torque FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 393 of 413

07-04-24

C-6 Automatic Transmission

07-04-24

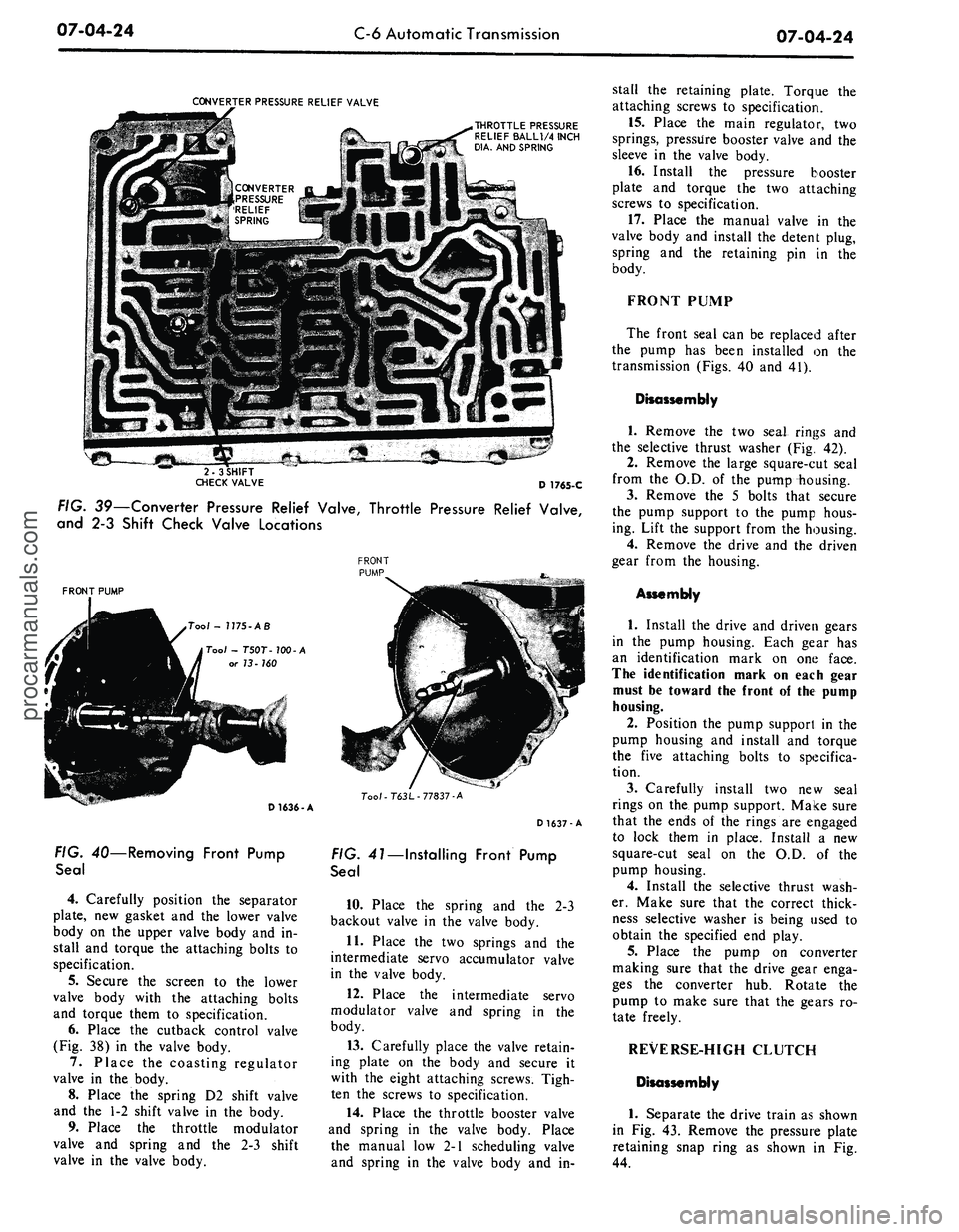

CONVERTER PRESSURE RELIEF VALVE

THROTTLE PRESSURE

RELIEF BALL1/4 INCH

DIA. AND SPRING

CONVERTER

PRESSURE

RELIEF

SPRING

2-3 SHIFT

CHECK VALVE

D 1765-C

FIG. 39—Converter Pressure Relief Valve, Throttle Pressure Relief Valve,

and

2-3

Shift Check Valve Locations

FRONT PUMP

Tool

-

7775-AS

Tool -

T50T-

100-A

or 73-760

Tool

-T63L- 77837 -A

D 1636 -A

FIG. 40—Removing Front Pump

Seal

4.

Carefully position

the

separator

plate,

new

gasket

and the

lower valve

body

on the

upper valve body

and in-

stall

and

torque

the

attaching bolts

to

specification.

5.

Secure

the

screen

to the

lower

valve body with

the

attaching bolts

and torque them

to

specification.

6. Place

the

cutback control valve

(Fig.

38) in the

valve body.

7.

Place

the

coasting regulator

valve

in the

body.

8. Place

the

spring

D2

shift valve

and

the 1-2

shift valve

in the

body.

9. Place

the

throttle modulator

valve

and

spring

and the 2-3

shift

valve

in the

valve body.

D 1637-A

FIG. 41—Installing Front Pump

Seal

10.

Place

the

spring

and the 2-3

backout valve

in the

valve body.

11.

Place

the two

springs

and the

intermediate servo accumulator valve

in

the

valve body.

12.

Place

the

intermediate servo

modulator valve

and

spring

in the

body.

13.

Carefully place

the

valve retain-

ing plate

on the

body

and

secure

it

with

the

eight attaching screws. Tigh-

ten

the

screws

to

specification.

14.

Place

the

throttle booster valve

and spring

in the

valve body. Place

the manual

low 2-1

scheduling valve

and spring

in the

valve body

and in-

stall

the

retaining plate. Torque

the

attaching screws

to

specification.

15.

Place

the

main regulator,

two

springs, pressure booster valve

and the

sleeve

in the

valve body.

16.

Install

the

pressure booster

plate

and

torque

the two

attaching

screws

to

specification.

17.

Place

the

manual valve

in the

valve body

and

install

the

detent plug,

spring

and the

retaining

pin in the

body.

