check engine FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 45 of 413

02-02-26

Brake System

02-02-26

14.

Remove the clutch pedal assist

spring.

15.

On non-power brakes, remove

the retainer clip from the clutch and

brake pedal shaft, then remove the

clutch pedal and shaft assembly, the

brake pedal assembly, and the bush-

ings from the pedal support bracket.

On power brakes, remove the retainer

nut from the brake pedal shaft then

remove the pedal shaft, the brake

pedal assembly and the bushings from

the pedal support bracket.

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

bushings in their proper places on the

clutch and brake pedal assemblies.

2.

On non-power brakes, position

the brake pedal to the pedal support

bracket, then install the clutch pedal

and shaft assembly through the sup-

port bracket and brake pedal assem-

bly. On power brakes position the

brake pedal to the pedal support

bracket, then install the pedal shaft

and nut.

3.

Install the clutch pedal assist

spring and pivot the clutch pedal

against its bumper stop. Secure the

pedal to the stop with a small C-

clamp as shown in Figs. 28 and 31.

4.

Position the pedal support

bracket assembly to the dash panel,

and to the steering column retainer

studs.

5.

Align the pedal support bracket

holes with the holes in the dash panel

and install the two attaching sheet

metal screws. On power brakes install

the nuts on the brake booster studs.

6. Install the two cap screws at-

taching the pedal support bracket to

the upper cowl bracket.

7. Install the cap screw attaching

the pedal support bracket to the top

inner cowl bracket (Figs. 28 and 31).

8. Install the inner nylon washer,

the master cylinder push rod, and the

bushing on the brake pedal pin. Posi-

tion the stop light switch so that it

straddles the push rod with the switch

slot on the pedal pin and the switch

outer hole just clearing the pin. Slide

the switch completely onto the pin,

and install the outer nylon washer as

shown in Figs. 28 and 31. Secure

these parts to the pin with the

self-

locking retainer.

9. Connect the stop light switch

wires to the connector.

10.

Connect the clutch pedal-

to-equalizer rod to the clutch pedal

assembly with the bushing and the

spring clip retainer. Apply SAE 10

engine oil to the bushing. Remove the

C-clamp from the clutch pedal.

11.

Working from the engine side

of the dash panel, on non-power

brakes, install the two cap screws at-

taching the pedal support bracket to

the dash panel. Then install the two

screws attaching the master cylinder

to the dash panel. On power brakes

install the cap screws retaining the

brake booster to the dash panel.

12.

Install the steering column.

Refer to Part 3-4, Section 2 for pro-

cedure.

13.

Adjust the clutch pedal free

play (Group 5) to specification, if re-

quired.

14.

Check the Brake Pedal Free

Height and Travel Measurements

(Part 2-1, Section 1).

15.

Connect the ground cable to the

battery.

FAIRLANE, MONTEGO,

FALCON, MUSTANG

AND COUGAR-

AUTOMATIC TRANSMISSION

Removal

1. Disconnect the stop light switch

wires at the connector.

2.

Remove the self-locking pin and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin. Slide the master cylinder or

booster push rod and the nylon wash-

ers and bushing off from the brake

pedal pin (Figs. 27, 28, 30 and 31).

3.

On all vehicles except Mustang

and Cougar with power brakes, re-

move the self-locking pin and washer

from the brake pedal shaft, then re-

move the shaft, the brake pedal as-

sembly and the bushings from the

pedal support bracket. On Mustang

and Cougar vehicles with power

brakes, remove the locknut and bolt

from the pedal. Remove the pedal as-

sembly from the support bracket (Fig.

3).

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

the bushings in their proper places on

the pedal assembly and pedal support

bracket (Figs. 27, 28, 30 and 31).

2.

Position the brake pedal assem-

bly to the support bracket, then install

the pedal shaft or bolt through the

support bracket and brake pedal as-

sembly. Install the retainer or locknut.

3.

Install the inner nylon washer,

the master cylinder or booster push

rod, and the bushing on the brake

pedal pin. Position the switch so that

it straddles the push rod with the

switch slot on the pedal pin, and the

switch outer hole just clearing the pin.

Slide the switch completely onto the

pin, and install the outer nylon washer

as shown in Figs. 27, 28, 30 and 31.

Secure these parts to the pin with the

self-locking pin.

4.

Connect the stop light switch

wires to the connector, and install the

wires in the retaining clip.

Check the Brake Pedal Free Height

and Travel Measurements, Part 2,

Section 1.

THUNDERBIRD

AND

CONTINENTAL MARK

III

Removal

1.

Loosen the booster mounting

nuts.

2.

Disconnect the stop light switch

wires at the connector.

3.

Remove the hairpin retainer.

Slide the stop light switch off from

the brake pedal pin just far enough

for

the

switch outer hole

to

clear

the

pin,

and then lift the switch straight

upward from the pin. Slide the master

cylinder push rod and the nylon wash-

ers and bushing off from the brake

pedal pin (Fig. 32).

4.

Remove the pivot bolt and nut

that holds the pedal to the pedal sup-

port bracket. Remove the brake pedal

assembly from the pedal support

bracket, and remove the bushings.

Installation

1. Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

the bushings in their proper places on

the pedal assembly (Fig. 32).

2.

Install the brake pedal assembly

and bushings to the support bracket,

and then install the pivot bolt through

the support bracket and brake pedal

assembly. Install the pivot bolt nut

and torque to specifications.

3.

Install the inner nylon washer,

the master cylinder push rod, and the

bushing on the brake pedal pin. Posi-

tion the switch so that it straddles the

push rod with the switch slot on the

pedal pin and the switch outer hole

just clearing the pin. Slide the switch

completely onto the pin, install the

outer nylon washer as shown in Fig.

32.

Secure these parts to the pin with

the hairpin retainer.procarmanuals.com

Page 46 of 413

02-02-27

Brake System

02-02-27

4.

Connect the stop light switch

wires to the connector, and install the

wires in the retaining clip.

5.

Torque the booster mounting

nuts to specifications.

LINCOLN CONTINENTAL

Removal

1.

Disconnect the battery ground

cable from the battery.

2.

It is necessary to obtain clear-

ance to remove vacuum hoses and the

electrical connector to the temperature

heat control box. Remove the two

screws retaining the relay to the fend-

er and push the relay aside. Discon-

nect the vacuum hoses and connector

at the heat control box.

3.

Working under the instrument

panel, disconnect the vacuum hoses,

wires and retaining clip from the tem-

perature heat control box. Remove the

two screws securing the temperature

control box to the dash panel.

4.

Remove the lower control hous-

ing retaining screws (6). Disconnect

the wire harnesses at the lower control

panel and place the panel aside. Re-

move the wire harness shield. Remove

the wire harness clip. Position the

wire harness aside. Remove the tem-

perature control box and position it

aside.

5.

Remove the hair-pin type retain-

er. Slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Lift the switch upward from the pin.

Slide the master cylinder push rod,

nylon washers and bushing off the

brake pedal pin.

6. Remove the pivot bolt and nut

that holds the pedal to the pedal sup-

port bracket. Remove the brake pedal

assembly from the support bracket

and remove the bushings.

7.

If required, remove the brake

pedal pad retaining nuts and remove

the brake pedal pad.

Installation

1.

If the brake pedal pad was re-

moved, position the pad on the pedal.

Install the pad retaining nuts and tor-

que them to specification.

2.

Apply SAE 10 engine oil to the

bushings and locate all the bushings in

their proper places on the pedal as-

sembly.

3.

Install the brake pedal assembly

and bushings to the support bracket,

and then install the pivot bolt through

the support bracket and pedal assem-

bly. Install the pivot bolt nut and tor-

que it to specification.

4.

Install the inner nylon washer,the

master cylinder push rod link, and the

bushing on the brake pedal pin. Posi-

tion the switch so that it straddles the

push rod link with the switch slot on

the pedal and the switch outer hole

just clearing the pin. Install the outer

nylon washer as shown in Fig. 33. In-

stall the hair-pin type retainer on the

brake pedal pin.

5.

Connect the stop light switch

wires to the connector, and install the

wires in the retaining clip.

6. Position the wire harness and

clip on the temperature control box

and install the retaining screw. Posi-

tion the temperature control box to

the dash panel and install the two re-

taining bolts.

7.

Connect the vacuum lines and

the electrical connector to the control

box. Position the wire harness to the

control box and install the retaining

clip.

8. Position the wire harness shield

and install two retaining bolts.

9. Connect the wire harnesses to

the lower control panel and install the

retaining screws.

10.

Working within the engine

compartment, connect the wire con-

nector to the temperature heat control

box.

11.

Position the relay to the fender

apron and install the retaining bolts.

12.

Connect the ground cable to the

battery.

13.

Check the brakes and light

switch for proper operation. Close the

hood.

PARKING BRAKE CONTROL

ASSEMBLY

FORD, MERCURY

AND METEOR

Removal

Refer to Fig. 34.

1.

Make sure the parking brake is

fully released.

2.

Remove all tension from the rear

cables by backing off the adjusting nut

from the equalizer.

3.

Remove the roll pin that secures

the release knob to the cable and re-

move the knob.

4.

Remove the nut that secures the

release cable to the instrument panel

and remove the cable from the rear of

the instrument panel.

5.

Remove the two nuts attaching

the control assembly to the dash

panel.

6. Remove the cap screw attaching

the control assembly to the cowl side

bracket.

7.

Disconnect the hose to the park-

ing brake vacuum unit, if so equipped.

8. Remove the front cable assembly

retainer clip from the cable assembly

and disconnect the cable ball from the

control clevis.

9. Remove the control assembly

from the vehicle.

Installation

1.

Position the control assembly in

the vehicle.

2.

Fit the cable assembly through

its mounting hole and install the re-

taining clip. Connect the cable ball to

the control clevis.

3.

Connect the vacuum hose to the

parking brake unit, if so equipped.

4.

Install the attaching cap screw to

the cowl side bracket. Do not tighten.

5.

