service FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 26 of 413

02-02-07

Brake System

02-02-07

ANTI-SKID CONTROL SYSTEM

RELEASE PAWL CAM PIN

RELEASE PAWL CAM LEVER

RELEASE CABLE

H

1636-

A

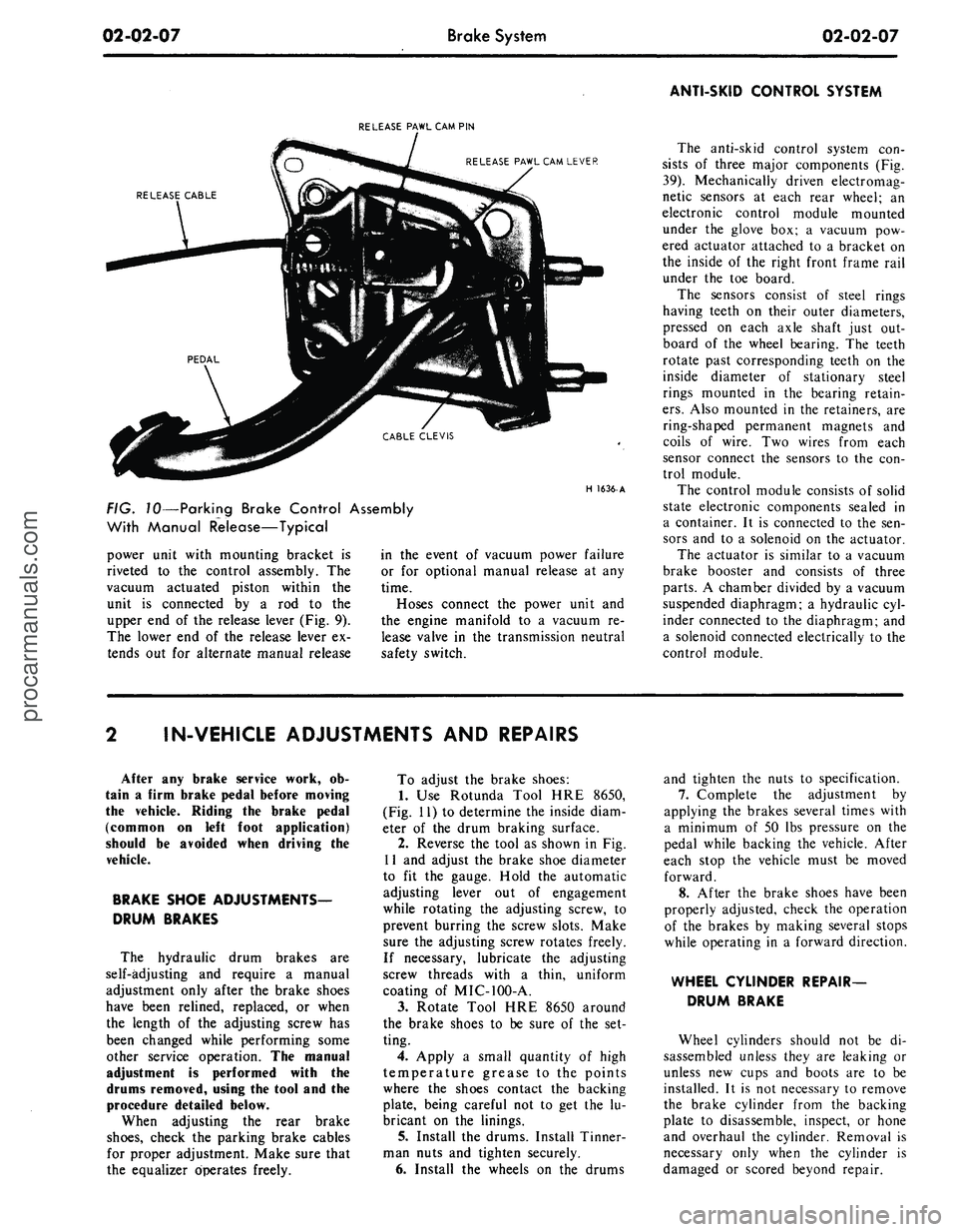

FIG. 10—Parking Brake Control Assembly

With Manual Release—Typical

power unit with mounting bracket is

riveted to the control assembly. The

vacuum actuated piston within the

unit is connected by a rod to the

upper end of the release lever (Fig. 9).

The lower end of the release lever ex-

tends out for alternate manual release

in the event of vacuum power failure

or for optional manual release at any

time.

Hoses connect the power unit and

the engine manifold to a vacuum re-

lease valve in the transmission neutral

safety switch.

The anti-skid control system con-

sists of three major components (Fig.

39).

Mechanically driven electromag-

netic sensors at each rear wheel; an

electronic control module mounted

under the glove box; a vacuum pow-

ered actuator attached to a bracket on

the inside of the right front frame rail

under the toe board.

The sensors consist of steel rings

having teeth on their outer diameters,

pressed on each axle shaft just out-

board of the wheel bearing. The teeth

rotate past corresponding teeth on the

inside diameter of stationary steel

rings mounted in the bearing retain-

ers.

Also mounted in the retainers, are

ring-shaped permanent magnets and

coils of wire. Two wires from each

sensor connect the sensors to the con-

trol module.

The control module consists of solid

state electronic components sealed in

a container. It is connected to the sen-

sors and to a solenoid on the actuator.

The actuator is similar to a vacuum

brake booster and consists of three

parts.

A chamber divided by a vacuum

suspended diaphragm; a hydraulic cyl-

inder connected to the diaphragm; and

a solenoid connected electrically to the

control module.

IN-VEHICLE ADJUSTMENTS AND REPAIRS

After any brake service work, ob-

tain a firm brake pedal before moving

the vehicle. Riding the brake pedal

(common on left foot application)

should be avoided when driving the

vehicle.

BRAKE SHOE ADJUSTMENTS—

DRUM BRAKES

The hydraulic drum brakes are

self-adjusting and require a manual

adjustment only after the brake shoes

have been relined, replaced, or when

the length of the adjusting screw has

been changed while performing some

other service operation. The manual

adjustment is performed with the

drums removed, using the tool and the

procedure detailed below.

When adjusting the rear brake

shoes,

check the parking brake cables

for proper adjustment. Make sure that

the equalizer operates freely.

To adjust the brake shoes:

1.

Use Rotunda Tool HRE 8650,

(Fig. 11) to determine the inside diam-

eter of the drum braking surface.

2.

Reverse the tool as shown in Fig.

11 and adjust the brake shoe diameter

to fit the gauge. Hold the automatic

adjusting lever out of engagement

while rotating the adjusting screw, to

prevent burring the screw slots. Make

sure the adjusting screw rotates freely.

If necessary, lubricate the adjusting

screw threads with a thin, uniform

coating of MIC-100-A.

3.

Rotate Tool HRE 8650 around

the brake shoes to be sure of the set-

ting.

4.

Apply a small quantity of high

temperature grease to the points

where the shoes contact the backing

plate, being careful not to get the lu-

bricant on the linings.

5. Install the drums. Install Tinner-

man nuts and tighten securely.

6. Install the wheels on the drums

and tighten the nuts to specification.

7.

