height FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 104 of 413

03-02-28

Suspension

03-02-28

used, these components should

be re-

placed

on the

bench.

Do not wash the ball joint with sol-

vent.

The

solvent

may

attack parts

within the joint.

BUSHING AND INNER

SHAFT REPLACEMENT

LINCOLN CONTINENTAL

Always replace both upper

arm

bushings,

if

either bushing

is

worn

or

damaged. Install only

new

bushings

when replacing

the

inner shaft. Refer

to Section

3 for

the upper arm remov-

al procedure.

1.

Remove

the

bolts, lock washers,

and flat washers from the ends

of

the

upper arm shaft.

2.

Assemble

the

remover, tool

3044-LA,

to the

shaft

at the

front

bushing. Press

the

bushing

out of the

arm using

the

support cup, tool 6069-

H,

and the

remover tool 3044-AB3

(Fig. 40).

PRESS RAM

FIG.

40

—Removing Upper

Arm

Front Bushing

3.

Remove

the

shaft.

4.

Remove

the

upper

arm

rear

bushing using

the

support

cup,

tool

3069-H, and

the

remover, tool 3069-L

(Fig. 41).

5.

Both upper

arm

bushings

are

pressed into the arm from the outside

toward the inside

of

the arm. To facil-

itate installation, use silicone

or

liquid

oap

as a

lubricant.

See

Fig.

41 for

PRESS RAM

Tool-3069-H

F 1480-A

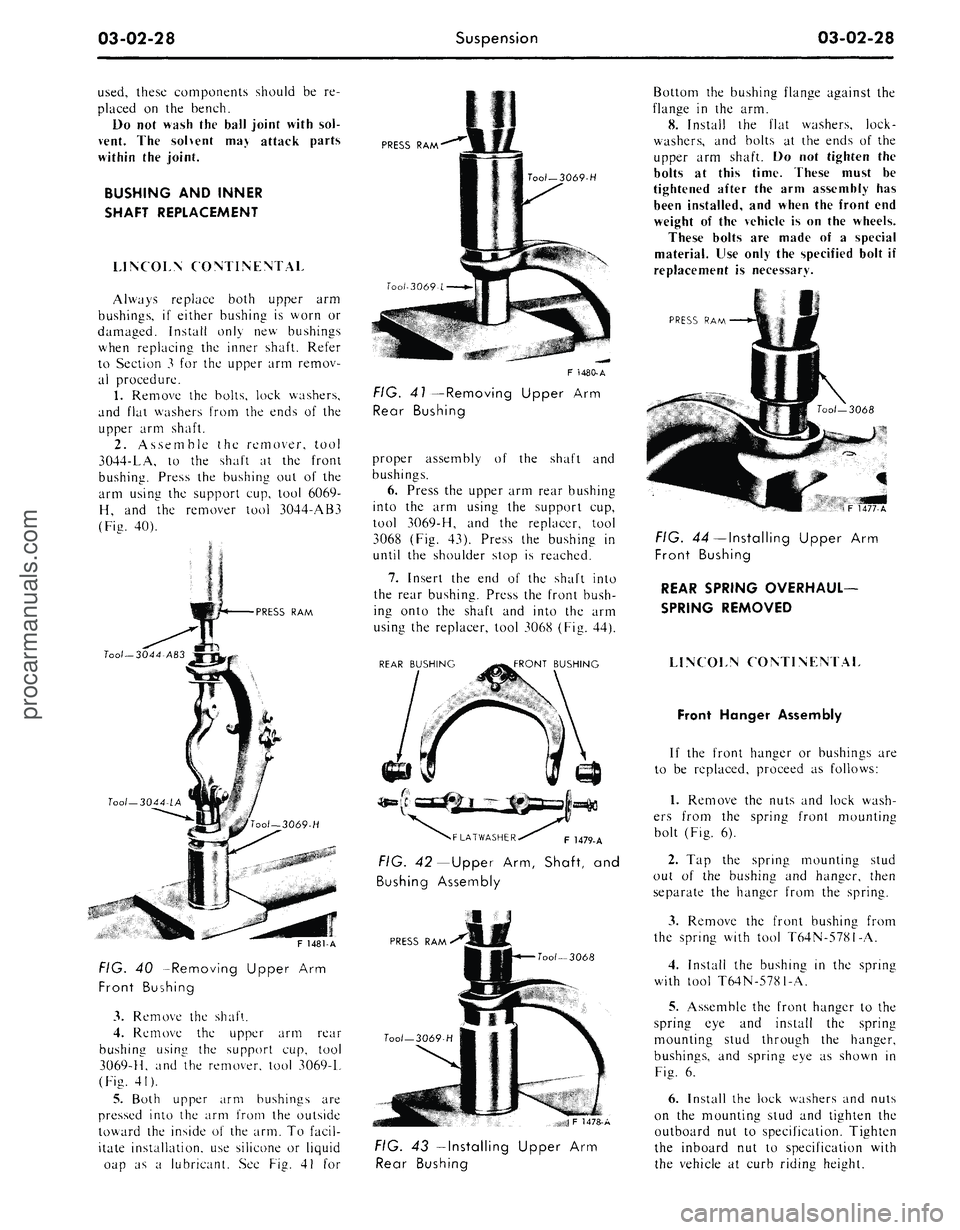

FIG. 41—Removing Upper

Arm

Rear Bushing

proper assembly

of the

shaft

and

bushings.

6. Press the upper arm rear bushing

into

the arm

using

the

support cup,

tool 3069-H,

and the

replacer, tool

3068 (Fig. 43). Press

the

bushing

in

until

the

shoulder stop

is

reached.

7.

Insert

the end of the

shaft into

the rear bushing. Press the front bush-

ing onto

the

shaft

and

into

the arm

using the replacer, tool 3068 (Fig. 44).

REAR BUSHING

FRONT BUSHING

F 1479-A

FIG. 42— Upper Arm, Shaft,

and

Bushing Assembly

PRESS RAM

Tool— 3068

JF 1478-A

Bottom the bushing flange against the

flange

in the

arm.

8. Install

the

flat washers, lock-

washers,

and

bolts

at

the ends

of

the

upper

arm

shaft.

Do not

tighten

the

bolts

at

this time. These must

be

tightened after

the

arm assembly

has

been installed, and when the front end

weight

of

the vehicle

is

on the wheels.

These bolts

are

made

of a

special

material. Use only the specified bolt

if

replacement

is

necessary.

PRESS

RAM

FIG. 43—Installing Upper

Arm

Rear Bushing

FIG. 44—Installing Upper

Arm

Front Bushing

REAR SPRING OVERHAUL-

SPRING REMOVED

LINCOLN CONTINENTAL

Front Hanger Assembly

If

the

front hanger

or

bushings

are

to

be

replaced, proceed

as

follows:

1.

Remove

the

nuts and lock wash-

ers from

the

spring front mounting

bolt (Fig.

6).

2.

Tap the

spring mounting stud

out

of the

bushing

and

hanger, then

separate

the

hanger from

the

spring.

3.

Remove

the

front bushing from

the spring with tool T64N-5781-A.

4.

Install

the

bushing

in the

spring

with tool T64N-5781-A.

