FORD MONDEO 1993 Service Repair Manual

Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 161 of 279

holding the piston rod with an 8 mm Allen key.

If the adaptor needed to do this is not

available, the nut can be tightened initially

with a ring spanner while the piston rod is

held. Final tightening can then be carried out

using a torque wrench and a conventional

socket (see illustration).

Warning: Before attempting to

dismantle the front suspension

strut, a tool to hold the coil spring

in compression must be obtained.

Do not attempt to use makeshift methods.

Uncontrolled release of the spring could

cause damage and personal injury. Use a

high-quality spring compressor, and

carefully follow the tool manufacturer’s

instructions provided with it. After removing

the coil spring with the compressor still

fitted, place it in a safe, isolated area.

1If the front suspension struts exhibit signs

of wear (leaking fluid, loss of damping

capability, sagging or cracked coil springs)

then they should be dismantled and

overhauled as necessary. The struts

themselves cannot be serviced, and should

be renewed if faulty, but the springs and

related components can be renewed. To

maintain balanced characteristics on both

sides of the vehicle, the components on both

sides should be renewed at the same time.

2With the strut removed from the vehicle, cleanaway all external dirt, then mount it in a vice.

3Fit the coil spring compressor tools

(ensuring that they are fully engaged), and

compress the spring until all tension is relieved

from the upper mounting (see illustration).

4Hold the strut piston with an Allen key, andunscrew the thrust bearing retaining nut with a

ring spanner (see illustration).

5Withdraw the top mounting, thrust bearing,

upper spring seat and spring, followed by the

gaiter and the bump stop (see illustrations).

6If a new spring is to be fitted, the original

5 Front suspension strut -

overhaul

Suspension and steering systems 10•7

10

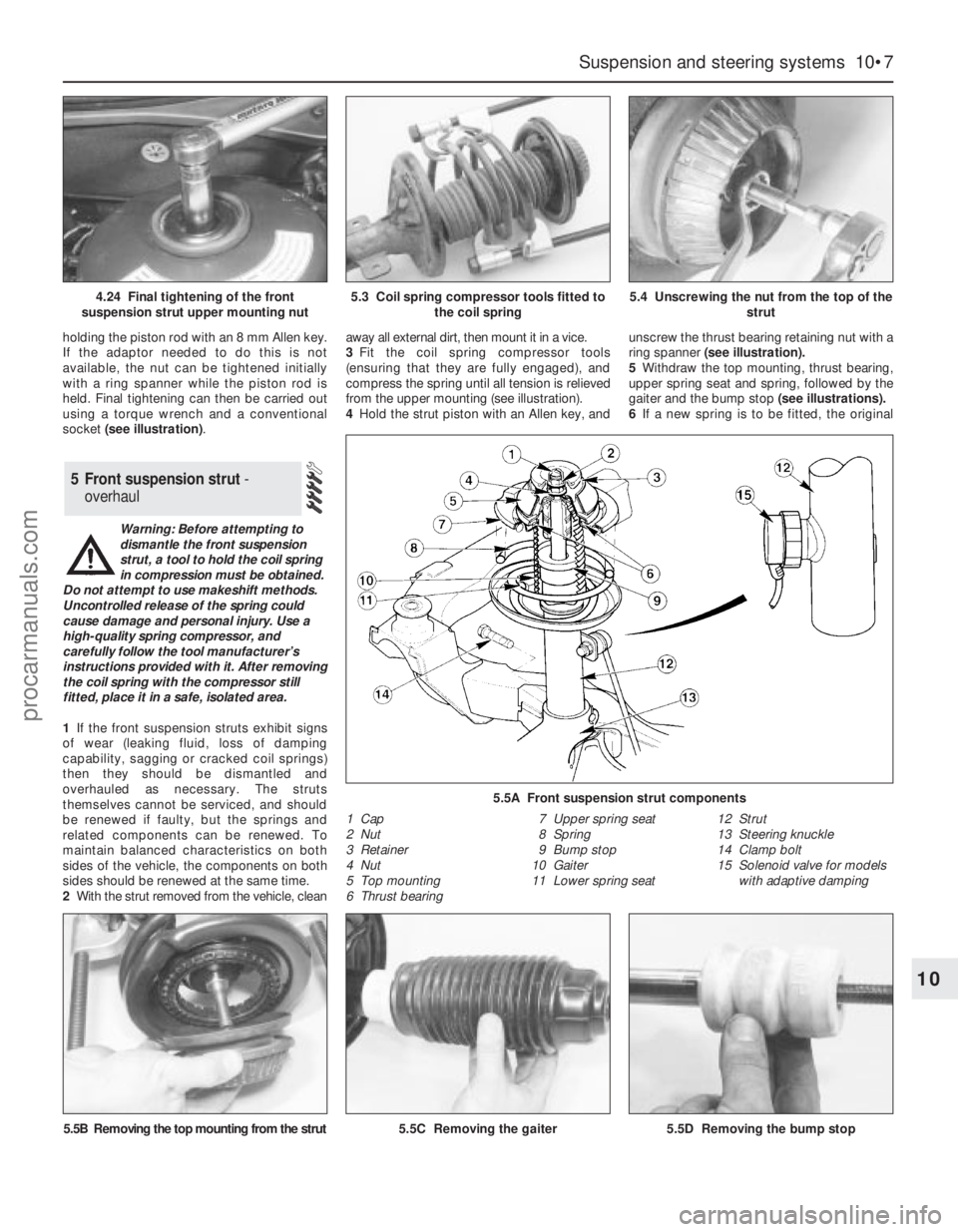

5.5A Front suspension strut components

1 Cap

2 Nut

3 Retainer

4 Nut

5 Top mounting

6 Thrust bearing7 Upper spring seat

8 Spring

9 Bump stop

10 Gaiter

11 Lower spring seat12 Strut

13 Steering knuckle

14 Clamp bolt

15 Solenoid valve for models

with adaptive damping

4.24 Final tightening of the front

suspension strut upper mounting nut5.3 Coil spring compressor tools fitted to

the coil spring5.4 Unscrewing the nut from the top of the

strut

5.5B Removing the top mounting from the strut5.5C Removing the gaiter5.5D Removing the bump stop

procarmanuals.com

Page 162 of 279

spring must now be carefully released from

the compressor. If it is to be re-used, the

spring can be left in compression.

7With the strut assembly now completely

dismantled, examine all the components for

wear and damage, and check the bearing for

smoothness of operation. Renew components

as necessary.

8Examine the strut for signs of fluid leakage.

Check the strut piston for signs of pitting

along its entire length, and check the strut

body for signs of damage. Test the operation

of the strut, while holding it in an upright

position, by moving the piston through a full

stroke, and then through short strokes of 50

to 100 mm. In both cases, the resistance felt

should be smooth and continuous. If the

resistance is jerky, uneven, or if there is any

visible sign of wear or damage to the strut,

renewal is necessary.

