation and the absence of leaks. Shut off

the engine, and recheck the fluid levels.

59Remember that, since the front suspension

subframe and steering gear have been

disturbed, the wheel alignment and steering

angles must be checked fully and carefully as

soon as possible, with any necessary

adjustments being made. This operation is best

carried out by an experienced mechanic, using

proper checking equipment; the vehicle should

therefore be taken to a Ford dealer or similarly-

qualified person for attention.

1It is much easier to dismantle and work on

the engine if it is mounted on a portable engine

stand. These stands can often be hired from a

tool hire shop. Before the engine is mounted

on a stand, the flywheel/driveplate should be

removed (Part A of this Chapter, Section 21)

so that the stand bolts can be tightened into

the end of the cylinder block/crankcase.

2If a stand is not available, it is possible to

dismantle the engine with it mounted on

blocks, on a sturdy workbench or on the floor.

Be extra-careful not to tip or drop the engine

when working without a stand.

3If you are going to obtain a reconditioned

engine, all external components must be

removed first, to be transferred to the

replacement engine (just as they will if you are

doing a complete engine overhaul yourself).

Note:When removing the external

components from the engine, pay close

attention to details that may be helpful or

important during refitting. Note the fitted

position of gaskets, seals, spacers, pins,

washers, bolts and other small items.These

external components include the following:

(a) Alternator and brackets (Chapter 5).

(b) HT leads and spark plugs (Chapter 1).

(c) Thermostat and housing (Chapter 3).

(d) Dipstick tube.

(e) Fuel injection system components

(Chapter 4).

(f) All electrical switches and sensors - refer

to the appropriate Chapter.

(g) Inlet and exhaust manifolds (Part A of this

Chapter).

(h) Oil filter (Chapter 1).

(i) Engine/transmission mounting brackets

(Part A of this Chapter, Section 22).

(j) Flywheel/driveplate (Part A of this

Chapter, Section 21).

4If you are obtaining a “short” engine (whichconsists of the engine cylinder

block/crankcase, crankshaft, pistons and

connecting rods all assembled), then the

cylinder head, sump, oil pump, and timing belt

will have to be removed also.

5If you are planning a complete overhaul, the

engine can be dismantled and the internal

components removed in the following order.

(a) Inlet and exhaust manifolds (Part A of this

Chapter).

(b) Timing belt, toothed pulleys and

tensioner, and timing belt inner cover

(Part A of this Chapter).

(c) Cylinder head (Part A of this Chapter,

Section 14).

(d) Flywheel/driveplate (Part A of this

Chapter, Section 21).

(e) Sump (Part A of this Chapter, Section 15).

(f) Oil pump (Part A of this Chapter, Sec-

tion 16).

(g) Piston/connecting rod assemblies

(Section 9).

(h) Crankshaft (Section 10).

6Before beginning the dismantling andoverhaul procedures, make sure that you have

all of the correct tools necessary. Refer to the

introductory pages at the beginning of this

manual for further information.

