service FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 193 of 413

04-01-06

General Axle Service

04-01-06

FLANGE BEARING

CUP RUNOUT

0.000

0.001

0.002

0.003

0.004

0.005

0.006

0.007

0.008

DRIVE SHAFT UNIVERSAL CROSS-SHAFT RUNOUT-INCH

0.000

0.000

0.001

0.002

0.003

0.004

0.005

0.006

0.007

0.008

0.001

0.001

0.0013

0.0022

0.0032

0.0042

0.0051

0.0061

0.0071

0.0081

0.002

0.002

0.0022

0.0027

0.0036

0.0045

0.0053

0.0062

0.0073

0.0082

0.003

0.003

0.0032

0.0037

0.0042

0.005

0.0058

0.0068

0.0075

0.0087

0.004

0.004

0.0042

0.0045

0.005

0.0057

0.0063

0.0072

0.0081

0.009

0.005

0.005

0.0051

0.0053

0.0058

0.0064

0.0071

0.0078

0.0087

0.0094

0.006

0.006

0.0061

0.0062

0.0067

0.0072

0.0078

0.0085

0.0093

0.010

0.007

0.007

0.0071

0.0072

0.0077

0.0081

0.0087

0.0092

0.0099

0.0104

0.008

0.008

0.0081

0.0082

0.0085

0.009

0.0094

0.010

0.0103

0.011

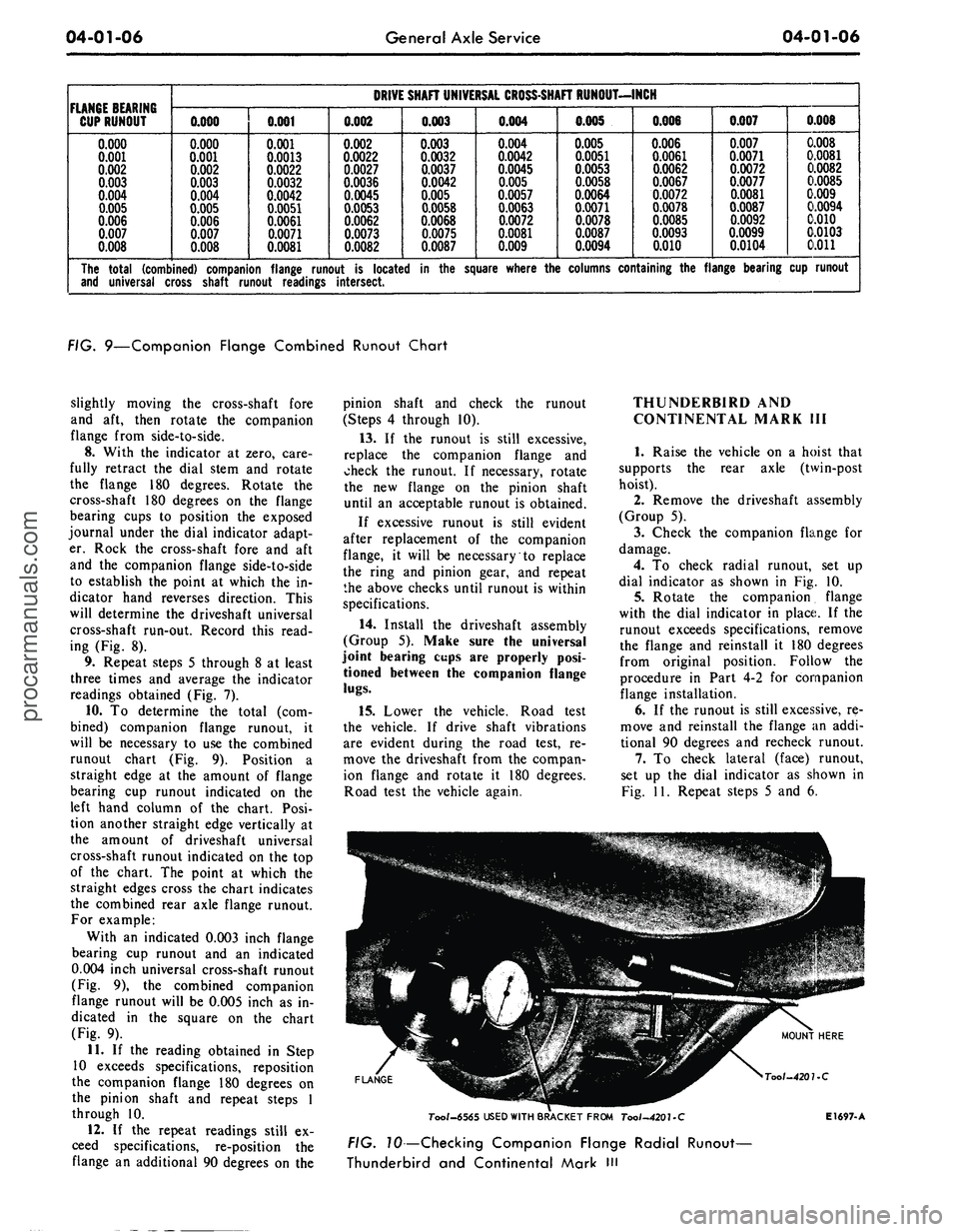

The total (combined) companion flange runout

is

located

in the

square where

the

columns containing

the

flange bearing cup runout

and universal cross shaft runout readings intersect.

FIG. 9—Companion Flange Combined Runout Chart

slightly moving the cross-shaft fore

and aft, then rotate the companion

flange from side-to-side.

8. With the indicator at zero, care-

fully retract the dial stem and rotate

the flange 180 degrees. Rotate the

cross-shaft 180 degrees on the flange

bearing cups to position the exposed

journal under the dial indicator adapt-

er. Rock the cross-shaft fore and aft

and the companion flange side-to-side

to establish the point at which the in-

dicator hand reverses direction. This

will determine the driveshaft universal

cross-shaft run-out. Record this read-

ing (Fig. 8).

9. Repeat steps 5 through 8 at least

three times and average the indicator

readings obtained (Fig. 7).

10.

To determine the total (com-

bined) companion flange runout, it

will be necessary to use the combined

runout chart (Fig. 9). Position a

straight edge at the amount of flange

bearing cup runout indicated on the

left hand column of the chart. Posi-

tion another straight edge vertically at

the amount of driveshaft universal

cross-shaft runout indicated on the top

of the chart. The point at which the

straight edges cross the chart indicates

the combined rear axle flange runout.

For example:

With an indicated 0.003 inch flange

bearing cup runout and an indicated

0.004 inch universal cross-shaft runout

(Fig. 9), the combined companion

flange runout will be 0.005 inch as in-

dicated in the square on the chart

(Fig. 9).

11.

If the reading obtained in Step

10 exceeds specifications, reposition

the companion flange 180 degrees on

the pinion shaft and repeat steps 1

through 10.

12.

If the repeat readings still ex-

ceed specifications, re-position the

flange an additional 90 degrees on the

pinion shaft and check the runout

(Steps 4 through 10).