9Reassembly is a reversal of dismantling,

noting the following points:

(a) Make sure that the coil spring ends are

correctly located in the upper and lower

seats before releasing the compressor.

(b) Check that the bearing is correctly fitted

to the piston rod seat.

(c) Tighten the thrust bearing retaining nut to

the specified torque.

Removal

1Apply the handbrake, jack up the front of

the vehicle and support it on axle stands.

Remove both front wheels.

2Unscrew the nuts, and disconnect the anti-

roll bar links from the front suspension struts

on both sides of the vehicle. Note that, on

models with ABS, the wheel sensor wiring

support brackets are located beneath the nuts

(see illustrations).

3Unscrew and remove the anti-roll bar

mounting bolts from the engine subframe on

both sides of the vehicle.

4Withdraw the anti-roll bar from one side of

the vehicle, taking care not to damage the

surrounding components.5If necessary, unscrew the nuts and remove

the links from the anti-roll bar.

Refitting

6Refitting is a reversal of the removal

procedure.

Removal

1Apply the handbrake, jack up the front of

the vehicle and support it on axle stands.

Remove the appropriate wheel.

2If removing the right-hand side lower arm,

remove the auxiliary drivebelt cover where

necessary.

3Unscrew and remove the nuts and bolts

securing the lower arm to the subframe (see

illustration).

4Unscrew the nuts and disconnect the anti-

roll bar links from the anti-roll bar on both

sides. Swivel the anti-roll bar upwards away

from the lower arm.

5Extract the split pin from the track rod end

balljoint nut. Unscrew the nut, and detach the

rod from the arm on the steering knuckle

using a conventional balljoint removal tool.

Take care not to damage the balljoint seal.

6Remove the clip securing the driveshaft

inner gaiter to the inner CV joint, and

disconnect the gaiter from the CV joint

housing. This is necessary to prevent damageto the gaiter when the steering knuckle is

moved outwards to remove the lower arm.

7Note which way round the front suspension

lower arm balljoint clamp bolt is fitted, then

unscrew and remove it from the knuckle

assembly. Lever the balljoint down from the

knuckle; if it is tight, prise the joint open carefully

using a large flat-bladed tool. Take care not to

damage the balljoint seal during the separation

procedure. Support the inner end of the

driveshaft on an axle stand (see illustrations).

8Remove the lower arm from the subframe,

and withdraw it from the vehicle.

Overhaul

9Examine the rubber bushes and the

suspension lower balljoint for wear and

damage. The balljoint may be renewed as

described in Section 8. The rubber bushes

may be removed using a press, or a length of

metal tubing together with a long bolt,

washers and nut.

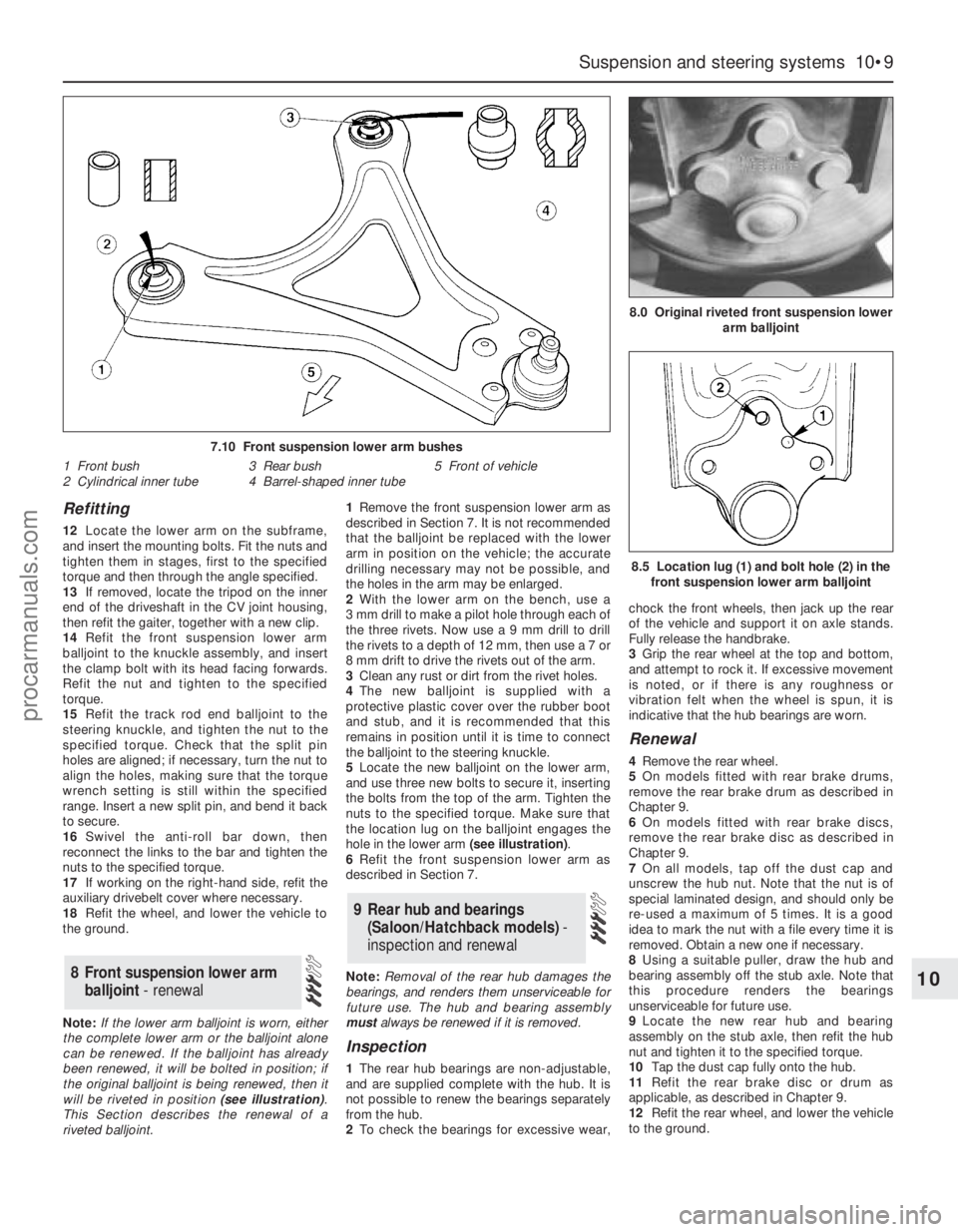

10Note that the front and rear bushes are

different. The front one has a solid rubber

bush with a cylindrical inner tube, whereas the

rear one has a voided rubber bush with a

barrel-shaped inner tube (see illustration).

11Press the new bushes into the lower arm,

using the same method as used for removal.

Note that, when fitting the rear bush, the voids

must be in line with the front bush location.