Complete the adjustment by

applying the brakes several times with

a minimum of 50 lbs pressure on the

pedal while backing the vehicle. After

each stop the vehicle must be moved

forward.

8. After the brake shoes have been

properly adjusted, check the operation

of the brakes by making several stops

while operating in a forward direction.

WHEEL CYLINDER REPAIR-

DRUM BRAKE

Wheel cylinders should not be di-

sassembled unless they are leaking or

unless new cups and boots are to be

installed. It is not necessary to remove

the brake cylinder from the backing

plate to disassemble, inspect, or hone

and overhaul the cylinder. Removal is

necessary only when the cylinder is

damaged or scored beyond repair.procarmanuals.com

Page 30 of 413

TUBE 2B253 TUBE 2263

SWITCH 2B264

TUBE 2265

VIEWZ

DRUM BRAKE

VIEWY

DISC BRAKE

VIEW IN CIRCLE M

VIEW Y

TYPICAL 2 PLACES

DRUM BRAKE

VIEW IN CIRCLE K

H 1639-A

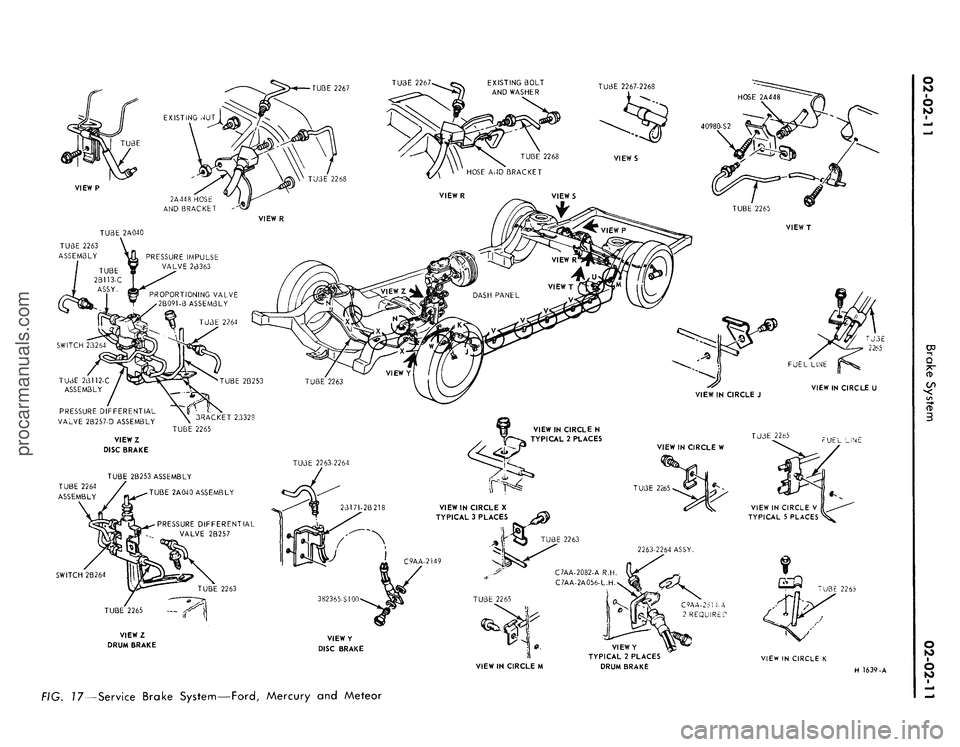

FIG. 17—Service Brake System—Ford, Mercury and Meteorprocarmanuals.com

Page 31 of 413

02-02-12

Brake System

02-02-12

TUBE ASSY. REF.

2 A 040

TUBE ASSY. REF.

2B113-B

PRESSURE

IMPULSE VALVE

PROPORTIONING

TUBE

>Y.

2B253 ASSY REF TUBE

/W W '

Kth#

2263 ASSY. R.H. REF.

TUBE

2B112-E

2264 ASSY. L.H. REF.

2B329

ASSY. REF.

HOSE

C8OA-2B218-C ASSY.L.H.

C80A-26171-D ASSY.R.H.

2B269 ASSY. REF.

VIEWZ

INSTALLATION-DISC BRAKE ONLY

BEND CLIP TO RETAIN

TUBE AS SHOWN

-TUBE

VIEW IN CIRCLE T

382365-S36

WASHER

8M-2149

TUBE-2A040

INSTALLATION-DISC BRAKES SAME AS

DRUM BRAKES AND MAIN VIEW

EXCEPT AS SHOWN

TUBE-2267 R.H.

TUBE-2B253

TUBE 2B329

PRESSURE DIFFERENTIAL

VALVE

TUBE 2B329

VIEW IN

CIRCLE U

TYPICAL ^,

CES^^

CLI

BOLT-

VIEW IN CIRCLE N

WASHER

34808-S8

PART OF AXLE

VENT ON STATION

WAGON ONLY

VENT ASSEMBLY

TUBE ASSEMBLY-2265

STANDARD AND POWER DRUM

3RAKES TUBE ASSEMBLY-2B1T2

POWER DISC BRAKES

MANUAL DISC

TUBE-2263 R.H.

3 REQUIRED

BOLT- 3 REQUIRED

CHECK BRAKE HOSE CLEARANCE „

TO ALL COMPONENTS IN

2A448"

METAL/METAL JOUNCE AND

METAL/METAL REBOUND-

TUBE-2267

ARMOR-390, 428 ENGINES ONLY

8 CYLINDER ENGINE REAR AXLE ONLY

TUBE ASSEMBLY-2268 L.H.

PRESSURE DIFFERENTIAL

VALVE

- GROMMET- 2

jl^REQUIRED

EWYN

TUBE

VIEW P

ROUTING FOR STATION WAGON ONLY

TUBE-22.S5

TUBE-2263 R.H. 2264 L.H.

VIEW IN CIRCLE Y

TYPICAL 2 PLACES

CHECK BRAKE HOSE CLEARANCE TO ALL

COMPONENTS IN METAL/METAL JOUNCE,

METAL/METAL REBOUND AND FULL

INSIDE AND OUTSIDE TURNS

VIEWX

TYPICAL 2 PLACES

DRUM BRAKES

TUBE-2263 R.H

2264 L.H.

VIEW IN CIRCLE U

TYPICAL 4 PLACES

HOSE-2A448

BRAKE HOSE-2078

GASKET-2149 2 REQUIRED

VIEW IN CIRCLE W

TYPICAL 2 PLACES

DRUM BRAKES

LIP

REINFORCEMENT ASSEMBLY-2B222

APPLY ESB-M4632-A SEALER AROUND

STUDS AND SCREW HOLE ON

FLOOR PAN SIDE

TUBE

TUBE ASSEMBLY-226J)

VIEW R

TUBE

VIEW IN CIRCLE M

POWER DISC BRAKES

BRAKE HOSE MUST BE ASSEMBLED

WITH WHEELS STRAIGHT AHEAD.

STRIPE ON HOLE HOSE ASSEMBLY

MUST SHOW NO EVIDENCE OF TWIST.