5.

Assemble the front hanger

to

the

spring

eye and

install

the

spring

mounting stud through

the

hanger,

bushings,

and

spring eye

as

shown

in

Fig.

6.

6. Install the lock washers and nuts

on

the

mounting stud

and

tighten

the

outboard

nut to

specification. Tighten

the inboard

nut to

specification with

the vehicle

at

curb riding height.procarmanuals.com

Page 106 of 413

03-03-01

Automatic

Air

Leveling System

03-03-01

PART

3-3

Automatic

Air

Leveling System

COMPONENT INDEX

AIR COMPRESSOR

Disassembly

and

Overhaul

Removal

and

Installation

AIR CYLINDER

Removal

and

Installation

DESCRIPTION

HEIGHT CONTROL VALVE

Disassembly

and

Overhaul

Removal

and

Installation

MODEL APPLICATION

All

Models

Ford

03-03

03-02

03-02

03-01

03-03

03-02

Mercury

03-03

03-02

03-02

03-01

03-03

03-02

Meteor

03-03

03-02

03-02

03-01

03-03

03-02

Cougar

N/A

N/A

N/A

N/A

N/A

N/A

Fairlane

N/A

N/A

N/A

N/A

N/A

N/A

A page number indicates that the item

is for the

vehicle listed

at

the head

of

the column.

N/A indicates that

the

item

is not

applicable

to the

vehicle listed.

Falcon

N/A

N/A

N/A

N/A

N/A

N/A

Montego

N/A

N/A

N/A

N/A

N/A

N/A

Mustang

N/A

N/A

N/A

N/A

N/A

N/A

Lincoln-

Continental

N/A

N/A

N/A

N/A

N/A

N/A

Thunderbird

N/A

N/A

N/A

N/A

N/A

N/A

Continental-

Mark III

N/A

N/A

N/A

N/A

N/A

N/A

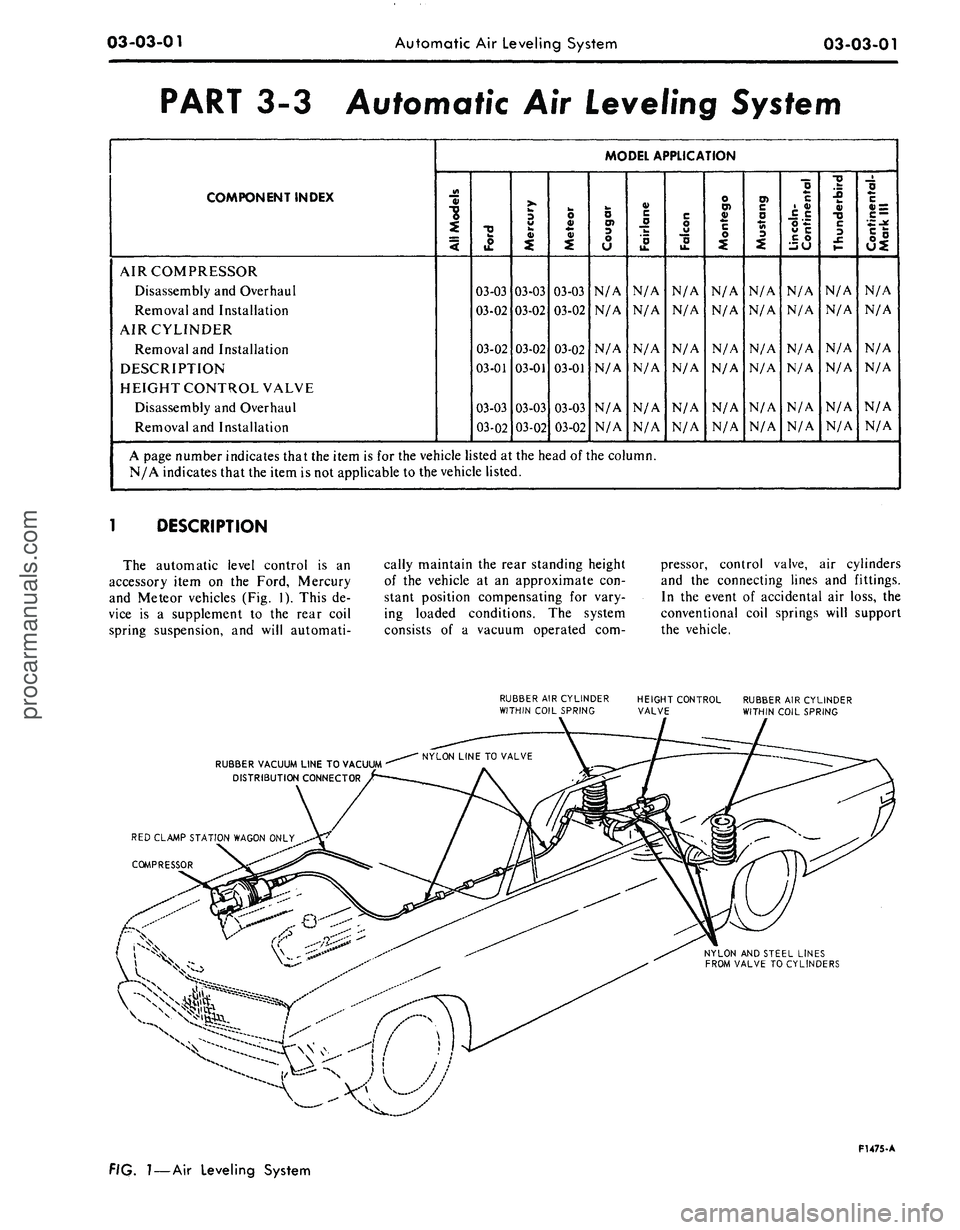

DESCRIPTION

The automatic level control

is an

accessory item

on the

Ford, Mercury

and Meteor vehicles

(Fig. 1).

This

de-

vice

is a

supplement

to the

rear coil

spring suspension,

and

will automati-

cally maintain

the

rear standing height

of

the

vehicle

at an

approximate

con-

stant position compensating

for

vary-

ing loaded conditions.

The

system

consists

of a

vacuum operated

com-

pressor, control valve,

air

cylinders

and

the

connecting lines

and

fittings.

In

the

event

of

accidental

air

loss,

the

conventional coil springs will support

the vehicle.

RUBBER

AIR

CYLINDER

WITHIN COIL SPRING

HEIGHT CONTROL

VALVE

RUBBER

AIR

CYLINDER

WITHIN COIL SPRING

RUBBER VACUUM LINE

TO

VACUUM

DISTRIBUTION CONNECTOR

RED CLAMP STATION WAGON ONLY

COMPRESSOR

NYLON

AND

STEEL LINES

FROM VALVE

TO

CYLINDERS

FIG.

1

—

Air Leveling System

FT475-A

procarmanuals.com

Page 107 of 413

03-03-02

Automatic Air Leveling System

03-03-02

REMOVAL AND INSTALLATION

AIR COMPRESSOR

REMOVAL

1.

Slip the vacuum line off the in-

take fitting on the side of the com-

pressor (Fig. 2).

2.

Disconnect the output line from

the rear of compressor.

3.