On later models, a pip on the rear bush must

be aligned with a triangular alignment mark on

the arm.

7 Front suspension lower arm -

removal, overhaul and refitting

6 Front anti-roll bar and links -

removal and refitting

10•8 Suspension and steering systems

6.2A Unscrew the nut . . .6.2B . . . and disconnect the anti-roll bar

link and (on ABS models) the sensor wiring

support bracket

7.3 One of the nuts and bolts securing the

lower arm to the subframe7.7A Unscrew the lower arm balljoint

clamp bolt . . .7.7B . . . and disconnect the balljoint from

the knuckle

procarmanuals.com

Page 163 of 279

Refitting

12Locate the lower arm on the subframe,

and insert the mounting bolts. Fit the nuts and

tighten them in stages, first to the specified

torque and then through the angle specified.

13If removed, locate the tripod on the inner

end of the driveshaft in the CV joint housing,

then refit the gaiter, together with a new clip.

14Refit the front suspension lower arm

balljoint to the knuckle assembly, and insert

the clamp bolt with its head facing forwards.

Refit the nut and tighten to the specified

torque.

15Refit the track rod end balljoint to the

steering knuckle, and tighten the nut to the

specified torque. Check that the split pin

holes are aligned; if necessary, turn the nut to

align the holes, making sure that the torque

wrench setting is still within the specified

range. Insert a new split pin, and bend it back

to secure.

16Swivel the anti-roll bar down, then

reconnect the links to the bar and tighten the

nuts to the specified torque.

17If working on the right-hand side, refit the

auxiliary drivebelt cover where necessary.

18Refit the wheel, and lower the vehicle to

the ground.

Note:If the lower arm balljoint is worn, either

the complete lower arm or the balljoint alone

can be renewed. If the balljoint has already

been renewed, it will be bolted in position; if

the original balljoint is being renewed, then it

will be riveted in position (see illustration).

This Section describes the renewal of a

riveted balljoint.1Remove the front suspension lower arm as

described in Section 7. It is not recommended

that the balljoint be replaced with the lower

arm in position on the vehicle; the accurate

drilling necessary may not be possible, and

the holes in the arm may be enlarged.

2With the lower arm on the bench, use a

3 mm drill to make a pilot hole through each of

the three rivets. Now use a 9 mm drill to drill

the rivets to a depth of 12 mm, then use a 7 or

8 mm drift to drive the rivets out of the arm.

3Clean any rust or dirt from the rivet holes.

4The new balljoint is supplied with a

protective plastic cover over the rubber boot

and stub, and it is recommended that this

remains in position until it is time to connect

the balljoint to the steering knuckle.

5Locate the new balljoint on the lower arm,

and use three new bolts to secure it, inserting

the bolts from the top of the arm. Tighten the

nuts to the specified torque. Make sure that

the location lug on the balljoint engages the

hole in the lower arm (see illustration).

6Refit the front suspension lower arm as

described in Section 7.

Note:Removal of the rear hub damages the

bearings, and renders them unserviceable for

future use. The hub and bearing assembly

mustalways be renewed if it is removed.

Inspection

1The rear hub bearings are non-adjustable,

and are supplied complete with the hub. It is

not possible to renew the bearings separately

from the hub.

2To check the bearings for excessive wear,chock the front wheels, then jack up the rear

of the vehicle and support it on axle stands.

Fully release the handbrake.

3Grip the rear wheel at the top and bottom,

and attempt to rock it. If excessive movement

is noted, or if there is any roughness or

vibration felt when the wheel is spun, it is

indicative that the hub bearings are worn.

Renewal

4Remove the rear wheel.

5On models fitted with rear brake drums,

remove the rear brake drum as described in

Chapter 9.

6On models fitted with rear brake discs,

remove the rear brake disc as described in

Chapter 9.

7On all models, tap off the dust cap and

unscrew the hub nut. Note that the nut is of

special laminated design, and should only be

re-used a maximum of 5 times. It is a good

idea to mark the nut with a file every time it is

removed. Obtain a new one if necessary.

8Using a suitable puller, draw the hub and

bearing assembly off the stub axle. Note that

this procedure renders the bearings

unserviceable for future use.

9Locate the new rear hub and bearing

assembly on the stub axle, then refit the hub

nut and tighten it to the specified torque.

10Tap the dust cap fully onto the hub.

11Refit the rear brake disc or drum as

applicable, as described in Chapter 9.

12Refit the rear wheel, and lower the vehicle

to the ground.

9 Rear hub and bearings

(Saloon/Hatchback models)-

inspection and renewal

8 Front suspension lower arm

balljoint - renewal

Suspension and steering systems 10•9

10

7.10 Front suspension lower arm bushes

1 Front bush

2 Cylindrical inner tube3 Rear bush

4 Barrel-shaped inner tube5 Front of vehicle

8.5 Location lug (1) and bolt hole (2) in the

front suspension lower arm balljoint

8.0 Original riveted front suspension lower

arm balljoint

procarmanuals.com

Page 164 of 279

Note:Removal of the rear hub from the

knuckle damages the bearings, and renders

them unserviceable for future use. The hub

and bearing assembly mustalways be

renewed if it is removed.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate rear wheel.

2When applicable, remove the ABS sensor

from the knuckle as described in Chapter 9.

3Remove the rear hub and bearing assembly

as described in Section 9.

Drum brake models

4Fit a brake hose clamp to the flexible brake

hose, then release the clip and detach the

flexible hose from the strut. Unscrew the

union nut, and detach the rigid brake pipe

from the wheel cylinder. If preferred (to

eliminate any bleeding procedure during

refitting) the rigid brake pipe may remain

attached to the wheel cylinder, provided that

care is taken to prevent damage to both the

rigid and flexible brake pipes.

5Unbolt the backplate from the rear

suspension knuckle (see illustration), and

support it to one side on an axle stand. The

brake shoes and handbrake cable can remain

attached.

Disc brake models

6Unbolt the splash shield from the rear

suspension knuckle.

All models

7Unscrew and remove the bolt securing the

tie-bar to the bottom of the knuckle, and

move the tie-bar downwards.

8Unscrew and remove the bolts securing the

front and rear lower arms to the knuckle, and

move the arms to one side.

9Support the knuckle on an axle stand, then

unscrew and remove the clamp bolt securing

the knuckle to the strut.

10Prise the top of the knuckle apart carefully

using a large flat-bladed tool, and withdrawthe knuckle downwards from the strut.

Withdraw the knuckle from under the rear

wheel arch.

Refitting

11Locate the knuckle fully on the strut, then

insert the clamp bolt and tighten to the

specified torque.

12Refit the front and rear lower arms to the

knuckle, and insert the bolts finger-tight at

this stage.

13Refit the tie-bar to the bottom of the

knuckle, and insert the bolt finger-tight at this

stage.