Install the two control assemb-

ly-to-dash panel nuts. Tighten the nuts

and the cap screw to specifications.

6. Insert the release cable into the

instrument panel and install the re-

taining nut.

7.

Install the release knob on the

cable with the roll pin.

8. Check the operation of the park-

ing brake. Adjust the parking brake

as required.

FAIRLANE, MONTEGO

AND FALCON

Removal

Refer to Fig. 35.

1.

Make sure the parking brake is

completely released.

2.

Remove all tension from the rear

cables by backing off the jam nut and

adjusting nut from the equalizer.

3.

Working inside the vehicle, re-

move the four bolts and one nut re-

taining the left air vent and cable as-

sembly to the dash and instrument

panels. Remove the vent assembly.

4.

Remove the parking brake front

cable ball retaining clip from the clev-

is.

5.

Disconnect the cable ball from

the notch in the brake clevis.

6. Remove the three screws that at-

tach the control assembly to the left

cowl inner side panel.procarmanuals.com

Page 67 of 413

03-01-02

Suspension — Steering, Wheels And Tires — General Service

03-01-02

1 TESTING

POWER STEERING-

PRELIMINARY TESTS

The following preliminary checks

should always be made before per-

forming any operations.

AIR BLEEDING

Air in the power steering system

(shown by bubbles in the fluid) should

be bled. After making sure that the

reservoir is filled to specification (the

fluid must be at normal operating

temperature when the check is made),

turn the steering wheel through its full

travel three or four times. Do not hold

the wheels against their stops. Re-

check the fluid level.

CHECK FLUID LEVEL

Run the engine until the fluid is at

normal operating temperature. Then

turn the steering wheel all the way to

the left and right several times, and

shut off the engine.

Check the fluid level in the power

steering reservoir. The level must show

on the cross hatching between the bot-

tom of the dipstick and the full mark

(Fig. 1). If the level is low, add

enough automatic transmission fluid

C1AZ-19582-A to raise the level to

the F mark on the dipstick. Do not

overfill the reservoir.

CHECK PUMP BELT

If the pump belt is broken, glazed,

or worn, replace it with a new belt.

Use only the specified type of belt.

Refer to Part 3-13 for belt adjustment

procedure.

CHECK FOR FLUID

LEAKS

With the engine idling, turn the

steering wheel from stop to stop sever-

al times. Check all possible leakage

points. Tighten all loose fittings, and

replace any damaged lines or defective

seats.

CHECK TURNING EFFORT

With the front wheels properly al-

igned and tire pressures correct, check

the effort required to turn the steering

wheel.

G 1508- A

FIG.

1—Power

Steering Pump

Dipstick

1.

With the vehicle on dry concrete,

set the parking brakes.

2.

With the engine warmed up and

running at idle speed, turn the steering

wheel to the left and right several

times to warm the fluid.

3.

Attach a pull scale to the rim of

the steering wheel. Measure the pull

required to turn the wheel one com-

plete revolution in each direction. The

effort required to rotate the steering

wheel should not exceed specifications

given in Part 3-13.

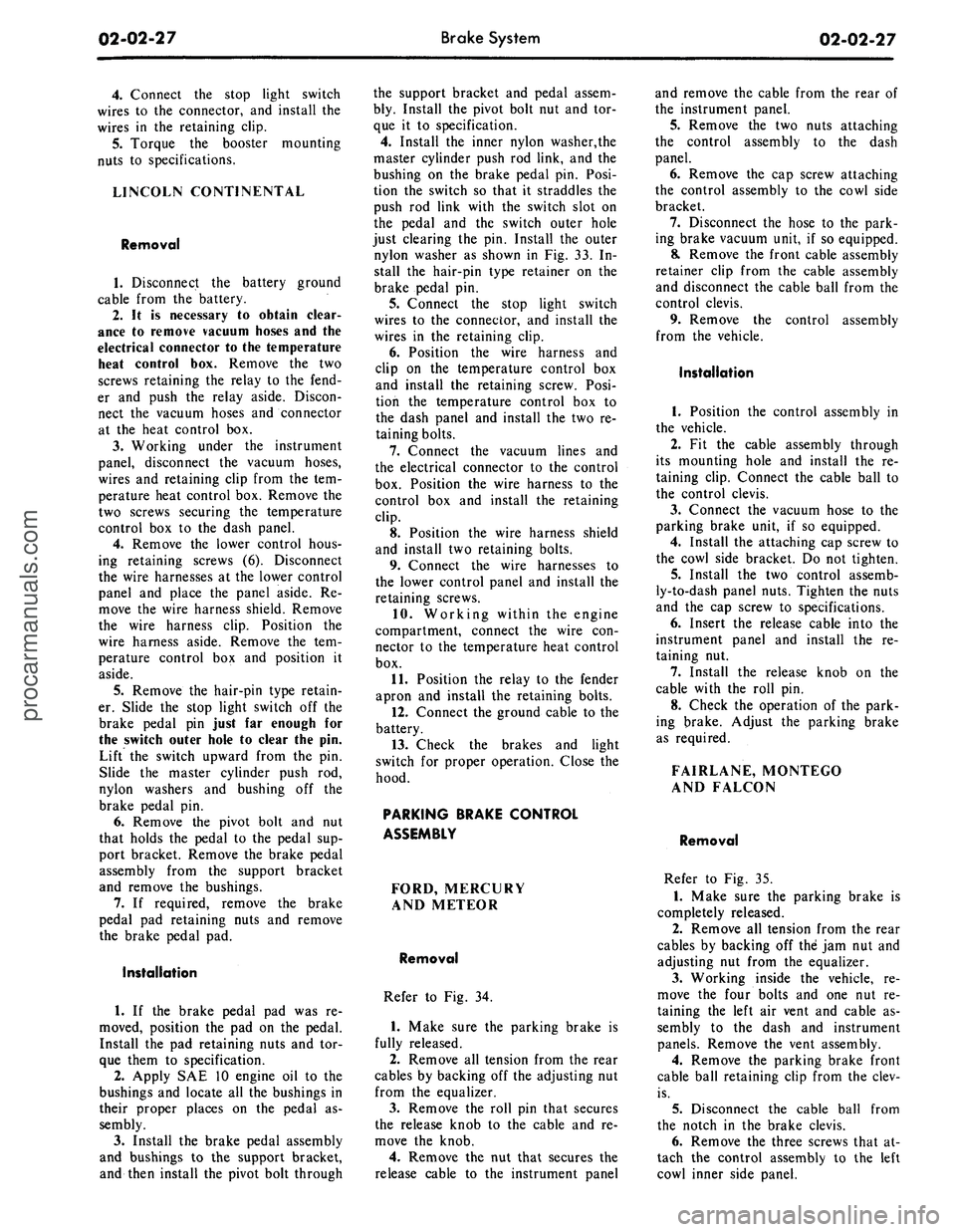

POWER STEERING PUMP FLOW

AND PRESSURE TESTS—

EXCEPT LINCOLN CONTINENTAL

AND CONTINENTAL MARK III

The power steering flow and pres-

sure tests will show whether the pump,

steering gear or power assist control

RETURN LINE

POWER

STEERING PUMP

Sr

valve is causing the trouble. Steps out-

lined below should be followed to de-

termine the cause of the trouble.

PUMP FLOW TEST

1.

Depending on the equipment

present on the vehicle (air condition-

ing, power brakes, standard transmis-

sion),

one of the following options

may be used to connect the pump

pressure and return hoses to the test

tool (T56L-3361O-D and T68L-

33610-A):

a. Disconnect the pressure and re-

turn lines at the power steering pump

(Fig. 2). Obtain a power steering re-

turn hose from stock and connect the

end with the fitting to the output fit-

ting of the tool using the

5/8-18

SAE

female, 1/4 N.P. thread male fitting

provided. The end of the stock hose

(without the fitting) should be con-

nected to the return tube of the pump.

Connect the pressure hose from the

tool to the outlet fitting of the pump.

b.

Disconnect the pressure line at

the pump and connect the pressure

line from the test tool to the outlet fit-

ting of the pump. Disconnect the re-

turn line at the gear and connect it to

the output fitting of the tool, using the

5/8-18

SAE female, 1/4 N.P. thread

male fitting provided.

2.

After installing the lines by the

most advantageous method, proceed

as follows:

3.

Open the manual valves A and B

fully (Fig. 2).

CALIBRATED FLOW

DETERMINING ORIFICE

PRESSURE LINE

FIG. 2—Power Steering Pump Test Circuit Diagram

PRESSURE GAGE

G1611-Aprocarmanuals.com

Page 68 of 413

03-01-03

Suspension — Steering, Wheels And Tires — General Service

03-01-03

4.

Connect a tachometer, start the

engine and operate it at idle speed

until the reservoir fluid temperature

reaches 165 to 175. This temperature

must be maintained throughout the

test. Valve B may be partially closed

to create a back pressure up to 350

psi to hasten the temperature rise. The

reservoir fluid must be at the proper

level.

5.

With the engine operating at rec-

ommended idle rpm and fluid temper-

ature noted in Step 4, close the manu-

al valve B. The minimum acceptable

pressure reading is 620 psi.

6. If the pressure gauge reading is

below the minimum specification, the

pump is at fault and should be re-

paired with necessary parts.

7.

If the reading is at or above the

minimum specification, the pump flow

is normal. Open manual valve B and

proceed to the Pump Fluid Pressure

Test.

PUMP FLUID

PRESSURE TEST

1.

Keep the lines and tools con-

nected as in the Pump Flow Test.

2.

With manual valves A and B

opened fully, operate the engine at

recommended idle speed (Fig. 2).

Close manual valve A, then manual

valve B. Do not keep both valves

closed for more than 5 seconds as this

would abnormally increase the fluid

temperature and cause undue pump

and/or gear wear.

3.

With the valves fully closed, the

pressure gauge should read 1000 psi

minimum for Ford, Mercury, Meteor

or Thunderbird and 750 psi minimum

for Cougar, Fairlane, Falcon, Monte-

go or Mustang.