H 1559-C

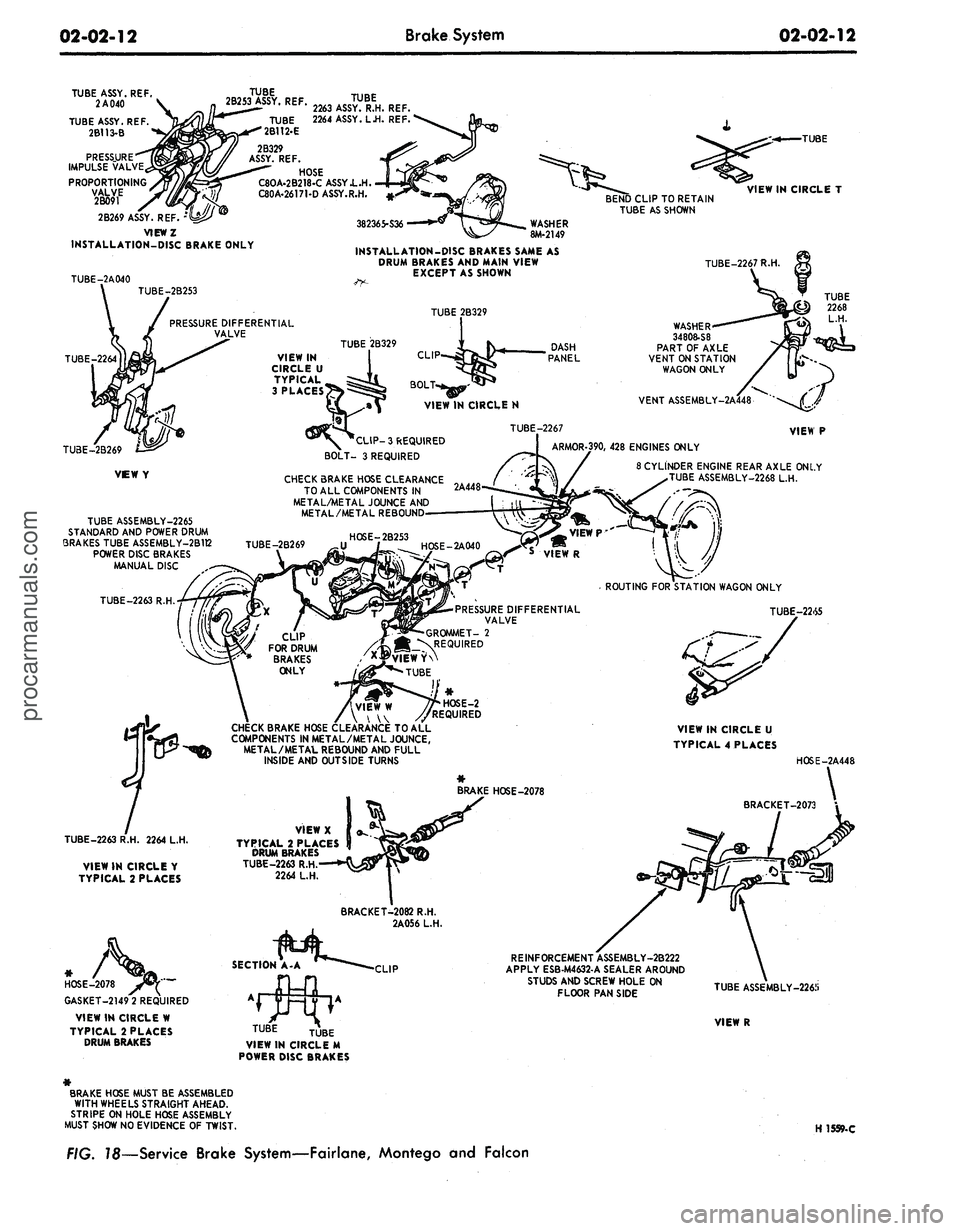

—Service Brake

System—Fairlane,

Montego

and

Falconprocarmanuals.com

Page 32 of 413

PRESSURE IMPULSE

VALVE

TUBE-2A040

TUBE-2B253

TUBE-2263 ASSY R.H.

2264 ASSY L.H.

TUBE-2267

PRESSURE

DIFFERENTIAL

VALVE

TUBE-2265

PROPORTIONING

VALVE

TUBE-2B112 \ TUBE-2263

L.H. FENDER APRON REF.

VIEWP

FOR POWER DISC BRAKES

TUBE-2B253

TUBE-

TUBE-22 64

TUBE-2B269

VIEWX

427 & 428 ENGINES 382410-S2

ALL EXCEPT

200 ENGINE

TUBE-2267

HOSE-2A448

TUBE-2265

TUBJ,-2268

VIEWY

ALL EXCEPT 200 ENGINE

PRESSURE DIFFERENTIAL

VALVE -2B257

VIEWS L&M //

BODY CROSSMEMBER

TUBE-2265

L.H. FENDER APRON REF.