13.

If the runout is still excessive,

replace the companion flange and

check the runout. If necessary, rotate

the new flange on the pinion shaft

until an acceptable runout is obtained.

If excessive runout is still evident

after replacement of the companion

flange, it will be necessary to replace

the ring and pinion gear, and repeat

the above checks until runout is within

specifications.

14.

Install the driveshaft assembly

(Group 5). Make sure the universal

joint bearing cups are properly posi-

tioned between the companion flange

lugs.

15.

Lower the vehicle. Road test

the vehicle. If drive shaft vibrations

are evident during the road test, re-

move the driveshaft from the compan-

ion flange and rotate it 180 degrees.

Road test the vehicle again.

THUNDERBIRD AND

CONTINENTAL MARK III

1.

Raise the vehicle on a hoist that

supports the rear axle (twin-post

hoist).

2.

Remove the driveshaft assembly

(Group 5).

3.

Check the companion flange for

damage.

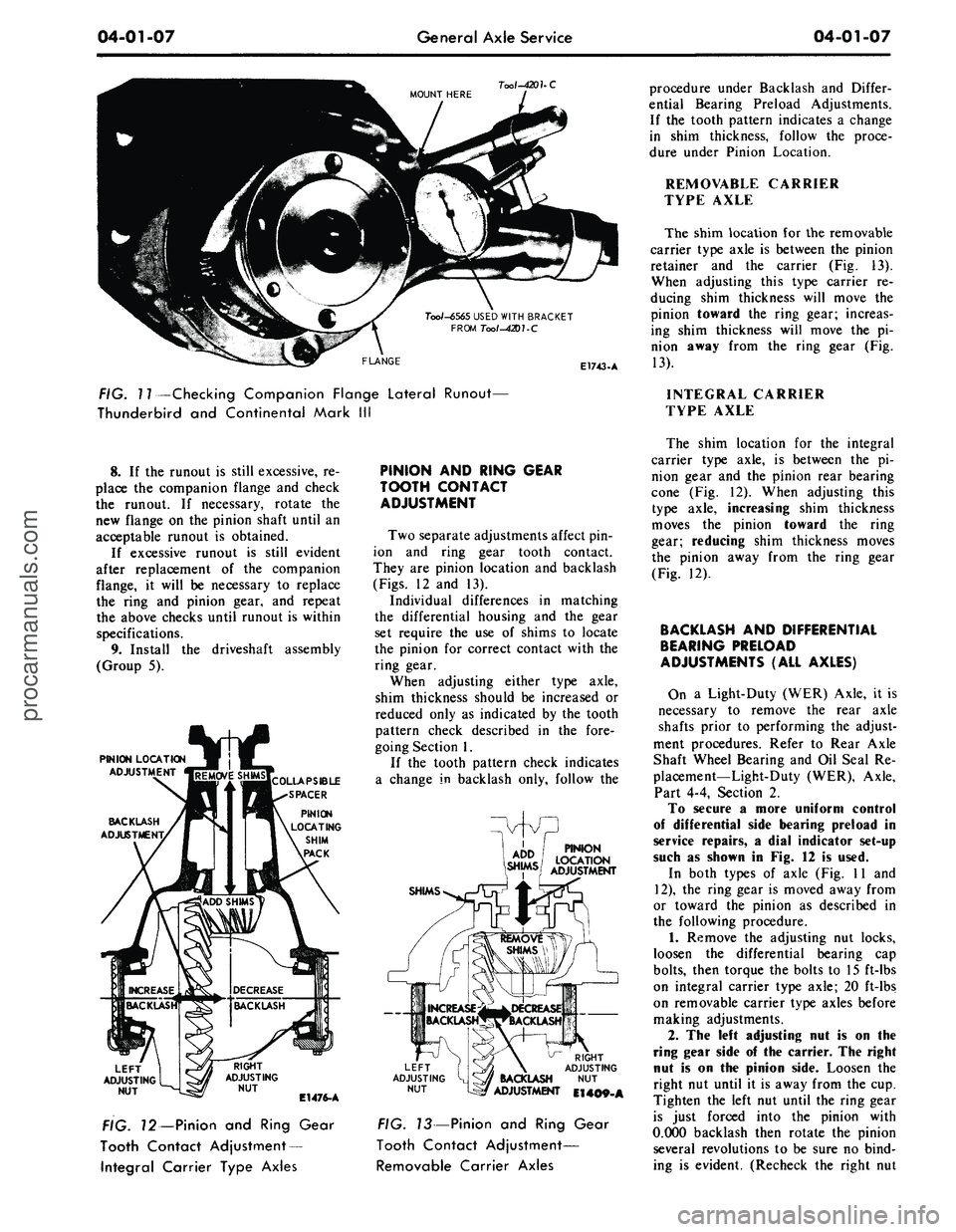

4.

To check radial runout, set up

dial indicator as shown in Fig. 10.

5.

Rotate the companion flange

with the dial indicator in place. If the

runout exceeds specifications, remove

the flange and reinstall it 180 degrees

from original position. Follow the

procedure in Part 4-2 for companion

flange installation.

6. If the runout is still excessive, re-

move and reinstall the flange an addi-

tional 90 degrees and recheck runout.

7.

To check lateral (face) runout,

set up the dial indicator as shown in

Fig. 11. Repeat steps 5 and 6.

FLANGE

MOUNT HERE

Too/-4207-C

Too/-6565 USED WITH BRACKET FROM Tool-4201

FIG. 10—Checking Companion Flange Radial Runout—

Thunderbird and Continental Mark III

E1697-Aprocarmanuals.com

Page 194 of 413

04-01-07

General Axle Service

04-01-07

Tool-4201-

C

Tool-6565 USED WITH BRACKET

FROM Too/^*207-C

FLANGE

E1743-A

procedure under Backlash and Differ-

ential Bearing Preload Adjustments.

If the tooth pattern indicates a change

in shim thickness, follow the proce-

dure under Pinion Location.

REMOVABLE CARRIER

TYPE AXLE

The shim location for the removable

carrier type axle is between the pinion

retainer and the carrier (Fig. 13).

When adjusting this type carrier re-

ducing shim thickness will move the

pinion toward the ring gear; increas-

ing shim thickness will move the pi-

nion away from the ring gear (Fig.

13).

FIG. 11—Checking Companion Flange Lateral Runout—

Thunderbird and Continental Mark III

INTEGRAL CARRIER

TYPE AXLE

8. If the runout is still excessive, re-

place the companion flange and check

the runout. If necessary, rotate the

new flange on the pinion shaft until an

acceptable runout is obtained.

If excessive runout is still evident

after replacement of the companion

flange, it will be necessary to replace

the ring and pinion gear, and repeat

the above checks until runout is within

specifications.

9. Install the driveshaft assembly

(Group 5).