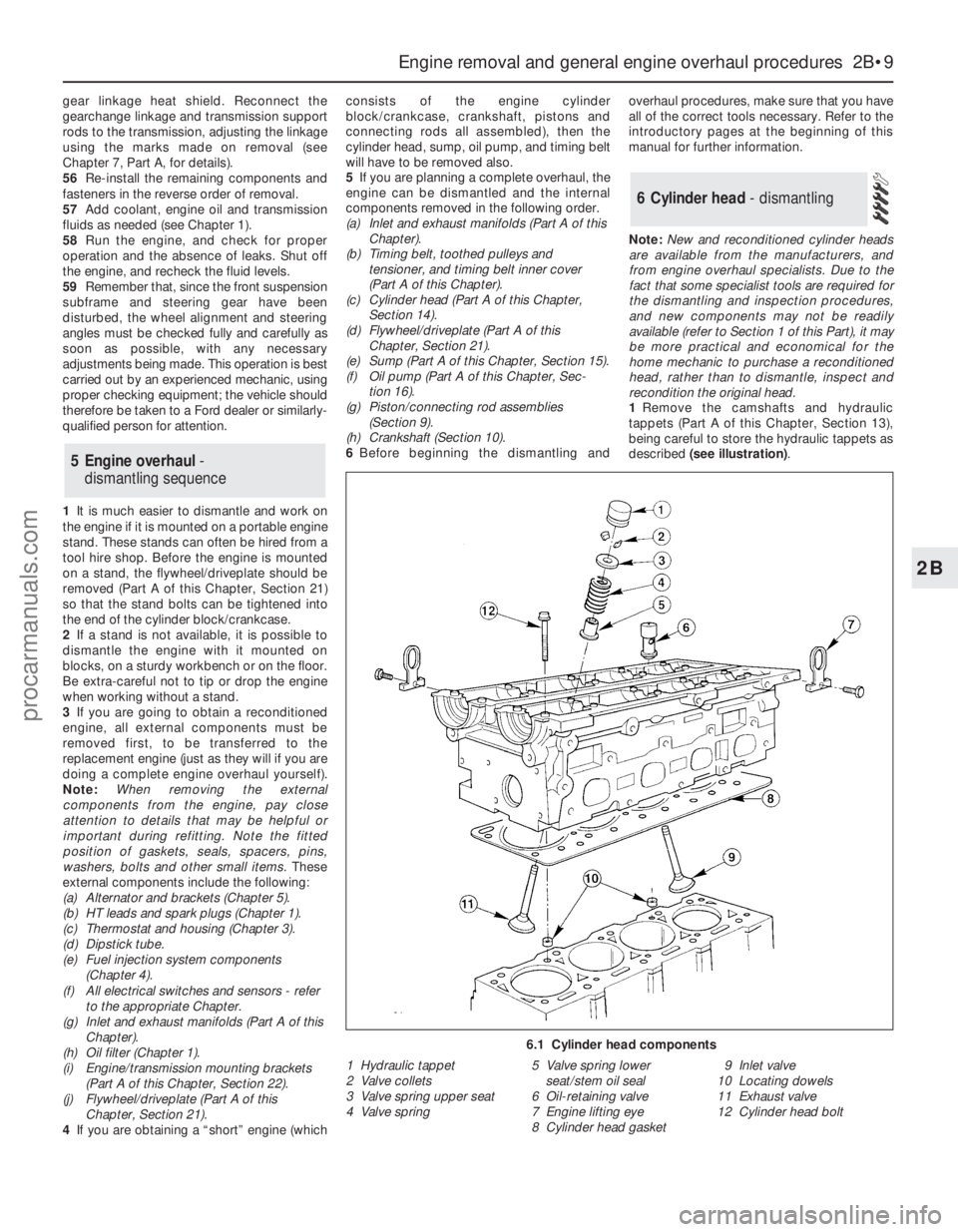

Note:New and reconditioned cylinder heads

are available from the manufacturers, and

from engine overhaul specialists. Due to the

fact that some specialist tools are required for

the dismantling and inspection procedures,

and new components may not be readily

available (refer to Section 1 of this Part), it may

be more practical and economical for the

home mechanic to purchase a reconditioned

head, rather than to dismantle, inspect and

recondition the original head.

1Remove the camshafts and hydraulic

tappets (Part A of this Chapter, Section 13),

being careful to store the hydraulic tappets as

described (see illustration).

6 Cylinder head - dismantling

5 Engine overhaul-

dismantling sequence

Engine removal and general engine overhaul procedures 2B•9

2B

6.1 Cylinder head components

1 Hydraulic tappet

2 Valve collets

3 Valve spring upper seat

4 Valve spring5 Valve spring lower

seat/stem oil seal

6 Oil-retaining valve

7 Engine lifting eye

8 Cylinder head gasket9 Inlet valve

10 Locating dowels

11 Exhaust valve

12 Cylinder head bolt

procarmanuals.com

Page 76 of 279

2Remove the cylinder head (Part A of this

Chapter, Section 14).

3Using a valve spring compressor, compress

each valve spring in turn until the split collets

can be removed. A special valve spring

compressor will be required, to reach into the

deep wells in the cylinder head without risk of

damaging the hydraulic tappet bores; such

compressors are now widely available from

most good motor accessory shops. Release

the compressor, and lift off the spring upper

seat and spring (see illustrations).

4If, when the valve spring compressor is

screwed down, the spring upper seat refuses

to free and expose the split collets, gently tap

the top of the tool, directly over the upper

seat, with a light hammer. This will free the

seat.

5Withdraw the valve through the combustionchamber. If it binds in the guide (won’t pull

through), push it back in, and de-burr the area

around the collet groove with a fine file or

whetstone; take care not to mark the

hydraulic tappet bores.

6Ford recommend the use of their service

tool 21-160 to extract the valve spring lower

seat/stem oil seals; while this is almost

indispensable if the seals are to be removed

without risk of (extremely expensive) damage

to the cylinder head, we found that a

serviceable substitute can be made from a

strong spring of suitable size. Screw on the

tool or spring so that it bites into the seal, then

draw the seal off the valve guide (see

illustrations).