4.

If the pressure gauge reading is

below the minimum specification, the

pump is at fault and should be re-

paired with necessary parts.

5.

If the pressure gauge reading is

at or above the minimum specifica-

tions,

the pump is normal and the

power steering gear or power assist

control valve is at fault.

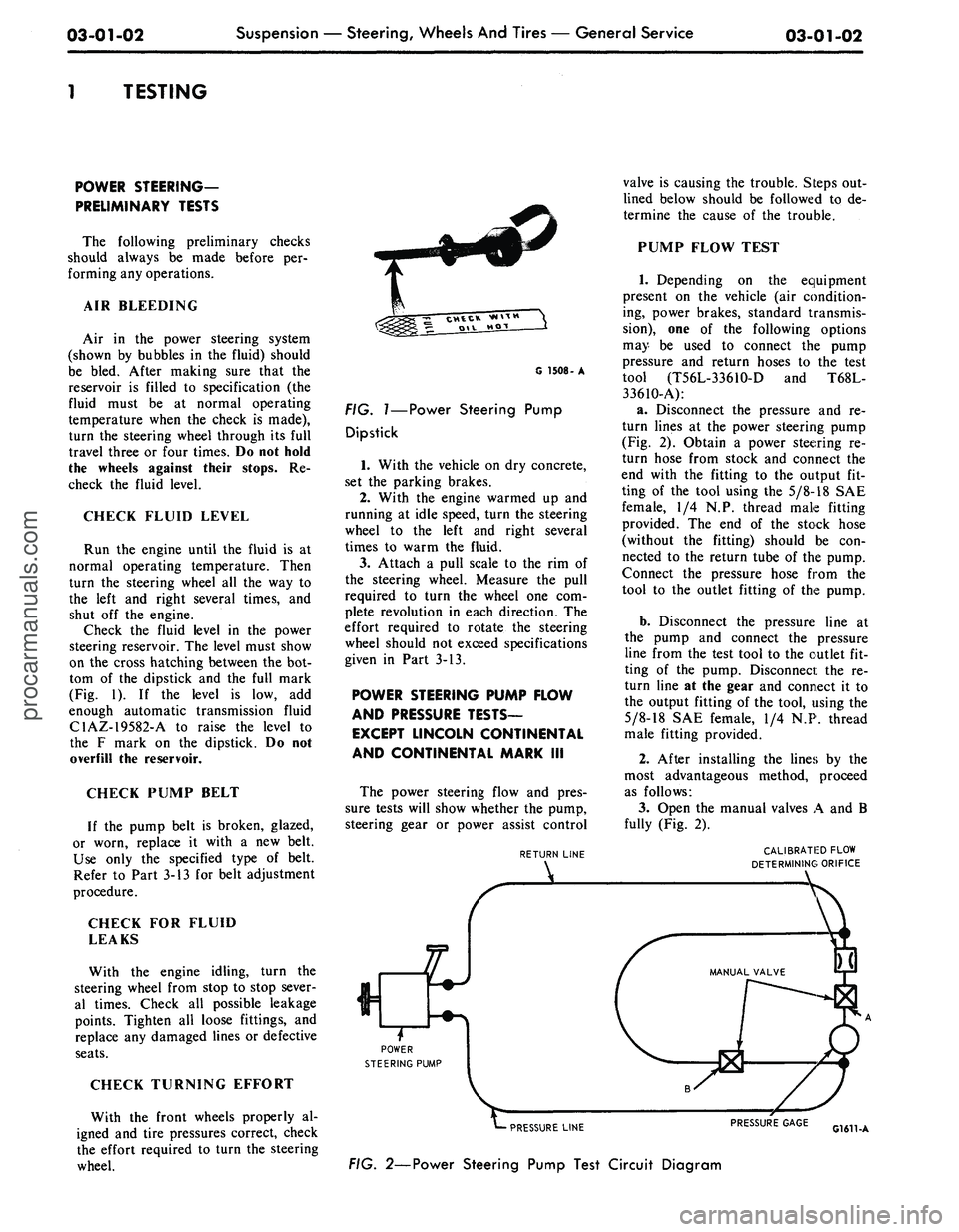

FLUID PRESSURE TEST-

LINCOLN CONTINENTAL AND

CONTINENTAL MARK III

The pressure testing gauge set, tool

T56L-33610-D, requires modification

to make it adaptable for installation

in the power steering hydraulic sys-

tem. The parts required and the modi-

fication procedure are as follows:

OWER STEERING

PRESSURE LINE

INVERTED FLARE

CONNECTOR

%* TUBE x VA" PIPE

FLARED FEMALE COUPW

%' TUBE x VA" PIPE

G1544.A

FIG. 3—Modified Pressure Gauge

Assembly

a. Power Steering Pressure Line

(refer to the appropriate Parts Catal-

og).

b.

Inverted Flare Connector (3/8

inch OD Tube x 1/4 inch Pipe

Thread).

c. Inverted Flare Connector (5/16

inch OD Tube x 1/4 inch Pipe

Thread).

d. Flared Tube Female Coupling

(3/8 inch OD Tube x 1/4 inch Pipe

Thread).

The connectors and the coupling are

standard-type fittings and can be pur-

chased locally.

e. To modify tool T56L-33610-D,

remove the hose from the hand shut-

off valve block. Install the 3/8 inch x

1/4 inch inverted flare connector in

the valve block, and assemble the

pressure line to the connector (Fig. 3).

Assemble the 3/8 x 1/4 inch coupling

and the 5/16-inch connector to the

free end of the hose leading to the.

pressure gauge.

1.

To check the pump pressure, dis-

connect the front and rear sections of

the pressure line over the number 6

cylinder. Connect the modified pres-

sure-testing gauge assembly, tool

T56L-3361O-D, between the two sec-

tions.

2.

Make sure the hand-valve at the

gauge is fully opened. Start the engine

and cycle the steering gear from stop

to stop to warm up the fluid. Check

the fluid level in the reservoir and add

fluid, if necessary.

3.

Turn the steering wheel to the

full right and full left turn positions

and observe the gauge readings.

Hold the wheels in this position

only long enough to obtain an accu-

rate reading. Do not exceed 5 seconds.

The gauge should read between

1120 and 1250 psi. If the pressure is

less than 1120 psi, close the valve at

the gauge and note the pump pressure.

If it is low with the valve closed, it in-

dicates that the pump is not operating

properly. If the pressure goes up with

the valve closed, it indicates that the

low pressure in the system must be

due to internal leakage in the power

unit, providing all connections are

tight.

4.

Remove the pressure testing

gauge set, and connect the pressure

line at the steering gear. Fill and bleed

the system.

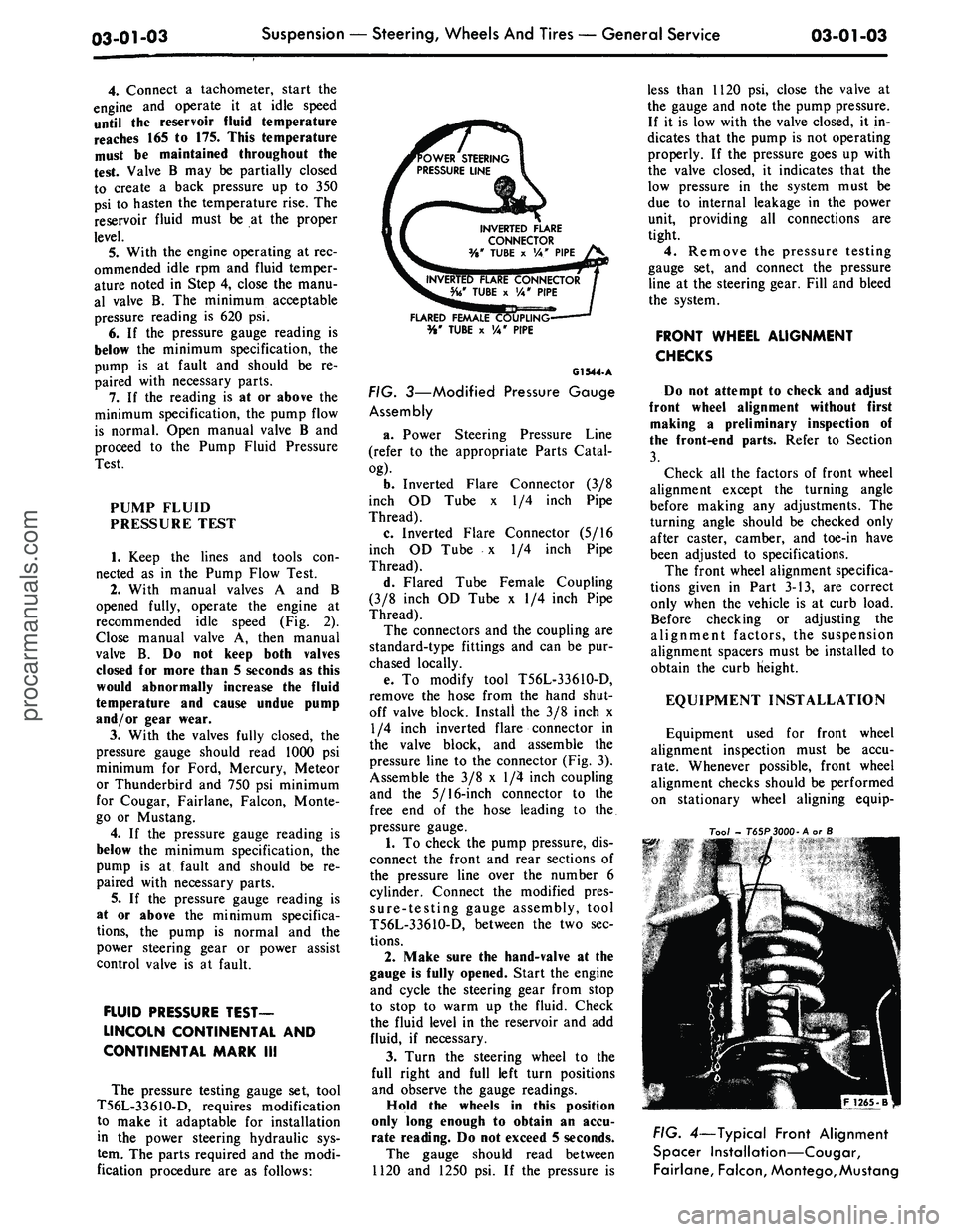

FRONT WHEEL ALIGNMENT

CHECKS

Do not attempt to check and adjust

front wheel alignment without first

making a preliminary inspection of

the front-end parts. Refer to Section

3.

