length FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 201 of 413

04-02-04

Rear Axle — Removable Carrier Type

04-02-04

IN-VEHICLE ADJUSTMENTS AND REPAIRS

REAR AXLE SHAFT, WHEEL

BEARING AND OIL SEAL

REPLACEMENT

The rear axle shafts, wheel bear-

ings,

and oil seal can be replaced

without removing the differential as-

sembly from the axle housing.

REMOVAL OF

AXLE SHAFT

Synthetic wheel bearing seals are

used in production only. Removal and

insertion of rear axle shafts must be

performed with caution. The entire

length of the shaft (including spline)

up to the seal journal must pass

through the seal without cutting of the

seal element during axle removal or

installation will result in early seal fai-

lure.

Leather seals only will be used as

service replacement for synthetic

wheel bearing seals.

1.

Remove the wheel cover, wheel

and tire from the brake drum.

2.

Remove the nuts that secure the

brake drum to the axle shaft flange,

then remove the drum from flange.

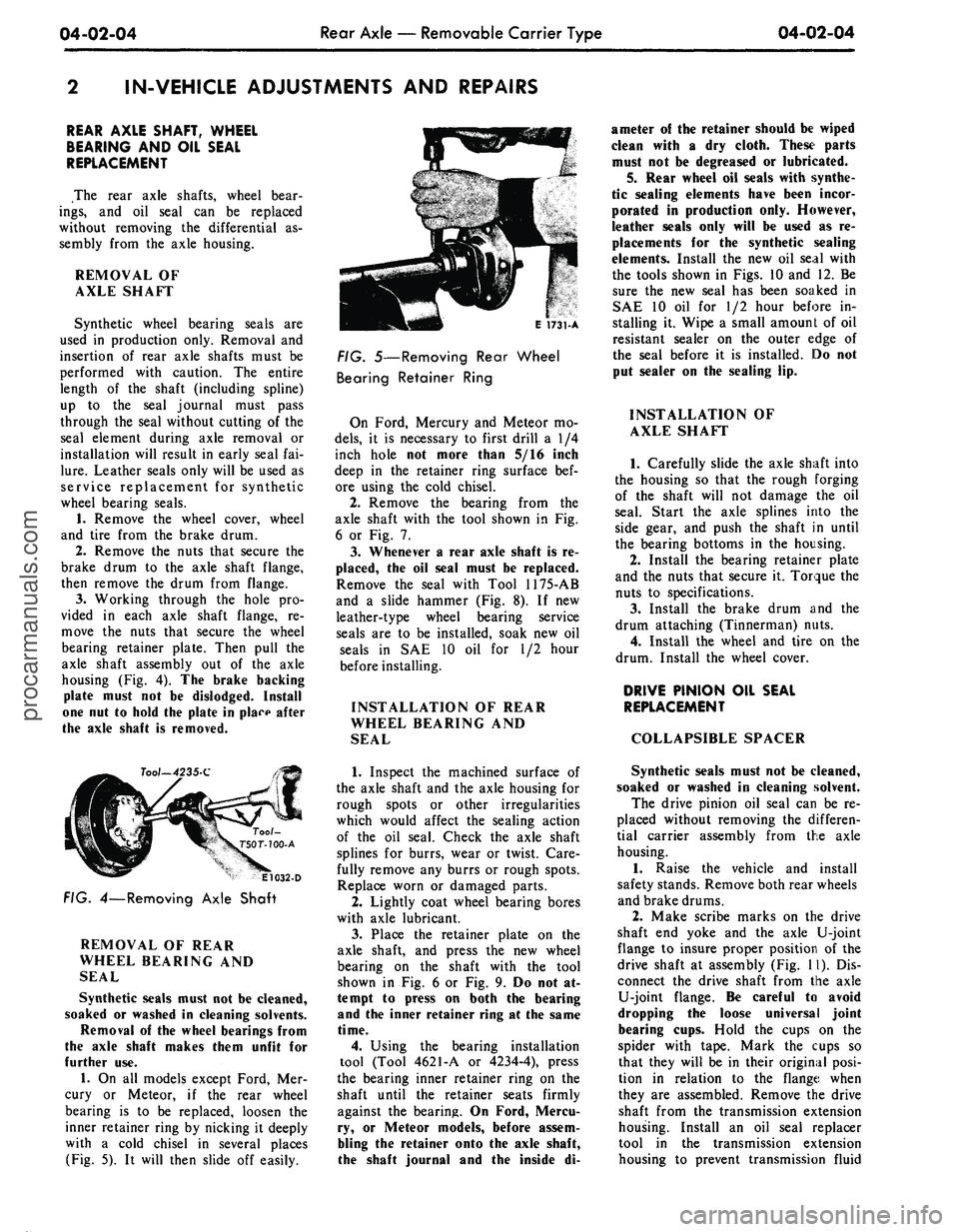

3.

Working through the hole pro-

vided in each axle shaft flange, re-

move the nuts that secure the wheel

bearing retainer plate. Then pull the

axle shaft assembly out of the axle

housing (Fig. 4). The brake backing

plate must not be dislodged. Install

one nut to hold the plate in place after

the axle shaft is removed.

Too/-4235-C

E1032-D

FIG. 4—Removing Axle Shaft

REMOVAL OF REAR

WHEEL BEARING AND

SEAL

Synthetic seals must not be cleaned,

soaked or washed in cleaning solvents.

Removal of the wheel bearings from

the axle shaft makes them unfit for

further use.

1.

On all models except Ford, Mer-

cury or Meteor, if the rear wheel

bearing is to be replaced, loosen the

inner retainer ring by nicking it deeply

with a cold chisel in several places

(Fig. 5). It will then slide off easily.

E 1731-A

FIG. 5—Removing Rear Wheel

Bearing Retainer Ring

On Ford, Mercury and Meteor mo-

dels,

it is necessary to first drill a 1/4

inch hole not more than 5/16 inch

deep in the retainer ring surface bef-

ore using the cold chisel.

2.

Remove the bearing from the

axle shaft with the tool shown in Fig.

6 or Fig. 7.

3.

Whenever a rear axle shaft is re-

placed, the oil seal must be replaced.

Remove the seal with Tool 1175-AB

and a slide hammer (Fig. 8). If new

leather-type wheel bearing service

seals are to be installed, soak new oil

seals in SAE 10 oil for 1/2 hour

before installing.

INSTALLATION OF REAR

WHEEL BEARING AND

SEAL

1.

Inspect the machined surface of

the axle shaft and the axle housing for

rough spots or other irregularities

which would affect the sealing action

of the oil seal. Check the axle shaft

splines for burrs, wear or twist. Care-

fully remove any burrs or rough spots.

Replace worn or damaged parts.

2.

Lightly coat wheel bearing bores

with axle lubricant.

3.

Place the retainer plate on the

axle shaft, and press the new wheel

bearing on the shaft with the tool

shown in Fig. 6 or Fig. 9. Do not at-

tempt to press on both the bearing

and the inner retainer ring at the same

time.

4.

Using the bearing installation

tool (Tool 4621-A or 4234-4), press

the bearing inner retainer ring on the

shaft until the retainer seats firmly

against the bearing. On Ford, Mercu-

ry, or Meteor models, before assem-

bling the retainer onto the axle shaft,

the shaft journal and the inside di-

ameter of the retainer should be wiped

clean with a dry cloth. These parts

must not be degreased or lubricated.

5. Rear wheel oil seals with synthe-

tic sealing elements have been incor-

porated in production only. However,

leather seals only will be used as re-

placements for the synthetic sealing

elements. Install the new oil seal with

the tools shown in Figs. 10 and 12. Be

sure the new seal has been soaked in

SAE 10 oil for 1/2 hour before in-

stalling it. Wipe a small amount of oil

resistant sealer on the outer edge of

the seal before it is installed. Do not

put sealer on the sealing lip.

INSTALLATION OF

AXLE SHAFT

1.

Carefully slide the axle shaft into

the housing so that the rough forging

of the shaft will not damage the oil

seal. Start the axle splines into the

side gear, and push the shaft in until

the bearing bottoms in the housing.

2.

Install the bearing retainer plate

and the nuts that secure it. Torque the

nuts to specifications.

3.

Install the brake drum and the

drum attaching (Tinnerman) nuts.

4.

Install the wheel and tire on the

drum. Install the wheel cover.

DRIVE PINION OIL SEAL

REPLACEMENT

COLLAPSIBLE SPACER

Synthetic seals must not be cleaned,

soaked or washed in cleaning solvent.

The drive pinion oil seal can be re-

placed without removing the differen-

tial carrier assembly from the axle

housing.

1.

Raise the vehicle and install

safety stands. Remove both rear wheels

and brake drums.