Remove the three compressor at-

taching nuts from the bracket. Lift the

compressor from the mounting brack-

et.

INSTALLATION

1.

Place the star washer on each in-

sulator. Position the compressor on

the mounting bracket and install and

torque the three attaching nuts to

specifications.

2.

Connect the vacuum line to the

intake fitting at the side of the com-

pression.

3.

Start the engine and check the

compressor output.

4.

Connect the output line to the

nylon fitting at the rear of the com-

pressor (Fig. 2).

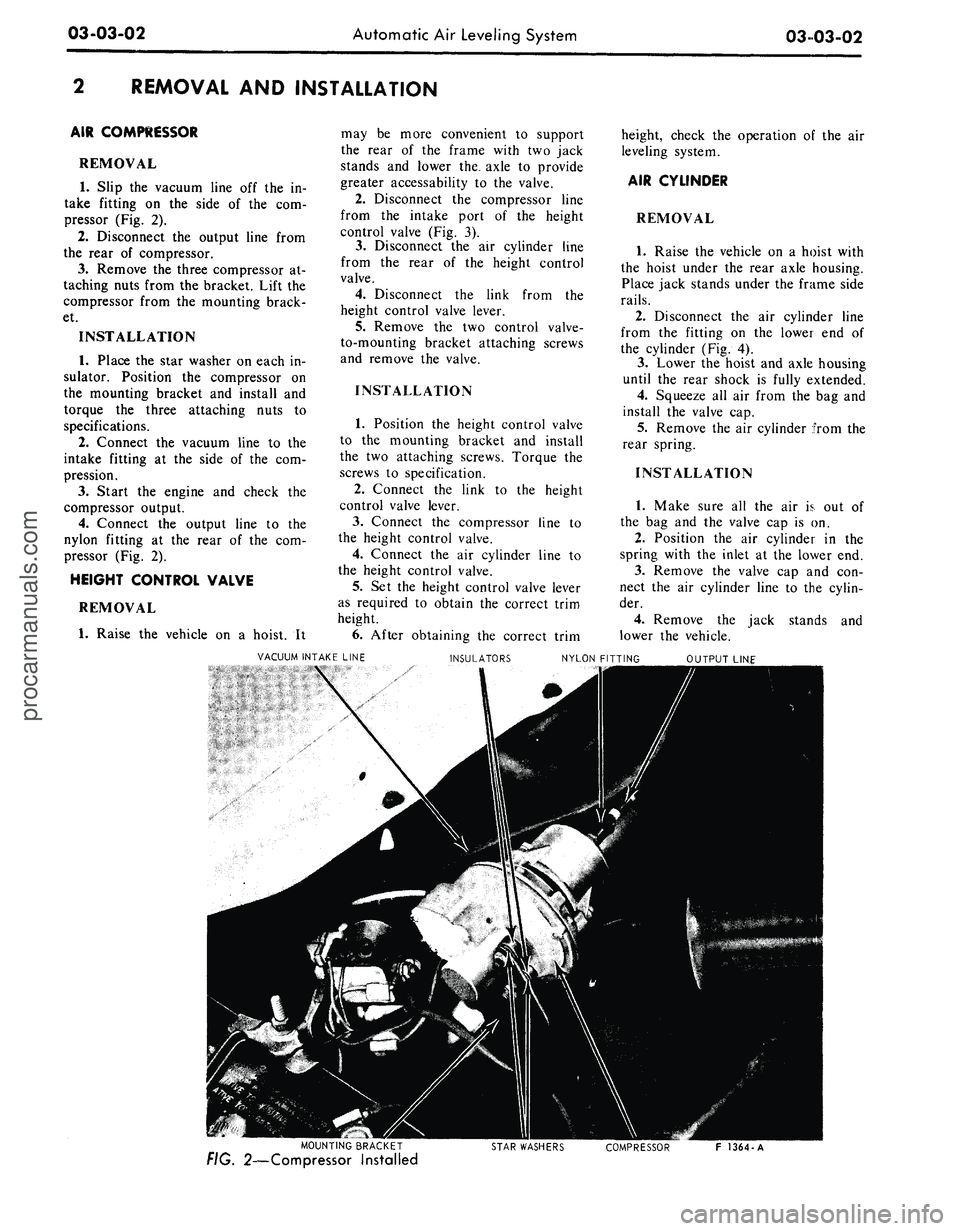

HEIGHT CONTROL VALVE

REMOVAL

1.

Raise the vehicle on a hoist. It

may be more convenient to support

the rear of the frame with two jack

stands and lower the, axle to provide

greater accessability to the valve.

2.

Disconnect the compressor line

from the intake port of the height

control valve (Fig. 3).

3.

Disconnect the air cylinder line

from the rear of the height control

valve.

4.

Disconnect the link from the

height control valve lever.

5.

Remove the two control valve-

to-mounting bracket attaching screws

and remove the valve.

INSTALLATION

1.

Position the height control valve

to the mounting bracket and install

the two attaching screws. Torque the

screws to specification.

2.

Connect the link to the height

control valve lever.

3.

Connect the compressor line to

the height control valve.

4.

Connect the air cylinder line to

the height control valve.

5.

Set the height control valve lever

as required to obtain the correct trim

height.

6. After obtaining the correct trim

height, check the operation of the air

leveling system.

