height FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 208 of 413

04-02-11

Rear Axle — Removable Carrier Type

04-02-11

If the axle housing is new, install a

new vent. The hose attaching portion

must face toward the front of the ve-

hicle.

2.

If leather-type wheel bearing ser-

vice seals are to be installed, soak the

new rear wheel bearing oil seals in

SAE 10 oil for 1/2 hour before instal-

lation. Wipe a small amount of an oil

resistant sealer on the outer edge of

each seal before it is installed. Do not

put any of the sealer on the sealing

lip.

Install the oil seals in the ends of

the axle housing with one of the tools

shown in Fig. 10 and 12.

3.

Position the replacement axle

housing under the vehicle, and raise

the axle with a hoist or floor jack.

Connect the suspension lower arms to

their mounting brackets on the axle

housing with pivot bolts and nuts. Do

not tighten the bolts and nuts at this

point.

4.

Position the suspension upper

arm in its mounting bracket on the

axle housing, and install the adjusting

bolt, eccentric washers, lock washer

and nut. Leave the bolt and nut loose

at this point.

5.

Position the brake lines to the

axle housing, and secure with the re-

taining clips.

6. Install the brake backing plates

on the axle housing flanges.

7.

Connect the track bar to the

mounting stud, install the washer and

attaching nut, and torque to specifica-

tions.

8. Position the rear coil springs and

insulators in the pockets provided.

9. Connect the lower studs of the

two rear shock absorbers to the

mounting brackets on the axle hous-

ing. Install the attaching nuts, and

torque to specifications.

10.

Connect the vent tube to the

vent on the housing. If axle housing is

new, install a new vent.

11.

Clean the mating surfaces of

the axle housing and differential car-

rier. Position the carrier on the

mounting studs on the housing using a

new gasket between carrier and hous-

ing. Install the copper washers and the

carrier-to-housing attaching nuts, and

torque to specifications.

12.

Make sure that both the front

and rear pivot bolts of the upper and

the two lower arms are loose, and

then raise the axle assembly to con-

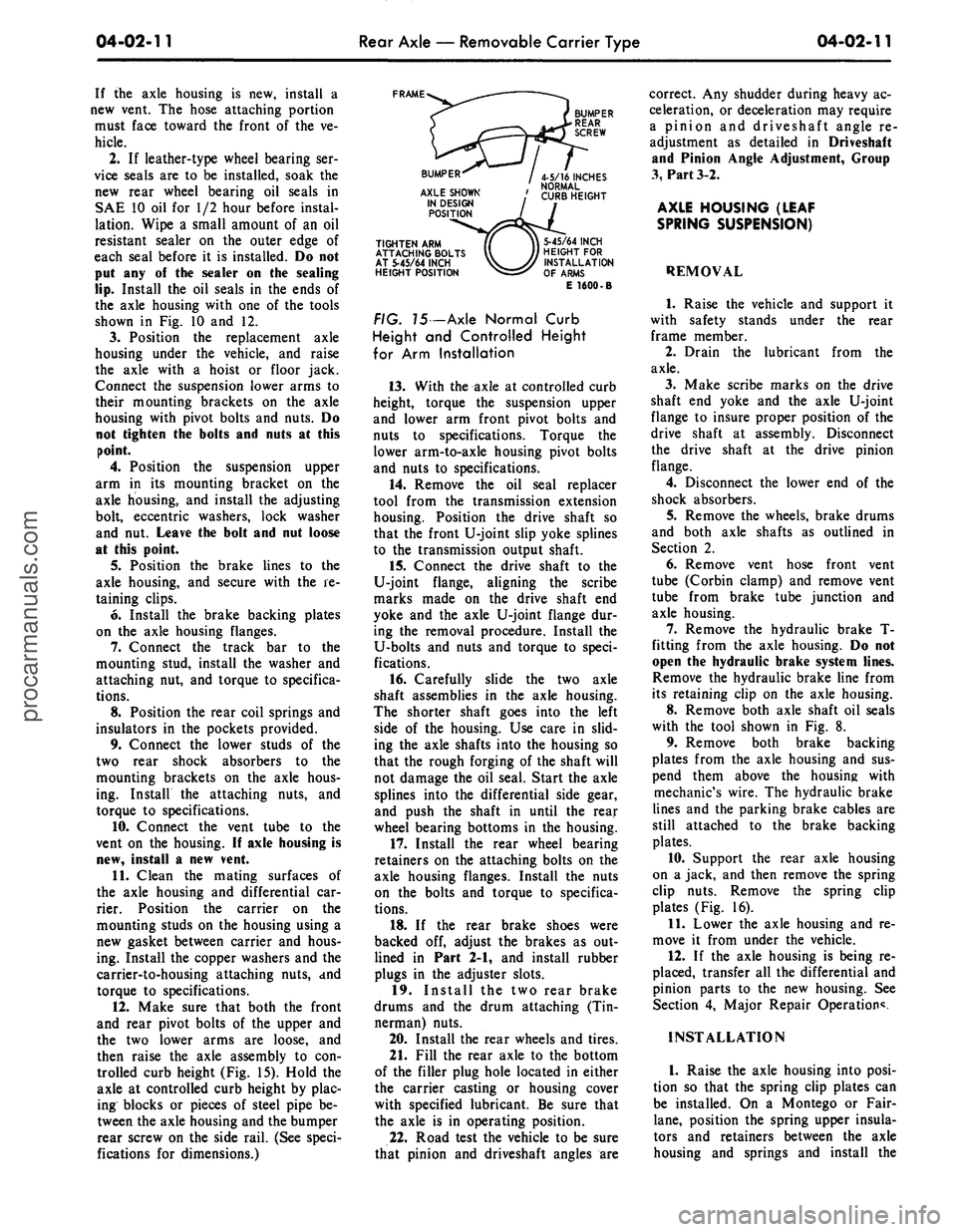

trolled curb height (Fig. 15). Hold the

axle at controlled curb height by plac-

ing blocks or pieces of steel pipe be-

tween the axle housing and the bumper

rear screw on the side rail. (See speci-

fications for dimensions.)

FRAME

TIGHTEN ARM

ATTACHING BOLTS

AT 5-45/64 INCH

HEIGHT POSITION

5-45/64 INCH

HEIGHT FOR

INSTALLATION

OF ARMS

E 1600-B

FIG. 75 -Axle Normal Curb

Height and Controlled Height

for Arm Installation

13.

With the axle at controlled curb

height, torque the suspension upper

and lower arm front pivot bolts and

nuts to specifications. Torque the

lower arm-to-axle housing pivot bolts

and nuts to specifications.

14.

Remove the oil seal replacer

tool from the transmission extension

housing. Position the drive shaft so

that the front U-joint slip yoke splines

to the transmission output shaft.

15.

Connect the drive shaft to the

U-joint flange, aligning the scribe

marks made on the drive shaft end

yoke and the axle U-joint flange dur-

ing the removal procedure. Install the

U-bolts and nuts and torque to speci-

fications.

16.

Carefully slide the two axle

shaft assemblies in the axle housing.

The shorter shaft goes into the left

side of the housing. Use care in slid-

ing the axle shafts into the housing so

that the rough forging of the shaft will

not damage the oil seal. Start the axle

splines into the differential side gear,

and push the shaft in until the rear

wheel bearing bottoms in the housing.

17.

Install the rear wheel bearing

retainers on the attaching bolts on the

axle housing flanges. Install the nuts

on the bolts and torque to specifica-

tions.

18.

If the rear brake shoes were

backed off, adjust the brakes as out-

lined in Part 2-1, and install rubber

plugs in the adjuster slots.

19.

Install the two rear brake

drums and the drum attaching (Tin-

nerman) nuts.

20.

Install the rear wheels and tires.

21.

Fill the rear axle to the bottom

of the filler plug hole located in either

the carrier casting or housing cover

with specified lubricant. Be sure that

the axle is in operating position.

22.

Road test the vehicle to be sure

that pinion and driveshaft angles are

correct. Any shudder during heavy ac-

celeration, or deceleration may require

a pinion and driveshaft angle re-

adjustment as detailed in Driveshaft

and Pinion Angle Adjustment, Group

3,

Part 3-2.

AXLE HOUSING (LEAF

SPRING SUSPENSION)

REMOVAL

1.

Raise the vehicle and support it

with safety stands under the rear

frame member.

2.

Drain the lubricant from the

axle.

3.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly. Disconnect

the drive shaft at the drive pinion

flange.

4.

Disconnect the lower end of the

shock absorbers.

5.

Remove the wheels, brake drums

and both axle shafts as outlined in

Section 2.

6. Remove vent hose front vent

tube (Corbin clamp) and remove vent

tube from brake tube junction and

axle housing.

7.

Remove the hydraulic brake T-

fitting from the axle housing. Do not

open the hydraulic brake system lines.

Remove the hydraulic brake line from

its retaining clip on the axle housing.

8. Remove both axle shaft oil seals

with the tool shown in Fig. 8.

9. Remove both brake backing

plates from the axle housing and sus-

pend them above the housing with

mechanic's wire. The hydraulic brake

lines and the parking brake cables are

still attached to the brake backing

plates.

10.

Support the rear axle housing

on a jack, and then remove the spring

clip nuts. Remove the spring clip

plates (Fig. 16).

11.

Lower the axle housing and re-

move it from under the vehicle.

12.

If the axle housing is being re-

placed, transfer all the differential and

pinion parts to the new housing. See

Section 4, Major Repair Operation*.

INSTALLATION

1.

Raise the axle housing into posi-

tion so that the spring clip plates can

be installed. On a Montego or Fair-

lane,

position the spring upper insula-

tors and retainers between the axle

housing and springs and install theprocarmanuals.com

Page 235 of 413

04-04-04

Rear Axle — Ford Light-Duty (WER)

04-04-04

REMOVAL AND INSTALLATION

AXLE HOUSING

Refer to Fig. 7.

REMOVAL

1.

Raise the vehicle on a hoist.

2.

Remove the wheels and tires

from the brake drums.

3.

Position a drain pan and loosen

the rear axle cover to housing attach-

ing bolts. Drain the housing.

4.

Remove the attaching (Tinner-

man) nuts that secure the brake drums

to the axle shaft flanges, and then re-

move the drums (Fig. 7).

5.

Remove the axle housing cover

bolts,

cover and gasket. Discard the

gasket. Remove the drain pan.