2.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly (Fig. 11). Dis-

connect the drive shaft from the axle

U-joint flange. Be careful to avoid

dropping the loose universal joint

bearing cups. Hold the cups on the

spider with tape. Mark the cups so

that they will be in their original posi-

tion in relation to the flange when

they are assembled. Remove the drive

shaft from the transmission extension

housing. Install an oil seal replacer

tool in the transmission extension

housing to prevent transmission fluidprocarmanuals.com

Page 222 of 413

04-03-02

Rear Axles — Integral Carrier Type

04-03-02

RING GEAR

4209

DRIVE PINION

BEARINGS

4630

4621

FLANGE-4676

E1905A

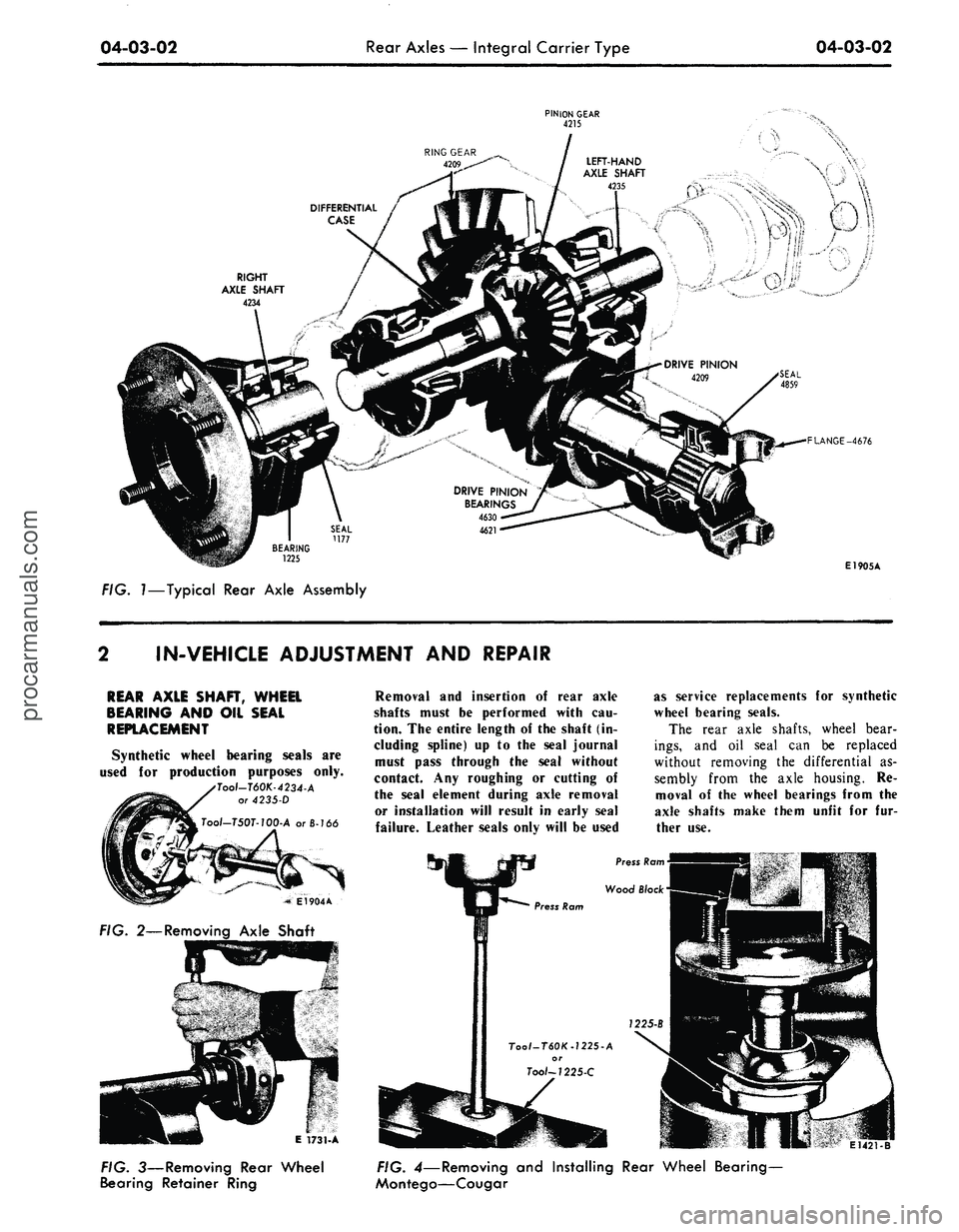

FIG. 7—Typical Rear Axle Assembly

IN-VEHICLE ADJUSTMENT

AND

REPAIR

REAR AXLE SHAFT, WHEEL

BEARING

AND OIL

SEAL

REPLACEMENT

Synthetic wheel bearing seals

are

used

for

production purposes only.

>Tool-T60K-4234-A

or 4235-D

Tool-T50T-W0-A

or 8-/66

* El904A

FIG. 2—Removing Axle Shaft

E 1731-A

FIG. 3—Removing Rear Wheel

Bearing Retainer Ring

Removal

and

insertion

of

rear axle

shafts must

be

performed with

cau-

tion.

The

entire length

of the

shaft

(in-

cluding spline)

up to the

seal journal

must pass through

the

seal without

contact.

Any

roughing

or

cutting

of

the seal element during axle removal

or installation will result

in

early seal

failure. Leather seals only will

be

used

as service replacements

for

synthetic

wheel bearing seals.

The rear axle shafts, wheel bear-

ings,

and oil

seal

can be

replaced

without removing

the

differential

as-

sembly from

the

axle housing.

Re-

moval

of the

wheel bearings from

the

axle shafts make them unfit

for fur-

ther

use.

E1421-B

FIG. 4—Removing and Installing Rear Wheel Bearing—

Montego—Cougarprocarmanuals.com

Page 233 of 413

04-04-02

Rear Axle

—

Ford Light-Duty (WER)

04-04-02

DIFFERENTIAL

PINION-4215

RING GEAR

-

4209

LEFT AXLE

SHAFT

-

4235

1

DRIVE PINION

-

4209

SEAL

-

4676

FLANGE-4851

DEFLECTOR -4859

SEAL-

1177

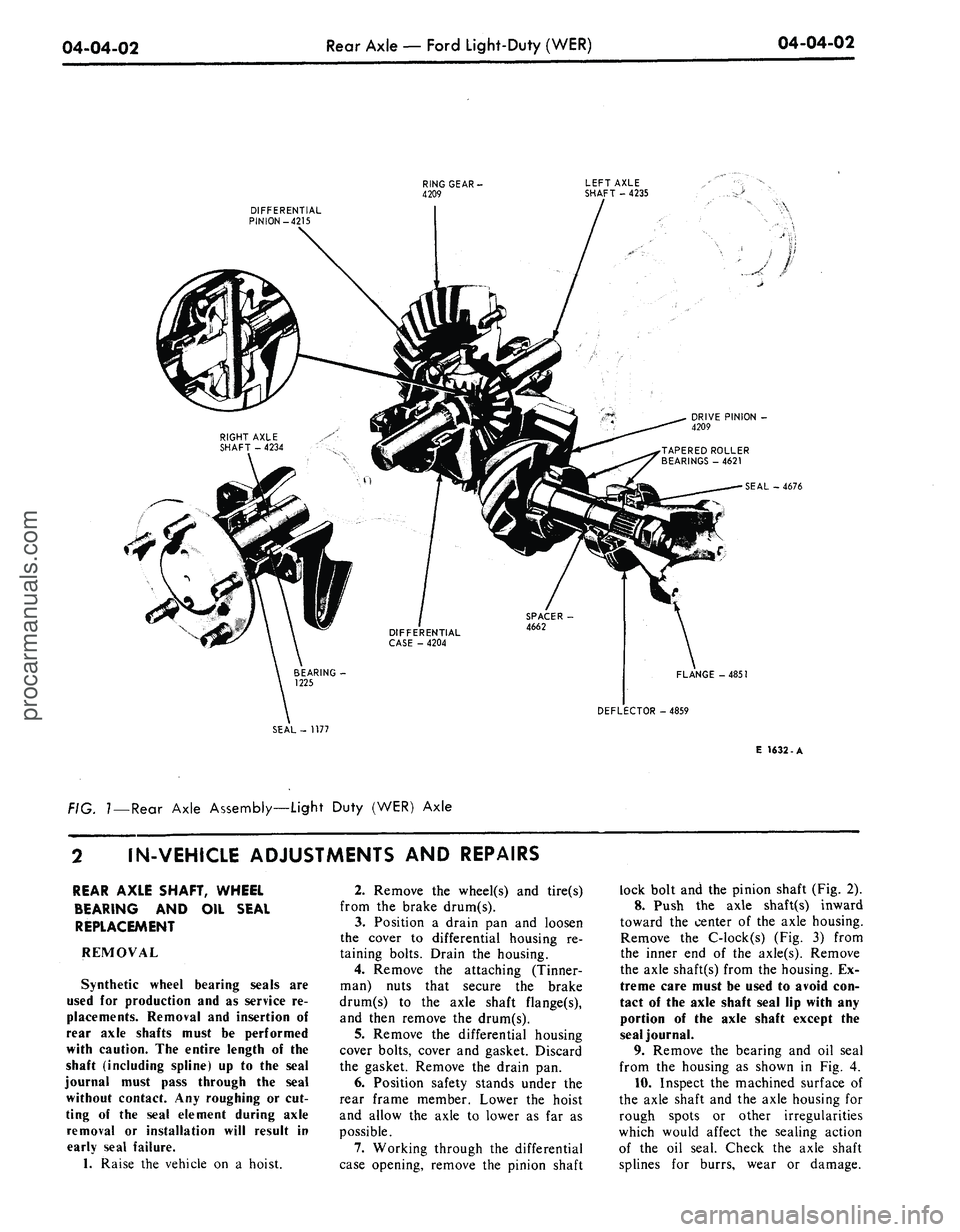

f\G.