VIEWR

FOR DRUM BRAKES

VIEW IN CIRCLE V

TYPICAL 4 PLACES

HOSE-2A448

VIEW IN CIRCLE U

VIEWW

VIEW IN CIRCLE T

VIEW IN CIRCLE S

TYPICAL 4 PLACES

VIEWN

H1640-A

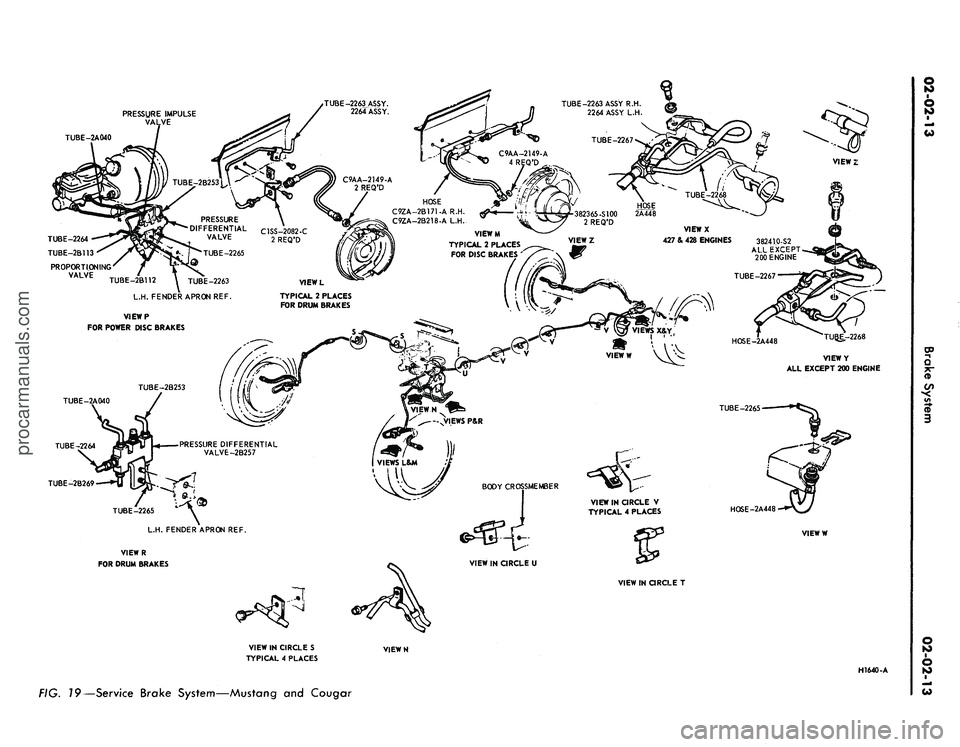

FIG. 19—Service Brake System—Mustang and Cougarprocarmanuals.com

Page 33 of 413

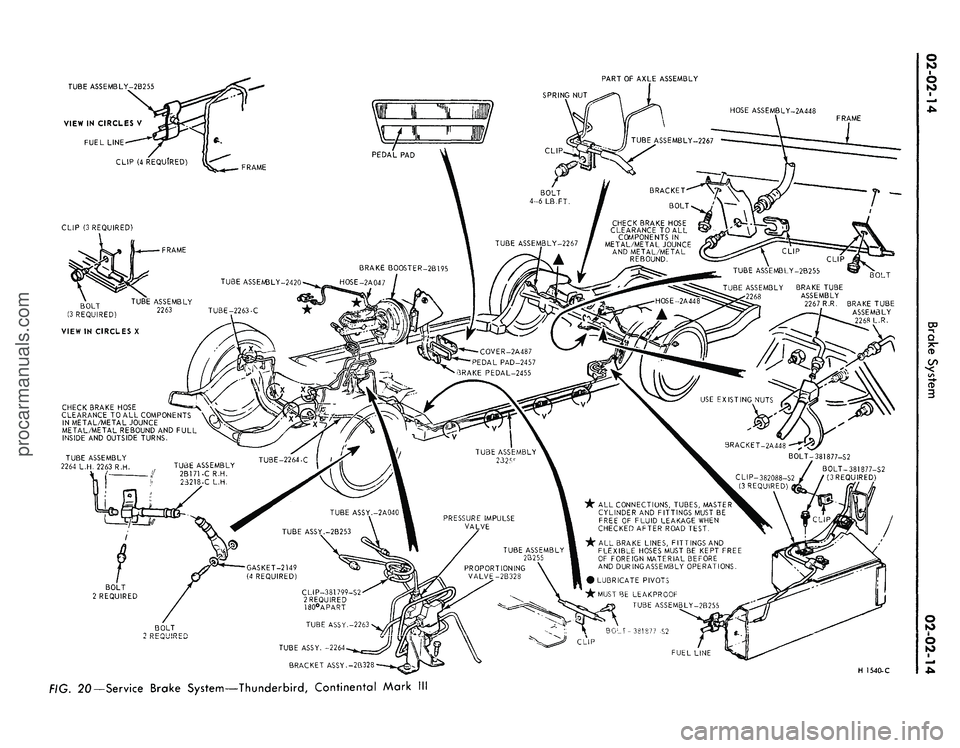

TUBE ASSEMBLY-2B255

VIEW IN CIRCLES V

FUEL LINE

CLIP (4 REQUfRED)

PART OF AXLE ASSEMBLY

HOSE ASSEMBLY-2A448

FRAME

TUBE ASSEMBLY-2267

CHECK BRAKE HOSE

CLEARANCE TO ALL

COMPONENTS IN

METAL/METAL JOUNCE

AND METAL/METAL

REBOUND.

CLIP (3 REQUIRED)

TUBE ASSEMBLY-2267

BRAKE BOOSTER-2B195

HOSE-2A047

TUBE ASSEMBLY-2B255

TUBE ASSEM3LY-2420

[

TUBE-2263-C *

TUBE ASSEMBLY BRAKE TUBE

2268 ASSEMBLY

2267 R.R. BRAKE TUBE

ASSEMBLY

TUBE ASSEMBLY

2263

VIEW IN CIRCLES X

COVER-2A487

PEDAL PAD-2457

BRAKE PEDAL-2455

USE EXISTING NUTS

TUBE ASSEMBLY

2325r

TUBE ASSEMBLY

2264 L.H. 2263 R.H.

TUBE ASSEMBLY

2B171-C R.H.

23218-C L.H.

BOLT-381877-S2

(3REQUIRED)

CLIP-382088-S2

(3 REQUIRED)

ALL CONNECTIONS, TUBES, MASTER

CYLINDER AND FITTINGS MUST BE

FREE OF FLUID LEAKAGE WHEN

CHECKED AFTER ROAD TEST.

TUBE ASSY.-2A040

TUBE ASSY.-2B253

PRESSURE IMPULSE

VALVE

ALL BRAKE LINES, FITTINGS AND

FLEXIBLE HOSES MUST BE KEPT FREE

OF FOREIGN MATERIAL BEFORE

AND DURING ASSEMBLY OPERATIONS.

TUBE ASSEMBLY

2B255

PROPORTIONING

VALVE-2B328

GASKET-2149

(4 REQUIRED)

#LUBRICATE PIVOTS

CLIP-381799-S2

2REQUIRED

180°APART

BE LEAKPROOF

TUBE ASSEMBLY-2B255

6

w

Q

7T

3

CHECK BRAKE HOSE

CLEARANCE TO ALL COMPONENTS

IN METAL/METAL JOUNCE

METAL/METAL REBOUND AND FULL

INSIDE AND OUTSIDE TURNS.