6. Disconnect the drive shaft at the

drive pinion companion flange. Re-

move the drive shaft from the trans-

mission extension housing. Install an

oil seal replacer tool in the transmis-

sion housing to prevent leakage. Refer

to the transmission group for the ap-

propriate tool.

7.

Disconnect the lower end of the

shock absorbers at the mounting

brackets.

8. Disconnect the track bar from

the axle housing stud. If the axle

housing is to be replaced, transfer the

stud to the new housing.

9. Position safety stands under the

rear frame members. Lower the vehi-

cle with the hoist and allow the axle

to lower far enough to relieve rear

spring tension.

10.

Remove the pinion shaft lock

bolt and pinion shaft (Fig. 2), differ-

ential pinion gears and thrust washers.

11.

Push the axle shaft(s) inward

toward the center of the axle housing.

Remove the C-locks from the inner

ends of the axles (Fig. 3). Remove the

axle shafts from the housing. Extreme

care must be used to avoid contacting

the axle shaft seal lip with any portion

of the axle shaft other than the seal

journal.

12.

Disconnect the vent hose from

the rear vent tube and remove all

brake lines from the axle housing re-

taining clips.

13.

Remove the brake backing

plate attaching nuts and the plates

from the axle housing. Suspend the

plates above the axle housing with

mechanics wire. The hydraulic brake

lines and the parking brake cables will

remain attached to the brake backing

plates.

14.

Support the rear axle housine

on a jack.

15.

Remove the right and left rear

springs and insulators.

16.

Remove the nuts, washers and

pivot bolts that connect the suspension

lower arms to the axle housing. Dis-

connect both arms from the axle

housing.

17.

Disconnect the upper suspen-

sion arm from the axle housing by re-

moving the pivot bolt, nut, lock wash-

er and two eccentric washers.

18.

Lower the rear axle to the floor

with the jack and remove the axle

from under the vehicle.

19.

Remove the wheel bearings and

oil seals with the tool shown in Fig. 4.

20.

If the axle housing is being re-

placed, transfer all the differential and

pinion parts to the new housing. Refer

to Section 4, Major Repair Operation

for the procedure.

INSTALLATION

1.

Lightly coat the wheel bearing

rollers with axle lubricant. Install

wheel bearings in the axle housing

with the tool shown in Fig. 5. The

bearings should seat firmly against the

shoulder.

2.

Wipe all lubricant from the oil

seal bore before installing the seal. If

axle housing is being replaced, new

seals must be installed.

3.

Inspect the original seal for

nicks,

scuffs or abnormal wear, and

replace if necessary. New seals are

pre-packed with lubricant and do not

require an oil soak.

4.

Install the seal with the tool

shown in Fig. 6. Installation without

the use of the proper tool will distort

the seal and cause leakage.

5. Raise the rear axle into position

under the vehicle with a hoist or floor

jack. Connect the suspension lower

arms to their mounting brackets on

the axle housing with pivot bolts and

nuts.

Do not tighten the mounting

bolts at this point.

6. Position the suspension upper

arm in its mounting bracket on the

axle housing and install the adjusting

bolt, eccentric washers, lock washer

and nut. Do not tighten the mounting

bolt at this point.

7.

Place the rear coil springs and

insulators into position in the pockets

provided.

8. Place the brake backing plates

on the axle housing flanges, install 4

attaching bolts and nuts and torque

them to specifications.

9. Position the brake lines to the

axle housing and secure them with the

retaining clips. If the axle housing is

new, install a new vent. When install-

ing the new axle vent apply a small

amount of Locktite (C5AZ-19554-B)

to prevent oil leakage between vent

and axle housing. Connect the vent

tube to the vent.

10.

Install the pinion side gears and

thrust washer.

11.

Slide the axle shafts into place

in the axle housing. Exercise care that

splines or any portion of the axle

shafts do not damage the oil seals and

that they engage with the splines of

the differential side gears.

12.

Install the axle shaft C-lock O-

ring and C-lock on the inner end of

the shaft and push the shaft outward

so that the shaft lock seats in the

counterbore of the differential side

gear.

13.

Position the pinion differential

gears and thrust washers 180 degrees

apart to the differential side gears.

Revolve the gear assembly until the

holes in the differential case are al-

igned with the pinion gears.

14.

Position the differential pinion

shaft through the case and pinions, al-

igning the hole in the shaft with the

lock bolt hole. Install the lock bolt

and tighten it to specification.

15.

Clean the gasket mounting sur-

face of the rear axle housing and the

cover. Install a new cover gasket,

cover and the attaching bolts. Torque

the bolts to specification.

16.

Raise the rear axle on a hoist

and remove the safety stands.

17.

Connect the track bar to the

mounting stud. Install the washer and

nut. Torque the nut to specification.

18.

Connect the two rear shock ab-

sorbers to the mounting brackets on

the axle housing and torque the at-

taching nuts to specification.

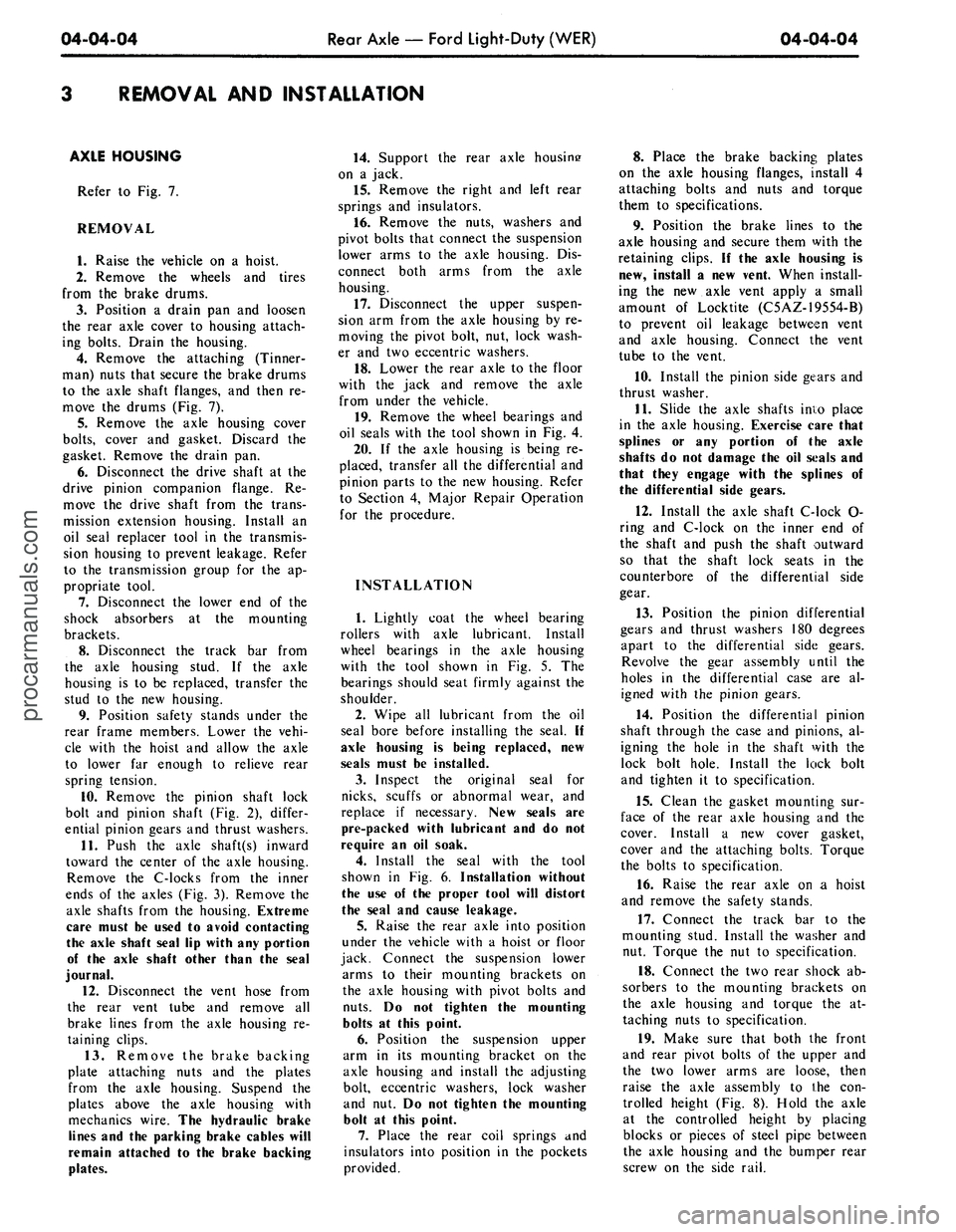

19.

Make sure that both the front

and rear pivot bolts of the upper and

the two lower arms are loose, then

raise the axle assembly to the con-

trolled height (Fig. 8). Hold the axle

at the controlled height by placing

blocks or pieces of steel pipe between

the axle housing and the bumper rear

screw on the side rail.procarmanuals.com

Page 237 of 413

04-04-06

Rear Axle — Ford Light-Duty (WER)

04-04-06

20.

With the axle at controlled

height, torque the suspension upper

and lower arm front pivot bolts and

nuts to specifications. Torque the

lower arm to axle housing pivot bolts

and nuts to specifications.

21.

Remove the oil seal replacer

from the transmission extension hous-

ing. Install the drive shaft in the ex-

tension housing. Align the scribe

marks on the cups, flange and drive

shaft and connect the drive shaft at

the drive pinion flange. Torque the at-

taching bolts to specification

FRAME

TIGHTEN ARM

ATTACHING BOLTS

AT 5-45/64 INCH

HEIGHT POSITION

5-45/64 INCH

HEIGHT FOR

INSTALLATION

OF ARMS

E 1600-B

FIG.8—

Axle

Normal Curb Height

and Controlled Height for Arm

Installation

22.

Install the brake drum and at-

taching (Tinnerman) nuts.

23.

Install the wheel and tire on the

brake drum. Install the wheel covers.

24.

Adjust the drive shaft and pin-

ion angle to specification.

25.

Add the amount of specified lu-

bricant required to reach to the bot-

tom of the filler plug hole. Make sure

the rear axle is in running position.

Install the filler plug and torque it to

specification.

26.

Lower the vehicle.