14Refit the backplate (or splash shield, as

applicable) to the rear suspension knuckle,

and tighten the bolts to the specified torque.

Drum brake models

15Reconnect the rigid brake pipe to the

wheel cylinder (if disconnected), and tighten

the union nut.

16Attach the flexible hose to the strut, refit

the clip, and remove the hose clamp.

All models

17Fit a new rear hub and bearing assembly

as described in Section 9.

18Where applicable, refit the ABS sensor as

described in Chapter 9.

19Refit the wheel, and lower the vehicle to

the ground.

20With the weight of the vehicle on the

suspension, fully tighten the mounting bolts

for the tie-bar and lower arms.

21Where applicable, bleed the hydraulic

brake circuit as described in Chapter 9.

Note:Before attempting to remove the rear

suspension strut, a tool to hold the coil spring

in compression must be obtained. Careful use

of conventional coil spring compressors will

prove satisfactory.

Removal

1In order to remove the rear suspension

strut, the coil spring must be temporarily

compressed. This will enable the piston rod tobe retracted into the strut, and will provide

additional room for releasing the strut from

the bump stop on top of the rear suspension

crossmember.

Warning: It is important to only

use a high-quality spring

compressor; carefully follow the

tool manufacturer’s instructions

provided with it.

2Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate wheel.

3Where fitted, unclip the ABS sensor wiring

from the strut, and remove the sensor from

the knuckle as described in Chapter 9 (see

illustration).

4On models fitted with adaptive damping,

unclip the wiring from the strut and

disconnect the multi-plug (see illustration).

5On drum brake models, fit a brake hose

clamp to the rear flexible brake hose, then

unscrew the union nut securing the rigid brake

pipe to the flexible hose on the strut. Extract

the clip, and disconnect the flexible hose from

the strut.

6On models fitted with rear disc brakes,

unbolt the caliper from the knuckle as

described in Chapter 9, but leave the

hydraulic hose attached. Support the caliper

on an axle stand, making sure that the flexible

hose is not strained.

7Unscrew the nut securing the rear anti-roll

bar link to the front lower arm on the

appropriate side. Hold the actual link with an

adjustable spanner or grips while unscrewing

the nut, to prevent damage to the link joint.

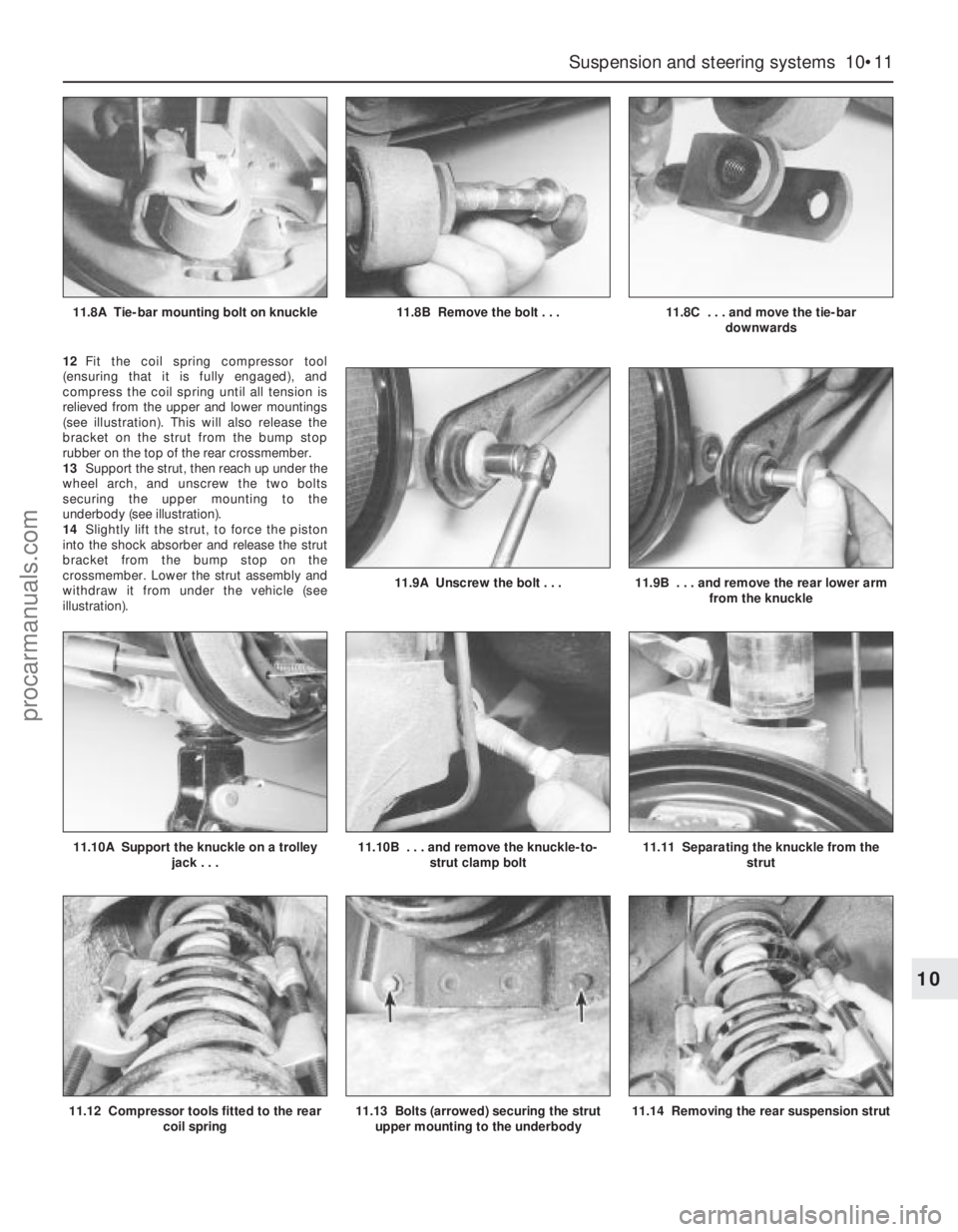

8Unscrew and remove the bolt securing the

tie-bar to the bottom of the knuckle. Move the

tie-bar downwards (see illustrations).

9Unscrew and remove the bolts securing the

front and rear lower arms to the knuckle, and

move the arms to one side (see illustrations).

10Support the knuckle on a trolley jack, then

unscrew and remove the clamp bolt securing

the knuckle to the strut (see illustrations).

11Prise the clamp on the knuckle apart

using a large flat-bladed tool. Disconnect the

knuckle from the strut, and lower it on the

trolley jack as far as possible, taking care not

to damage the handbrake cable (see

illustration).