7

—Rear Axle Assembly—Light Duty

(WER)

Axle

E 1632-A

IN-VEHICLE ADJUSTMENTS AND REPAIRS

REAR AXLE SHAFT, WHEEL

BEARING

AND OIL

SEAL

REPLACEMENT

REMOVAL

Synthetic wheel bearing seals

are

used

for

production

and as

service

re-

placements. Removal

and

insertion

of

rear axle shafts must

be

performed

with caution.

The

entire length

of the

shaft (including spline)

up to the

seal

journal must pass through

the

seal

without contact.

Any

roughing

or cut-

ting

of the

seal element during axle

removal

or

installation will result

in

early seal failure.

1.

Raise

the

vehicle

on a

hoist.

2.

Remove

the

wheel(s)

and

tire(s)

from

the

brake drum(s).

3.

Position

a

drain

pan and

loosen

the cover

to

differential housing

re-

taining bolts. Drain

the

housing.

4.

Remove

the

attaching (Tinner-

man) nuts that secure

the

brake

drum(s)

to the

axle shaft flange(s),

and then remove

the

drum(s).

5.

Remove

the

differential housing

cover bolts, cover

and

gasket. Discard

the gasket. Remove

the

drain

pan.

6. Position safety stands under

the

rear frame member. Lower

the

hoist

and allow

the

axle

to

lower

as far as

possible.

7.

Working through

the

differential

case opening, remove

the

pinion shaft

lock bolt

and the

pinion shaft

(Fig. 2).

8. Push

the

axle shaft(s) inward

toward

the

center

of the

axle housing.

Remove

the

C-lock(s)

(Fig. 3)

from

the inner

end of the

axle(s). Remove

the axle shaft(s) from

the

housing.

Ex-

treme care must

be

used

to

avoid

con-

tact

of the

axle shaft seal

lip

with

any

portion

of the

axle shaft except

the

seal journal.

9. Remove

the

bearing

and oil

seal

from

the

housing

as

shown

in Fig. 4.

10.

Inspect

the

machined surface

of

the axle shaft

and the

axle housing

for

rough spots

or

other irregularities

which would affect

the

sealing action

of

the oil

seal. Check

the

axle shaft

splines

for

burrs, wear

or

damage.procarmanuals.com

Page 261 of 413

05-03-03

Clutch

05-03-03

CLUTCH PEDAL

ADJUSTMENTS

Adjust

the

clutch pedal free travel

whenever

the

clutch does

not

disen-

gage properly,

or

when

new

clutch

parts

are

installed. Improper adjust-

ment

of the

clutch pedal

is one of the

most frequent causes

of

clutch failure

and

can be a

contributing factor

in

some transmission failures.

FREE TRAVEL

1.

Disconnect

the

clutch return

spring from

the

release lever.

2.

Loosen

the

release lever

rod

locknut

and

adjusting

nut

(Figs.

1, 2

and

3).

3.

Move

the

clutch release lever

rearward until

the

release bearing

lightly contacts

the

clutch pressure

plate release fingers.

4.

Adjust

the rod

length until

the

rod seats

in the

release lever pocket.

5.

Insert

the

specified feeler gauge

between

the

adjusting

nut and the

swivel sleeve. Then tighten

the

adjust-

ing

nut

against

the

gauge finger tight.

6. Tighten

the

locknut against

the

adjusting

nut,

being careful

not to di-

sturb

the

adjustment. Torque

the

lock-

nut

to

specification

and

remove

the

feeler gauge.

7.

Install

the

clutch return spring.

8. Check

the

free travel

at the

pedal

for conformance

to

specification.

Re-

adjust

if

necessary.

9.

As a

final check, measure

the

pedal free travel with

the

transmission

in neutral

and the

engine running

at

about 3000

rpm. If the

pedal free

travel

at

this speed

is not a

minimum

of

1/2

inch, readjust

the

clutch pedal

free travel. Otherwise,

the

release

fin-

gers

may

contact

the

release bearing

continuously, resulting

in

premature

bearing

and

clutch failure. Free travel

must

be

exactly

to

specification.

CLUTCH ASSIST

SPRING REPLACEMENT

(FAIRLANE, FALCON,

MONTEGO)

1.

Remove

the

cotter

pin

from

the

clutch

rod at the

clutch pedal lever

as-

sembly inside

the

passenger compart-

ment.

2.

Grasp

the

clutch pedal lever

firmly

to

prevent slipping

and

remove

the clutch

rod

from

the

lever. Allow

the clutch pedal lever

to

rest

on the

floor panel.

3.

Remove

the

forward bolt secur-

ing

the

assist spring bracket

to the

brake pedal bracket

and

loosen

the

rear bolt

two or

three turns.

Do not

remove

the

rear bolt.

4.

Grasp

the

assist spring bracket

with pliers

and

rotate upward until

the

spring

can be

separated from

the

bracket.

BRAKE PEDAL

BRACKET

CLUTCH ASSIST SPRING

BRACKET

-

7535

CLUTCH PEDAL

7519

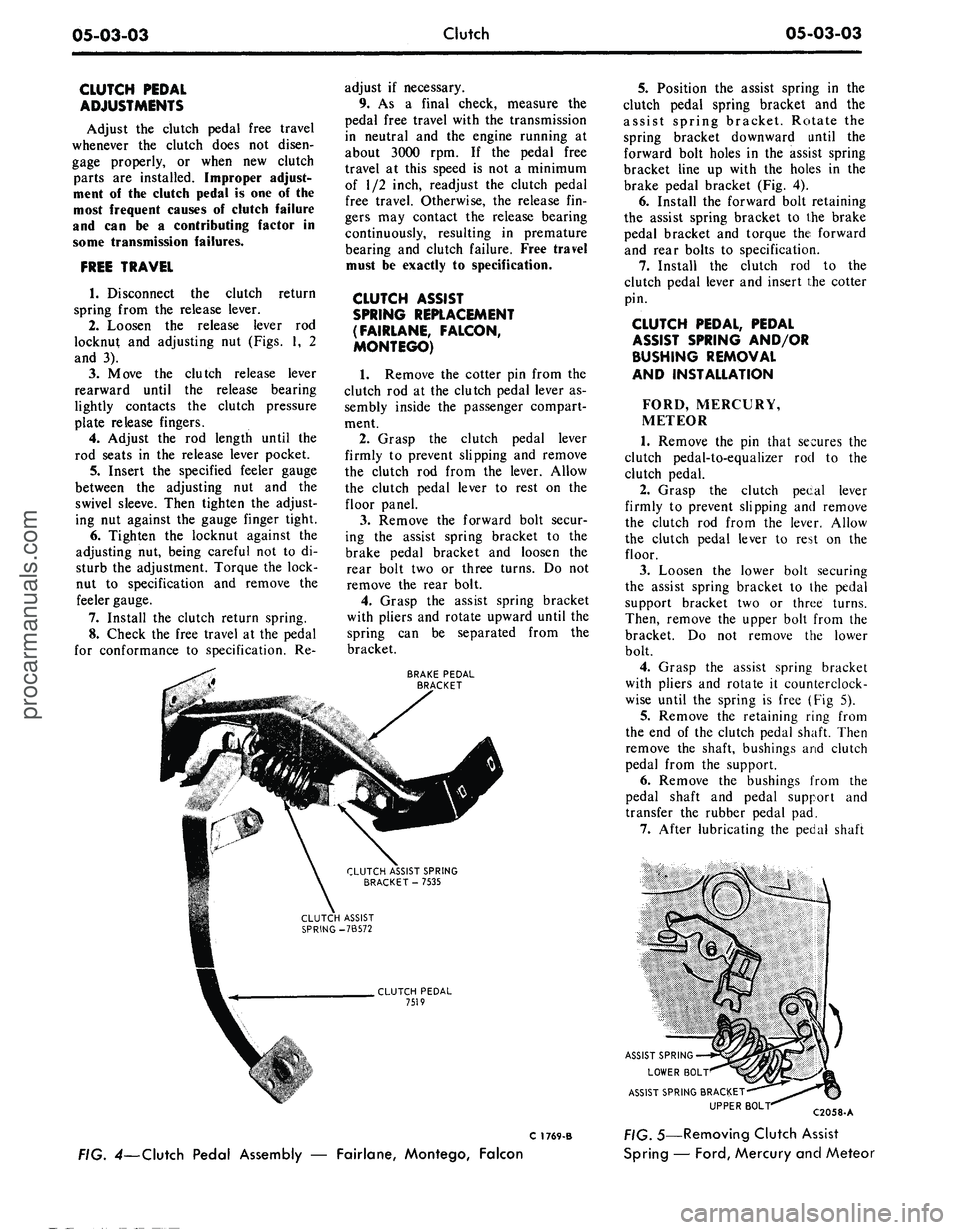

5.