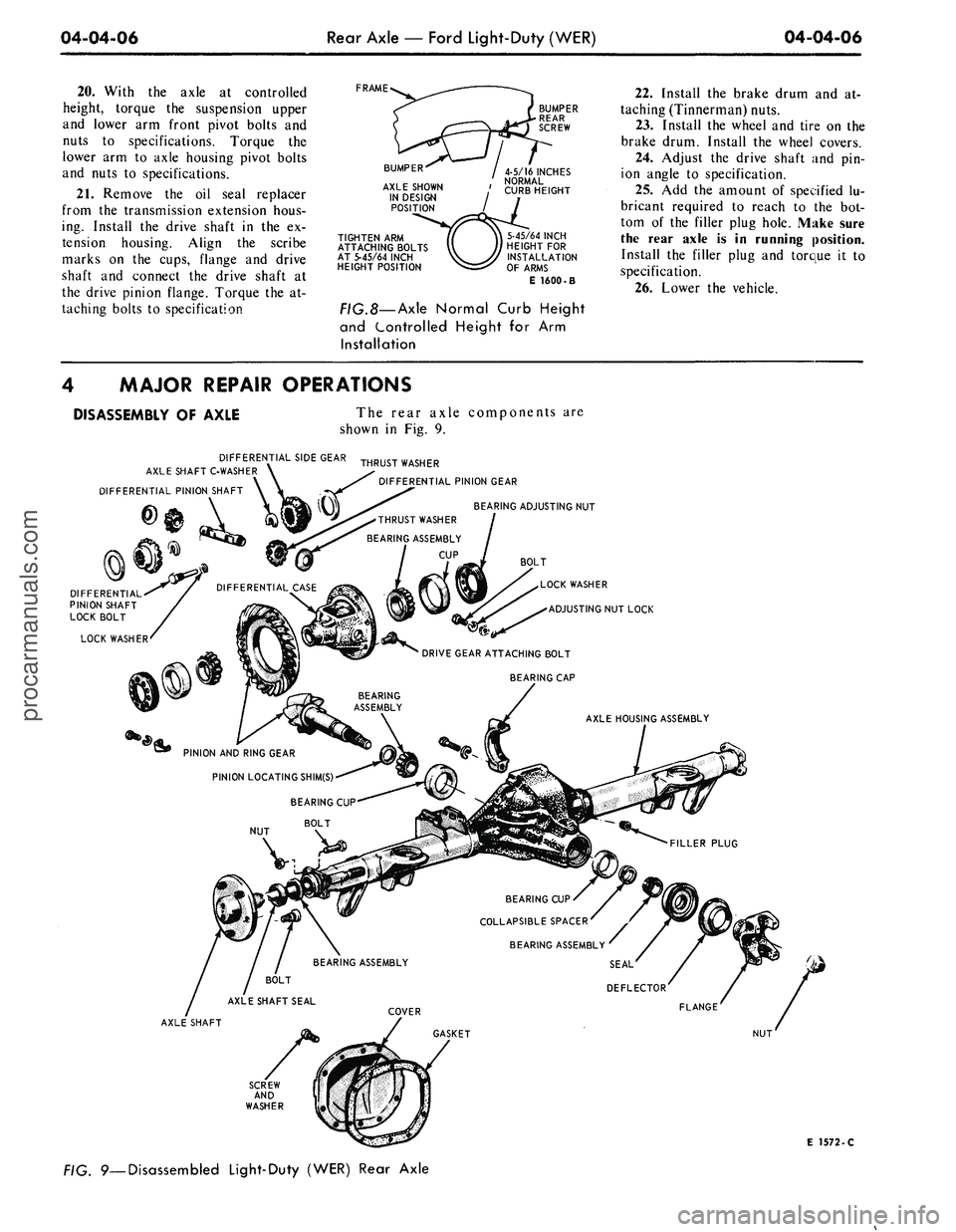

4 MAJOR REPAIR OPERATIONS

DISASSEMBLY OF AXLE

The rear axle components are

shown in Fig. 9.

DIFFERENTIAL SIDE GEAR

AXLE SHAFT C-WASHER \

DIFFERENTIAL PINION SHAFT

THRUST WASHER

BEARING ASSEMBLY

CUP

THRUST WASHER

^^ DIFFERENTIAL PINION GEAR

BEARING ADJUSTING NUT

DIFFERENTIAL

PINION SHAFT

LOCK BOLT

LOCK WASHER

BOLT

LOCK WASHER

ADJUSTING NUT LOCK

DRIVE GEAR ATTACHING BOLT

BEARING CAP

AXLE HOUSING ASSEMBLY

PINION AND RING GEAR

PINION LOCATING SHIM(S)

BEARING CUP

BOLT

NUT

BEARING CUP

COLLAPSIBLE SPACER

AXLE SHAFT

E 1572-C

FIG. 9—Disassembled Light-Duty (WER) Rear Axleprocarmanuals.com

Page 262 of 413

05-03-04

Clutch

05-03-04

bushings, position the clutch pedal and

bushings in the pedal support.

8. Install the retaining ring on the

clutch pedal shaft.

9. Position the assist spring in the

pedal support bracket and the assist

spring bracket. Rotate the assist

spring bracket clockwise until the

upper bolt holes line up and install the

bolt. Torque both the upper and lower

bolts to specification.

10.

Check the clutch pedal free

travel and adjust as required.

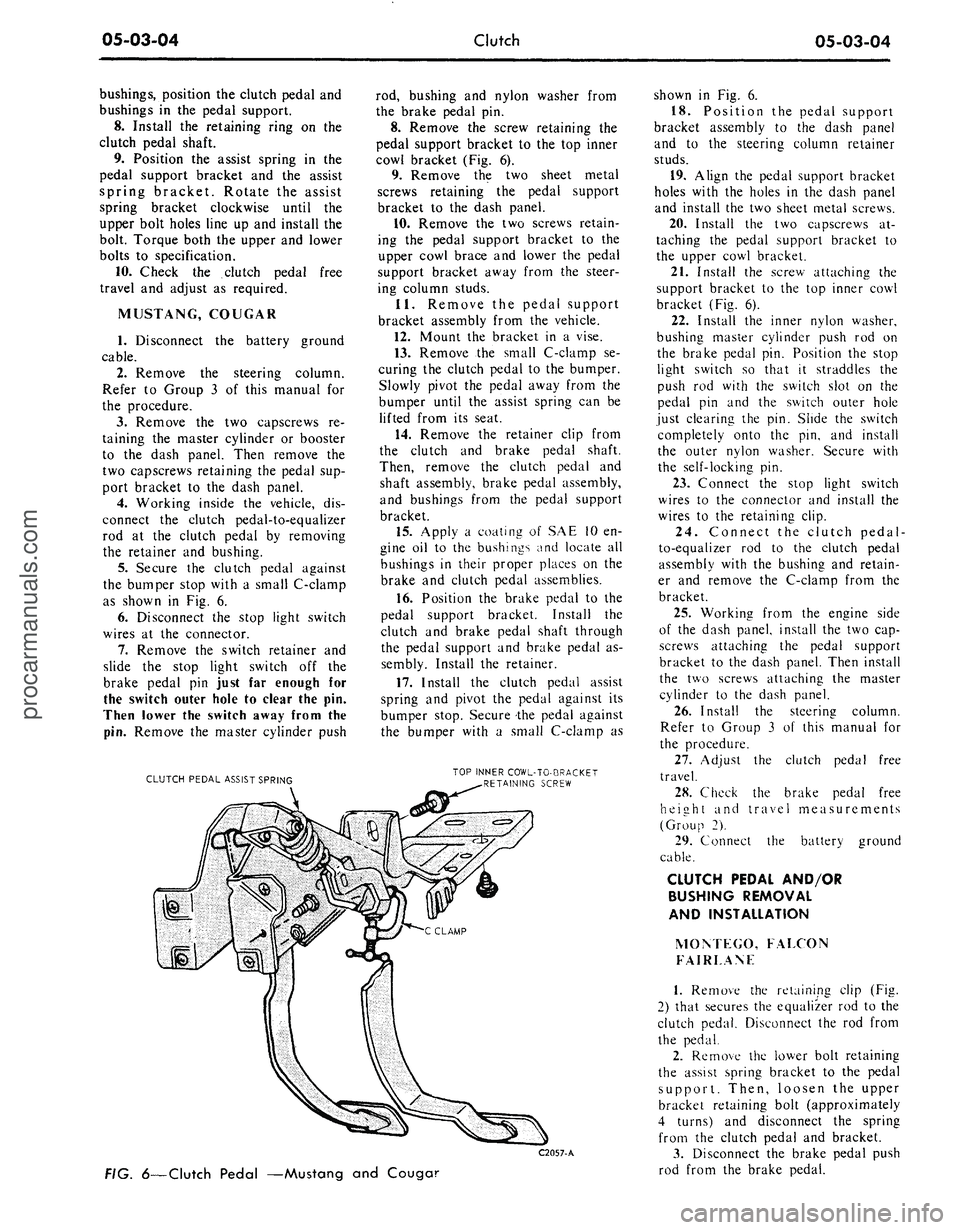

MUSTANG, COUGAR

1.

Disconnect the battery ground

cable.

2.

Remove the steering column.

Refer to Group 3 of this manual for

the procedure.

3.

Remove the two capscrews re-

taining the master cylinder or booster

to the dash panel. Then remove the

two capscrews retaining the pedal sup-

port bracket to the dash panel.

4.

Working inside the vehicle, dis-

connect the clutch pedal-to-equalizer

rod at the clutch pedal by removing

the retainer and bushing.

5.

Secure the clutch pedal against

the bumper stop with a small C-clamp

as shown in Fig. 6.

6. Disconnect the stop light switch

wires at the connector.

7.

Remove the switch retainer and

slide the stop light switch off the

brake pedal pin just far enough for

the switch outer hole to clear the pin.

Then lower the switch away from the

pin.

Remove the master cylinder push

CLUTCH PEDAL ASSIST SPRING

rod, bushing and nylon washer from

the brake pedal pin.

8. Remove the screw retaining the

pedal support bracket to the top inner

cowl bracket (Fig. 6).

9. Remove the two sheet metal

screws retaining the pedal support

bracket to the dash panel.

10.

Remove the two screws retain-

ing the pedal support bracket to the

upper cowl brace and lower the pedal

support bracket away from the steer-

ing column studs.