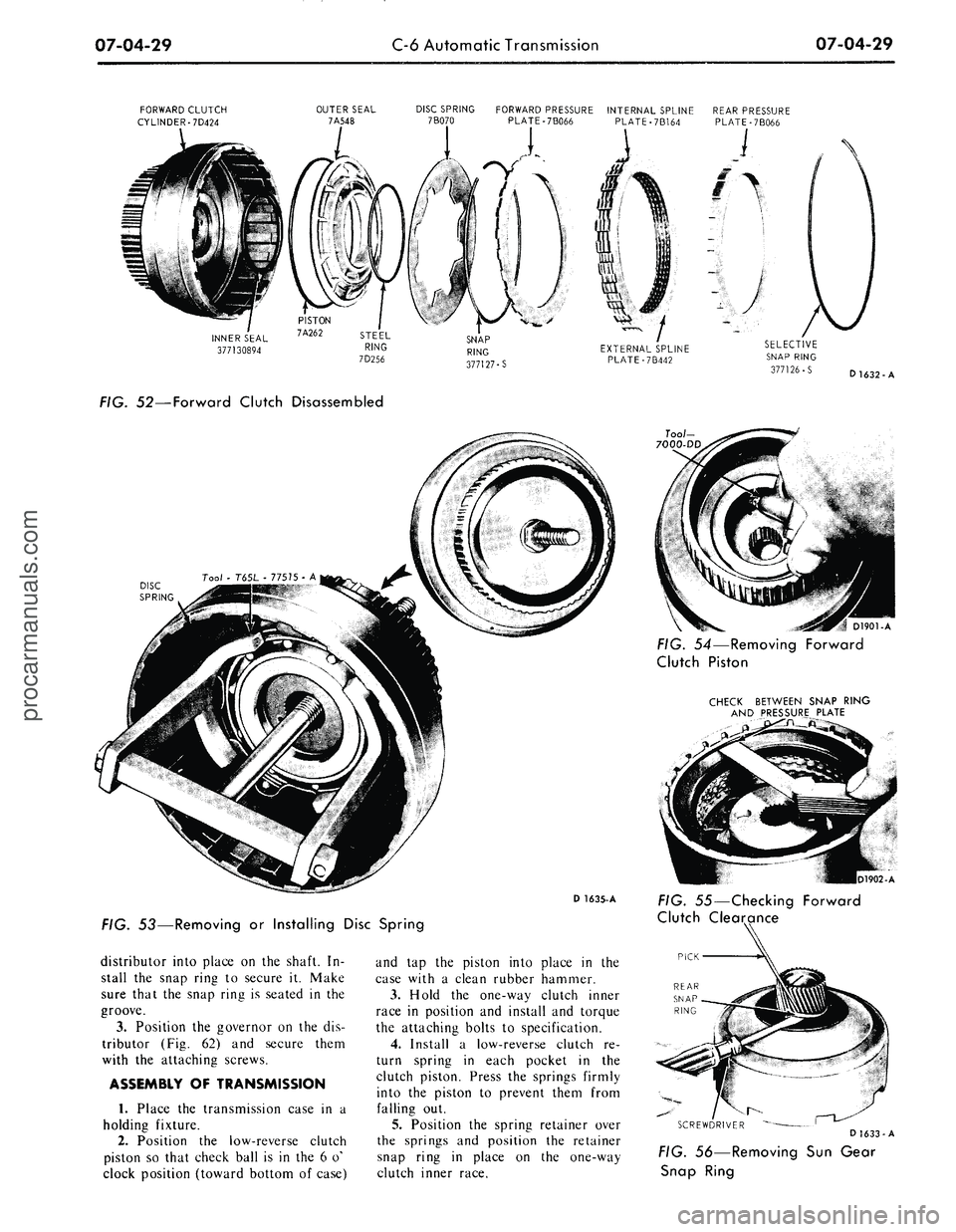

FRONT PUMP

The front seal

can be

replaced after

the pump

has

been installed

on the

transmission (Figs.

40 and 41).

Disassembly

1.

Remove

the two

seal-rings

and

the selective thrust washer (Fig.

42).

2.

Remove

the

large square-cut seal

from

the

O.D.

of the

pump housing.

3.

Remove

the 5

bolts that secure

the pump support

to the

pump hous-

ing. Lift

the

support from

the

housing.

4.

Remove

the

drive

and the

driven

gear from

the

housing.

Assembly

1.

Install

the

drive

and

driven gears

in

the

pump housing. Each gear

has

an identification mark

on one

face.

The identification mark

on

each gear

must

be

toward

the

front

of the

pump

housing.

2.

Position

the

pump support

in the

pump housing

and

install

and

torque

the five attaching bolts

to

specifica-

tion.

3.

Carefully install

two new

seal

rings

on the

pump support. Make sure

that

the

ends

of the

rings

are

engaged

to lock them

in

place. Install

a new

square-cut seal

on the O.D. of the

pump housing.

4.

Install

the

selective thrust wash-

er. Make sure that

the

correct thick-

ness selective washer

is

being used

to

obtain

the

specified

end

play.

5.

Place

the

pump

on

converter

making sure that

the

drive gear enga-

ges

the

converter

hub.

Rotate

the

pump

to

make sure that

the

gears

ro-

tate freely.

REVERSE-HIGH CLUTCH

Disassembly

1.

Separate

the

drive train

as

shown

in

Fig. 43.

Remove

the

pressure plate

retaining snap ring

as

shown

in Fig.

44.procarmanuals.com

Page 398 of 413

07-04-29

C-6 Automatic Transmission

07-04-29

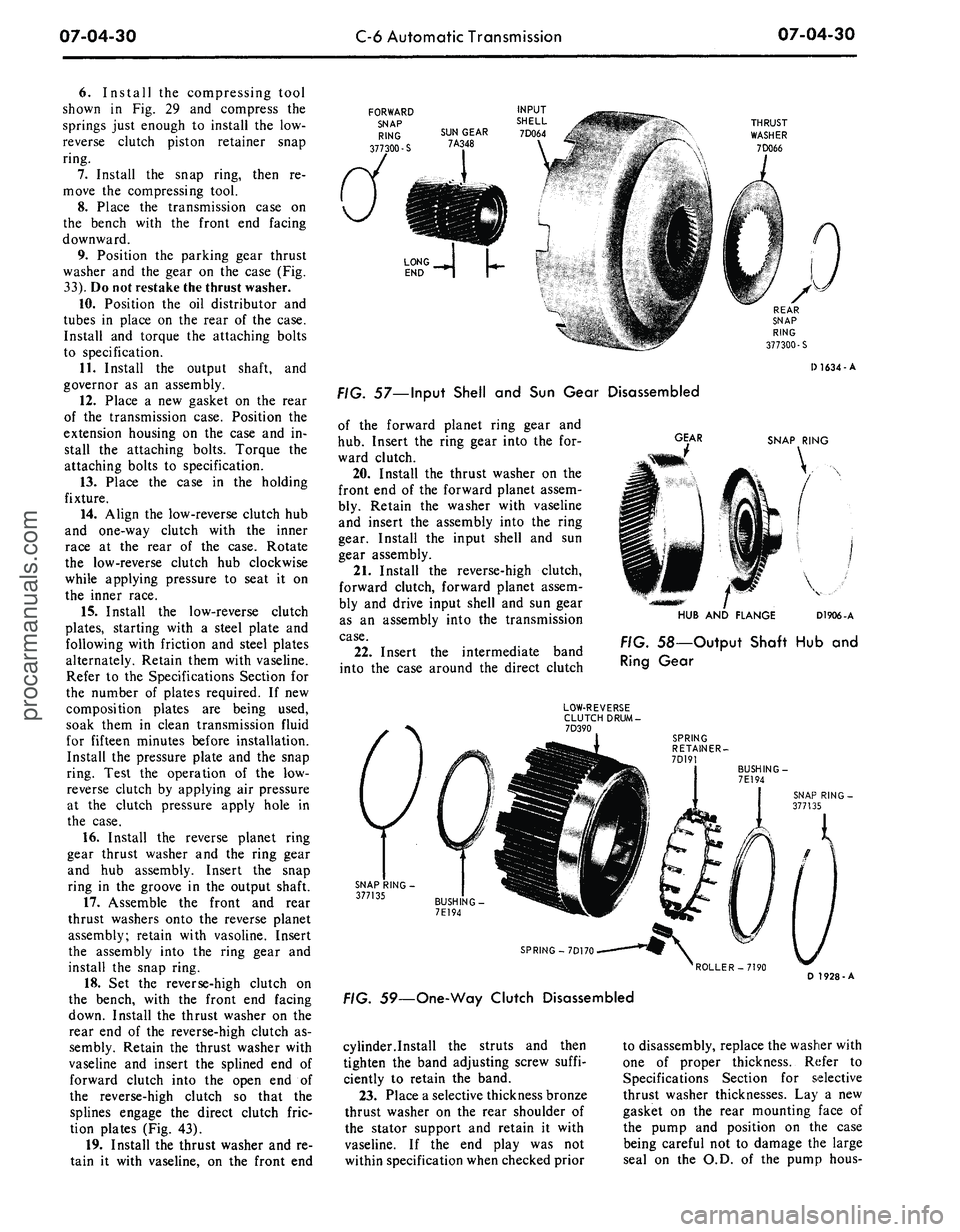

FORWARD CLUTCH

CYLINDER-7D424

OUTER SEAL

7A548

DISC SPRING FORWARD PRESSURE INTERNAL SPLINE REAR PRESSURE

7B070

PLATE-7B066

PLATE-7B164 PLATE-7B066

INNER SEAL

377130894

PISTON

7A262 STEEL

RING

7D256

SNAP

RING

377127-S

FIG. 52—Forward Clutch Disassembled

DISC

SPRING

EXTERNAL SPLINE

PLATE-7B442

7oo/-

7000-DD

SELECTIVE

SNAP RING

377126-S

D 1635-A

FIG. 53—Removing or Installing Disc Spring

distributor into place on the shaft. In-

stall the snap ring to secure it. Make

sure that the snap ring is seated in the

groove.

3.

Position the governor on the dis-

tributor (Fig. 62) and secure them

with the attaching screws.

ASSEMBLY OF TRANSMISSION

1.

Place the transmission case in a

holding fixture.

2.

Position the low-reverse clutch

piston so that check ball is in the 6 o'

clock position (toward bottom of case)

and tap the piston into place in the

case with a clean rubber hammer.

3.

Hold the one-way clutch inner

race in position and install and torque

the attaching bolts to specification.

4.

Install a low-reverse clutch re-

turn spring in each pocket in the

clutch piston. Press the springs firmly

into the piston to prevent them from

falling out.

5.

Position the spring retainer over

the springs and position the retainer

snap ring in place on the one-way

clutch inner race.

D1632-A

D1901-A

FIG. 54—Removing Forward

Clutch Piston

CHECK BETWEEN SNAP RING

AND PRESSURE PLATE

1902-A

FIG. 55—Checking Forward

Clutch Clearance

PICK

SCREWDRIVER

D 1633-A

FIG. 56—Removing Sun Gear

Snap Ringprocarmanuals.com

Page 399 of 413

07-04-30

C-6 Automatic Transmission

07-04-30

6. Install the compressing tool

shown in Fig. 29 and compress the

springs just enough to install the low-

reverse clutch piston retainer snap

ring.