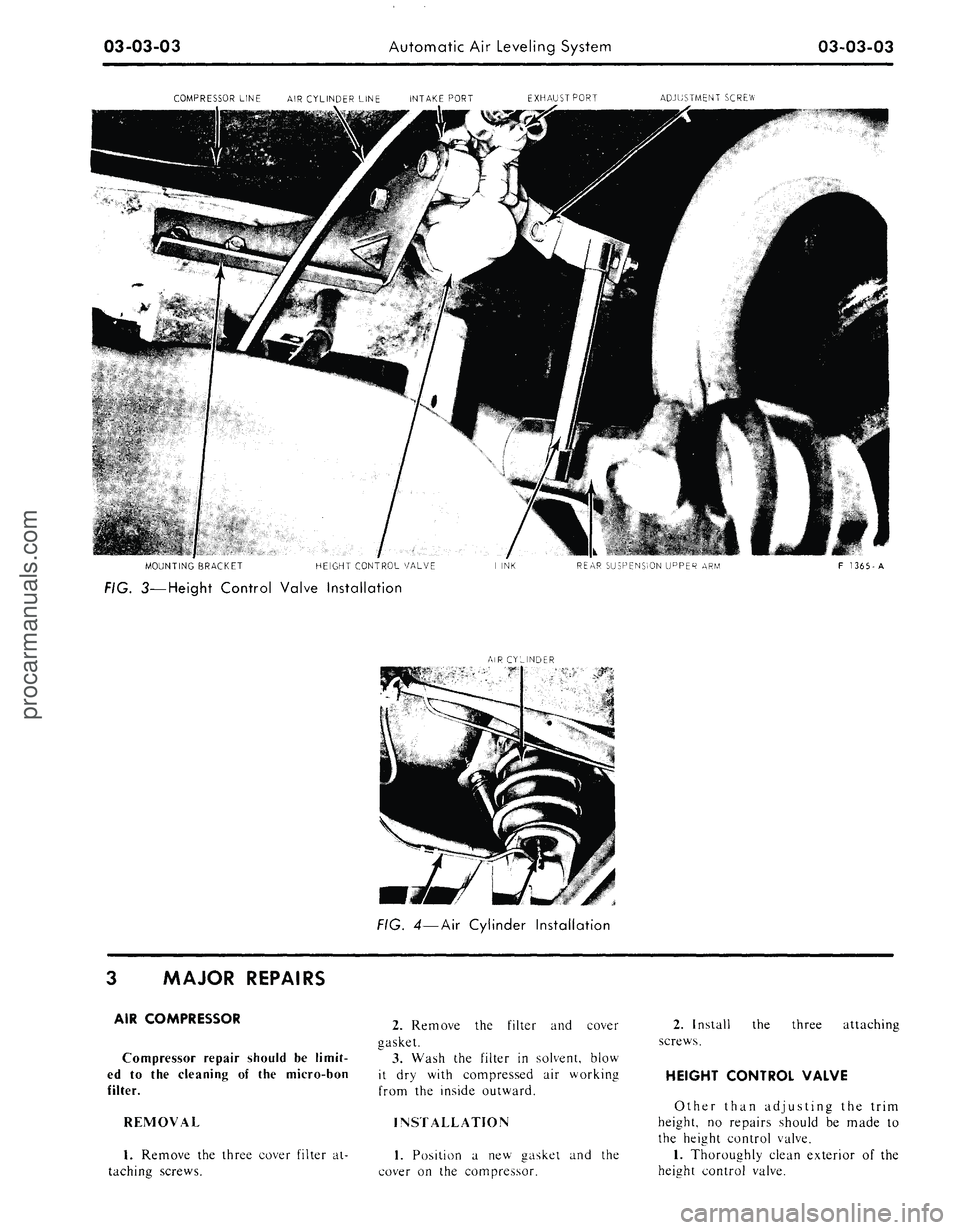

AIR CYLINDER

REMOVAL

1.

Raise the vehicle on a hoist with

the hoist under the rear axle housing.

Place jack stands under the frame side

rails.

2.

Disconnect the air cylinder line

from the fitting on the lower end of

the cylinder (Fig. 4).

3.

Lower the hoist and axle housing

until the rear shock is fully extended.

4.

Squeeze all air from the bag and

install the valve cap.

5.

Remove the air cylinder from the

rear spring.

INSTALLATION

1.

Make sure all the air is out of

the bag and the valve cap is on.

2.

Position the air cylinder in the

spring with the inlet at the lower end.

3.

Remove the valve cap and con-

nect the air cylinder line to the cylin-

der.

4.

Remove the jack stands and

lower the vehicle.

VACUUM INTAKE LINE

INSULATORS

NYLON FITTING

MOUNTING BRACKET

FIG. 2—Compressor Installed

STAR WASHERS

COMPRESSOR

F 1364-Aprocarmanuals.com

Page 108 of 413

03-03-03

Automatic Air Leveling System

03-03-03

COMPRESSOR LINE

AIR

CYLINDER LINE INTAKE PORT EXHAUSTPORT

ADJUSTMENT SCREW

MOUNTING BRACKET

HEIGHT CONTROL VALVE

REAR SUSPENSION UPPER

ARM

FIG. 3—Height Control Valve Installation

Al R CYLINDER

F 1365-A

FIG. 4—Air Cylinder Installation

3 MAJOR REPAIRS

AIR COMPRESSOR

Compressor repair should

be

limit-

ed

to the

cleaning

of the

micro-bon

filter.

REMOVAL

1.

Remove

the

three cover filter

at-

taching screws.

2.

Remove

the

filter

and

cover

gasket.

3.

Wash

the

filter

in

solvent, blow

it

dry

with compressed

air

working

from

the

inside outward.

INSTALLATION

1.

Position

a new

gasket

and the

cover

on the

compressor.

2.

Install

the

three attaching

screws.

HEIGHT CONTROL VALVE

Other than adjusting

the

trim

height,

no

repairs should

be

made

to

the height control valve.

1.

Thoroughly clean exterior

of the

height control valve.procarmanuals.com

Page 111 of 413

03-04-02

Automatic Air Leveling System — Lincoln Continental

03-04-02

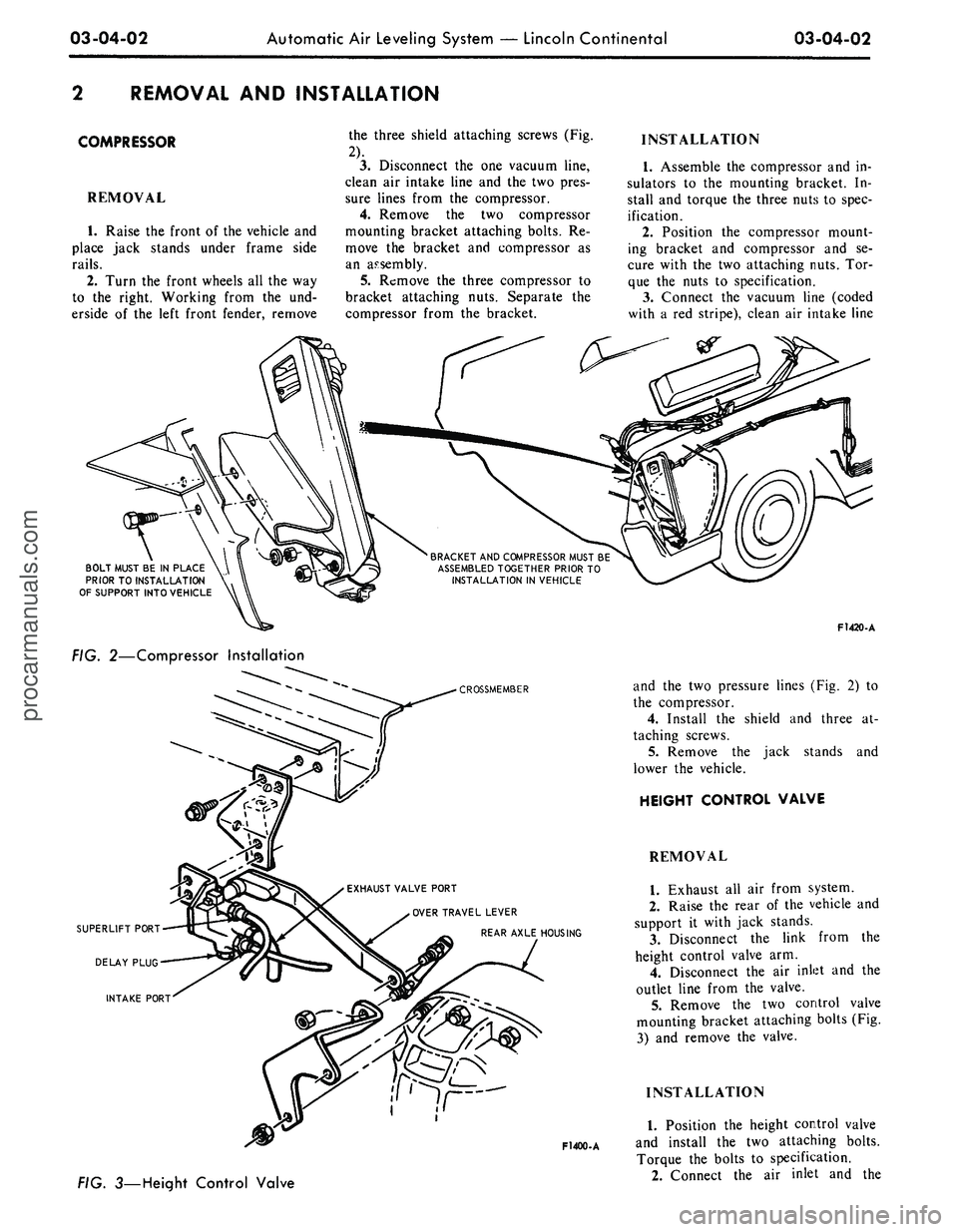

REMOVAL AND INSTALLATION

COMPRESSOR

REMOVAL

1.