Check all the factors of front wheel

alignment except the turning angle

before making any adjustments. The

turning angle should be checked only

after caster, camber, and toe-in have

been adjusted to specifications.

The front wheel alignment specifica-

tions given in Part 3-13, are correct

only when the vehicle is at curb load.

Before checking or adjusting the

alignment factors, the suspension

alignment spacers must be installed to

obtain the curb Height.

EQUIPMENT INSTALLATION

Equipment used for front wheel

alignment inspection must be accu-

rate.

Whenever possible, front wheel

alignment checks should be performed

on stationary wheel aligning equip-

Too/

- T65P3000-A or S

FIG. 4—Typical Front Alignment

Spacer Installation—Cougar,

Fairlane, Falcon,

Montego,

Mustangprocarmanuals.com

Page 70 of 413

03-01-05

Suspension — Steering, Wheels And Tires — General Service

03-01-05

type of equipment is used, follow the

installation and inspection instructions

provided by the equipment manufactu-

rer.

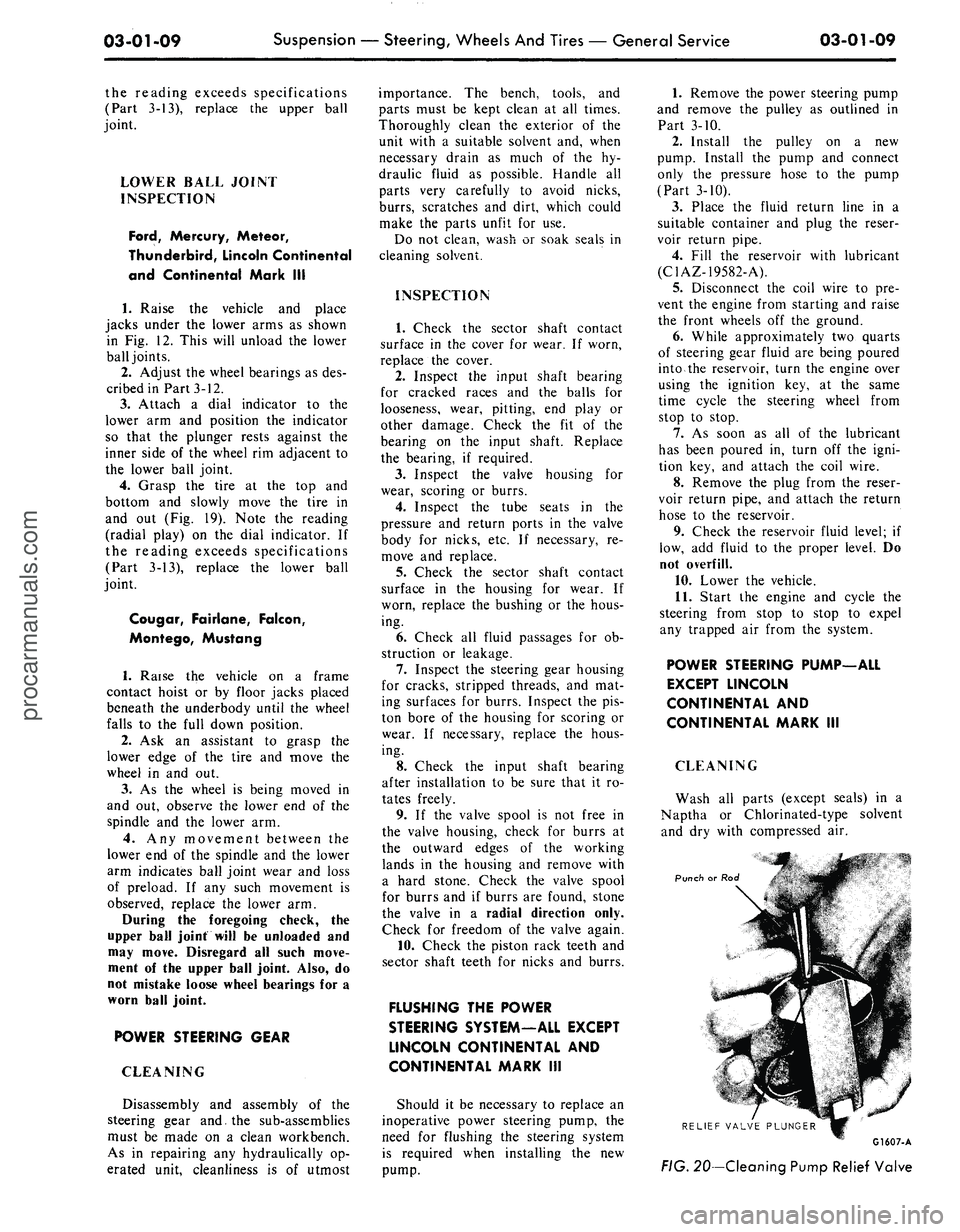

CASTER

Check the caster angle at each front

wheel.

The caster is the forward or rear-

ward tilt of the top of the wheel

spindle (Fig. 12). If the spindle tilts to

the rear, caster is positive. If the

spindle tilts to the front, caster is neg-

ative. The correct caster angle, or tilt,

is specified in Part 3-13.

On Mustang, Cougar, Fairlane,

Falcon and Montego vehicles, the

maximum caster difference for check-

ing purposes must not exceed one de-

gree.

If setting is necessary, then the

maximum difference must not exceed

1/2 degree. On all other vehicles, the

maximum caster difference must never

exceed 1/2 degree.

CAMBER

Check the camber angle at each

front wheel.

Camber is the amount the front

wheels are tilted at the top (Fig. 12).

If a wheel tilts outward, camber is

positive. If a wheel tilts inward, cam-

ber is negative. The correct camber

angle, or outward (positive) tilt is

specified in Part 3-13.

On Mustang, Cougar, Fairlane,

Falcon and Montego vehicles, the

maximum camber difference for

checking purposes must not exceed

one degree. If setting is necessary,

then the maximum difference must

not exceed 1/2 degree. On all other

vehicles, the maximum camber differ-

ence must never exceed 1/2 degree.

TOE-IN

Alignment height spacers should not

be used to check and adjust toe-in.

Toe-in should only be checked and ad-

justed after the caster and camber

have been adjusted to specifications.

Check the toe-in with the front

wheels in the straight-ahead position.

Run the engine so that the power

steering control valve will be in the

center (neutral) position (if so

equipped). Measure the distance be-

tween the extreme front and also be-

tween the extreme rear of both front

wheels. The difference between these

two distances is the toe-in or toe-out.

Correct toe-in, or inward pointing

of both front wheels at the front is

specified in Part 3-13.

FRONT WHEEL

TURNING ANGLE

When the inside wheel is turned 20

degrees, the turning angle of the out-

side wheel should be as specified in

Part 3-13. The turning angle cannot

be adjusted directly, because it is a re-

sult of the combination of caster,

camber, and toe-in adjustments and

should, therefore, be measured only

after these adjustments have been

made. If the turning angle does not

measure to specifications, check the

spindle or other suspension parts for a

bent condition.