7It is essential that the valves are kept

together with their collets, spring seats and

springs, and in their correct sequence (unless

they are so badly worn that they are to be

renewed). If they are going to be kept and

used again, place them in a labelled polythene

bag or similar small container (see

illustration). Note that No 1 valve is nearest to

the timing belt end of the engine.

8If the oil-retaining valve is to be removed (to

flush out the cylinder head oil galleries

thoroughly), seek the advice of a Ford dealer

as to how it can be extracted; it may be that

the only course of action involves destroying

the valve as follows. Screw a self-tapping

screw into its ventilation hole, and use the

screw to provide purchase with which the

valve can be drawn out; a new valve must be

purchased and pressed into place on

reassembly (see illustration).Note:Always check first what replacement

parts are available before planning any

overhaul operation; refer to Section 1 of this

Part. A Ford dealer, or a good engine

reconditioning specialist/automotive parts

supplier, may be able to suggest alternatives

which will enable you to overcome the lack of

replacement parts.

1Thorough cleaning of the cylinder head and

valve components, followed by a detailed

inspection, will enable you to decide how

much valve service work must be carried out

during the engine overhaul. Note:If the

engine has been severely overheated, it is best

to assume that the cylinder head is warped,

and to check carefully for signs of this.

Cleaning

2Scrape away all traces of old gasket

material and sealing compound from the

cylinder head (see Part A of this Chapter,

Section 14 for details).

3Scrape away the carbon from the

combustion chambers and ports, then wash

the cylinder head thoroughly with paraffin or a

suitable solvent.

7 Cylinder head and valve

components-

cleaning and inspection

2B•10 Engine removal and general engine overhaul procedures

6.3A Standard valve spring compressor

modified as shown . . .6.3B . . . or purpose-built special version,

is required to compress valve springs

without damaging cylinder head . . .

6.3C . . . so that both valve split collets

can be removed from the valve’s stem -

small magnetic pick-up tool prevents loss

of small metal components on removal

and refitting

6.6B . . . can be replaced by home-made

tool if suitable spring can be found

6.6A Ford service tool in use to remove

valve spring lower seat/stem oil seals . . .

6.7 Use clearly-marked containers to

identify components and to keep matched

assemblies together6.8 Cylinder head oil-retaining valve

(arrowed)

procarmanuals.com

Page 77 of 279

4Scrape off any heavy carbon deposits that

may have formed on the valves, then use a

power-operated wire brush to remove

deposits from the valve heads and stems.

Inspection

Note:Be sure to perform all the following

inspection procedures before concluding that

the services of a machine shop or engine

overhaul specialist are required. Make a list of

all items that require attention.