11 Rear suspension strut

(Saloon/Hatchback models) -

removal and refitting

10 Rear suspension knuckle

(Saloon/Hatchback models)-

removal and refitting

10•10 Suspension and steering systems

10.5 Two of the bolts securing the brake

backplate to the rear suspension knuckle11.3 Unclipping the ABS sensor wiring

from the strut11.4 Location of the adaptive damping

lead (1) and multi-plug (2)

procarmanuals.com

Page 165 of 279

12Fit the coil spring compressor tool

(ensuring that it is fully engaged), and

compress the coil spring until all tension is

relieved from the upper and lower mountings

(see illustration). This will also release the

bracket on the strut from the bump stop

rubber on the top of the rear crossmember.

13Support the strut, then reach up under the

wheel arch, and unscrew the two bolts

securing the upper mounting to the

underbody (see illustration).

14Slightly lift the strut, to force the piston

into the shock absorber and release the strut

bracket from the bump stop on the

crossmember. Lower the strut assembly and

withdraw it from under the vehicle (see

illustration).

Suspension and steering systems 10•11

10

11.12 Compressor tools fitted to the rear

coil spring11.13 Bolts (arrowed) securing the strut

upper mounting to the underbody11.14 Removing the rear suspension strut

11.10A Support the knuckle on a trolley

jack . . .11.10B . . . and remove the knuckle-to-

strut clamp bolt11.11 Separating the knuckle from the

strut

11.9A Unscrew the bolt . . .11.9B . . . and remove the rear lower arm

from the knuckle

11.8A Tie-bar mounting bolt on knuckle11.8B Remove the bolt . . .11.8C . . . and move the tie-bar

downwards

procarmanuals.com

Page 166 of 279

Refitting

15Locate the strut assembly (together with

the coil spring compressor tool) under the

wheel arch, and locate the bracket on the

bump stop on the rear suspension

crossmember. Insert the two bolts securing

the upper mounting to the underbody tower,

and tighten them to the specified torque.

16Carefully release the coil spring

compressor tool, making sure that the spring

locates correctly in the upper and lower seats,

and that the strut bracket locates on the

crossmember bump stop. The bump stop is

tapered inwards, and the strut bracket should

be fully engaged with it before releasing the

coil spring.

17Raise the knuckle and engage it with the

strut, then insert the clamp bolt and tighten to

the specified torque.

18Reconnect the front and rear lower armsto the knuckle, and finger-tighten the bolts at

this stage.

19Reconnect the tie-bar to the bottom of the

knuckle, and finger-tighten the bolt at this

stage.

20Refit the anti-roll bar link to the lower arm,

and tighten the nut to the specified torque.

21On disc brake models, refit the caliper

bracket to the knuckle, and tighten the

mounting bolts to the specified torque (see

Chapter 9). Make sure that the flexible brake

hose is not twisted.

22On drum brake models, connect the

flexible hose to the strut, insert the clip, then

insert the rigid brake line and tighten the union

nut. Remove the brake hose clamp, then

bleed the hydraulic brake circuit as described

in Chapter 9.

23Where applicable, reconnect the wiring

multi-plug for the adaptive damping, and clip

the wiring to the strut.24Where applicable, refit the ABS sensor as

described in Chapter 9, and clip the wiring to

the strut.

25Refit the wheel, and lower the vehicle to

the ground.

26With the weight of the vehicle on the rear

suspension, fully tighten the lower arm and

tie-bar mounting bolts.

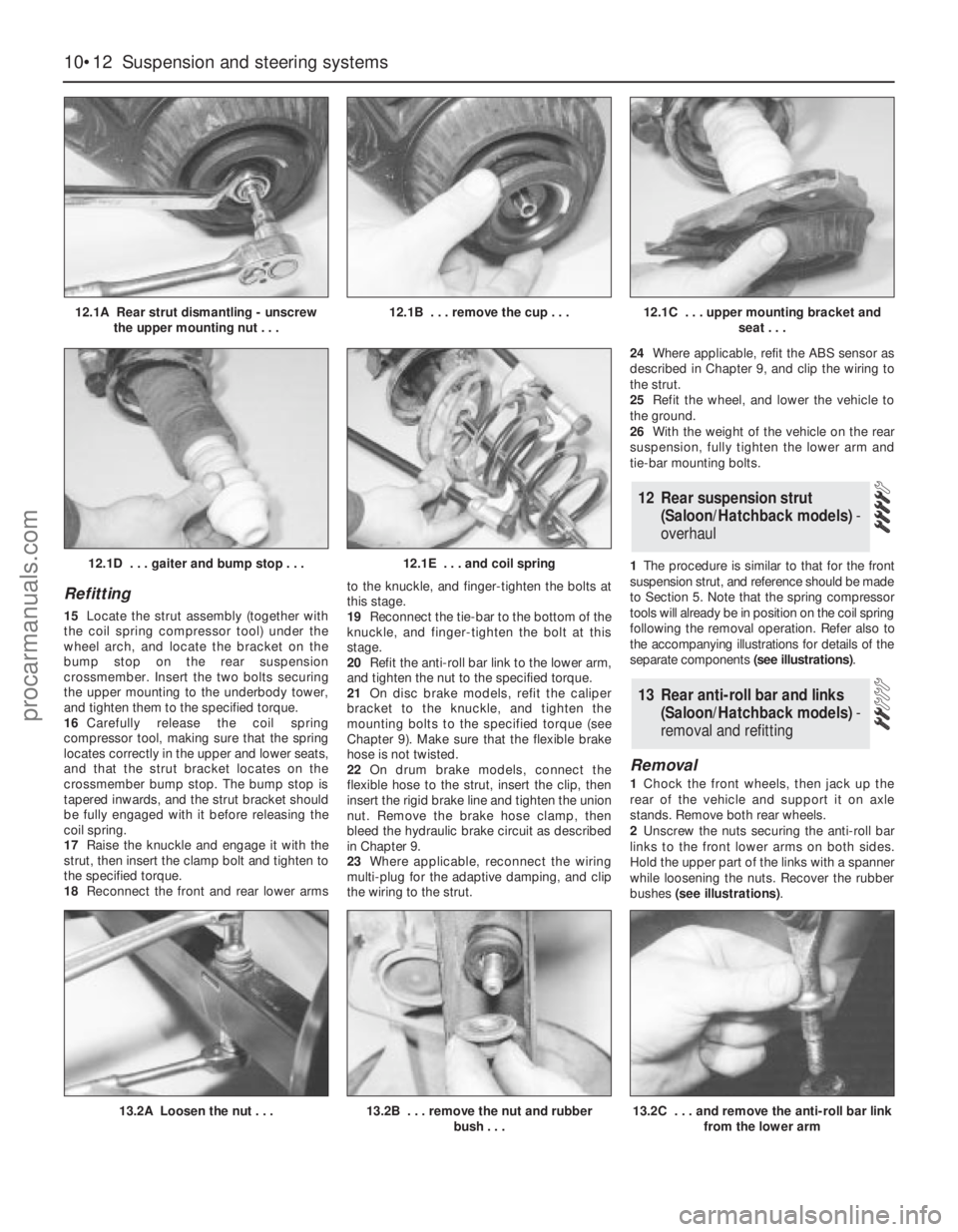

1The procedure is similar to that for the front

suspension strut, and reference should be made

to Section 5. Note that the spring compressor

tools will already be in position on the coil spring

following the removal operation. Refer also to

the accompanying illustrations for details of the

separate components (see illustrations).