11.

Remove the pedal support

bracket assembly from the vehicle.

12.

Mount the bracket in a vise.

13.

Remove the small C-clamp se-

curing the clutch pedal to the bumper.

Slowly pivot the pedal away from the

bumper until the assist spring can be

lifted from its seat.

14.

Remove the retainer clip from

the clutch and brake pedal shaft.

Then, remove the clutch pedal and

shaft assembly, brake pedal assembly,

and bushings from the pedal support

bracket.

15.

Apply a coating of SAE 10 en-

gine oil to the bushings and locate all

bushings in their proper places on the

brake and clutch pedal assemblies.

16.

Position the brake pedal to the

pedal support bracket. Install the

clutch and brake pedal shaft through

the pedal support and brake pedal as-

sembly. Install the retainer.

17.

Install the clutch pedal assist

spring and pivot the pedal against its

bumper stop. Secure the pedal against

the bumper with a small C-clamp as

TOP INNER COWL-TO-BRACKET

RETAINING SCREW

C2057-A

FIG.

6—Clutch

Pedal —Mustang and Couga?

shown in Fig. 6.

18.

Position the pedal support

bracket assembly to the dash panel

and to the steering column retainer

studs.

19.

Align the pedal support bracket

holes with the holes in the dash panel

and install the two sheet metal screws.

20.

Install the two capscrews at-

taching the pedal support bracket to

the upper cowl bracket.

21.

Install the screw attaching the

support bracket to the top inner cowl

bracket (Fig. 6).

22.

Install the inner nylon washer,

bushing master cylinder push rod on

the brake pedal pin. Position the stop

light switch so that it straddles the

push rod with the switch slot on the

pedal pin and the switch outer hole

just clearing the pin. Slide the switch

completely onto the pin, and install

the outer nylon washer. Secure with

the self-locking pin.

23.

Connect the stop light switch

wires to the connector and install the

wires to the retaining clip.

24.

Connect the clutch pedal-

to-equalizer rod to the clutch pedal

assembly with the bushing and retain-

er and remove the C-clamp from the

bracket.

25.

Working from the engine side

of the dash panel, install the two cap-

screws attaching the pedal support

bracket to the dash panel. Then install

the two screws attaching the master

cylinder to the dash panel.

26.

Install the steering column.

Refer to Group 3 of this manual for

the procedure.

27.

Adjust the clutch pedal free

travel.

28.

Check the brake pedal free

height and travel measurements

(Group 2).

29.

Connect the battery ground

cable.

CLUTCH PEDAL AND/OR

BUSHING REMOVAL

AND INSTALLATION

MOM EGO, FALCON

FAIRLANF

1.

Remove the retaining clip (Fig.

2) that secures the equalizer rod to the

clutch pedal. Disconnect the rod from

the pedal.

2.

Remove the lower bolt retaining

the assist spring bracket to the pedal

support. Then, loosen the upper

bracket retaining bolt (approximately

4 turns) and disconnect the spring

from the clutch pedal and bracket.

3.

Disconnect the brake pedal push

rod from the brake pedal.procarmanuals.com

Page 272 of 413

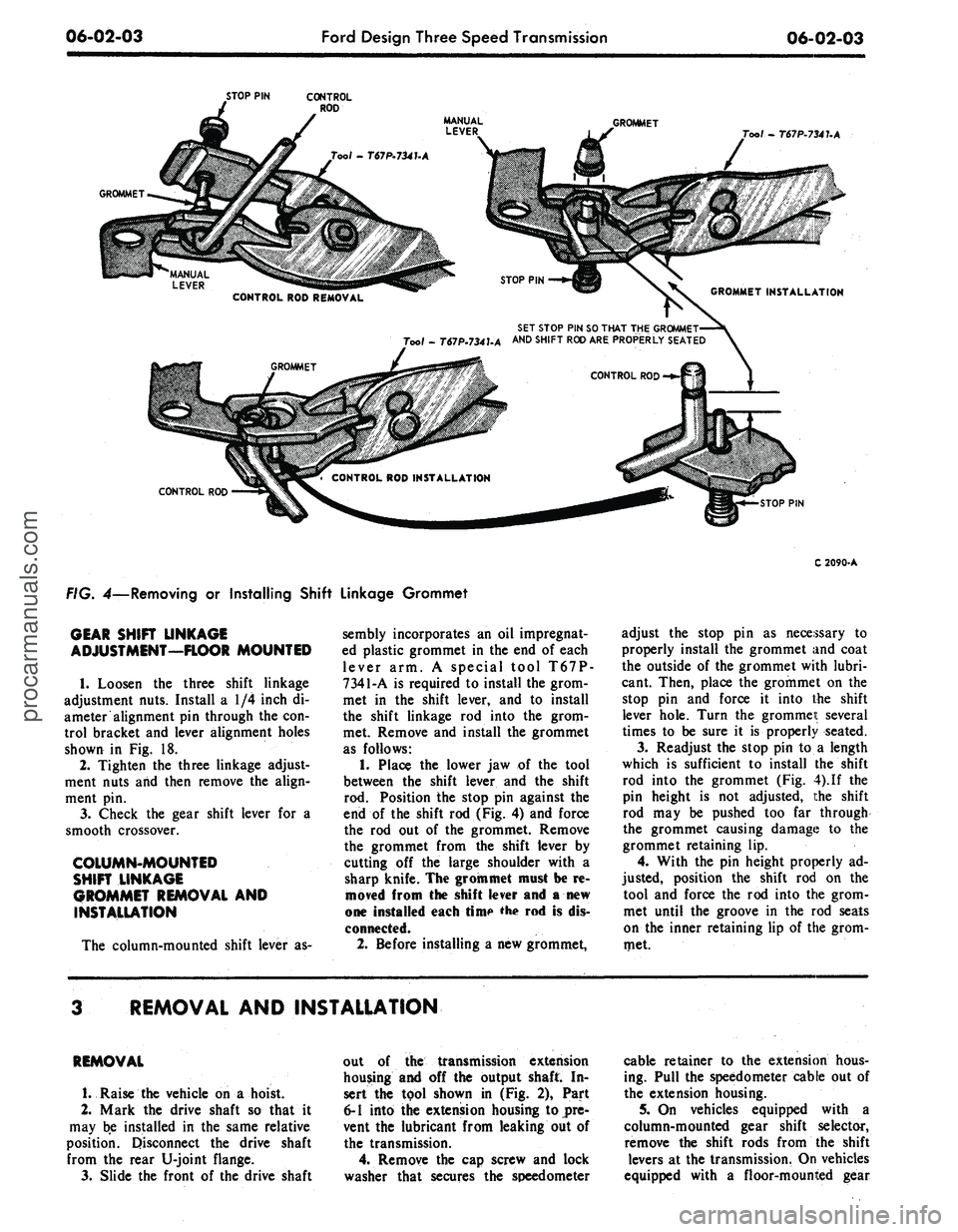

06-02-03

Ford Design Three Speed Transmission

06-02-03

STOP

PIN

GROMMET

Tool -

T67P.7347.A

GROMMET

LEVER

CONTROL ROD REMOVAL

^S.

GROMMET INSTALLATION

SET STOP PIN SO THAT THE GROMMET

Tool

-

T67P.734LA

AND

SHIFT ROD ARE PROPERLY SEATED

OMMET—^

SEATED

\

CONTROL ROD INSTALLATION

CONTROL ROD

STOP

PIN

FIG. 4—Removing

or

Installing Shift Linkage Grommet

GEAR SHIFT LINKAGE

ADJUSTMENT—FLOOR MOUNTED

1.

Loosen

the

three shift linkage

adjustment nuts. Install

a 1/4

inch

di-

ameter alignment pin through the con-

trol bracket and lever alignment holes

shown

in Fig. 18.

2.

Tighten

the

three linkage adjust-

ment nuts

and

then remove

the

align-

ment

pin.

3.

Check

the

gear shift lever

for a

smooth crossover.

COLUMN-MOUNTED

SHIFT LINKAGE

GROMMET REMOVAL

AND

INSTALLATION

The column-mounted shift lever

as-

sembly incorporates

an oil

impregnat-

ed plastic grommet

in the

end

of

each

lever

arm. A

special tool T67P-

7341-A

is

required

to

install the grom-

met

in the

shift lever,

and to

install

the shift linkage

rod

into

the

grom-

met. Remove

and

install

the

grommet

as follows:

1.

Place

the

lower

jaw of the

tool

between

the

shift lever

and the

shift

rod.

Position

the

stop

pin

against

the

end

of the

shift

rod

(Fig.

4)

and force

the

rod out of the

grommet. Remove

the grommet from

the

shift lever

by

cutting

off the

large shoulder with

a

sharp knife. The groin met must

be re-

moved from

the

shift lever

and a new

one installed each rime

'he rod is

dis-

connected.

2.

Before installing

a

new grommet,

C 2090-A

adjust

the

stop

pin as

necessary

to

properly install

the

grommet and coat

the outside

of

the grommet with lubri-

cant. Then, place

the

grommet

on the

stop

pin and

force

it

into

the

shift

lever hole. Turn

the

grommeit several

times

to be

sure

it is

properly seated.

3.

Readjust

the

stop

pin to a

length

which

is

sufficient

to

install

the

shift

rod into

the

grommet

(Fig.

4).

If

the

pin height

is not

adjusted,

the

shift

rod

may be

pushed

too far

through

the grommet causing damage

to the

grommet retaining

lip.

4.

With

the pin

height properly

ad-

justed, position

the

shift

rod on the

tool

and

force

the rod

into

the

grom-

met until

the

groove

in the rod

seats

on

the

inner retaining

lip of

the grom-

met.

REMOVAL AND INSTALLATION

REMOVAL

1.

Raise

the

vehicle

on a

hoist.

2.

Mark

the

drive shaft

so

that

it

may

be

installed

in the

same relative

position. Disconnect

the

drive shaft

from

the

rear U-joint flange.

3.

Slide

the

front

of the

drive shaft

out

of the

transmission extension

housing

and off the

output shaft

In-

sert

the

tool shown

in (Fig. 2),

Part

6-1 into the extension housing

to

pre-

vent

the

lubricant from leaking

out of

the transmission.

4.

Remove

the cap

screw

and

lock

washer that secures

the

speedometer

cable retainer

to the

extension hous-

ing. Pull

the

speedometer cable

out of

the extension housing.