7.

Install the snap ring, then re-

move the compressing tool.

8. Place the transmission case on

the bench with the front end facing

downward.

9. Position the parking gear thrust

washer and the gear on the case (Fig.

33).

Do not restake the thrust washer.

10.

Position the oil distributor and

tubes in place on the rear of the case.

Install and torque the attaching bolts

to specification.

11.

Install the output shaft, and

governor as an assembly.

12.

Place a new gasket on the rear

of the transmission case. Position the

extension housing on the case and in-

stall the attaching bolts. Torque the

attaching bolts to specification.

13.

Place the case in the holding

fixture.

14.

Align the low-reverse clutch hub

and one-way clutch with the inner

race at the rear of the case. Rotate

the low-reverse clutch hub clockwise

while applying pressure to seat it on

the inner race.

15.

Install the low-reverse clutch

plates,

starting with a steel plate and

following with friction and steel plates

alternately. Retain them with vaseline.

Refer to the Specifications Section for

the number of plates required. If new

composition plates are being used,

soak them in clean transmission fluid

for fifteen minutes before installation.

Install the pressure plate and the snap

ring. Test the operation of the low-

reverse clutch by applying air pressure

at the clutch pressure apply hole in

the case.

16.

Install the reverse planet ring

gear thrust washer and the ring gear

and hub assembly. Insert the snap

ring in the groove in the output shaft.

17.

Assemble the front and rear

thrust washers onto the reverse planet

assembly; retain with vasoline. Insert

the assembly into the ring gear and

install the snap ring.

18.

Set the reverse-high clutch on

the bench, with the front end facing

down. Install the thrust washer on the

rear end of the reverse-high clutch as-

sembly. Retain the thrust washer with

vaseline and insert the splined end of

forward clutch into the open end of

the reverse-high clutch so that the

splines engage the direct clutch fric-

tion plates (Fig. 43).

19.

Install the thrust washer and re-

tain it with vaseline, on the front end

FORWARD

SNAP

RING

377300-S

SUN

GEAR

7A348

•

INPUT

SHELL

7D064

\

THRUST

WASHER

7D066

-IT

REAR

SNAP

RING

377300-S

I)

1634-A

57—Input Shell and Sun Gear Disassembled

of the forward planet ring gear and

hub.

Insert the ring gear into the for-

ward clutch.

20.

Install the thrust washer on the

front end of the forward planet assem-

bly. Retain the washer with vaseline

and insert the assembly into the ring

gear. Install the input shell and sun

gear assembly.

21.

Install the reverse-high clutch,

forward clutch, forward planet assem-

bly and drive input shell and sun gear

as an assembly into the transmission

case.

22.

Insert the intermediate band

into the case around the direct clutch

GEAR

SNAP RING

HUB AND FLANGE

D1906-A

FIG. 58—Output Shaft Hub and

Ring Gear

LOW-REVERSE

CLUTCH

DRUM-

7D390

SPRING

RETAINER-

7D191

BUSHING

-

7E194

SPRING

-

7D170

ROLLER-7190

D 1928-A

FIG. 59—One-Way Clutch Disassembled

cylinder.Install the struts and then

tighten the band adjusting screw suffi-

ciently to retain the band.

23.

Place a selective thickness bronze

thrust washer on the rear shoulder of

the stator support and retain it with

vaseline. If the end play was not

within specification when checked prior

to disassembly, replace the washer with

one of proper thickness. Refer to

Specifications Section for selective

thrust washer thicknesses. Lay a new

gasket on the rear mounting face of

the pump and position on the case

being careful not to damage the large

seal on the O.D. of the pump hous-procarmanuals.com

Page 400 of 413

07-04-31

C-6 Automatic Transmission

07-04-31

ing. Install six of the seven mounting

bolts and torque them to specifica-

tion.

24.

Adjust the intermediate band as

detailed in Section 2 and install the

input shaft with the long splined end

inserted into the forward clutch as-

sembly.

LOW-REVERSE

SPRING LOAD ON ROLLERS CLUTCH HUB

MUST BE IN A COUNTERCLOCKWISE

DIRECTION FOR INSTALLATION Q 192O A

FIG. 60—Installing One-Way

Clutch

25.

Install tool 4201-C at the sev-

enth pump mounting bolt (Fig. 24)

and check the transmission end play.

Remove the tool.

26.

Install the control valve in the

case,

making sure that the levers en-

gage the valves properly. Install the

primary throttle valve, rod, and the

vacuum diaphragm in the case.

27.

Install a new pan gasket and

the pan.

28.

Install the converter assembly.

29.

Install the transmission in the

vehicle.

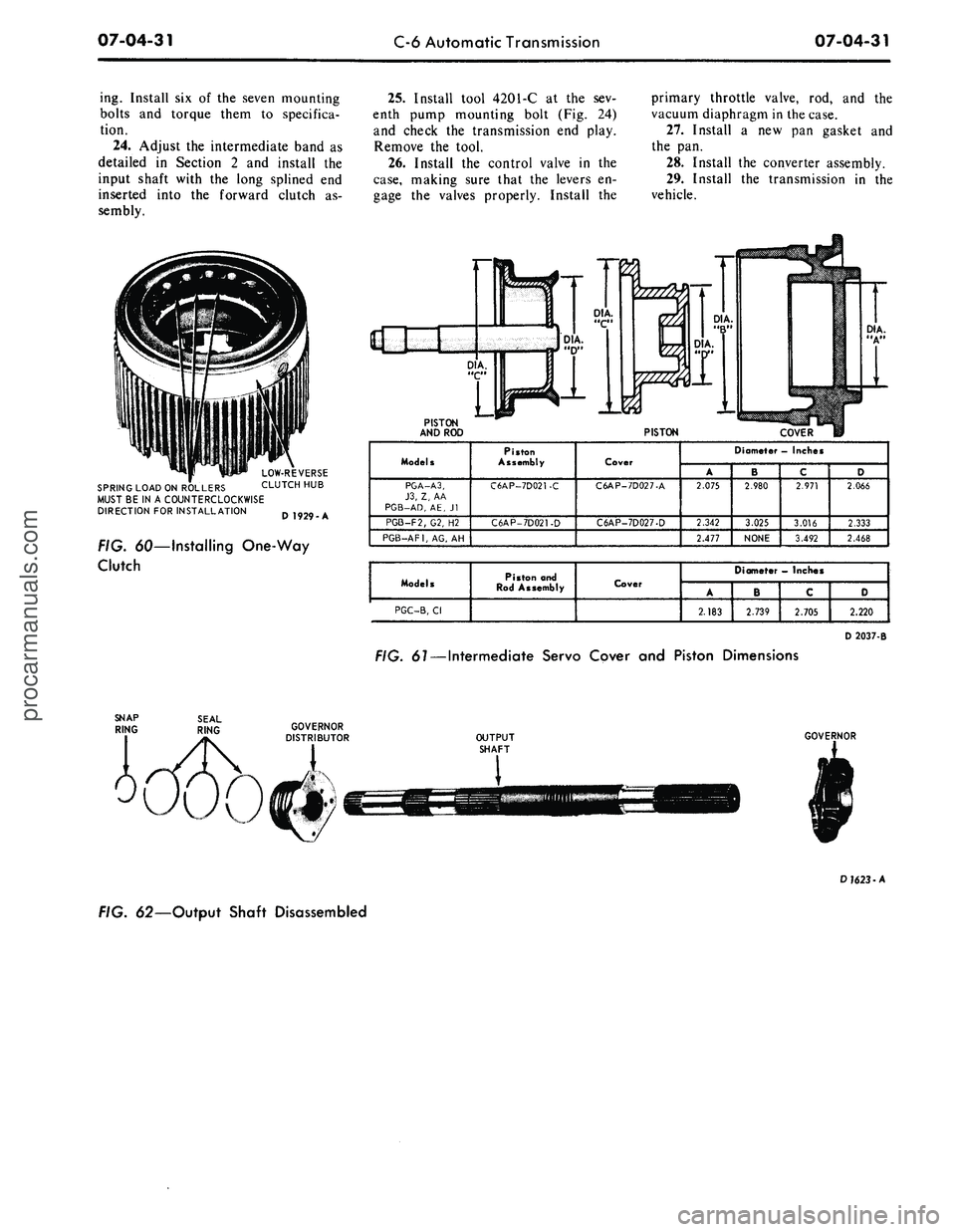

PISTON

AND ROD

PISTON

COVER

Models

PGA-A3,

J3,

Z, AA

PGB-AD,

AE, Jl

PGB-F2/G2, H2

PGB-AF1,

AG, AH

Piston

Assembly

C6AP-7D021-C

C6AP-7D021-D

Cover

C6AP-7D027-A

C6AP-7D027-D

Diameter - Inches

A

2.075

2.342

2.477

' B

2.980

3.025

NONE

c

2.971

3.016

3.492

D

2.066

2.333

2.468

Models

PGC-B,

Cl

Piston and

Rod Assembly

Cover

Diameter

—

Inches

A

2.183

B

2.739

C

2.705

D

2.220

D 2037-B

FIG.