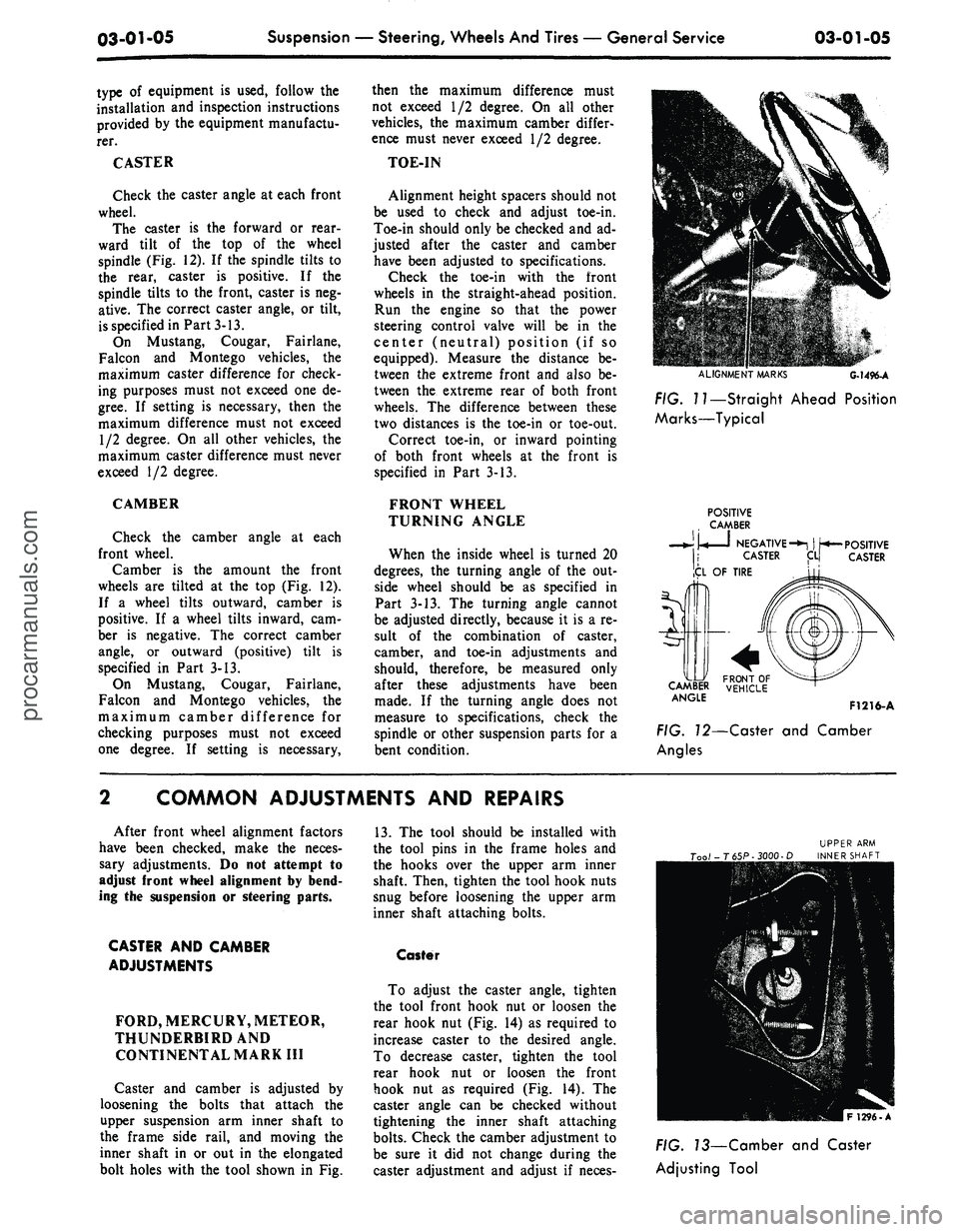

ALIGNMENT

MARKS

G-1496-A

FIG. I?—Straight Ahead Position

Marks—Typical

POSITIVE

CAMBER

• •

NEGATIVE-*!

| ^*—

CASTER

ICL

OF TIRE

POSITIVE

CASTER

5r\

CA&U

ANGlE

F1216-A

FIG. 72—Caster and Camber

Angles

COMMON ADJUSTMENTS AND REPAIRS

After front wheel alignment factors

have been checked, make the neces-

sary adjustments. Do not attempt to

adjust front wheel alignment by bend-

ing the suspension or steering parts.

CASTER AND CAMBER

ADJUSTMENTS

FORD, MERCURY, METEOR,

THUNDERBIRDAND

CONTINENTAL MARK III

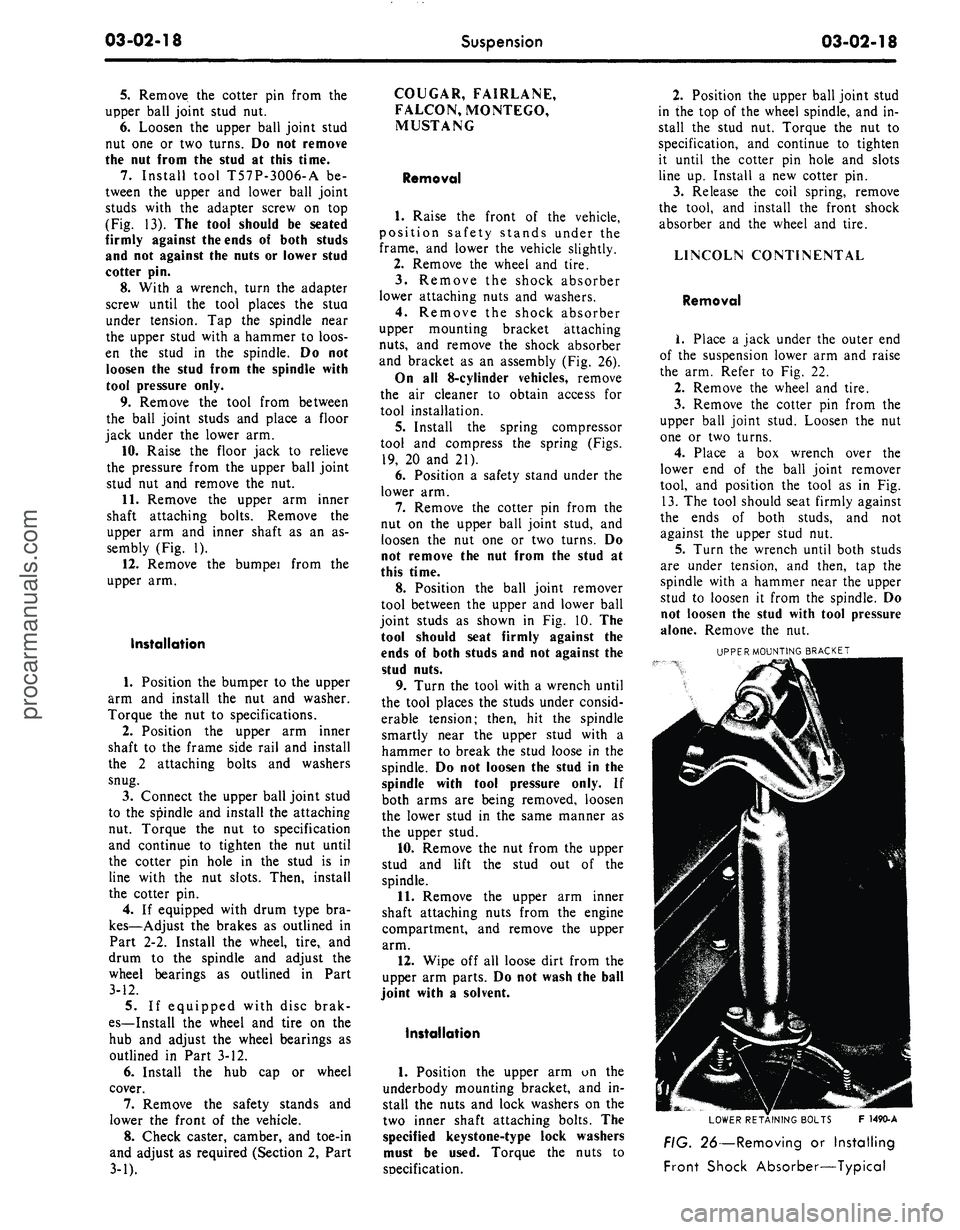

Caster and camber is adjusted by

loosening the bolts that attach the

upper suspension arm inner shaft to

the frame side rail, and moving the

inner shaft in or out in the elongated

bolt holes with the tool shown in Fig.

13.

The tool should be installed with

the tool pins in the frame holes and

the hooks over the upper arm inner

shaft. Then, tighten the tool hook nuts

snug before loosening the upper arm

inner shaft attaching bolts.

Caster

To adjust the caster angle, tighten

the tool front hook nut or loosen the

rear hook nut (Fig. 14) as required to

increase caster to the desired angle.

To decrease caster, tighten the tool

rear hook nut or loosen the front

hook nut as required (Fig. 14). The

caster angle can be checked without

tightening the inner shaft attaching

bolts.

Check the camber adjustment to

be sure it did not change during the

caster adjustment and adjust if neces-

FIG. 73—Camber and Caster

Adjusting Toolprocarmanuals.com

Page 74 of 413

03-01-09

Suspension — Steering, Wheels And Tires — General Service

03-01-09

the reading exceeds specifications

(Part 3-13), replace the upper ball

joint.

LOWER BALL JOINT

INSPECTION

Ford,

Mercury, Meteor,

Thunderbird, Lincoln Continental

and Continental Mark III

1.

Raise the vehicle and place

jacks under the lower arms as shown

in Fig. 12. This will unload the lower

ball joints.

2.

Adjust the wheel bearings as des-

cribed in Part 3-12.

3.

Attach a dial indicator to the

lower arm and position the indicator

so that the plunger rests against the

inner side of the wheel rim adjacent to

the lower ball joint.

4.

Grasp the tire at the top and

bottom and slowly move the tire in

and out (Fig. 19). Note the reading

(radial play) on the dial indicator. If

the reading exceeds specifications

(Part 3-13), replace the lower ball

joint.

Cougar, Fairlane, Falcon,

Montego, Mustang

1.

Raise the vehicle on a frame

contact hoist or by floor jacks placed

beneath the underbody until the wheel

falls to the full down position.

2.

Ask an assistant to grasp the

lower edge of the tire and move the

wheel in and out.

3.

As the wheel is being moved in

and out, observe the lower end of the

spindle and the lower arm.

4.

Any movement between the

lower end of the spindle and the lower

arm indicates ball joint wear and loss

of preload. If any such movement is

observed, replace the lower arm.

During the foregoing check, the

upper ball joint will be unloaded and

may move. Disregard all such move-

ment of the upper ball joint. Also, do

not mistake loose wheel bearings for a

worn ball joint.

POWER STEERING GEAR

CLEANING

Disassembly and assembly of the

steering gear and. the sub-assemblies

must be made on a clean workbench.

As in repairing any hydraulically op-

erated unit, cleanliness is of utmost

importance. The bench, tools, and

parts must be kept clean at all times.

Thoroughly clean the exterior of the

unit with a suitable solvent and, when

necessary drain as much of the hy-

draulic fluid as possible. Handle all

parts very carefully to avoid nicks,

burrs,

scratches and dirt, which could

make the parts unfit for use.

Do not clean, wash or soak seals in

cleaning solvent.

INSPECTION

1.

Check the sector shaft contact

surface in the cover for wear. If worn,

replace the cover.

2.

Inspect the input shaft bearing

for cracked races and the balls for

looseness, wear, pitting, end play or

other damage. Check the fit of the

bearing on the input shaft. Replace

the bearing, if required.

3.

Inspect the valve housing for

wear, scoring or burrs.

4.

Inspect the tube seats in the

pressure and return ports in the valve

body for nicks, etc. If necessary, re-

move and replace.

5.

Check the sector shaft contact

surface in the housing for wear. If

worn, replace the bushing or the hous-

ing.

6. Check all fluid passages for ob-

struction or leakage.

7.