5.

On

vehicles equipped with

a

column-mounted gear shift selector,

remove

the

shift rods from

the

shift

levers

at

the transmission. On vehicles

equipped with

a

floor-mounted gearprocarmanuals.com

Page 302 of 413

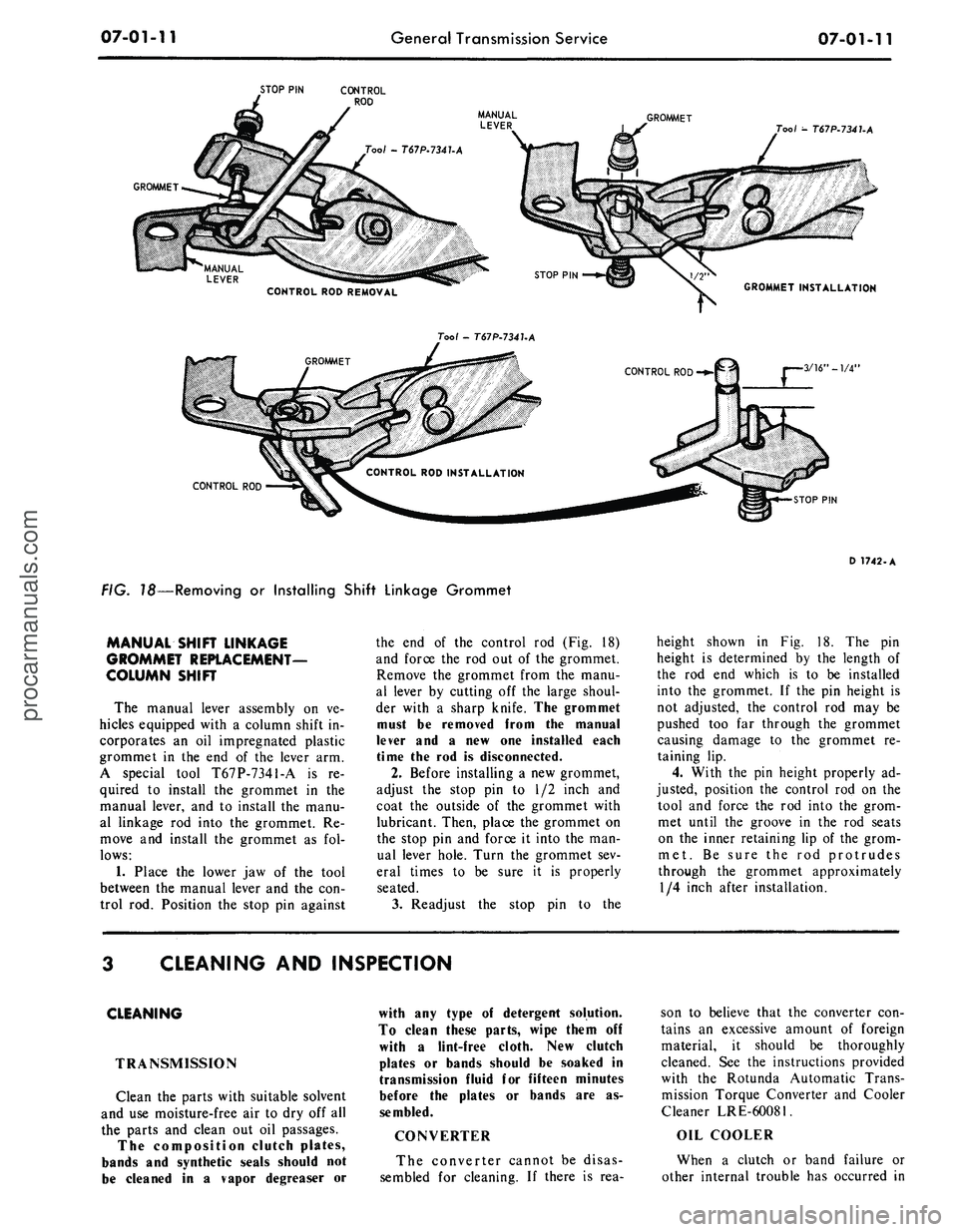

07-01-11

General Transmission Service

07-01-11

STOP

PIN

GROMMET

Tool - T67P-734LA

GROMMET

LEVER

CONTROL ROD REMOVAL

GROMMET INSTALLATION

Tool - T67P-734LA

r

CONTROL ROD INSTALLATION

3/16"-1/4'

CONTROL ROD

STOP

PIN

FIG. 18—Removing

or

Installing Shift Linkage Grommet

D 1742-A

MANUAL SHIFT LINKAGE

GROMMET REPLACEMENT-

COLUMN SHIFT

The manual lever assembly

on ve-

hicles equipped with

a

column shift

in-

corporates

an oil

impregnated plastic

grommet

in the end of the

lever

arm.

A special tool T67P-7341-A

is re-

quired

to

install

the

grommet

in the

manual lever,

and to

install

the

manu-

al linkage

rod

into

the

grommet.

Re-

move

and

install

the

grommet

as fol-

lows:

1.

Place

the

lower

jaw of the

tool

between

the

manual lever

and the con-

trol

rod.

Position

the

stop

pin

against

the

end of the

control

rod (Fig. 18)

and force

the rod out of the

grommet.

Remove

the

grommet from

the

manu-

al lever

by

cutting

off the

large shoul-

der with

a

sharp knife.

The

grommet

must

be

removed from

the

manual

lever

and a new one

installed each

time

the rod is

disconnected.

2.

Before installing

a

new grommet,

adjust

the

stop

pin to 1/2

inch

and

coat

the

outside

of the

grommet with

lubricant. Then, place

the

grommet

on

the stop

pin and

force

it

into

the

man-

ual lever hole. Turn

the

grommet

sev-

eral times

to be

sure

it is

properly

seated.

3.

Readjust

the

stop

pin to the

height shown

in Fig. 18. The pin

height

is

determined

by the

length

of

the

rod end

which

is to be

installed

into

the

grommet.

If the pin

height

is

not adjusted,

the

control

rod may be

pushed

too far

through

the

grommet

causing damage

to the

grommet

re-

taining

lip.

4.

With

the pin

height properly

ad-

justed, position

the

control

rod on the

tool

and

force

the rod

into

the

grom-

met until

the

groove

in the rod

seats

on

the

inner retaining

lip of the

grom-

met.

Be

sure

the rod

protrudes

through

the

grommet approximately

1/4 inch after installation.

CLEANING

AND

INSPECTION

CLEANING

TRANSMISSION

Clean

the

parts with suitable solvent

and

use

moisture-free

air to dry off all

the parts

and

clean

out oil

passages.

The composition clutch plates,

bands

and

synthetic seals should

not

be cleaned

in a

vapor degreaser

or

with

any

type

of

detergent solution.

To clean these parts, wipe them

off

with

a

lint-free cloth.

New

clutch

plates

or

bands should

be

soaked

in

transmission fluid

for

fifteen minutes

before

the

plates

or

bands

are as-

sembled.

CONVERTER

The converter cannot

be

disas-

sembled

for

cleaning.

If

there

is rea-

son

to

believe that

the

converter

con-

tains

an

excessive amount

of

foreign

material,

it

should

be

thoroughly

cleaned.

See the

instructions provided

with

the

Rotunda Automatic Trans-

mission Torque Converter

and

Cooler

Cleaner LRE-60081.

OIL COOLER

When

a

clutch

or

band failure

or

other internal trouble

has

occurred

inprocarmanuals.com

Page 316 of 413

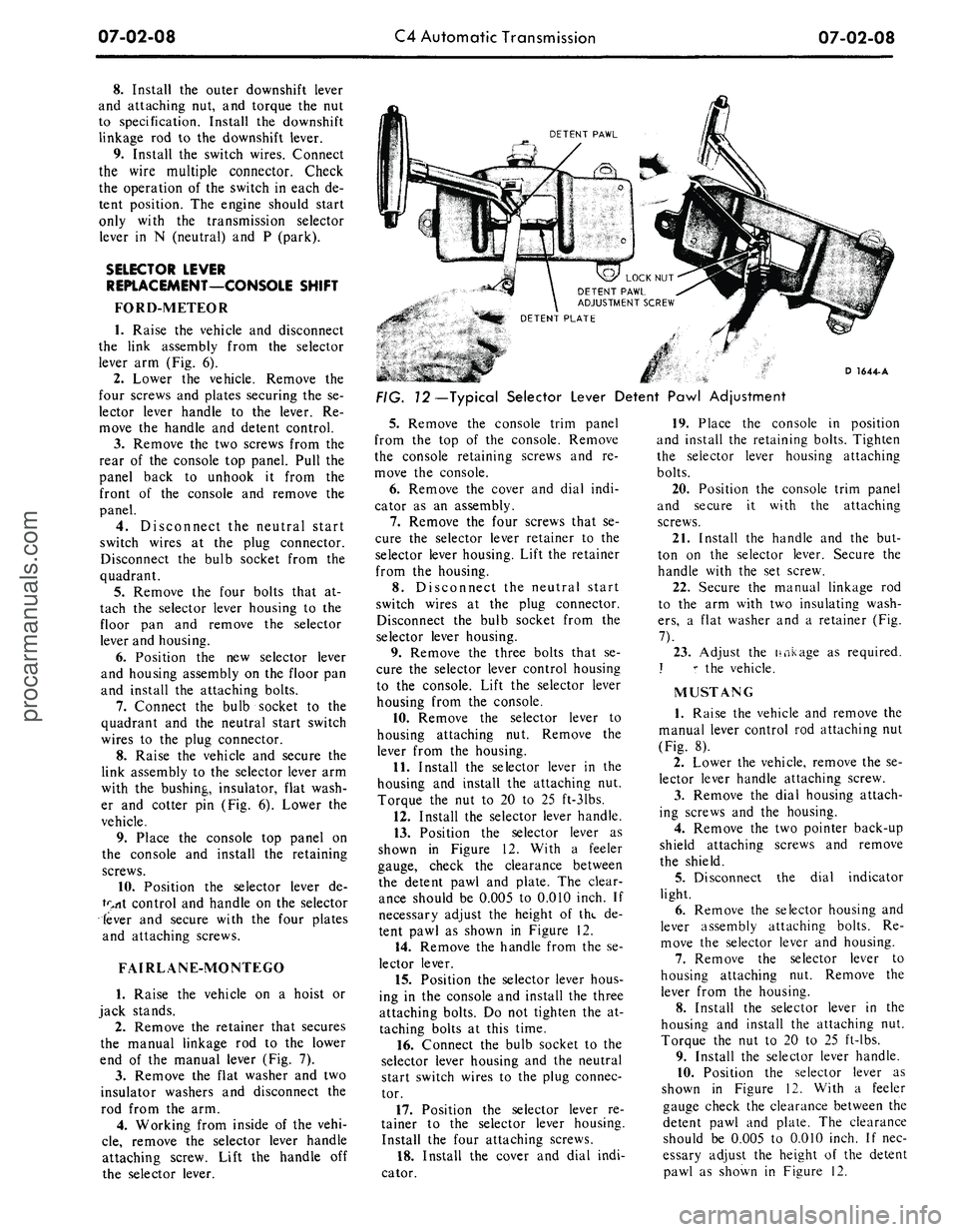

07-02-08

C4 Automatic Transmission

07-02-08

8. Install the outer downshift lever

and attaching nut, and torque the nut

to specification. Install the downshift

linkage rod to the downshift lever.