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove both rear wheels.

2Unscrew the nuts securing the anti-roll bar

links to the front lower arms on both sides.

Hold the upper part of the links with a spanner

while loosening the nuts. Recover the rubber

bushes (see illustrations).

13 Rear anti-roll bar and links

(Saloon/Hatchback models) -

removal and refitting

12 Rear suspension strut

(Saloon/Hatchback models)-

overhaul

10•12 Suspension and steering systems

12.1A Rear strut dismantling - unscrew

the upper mounting nut . . .12.1B . . . remove the cup . . .12.1C . . . upper mounting bracket and

seat . . .

13.2A Loosen the nut . . .13.2B . . . remove the nut and rubber

bush . . .

12.1D . . . gaiter and bump stop . . .12.1E . . . and coil spring

13.2C . . . and remove the anti-roll bar link

from the lower arm

procarmanuals.com

Page 167 of 279

3Unscrew the bolts securing the anti-roll bar

mounting clamps to the rear suspension

crossmember, then unhook the clamps and

withdraw the anti-roll bar from under the

vehicle (see illustration).

4Examine the rubber bushes for the

mounting clamps and links, and if necessary

renew them. The links are available

individually.

Refitting

5Locate the anti-roll bar on the rear

crossmember, hook the mounting clamps in

position, and insert the bolts. Tighten the

bolts to the specified torque.

6Locate the anti-roll bar links in the front

lower arms on both sides, making sure that

the rubber bushes are in position. Refit the

nuts and tighten them to the specified torque.

7Refit the rear wheels, and lower the vehicle

to the ground.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate rear wheel.

Front lower arm

2To remove the front lower arm, it is

necessary to remove the fuel tank first. Refer

to Chapter 4 for details.

3Unscrew the nut and disconnect the anti-

roll bar link from the lower arm. Hold the

actual link with an adjustable spanner or grips

while unscrewing the nut, to prevent damage

to the link joint. Recover the rubber bush.

4Unscrew and remove the bolt securing the

front lower arm to the knuckle.

5Unscrew and remove the bolt securing the

front lower arm to the crossmember.

6Withdraw the front lower arm from under

the vehicle.

Rear lower arm

7Unscrew and remove the bolt securing the

rear lower arm to the knuckle.8The bolt securing the rear lower arm to the

crossmember has an eccentric head and

spacer, which are used to adjust the rear toe

setting. Before removing this bolt, mark its

position, using a scriber or similar sharp

instrument through the aperture in the

crossmember.

9Unscrew and remove the bolt securing the

rear lower arm to the crossmember (see

illustration). The bolt may be removed

through the aperture in the crossmember.

Recover the eccentric spacer.

10Withdraw the rear lower arm from under

the vehicle.

Refitting

11Refitting is a reversal of the removal

procedure, but the arm mounting bolts should

be finger-tightened initially, and only fully

tightened after the vehicle is lowered to the

ground, so that its weight is on the rear

suspension. Note that the rear lower arm is

marked “TOP” for correct refitting (see

illustration). The rear toe setting should be

checked, and if necessary adjusted, at the

earliest opportunity.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate rear wheel.

2Disconnect the handbrake cable from the

tie-bar bracket on the underbody.

3Unscrew and remove the bolt securing the

tie-bar bracket to the rear suspension

knuckle.

4Unscrew the bolts securing the tie-bar

bracket to the underbody, and withdraw the

bracket from the vehicle (see illustration).

5Mount the bracket in a vice, then unscrew

and remove the bolt, and remove the tie-bar

from the bracket.

6It is not possible to renew the rubber

bushes - if they are worn excessively, the tie-

bar should be renewed complete.

Refitting

7Refitting is a reversal of the removal

procedure. The bracket-to-underbody bolts

should be fully tightened to the specified

torque before lowering the vehicle. The bolts

securing the tie-bar to the bracket and

knuckle should be finger-tightened initially,

and only fully tightened after the vehicle is

lowered to the ground, so that its weight is on

the rear suspension.

Note:Before attempting to remove the rear

suspension crossmember, tools to hold the

coil springs in compression must be obtained.

Careful use of conventional coil spring

compressors will prove satisfactory.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove both rear wheels.

2Remove the complete exhaust system as

described in Chapter 4.

3Unscrew and remove the bolts securing the

tie-bars to the rear suspension knuckles, and

disconnect the tie-bars.

4Unscrew the nuts securing the rear anti-roll

bar links to the front lower arms. Hold the

16 Rear suspension

crossmember

(Saloon/Hatchback models) -

removal and refitting

15 Rear suspension tie-bar

(Saloon/Hatchback models) -

removal and refitting

14 Rear suspension lower arms

(Saloon/Hatchback models)-

removal and refitting

Suspension and steering systems 10•13

10

14.11 “TOP” marking on the rear lower

arm

15.4 Tie-bar bracket on the underbody

13.3 Rear anti-roll bar mounting clamp14.9 Bolt securing the rear lower arm to

the crossmember

procarmanuals.com

Page 168 of 279

actual links stationary while the nuts are being

unscrewed, to prevent damage to the joints.

Swivel the anti-roll bar upwards, and recover

the rubber bushes.

5Where applicable, remove the ABS wheel

sensor from the rear suspension knuckle as

described in Chapter 9.

6Unscrew and remove the bolts, and

disconnect both lower arms from the rear

suspension knuckle.

7To allow the rear suspension struts to be

released from the rubber stops on the top of

the crossmember, it is necessary to fit coil

spring compressor tools to both of the rear

coil springs, and compress them until all

tension is removed from the upper and lower

mountings.

Warning: It is important to only

use high-quality spring

compressors, and to carefully

follow the tool manufacturer’s

instructions provided with them. With the

compressor tools fitted, support the struts

to one side.

8Support the rear suspension crossmember

on a trolley jack, then unscrew the four

mounting bolts from the underbody (see

illustration).

9Lower the crossmember to the ground.

10Unscrew the bolts securing the anti-roll

bar clamps to the crossmember, then remove

the clamps and withdraw the anti-roll bar.

11Remove the lower arms from the

crossmember as described in Section 14.

Refitting

12Refitting is a reversal of the removal

procedure. Ford specify the use of a special

tool (tool number 15-097) to accurately align

the crossmember onto the underbody before

tightening the mounting bolts. This tool

should be obtained if possible, since

inaccurate alignment would result in bad

handling and excessive tyre wear. The tie-bar

and arm mounting bolts should be finger-

tightened initially, and only fully tightened

after the vehicle is lowered to the ground, so

that its weight is on the rear suspension. The

rear toe setting should be checked, and if

necessary adjusted, at the earliest

opportunity.