Inspect the steering gear housing

for cracks, stripped threads, and mat-

ing surfaces for burrs. Inspect the pis-

ton bore of the housing for scoring or

wear. If necessary, replace the hous-

ing.

8. Check the input shaft bearing

after installation to be sure that it ro-

tates freely.

9. If the valve spool is not free in

the valve housing, check for burrs at

the outward edges of the working

lands in the housing and remove with

a hard stone. Check the valve spool

for burrs and if burrs are found, stone

the valve in a radial direction only.

Check for freedom of the valve again.

10.

Check the piston rack teeth and

sector shaft teeth for nicks and burrs.

FLUSHING THE POWER

STEERING SYSTEM—ALL EXCEPT

LINCOLN CONTINENTAL AND

CONTINENTAL MARK III

Should it be necessary to replace an

inoperative power steering pump, the

need for flushing the steering system

is required when installing the new

pump.

1.

Remove the power steering pump

and remove the pulley as outlined in

Part 3-10.

2.

Install the pulley on a new

pump. Install the pump and connect

only the pressure hose to the pump

(Part 3-10).

3.

Place the fluid return line in a

suitable container and plug the reser-

voir return pipe.

4.

Fill the reservoir with lubricant

(C1AZ-19582-A).

5.

Disconnect the coil wire to pre-

vent the engine from starting and raise

the front wheels off the ground.

6. While approximately two quarts

of steering gear fluid are being poured

into the reservoir, turn the engine over

using the ignition key, at the same

time cycle the steering wheel from

stop to stop.

7.

As soon as all of the lubricant

has been poured in, turn off the igni-

tion key, and attach the coil wire.

8. Remove the plug from the reser-

voir return pipe, and attach the return

hose to the reservoir.

9. Check the reservoir fluid level; if

low, add fluid to the proper level. Do

not overfill.

10.

Lower the vehicle.

11.

Start the engine and cycle the

steering from stop to stop to expel

any trapped air from the system.

POWER STEERING PUMP—ALL

EXCEPT LINCOLN

CONTINENTAL AND

CONTINENTAL MARK III

CLEANING

Wash all parts (except seals) in a

Naptha or Chlorinated-type solvent

and dry with compressed air.

Punch or Rod

RELIEF VALVE PLUNGER

G1607-A

FIG.

20—Cleaning Pump Relief Valveprocarmanuals.com

Page 94 of 413

03-02-18

Suspension

03-02-18

5.

Remove the cotter pin from the

upper ball joint stud nut.

6. Loosen the upper ball joint stud

nut one or two turns. Do not remove

the nut from the stud at this time.

7.

Install tool T57P-3006-A be-

tween the upper and lower ball joint

studs with the adapter screw on top

(Fig. 13). The tool should be seated

firmly against the ends of both studs

and not against the nuts or lower stud

cotter pin.

8. With a wrench, turn the adapter

screw until the tool places the stua

under tension. Tap the spindle near

the upper stud with a hammer to loos-

en the stud in the spindle. Do not

loosen the stud from the spindle with

tool pressure only.

9. Remove the tool from between

the ball joint studs and place a floor

jack under the lower arm.

10.

Raise the floor jack to relieve

the pressure from the upper ball joint

stud nut and remove the nut.

11.

Remove the upper arm inner

shaft attaching bolts. Remove the

upper arm and inner shaft as an as-

sembly (Fig. 1).

12.

Remove the bumpei from the

upper arm.

Installation

1.

Position the bumper to the upper

arm and install the nut and washer.

Torque the nut to specifications.

2.

Position the upper arm inner

shaft to the frame side rail and install

the 2 attaching bolts and washers

snug.

3.

Connect the upper ball joint stud

to the spindle and install the attaching

nut. Torque the nut to specification

and continue to tighten the nut until

the cotter pin hole in the stud is in

line with the nut slots. Then, install

the cotter pin.

4.

If equipped with drum type bra-

kes—Adjust the brakes as outlined in

Part 2-2. Install the wheel, tire, and

drum to the spindle and adjust the

wheel bearings as outlined in Part

3-12.

5.

If equipped with disc brak-

es—Install the wheel and tire on the

hub and adjust the wheel bearings as

outlined in Part 3-12.

6. Install the hub cap or wheel

cover.

7.

Remove the safety stands and

lower the front of the vehicle.

8. Check caster, camber, and toe-in

and adjust as required (Section 2, Part

3-D.

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1.

Raise the front of the vehicle,

position safety stands under the

frame, and lower the vehicle slightly.

2.

Remove the wheel and tire.

3.

Remove the shock absorber

lower attaching nuts and washers.

4.

Remove the shock absorber

upper mounting bracket attaching

nuts,

and remove the shock absorber

and bracket as an assembly (Fig. 26).

On all 8-cylinder vehicles, remove

the air cleaner to obtain access for

tool installation.

5.

Install the spring compressor

tool and compress the spring (Figs.

19,

20 and 21).

6. Position a safety stand under the

lower arm.

7.

Remove the cotter pin from the

nut on the upper ball joint stud, and

loosen the nut one or two turns. Do

not remove the nut from the stud at

this time.

8. Position the ball joint remover

tool between the upper and lower ball

joint studs as shown in Fig. 10. The

tool should seat firmly against the

ends of both studs and not against the

stud nuts.

9. Turn the tool with a wrench until

the tool places the studs under consid-

erable tension; then, hit the spindle

smartly near the upper stud with a

hammer to break the stud loose in the

spindle. Do not loosen the stud in the

spindle with tool pressure only. If

both arms are being removed, loosen

the lower stud in the same manner as

the upper stud.

10.

Remove the nut from the upper

stud and lift the stud out of the

spindle.

11.

Remove the upper arm inner

shaft attaching nuts from the engine

compartment, and remove the upper

arm.

12.

Wipe off all loose dirt from the

upper arm parts. Do not wash the ball

joint with a solvent.

Installation

1.

Position the upper arm on the

underbody mounting bracket, and in-

stall the nuts and lock washers on the

two inner shaft attaching bolts. The

specified keystone-type lock washers

must be used. Torque the nuts to

soecification.

2.

Position the upper ball joint stud

in the top of the wheel spindle, and in-

stall the stud nut. Torque the nut to

specification, and continue to tighten

it until the cotter pin hole and slots

line up. Install a new cotter pin.

3.

Release the coil spring, remove

the tool, and install the front shock

absorber and the wheel and tire.

LINCOLN CONTINENTAL

Removal

1.

Place a jack under the outer end

of the suspension lower arm and raise

the arm. Refer to Fig. 22.

2.

Remove the wheel and tire.

3.

Remove the cotter pin from the

upper ball joint stud. Loosen the nut

one or two turns.

4.

Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig.

13.

The tool should seat firmly against

the ends of both studs, and not

against the upper stud nut.

5.

Turn the wrench until both studs

are under tension, and then, tap the

spindle with a hammer near the upper

stud to loosen it from the spindle. Do

not loosen the stud with tool pressure

alone. Remove the nut.

UPPER MOUNTING BRACKET

LOWER RETAINING BOLTS F 1490-A

FIG. 26—Removing or Installing

Front Shock Absorber—Typicalprocarmanuals.com

Page 107 of 413

03-03-02

Automatic Air Leveling System

03-03-02

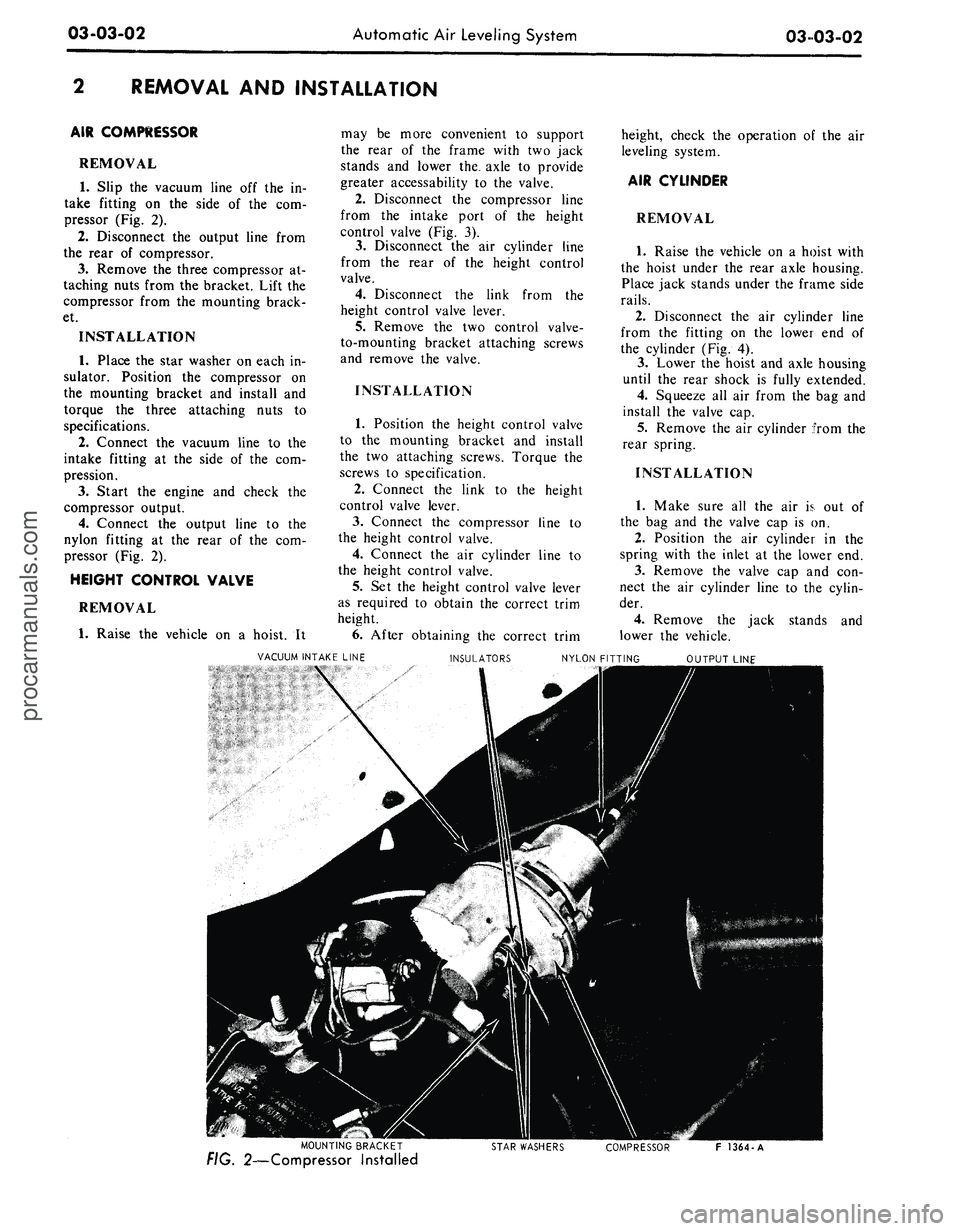

REMOVAL AND INSTALLATION

AIR COMPRESSOR

REMOVAL

1.