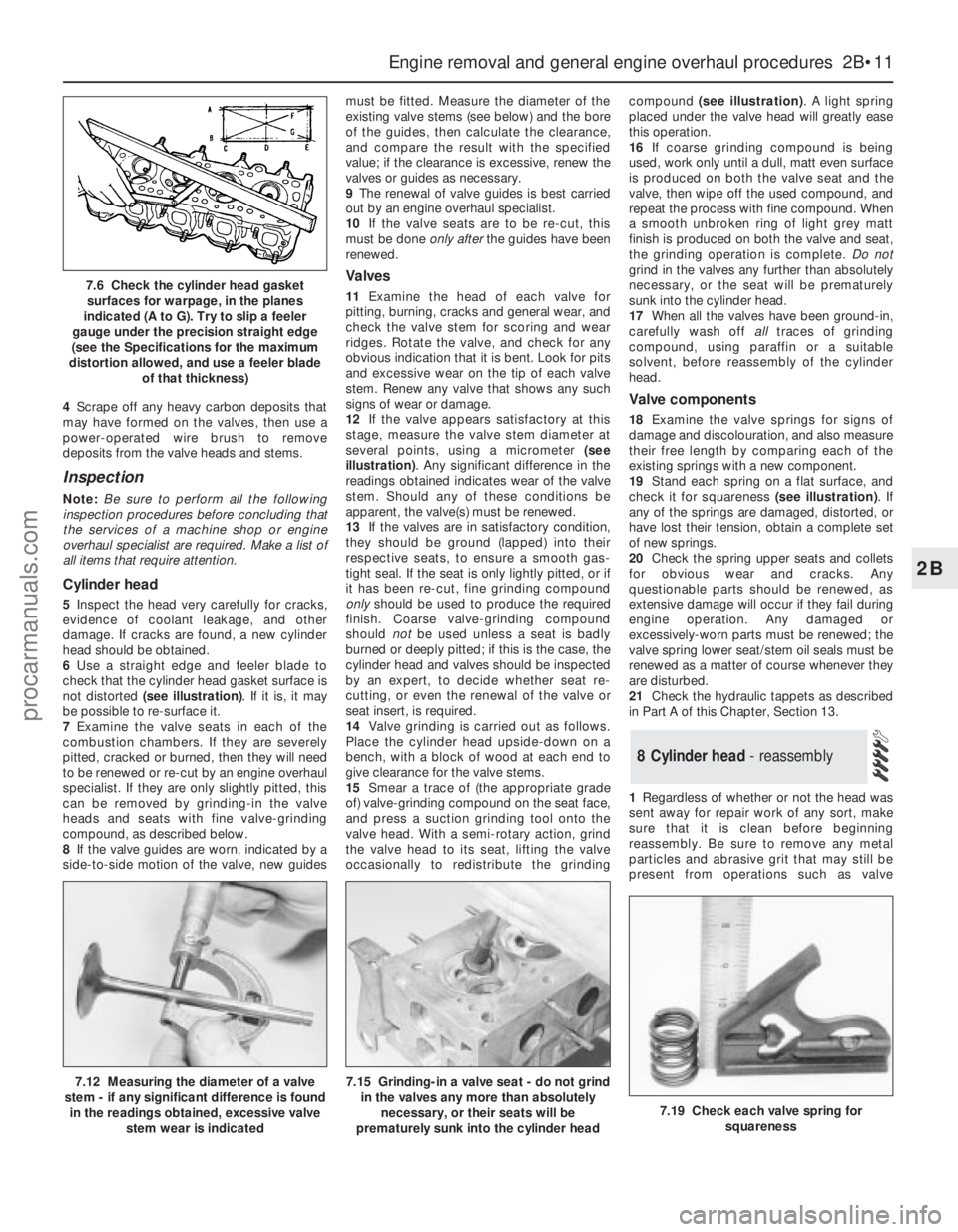

Cylinder head

5Inspect the head very carefully for cracks,

evidence of coolant leakage, and other

damage. If cracks are found, a new cylinder

head should be obtained.

6Use a straight edge and feeler blade to

check that the cylinder head gasket surface is

not distorted (see illustration). If it is, it may

be possible to re-surface it.

7Examine the valve seats in each of the

combustion chambers. If they are severely

pitted, cracked or burned, then they will need

to be renewed or re-cut by an engine overhaul

specialist. If they are only slightly pitted, this

can be removed by grinding-in the valve

heads and seats with fine valve-grinding

compound, as described below.

8If the valve guides are worn, indicated by a

side-to-side motion of the valve, new guidesmust be fitted. Measure the diameter of the

existing valve stems (see below) and the bore

of the guides, then calculate the clearance,

and compare the result with the specified

value; if the clearance is excessive, renew the

valves or guides as necessary.

9The renewal of valve guides is best carried

out by an engine overhaul specialist.

10If the valve seats are to be re-cut, this

must be done only afterthe guides have been

renewed.

Valves

11Examine the head of each valve for

pitting, burning, cracks and general wear, and

check the valve stem for scoring and wear

ridges. Rotate the valve, and check for any

obvious indication that it is bent. Look for pits

and excessive wear on the tip of each valve

stem. Renew any valve that shows any such

signs of wear or damage.

12If the valve appears satisfactory at this

stage, measure the valve stem diameter at

several points, using a micrometer (see

illustration). Any significant difference in the

readings obtained indicates wear of the valve

stem. Should any of these conditions be

apparent, the valve(s) must be renewed.

13If the valves are in satisfactory condition,

they should be ground (lapped) into their

respective seats, to ensure a smooth gas-

tight seal. If the seat is only lightly pitted, or if

it has been re-cut, fine grinding compound

onlyshould be used to produce the required

finish. Coarse valve-grinding compound

should notbe used unless a seat is badly

burned or deeply pitted; if this is the case, the

cylinder head and valves should be inspected

by an expert, to decide whether seat re-

cutting, or even the renewal of the valve or

seat insert, is required.

14Valve grinding is carried out as follows.

Place the cylinder head upside-down on a

bench, with a block of wood at each end to

give clearance for the valve stems.