Raise the front of the vehicle and

place jack stands under frame side

rails.

2.

Turn the front wheels all the way

to the right. Working from the und-

erside of the left front fender, remove

the three shield attaching screws (Fig.

2).

3.

Disconnect the one vacuum line,

clean air intake line and the two pres-

sure lines from the compressor.

4.

Remove the two compressor

mounting bracket attaching bolts. Re-

move the bracket and compressor as

an assembly.

5.

Remove the three compressor to

bracket attaching nuts. Separate the

compressor from the bracket.

INSTALLATION

1.

Assemble the compressor and in-

sulators to the mounting bracket. In-

stall and torque the three nuts to spec-

ification.

2.

Position the compressor mount-

ing bracket and compressor and se-

cure with the two attaching nuts. Tor-

que the nuts to specification.

3.

Connect the vacuum line (coded

with a red stripe), clean air intake line

BRACKET

AND

COMPRESSOR

MUST

BE

ASSEMBLED

TOGETHER

PRIOR

TO

INSTALLATION

IN

VEHICLE

BOLT MUST

BE IN

PLACE

PRIOR

TO

INSTALLATION

OF

SUPPORT

INTO

VEHICLE

FIG. 2—Compressor Installation

CROSSMEMBER

EXHAUST

VALVE PORT

OVER

TRAVEL

LEVER

REAR AXLE

HOUSING

F1400-A

3—Height Control Valve

F1420-A

and the two pressure lines (Fig. 2) to

the compressor.

4.

Install the shield and three at-

taching screws.

5.

Remove the jack stands and

lower the vehicle.

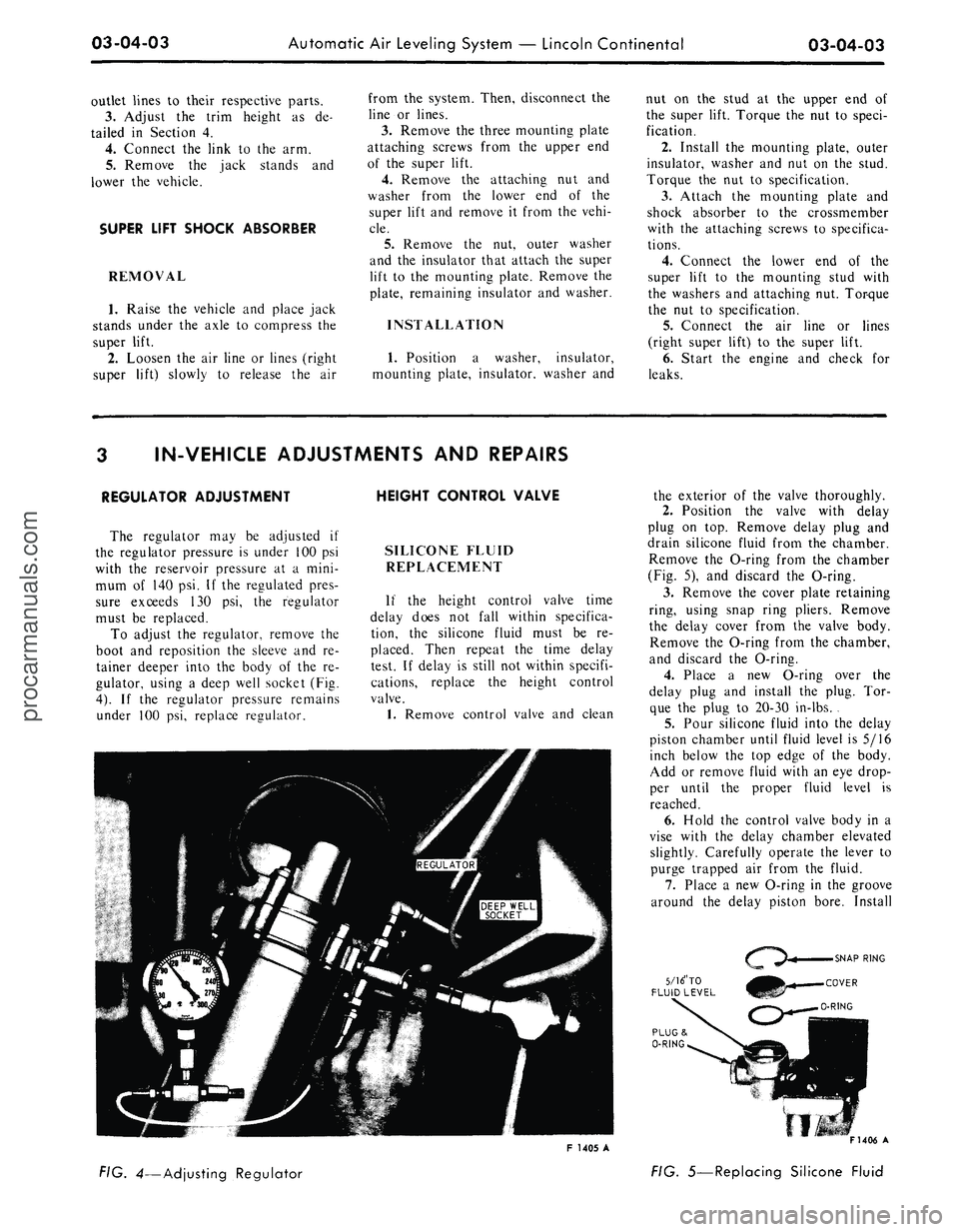

HEIGHT CONTROL VALVE

REMOVAL

1.

Exhaust all air from system.

2.

Raise the rear of the vehicle and

support it with jack stands.

3.

Disconnect the link from the

height control valve arm.

4.

Disconnect the air inlet and the

outlet line from the valve.

5.

Remove the two control valve

mounting bracket attaching bolts (Fig.

3) and remove the valve.

INSTALLATION

1.

Position the height control valve

and install the two attaching bolts.

Torque the bolts to specification.

2.

Connect the air inlet and theprocarmanuals.com

Page 112 of 413

03-04-03

Automatic Air Leveling System — Lincoln Continental

03-04-03

outlet lines to their respective parts.

3.

Adjust the trim height as de-

tailed in Section 4.