Inspection

1The rear hub bearings are non-adjustable,

and are supplied complete with the hub. It is

not possible to renew the bearings separately

from the hub.

2To check the bearings for excessive wear,

chock the front wheels, then jack up the rear

of the vehicle and support it on axle stands.

Fully release the handbrake.

3Grip the rear wheel at the top and bottom,

and attempt to rock it. If excessive movement

is noted, or if there is any roughness or

vibration felt when the wheel is spun, it is

indicative that the hub bearings are worn.

Renewal

4Remove the rear wheel.

5On drum brake models, remove the rear

brake drum as described in Chapter 9.

6On disc brake models, remove the rear

brake disc as described in Chapter 9.

7Turning the hub as necessary, line up the

hole in the flange with the each of the bolts

securing the hub assembly to the rear

suspension knuckle; unscrew and remove the

bolts (see illustration).

8Withdraw the hub and bearing assembly.

Refit two of the hub mounting bolts, to hold

the backplate/splash shield in place.

9If necessary, the stub shaft may be

removed from the hub for inspection of the

bearing, by unscrewing the hub nut. Note that

the hub nut is of special laminated design,

and may only be re-used a maximum of five

times. (It is a good idea to file a small notch on

the nut every time it is removed; obtain a new

nut if necessary.) Tighten the nut on

reassembly.

10Fit the new hub and bearing assembly

using a reversal of the removal procedure.

Tighten all nuts and bolts to the specified

torque.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate rear wheel,

and release the handbrake.

2Position a trolley jack or axle stand beneath

the rear suspension lower arm, to keep the

coil spring in compression.

3Where applicable, remove the ABS sensor

as described in Chapter 9.

Drum brake models

4Remove the rear brake drum as described

in Chapter 9.

5Disconnect the flexible hydraulic brake

hose at the bracket on the rear suspension

crossmember as described in Chapter 9.

Disc brake models

6Remove the rear brake disc as described in

Chapter 9.

All models

7Remove the rear hub as described in

Section 17.

8Remove the backplate or splash shield, as

applicable. On drum brake models, support

the backplate assembly on an axle stand, to

prevent damage to the handbrake cable.

9Unscrew and remove the shock absorber

lower mounting bolt.

10Unscrew and remove the three bolts

securing the tie-bar to the knuckle.

11Unscrew and remove the bolt securing

the front lower arm to the knuckle.

12Unscrew and remove the bolt securing

the upper arm to the knuckle.

13Support the knuckle, then unscrew and

remove the bolt securing the rear lower arm to

the knuckle, and withdraw the knuckle.

Refitting

14Refitting is a reversal of the removal

procedure, but delay fully tightening the

rubber bush mounting bolts until the weight of

the vehicle is on the suspension. Tighten all

bolts to the specified torque. Where the

flexible rear brake hose was disconnected,

bleed the hydraulic system as described in

Chapter 9. Finally check, and if necessary

adjust, the rear wheel toe setting as described

in Section 36.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate wheel.

19 Rear shock absorber

(Estate models) -

removal, testing and refitting

18 Rear suspension knuckle

(Estate models) -

removal and refitting

17 Rear hub and bearings

(Estate models) -

inspection and renewal

10•14 Suspension and steering systems

16.8 One of the rear suspension

crossmember mounting bolts

17.7 Mounting bolts (arrowed) for the rear

hub on Estate models

procarmanuals.com

Page 169 of 279

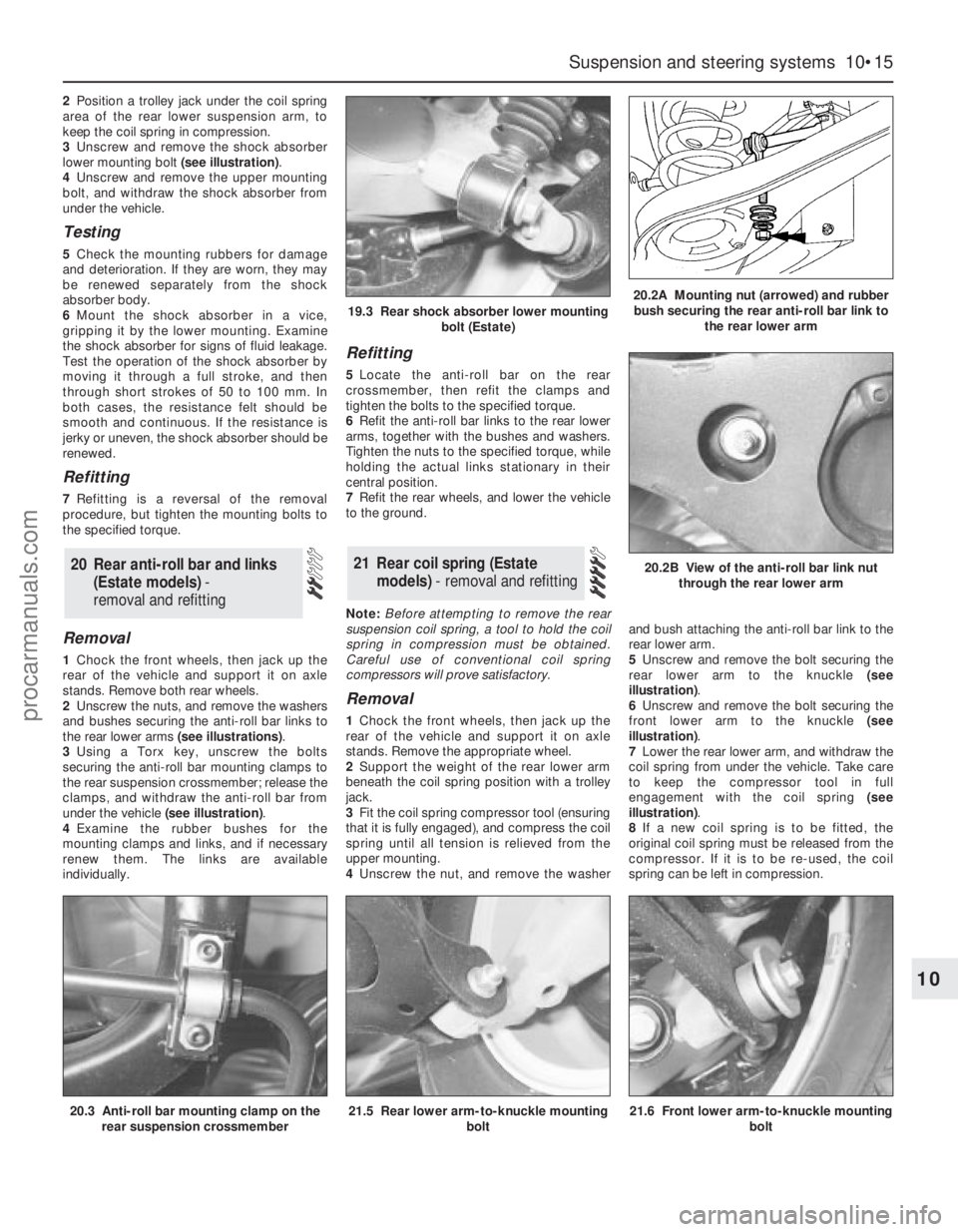

2Position a trolley jack under the coil spring

area of the rear lower suspension arm, to

keep the coil spring in compression.