PINION LOCATION

ADJUSTMENT

BACKLASH

ADJUSTMENT,

LEFT

ADJUSTING

NUT

E1476-A

FIG. 12—Pinion and Ring Gear

Tooth Contact Adjustment

—

Integral Carrier Type Axles

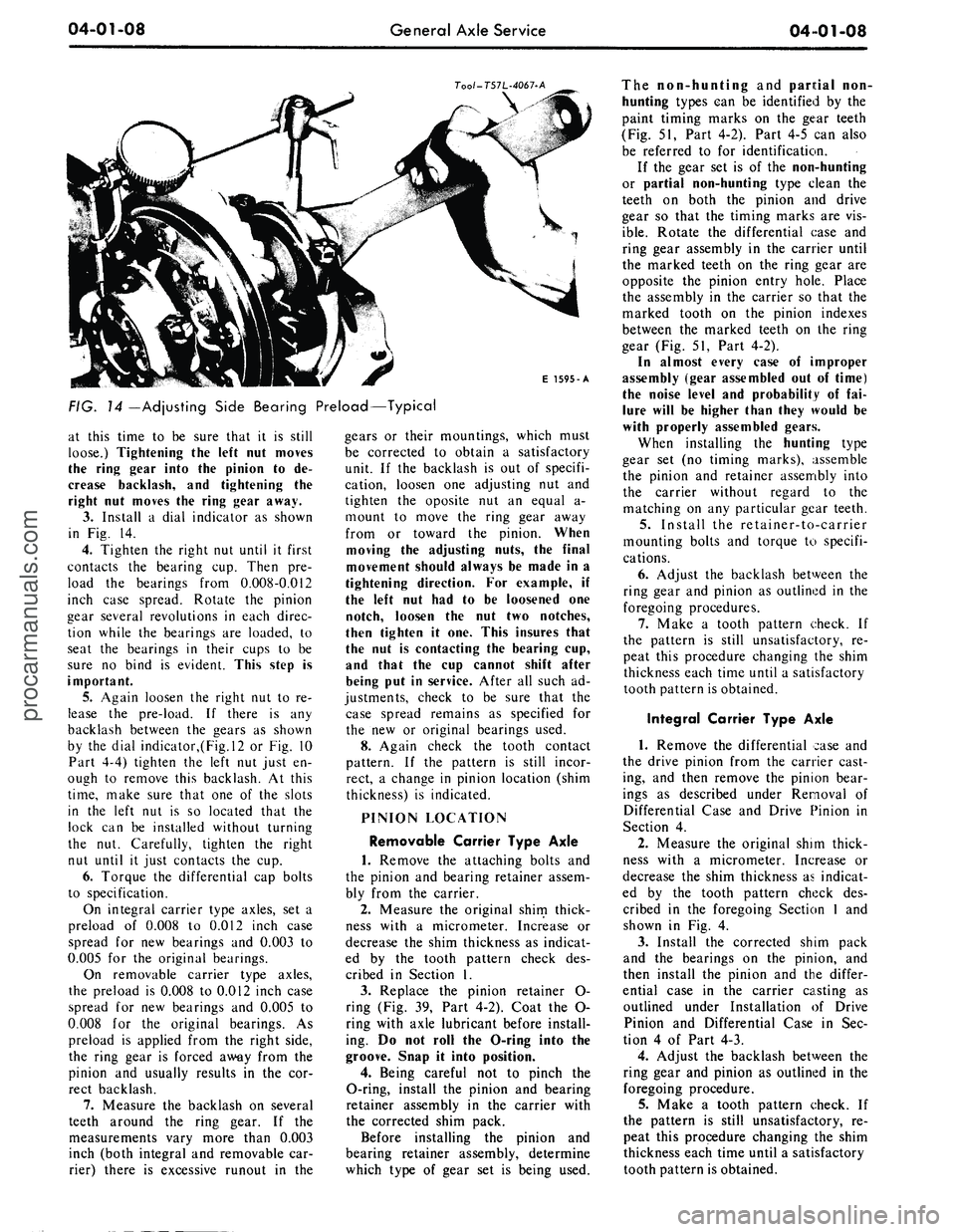

PINION AND RING GEAR

TOOTH CONTACT

ADJUSTMENT

Two separate adjustments affect pin-

ion and ring gear tooth contact.

They are pinion location and backlash

(Figs.

12 and 13).

Individual differences in matching

the differential housing and the gear

set require the use of shims to locate

the pinion for correct contact with the

ring gear.

When adjusting either type axle,

shim thickness should be increased or

reduced only as indicated by the tooth

pattern check described in the fore-

going Section 1.

If the tooth pattern check indicates

a change in backlash only, follow the

PINION

LOCATION

ADJUSTMENT

SHIMS

LEFT

ADJUSTING

NUT

RIGHT

ADJUSTING

BACKLASH NUT

ADJUSTMENT El 409-A

FIG. 13—Pinion and Ring Gear

Tooth Contact Adjustment—

Removable Carrier Axles

The shim location for the integral

carrier type axle, is between the pi-

nion gear and the pinion rear bearing

cone (Fig. 12). When adjusting this

type axle, increasing shim thickness

moves the pinion toward the ring

gear; reducing shim thickness moves

the pinion away from the ring gear

(Fig. 12).

BACKLASH AND DIFFERENTIAL

BEARING PRELOAD

ADJUSTMENTS (ALL AXLES)

On a Light-Duty (WER) Axle, it is

necessary to remove the rear axle

shafts prior to performing the adjust-

ment procedures. Refer to Rear Axle

Shaft Wheel Bearing and Oil Seal Re-

placement—Light-Duty (WER), Axle,

Part 4-4, Section 2.

To secure a more uniform control

of differential side bearing preload in

service repairs, a dial indicator set-up

such as shown in Fig. 12 is used.

In both types of axle (Fig. 11 and

12),

the ring gear is moved away from

or toward the pinion as described in

the following procedure.

1.

Remove the adjusting nut locks,

loosen the differential bearing cap

bolts,

then torque the bolts to 15 ft-lbs

on integral carrier type axle; 20 ft-lbs

on removable carrier type axles before

making adjustments.

2.

The left adjusting nut is on the

ring gear side of the carrier. The right

nut is on the pinion side. Loosen the

right nut until it is away from the cup.