4.

Connect the link to the arm.

5.

Remove the jack stands and

lower the vehicle.

SUPER LIFT SHOCK ABSORBER

REMOVAL

1.

Raise the vehicle and place jack

stands under the axle to compress the

super lift.

2.

Loosen the air line or lines (right

super lift) slowly to release the air

from the system. Then, disconnect the

line or lines.

3.

Remove the three mounting plate

attaching screws from the upper end

of the super lift.

4.

Remove the attaching nut and

washer from the lower end of the

super lift and remove it from the vehi-

cle.

5.

Remove the nut, outer washer

and the insulator that attach the super

lift to the mounting plate. Remove the

plate, remaining insulator and washer.

INSTALLATION

1.

Position a washer, insulator,

mounting plate, insulator, washer and

nut on the stud at the upper end of

the super lift. Torque the nut to speci-

fication.

2.

Install the mounting plate, outer

insulator, washer and nut on the stud.

Torque the nut to specification.

3.

Attach the mounting plate and

shock absorber to the crossmember

with the attaching screws to specifica-

tions.

4.

Connect the lower end of the

super lift to the mounting stud with

the washers and attaching nut. Torque

the nut to specification.

5.

Connect the air line or lines

(right super lift) to the super lift.

6. Start the engine and check for

leaks.

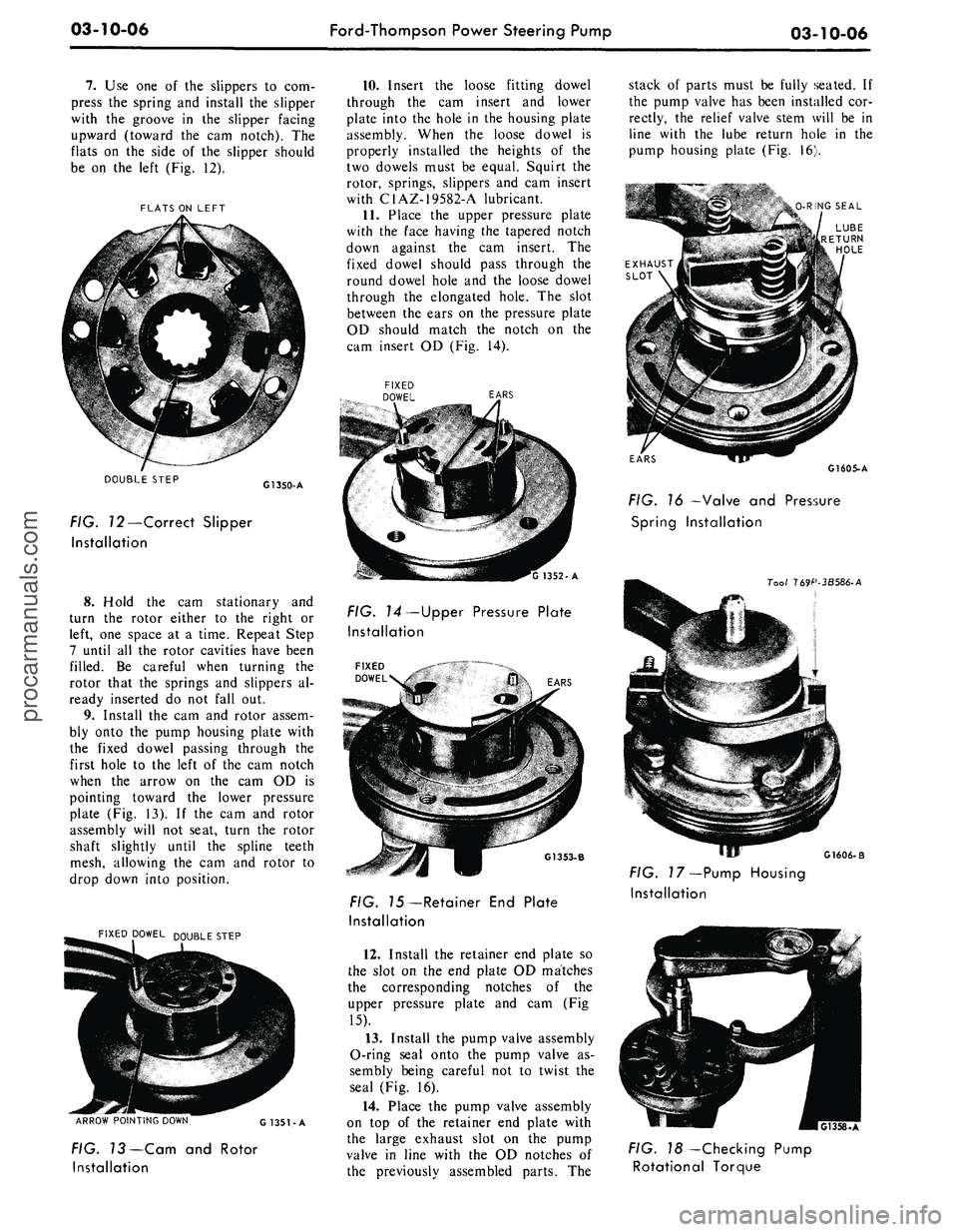

3 IN-VEHICLE ADJUSTMENTS AND REPAIRS

REGULATOR ADJUSTMENT HEIGHT CONTROL VALVE

The regulator may be adjusted if

the regulator pressure is under 100 psi

with the reservoir pressure at a mini-

mum of 140 psi. If the regulated pres-

sure exceeds 130 psi, the regulator

must be replaced.

To adjust the regulator, remove the

boot and reposition the sleeve and re-

tainer deeper into the body of the re-

gulator, using a deep well socket (Fig.

4).

If the regulator pressure remains

under 100 psi, replace regulator.

SILICONE FLUID

REPLACEMENT

If the height control valve time

delay does not fall within specifica-

tion, the silicone fluid must be re-

placed. Then repeat the time delay

test. If delay is still not within specifi-

cations, replace the height control

valve.

1.

Remove control valve and clean

the exterior of the valve thoroughly.

2.

Position the valve with delay

plug on top. Remove delay plug and

drain silicone fluid from the chamber.

Remove the O-ring from the chamber

(Fig. 5), and discard the O-ring.

3.

Remove the cover plate retaining

ring, using snap ring pliers. Remove

the delay cover from the valve body.

Remove the O-ring from the chamber,

and discard the O-ring.

4.

Place a new O-ring over the

delay plug and install the plug. Tor-

que the plug to 20-30 in-lbs. .

5.

Pour silicone fluid into the delay

piston chamber until fluid level is 5/16

inch below the top edge of the body.

Add or remove fluid with an eye drop-

per until the proper fluid level is

reached.

6. Hold the control valve body in a

vise with the delay chamber elevated

slightly. Carefully operate the lever to

purge trapped air from the fluid.

7.