61

— Intermediate Servo Cover and Piston Dimensions

OUTPUT

SHAFT

GOVERNOR

D

1623

-A

FIG. 62—Output Shaft Disassembledprocarmanuals.com

Page 403 of 413

07-05-03

Specifications

07-05-03

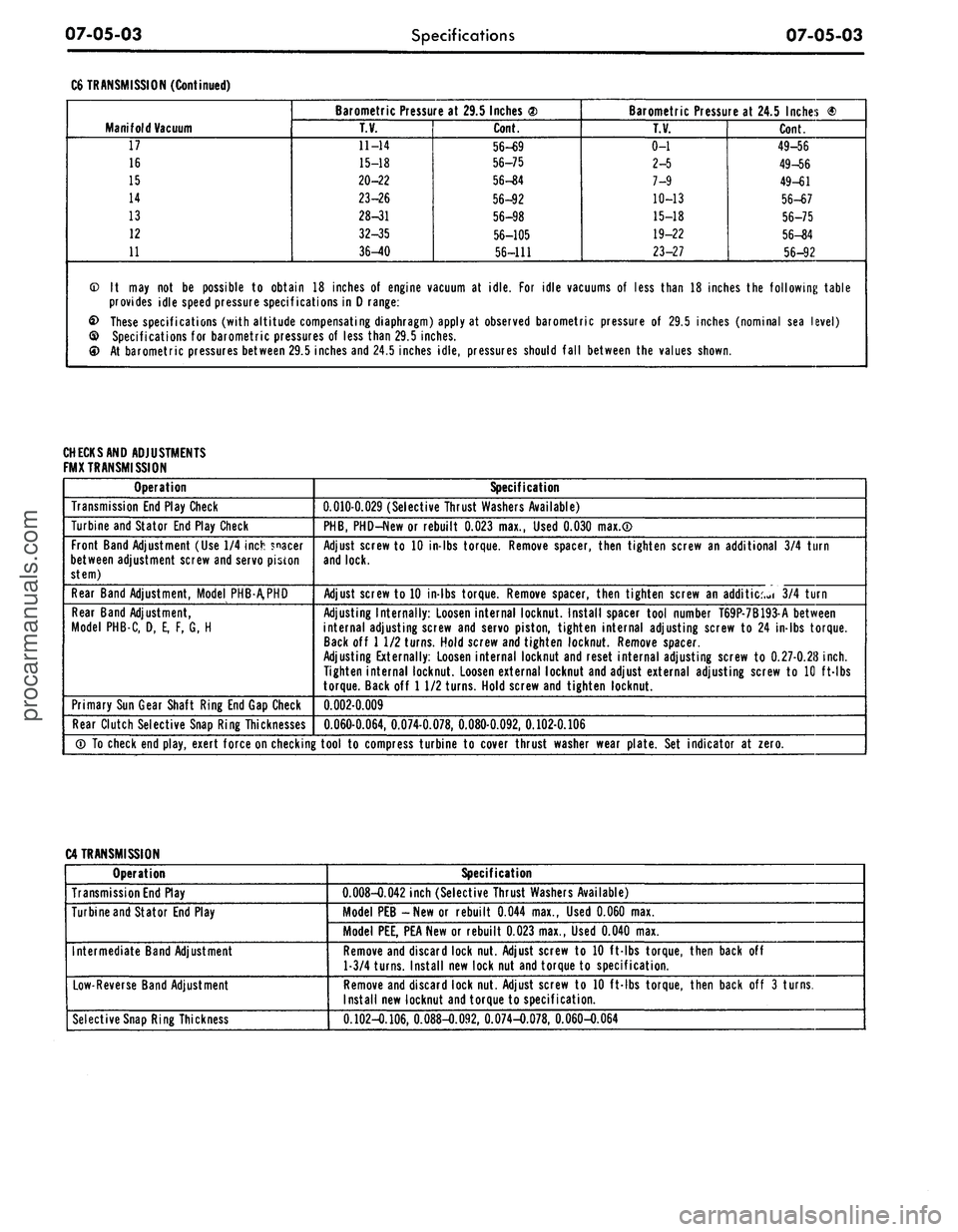

C6 TRANSMISSION (Continued)

Manifold Vacuum

17

16

15

14

13

12

11

Barometric Pressure at 29.5 Inches <2)

T.V.

11-14

15-18

20-22

23-26

28-31

32-35

36-40

Cont.

56-69

56-75

56-S4

56-92

56-98

56-105

56-111

Barometric Pressure at 24.5 Inches ®

T.V.

0-1

2-5

7-9

10-13

15-18

19-22

23-27

Cont.

49-56

49-56

49-61

56-67

56-75

56-84

56-92

© It may not be possible to obtain 18 inches of engine vacuum at idle. For idle vacuums of less than 18 inches the following table

provides idle speed pressure specifications in D range:

£> These specifications (with altitude compensating diaphragm) apply at observed barometric pressure of 29.5 inches (nominal sea level)

© Specifications for barometric pressures of less than 29.5 inches.

At barometric pressures between 29.5 inches and 24.5 inches idle, pressures should fall between the values shown.

CHECK

SAND ADJUSTMENTS

FMX TRANSMISSION

Operation

Transmission End Play Check

Turbine and Stator End Play Check

Front Band Adjustment (Use 1/4 inch spacer

between adjustment screw and servo piston

stem)

Rear Band Adjustment, Model PHB-A.PHD

Rear Band Adjustment,

Model PHB-C, D, E, F, G, H

Primary Sun Gear Shaft Ring End Gap Check

Rear Clutch Selective Snap Ring Thicknesses

Specification

0.010-0.029 (Selective Thrust Washers Available)

PHB,

PHD-New or rebuilt 0.023 max., Used 0.030 max.®

Adjust screw to 10 in-lbs torque. Remove spacer, then tighten screw an additional 3/4 turn

and lock.

Adjust screw to 10 in-lbs torque. Remove spacer, then tighten screw an addition 3/4 turn

Adjusting Internally: Loosen internal locknut. Install spacer tool number T69P-7B193-A between

internal adjusting screw and servo piston, tighten internal adjusting screw to 24 in-lbs torque.

Back off 1 1/2 turns. Hold screw and tighten locknut. Remove spacer.

Adjusting Externally: Loosen internal locknut and reset internal adjusting screw to 0.27-0.28

inch.

Tighten internal locknut. Loosen external locknut and adjust external adjusting screw to 10 ft-lbs

torque. Back off 1 1/2 turns. Hold screw and tighten locknut.

0.002-0.009

0.060-0.064, 0.074-0.078, 0.080-0.092, 0.102-0.106

® To check end play, exert force on checking tool to compress turbine to cover thrust washer wear plate. Set indicator at zero.

C4 TRANSMISSION

Operation

Transmission End Play

Turbine and Stator End Play

Intermediate Band Adjustment

Low-Reverse Band Adjustment

Selective Snap Ring Thickness

Specification

0.008-0.042 inch (Selective Thrust Washers Available)

Model PEB -New or rebuilt 0.044 max., Used 0.060 max.

Model PEE, PEA New or rebuilt 0.023 max., Used 0.040 max.

Remove and discard lock nut. Adjust screw to 10 ft-lbs torque, then back off

1-3/4 turns. Install new lock nut and torque to specification.

Remove and discard lock nut. Adjust screw to 10 ft-lbs torque, then back off 3 turns.

Install new locknut and torque to specification.