Slip the vacuum line off the in-

take fitting on the side of the com-

pressor (Fig. 2).

2.

Disconnect the output line from

the rear of compressor.

3.

Remove the three compressor at-

taching nuts from the bracket. Lift the

compressor from the mounting brack-

et.

INSTALLATION

1.

Place the star washer on each in-

sulator. Position the compressor on

the mounting bracket and install and

torque the three attaching nuts to

specifications.

2.

Connect the vacuum line to the

intake fitting at the side of the com-

pression.

3.

Start the engine and check the

compressor output.

4.

Connect the output line to the

nylon fitting at the rear of the com-

pressor (Fig. 2).

HEIGHT CONTROL VALVE

REMOVAL

1.

Raise the vehicle on a hoist. It

may be more convenient to support

the rear of the frame with two jack

stands and lower the, axle to provide

greater accessability to the valve.

2.

Disconnect the compressor line

from the intake port of the height

control valve (Fig. 3).

3.

Disconnect the air cylinder line

from the rear of the height control

valve.

4.

Disconnect the link from the

height control valve lever.

5.

Remove the two control valve-

to-mounting bracket attaching screws

and remove the valve.

INSTALLATION

1.

Position the height control valve

to the mounting bracket and install

the two attaching screws. Torque the

screws to specification.

2.

Connect the link to the height

control valve lever.

3.

Connect the compressor line to

the height control valve.

4.

Connect the air cylinder line to

the height control valve.

5.

Set the height control valve lever

as required to obtain the correct trim

height.

6. After obtaining the correct trim

height, check the operation of the air

leveling system.

AIR CYLINDER

REMOVAL

1.

Raise the vehicle on a hoist with

the hoist under the rear axle housing.

Place jack stands under the frame side

rails.

2.

Disconnect the air cylinder line

from the fitting on the lower end of

the cylinder (Fig. 4).

3.

Lower the hoist and axle housing

until the rear shock is fully extended.

4.

Squeeze all air from the bag and

install the valve cap.

5.

Remove the air cylinder from the

rear spring.

INSTALLATION

1.

Make sure all the air is out of

the bag and the valve cap is on.

2.

Position the air cylinder in the

spring with the inlet at the lower end.

3.

Remove the valve cap and con-

nect the air cylinder line to the cylin-

der.

4.

Remove the jack stands and

lower the vehicle.

VACUUM INTAKE LINE

INSULATORS

NYLON FITTING

MOUNTING BRACKET

FIG. 2—Compressor Installed

STAR WASHERS

COMPRESSOR

F 1364-Aprocarmanuals.com

Page 112 of 413

03-04-03

Automatic Air Leveling System — Lincoln Continental

03-04-03

outlet lines to their respective parts.

3.

Adjust the trim height as de-

tailed in Section 4.

4.

Connect the link to the arm.

5.

Remove the jack stands and

lower the vehicle.

SUPER LIFT SHOCK ABSORBER

REMOVAL

1.

Raise the vehicle and place jack

stands under the axle to compress the

super lift.

2.

Loosen the air line or lines (right

super lift) slowly to release the air

from the system. Then, disconnect the

line or lines.

3.

Remove the three mounting plate

attaching screws from the upper end

of the super lift.

4.

Remove the attaching nut and

washer from the lower end of the

super lift and remove it from the vehi-

cle.

5.

Remove the nut, outer washer

and the insulator that attach the super

lift to the mounting plate. Remove the

plate, remaining insulator and washer.

INSTALLATION

1.

Position a washer, insulator,

mounting plate, insulator, washer and

nut on the stud at the upper end of

the super lift. Torque the nut to speci-

fication.

2.

Install the mounting plate, outer

insulator, washer and nut on the stud.

Torque the nut to specification.

3.

Attach the mounting plate and

shock absorber to the crossmember

with the attaching screws to specifica-

tions.

4.

Connect the lower end of the

super lift to the mounting stud with

the washers and attaching nut. Torque

the nut to specification.

5.

Connect the air line or lines

(right super lift) to the super lift.

6. Start the engine and check for

leaks.

3 IN-VEHICLE ADJUSTMENTS AND REPAIRS

REGULATOR ADJUSTMENT HEIGHT CONTROL VALVE

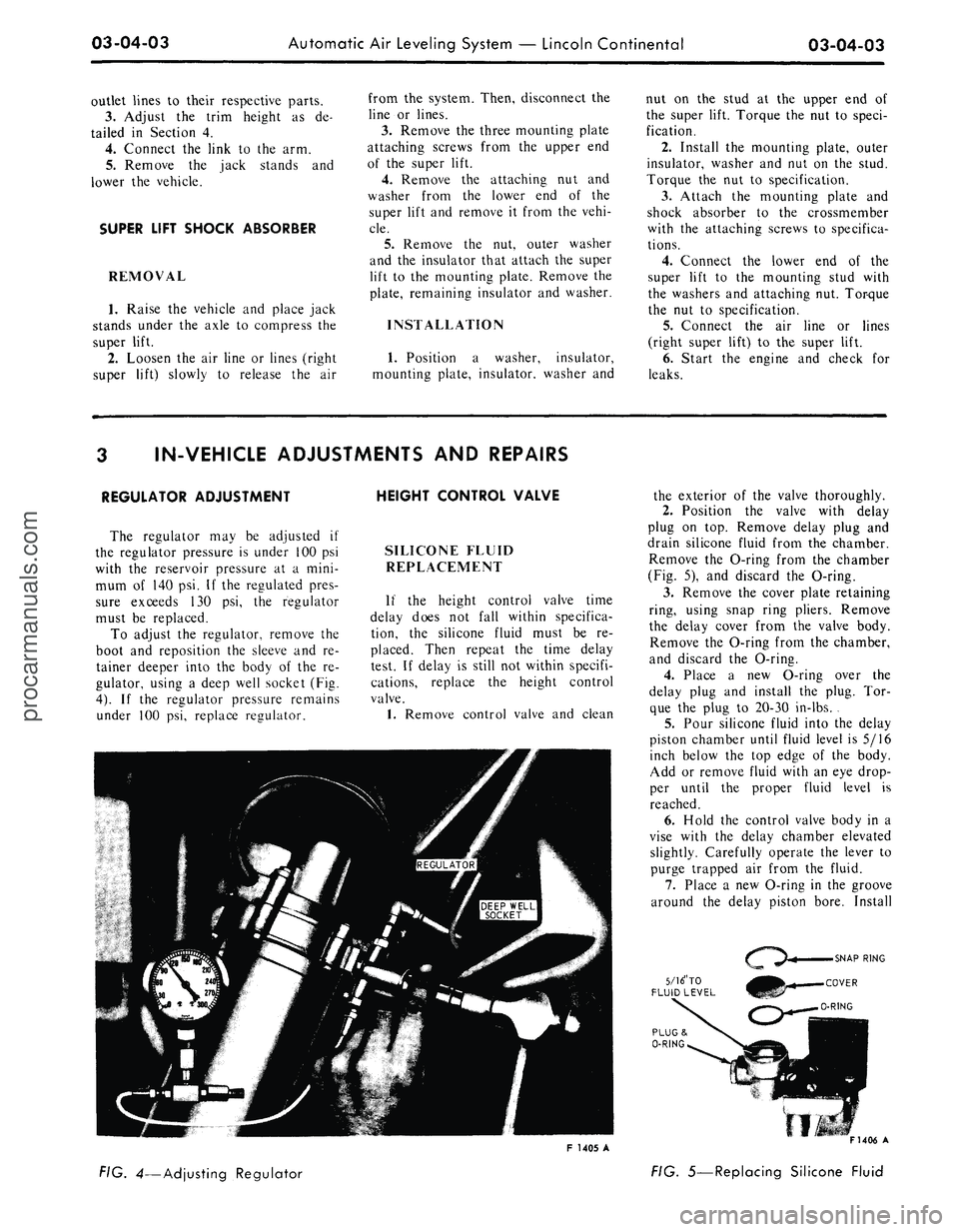

The regulator may be adjusted if

the regulator pressure is under 100 psi

with the reservoir pressure at a mini-

mum of 140 psi. If the regulated pres-

sure exceeds 130 psi, the regulator

must be replaced.

To adjust the regulator, remove the

boot and reposition the sleeve and re-

tainer deeper into the body of the re-

gulator, using a deep well socket (Fig.

4).

If the regulator pressure remains

under 100 psi, replace regulator.