BOLT

2 REQUIRED

TUBE ASSY. -2264

BRACKET ASSY.-2B328

O

6

H 1540-C

FIG. 20—Service Brake System—Thunderbird, Continental Markprocarmanuals.com

Page 34 of 413

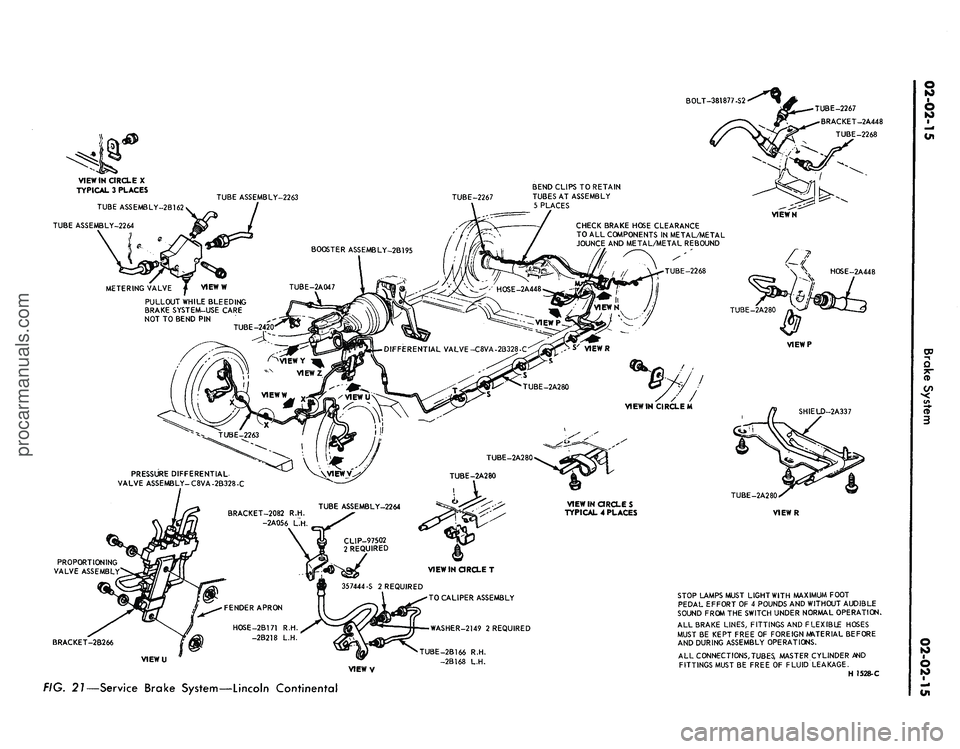

BOLT-381877

TUBE-2267

BRACKET-2A448

TUBE-2268

VIEW IN CIRCLE X

TYPICAL 3 PLACES

TUBE ASSEMBLY-2B162

TUBE ASSEMBLY-2264

TUBE ASSEMBLY-2263

TUBE-2267

BEND CLIPS TO RETAIN

TUBES AT ASSEMBLY

5 PLACES

CHECK BRAKE HOSE CLEARANCE

TO ALL COMPONENTS IN METAL/METAL

JOUNCE AND METAL/METAL REBOUND

TUBE-2268

PROPORTIONING

VALVE ASSEMBLY

BRACKET-2B266

BOOSTER ASSEMBLY-2B195

PULLOUT WHILE BLEEDING

BRAKE SYSTEM-USE CARE

NOT TO BEND PIN

TUBE-2420

DIFFERENTIAL VALVE-C8VA

VIEW IN CIRCLE M

TUBE-2A280

TUBE-2A280

PRESSURE DIFFERENTIAL

VALVE ASSEMBLY-C8VA-2B328-C

TUBE ASSEMBLY-2264

BRACKET-2082 R.H.

-2AO56 L.H.

CLIP-97502

2 REQUIRED

357444-S 2 REQUIRED

TO CALIPER ASSEMBLY

HOSE-2B171 R.H.

-2B218 L.H.

VIEWN

HOSE-2A448

TUBE-2A280

VIEWP

SHIELD-2A337

VIEW IN CIRCLE S

TYPICAL 4 PLACES

TUBE-2A280

VIEWR

V1EWU

VIEWV

WASHER-2149 2 REQUIRED

TUBE-2B166 R.H.

-2B168 L.H.

STOP LAMPS MUST LIGHT WITH MAXIMUM FOOT

PEDAL EFFORT OF 4 POUNDS AND WITHOUT AUDIBLE

SOUND FROM THE SWITCH UNDER NORMAL OPERATION.

ALL BRAKE LINES, FITTINGS AND FLEXIBLE HOSES

MUST BE KEPT FREE OF FOREIGN MATERIAL BEFORE

AND DURING ASSEMBLY OPERATIONS.

ALL CONNECT

IONS,

TUBES,

MASTER CYLINDER AND

FITTINGS MUST BE FREE OF FLUID LEAKAGE.

H 1528-C

FIG. 21—Service Brake System—Lincoln Continentalprocarmanuals.com

Page 41 of 413

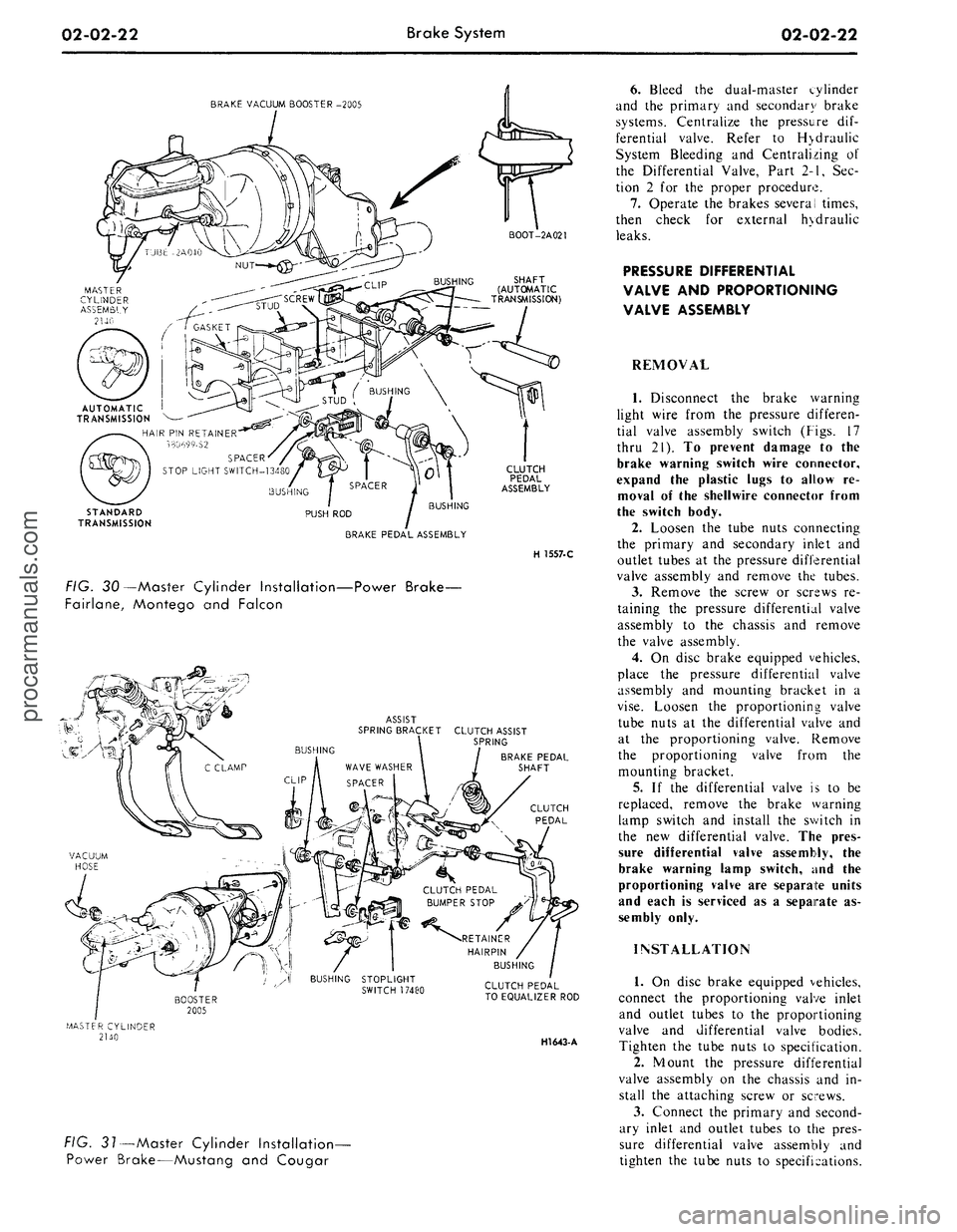

02-02-22

Brake System

02-02-22

BRAKE VACUUM BOOSTER -2005

AUTOMATIC I

TRANSMISSION

HAIR PIN RETAINER

330699-S2

SPACER

STOP LIGHT SWITCH-13480

STANDARD

TRANSMISSION

BUSHING

BUSHING

PUSH ROD

BRAKE PEDAL ASSEMBLY

CLUTCH

PEDAL

ASSEMBLY

H 1557-C

FIG. 30—Master Cylinder Installation—Power Brake-

Fairlane, Montego and Falcon

ASSIST

SPRING BRACKET CLUTCH ASSIST

\ SPRING

BRAKE PEDAL

SHAFT

CLUTCH

PEDAL

CLUTCH PEDAL

TO EQUALIZER ROD

HI643-

A

FIG. 31—Master Cylinder Installation-

Power Brake—Mustang and Cougar

6. Bleed the dual-master cylinder

and the primary and secondary brake

systems. Centralize the pressure dif-

ferential valve. Refer to H>draulic

System Bleeding and Centralizing of

the Differential Valve, Part 2-1, Sec-

tion 2 for the proper procedure.