0.102-0.106, 0.088-0.092, 0.074-0.078, 0.060-O.064procarmanuals.com

Page 404 of 413

07-05-04

Specifications

07-05-04

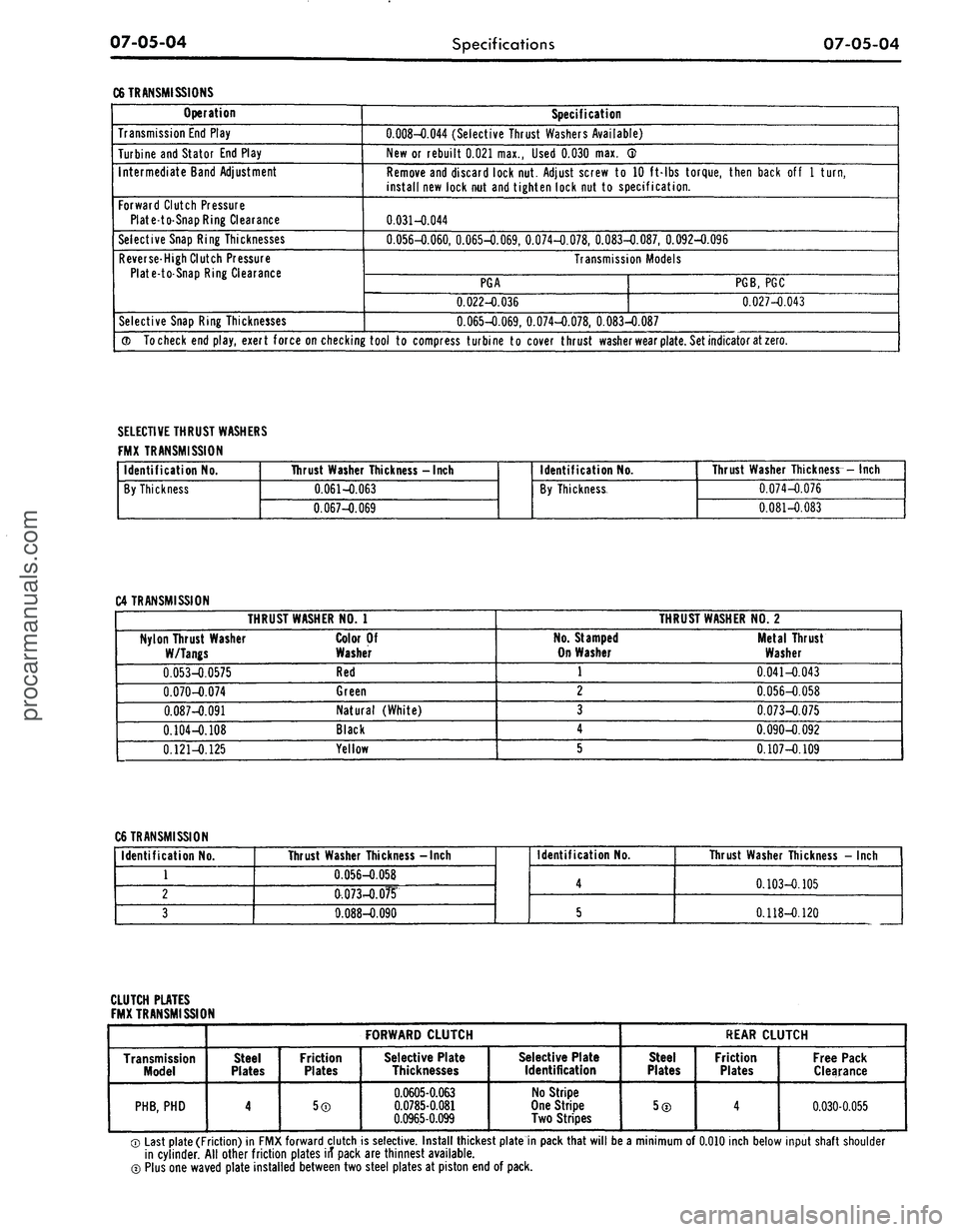

C6 TRANSMISSIONS

Operation

Transmission End Play

Turbine and Stator End Play

Intermediate Band Adjustment

Forward Clutch Pressure

Plat eto-Snap Ring Clearance

Selective Snap Ring Thicknesses

Reverse-High Clutch Pressure

Plate-to-Snap Ring Clearance

Selective Snap Ring Thicknesses

Specification

0.008-0.044 (Selective Thrust Washers Available)

New or rebuilt 0.021 max., Used

0.030

max. G)

Remove and discard lock nut. Adjust screw to 10 f

t

-

lbs

torque, then back off 1

turn,

install new lock nut and tighten lock nut to specification.

0.031-0.044

0.056-0.060, 0.065-0.069, 0.074-0.078, 0.083-0.087, 0.092-0.096

Transmission Models

PGA

0.022-0.036

PGB,

PGC

0.027-0.043

0.065-0.069, 0.074-0.078, 0.083-0.087

(D To check end play, exert force on checking tool to compress turbine to cover thrust washer wear plate. Set indicator at zero.

SELECTIVE THRUST WASHERS

FMX TRANSMISSION

Identification No.

By Thickness

Thrust Washer Thickness -Inch

0.061-0.063

0.067-0.069

Identification No.

By Thickness.

Thrust Washer Thickness - Inch

0.074-0.076

0.081-0.083

C4 TRANSMISSION

Nylon Thrust Washer

W/Tangs

0.053-4.0575

0.070-0.074

0.087-0.091

0.104-0.108

0.121-0.125

THRUST WASHER NO. 1

Color Of

Washer

Red

Green

Natural (White)

Black

Yellow

No.

Stamped

On Washer

1

2

3

4

5

THRUST WASHER NO. 2

Metal Thrust

Washer

0.041-0.043

0.056-O.058

0.073-0.075

0.090-0.092

0.107-0.109

C6 TRANSMISSION

Identification No.

1

2

3

Thrust Washer Thickness -Inch

0.056-0.058

a.073-0.07F

0.088-0.090

Identification No.

4

5

Thrust Washer Thickness - Inch

0.103-0.105

0.118-0.120

CLUTCH PLATES

FMX TRANSMISSION

Transmission

Model

PHB,

PHD

FORWARD CLUTCH

Steel

Plates

4

Friction

Plates

5©

Selective Plate

Thicknesses

0.0605-0.063

0.0785-0.081

0.0965-0.099

Selective Plate

Identification

No Stripe

One Stripe

Two Stripes

REAR CLUTCH

Steel

Plates

5®

Friction

Plates

4

Free Pack

Clearance

0.030-0.055

© Last plate (Friction) in FMX forward clutch is selective. Install thickest plate in pack that will be a minimum of 0.010 inch below input shaft shoulder

in cylinder. All other friction plates in* pack are thinnest available.

© Plus one waved plate installed between two steel plates at piston end of pack.procarmanuals.com