Tighten the left nut until the ring gear

is just forced into the pinion with

0.000 backlash then rotate the pinion

several revolutions to be sure no bind-

ing is evident. (Recheck the right nutprocarmanuals.com

Page 195 of 413

04-01-08

General Axle Service

04 01-08

Too/-T57L-4067-A

E 1595-A

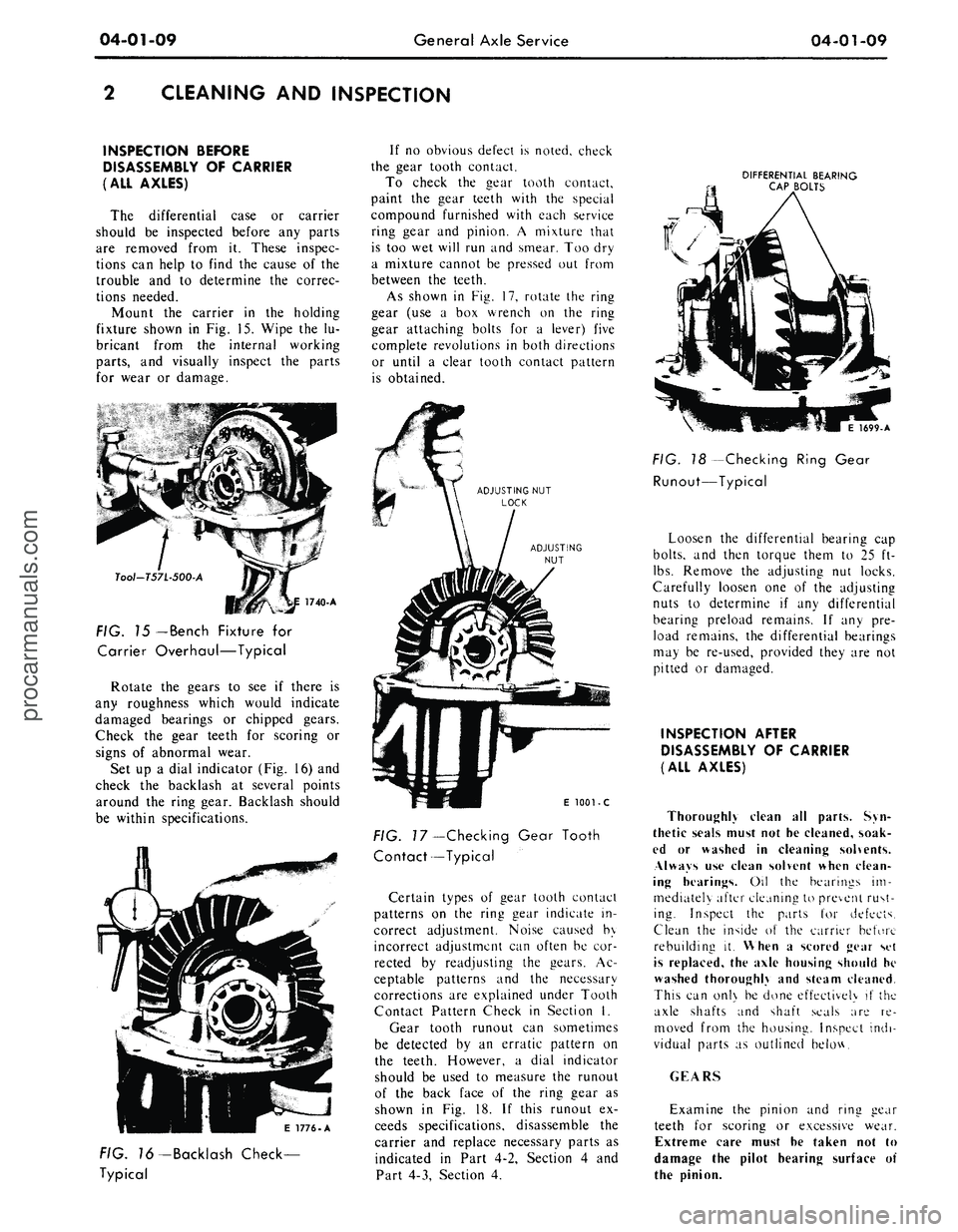

FIG.

14

—Adjusting Side Bearing Preload—Typical

at this time to be sure that it is still

loose.) Tightening the left nut moves

the ring gear into the pinion to de-

crease backlash, and tightening the

right nut moves the ring gear away.

3.

Install a dial indicator as shown

in Fig. 14.

4.

Tighten the right nut until it first

contacts the bearing cup. Then pre-

load the bearings from 0.008-0.012

inch case spread. Rotate the pinion

gear several revolutions in each direc-

tion while the bearings are loaded, to

seat the bearings in their cups to be

sure no bind is evident. This step is

important.

5. Again loosen the right nut to re-

lease the pre-load. If there is any

backlash between the gears as shown

by the dial indicator,(Fig.l2 or Fig. 10

Part 4-4) tighten the left nut just en-

ough to remove this backlash. At this

time,

make sure that one of the slots

in the left nut is so located that the

lock can be installed without turning

the nut. Carefully, tighten the right

nut until it just contacts the cup.

6. Torque the differential cap bolts

to specification.

On integral carrier type axles, set a

preload of 0.008 to 0.012 inch case

spread for new bearings and 0.003 to

0.005 for the original bearings.

On removable carrier type axles,

the preload is 0.008 to 0.012 inch case

spread for new bearings and 0.005 to

0.008 for the original bearings. As

preload is applied from the right side,

the ring gear is forced away from the

pinion and usually results in the cor-

rect backlash.

7.

Measure the backlash on several

teeth around the ring gear. If the

measurements vary more than 0.003

inch (both integral and removable car-

rier) there is excessive runout in the

gears or their mountings, which must

be corrected to obtain a satisfactory

unit. If the backlash is out of specifi-

cation, loosen one adjusting nut and

tighten the oposite nut an equal a-

mount to move the ring gear away

from or toward the pinion. When

moving the adjusting nuts, the final

movement should always be made in a

tightening direction. For example, if

the left nut had to be loosened one

notch, loosen the nut two notches,

then tighten it one. This insures that

the nut is contacting the bearing cup,

and that the cup cannot shift after

being put in service. After all such ad-

justments, check to be sure that the

case spread remains as specified for

the new or original bearings used.

8. Again check the tooth contact

pattern. If the pattern is still incor-

rect, a change in pinion location (shim

thickness) is indicated.

PINION LOCATION

Removable Carrier Type Axle

1.

Remove the attaching bolts and

the pinion and bearing retainer assem-

bly from the carrier.

2.

Measure the original shim thick-

ness with a micrometer. Increase or

decrease the shim thickness as indicat-

ed by the tooth pattern check des-

cribed in Section 1.

3.

Replace the pinion retainer O-

ring (Fig. 39, Part 4-2). Coat the O-

ring with axle lubricant before install-

ing. Do not roll the O-ring into the

groove. Snap it into position.

4.

Being careful not to pinch the

O-ring, install the pinion and bearing

retainer assembly in the carrier with

the corrected shim pack.

Before installing the pinion and

bearing retainer assembly, determine

which type of gear set is being used.

The non-hunting and pantial non-

hunting types can be identified by the

paint timing marks on the gear teeth

(Fig. 51, Part 4-2). Part 4-5 can also

be referred to for identification.

If the gear set is of the non-hunting

or partial non-hunting type clean the

teeth on both the pinion and drive

gear so that the timing marks are vis-

ible.

Rotate the differential case and

ring gear assembly in the carrier until

the marked teeth on the ring gear are

opposite the pinion entry hole. Place

the assembly in the carrier so that the

marked tooth on the pinion indexes

between the marked teeth on the ring

gear (Fig. 51, Part 4-2).

In almost every case of improper

assembly (gear assembled out of time)

the noise level and probability of fai-

lure will be higher than they would be

with properly assembled gears.