Position

the

assist spring

in the

clutch pedal spring bracket

and the

assist spring bracket. Rotate

the

spring bracket downward until

the

forward bolt holes

in the

assist spring

bracket line

up

with

the

holes

in the

brake pedal bracket

(Fig. 4).

6. Install

the

forward bolt retaining

the assist spring bracket

to the

brake

pedal bracket

and

torque

the

forward

and rear bolts

to

specification.

7.

Install

the

clutch

rod to the

clutch pedal lever

and

insert

the

cotter

pin.

CLUTCH PEDAL, PEDAL

ASSIST SPRING AND/OR

BUSHING REMOVAL

AND INSTALLATION

FORD, MERCURY,

METEOR

1.

Remove

the pin

that secures

the

clutch pedal-to-equalizer

rod to the

clutch pedal.

2.

Grasp

the

clutch pecal lever

firmly

to

prevent slipping

and

remove

the clutch

rod

from

the

lever. Allow

the clutch pedal lever

to

rest

on the

floor.

3.

Loosen

the

lower bolt securing

the assist spring bracket

to the

pedal

support bracket

two or

three turns.

Then, remove

the

upper bolt from

the

bracket.

Do not

remove

the

lower

bolt.

4.

Grasp

the

assist spring bracket

with pliers

and

rotate

it

counterclock-

wise until

the

spring

is

free

(Fig 5).

5.

Remove

the

retaining ring from

the

end of the

clutch pedal shaft. Then

remove

the

shaft, bushings

and

clutch

pedal from

the

support.

6. Remove

the

bushings from

the

pedal shaft

and

pedal support

and

transfer

the

rubber pedal

pad.

7.

After lubricating

the

pedal shaft

ASSIST SPRING

LOWER BOLT

ASSIST SPRING BRACKET-

UPPER

BOL"

C 1769-B

FIG. 4—Clutch Pedal Assembly

—

Fairlane, Montego, Falcon

C2058-A

;. 5—Removing Clutch Assist

Spring

—

Ford,

Mercury and Meteorprocarmanuals.com

Page 272 of 413

06-02-03

Ford Design Three Speed Transmission

06-02-03

STOP

PIN

GROMMET

Tool -

T67P.7347.A

GROMMET

LEVER

CONTROL ROD REMOVAL

^S.

GROMMET INSTALLATION

SET STOP PIN SO THAT THE GROMMET

Tool

-

T67P.734LA

AND

SHIFT ROD ARE PROPERLY SEATED

OMMET—^

SEATED

\

CONTROL ROD INSTALLATION

CONTROL ROD

STOP

PIN

FIG. 4—Removing

or

Installing Shift Linkage Grommet

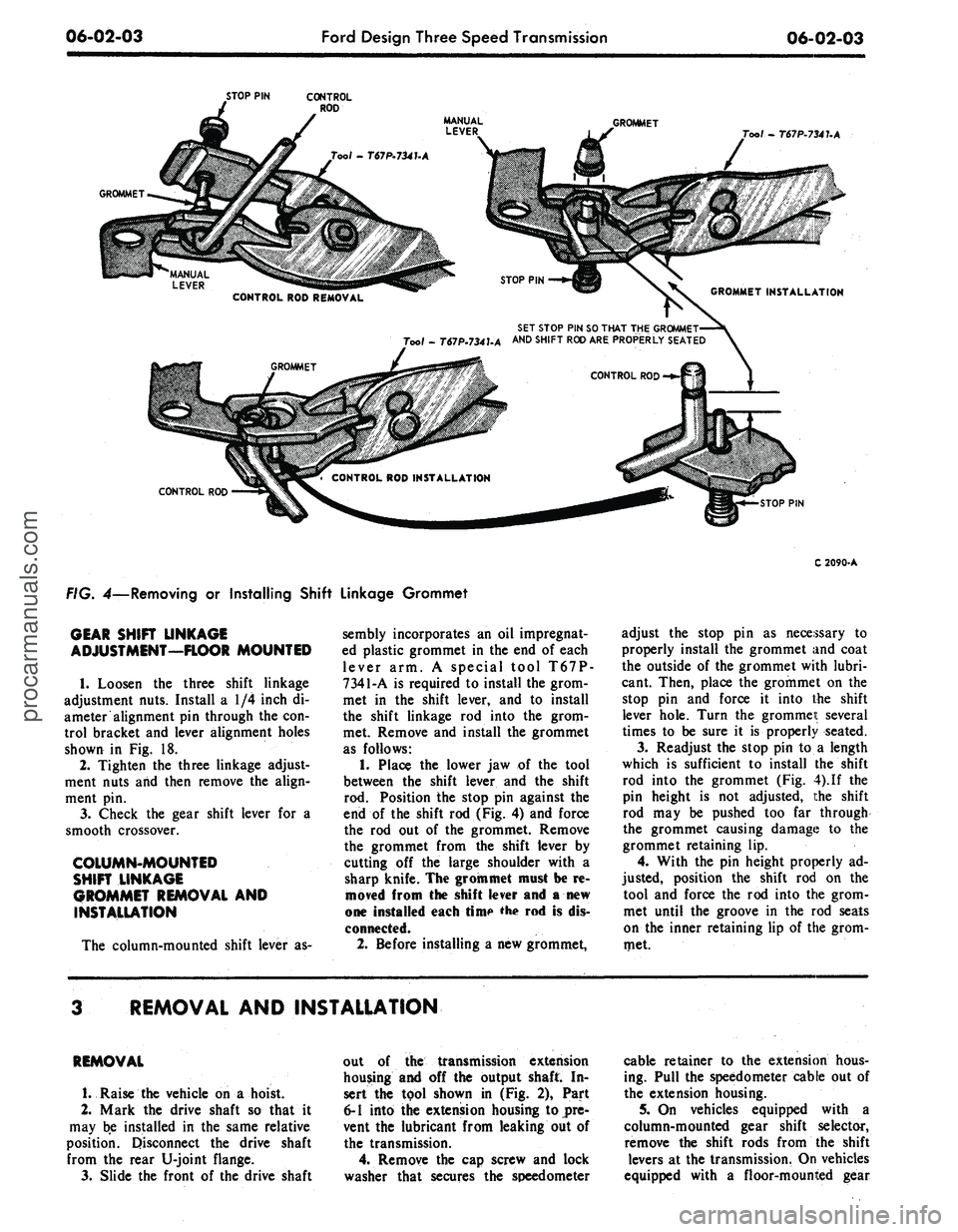

GEAR SHIFT LINKAGE

ADJUSTMENT—FLOOR MOUNTED

1.

Loosen

the

three shift linkage

adjustment nuts. Install

a 1/4

inch

di-

ameter alignment pin through the con-

trol bracket and lever alignment holes

shown

in Fig. 18.

2.

Tighten

the

three linkage adjust-

ment nuts

and

then remove

the

align-

ment

pin.

3.

Check

the

gear shift lever

for a

smooth crossover.

COLUMN-MOUNTED

SHIFT LINKAGE

GROMMET REMOVAL

AND

INSTALLATION

The column-mounted shift lever

as-

sembly incorporates

an oil

impregnat-

ed plastic grommet

in the

end

of

each

lever

arm. A

special tool T67P-

7341-A

is

required

to

install the grom-

met

in the

shift lever,

and to

install

the shift linkage

rod

into

the

grom-

met. Remove

and

install

the

grommet

as follows:

1.

Place

the

lower

jaw of the

tool

between

the

shift lever

and the

shift

rod.

Position

the

stop

pin

against

the

end

of the

shift

rod

(Fig.

4)

and force

the

rod out of the

grommet. Remove

the grommet from

the

shift lever

by

cutting

off the

large shoulder with

a

sharp knife. The groin met must

be re-

moved from

the

shift lever

and a new

one installed each rime

'he rod is

dis-

connected.

2.

Before installing

a

new grommet,

C 2090-A

adjust

the

stop

pin as

necessary

to

properly install

the

grommet and coat

the outside

of

the grommet with lubri-

cant. Then, place

the

grommet

on the

stop

pin and

force

it

into

the

shift

lever hole. Turn

the

grommeit several

times

to be

sure

it is

properly seated.

3.

Readjust

the

stop

pin to a

length

which

is

sufficient

to

install

the

shift

rod into

the

grommet

(Fig.

4).

If

the

pin height

is not

adjusted,

the

shift

rod

may be

pushed

too far

through

the grommet causing damage

to the

grommet retaining

lip.

4.

With

the pin

height properly

ad-

justed, position

the

shift

rod on the

tool

and

force

the rod

into

the

grom-

met until

the

groove

in the rod

seats

on

the

inner retaining

lip of

the grom-

met.

REMOVAL AND INSTALLATION

REMOVAL

1.

Raise

the

vehicle

on a

hoist.