Page 407 of 413

07-05-07

Specifications

07-05-07

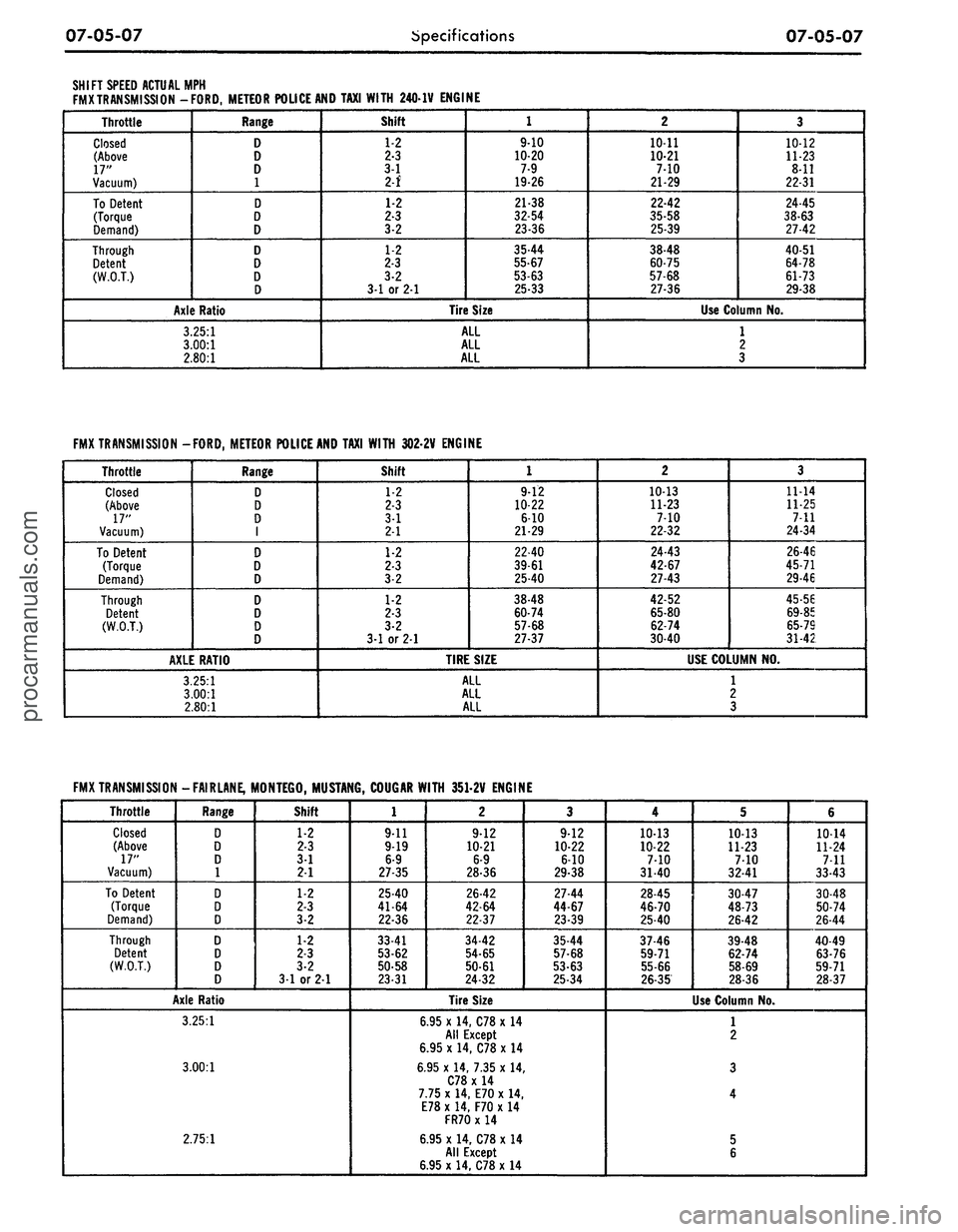

SHIFT SPEED ACTUAL

MPH

FMXTRANSMISSION -FORD, METEOR POLICE AND TAXI WITH 2401V ENGINE

Throttle

Closed

(Above

17"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

Axle Ratio

3.25:1

3.00:1

2.80:1

Shift

1-2

2-3

3-1

2-f

1-2

2-3

3-2

1-2

2-3

3-2

31

or 2-1

1

910

10-20

7-9

19-26

21-38

32-54

23-36

35-44

55-67

53-63

25-33

Tire Size

ALL

ALL

ALL

2

10-11

10-21

7-10

21-29

22-42

35-58

25-39

38-48

60-75

57-68

27-36

3

10-12

11-23

8-11

22-31

24-45

38-63

27-42

40-51

64-78

61-73

29-38

Use Column

No.

1

2

3

FMXTRANSMISSION -FORD, METEOR POLICE AND TAXI WITH 3022V ENGINE

Throttle

Closed

(Above

17"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

AXLE RATIO

3.25:1

3.00:1

2.80:1

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

1-2

2-3

3-2

3-1

or 21

1

9-12

10-22

6-10

21-29

22-40

39-61

25-40

38-48

60-74

57-68

27-37

TIRE SIZE

ALL

ALL

ALL

2

10-13

11-23

7-10

22-32

24-43

42-67

27-43

42-52

65-80

62-74

30-40

3

11-14

11-25

7-11

24-34

26-46

45-71

29-46

45-56

69-85

65-79

31-42

USE COLUMN

NO.

1

2

3

FMXTRANSMISSION

Throttle

Closed

(Above

17"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

-FAIRLANE, MONTEGO, MUSTANG, COUGAR WITH 351-2V ENGINE

Range

D

D

D

1

D

D

D

D

D

D

D

Shift

1-2

2-3

3-1

21

1-2

2-3

3-2

1-2

2-3

3-2

3-1

or 2-1

Axle Ratio

3.25:1

3.00:1

2.75:1

1

9-11

9-19

6-9

27-35

25-40

41-64

22-36

33-41

53-62

50-58

23-31

2

9-12

10-21

6-9

28-36

26-42

42-64

22-37

34-42

54-65

50-61

24-32

3

9-12

10-22

6-10

29-38

27-44

44-67

23-39

35-44

57-68

53-63

25-34

Tire Size

6.95

x

14, C78 x

14

All Except

6.95

x

14, C78 x

14

6.95

x

14, 7.35

x 14,

C78 x

14

7.75

x

14, E70

x 14,

E78 x 14, F70 x

14

FR70

x 14

6.95 x 14, C78 x

14

All Except

6.95 x 14, C78 x

14

4

10-13

10-22

7-10

31-40

28-45

46-70

25-40

37-46

59-71

55-66

26-35

5

10-13

11-23

7-10

32-41

30-47

48-73

26-42

39-48

62-74

58-69

28-36

Use Column

No.

6

10-14

11-24

7-11

33-43

30-48

50-74

26-44

40-49

63-76

59-71

28-37

1

2

3

4

5

6procarmanuals.com

Page 408 of 413

07-05-08

Specifications

07-05-08

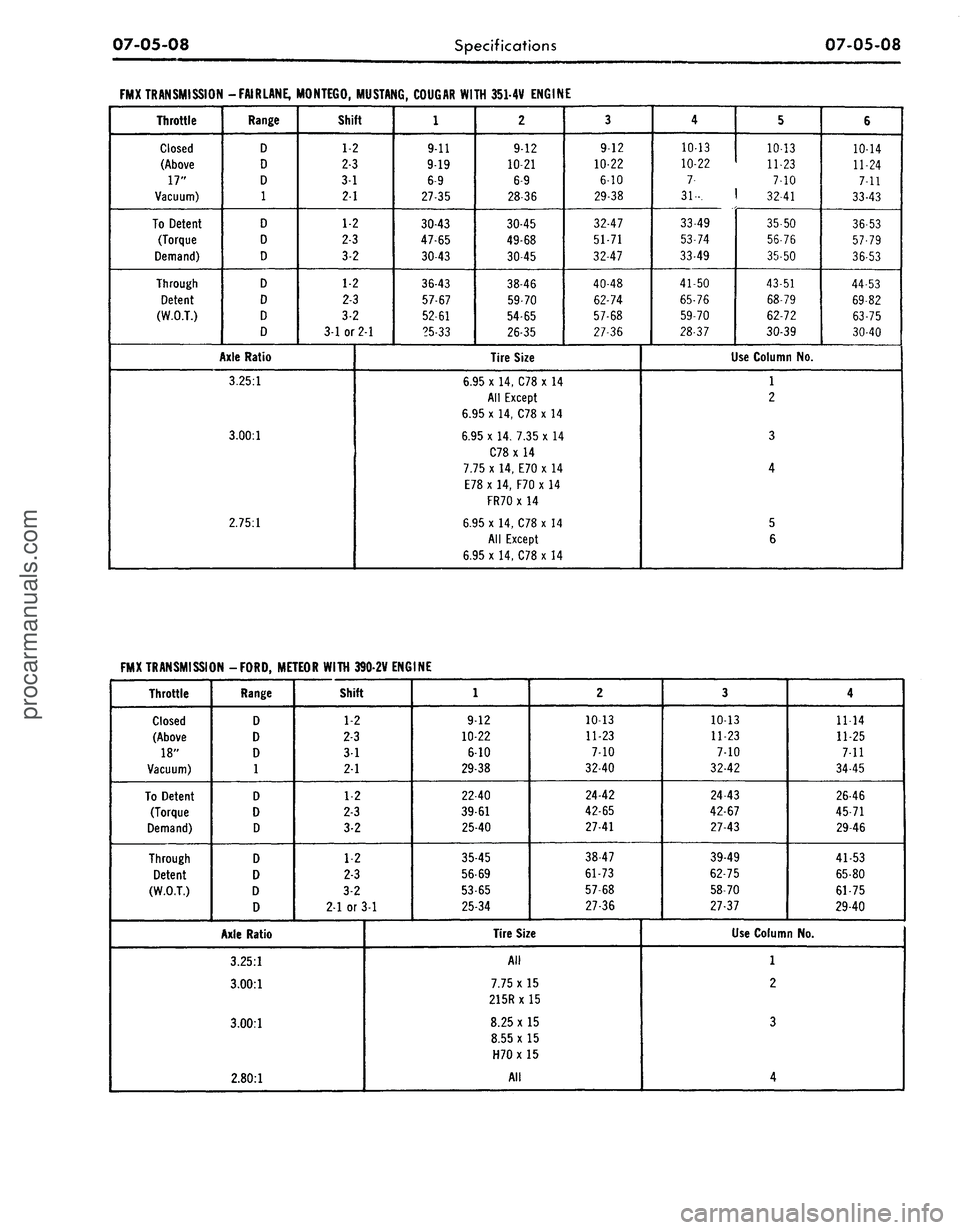

FMX TRANSMISSION

Throttle

Closed

(Above

17"

Vacuum)

To

Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

-FAIRLANE,

1

Range

D

D

D

1

D

D

D

D

D

D

D

MONTEGO,

MUSTANG,

COUGAR

WITH 351-4V ENGINE

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

1-2

2-3

3-2

3-1 or 2-1

Axle Ratio

3.25:1

3.00:1

2.75:1

1

9-11

9-19

6-9

27-35

30-43

47-65

30-43

36-43

57-67

52-61

?5-33

2

9-12

10-21

6-9

28-36

30-45

49-68

30-45

38-46

59-70

54-65

26-35

3

9-12

10-22

6-10

29-38

32-47

51-71

32-47

40-48

62-74

57-68

27-36

Tire Size

6.95 x 14, C78 x

14

All

Except

6.95

x

14, C78

x

14

6.95

x

14. 7.35

x

14

C78

x

14

7.75

x

14, E70

x

14

E78

x

14, F70

x

14

FR70

x 14

6.95

x

14, C78

x

14

All

Except

6.95

x

14, C78

x

14

4

1013

10-22

7

31-.