SILICONE FLUID

REPLACEMENT

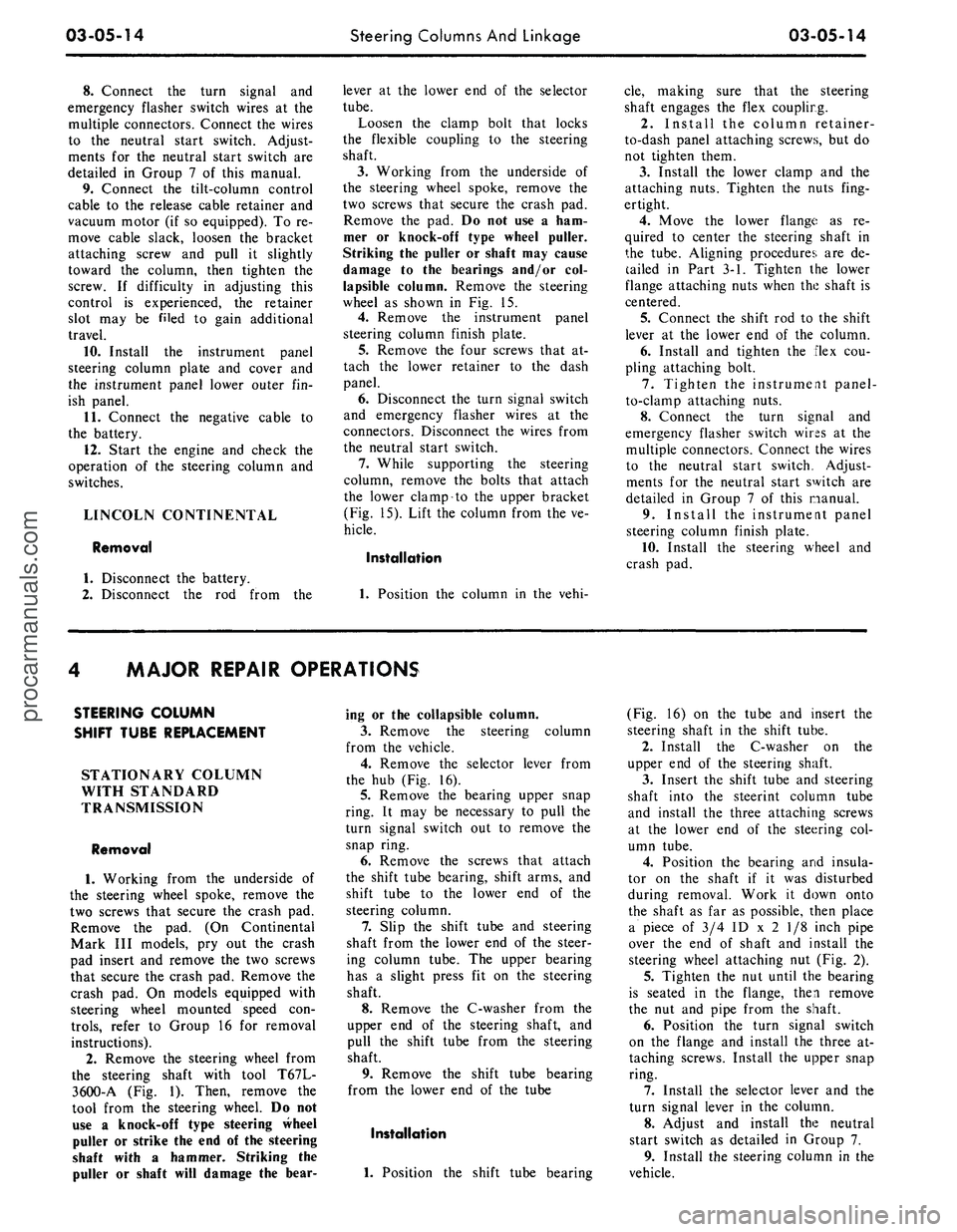

If the height control valve time

delay does not fall within specifica-

tion, the silicone fluid must be re-

placed. Then repeat the time delay

test. If delay is still not within specifi-

cations, replace the height control

valve.

1.

Remove control valve and clean

the exterior of the valve thoroughly.

2.

Position the valve with delay

plug on top. Remove delay plug and

drain silicone fluid from the chamber.

Remove the O-ring from the chamber

(Fig. 5), and discard the O-ring.

3.

Remove the cover plate retaining

ring, using snap ring pliers. Remove

the delay cover from the valve body.

Remove the O-ring from the chamber,

and discard the O-ring.

4.

Place a new O-ring over the

delay plug and install the plug. Tor-

que the plug to 20-30 in-lbs. .

5.

Pour silicone fluid into the delay

piston chamber until fluid level is 5/16

inch below the top edge of the body.

Add or remove fluid with an eye drop-

per until the proper fluid level is

reached.

6. Hold the control valve body in a

vise with the delay chamber elevated

slightly. Carefully operate the lever to

purge trapped air from the fluid.

7.

Place a new O-ring in the groove

around the delay piston bore. Install

5/16" TO

FLUID LEVEL

F 1405 A

FIG. 4—Adjusting Regulator

F1406 A

FIG. 5—Replacing Silicone Fluidprocarmanuals.com

Page 127 of 413

03-05-14

Steering Columns And Linkage

03-05-14

8. Connect the turn signal and

emergency flasher switch wires at the

multiple connectors. Connect the wires

to the neutral start switch. Adjust-

ments for the neutral start switch are

detailed in Group 7 of this manual.

9. Connect the tilt-column control

cable to the release cable retainer and

vacuum motor (if so equipped). To re-

move cable slack, loosen the bracket

attaching screw and pull it slightly

toward the column, then tighten the

screw. If difficulty in adjusting this

control is experienced, the retainer

slot may be filed to gain additional

travel.

10.

Install the instrument panel

steering column plate and cover and

the instrument panel lower outer fin-

ish panel.

11.

Connect the negative cable to

the battery.

12.

Start the engine and check the

operation of the steering column and

switches.

LINCOLN CONTINENTAL

Removal

1.

Disconnect the battery.

2.

Disconnect the rod from the

lever at the lower end of the selector

tube.

Loosen the clamp bolt that locks

the flexible coupling to the steering

shaft.

3.

Working from the underside of

the steering wheel spoke, remove the

two screws that secure the crash pad.

Remove the pad. Do not use a ham-

mer or knock-off type wheel puller.

Striking the puller or shaft may cause

damage to the bearings and/or col-

lapsible column. Remove the steering

wheel as shown in Fig. 15.

4.

Remove the instrument panel

steering column finish plate.

5.

Remove the four screws that at-

tach the lower retainer to the dash

panel.

6. Disconnect the turn signal switch

and emergency flasher wires at the

connectors. Disconnect the wires from

the neutral start switch.

7.

While supporting the steering

column, remove the bolts that attach

the lower clamp to the upper bracket

(Fig. 15). Lift the column from the ve-

hicle.

Installation

1.

Position the column in the vehi-

cle,

making sure that the steering

shaft engages the flex coupling.

2.

Install the column retainer-

to-dash panel attaching screws, but do

not tighten them.

3.

Install the lower clamp and the

attaching nuts. Tighten the nuts fing-

ertight.

4.

Move the lower flange as re-

quired to center the steering shaft in

the tube. Aligning procedures are de-

tailed in Part 3-1. Tighten the lower

flange attaching nuts when the shaft is

centered.

5.

Connect the shift rod to the shift

lever at the lower end of the column.

6. Install and tighten the flex cou-

pling attaching bolt.

7.

Tighten the instrument panel-

to-clamp attaching nuts.

8. Connect the turn signal and

emergency flasher switch wirss at the

multiple connectors. Connect the wires

to the neutral start switch. Adjust-

ments for the neutral start switch are

detailed in Group 7 of this manual.

9. Install the instrument panel

steering column finish plate.

10.

Install the steering wheel and

crash pad.

MAJOR REPAIR OPERATIONS

STEERING COLUMN

SHIFT TUBE REPLACEMENT

STATIONARY COLUMN

WITH STANDARD

TRANSMISSION

Removal

1.

Working from the underside of

the steering wheel spoke, remove the

two screws that secure the crash pad.

Remove the pad. (On Continental

Mark III models, pry out the crash

pad insert and remove the two screws

that secure the crash pad. Remove the

crash pad. On models equipped with

steering wheel mounted speed con-

trols,

refer to Group 16 for removal

instructions).

2.

Remove the steering wheel from

the steering shaft with tool T67L-

3600-A (Fig. 1). Then, remove the

tool from the steering wheel. Do not

use a knock-off type steering Wheel

puller or strike the end of the steering

shaft with a hammer. Striking the

puller or shaft will damage the bear-

ing or the collapsible column.

3.

Remove the steering column

from the vehicle.

4.

Remove the selector lever from

the hub (Fig. 16).

5.

Remove the bearing upper snap

ring. It may be necessary to pull the

turn signal switch out to remove the

snap ring.

6. Remove the screws that attach

the shift tube bearing, shift arms, and

shift tube to the lower end of the

steering column.

7.

Slip the shift tube and steering

shaft from the lower end of the steer-

ing column tube. The upper bearing

has a slight press fit on the steering

shaft.

8. Remove the C-washer from the

upper end of the steering shaft, and

pull the shift tube from the steering

shaft.

9. Remove the shift tube bearing

from the lower end of the tube

Installation

1.

Position the shift tube bearing

(Fig. 16) on the tube and insert the

steering shaft in the shift tube.

2.

Install the C-washer on the

upper end of the steering shaft.

3.

Insert the shift tube and steering

shaft into the steerint column tube

and install the three attaching screws

at the lower end of the steering col-

umn tube.

4.

Position the bearing and insula-

tor on the shaft if it was disturbed

during removal. Work it down onto

the shaft as far as possible, then place

a piece of 3/4 ID x 2 1/8 inch pipe

over the end of shaft and install the

steering wheel attaching nut (Fig. 2).

5.

Tighten the nut until the bearing

is seated in the flange, then remove

the nut and pipe from the shaft.

6. Position the turn signal switch

on the flange and install the three at-

taching screws. Install the upper snap

ring.

7.

Install the selector lever and the

turn signal lever in the column.

8. Adjust and install the neutral

start switch as detailed in Group 7.

9. Install the steering column in the

vehicle.procarmanuals.com