7.

Operate the brakes several times,

then check for external hydraulic

leaks.

PRESSURE DIFFERENTIAL

VALVE AND PROPORTIONING

VALVE ASSEMBLY

REMOVAL

1.

Disconnect the brake warning

light wire from the pressure differen-

tial valve assembly switch (Figs. 17

thru 21). To prevent damage to the

brake warning switch wire connector,

expand the plastic lugs to allow re-

moval of the shellwire connector from

the switch body.

2.

Loosen the tube nuts connecting

the primary and secondary inlet and

outlet tubes at the pressure differential

valve assembly and remove the tubes.

3.

Remove the screw or screws re-

taining the pressure differential valve

assembly to the chassis and remove

the valve assembly.

4.

On disc brake equipped vehicles,

place the pressure differential valve

assembly and mounting bracket in a

vise.

Loosen the proportioning valve

tube nuts at the differential valve and

at the proportioning valve. Remove

the proportioning valve from the

mounting bracket.

5.

If the differential valve is to be

replaced, remove the brake warning

lamp switch and install the switch in

the new differential valve. The pres-

sure differential valve assembly, the

brake warning lamp switch, and the

proportioning valve are separate units

and each is serviced as a separate as-

sembly only.

INSTALLATION

1.

On disc brake equipped vehicles,

connect the proportioning valve inlet

and outlet tubes to the proportioning

valve and differential valve bodies.

Tighten the tube nuts to specification.

2.

Mount the pressure differential

valve assembly on the chassis and in-

stall the attaching screw or screws.

3.

Connect the primary and second-

ary inlet and outlet tubes to the pres-

sure differential valve assembly and

tighten the tube nuts to specifications.procarmanuals.com

Page 58 of 413

02-02-39

Brake System

02-02-39

MAJOR REPAIR OPERATIONS

BRAKE DRUM REFINISHING

Minor scores on a brake drum can

be removed with sandpaper. A drum

that is excessively scored or shows a

total indicator runout of over 0.007

inch should be turned down. Remove

only enough stock to eliminate the

scores and true up the drum. The refi-

nished diameter must not exceed 0.060

inch oversize.

Check the inside diameter of the

brake drum with a brake drum mi-

crometer (Tool FRE-14^1).

If the drum diameter is less than

0.030 inch oversize after refinishing^

standard lining may be installed. If

the drum diameter is 0.030—0.060

inch oversize after refinishing, oversize

lining must be installed.

After a drum is turned down, wipe

the refinished surface with a cloth

soaked in clean denatured alcohol. If

one drum is turned down, the opposite

drum on the same axle should also be

cut down to the same size.

ROTOR REFINISHING

Rotunda Disc Brake Attachment,

FRE-2249-2, is the only recommended

tool to refinish the disc brake rotors.

The step-by-step resurfacing procedure

provided with the tool must be ad-

hered to.

The finished braking surfaces of the

rotor must be flat and parallel within

0.0007 inch; lateral runout must not

exceed 0.003 inch total indicator read-

ing, and the surface finish of the brak-

ing surfaces are to be 80/15 micro

inches. The minimum limiting dimen-

sions (Figs. 11 and 12, Part 2-1) from

the inboard bearing cup to the out-

board rotor face and from the inboard

bearing cup to the inboard rotor face

must be observed when removing ma-

terial from the rotor braking surfaces.

On all models except Lincoln Con-

tinental, the limiting dimensions are to

be measured with a ball and gage bar

(Rotunda Kit FRE-70160).

BRAKE SHOE RELINING

Brake linings that are worn to with-

in 1/32 inch of the rivet head or are

less than 0.030 inch thick (bonded lin-

ing) or have been contaminated with

brake fluid, grease or oil must be re-

placed. Failure to replace worn linings

will result in a scored drum. When it

is necessary to replace linings, they

must also be replaced on the wheel on

the opposite side of the vehicle.

Inspect brake shoes for distortion,

cracks, or looseness. If this condition

exists,

the shoe must be discarded. Do

not attempt to repair a defective brake

shoe.

1.

Wash the brake shoes thoroughly

in a clean solvent. Remove all burrs

or rough spots from the shoes.

2.

Check the inside diameter of the

brake drum with a brake drum mi-

crometer (tool FRE-1431). If the di-

ameter is less than 0.030 inches over-

size,

standard lining may be installed.

If the diameter is 0.030—0.060 inches

oversize, oversize lining should be in-

stalled.

3.

Position the new lining on the

shoe.

Starting in the center, insert and

secure the rivets, working alternately

towards each end. Replacement lin-

ings are ground and no further grind-

ing is required.

4.

Check the clearance between the

shoe and lining. The lining must seat

tightly against the shoe with not more

than 0.008 inch clearance between any

two rivets.