2.

Mark

the

drive shaft

so

that

it

may

be

installed

in the

same relative

position. Disconnect

the

drive shaft

from

the

rear U-joint flange.

3.

Slide

the

front

of the

drive shaft

out

of the

transmission extension

housing

and off the

output shaft

In-

sert

the

tool shown

in (Fig. 2),

Part

6-1 into the extension housing

to

pre-

vent

the

lubricant from leaking

out of

the transmission.

4.

Remove

the cap

screw

and

lock

washer that secures

the

speedometer

cable retainer

to the

extension hous-

ing. Pull

the

speedometer cable

out of

the extension housing.

5.

On

vehicles equipped with

a

column-mounted gear shift selector,

remove

the

shift rods from

the

shift

levers

at

the transmission. On vehicles

equipped with

a

floor-mounted gearprocarmanuals.com

Page 302 of 413

07-01-11

General Transmission Service

07-01-11

STOP

PIN

GROMMET

Tool - T67P-734LA

GROMMET

LEVER

CONTROL ROD REMOVAL

GROMMET INSTALLATION

Tool - T67P-734LA

r

CONTROL ROD INSTALLATION

3/16"-1/4'

CONTROL ROD

STOP

PIN

FIG. 18—Removing

or

Installing Shift Linkage Grommet

D 1742-A

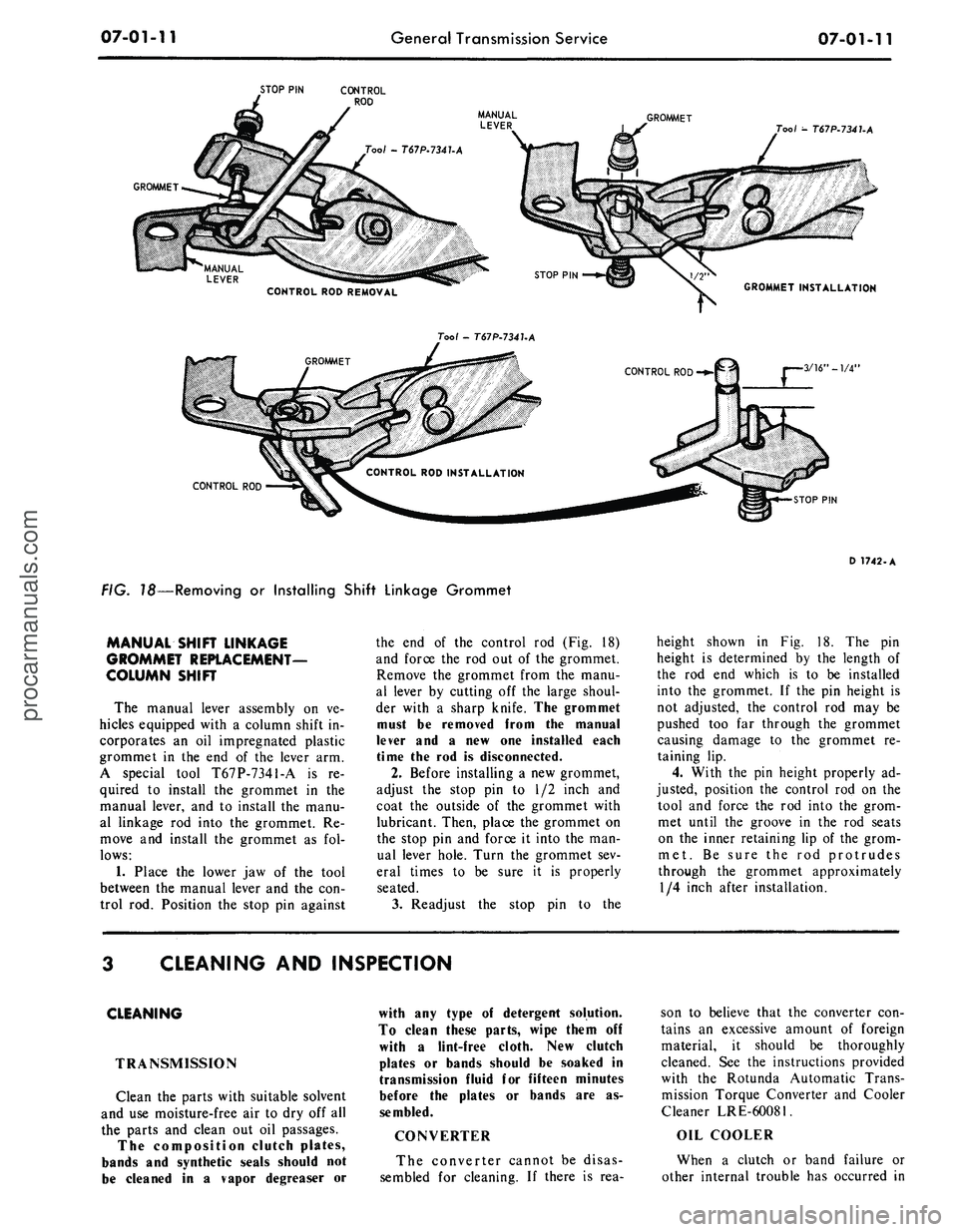

MANUAL SHIFT LINKAGE

GROMMET REPLACEMENT-

COLUMN SHIFT

The manual lever assembly

on ve-

hicles equipped with

a

column shift

in-

corporates

an oil

impregnated plastic

grommet

in the end of the

lever

arm.

A special tool T67P-7341-A

is re-

quired

to

install

the

grommet

in the

manual lever,

and to

install

the

manu-

al linkage

rod

into

the

grommet.

Re-

move

and

install

the

grommet

as fol-

lows:

1.

Place

the

lower

jaw of the

tool

between

the

manual lever

and the con-

trol

rod.

Position

the

stop

pin

against

the

end of the

control

rod (Fig. 18)

and force

the rod out of the

grommet.

Remove

the

grommet from

the

manu-

al lever

by

cutting

off the

large shoul-

der with

a

sharp knife.

The

grommet

must

be

removed from

the

manual

lever

and a new one

installed each

time

the rod is

disconnected.

2.

Before installing

a

new grommet,

adjust

the

stop

pin to 1/2

inch

and

coat

the

outside

of the

grommet with

lubricant. Then, place

the

grommet

on

the stop

pin and

force

it

into

the

man-

ual lever hole. Turn

the

grommet

sev-

eral times

to be

sure

it is

properly

seated.

3.

Readjust

the

stop

pin to the

height shown

in Fig. 18. The pin

height

is

determined

by the

length

of

the

rod end

which

is to be

installed

into

the

grommet.

If the pin

height

is

not adjusted,

the

control

rod may be

pushed

too far

through

the

grommet

causing damage

to the

grommet

re-

taining

lip.

4.

With

the pin

height properly

ad-

justed, position

the

control

rod on the

tool

and

force

the rod

into

the

grom-

met until

the

groove

in the rod

seats

on

the

inner retaining

lip of the

grom-

met.

Be

sure

the rod

protrudes

through

the

grommet approximately

1/4 inch after installation.

CLEANING

AND

INSPECTION

CLEANING

TRANSMISSION

Clean

the

parts with suitable solvent

and

use

moisture-free

air to dry off all

the parts

and

clean

out oil

passages.

The composition clutch plates,

bands

and

synthetic seals should

not

be cleaned

in a

vapor degreaser

or

with

any

type

of

detergent solution.

To clean these parts, wipe them

off

with

a

lint-free cloth.

New

clutch

plates

or

bands should

be

soaked

in

transmission fluid

for

fifteen minutes

before

the

plates

or

bands

are as-

sembled.

CONVERTER

The converter cannot

be

disas-

sembled

for

cleaning.

If

there

is rea-

son

to

believe that

the

converter

con-

tains

an

excessive amount

of

foreign

material,

it

should

be

thoroughly

cleaned.

See the

instructions provided

with

the

Rotunda Automatic Trans-

mission Torque Converter

and

Cooler

Cleaner LRE-60081.