When installing the hunting type

gear set (no timing marks), assemble

the pinion and retainer assembly into

the carrier without regard to the

matching on any particular gear teeth.

5.

Install the retainer-to-carrier

mounting bolts and torque to specifi-

cations.

6. Adjust the backlash between the

ring gear and pinion as outlined in the

foregoing procedures.

7.

Make a tooth pattern check. If

the pattern is still unsatisfactory, re-

peat this procedure changing the shim

thickness each time until a satisfactory

tooth pattern is obtained.

Integral Carrier Type Axle

1.

Remove the differential case and

the drive pinion from the carrier cast-

ing, and then remove the pinion bear-

ings as described under Removal of

Differential Case and Drive Pinion in

Section 4.

2.

Measure the original shim thick-

ness with a micrometer. Increase or

decrease the shim thickness as indicat-

ed by the tooth pattern check des-

cribed in the foregoing Section 1 and

shown in Fig. 4.

3.

Install the corrected shim pack

and the bearings on the pinion, and

then install the pinion and the differ-

ential case in the carrier casting as

outlined under Installation of Drive

Pinion and Differential Case in Sec-

tion 4 of Part 4-3.

4.

Adjust the backlash between the

ring gear and pinion as outlined in the

foregoing procedure.

5.

Make a tooth pattern check. If

the pattern is still unsatisfactory, re-

peat this procedure changing the shim

thickness each time until a satisfactory

tooth pattern is obtained.procarmanuals.com

Page 196 of 413

04-01-09

General Axle Service

04-01-09

CLEANING AND INSPECTION

INSPECTION BEFORE

DISASSEMBLY OF CARRIER

(ALL AXLES)

The differential case or carrier

should be inspected before any parts

are removed from it. These inspec-

tions can help to find the cause of the

trouble and to determine the correc-

tions needed.

Mount the carrier in the holding

fixture shown in Fig. 15. Wipe the lu-

bricant from the internal working

parts,

and visually inspect the parts

for wear or damage.

Tool-T57L-500-A

FIG. 15

— Bench

Fixture for

Carrier Overhaul—Typical

Rotate the gears to see if there is

any roughness which would indicate

damaged bearings or chipped gears.

Check the gear teeth for scoring or

signs of abnormal wear.

Set up a dial indicator (Fig. 16) and

check the backlash at several points

around the ring gear. Backlash should

be within specifications.

If no obvious defect is noted, check

the gear tooth contact.

To check the gear tooth contact,

paint the gear teeth with the special

compound furnished with each service

ring gear and pinion. A mixture that

is too wet will run and smear. Too dry

a mixture cannot be pressed out from

between the teeth.

As shown in Fig. 17, rotate the ring

gear (use a box wrench on the ring

gear attaching bolts for a lever) five

complete revolutions in both directions

or until a clear tooth contact pattern

is obtained.

DIFFERENTIAL BEARING

CAP BOLTS

E 1776-A

FIG. 76-Backlash Check-

Typical

E

1001 - C

FIG.

7

7—Checking Gear Tooth

Contact—Typical

Certain types of gear tooth contact

patterns on the ring gear indicate in-

correct adjustment. Noise caused by

incorrect adjustment can often be cor-

rected by readjusting the gears. Ac-

ceptable patterns and the necessary

corrections are explained under Tooth

Contact Pattern Check in Section I.

Gear tooth runout can sometimes

be detected by an erratic pattern on

the teeth. However, a dial indicator

should be used to measure the runout

of the back face of the ring gear as

shown in Fig. 18. If this runout ex-

ceeds specifications, disassemble the

carrier and replace necessary parts as

indicated in Part 4-2, Section 4 and

Part 4-3, Section 4.

1699-A

FIG. 18 -Checking Ring Gear

Runout—Typical

Loosen the differential bearing cap

bolts,

and then torque them to 25 ft-

lbs.

Remove the adjusting nut locks.

Carefully loosen one of the adjusting

nuts to determine if any differential

bearing preload remains. If any pre-

load remains, the differential bearings

may be re-used, provided they are not

pitted or damaged.

INSPECTION AFTER

DISASSEMBLY OF CARRIER

(ALL AXLES)

Thoroughly clean all parts. Syn-

thetic seals must not he cleaned, soak-

ed or washed in cleaning solvents.

Always use clean solvent when clean-

ing hearings. Oil the bearings im-

mediately after cleaning to prevent rust-

ing. Inspect the parts for defects.

Clean the inside of the carrier before

rebuilding it. When a scored gear set

is replaced, the axle housing should he

washed thoroughly and steam cleaned.

This can onl\ be done effectively if the

axle shafts and shaft seals are re-

moved from the housing. Inspect indi-

vidual parts as outlined below.

GEARS

Examine the pinion and ring gear

teeth for scoring or excessive wear.

Extreme care must he taken not to

damage the pilot hearing surface of

the pinion.procarmanuals.com

Page 197 of 413

04-01-10

General Axle Service

04-01-10

The pattern taken during disassem-

bly should be helpful in judging if

gears can be re-used. Worn gears can-

not be rebuilt to correct a noisy condi-

tion. Gear scoring is the result of ex-

cessive shock loading or the use of an

incorrect lubricant. Scored gears can-

not be re-used.

Examine the teeth and thrust surfa-

ces of the differential gears. Wear on

the hub of the differential gear can

cause a chucking noise known as

chuckle when the vehicle is driven at

low speeds. Wear of splines, thrust

surfaces, or thrust washers, can con-

tribute to excessive drive line back-

lash.

BEARING CUPS AND

CONE AND ROLLER

ASSEMBLIES

Check bearing cups for rings,

scores, galling, or excessively worn

wear patterns. Pinion cups must be

solidly seated. Check by attempting to

insert a 0.0015-inch feeler between

these cups and the bottoms of their

bores.

When operated in the cups, cone

and roller assemblies must turn with-

out roughness. Examine the roller

ends for wear. Step-wear on the roller

ends indicates the bearings were not

preloaded properly, or the rollers were

slightly misaligned.

If inspection reveals either a defec-

tive cup or a defective cone and roller

assembly, both parts should be re-

placed to avoid early failure.

DIFFERENTIAL BEARING

ADJUSTING NUTS

Temporarily install the bearing caps

and test the fit of the adjusting nuts in

their threads. The nuts should turn

easily when the caps are tightened to

25 ft-lbs. The faces of the nuts that

contact the bearing cups must be

smooth and square. Replace the nuts

or examine the threads in the carrier

if their fit is not proper. Be sure that

the bearing caps and adjusting nuts

are on the side they were machined to

fit. Observe the punch marks and

scribe marks made during disassem-

bly.

U-JOINT FLANGE

Be sure that the eai» of the flange

have not been damaged in removing

the drive shaft or in removing the

flange from the axle. The end of the

flange that contacts the front pinion

bearing inner race as well as the flat

surface of the pinion nut counterbore

must be smooth. Polish these surfaces

if necessary. Roughness aggravates

backlash noises and causes wear of

the flange and pinion nut with a resul-

tant loss in pinion bearing preload.