33-49

53-74

33-49

41-50

65-76

59-70

28-37

5

10-13

11-23

7-10

32-41

35-50

56-76

35-50

43-51

68-79

62-72

30-39

6

10-14

11-24

7-11

33-43

36-53

57-79

36-53

44-53

69-82

63-75

30-40

Use

Column

No.

1

2

3

4

5

6

FMX TRANSMISSION -FORD, METEOR WITH 390-2V ENGINE

Throttle

Closed

(Above

18"

Vacuum)

To

Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

1-2

2-3

3-2

2-1 or 3-1

Axle Ratio

3.25:1

3.00:1

3.00:1

2.80:1

1

9-12

10-22

6-10

29-38

22-40

39-61

25-40

35-45

56-69

53-65

25-34

2

10-13

11-23

7-10

32-40

24-42

42-65

27-41

38-47

61-73

57-68

27-36

Tire Size

All

7.75x15

215R

x15

8.25 x

15

8.55

x

15

H70

x

15

All

3

10-13

11-23

7-10

32-42

24-43

42-67

27-43

39-49

62-75

58-70

27-37

4

11-14

11-25

7-11

34-45

26-46

45-71

29-46

41-53

65-80

61-75

29-40

Use

Column

No.

1

2

3

4procarmanuals.com

Page 409 of 413

07-05-09

Specifications

07-05-09

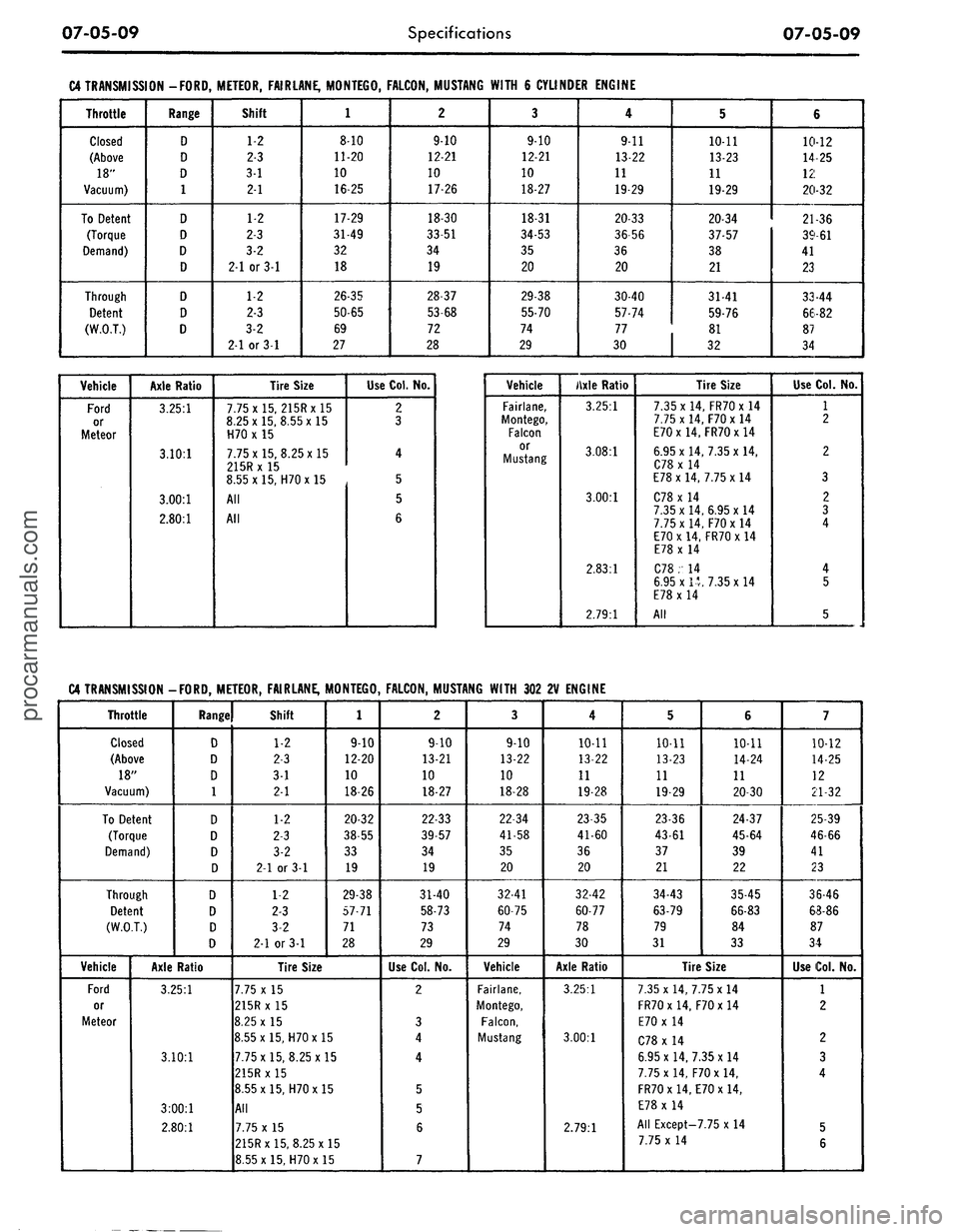

C4 TRANSMISSION-FORD,

Throttle

Closed

(Above

18"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

METEOR, FAIRLANE, MONTEGO, FALCON, MUSTANG

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

2-1

or 3-1

1-2

2-3

3-2

2-1

or 3-1

1

8-10

11-20

10

16-25

17-29

31-49

32

18

26-35

50-65

69

27

2

9-10

12-21

10

17-26

18-30

33-51

34

19

28-37

53-68

72

28

WITH

6

CYLINDER ENGINE

3

9-10

12-21

10

18-27

18-31

34-53

35

20

29-38

55-70

74

29

4

9-11

13-22

11

19-29

20-33

36-56

36

20

30-40

57-74

77

30

5

10-11

13-23

11

19-29

20-34

37-57

38

21

31-41

59-76

81

32

6

10-12

14

25

12:

20-32

21-36

39-61

41

23

33-44

66-82

87

34

Vehicle

Ford

or

Meteor

Axle Ratio

3.25:1

3.10:1

3.00:1

2.80:1

Tire Size

7.75x15, 215Rx

15

8.25x15,8.55x15

H70

x

15

7.75x15,8.25x15

215Rx

15

8.55x15, H70x

15

All

All

Use Col.

No.

2

3

4

5

5

6

Vehicle

Fairlane,

Montego,

Falcon

or

Mustang

Axle Ratio

3.25:1

3.08:1

3.00:1

2.83:1

2.79:1

Tire Size

7.35x14, FR70x

14

7.75x14, F70x

14

E70xl4, FR70xl4

6.95x14,7.35x14,

C78 x

14

E78

x

14, 7.75 x 14

C78 x

14

7.35x14,6.95x14

7.75x14, F70 x

14

E70 x14, FR70

x14

E78

x 14

C78

:

14

6.95x1-:,

7.35x14

E78 x

14

All

Use Col.

No.

1

2

2

3

2

3

4

4

5

5

C4 TRANSMISSION -FORD, METEOR, FAIRLANE,

Throttle

Closed

(Above

18"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Vehicle

Ford

or

Meteor

Range

D

D

D

1

D

D

D

D

D

D

D

D

Axle Ratio

3.25:1

3.10:1

3:00:1

2.80:1

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

2-1

or 3-1

1-2

2-3

3-2

2-1

or 3-1

MONTEGO,

1

9-10

12-20

10

18-26

20-32

38-55

33

19

29-38

57-71

71

28

Tire Size

7.75

x 15

215R

x15

8.25x15

8.55x15, H70x

15

7.75x15,

8.25

x

215R

x15

15

8.55x15, H70x

15

All

7.75

x 15

215Rxl5,8.25x

15

8.55x15, H70x

15

FALCON, MUSTANG WITH

302

2

9-10

13-21

10

18-27

22-33

39-57

34

19

31-40

58-73

73

29

Use Col.

No.