OIL COOLER

When

a

clutch

or

band failure

or

other internal trouble

has

occurred

inprocarmanuals.com

Page 325 of 413

07-02-17

C4 Automatic Transmission

07-02-17

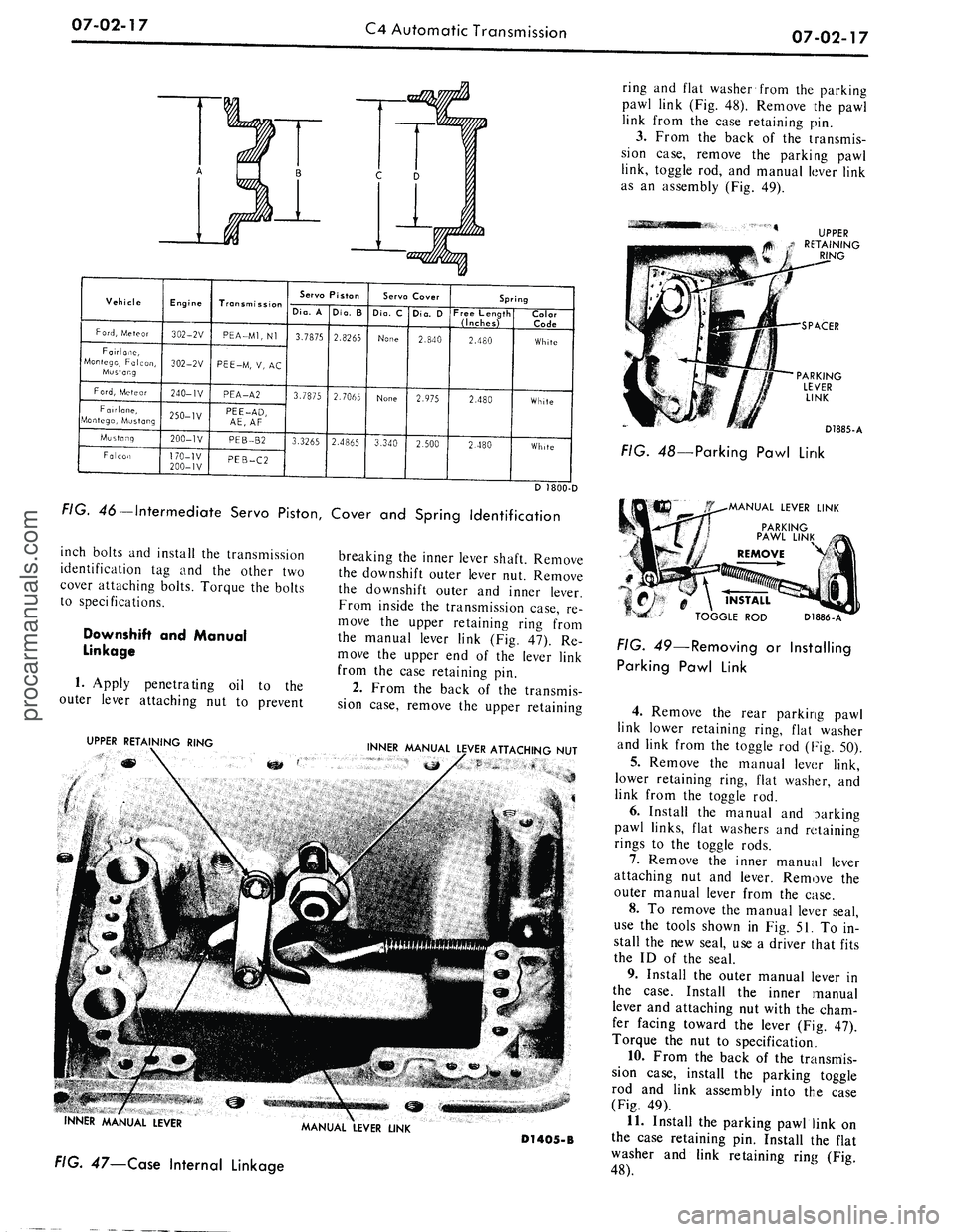

Vehicle

Ford,

Meteor

Fairlane,

Montegc,

Falcon,

Mustang

Ford,

Meteor

Fairlane,

Montego,

Mustang

Mustang

Falcon

Engine

302-2V

302-2V

240-IV

250-1V

200-1V

170-1V

200-1V

Transmi ssion

PEA-MI,

Nl

PEE-M,

V, AC

PEA-A2

PEE-AD,

AE,

AF

PEB-B2

PEB-C2

Servo Piston

Dia.

A

3.7875

3.7875

3.3265

Dia.

B

2.8265

2.7065

2.4865

Servo Cover

Dia.

C

None

None

3.340

Dia.

D

2.840

2.975

2.500

Spring

Free Length

(Inches)

2.480

2.480

2.480

Color

Cniif

White

White

White

D 1800-D

FIG. 46—Intermediate Servo Piston, Cover and Spring Identification

inch bolts and install the transmission

identification tag and the other two

cover attaching bolts. Torque the bolts

to specifications.

Downshift and Manual

Linkage

1.

Apply penetrating oil to the

outer lever attaching nut to prevent

UPPER RETAINING RING

breaking the inner lever shaft. Remove

the downshift outer lever nut. Remove

the downshift outer and inner lever.

From inside the transmission case, re-

move the upper retaining ring from

the manual lever link (Fig. 47). Re-

move the upper end of the lever link

from the case retaining pin.

2.

From the back of the transmis-

sion case, remove the upper retaining

INNER MANUAL

'ER ATTACHING NUT

mmMm

INNER MANUAL LEVER MANUAL LEVER LINK

FIG. 47—Case Internal Linkage

ring and flat washer from the parking

pawl link (Fig. 48). Remove the pawl

link from the case retaining pin.

3.

From the back of the transmis-

sion case, remove the parking pawl

link, toggle rod, and manual lever link

as an assembly (Fig. 49).

UPPER

r RETAINING

RING

D1885-A

FIG. 48—Parking Pawl Link

/7^-MANUAL LEVER LINK

D1405-B

FIG. 49—Removing or Installing

Parking Pawl Link

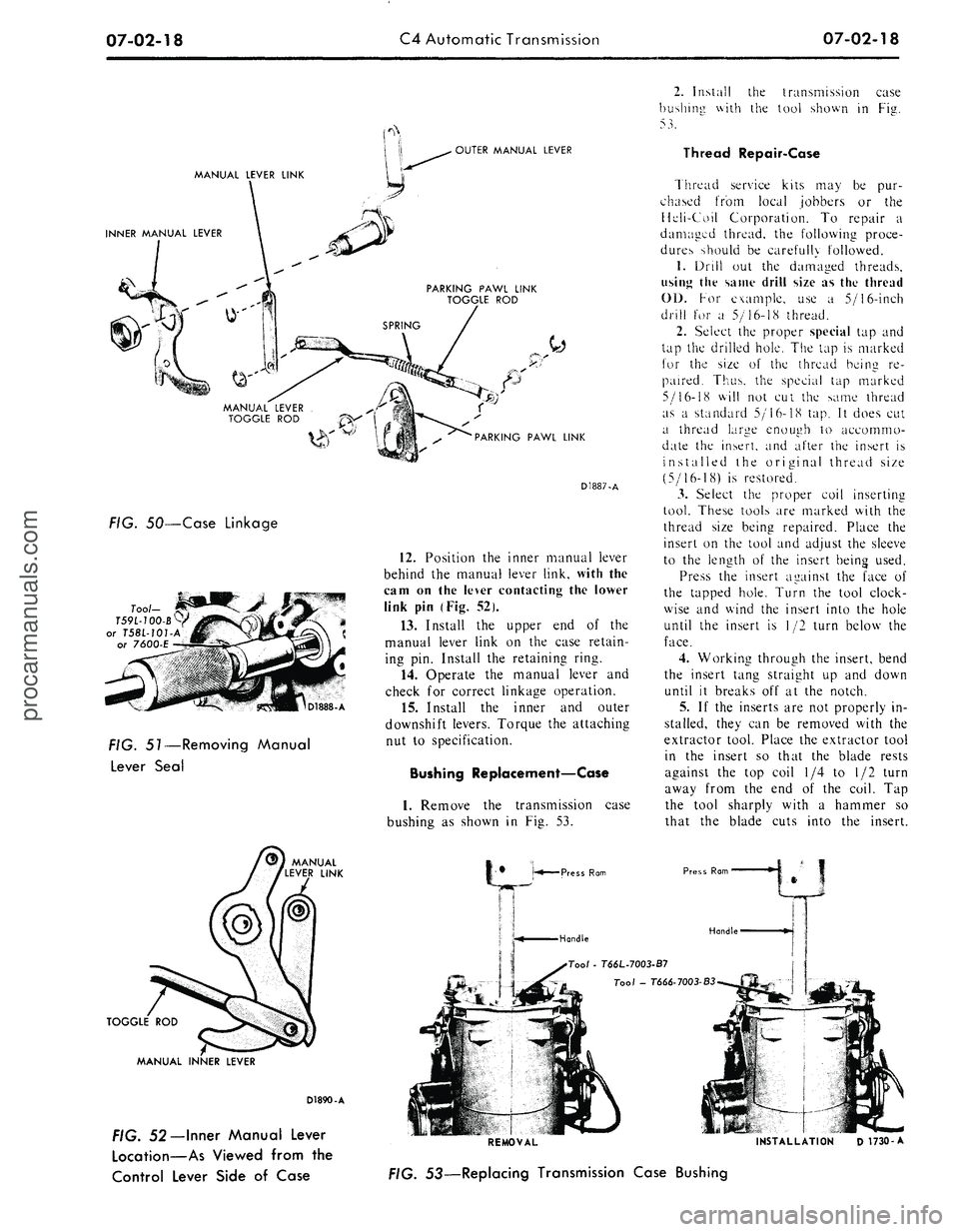

4.

Remove the rear parking pawl

link lower retaining ring, flat washer

and link from the toggle rod (Fig. 50).

5.

Remove the manual lever link,

lower retaining ring, flat washer, and

link from the toggle rod.