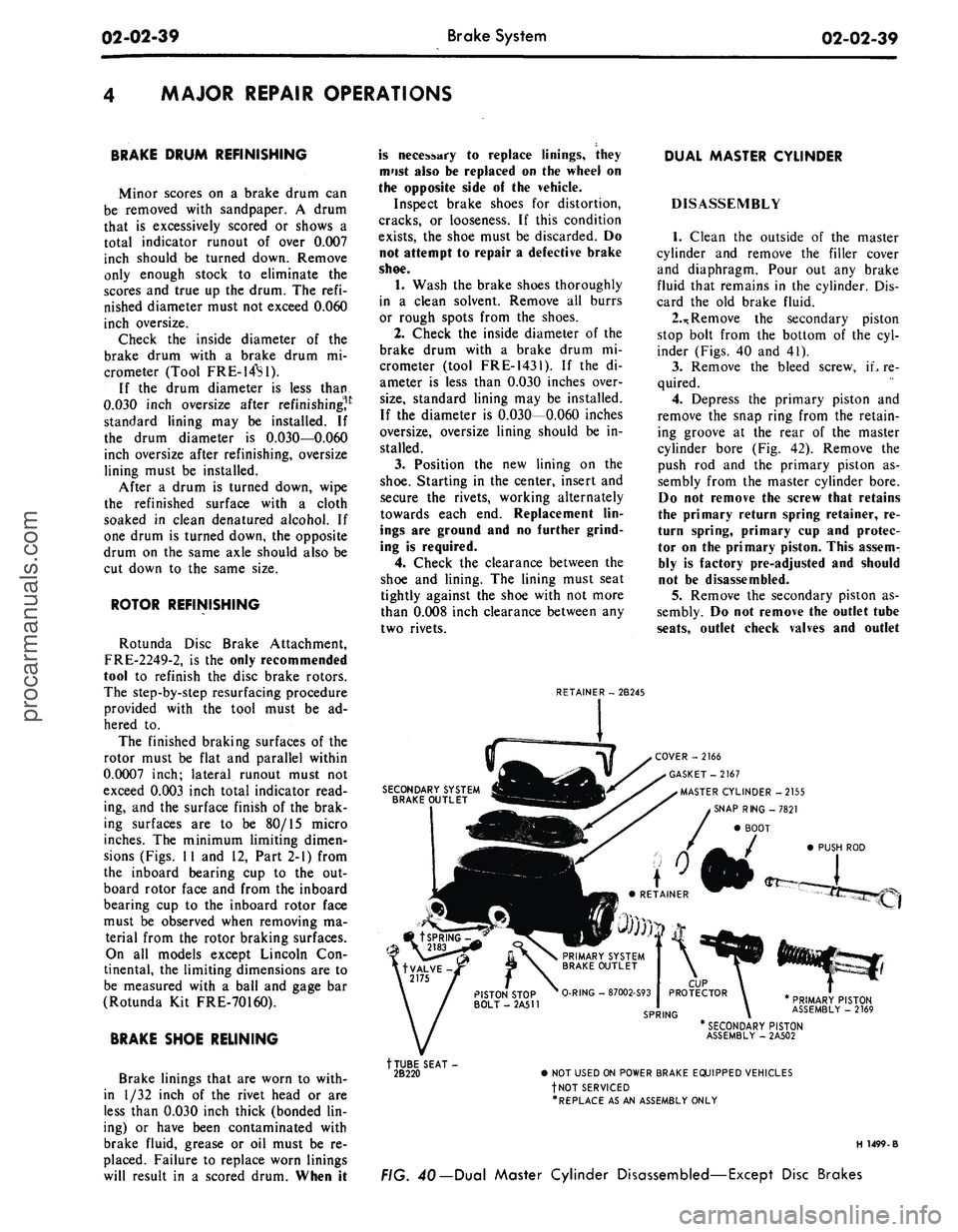

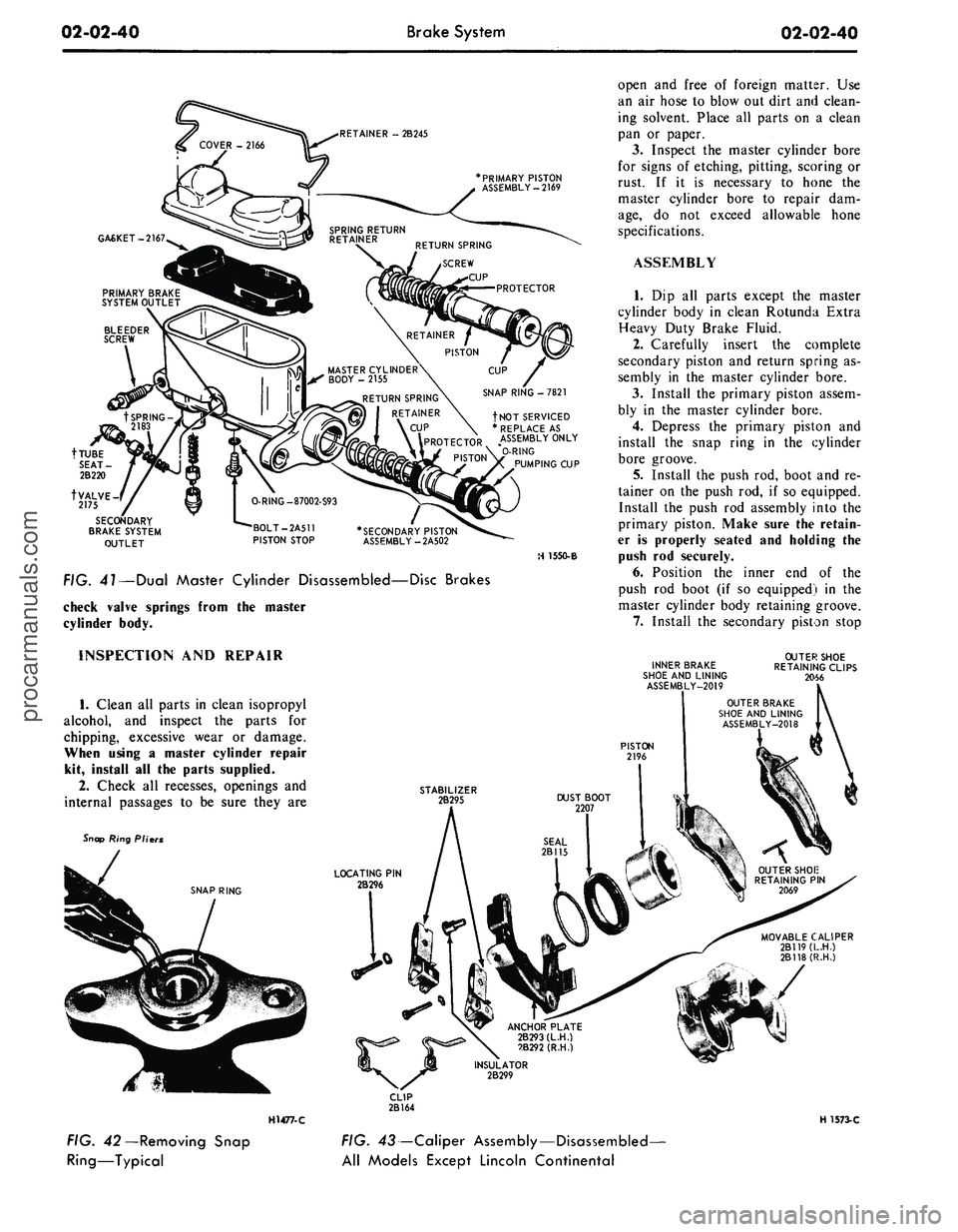

RETAINER - 2B245

DUAL MASTER CYLINDER

DISASSEMBLY

1.

Clean the outside of the master

cylinder and remove the filler cover

and diaphragm. Pour out any brake

fluid that remains in the cylinder. Dis-

card the old brake fluid.

2.*

Remove the secondary piston

stop bolt from the bottom of the cyl-

inder (Figs. 40 and 41).

3.

Remove the bleed screw, iL re-

quired.

4.

Depress the primary piston and

remove the snap ring from the retain-

ing groove at the rear of the master

cylinder bore (Fig. 42). Remove the

push rod and the primary piston as-

sembly from the master cylinder bore.

Do not remove the screw that retains

the primary return spring retainer, re-

turn spring, primary cup and protec-

tor on the primary piston. This assem-

bly is factory pre-adjusted and should

not be disassembled.

5.

Remove the secondary piston as-

sembly. Do not remove the outlet tube

seats,

outlet check valves and outlet

SECONDARY SYSTEM

BRAKE OUTLET

COVER -2166

GASKET-2167

MASTER CYLINDER -2155

SNAP RING -7821

BOOT

PUSH ROD

PRIMARY PISTON

ASSEMBLY - 2169

tTUBE SEAT-

2B220

* SECONDARY PISTON

ASSEMBLY - 2A502

• NOT USED ON POWER BRAKE EQUIPPED VEHICLES

fNOT SERVICED

•REPLACE AS AN ASSEMBLY ONLY

H 1499-B

FIG. 40— Dual Master Cylinder Disassembled—Except Disc Brakesprocarmanuals.com

Page 59 of 413

02-02-40

Brake System

02-02-40

RETAINER - 2B245

PRIMARY PISTON

ASSEMBLY-2169

GASKET-2167

RETURN SPRING

RETAINER

\ CUP

\\PROTECTOR

^\i # PISTON

fNOT SERVICED

* REPLACE AS

ASSEMBLY ONLY

*O-RING

PUMPING CUP

tVALVE

2175

SECONDARY

BRAKE SYSTEM

OUTLET

*SECONDARY PISTON

ASSEMBLY-2A502

H 1550-B

FIG. 41—Dual Master Cylinder Disassembled—Disc Brakes

check valve springs from the master

cylinder body.

open and free of foreign matter. Use

an air hose to blow out dirt and clean-

ing solvent. Place all parts on a clean

pan or paper.