2

3

4

4

5

5

6

7

3

9-10

13-22

10

18-28

22-34

41-58

35

20

32-41

60-75

74

29

Vehicle

Fairlane,

Montego,

Falcon,

Mustang

2V ENGINE

4

10-11

13-22

11

19-28

23-35

41-60

36

20

32-42

60-77

78

30

Axle Ratio

3.25:1

3.00:1

2.79:1

5

10-11

13-23

11

19-29

23-36

43-61

37

21

34-43

63-79

79

31

6

10-11

14-24

11

20-30

24-37

45-64

39

22

35-45

66-83

84

33

Tire Size

7.35x14,7.75x14

FR70 x14, F70

x14

E70

x 14

C78 x

14

6.95x14,7.35x14

7.75

x

14, F70xl4,

FR70xl4, E70xl4,

E78

x 14

All Except-7.75

x

14

7.75

x 14

7

10-12

14-25

12

21-32

25-39

46-66

41

23

36-46

63-86

87

34

Use Col. No.

1

2

2

3

4

5

6procarmanuals.com

Page 410 of 413

07-05-10

Specifications

07-05-10

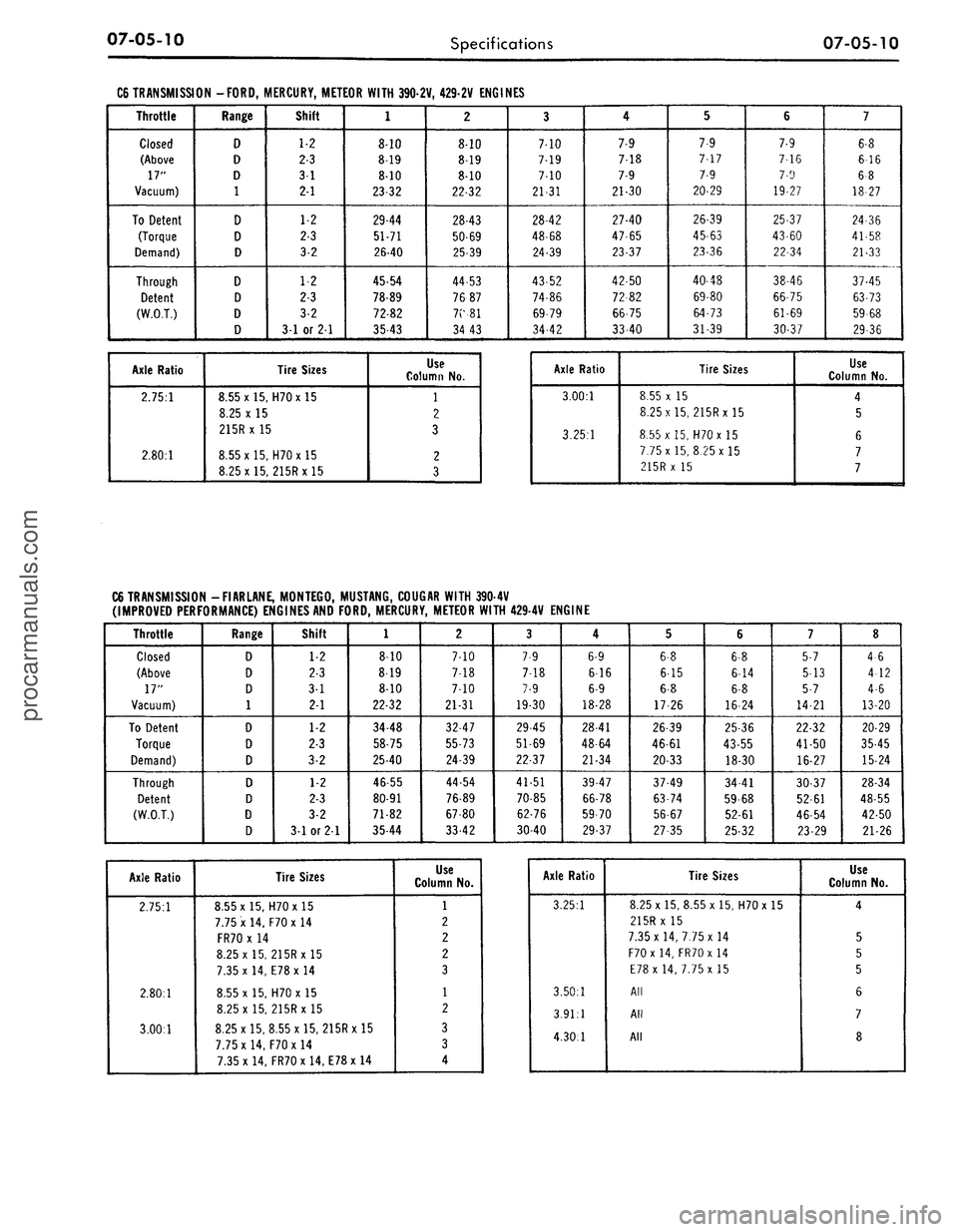

C6 TRANSMISSION -FORD,

1

Throttle

Closed

(Above

17"

Vacuum)

To Detent

(Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

MERCURY, METEOR WITH 390-2V, 429-2V ENGINES

Shift

1-2

2-3

3-1

2-1

1-2

2-3

3-2

1-2

2-3

3-2

3-1

or 21

1

8-10

8-19

8-10

23-32

29-44

51-71

26-40

45-54

78-89

72-82

35-43

2

8-10

8-19

8-10

22-32

28-43

50-69

25-39

44-53

7687

70

81

34

43

3

7-10

7-19

7-10

21-31

28-42

48-68

24-39

43-52

74-86

69-79

34-42

4

7-9

7-18

7-9

21-30

27-40

47-65

23-37

42-50

72-82

66-75

33-40

5

7-9

7-17

7-9

20-29

26-39

45-63

23-36

40-48

69-80

64-73

31-39

6

7-9

7-16

7-9

19-27

25-37

43-60

22-34

38-46

66-75

61-69

30-37

7

6-8

6-16

6-8

18-27

24-36

41-58

21-33

37-45

63-73

59

68

29-36

Axle Ratio

2.75:1

2.80:1

Tire Sizes

8.55x15,

H70x

15

8.25x15

215RX

15

8.55x15,

H70x

15

8.25x15,

215Rx

15

Use

Column

No.

1

2

3

2

3

Axle Ratio

3.00:1

3.25:1

Tire Sizes

8.55 x

15

8.25x15, 215Rx

15

8.55

x 15r

H70x

15

7.75x15,8.25x15

215R

x 15

Use

Column

No.

4

5

6

7

7

C6 TRANSMISSION -FIARLANE, MONTEGO, MUSTANG, COUGAR WITH 390-4V

(IMPROVED PERFORMANCE) ENGINES AND FORD, MERCURY, METEOR WITH 429-4V ENGINE

Throttle

Closed

(Above

17"

Vacuum)

To Detent

Torque

Demand)

Through

Detent

(W.O.T.)

Range

D

D

D

1

D

D

D

D

D

D

D

Shift

1-2

2-3

3-1

21

1-2

2-3

3-2

1-2

2-3

3-2

3-1 or 2-1

1

8-10

819

8-10

22-32

34-48

58-75

25-40

46-55

80-91

71-82

35-44

2

7-10

7-18

710

21-31

32-47

55-73

24-39

44-54

76-89

67-80

33-42

3

7-9

7-18

7-9

19-30

29-45

51-69

22-37

41-51

70-85

62-76

30-40

4

6-9

6-16

6-9

18-28

28-41

48-64

21-34

39-47

66-78

59-70

29-37

5

6-8

615

6-8

17-26

26-39

46-61

20-33

37-49

63-74

56-67

27-35

6

6-8

6-14

6-8

16-24

25-36

43-55

18-30

34-41

59-68

52-61

25-32

7

5-7

5-13

5-7

14-21

22-32

41-50

16-27

30-37

52-61

46-54

23-29

8

4 6

4 12

4-6

13-20

20-29

35-45

15-24

28-34

48-55

42-50

21-26

Axle Ratio

2.75:1

2.80:1

3.00:1

Tire Sizes

8.55x15, H70xl5

7.75 x 14, F70

x

14

FR70

x 14

8.25x15, 215Rx

15

7.35 x 14, E78 x

14

8.55

x 15,

H70x

15

8.25x15, 215Rx

15

8.25 x 15, 8.55 x 15, 215R x

15

7.75x14, F70x

14

7.35x14, FR70x

14,

E78

x 14

Use

Column

No.

1

2

2

2

3

1

2

3

3

4

Axle Ratio

3.25:1

3.50:1

3.91:1

4.30:1

Tire Sizes

8.25

x

15,

8.55 x

15, H70xl5

215Rx

15

7.35x14,7.75x14

F70x 14, FR70x

14

E78x 14,

7.75x15

All

All

All

Use

Column

No.

4

5

5

5

6

7

8procarmanuals.com