15Smear a trace of (the appropriate grade

of) valve-grinding compound on the seat face,

and press a suction grinding tool onto the

valve head. With a semi-rotary action, grind

the valve head to its seat, lifting the valve

occasionally to redistribute the grindingcompound (see illustration). A light spring

placed under the valve head will greatly ease

this operation.

16If coarse grinding compound is being

used, work only until a dull, matt even surface

is produced on both the valve seat and the

valve, then wipe off the used compound, and

repeat the process with fine compound. When

a smooth unbroken ring of light grey matt

finish is produced on both the valve and seat,

the grinding operation is complete. Do not

grind in the valves any further than absolutely

necessary, or the seat will be prematurely

sunk into the cylinder head.

17When all the valves have been ground-in,

carefully wash off alltraces of grinding

compound, using paraffin or a suitable

solvent, before reassembly of the cylinder

head.

Valve components

18Examine the valve springs for signs of

damage and discolouration, and also measure

their free length by comparing each of the

existing springs with a new component.

19Stand each spring on a flat surface, and

check it for squareness (see illustration). If

any of the springs are damaged, distorted, or

have lost their tension, obtain a complete set

of new springs.

20Check the spring upper seats and collets

for obvious wear and cracks. Any

questionable parts should be renewed, as

extensive damage will occur if they fail during

engine operation. Any damaged or

excessively-worn parts must be renewed; the

valve spring lower seat/stem oil seals must be

renewed as a matter of course whenever they

are disturbed.

21Check the hydraulic tappets as described

in Part A of this Chapter, Section 13.

1Regardless of whether or not the head was

sent away for repair work of any sort, make

sure that it is clean before beginning

reassembly. Be sure to remove any metal

particles and abrasive grit that may still be

present from operations such as valve

8 Cylinder head - reassembly

Engine removal and general engine overhaul procedures 2B•11

2B

7.12 Measuring the diameter of a valve

stem - if any significant difference is found

in the readings obtained, excessive valve

stem wear is indicated7.15 Grinding-in a valve seat - do not grind

in the valves any more than absolutely

necessary, or their seats will be

prematurely sunk into the cylinder head

7.19 Check each valve spring for

squareness

7.6 Check the cylinder head gasket

surfaces for warpage, in the planes

indicated (A to G). Try to slip a feeler

gauge under the precision straight edge

(see the Specifications for the maximum

distortion allowed, and use a feeler blade

of that thickness)

procarmanuals.com

Page 78 of 279

grinding or head resurfacing. Use

compressed air, if available, to blow out all the

oil holes and passages.

2Beginning at one end of the head, lubricate

and install the first valve. Apply molybdenum

disulphide-based grease or clean engine oil to

the valve stem, and refit the valve. Where the

original valves are being re-used, ensure that

each is refitted in its original guide. If new

valves are being fitted, insert them into the

locations to which they have been ground.

3Fit the plastic protector supplied with new

valve spring lower seat/stem oil seals to the

end of the valve stem, then put the new seal

squarely on top of the guide, and leave it

there; the action of refitting the valve spring

presses the lower seat/stem oil seal into place

(see illustration).

4Refit the valve spring and upper seat.

5Compress the spring with a valve spring

compressor, and carefully install the collets in

the stem groove. Apply a small dab of grease

to each collet to hold it in place if necessary

(see illustration). Slowly release the

compressor, and make sure the collets seat

properly.

6When the valve is installed, place the

cylinder head flat on the bench and, using a

hammer and interposed block of wood, tap

the end of the valve stem gently, to settle the

components.7Repeat the procedure for the remaining

valves. Be sure to return the components to

their original locations - don’t mix them up!

8Refit the hydraulic tappets (Part A of this

Chapter, Section 13).

Note:Always check first what replacement

parts are available before planning any

overhaul operation; refer to Section 1 of this

Part. A Ford dealer, or a good engine

reconditioning specialist/automotive parts

supplier, may be able to suggest alternatives

which will enable you to overcome the lack of

replacement parts.

Note:While this task is theoretically possible

when the engine is in place in the vehicle, in

practice, it requires so much preliminary

dismantling, and is so difficult to carry out due

to the restricted access, that owners are

advised to remove the engine from the vehicle

first. In addition to the new gaskets and other

replacement parts required, a hoist will be

needed. Alternatively, an adjustable engine

support bar, fitting into the water drainchannels on each side of the bonnet aperture,

and having a hook which will engage the

engine lifting eyes and allow the height of the

engine to be adjusted, could be used. Lifting

equipment such as this can be hired from

most tool hire shops - be sure that any such

equipment is rated well in excess of the

combined weight of the engine/transmission

unit.