Place a new O-ring in the groove

around the delay piston bore. Install

5/16" TO

FLUID LEVEL

F 1405 A

FIG. 4—Adjusting Regulator

F1406 A

FIG. 5—Replacing Silicone Fluidprocarmanuals.com

Page 113 of 413

03-04-04 Automatic Air Leveling System — Lincoln Continental 03-04-04

the cover and secure it with a snap down. Move the overtravel lever up vehicle. If delay is not within 4-18 sec-

ring, using snap ring pliers. and down for one minute to vent air onds, recheck the fluid level in the

8. Place the control valve vertically from the delay piston pin chamber. delay chamber. If the level is within

in a vise with the delay chamber Perform a time delay check off the specifications, replace the valve.

9. Install the height control valve.procarmanuals.com

Page 167 of 413

03-10-06

Ford-Thompson Power Steering Pump

03-10-06

7.

Use one of the slippers to com-

press the spring and install the slipper

with the groove in the slipper facing

upward (toward the cam notch). The

flats on the side of the slipper should

be on the left (Fig. 12).

FLATS ON LEFT

DOUBLE STEP

G1350-A

FIG. 72—Correct Slipper

Installation

8. Hold the cam stationary and

turn the rotor either to the right or

left, one space at a time. Repeat Step

7 until all the rotor cavities have been

filled. Be careful when turning the

rotor that the springs and slippers al-

ready inserted do not fall out.

9. Install the cam and rotor assem-

bly onto the pump housing plate with

the fixed dowel passing through the

first hole to the left of the cam notch

when the arrow on the cam OD is

pointing toward the lower pressure

plate (Fig. 13). If the cam and rotor

assembly will not seat, turn the rotor

shaft slightly until the spline teeth

mesh, allowing the cam and rotor to

drop down into position.

FIXED DOWEL D0|JBLE STEP

ARROW POINTING DOWN

G 1351-A

FIG. 13—Cam and Rotor

Installation

10.

Insert the loose fitting dowel

through the cam insert and lower

plate into the hole in the housing plate

assembly. When the loose dowel is

properly installed the heights of the

two dowels must be equal. Squirt the

rotor, springs, slippers and cam insert

with C1AZ-19582-A lubricant.

11.

Place the upper pressure plate

with the face having the tapered notch

down against the cam insert. The

fixed dowel should pass through the

round dowel hole and the loose dowel

through the elongated hole. The slot

between the ears on the pressure plate

OD should match the notch on the

cam insert OD (Fig. 14).

EARS

'G 1352-A

FIG. 74—Upper Pressure Plate

Installation

\ EARS

G1353-B

FIG. 75—Retainer End Plate

Installation

12.

Install the retainer end plate so

the slot on the end plate OD matches

the corresponding notches of the

upper pressure plate and cam (Fig

15).

13.

Install the pump valve assembly

O-ring seal onto the pump valve as-

sembly being careful not to twist the

seal (Fig. 16).

14.

Place the pump valve assembly

on top of the retainer end plate with

the large exhaust slot on the pump

valve in line with the OD notches of

the previously assembled parts. The

stack of parts must be fully seated. If

the pump valve has been installed cor-

rectly, the relief valve stem will be in

line with the lube return hole in the

pump housing plate (Fig. 16).

O-RING SEAL

EARS

G1605-A

FIG. 16 —Valve and Pressure

Spring Installation

Tool 169P-3B586-A

G1606-B

FIG. 17—Pump Housing

Installation

FIG. 18 -Checking Pump

Rotational Torqueprocarmanuals.com

Page 185 of 413

03-13-06

Specifications

03-13-06

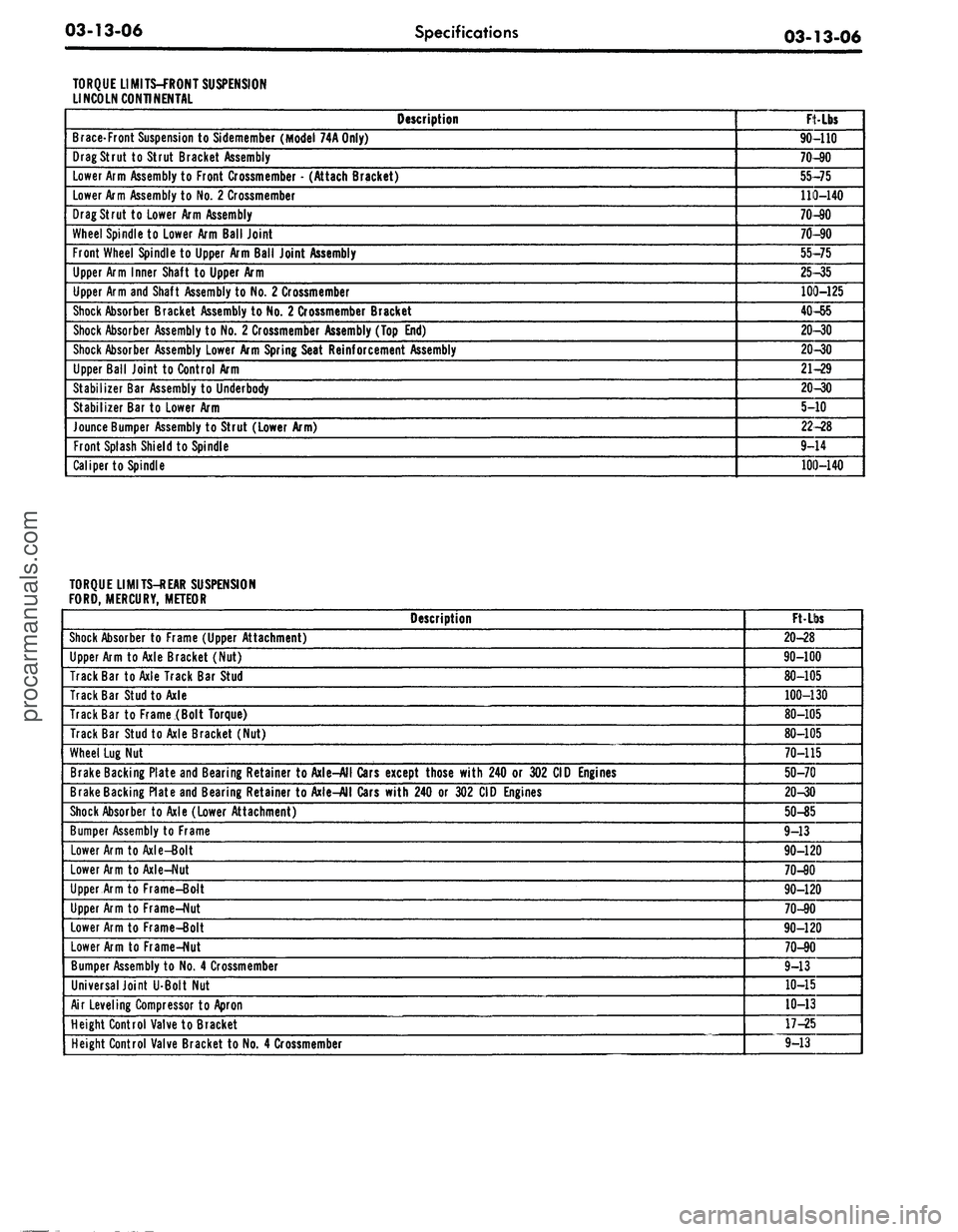

TORQUE LIMITS-FRONT SUSPENSION

LINCOLN CONTINENTAL

Description

Brace-Front Suspension to Sidemember (Model 74A Only)