PINION RETAINER

Be sure that the pinion bearing cups

are seated. Remove any chips or burrs

from the mounting flange. Clean the

groove for the O-ring seal and all lu-

bricant passages. If the cups were re-

moved, examine the bores carefully.

Any nicks or burrs in these bores

must be removed to permit proper

seating of the cups.

CARRIER HOUSING

Make sure that the differential

bearing bores are smooth and the

threads are not damaged. Remove any

nicks or burrs from the mounting sur-

faces of the carrier housing.

DIFFERENTIAL CASE

Make sure that the hubs where the

bearings mount are smooth. Carefully

examine the differential case bearing

shoulders, which may have been dam-

aged when the bearings were removed.

The bearing assemblies will fail if they

do not seat firmly against the shoul-

ders.

Check the fit (free rotation) of

the differential side gears in their

counterbores. Be sure that the mating

surfaces of the two parts of the case

are smooth and free from nicks or

burrs.

LIMITED SLIP AND

TRACTION-LOK

DIFFERENTIAL PARTS

Inspect the clutch plates for uneven

or extreme wear. The dog-eared clutch

plates must be free from burrs, nicks

or scratches which could cause excess-

ive or erratic wear to the bonding ma-

terial of the internally splined clutch

plates.

The internally splined clutch

plates should be inspected for condi-

tion of the bond, bonding material,

and wear. Replace the bonded plates

if their thickness is less than 0.085

inch or if the bonded material is

scored or badly worn. Inspect the

bonded plate internal teeth for wear.

Replace them, if excessive wear is evi-

dent. Bonded plates should be re-

placed as a set only

Examine all thrust surfaces and

hubs for wear. Abnormal wear on

these surfaces can contribute to a

noisy axle.

Inspect the Belleville spring (limited

slip) for proper free height of 1/4

inch.

LUBRICANT LEVEL

The lubricant level should be

checked every 6000 miles with the ve-

hicle in normal curb attitude. The lu-

bricant level should be at the lower

edge of the filler plug hole located in

either the carrier casting or housing

cover. It is unnecessary to periodically

drain the axle lubricant. The factory

fill should remain in the housing for

the life of the vehicle, except when re-

pairs are made. The specified lubri-

cant should be installed when the axle

is overhauled.procarmanuals.com

Page 201 of 413

04-02-04

Rear Axle — Removable Carrier Type

04-02-04

IN-VEHICLE ADJUSTMENTS AND REPAIRS

REAR AXLE SHAFT, WHEEL

BEARING AND OIL SEAL

REPLACEMENT

The rear axle shafts, wheel bear-

ings,

and oil seal can be replaced

without removing the differential as-

sembly from the axle housing.

REMOVAL OF

AXLE SHAFT

Synthetic wheel bearing seals are

used in production only. Removal and

insertion of rear axle shafts must be

performed with caution. The entire

length of the shaft (including spline)

up to the seal journal must pass

through the seal without cutting of the

seal element during axle removal or

installation will result in early seal fai-

lure.

Leather seals only will be used as

service replacement for synthetic

wheel bearing seals.

1.

Remove the wheel cover, wheel

and tire from the brake drum.

2.

Remove the nuts that secure the

brake drum to the axle shaft flange,

then remove the drum from flange.

3.

Working through the hole pro-

vided in each axle shaft flange, re-

move the nuts that secure the wheel

bearing retainer plate. Then pull the

axle shaft assembly out of the axle

housing (Fig. 4). The brake backing

plate must not be dislodged. Install

one nut to hold the plate in place after

the axle shaft is removed.

Too/-4235-C

E1032-D

FIG. 4—Removing Axle Shaft

REMOVAL OF REAR

WHEEL BEARING AND

SEAL

Synthetic seals must not be cleaned,

soaked or washed in cleaning solvents.

Removal of the wheel bearings from

the axle shaft makes them unfit for

further use.

1.

On all models except Ford, Mer-

cury or Meteor, if the rear wheel

bearing is to be replaced, loosen the

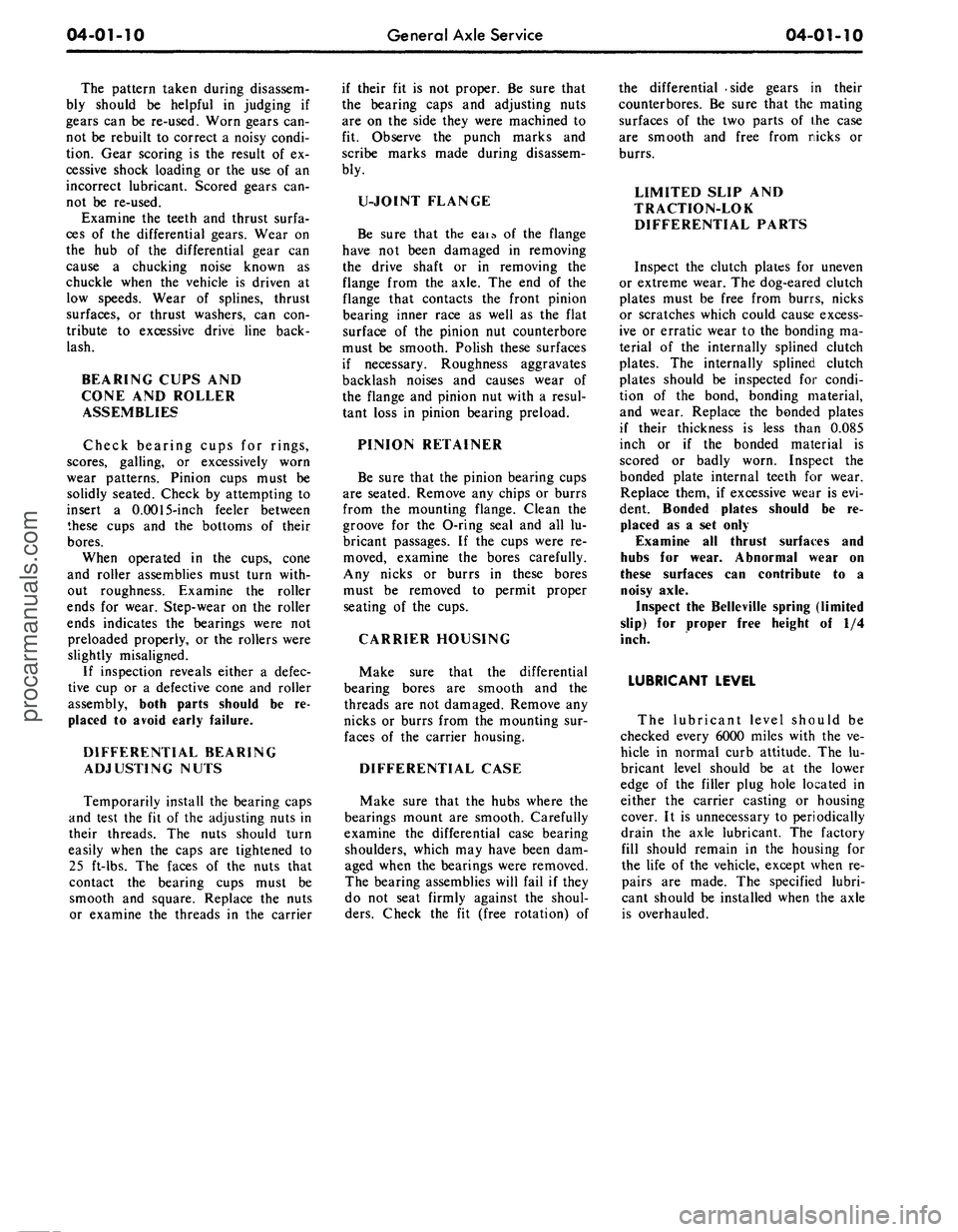

inner retainer ring by nicking it deeply

with a cold chisel in several places

(Fig. 5). It will then slide off easily.