1Remove the cylinder head (Part A of this

Chapter, Section 14).

2Bolt lifting eyes to suitable points on the

engine and transmission, then attach the

lifting equipment so that the engine/

transmission unit is supported securely.

3Remove the sump (Part A of this Chapter,

Section 15).

4Undo the screws securing the oil pump

pick-up/strainer pipe to the pump, then

unscrew the four nuts, and withdraw the oil

pump pick-up/strainer pipe and oil baffle (see

illustration).

5Temporarily refit the crankshaft pulley, so

that the crankshaft can be rotated. Note that

each piston/connecting rod assembly can be

identified by its cylinder number (counting

from the timing belt end of the engine) etched

into the flat-machined surface of both the

connecting rod and its cap. The numbers are

visible from the front (exhaust side) of the

engine. Furthermore, each piston has an

arrow stamped into its crown, pointing

towards the timing belt end of the engine. If

no marks can be seen, make your own before

disturbing any of the components, so that you

can be certain of refitting each

piston/connecting rod assembly the right way

round, to its correct (original) bore, with the

cap also the right way round (see

illustrations).

6Use your fingernail to feel if a ridge has

formed at the upper limit of ring travel (about a

quarter-inch down from the top of each

cylinder). If carbon deposits or cylinder wear

have produced ridges, they must be

completely removed with a special tool (see

illustration). Follow the manufacturer’s

instructions provided with the tool. Failure to

remove the ridges before attempting to

9 Piston/connecting rod

assemblies- removal

2B•12 Engine removal and general engine overhaul procedures

8.3 Valve spring pressure is sufficient to

seat lower seat/stem oil seals on

reassembly8.5 Apply a small dab of grease to each

collet before installation - it will hold them

in place on the valve stem until the spring

is released9.4 Removing the oil baffle to provide

access to crankshaft and bearings

9.5A Each connecting rod and big-end

bearing cap will have a flat-machined

surface visible from the front (exhaust)

side of the engine, with the cylinder

number etched in it

9.5B Piston crown markings

A 1.6 and 1.8 litre engines

B 2.0 litre engines

1 Gudgeon pin diameter grade - when used

2 Piston skirt diameter grade

3 Arrow mark - pointing to timing belt end of

engine

procarmanuals.com

Page 79 of 279

remove the piston/connecting rod assemblies

may result in piston ring breakage.

7Slacken each of the big-end bearing cap

bolts half a turn at a time, until they can be

removed by hand. Remove the No 1 cap and

bearing shell. Don’t drop the shell out of the

cap.

8Remove the upper bearing shell, and push

the connecting rod/piston assembly out

through the top of the engine. Use a wooden

hammer handle to push on the connecting

rod’s bearing recess. If resistance is felt,

double-check that all of the ridge was

removed from the cylinder.

9Repeat the procedure for the remaining

cylinders.

10After removal, reassemble the big-end

bearing caps and shells on their respective

connecting rods, and refit the bolts finger-

tight. Leaving the old shells in place until

reassembly will help prevent the bearing

recesses from being accidentally nicked or

gouged. New shells should be used on

reassembly.

11Don’t attempt to separate the pistons

from the connecting rods - see Section 12.