Drag Strut

to

Strut Bracket Assembly

Lower Arm Assembly to Front Crossmember

-

(Attach Bracket)

Lower Arm Assembly to No. 2 Crossmember

Drag Strut

to

Lower Arm Assembly

Wheel Spindle to Lower Arm Ball Joint

Front Wheel Spindle to Upper Arm Ball Joint Assembly

Upper Arm Inner Shaft

to

Upper Arm

Upper Arm and Shaft Assembly to No. 2 Crossmember

Shock Absorber Bracket Assembly to No. 2 Crossmember Bracket

Shock Absorber Assembly to No. 2 Crossmember Assembly (Top End)

Shock Absorber Assembly Lower Arm Spring Seat Reinforcement Assembly

Upper Ball Joint

to

Control Arm

Stabilizer Bar Assembly

to

Underbody

Stabilizer Bar

to

Lower Arm

Jounce Bumper Assembly

to

Strut (Lower Arm)

Front Splash Shield to Spindle

Caliper to Spindle

FtLbs

90-110

70-90

55-75

110-140

70-90

70-90

55-75

25-35

100-125

40-55

20-30

20-30

21-29

20-30

5-10

22-28

9-14

100-140

TORQUE LIMITS-REAR SUSPENSION

FORD, MERCURY, METEOR

Description

Shock Absorber

to

Frame (Upper Attachment)

Upper Arm to Axle Bracket (Nut)

Track Bar to Axle Track Bar Stud

Track Bar Stud to Axle

Track Bar

to

Frame (Bolt Torque)

Track Bar Stud to Axle Bracket (Nut)

Wheel Lug Nut

Brake Backing Plate and Bearing Retainer to Axle-All Cars except those with 240

or

302 CID Engines

Brake Backing Plate and Bearing Retainer to Axle-All Cars with 240

or

302 CID Engines

Shock Absorber to Axle (Lower Attachment)

Bumper Assembly

to

Frame

Lower Arm to Axle-Bolt

Lower Arm to Axle-Nut

Upper Arm

to

Frame-BoU

Upper Arm

to

Frame-Nut

Lower Arm

to

Frame-Bolt

Lower Arm

to

Frame-Nut

Bumper Assembly to No. 4 Crossmember

Universal Joint

U-Bolt

Nut

Air Leveling Compressor

to

Apron

Height Control Valve to Bracket

Height Control Valve Bracket to No. 4 Crossmember

FtLbs

20-28

90-100

80-105

100-130

80-105

80-105

70-115

50-70

20-30

50-35

9-13

90-120

70-90

90-120

70-90

90-120

70-90

9-13

10-15

10-13

17-25

9-13procarmanuals.com

Page 197 of 413

04-01-10

General Axle Service

04-01-10

The pattern taken during disassem-

bly should be helpful in judging if

gears can be re-used. Worn gears can-

not be rebuilt to correct a noisy condi-

tion. Gear scoring is the result of ex-

cessive shock loading or the use of an

incorrect lubricant. Scored gears can-

not be re-used.

Examine the teeth and thrust surfa-

ces of the differential gears. Wear on

the hub of the differential gear can

cause a chucking noise known as

chuckle when the vehicle is driven at

low speeds. Wear of splines, thrust

surfaces, or thrust washers, can con-

tribute to excessive drive line back-

lash.

BEARING CUPS AND

CONE AND ROLLER

ASSEMBLIES

Check bearing cups for rings,

scores, galling, or excessively worn

wear patterns. Pinion cups must be

solidly seated. Check by attempting to

insert a 0.0015-inch feeler between

these cups and the bottoms of their

bores.

When operated in the cups, cone

and roller assemblies must turn with-

out roughness. Examine the roller

ends for wear. Step-wear on the roller

ends indicates the bearings were not

preloaded properly, or the rollers were

slightly misaligned.

If inspection reveals either a defec-

tive cup or a defective cone and roller

assembly, both parts should be re-

placed to avoid early failure.

DIFFERENTIAL BEARING

ADJUSTING NUTS

Temporarily install the bearing caps

and test the fit of the adjusting nuts in

their threads. The nuts should turn

easily when the caps are tightened to

25 ft-lbs. The faces of the nuts that

contact the bearing cups must be

smooth and square. Replace the nuts

or examine the threads in the carrier

if their fit is not proper. Be sure that

the bearing caps and adjusting nuts

are on the side they were machined to

fit. Observe the punch marks and

scribe marks made during disassem-

bly.

U-JOINT FLANGE

Be sure that the eai» of the flange

have not been damaged in removing

the drive shaft or in removing the

flange from the axle. The end of the

flange that contacts the front pinion

bearing inner race as well as the flat

surface of the pinion nut counterbore

must be smooth. Polish these surfaces

if necessary. Roughness aggravates

backlash noises and causes wear of

the flange and pinion nut with a resul-

tant loss in pinion bearing preload.

PINION RETAINER

Be sure that the pinion bearing cups

are seated. Remove any chips or burrs

from the mounting flange. Clean the

groove for the O-ring seal and all lu-

bricant passages. If the cups were re-

moved, examine the bores carefully.

Any nicks or burrs in these bores

must be removed to permit proper

seating of the cups.

CARRIER HOUSING

Make sure that the differential

bearing bores are smooth and the

threads are not damaged. Remove any

nicks or burrs from the mounting sur-

faces of the carrier housing.

DIFFERENTIAL CASE

Make sure that the hubs where the

bearings mount are smooth. Carefully

examine the differential case bearing

shoulders, which may have been dam-

aged when the bearings were removed.

The bearing assemblies will fail if they

do not seat firmly against the shoul-

ders.

Check the fit (free rotation) of

the differential side gears in their

counterbores. Be sure that the mating

surfaces of the two parts of the case

are smooth and free from nicks or

burrs.

LIMITED SLIP AND

TRACTION-LOK

DIFFERENTIAL PARTS

Inspect the clutch plates for uneven

or extreme wear. The dog-eared clutch

plates must be free from burrs, nicks

or scratches which could cause excess-

ive or erratic wear to the bonding ma-

terial of the internally splined clutch

plates.

The internally splined clutch

plates should be inspected for condi-

tion of the bond, bonding material,

and wear. Replace the bonded plates

if their thickness is less than 0.085

inch or if the bonded material is

scored or badly worn. Inspect the

bonded plate internal teeth for wear.

Replace them, if excessive wear is evi-

dent. Bonded plates should be re-

placed as a set only

Examine all thrust surfaces and

hubs for wear. Abnormal wear on

these surfaces can contribute to a

noisy axle.

Inspect the Belleville spring (limited

slip) for proper free height of 1/4

inch.

LUBRICANT LEVEL

The lubricant level should be

checked every 6000 miles with the ve-

hicle in normal curb attitude. The lu-

bricant level should be at the lower

edge of the filler plug hole located in

either the carrier casting or housing

cover. It is unnecessary to periodically

drain the axle lubricant. The factory

fill should remain in the housing for

the life of the vehicle, except when re-

pairs are made. The specified lubri-

cant should be installed when the axle

is overhauled.procarmanuals.com