E 1731-A

FIG. 5—Removing Rear Wheel

Bearing Retainer Ring

On Ford, Mercury and Meteor mo-

dels,

it is necessary to first drill a 1/4

inch hole not more than 5/16 inch

deep in the retainer ring surface bef-

ore using the cold chisel.

2.

Remove the bearing from the

axle shaft with the tool shown in Fig.

6 or Fig. 7.

3.

Whenever a rear axle shaft is re-

placed, the oil seal must be replaced.

Remove the seal with Tool 1175-AB

and a slide hammer (Fig. 8). If new

leather-type wheel bearing service

seals are to be installed, soak new oil

seals in SAE 10 oil for 1/2 hour

before installing.

INSTALLATION OF REAR

WHEEL BEARING AND

SEAL

1.

Inspect the machined surface of

the axle shaft and the axle housing for

rough spots or other irregularities

which would affect the sealing action

of the oil seal. Check the axle shaft

splines for burrs, wear or twist. Care-

fully remove any burrs or rough spots.

Replace worn or damaged parts.

2.

Lightly coat wheel bearing bores

with axle lubricant.

3.

Place the retainer plate on the

axle shaft, and press the new wheel

bearing on the shaft with the tool

shown in Fig. 6 or Fig. 9. Do not at-

tempt to press on both the bearing

and the inner retainer ring at the same

time.

4.

Using the bearing installation

tool (Tool 4621-A or 4234-4), press

the bearing inner retainer ring on the

shaft until the retainer seats firmly

against the bearing. On Ford, Mercu-

ry, or Meteor models, before assem-

bling the retainer onto the axle shaft,

the shaft journal and the inside di-

ameter of the retainer should be wiped

clean with a dry cloth. These parts

must not be degreased or lubricated.

5. Rear wheel oil seals with synthe-

tic sealing elements have been incor-

porated in production only. However,

leather seals only will be used as re-

placements for the synthetic sealing

elements. Install the new oil seal with

the tools shown in Figs. 10 and 12. Be

sure the new seal has been soaked in

SAE 10 oil for 1/2 hour before in-

stalling it. Wipe a small amount of oil

resistant sealer on the outer edge of

the seal before it is installed. Do not

put sealer on the sealing lip.

INSTALLATION OF

AXLE SHAFT

1.

Carefully slide the axle shaft into

the housing so that the rough forging

of the shaft will not damage the oil

seal. Start the axle splines into the

side gear, and push the shaft in until

the bearing bottoms in the housing.

2.

Install the bearing retainer plate

and the nuts that secure it. Torque the

nuts to specifications.

3.

Install the brake drum and the

drum attaching (Tinnerman) nuts.

4.

Install the wheel and tire on the

drum. Install the wheel cover.

DRIVE PINION OIL SEAL

REPLACEMENT

COLLAPSIBLE SPACER

Synthetic seals must not be cleaned,

soaked or washed in cleaning solvent.

The drive pinion oil seal can be re-

placed without removing the differen-

tial carrier assembly from the axle

housing.

1.

Raise the vehicle and install

safety stands. Remove both rear wheels

and brake drums.

2.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly (Fig. 11). Dis-

connect the drive shaft from the axle

U-joint flange. Be careful to avoid

dropping the loose universal joint

bearing cups. Hold the cups on the

spider with tape. Mark the cups so

that they will be in their original posi-

tion in relation to the flange when

they are assembled. Remove the drive

shaft from the transmission extension

housing. Install an oil seal replacer

tool in the transmission extension

housing to prevent transmission fluidprocarmanuals.com

Page 205 of 413

04-02-08

Rear Axle — Removable Carrier Type

04-02-08

REMOVAL AND INSTALLATION

CARRIER ASSEMBLY

REMOVAL

1.

Raise the vehicle on a hoist and

remove the two rear wheels and tires.

2.

Remove the two brake drums (3

Tinnerman nuts at each drum) from

the axle shaft flange studs. If diffi-

culty is experienced in removing the

drums, remove the brake adjuster

knockout slug or rubber plug (if so

equipped) and back off the brake

shoes.

3.

Working through the hole pro-

vided in each axle shaft flange, re-

move the nuts that secure the rear

wheel bearing retainer plate. Pull each

axle shaft assembly out of the axle

housing using axle shaft remover,

Tool 4235-C. (Fig. 4). Care must be

exercised to prevent damage to the

production-type synthetic oil seal, if so

equipped. Any roughing or cutting of

the seal element during removal or in-

stallation can result in early seal fail-

ure.

Install a nut on one of the brake

backing plate attaching bolts to hold

the plate to the axle housing after the

shaft has been removed. Whenever a

rear axle shaft is replaced, the wheel

bearing oil seals must be replaced.

Remove the seals with tool 1175AB.

4.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position at as-

sembly. Disconnect the drive shaft at

the rear axle U-joint. Hold the cups

on the spider with tape. Mark the

cups so that they will be in their orig-

inal position relative to the flange

when they are assembled. Remove the

drive shaft from the transmission ex-

tension housing. Install an oil seal re-

placer tool in the housing to prevent

transmission leakage. Refer to the

transmission group for the appropriate

tool.

5.

Clean area around carrier to

housing surfaced with a wire brush and

wipe clean, to prevent dirt entry into

the housing. Place a drain pan under

the carrier and housing, remove the

carrier attaching nuts, and drain the

axle.

Remove the carrier assembly

from the axle housing.

INSTALLATION

Synthetic production-type wheel

bearing seals must not be cleaned,

soaked or washed in cleaning solvent.

1.

Clean the axle housing and

shafts using kerosene and swabs. To

avoid contamination of the grease in

the sealed ball bearings, do not allow

any quantity of solvent directly on the

wheel bearings. Clean the mating sur-

faces of the axle housing and carrier.

2.

Position the differential carrier

on the studs in the axle housing using

a new gasket between carrier and

housing. Install the carrier-to-housing

attaching nuts, and torque them to

specifications.

3.

Remove the oil seal replacer tool

from the transmission extension hous-

ing. Position the drive shaft so that

the front U-joint slip yoke splines to

the transmission output shaft.