6. Install the manual and marking

pawl links, flat washers and retaining

rings to the toggle rods.

7.

Remove the inner manual lever

attaching nut and lever. Remove the

outer manual lever from the case.

8. To remove the manual lever seal,

use the tools shown in Fig. 51. To in-

stall the new seal, use a driver that fits

the ID of the seal.

9. Install the outer manual lever in

the case. Install the inner manual

lever and attaching nut with the cham-

fer facing toward the lever (Fig. 47).

Torque the nut to specification.

10.

From the back of the transmis-

sion case, install the parking toggle

rod and link assembly into the case

(Fig. 49).

11.

Install the parking pawl link on

the case retaining pin. Install the flat

washer and link retaining ring (Fig.

48).procarmanuals.com

Page 326 of 413

07-02-18

C4 Automatic Transmission

07-02-18

OUTER MANUAL LEVER

MANUAL LEVER LINK

INNER MANUAL LEVER

PARKING PAWL LINK

TOGGLE ROD

PARKING PAWL LINK

FIG. 50—Case Linkage

D1888-A

FIG. 51—Removing Manual

Lever Seal

TOGGLE ROD

D1887-A

12.

Position the inner manual lever

behind the manual lever link, with the

cam on the lever contacting the lower

link pin (Fig. 52).

13.

Install the upper end of the

manual lever link on the case retain-

ing pin. Install the retaining ring.

14.

Operate the manual lever and

check for correct linkage operation.

15.

Install the inner and outer

downshift levers. Torque the attaching

nut to specification.

Bushing Replacement—Case

1.

Remove the transmission case

bushing as shown in Fig. 53.

Press Ram

Handle

MANUAL INNER LEVER

D1890-A

FIG. 52— Inner Manual Lever

Location—As Viewed from the

Control Lever Side of Case

2.

Install the transmission case

bushing with the tool shown in Fig.

53.

Thread Repair-Case

Thread service kits may be pur-

chased from local jobbers or the

Heli-Coil Corporation. To repair a

damaged thread, the following proce-

dures should be carefully followed.

1.

Drill out the damaged threads,

using the same drill size as the thread

01).

For example, use a 5/16-inch

drill for a 5/16-18 thread.

2.

Select the proper special tap and

tap the drilled hole. The tap is marked

for the size of the thread being re-

paired. Thus, the special tap marked

5/16-18 will not cut the same thread

as a standard 5/16-18 tap. It does cut

a thread large enough to accommo-

date the insert, and after the insert is

installed the original thread size

(5/16-18) is restored.

3.

Select the proper coil inserting

tool. These tools are marked with the

thread size being repaired. Place the

insert on the tool and adjust the sleeve

to the length of the insert being used.

Press the insert against the face of

the tapped hole. Turn the tool clock-

wise and wind the insert into the hole

until the insert is 1/2 turn below the

face.

4.

Working through the insert, bend

the insert tang straight up and down

until it breaks off at the notch.

5.

If the inserts are not properly in-

stalled, they can be removed with the

extractor tool. Place the extractor tool

in the insert so that the blade rests

against the top coil 1/4 to 1/2 turn

away from the end of the coil. Tap

the tool sharply with a hammer so

that the blade cuts into the insert.

Press Rom

Handle

Too/

- T66L-7003-B7

Tool - T666-7003-B3

REMOVAL INSTALLATION D 1730-A

FIG. 53—Replacing Transmission Case Bushingprocarmanuals.com

Page 330 of 413

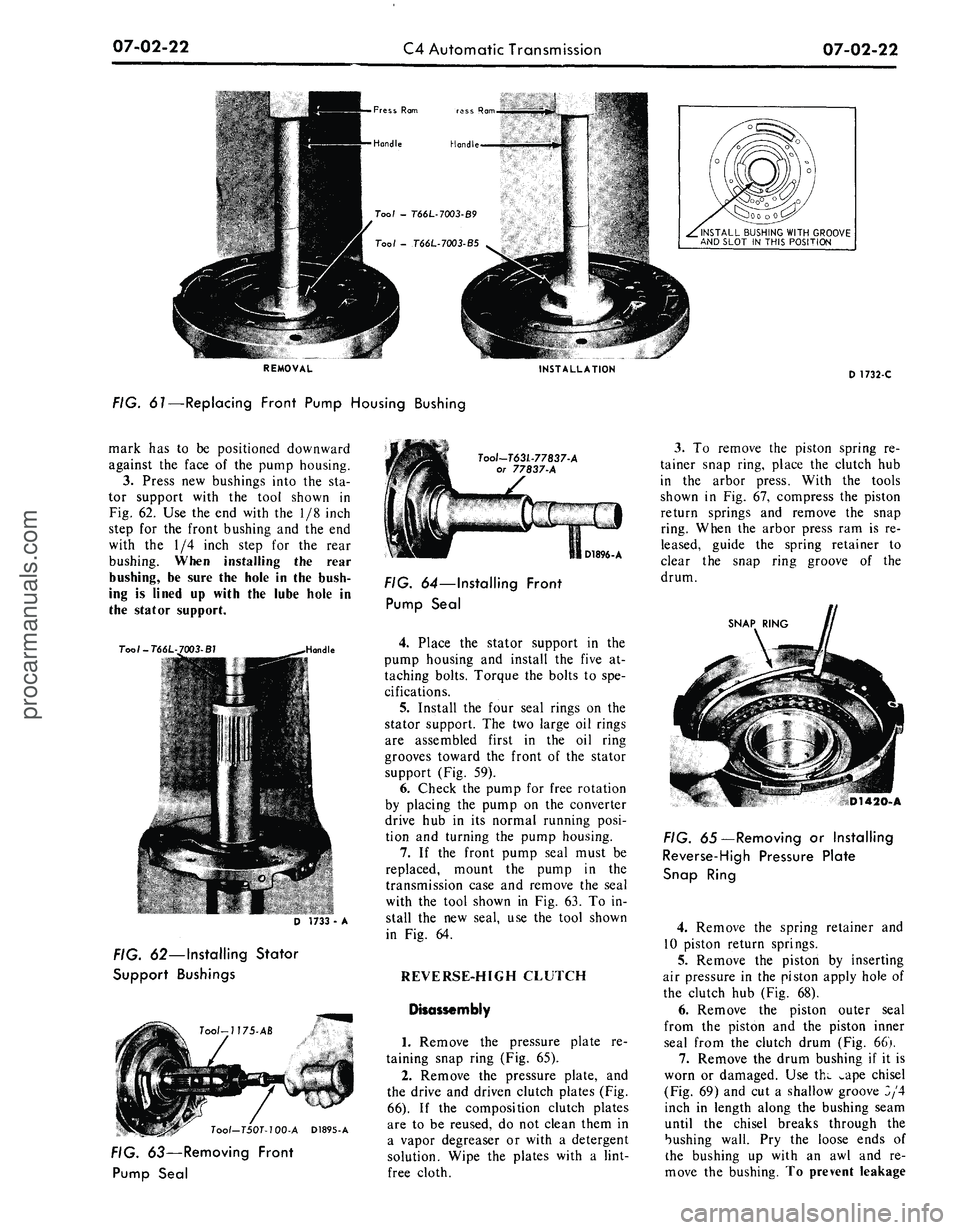

07-02-22

C4 Automatic Transmission

07-02-22

Handle

Fress

Ram

ress

Ram

Hand!

Tool

-

T66L-7003-S9

Too/

-

T66L-7003-B5

INSTALL BUSHING WITH GROOVE

JAND SLOT

IN

THIS POSITION

REMOVAL

INSTALLATION

FIG. 61—Replacing Front Pump Housing Bushing

D 1732-C

mark

has to be

positioned downward

against

the

face

of the

pump housing.

3.

Press

new

bushings into

the sta-

tor support with

the

tool shown

in

Fig. 62.

Use the end

with

the 1/8

inch

step

for the

front bushing

and the end

with

the 1/4

inch step

for the

rear

bushing. When installing

the

rear

bushing,

be

sure

the

hole

in the

bush-

ing

is

lined

up

with

the

lube hole

in

the stator support.

T00I-T66L

Toot-T63L-77837-A

or 77837-A

D 1733

-

A

FIG. 62—Installing Stator

Support Bushings

Tool-T50T-100-A D1895-A

FIG. 63—Removing Front

Pump Seal

D1896-A

FIG. 64—Installing Front

Pump Seal

4.

Place

the

stator support

in the

pump housing

and

install

the

five

at-

taching bolts. Torque

the

bolts

to

spe-

cifications.

5.

Install

the

four seal rings

on the

stator support.

The two

large

oil

rings

are assembled first

in the oil

ring

grooves toward

the

front

of the

stator

support (Fig.

59).

6. Check

the

pump

for

free rotation

by placing

the

pump

on the

converter

drive

hub in its

normal running posi-

tion

and

turning

the

pump housing.

7.

If the

front pump seal must

be

replaced, mount

the

pump

in the

transmission case

and

remove

the

seal

with

the

tool shown

in Fig.

63.

To in-

stall

the new

seal,

use the

tool shown

in

Fig. 64.