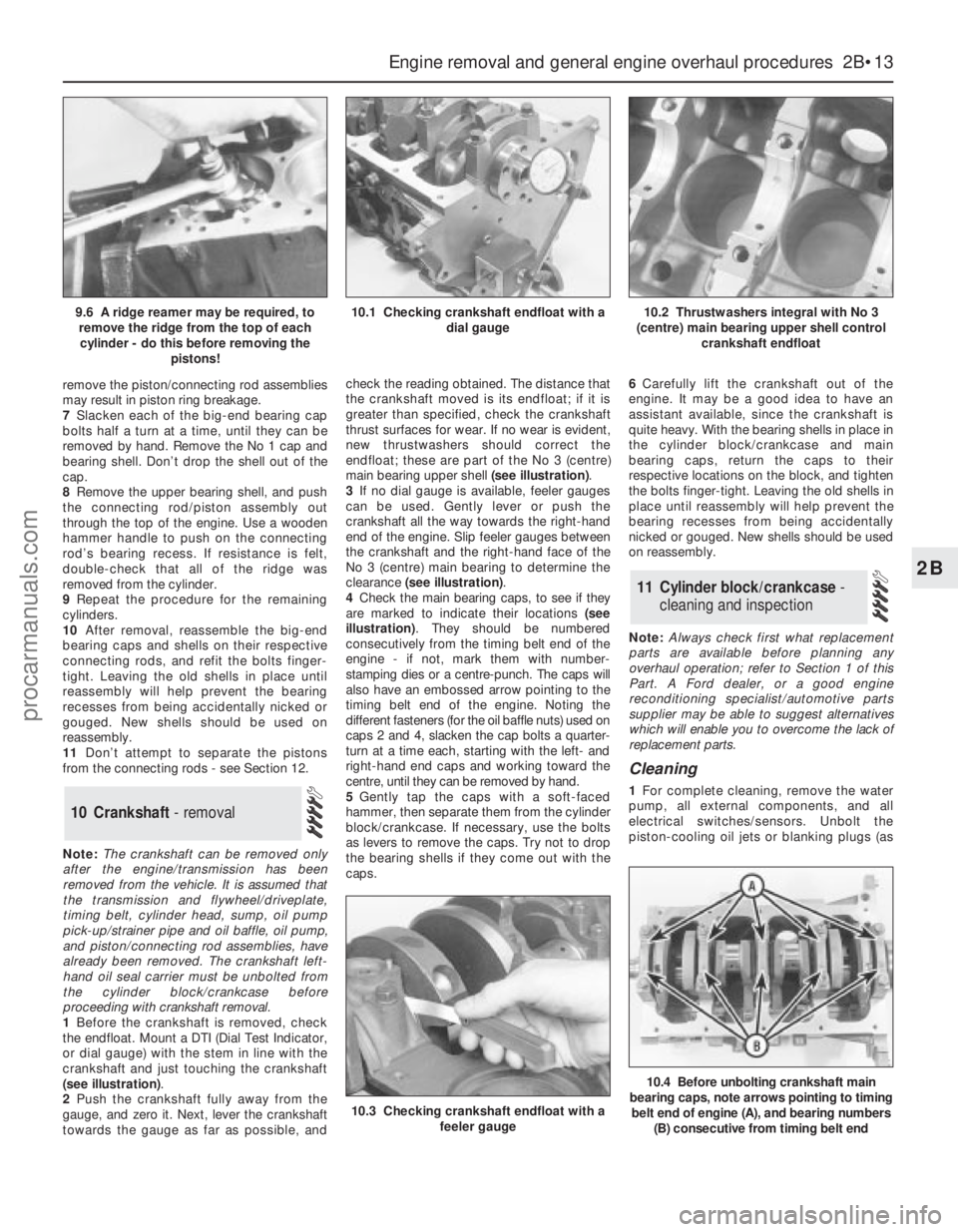

Note:The crankshaft can be removed only

after the engine/transmission has been

removed from the vehicle. It is assumed that

the transmission and flywheel/driveplate,

timing belt, cylinder head, sump, oil pump

pick-up/strainer pipe and oil baffle, oil pump,

and piston/connecting rod assemblies, have

already been removed. The crankshaft left-

hand oil seal carrier must be unbolted from

the cylinder block/crankcase before

proceeding with crankshaft removal.

1Before the crankshaft is removed, check

the endfloat. Mount a DTI (Dial Test Indicator,

or dial gauge) with the stem in line with the

crankshaft and just touching the crankshaft

(see illustration).

2Push the crankshaft fully away from the

gauge, and zero it. Next, lever the crankshaft

towards the gauge as far as possible, andcheck the reading obtained. The distance that

the crankshaft moved is its endfloat; if it is

greater than specified, check the crankshaft

thrust surfaces for wear. If no wear is evident,

new thrustwashers should correct the

endfloat; these are part of the No 3 (centre)

main bearing upper shell (see illustration).

3If no dial gauge is available, feeler gauges

can be used. Gently lever or push the

crankshaft all the way towards the right-hand

end of the engine. Slip feeler gauges between

the crankshaft and the right-hand face of the

No 3 (centre) main bearing to determine the

clearance (see illustration).

4Check the main bearing caps, to see if they

are marked to indicate their locations (see

illustration). They should be numbered

consecutively from the timing belt end of the

engine - if not, mark them with number-

stamping dies or a centre-punch. The caps will

also have an embossed arrow pointing to the

timing belt end of the engine. Noting the

different fasteners (for the oil baffle nuts) used on

caps 2 and 4, slacken the cap bolts a quarter-

turn at a time each, starting with the left- and

right-hand end caps and working toward the

centre, until they can be removed by hand.