9. Install the switch wires. Connect

the wire multiple connector. Check

the operation of the switch in each de-

tent position. The engine should start

only with the transmission selector

lever in N (neutral) and P (park).

SELECTOR LEVER

REPLACEMENT—CONSOLE SHIFT

FORD-METEOR

1.

Raise the vehicle and disconnect

the link assembly from the selector

lever arm (Fig. 6).

2.

Lower the vehicle. Remove the

four screws and plates securing the se-

lector lever handle to the lever. Re-

move the handle and detent control.

3.

Remove the two screws from the

rear of the console top panel. Pull the

panel back to unhook it from the

front of the console and remove the

panel.

4.

Disconnect the neutral start

switch wires at the plug connector.

Disconnect the bulb socket from the

quadrant.

5.

Remove the four bolts that at-

tach the selector lever housing to the

floor pan and remove the selector

lever and housing.

6. Position the new selector lever

and housing assembly on the floor pan

and install the attaching bolts.

7.

Connect the bulb socket to the

quadrant and the neutral start switch

wires to the plug connector.

8. Raise the vehicle and secure the

link assembly to the selector lever arm

with the bushing, insulator, flat wash-

er and cotter pin (Fig. 6). Lower the

vehicle.

9. Place the console top panel on

the console and install the retaining

screws.

10.

Position the selector lever de-

tr*rtt control and handle on the selector

lever and secure with the four plates

and attaching screws.

FAIRLANE-MONTEGO

1.

Raise the vehicle on a hoist or

jack stands.

2.

Remove the retainer that secures

the manual linkage rod to the lower

end of the manual lever (Fig. 7).

3.

Remove the flat washer and two

insulator washers and disconnect the

rod from the arm.

4.

Working from inside of the vehi-

cle,

remove the selector lever handle

attaching screw. Lift the handle off

the selector lever.

DETENT PAWL

LOCK NUT

DETENT PAWL

ADJUSTMENT SCREW

DETENT PLATE

D 1644-A

FIG. 72—Typical Selector Lever Detent Pawl Adjustment

5.

Remove the console trim panel

from the top of the console. Remove

the console retaining screws and re-

move the console.

6. Remove the cover and dial indi-

cator as an assembly.

7.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

8. Disconnect the neutral start

switch wires at the plug connector.

Disconnect the bulb socket from the

selector lever housing.

9. Remove the three bolts that se-

cure the selector lever control housing

to the console. Lift the selector lever

housing from the console.

10.

Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

11.

Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-31bs.

12.

Install the selector lever handle.

13.

Position the selector lever as

shown in Figure 12. With a feeler

gauge, check the clearance between

the detent pawl and plate. The clear-

ance should be 0.005 to 0.010 inch. If

necessary adjust the height of the de-

tent pawl as shown in Figure 12.

14.

Remove the handle from the se-

lector lever.

15.

Position the selector lever hous-

ing in the console and install the three

attaching bolts. Do not tighten the at-

taching bolts at this time.

16.

Connect the bulb socket to the

selector lever housing and the neutral

start switch wires to the plug connec-

tor.

17.

Position the selector lever re-

tainer to the selector lever housing.

Install the four attaching screws.

18.

Install the cover and dial indi-

cator.

19.

Place the console in position

and install the retaining bolts. Tighten

the selector lever housing attaching

bolts.

20.

Position the console trim panel

and secure it with the attaching

screws.

21.

Install the handle and the but-

ton on the selector lever. Secure the

handle with the set screw.

22.

Secure the manual linkage rod

to the arm with two insulating wash-

ers,

a flat washer and a retainer (Fig.

7).

23.

Adjust the linkage as required.

J r the vehicle.

MUSTANG

1.

Raise the vehicle and remove the

manual lever control rod attaching nut

(Fig. 8).

2.

Lower the vehicle, remove the se-

lector lever handle attaching screw.

3.

Remove the dial housing attach-

ing screws and the housing.

4.

Remove the two pointer back-up

shield attaching screws and remove

the shield.

5.

Disconnect the dial indicator

light.

6. Remove the selector housing and

lever assembly attaching bolts. Re-

move the selector lever and housing.

7.

Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

8. Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-lbs.

9. Install the selector lever handle.

10.

Position the selector lever as

shown in Figure 12. With a feeler

gauge check the clearance between the

detent pawl and plate. The clearance

should be 0.005 to 0.010 inch. If nec-

essary adjust the height of the detent

pawl as shown in Figure 12.procarmanuals.com

Page 348 of 413

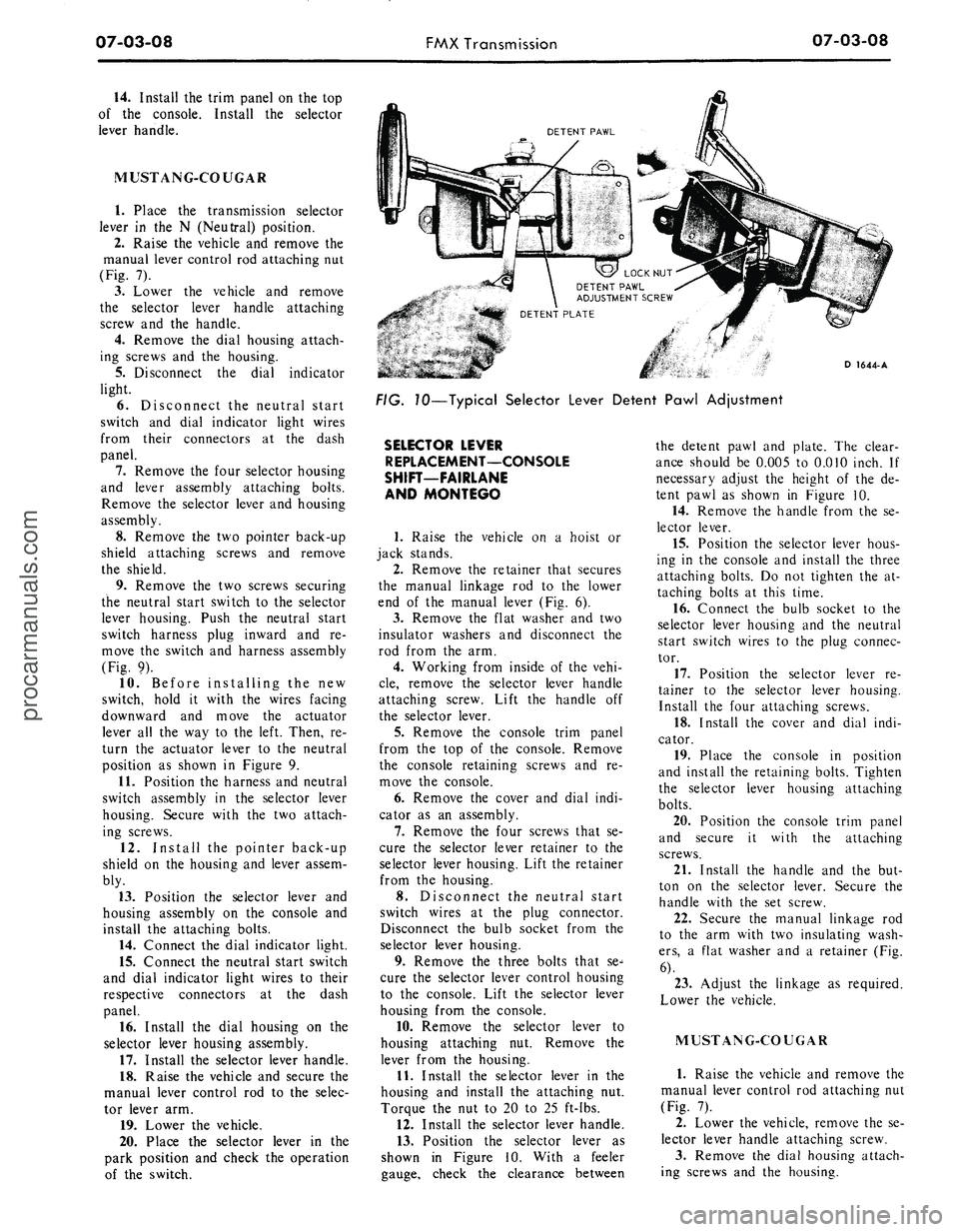

07-03-08

FAAX Transmission

07-03-08

14.

Install the trim panel on the top

of the console. Install the selector

lever handle.

MUSTANG-COUGAR

1.

Place the transmission selector

lever in the N (Neutral) position.

2.

Raise the vehicle and remove the

manual lever control rod attaching nut

(Fig. 7).

3.

Lower the vehicle and remove

the selector lever handle attaching

screw and the handle.

4.

Remove the dial housing attach-

ing screws and the housing.

5.

Disconnect the dial indicator

light.

6. Disconnect the neutral start

switch and dial indicator light wires

from their connectors at the dash

panel.

7.

Remove the four selector housing

and lever assembly attaching bolts.

Remove the selector lever and housing

assembly.

8. Remove the two pointer back-up

shield attaching screws and remove

the shield.