REVERSE-HIGH CLUTCH

Disassembly

1.

Remove

the

pressure plate

re-

taining snap ring (Fig.

65).

2.

Remove

the

pressure plate,

and

the drive

and

driven clutch plates (Fig.

66).

If the

composition clutch plates

are

to be

reused,

do not

clean them

in

a vapor degreaser

or

with

a

detergent

solution. Wipe

the

plates with

a

lint-

free cloth.

3.

To

remove

the

piston spring

re-

tainer snap ring, place

the

clutch

hub

in

the

arbor press. With

the

tools

shown

in Fig. 67,

compress

the

piston

return springs

and

remove

the

snap

ring. When

the

arbor press

ram is re-

leased, guide

the

spring retainer

to

clear

the

snap ring groove

of the

drum.

SNAP RING

D1420-A

FIG. 65—Removing

or

Installing

Reverse-High Pressure Plate

Snap Ring

4.

Remove

the

spring retainer

and

10 piston return springs.

5.

Remove

the

piston

by

inserting

air pressure

in the

piston apply hole

of

the clutch

hub

(Fig.

68).

6. Remove

the

piston outer seal

from

the

piston

and the

piston inner

seal from

the

clutch drum (Fig.

66).

7.

Remove

the

drum bushing

if it is

worn

or

damaged.

Use

thw ^ape chisel

(Fig. 69)

and cut a

shallow groove

3/4

inch

in

length along

the

bushing seam

until

the

chisel breaks through

the

bushing wall.

Pry the

loose ends

of

the bushing

up

with

an awl and re-

move

the

bushing.

To

prevent leakageprocarmanuals.com

Page 390 of 413

07-04-21

C-6 Automatic Transmission

07-04-21

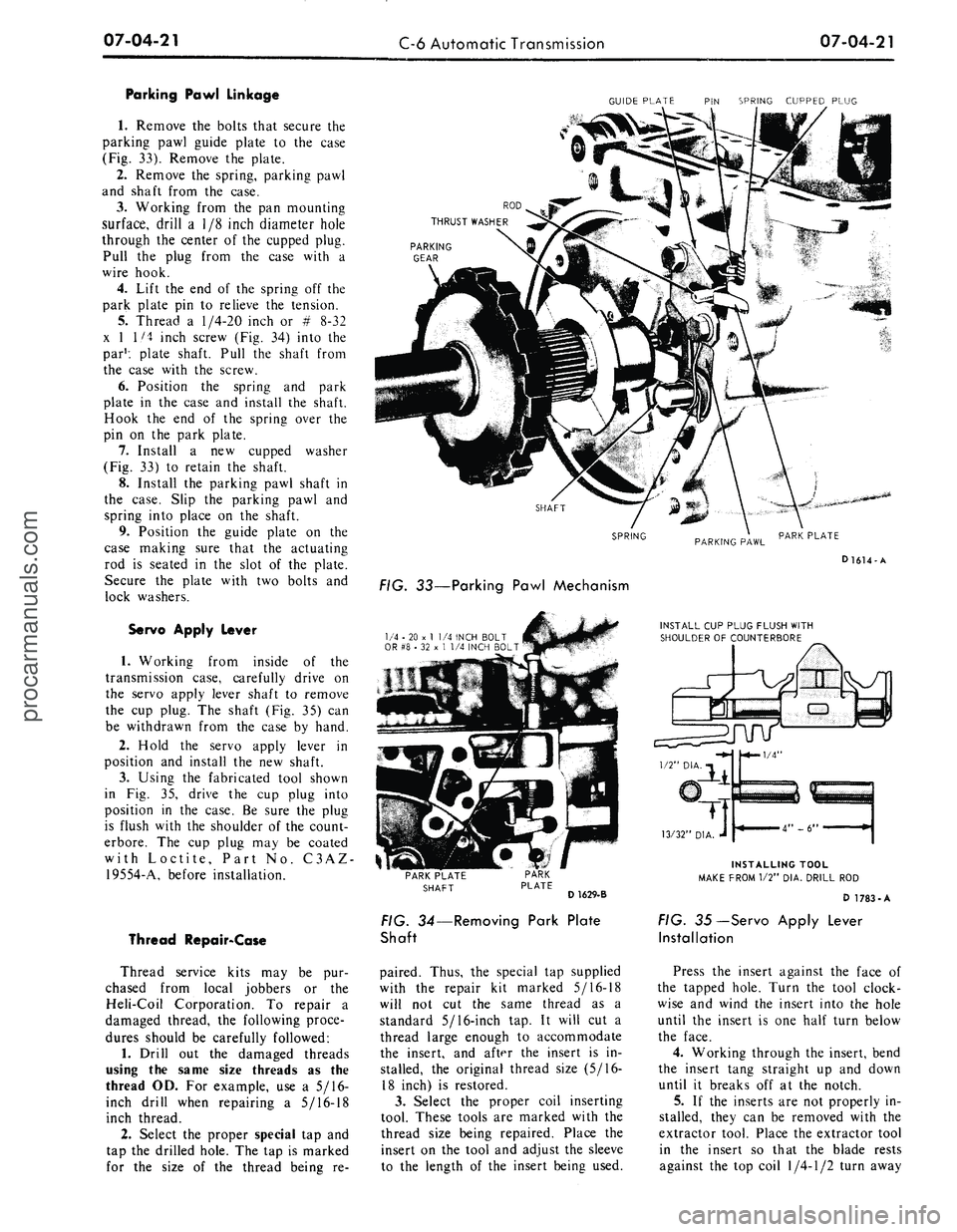

Parking Pawl Linkage

1.

Remove the bolts that secure the

parking pawl guide plate to the case

(Fig. 33). Remove the plate.

2.

Remove the spring, parking pawl

and shaft from the case.

3.

Working from the pan mounting

surface, drill a 1/8 inch diameter hole

through the center of the cupped plug.

Pull the plug from the case with a

wire hook.

4.

Lift the end of the spring off the

park plate pin to relieve the tension.

5.

Thread a

1/4-20

inch or # 8-32

x 1 1/4 inch screw (Fig. 34) into the

par1: plate shaft. Pull the shaft from

the case with the screw.

6. Position the spring and park

plate in the case and install the shaft.

Hook the end of the spring over the

pin on the park plate.

7.

Install a new cupped washer

(Fig. 33) to retain the shaft.

8. Install the parking pawl shaft in

the case. Slip the parking pawl and

spring into place on the shaft.

9. Position the guide plate on the

case making sure that the actuating

rod is seated in the slot of the plate.

Secure the plate with two bolts and

lock washers.

Servo Apply Lever

1.

Working from inside of the

transmission case, carefully drive on

the servo apply lever shaft to remove

the cup plug. The shaft (Fig. 35) can

be withdrawn from the case by hand.

2.

Hold the servo apply lever in

position and install the new shaft.

3.

Using the fabricated tool shown

in Fig. 35, drive the cup plug into

position in the case. Be sure the plug

is flush with the shoulder of the count-

erbore. The cup plug may be coated

with Loctite, Part No. C3AZ-

19554-A, before installation.

Thread Repair-Case

Thread service kits may be pur-

chased from local jobbers or the

Heli-Coil Corporation. To repair a

damaged thread, the following proce-

dures should be carefully followed:

1.

Drill out the damaged threads

using the same size threads as the

thread OD. For example, use a 5/16-

inch drill when repairing a 5/16-18

inch thread.

2.

Select the proper special tap and

tap the drilled hole. The tap is marked

for the size of the thread being re-

GUIDE PLATE PIN SPRING CUPPED PLUG

PARKING

GEAR

SHAFT

SPRING

PARKING PAWL

PARK PLATE

D1614-A

FIG. 33—Parking Pawl Mechanism

1/4 - 20 x

1

1/4 INCH BOLT

OR #8 • 32 x 1 1/4 INCH BOLT

INSTALL CUP PLUG FLUSH WITH

SHOULDER OF COUNTERBORE

PARK PLATE

SHAFT

D 1629-B

FIG. 34—Removing Park Plate

Shaft

paired. Thus, the special tap supplied

with the repair kit marked 5/16-18

will not cut the same thread as a

standard 5/16-inch tap. It will cut a

thread large enough to accommodate

the insert, and after the insert is in-

stalled, the original thread size (5/16-

18 inch) is restored.

3.

Select the proper coil inserting

tool. These tools are marked with the

thread size being repaired. Place the

insert on the tool and adjust the sleeve

to the length of the insert being used.

INSTALLING TOOL

MAKE FROM 1/2" DIA. DRILL ROD

D 1783-A

FIG. 35—Servo Apply Lever

Installation

Press the insert against the face of

the tapped hole. Turn the tool clock-

wise and wind the insert into the hole

until the insert is one half turn below

the face.

4.

Working through the insert, bend

the insert tang straight up and down

until it breaks off at the notch.

5.

If the inserts are not properly in-

stalled, they can be removed with the

extractor tool. Place the extractor tool

in the insert so that the blade rests

against the top coil

1/4-1/2

turn awayprocarmanuals.com