5Gently tap the caps with a soft-faced

hammer, then separate them from the cylinder

block/crankcase. If necessary, use the bolts

as levers to remove the caps. Try not to drop

the bearing shells if they come out with the

caps.6Carefully lift the crankshaft out of the

engine. It may be a good idea to have an

assistant available, since the crankshaft is

quite heavy. With the bearing shells in place in

the cylinder block/crankcase and main

bearing caps, return the caps to their

respective locations on the block, and tighten

the bolts finger-tight. Leaving the old shells in

place until reassembly will help prevent the

bearing recesses from being accidentally

nicked or gouged. New shells should be used

on reassembly.

Note:Always check first what replacement

parts are available before planning any

overhaul operation; refer to Section 1 of this

Part. A Ford dealer, or a good engine

reconditioning specialist/automotive parts

supplier may be able to suggest alternatives

which will enable you to overcome the lack of

replacement parts.

Cleaning

1For complete cleaning, remove the water

pump, all external components, and all

electrical switches/sensors. Unbolt the

piston-cooling oil jets or blanking plugs (as

11 Cylinder block/crankcase -

cleaning and inspection

10 Crankshaft - removal

Engine removal and general engine overhaul procedures 2B•13

2B

10.3 Checking crankshaft endfloat with a

feeler gauge

10.4 Before unbolting crankshaft main

bearing caps, note arrows pointing to timing

belt end of engine (A), and bearing numbers

(B) consecutive from timing belt end

9.6 A ridge reamer may be required, to

remove the ridge from the top of each

cylinder - do this before removing the

pistons!10.1 Checking crankshaft endfloat with a

dial gauge10.2 Thrustwashers integral with No 3

(centre) main bearing upper shell control

crankshaft endfloat

procarmanuals.com

Page 80 of 279

applicable); note that Ford state that the

piston-cooling oil jets (where fitted) must be

renewed whenever the engine is dismantled

for full overhaul (see illustrations).

2Remove the main bearing caps, and

separate the bearing shells from the caps and

the cylinder block/crankcase. Mark or label

the shells, indicating which bearing they were

removed from, and whether they were in the

cap or the block, then set them aside (see

illustration). Wipe clean the block and cap

bearing recesses, and inspect them for nicks,

gouges and scratches.

3Scrape all traces of gasket from the cylinderblock/crankcase, taking care not to damage

the sealing surfaces.

4Remove all oil gallery plugs (where fitted).

The plugs are usually very tight - they may

have to be drilled out and the holes re-tapped.

Use new plugs when the engine is

reassembled. Drill a small hole in the centre of

each core plug, and pull them out with a car

bodywork dent puller (see illustration).

Caution: The core plugs (also

known as freeze or soft plugs)

may be difficult or impossible to

retrieve if they are driven into the

block coolant passages.5If any of the castings are extremely dirty, all

should be steam-cleaned.

6After the castings are returned from steam-

cleaning, clean all oil holes and oil galleries

one more time. Flush all internal passages

with warm water until the water runs clear,

then dry thoroughly, and apply a light film of

oil to all machined surfaces, to prevent

rusting. If you have access to compressed air,

use it to speed the drying process, and to

blow out all the oil holes and galleries.

Warning: Wear eye protection

when using compressed air!

7If the castings are not very dirty, you can do

an adequate cleaning job with hot soapy

water (as hot as you can stand!) and a stiff

brush. Take plenty of time, and do a thorough

job. Regardless of the cleaning method used,

be sure to clean all oil holes and galleries very

thoroughly, and to dry all components

completely; protect the machined surfaces as

described above, to prevent rusting.

8All threaded holes must be clean and dry,

to ensure accurate torque readings during

reassembly; now is also a good time to clean

and check the threads of all principal bolts -

however, note that some, such as the cylinder

head and flywheel/driveplate bolts, are to be

renewed as a matter of course whenever they

are disturbed. Run the proper-size tap into

2B•14 Engine removal and general engine overhaul procedures

11.1A Remove water pump . . .11.1B . . . crankcase breather pipe and

PCV valve . . .11.1C . . . unbolt crankcase ventilation

system oil separator . . .

11.1F . . . but note that piston-cooling oil

jets (where fitted) must be renewed as a

matter of course whenever engine is

overhauled11.2 Felt marker pens can be used as

shown to identify bearing shells without

damaging them

11.1D . . . remove electrical

switches/sensors such as crankshaft

speed/position sensor . . .11.1E . . . unbolt blanking plugs (where

fitted) to clean out oilways . . .

11.4 The core plugs should be removed

with a puller - if they’re driven into the

block, they may be impossible to

retrieve

procarmanuals.com