3Unscrew and remove the shock absorber

lower mounting bolt (see illustration).

4Unscrew and remove the upper mounting

bolt, and withdraw the shock absorber from

under the vehicle.

Testing

5Check the mounting rubbers for damage

and deterioration. If they are worn, they may

be renewed separately from the shock

absorber body.

6Mount the shock absorber in a vice,

gripping it by the lower mounting. Examine

the shock absorber for signs of fluid leakage.

Test the operation of the shock absorber by

moving it through a full stroke, and then

through short strokes of 50 to 100 mm. In

both cases, the resistance felt should be

smooth and continuous. If the resistance is

jerky or uneven, the shock absorber should be

renewed.

Refitting

7Refitting is a reversal of the removal

procedure, but tighten the mounting bolts to

the specified torque.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove both rear wheels.

2Unscrew the nuts, and remove the washers

and bushes securing the anti-roll bar links to

the rear lower arms (see illustrations).

3Using a Torx key, unscrew the bolts

securing the anti-roll bar mounting clamps to

the rear suspension crossmember; release the

clamps, and withdraw the anti-roll bar from

under the vehicle (see illustration).

4Examine the rubber bushes for the

mounting clamps and links, and if necessary

renew them. The links are available

individually.

Refitting

5Locate the anti-roll bar on the rear

crossmember, then refit the clamps and

tighten the bolts to the specified torque.

6Refit the anti-roll bar links to the rear lower

arms, together with the bushes and washers.

Tighten the nuts to the specified torque, while

holding the actual links stationary in their

central position.

7Refit the rear wheels, and lower the vehicle

to the ground.

Note:Before attempting to remove the rear

suspension coil spring, a tool to hold the coil

spring in compression must be obtained.

Careful use of conventional coil spring

compressors will prove satisfactory.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate wheel.

2Support the weight of the rear lower arm

beneath the coil spring position with a trolley

jack.

3Fit the coil spring compressor tool (ensuring

that it is fully engaged), and compress the coil

spring until all tension is relieved from the

upper mounting.

4Unscrew the nut, and remove the washerand bush attaching the anti-roll bar link to the

rear lower arm.

5Unscrew and remove the bolt securing the

rear lower arm to the knuckle (see

illustration).

6Unscrew and remove the bolt securing the

front lower arm to the knuckle (see

illustration).

7Lower the rear lower arm, and withdraw the

coil spring from under the vehicle. Take care

to keep the compressor tool in full

engagement with the coil spring (see

illustration).

8If a new coil spring is to be fitted, the

original coil spring must be released from the

compressor. If it is to be re-used, the coil

spring can be left in compression.

21 Rear coil spring (Estate

models) - removal and refitting20 Rear anti-roll bar and links

(Estate models) -

removal and refitting

Suspension and steering systems 10•15

10

20.3 Anti-roll bar mounting clamp on the

rear suspension crossmember21.5 Rear lower arm-to-knuckle mounting

bolt21.6 Front lower arm-to-knuckle mounting

bolt

19.3 Rear shock absorber lower mounting

bolt (Estate)20.2A Mounting nut (arrowed) and rubber

bush securing the rear anti-roll bar link to

the rear lower arm

20.2B View of the anti-roll bar link nut

through the rear lower arm

procarmanuals.com

Page 170 of 279

Refitting

9Refitting is a reversal of the removal

procedure, but make sure that the coil spring

is located correctly in the upper and lower

seats (see illustration). Delay fully tightening

the two lower arm mounting bolts until the

weight of the vehicle is on the rear

suspension. Finally check, and if necessary

adjust, the rear wheel toe setting as described

in Section 36.

Removal

1Remove the rear suspension coil spring as

described in Section 21.

2The bolt securing the rear lower arm to the

crossmember has an eccentric head and

spacer, which are used to adjust the rear toe

setting. Before removing this bolt, mark its

position, using a scriber or similar sharp

instrument through the aperture in the

crossmember.

3Unscrew and remove the bolt securing the

rear lower arm to the crossmember. The bolt

may be removed through the aperture in the

crossmember. Recover the eccentric spacer

(see illustration).

4Withdraw the rear lower arm from under the

vehicle.

Refitting

5Refitting is a reversal of the removal

procedure, but delay fully tightening the lower

arm mounting bolts until the weight of the

vehicle is on the rear suspension. Finally

check, and if necessary adjust, the rear wheel

toe setting as described in Section 36.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate wheel.

2Unscrew and remove the bolt securing the

front lower arm to the crossmember (see

illustration).

3Unscrew and remove the bolt securing the

front lower arm to the knuckle, and withdraw

the arm from under the vehicle (see

illustration).

Refitting

4Refitting is a reversal of the removal

procedure, but delay fully tightening the

mounting bolts until the weight of the vehicle

is on the rear suspension.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate wheel.

2Using a trolley jack, support the rear lower

arm beneath the coil spring position.

3Unscrew and remove the bolt securing the

upper arm to the knuckle (see illustration).

4Unscrew and remove the bolt securing the

upper arm to the crossmember, and withdraw

the arm from under the vehicle.

Refitting

5Refitting is a reversal of the removal

procedure, but delay fully tightening the

mounting bolts until the weight of the vehicle

is on the rear suspension.

Removal

1Chock the front wheels, then jack up the

rear of the vehicle and support it on axle

stands. Remove the appropriate wheel.

25 Rear suspension tie-bar

(Estate models) -

removal and refitting

24 Rear suspension upper arm

(Estate models) -

removal and refitting

23 Rear suspension front lower

arm (Estate models)-

removal and refitting

22 Rear suspension rear lower

arm (Estate models) -

removal and refitting

10•16 Suspension and steering systems

21.7 Removing the coil spring, with

compressor tool attached, from under the

vehicle21.9 Correct location of the coil spring in

the upper seat (arrowed)22.3 Bolts securing the rear lower arms to

the crossmember - note the eccentric

spacers

23.2 Front lower arm-to-crossmember

securing bolt23.3 Front lower arm (arrowed)24.3 Bolt (arrowed) securing the upper

arm to the knuckle

procarmanuals.com