3.

Inspect the master cylinder bore

for signs of etching, pitting, scoring or

rust. If it is necessary to hone the

master cylinder bore to repair dam-

age,

do not exceed allowable hone

specifications.

ASSEMBLY

1.

Dip all parts except the master

cylinder body in clean Rotunda Extra

Heavy Duty Brake Fluid.

2.

Carefully insert the complete

secondary piston and return spring as-

sembly in the master cylinder bore.

3.

Install the primary piston assem-

bly in the master cylinder bore.

4.

Depress the primary piston and

install the snap ring in the cylinder

bore groove.

5.

Install the push rod, boot and re-

tainer on the push rod, if so equipped.

Install the push rod assembly into the

primary piston. Make sure the retain-

er is properly seated and holding the

push rod securely.

6. Position the inner end of the

push rod boot (if so equipped) in the

master cylinder body retaining groove.

7.

Install the secondary piston stop

INSPECTION AND REPAIR

1.

Clean all parts in clean isopropyl

alcohol, and inspect the parts for

chipping, excessive wear or damage.

When using a master cylinder repair

kit, install all the parts supplied.

2.

Check all recesses, openings and

internal passages to be sure they are

Snap Ring Pliers

SNAP RING

H1477-C

FIG. 42—Removing Snap

Ring—Typical

INNER BRAKE

SHOE AND LINING

ASSEMBLY-2019

OUTER SHOE

RETAINING CLIPS

2066

STABILIZER

2B295

LOCATING PIN

2B296

ANCHOR PLATE

2B293(L.H.)

2B292 (R.H.)

MOVABLE CALIPER

2B119(L.H.)

2B118(R.H.)

H 1573-C

FIG. 43—Caliper Assembly—Disassembled-

All Models Except Lincoln Continentalprocarmanuals.com

Page 65 of 413

02-03-04

Specifications

02-03-04

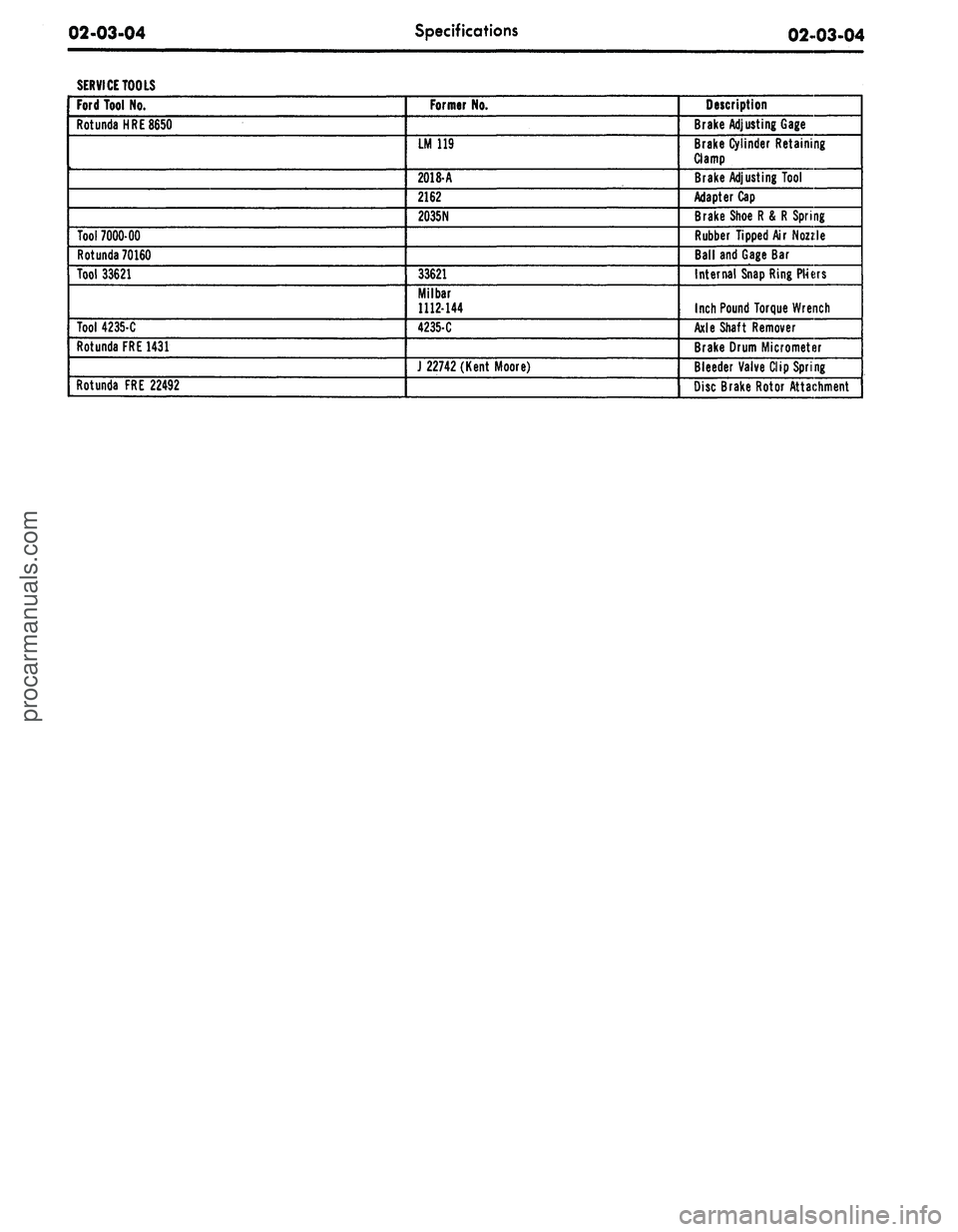

SERVICE TOOLS

Ford Tool

No.

Rotunda

HRE

8650

Tool

7000-00

Rotunda

70160

Tool 33621

Tool 4235-C

Rotunda

FRE 1431

Rotunda

FRE

22492

Former

No.

LM 119

2018-A

2162

2035N

33621

Milbar

1112-144

4235-C

J

22742 (Kent Moore)

Description

Brake

Adjusting

Gage

Brake

Cylinder

Retaining

Clamp

Brake

Adjusting

Tool

Adapter

Cap

Brake Shoe

R

&

R

Spring

Rubber

Tipped

Air

Nozzle

Ball

and

Gage

Bar

Internal

Snap Ring PMers

Inch Pound Torque

Wrench

Axle Shaft

Remover

Brake Drum

Micrometer

Bleeder

Valve Clip Spring

Disc Brake Rotor

Attachmentprocarmanuals.com