9. Remove the two screws securing

the neutral start switch to the selector

lever housing. Push the neutral start

switch harness plug inward and re-

move the switch and harness assembly

(Fig. 9).

10.

Before installing the new

switch, hold it with the wires facing

downward and move the actuator

lever all the way to the left. Then, re-

turn the actuator lever to the neutral

position as shown in Figure 9.

11.

Position the harness and neutral

switch assembly in the selector lever

housing. Secure with the two attach-

ing screws.

12.

Install the pointer back-up

shield on the housing and lever assem-

bly.

13.

Position the selector lever and

housing assembly on the console and

install the attaching bolts.

14.

Connect the dial indicator light.

15.

Connect the neutral start switch

and dial indicator light wires to their

respective connectors at the dash

panel.

16.

Install the dial housing on the

selector lever housing assembly.

17.

Install the selector lever handle.

18.

Raise the vehicle and secure the

manual lever control rod to the selec-

tor lever arm.

19.

Lower the vehicle.

20.

Place the selector lever in the

park position and check the operation

of the switch.

DETENT PAWL

LOCK

NUT

DETENT PAWL

ADJUSTMENT SCREW

DETENT PLATE

D 1644-A

FIG.

10—Typical Selector Lever Detent Pawl Adjustment

SELECTOR LEVER

REPLACEMENT—CONSOLE

SHIFT—FAIRLANE

AND

MONTEGO

1.

Raise the vehicle on a hoist or

jack stands.

2.

Remove the retainer that secures

the manual linkage rod to the lower

end of the manual lever (Fig. 6).

3.

Remove the flat washer and two

insulator washers and disconnect the

rod from the arm.

4.

Working from inside of the vehi-

cle,

remove the selector lever handle

attaching screw. Lift the handle off

the selector lever.

5.

Remove the console trim panel

from the top of the console. Remove

the console retaining screws and re-

move the console.

6. Remove the cover and dial indi-

cator as an assembly.

7.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

8. Disconnect the neutral start

switch wires at the plug connector.

Disconnect the bulb socket from the

selector lever housing.

9. Remove the three bolts that se^

cure the selector lever control housing

to the console. Lift the selector lever

housing from the console.

10.

Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

11.

Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-lbs.

12.

Install the selector lever handle.

13.

Position the selector lever as

shown in Figure 10. With a feeler

gauge,

check the clearance between

the detent pawl and plate. The clear-

ance should be 0.005 to 0.010 inch. If

necessary adjust the height of the de-

tent pawl as shown in Figure 10.

14.

Remove the handle from the se-

lector lever.

15.

Position the selector lever hous-

ing in the console and install the three

attaching bolts. Do not tighten the at-

taching bolts at this time.

16.

Connect the bulb socket to the

selector lever housing and the neutral

start switch wires to the plug connec-

tor.

17.

Position the selector lever re-

tainer to the selector lever housing.

Install the four attaching screws.

18.

Install the cover and dial indi-

cator.

19.

Place the console in position

and install the retaining bolts. Tighten

the selector lever housing attaching

bolts.

20.

Position the console trim panel

and secure it with the attaching

screws.

21.

Install the handle and the but-

ton on the selector lever. Secure the

handle with the set screw.

22.

Secure the manual linkage rod

to the arm with two insulating wash-

ers,

a flat washer and a retainer (Fig.

6).

23.

Adjust the linkage as required.

Lower the vehicle.

MUSTANG-COUGAR

1.

Raise the vehicle and remove the

manual lever control rod attaching nut

(Fig. 7).

2.

Lower the vehicle, remove the se-

lector lever handle attaching screw.

3.

Remove the dial housing attach-

ing screws and the housing.procarmanuals.com

Page 349 of 413

07-03-09

FMX Transmission

07-03-09

4.

Remove the pointer back-up

shield attaching screws and the shield.

5.

Disconnect the dial indicator

light.

6. Disconnect the neutral start

switch and dial indicator light wires

from their connectors at the dash

panel.

7.

Remove the selector housing and

lever assembly attaching bolts. Re-

move the selector lever and housing.

8. Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

9. Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-lbs.

10.

Install the selector lever handle.

11.

Position the selector lever as

shown in Figure 10. With a feeler

gauge check the clearance between the

detent pawl and plate. The clearince

should be 0.005 to 0.010 inch. If nec-

essary, adjust the height of the detent

pawl as shown in Figure 10.

12.

Remo"~ the handle from tte se-

lector lever.

13.

Install the selector housing and

lever assembly as shown in Figure 4.

Torque the attaching bolts 4-6 ft-lbs.

14.

Connect the dial indicator light.

15.

Connect the neutral start switch

and dial indicator light wires to their

respective connectors at the dash

panel.

16.

Install the pointer back-up

shield and tighten the attaching

screws.

17.

Install the selector lever handle

and tighten the attaching screw.

18.

Position the selector lever in the

D position.

19.

Raise the vehicle. Install the

transmission manual lever rod to the

selector lever. Adjust the manual link-

age.

20.

Lower the vehicle and check the

transmission operation in each selec-

tor lever detent position.

BAND ADJUSTMENTS

FRONT BAND

ADJUSTMENT

1.

Drain the fluid from the trans-

mission by loosening the pan attach-

ing bolts starting at the rear of the

pan and working toward the front.

When most of the fluid has drained

from the pan, remove the remainder

of the attaching bolts. Use a clean

drain can equipped with a 100-mesh

screen if the fluid is to be reused.

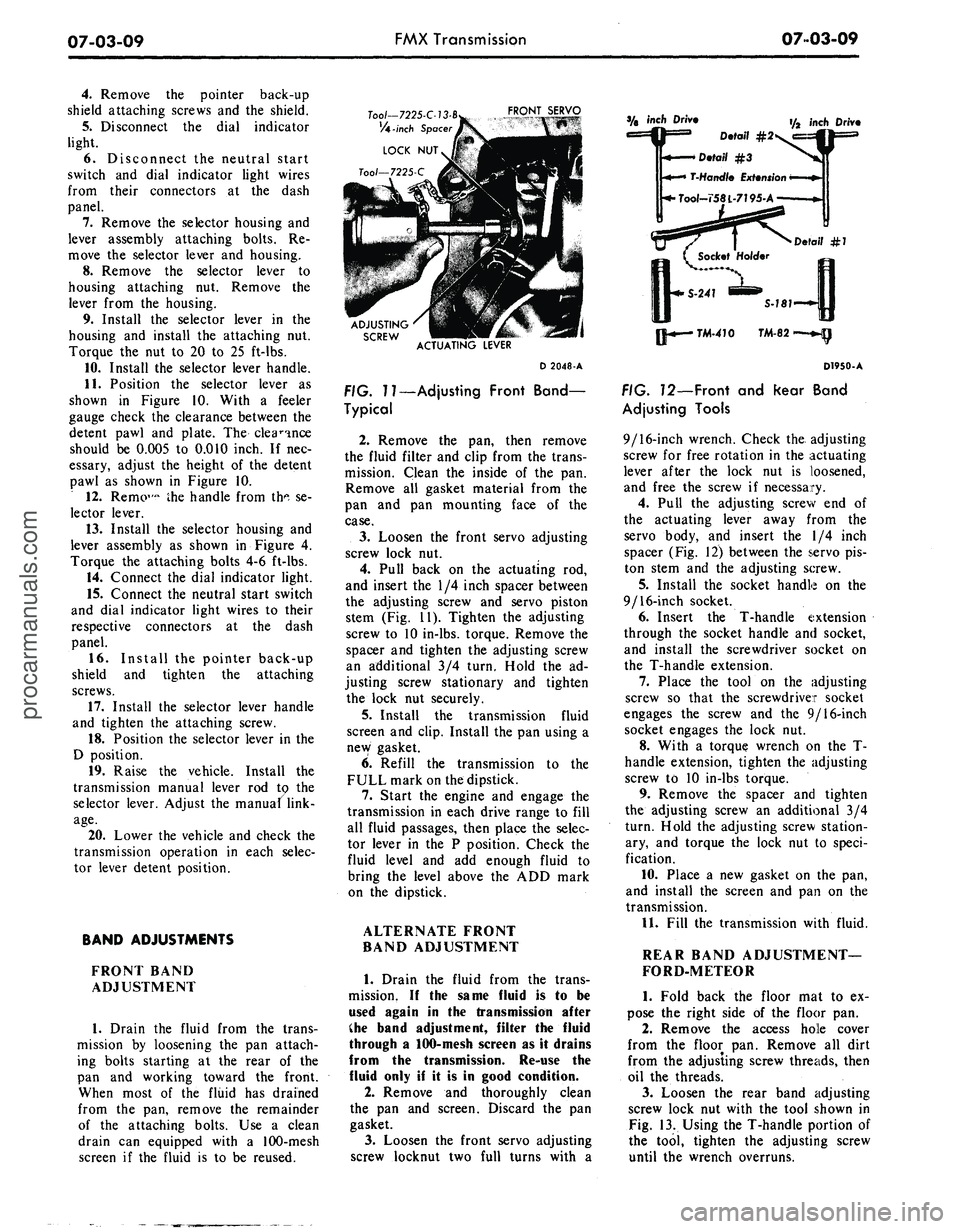

Too/—

7225-C-13B

/A

-inch

Spacer

FRONT SERVO

ACTUATING LEVER

D 2048-A

FIG.

7

7—Adjusting Front Band—

Typical

2.

Remove the pan, then remove

the fluid filter and clip from the trans-

mission. Clean the inside of the pan.

Remove all gasket material from the

pan and pan mounting face of the

case.

3.

Loosen the front servo adjusting

screw lock nut.

4.

Pull back on the actuating rod,

and insert the 1/4 inch spacer between

the adjusting screw and servo piston

stem (Fig. 11). Tighten the adjusting

screw to 10 in-lbs. torque. Remove the

spacer and tighten the adjusting screw

an additional 3/4 turn. Hold the ad-

justing screw stationary and tighten

the lock nut securely.

5.

Install the transmission fluid

screen and clip. Install the pan using a

new gasket.

6. Refill the transmission to the

FULL mark on the dipstick.

7.

Start the engine and engage the

transmission in each drive range to fill

all fluid passages, then place the selec-

tor lever in the P position. Check the

fluid level and add enough fluid to

bring the level above the ADD mark

on the dipstick.

ALTERNATE FRONT

BAND ADJUSTMENT

1.

Drain the fluid from the trans-

mission. If the same fluid is to be

used again in the transmission after

Che band adjustment, filter the fluid

through a 100-mesh screen as it drains

from the transmission. Re-use the

fluid only if it is in good condition.

2.

Remove and thoroughly clean

the pan and screen. Discard the pan

gasket.

3.

Loosen the front servo adjusting

screw locknut two full turns with a

inch Driv

Detail #2

D.tai\

#3

T-Hond/e

Extension

Tool-758L-7195-A

f/2 inch Driv

Detail

#7

Qj-«—

TM-470 TM-82

D1950-A

FIG. 12—Front and Rear Band

Adjusting Tools

9/16-inch wrench. Check the. adjusting

screw for free rotation in the actuating

lever after the lock nut is loosened,

and free the screw if necessary.

4.

Pull the adjusting screw end of

the actuating lever away from the

servo body, and insert the 1/4 inch

spacer (Fig. 12) between the servo pis-

ton stem and the adjusting screw.

5.

Install the socket handle on the

9/16-inch socket.

6. Insert the T-handle extension

through the socket handle and socket,

and install the screwdriver socket on

the T-handle extension.

7.

Place the tool on the adjusting

screw so that the screwdriver socket

engages the screw and the 9/16-inch

socket engages the lock nut.

8. With a torque wrench on the T-

handle extension, tighten the adjusting

screw to 10 in-lbs torque.

9. Remove the spacer and tighten

the adjusting screw an additional 3/4

turn. Hold the adjusting screw station-

ary, and torque the lock nut to speci-

fication.

10.

Place a new gasket on the pan,

and install the screen and pan on the

transmission.

11.

Fill the transmission with fluid.

REAR BAND ADJUSTMENT—

FORD-METEOR

1.

Fold back the floor mat to ex-

pose the right side of the floor pan.

2.

Remove the access hole cover

from the floor pan. Remove all dirt

from the adjusting screw threads, then

oil the threads.

3.

Loosen the rear band adjusting

screw lock nut with the tool shown in

Fig. 13. Using the T-handle portion of

the tool, tighten the adjusting screw

until the wrench overruns.procarmanuals.com

Page 379 of 413

07-04-10

C-6 Automatic Transmission

07-04-10

5.

Remove the four bolts that at-

tach the selector lever housing to the

floor pan and remove the selector

lever and housing.

6. Position the new selector lever

and housing assembly on the floor pan

and install the attaching bolts.

7.

Connect the bulb socket to the

quadrant and the neutral start switch

wires to the plug connector.

8. Raise the vehicle and secure the

link assembly to the selector lever arm

with the bushing, insulator, flat wash-

er and cotter pin (Fig. 8). Lower the

vehicle.

9. Place the console top panel on

the console and install the retaining

screws.

10.

Position the selector lever de-

tent control and handle on the selector

lever and secure with the four plates

and attaching screws.

FAIRLANE AND MONTEGO

1.

Raise the vehicle on a hoist or

jack stands.

2.

Remove the retainer that secures

the manual linkage rod to the lower

end of the manual lever (Fig. 9).

3.

Remove the flat washer and two

insulator washers and disconnect the

rod from the arm.

4.

Working from inside of the vehi-

cle,

remove the selector lever handle

attaching screw. Lift the handle off

the selector lever.

5.

Remove the console trim panel

from the top of the console. Remove

the console retaining screws and re-

move the console.

6. Remove the cover and dial indi-

cator as an assembly.

7.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

8. Disconnect the neutral start

switch wires at the plug connector.

Disconnect the bulb socket from the

selector lever housing.

9. Remove the three bolts that se-

cure the selector lever control housing

to the console. Lift the selector lever

housing from the console.

10.

Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

11.

Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-lbs.

12.

Install the selector lever handle.

13.

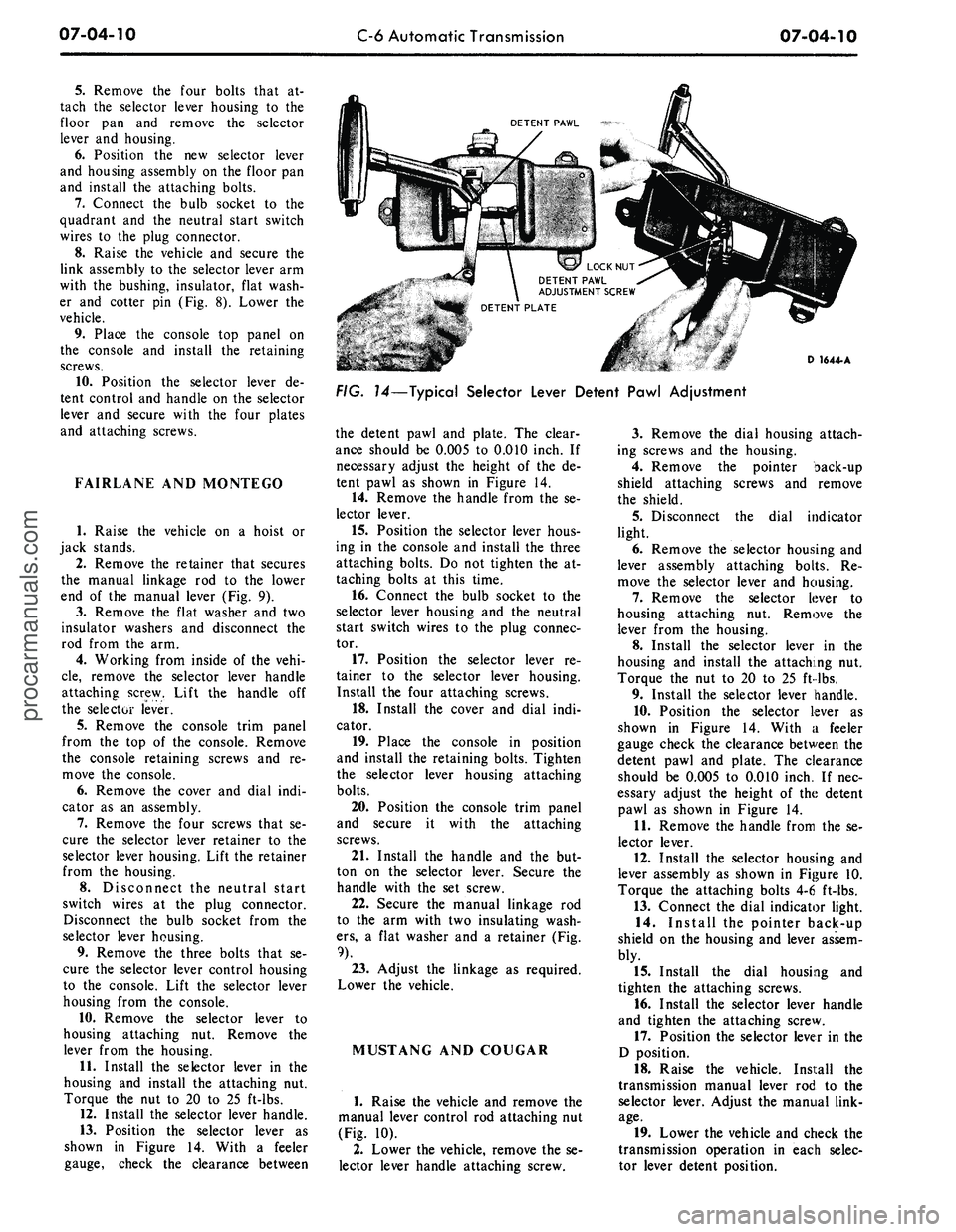

Position the selector lever as

shown in Figure 14. With a feeler

gauge, check the clearance between

DETENT

PAWL

LOCK

NUT

DETENT

PAWL

ADJUSTMENT

SCREW

DETENT

PLATE

D

1644-A

FIG. 14—Typical Selector Lever Detent Pawl Adjustment

the detent pawl and plate. The clear-

ance should be 0.005 to 0.010 inch. If

necessary adjust the height of the de-

tent pawl as shown in Figure 14.

14.

Remove the handle from the se-

lector lever.

15.

Position the selector lever hous-

ing in the console and install the three

attaching bolts. Do not tighten the at-

taching bolts at this time.

16.

Connect the bulb socket to the

selector lever housing and the neutral

start switch wires to the plug connec-

tor.

17.

Position the selector lever re-

tainer to the selector lever housing.

Install the four attaching screws.

18.

Install the cover and dial indi-

cator.

19.

Place the console in position

and install the retaining bolts. Tighten

the selector lever housing attaching

bolts.

20.

Position the console trim panel

and secure it with the attaching

screws.

21.

Install the handle and the but-

ton on the selector lever. Secure the

handle with the set screw.

22.

Secure the manual linkage rod

to the arm with two insulating wash-

ers,

a flat washer and a retainer (Fig.

9).

23.

Adjust the linkage as required.

Lower the vehicle.

MUSTANG AND COUGAR

1.

Raise the vehicle and remove the

manual lever control rod attaching nut

(Fig. 10).

2.

Lower the vehicle, remove the se-

lector lever handle attaching screw.

3.

Remove the dial housing attach-

ing screws and the housing.

4.

Remove the pointer back-up

shield attaching screws and remove

the shield.

5.

Disconnect the dial indicator

light.

6. Remove the selector housing and

lever assembly attaching bolts. Re-

move the selector lever and housing.

7.

Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

8. Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-lbs.

9. Install the selector lever handle.

10.

Position the selector lever as

shown in Figure 14. With a feeler

gauge check the clearance between the

detent pawl and plate. The clearance

should be 0.005 to 0.010 inch. If nec-

essary adjust the height of the detent

pawl as shown in Figure 14.

11.

Remove the handle from the se-

lector lever.

12.

Install the selector housing and

lever assembly as shown in Figure 10.

Torque the attaching bolts 4-6 ft-lbs.

13.

Connect the dial indicator light.

14.

Install the pointer back-up

shield on the housing and lever assem-

bly.

15.

Install the dial housing and

tighten the attaching screws.

16.

Install the selector lever handle

and tighten the attaching screw.

17.

Position the selector lever in the

D position.

18.

Raise the vehicle. Install the

transmission manual lever rod to the

selector lever. Adjust the manual link-

age.

19.

Lower the vehicle and check the

transmission operation in each selec-

tor lever detent position.procarmanuals.com