4.

Connect the drive shaft to the

axle U-joint flange, aligning the scribe

marks made on the drive shaft end

yoke and the axle U-joint flange dur-

ing the removal procedure. Install the

U-bolts and nuts and torque to speci-

fications.

5.

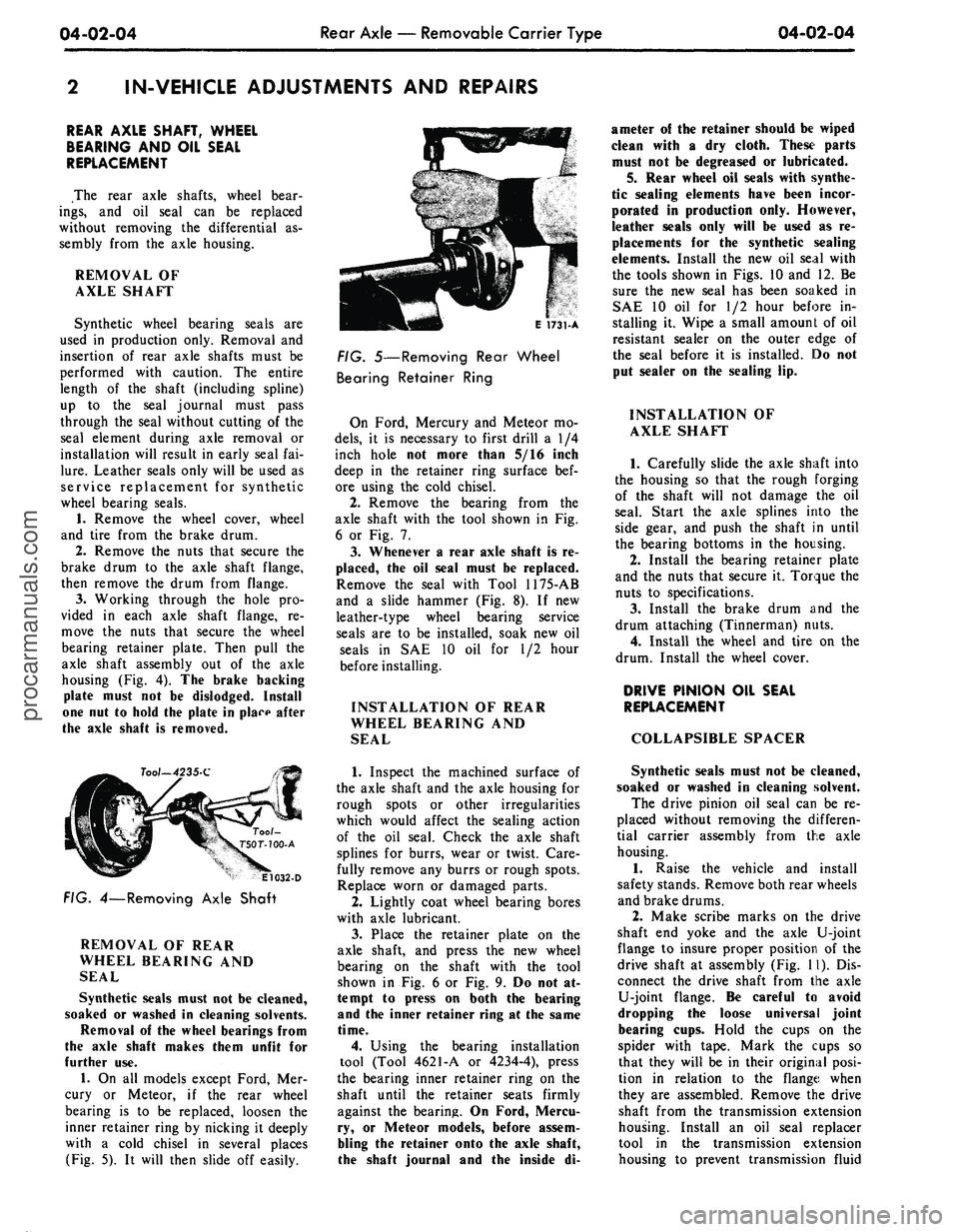

If the synthetic, production-type

wheel bearing seals were replaced with

service-type leather seals, soak the

new rear wheel bearing oil seals in

SAE 10 oil for 1/2 hour before instal-

lation. Wipe a small amount of an oil

resistant sealer on the outer edge of

each seal before it is installed. Do not

put any of the sealer on the sealing

lip.

Install the oil seals in the ends of

the rear axle housing with one of the

tools shown in Figs. 10 and 12.

Tool

T65F-1177.A

E 1571-A

FIG. 12—Rear Axle Shaft Bearing

Seal Installation

6. Install the two axle shaft assem-

blies in the axle housing. Care must

be exercised to prevent damage to the

oil seals. The shorter shaft goes into

the left side of the housing.

Carefully slide the axle shaft into

the housing so that the rough forging

of the shaft will not damage the oil

seal. Start the axle splines into the

differential side gear, and push the

shaft in until the bearing bottoms in

the housing.

7.

Install the bearing retainers on

the attaching bolts on the axle housing

flanges. Install the nuts on the bolts

and torque to specifications.

8. If the rear brake shoes were

backed off, adjust the brakes as out-

lined in Part 2-1 and install rubber

plugs in the adjuster slots.

9. Install the two rear brake drums

and the drum Tinnerman nuts.

10.

Install the rear wheels and tires.

11.

Fill the rear axle with specified

lubricant.

AXLE HOUSING (COIL

SPRING SUSPENSION)

REMOVAL

1.

Remove the carrier assembly

from the axle housing as outlined in

Differential Carrier Removal and In-

stallation.

2.

Position safety stands under the

frame rear members, and support the

axle housing with either a floor jack

or hoist.

3.

Disengage the brake line from

the clips that retain the line to the

axle housing.

4.

Disconnect the vent tube from

the rear axle housing.

5.

Remove the brake backing plate

assemblies from the axle housing, and

support them with wire. Do not dis-

connect the brake line.

6. Disconnect the lower studs of the

two rear shock absorbers from the

mounting brackets on the axle housing

(Fig. 13 and 14).

7.

Remove the attaching nut and

washer, and disconnect the track bar

from the mounting stud on the axle

housing bracket.

8. Lower the axle housing until the

coil springs are released. Lift out the

coil springs and insulators.

9. Remove the nuts, washers and

pivot bolts that connect the suspension

lower arms to the axle housing. Dis-

connect both arms from the axle

housing.

10.

Disconnect the upper suspen-

sion arm from the axle housing by re-

moving the pivot bolt, nut, lock wash-

er and the two eccentric washers (Fig.

13 and 14).

11.

Lower the axle housing and re-

move it from under the vehicle.

INSTALLATION

1.

Transfer the track bar mounting

stud from the old to the new housing.procarmanuals.com

Page 215 of 413

04-02-18

Rear Axle — Removable Carrier Type

04-02-18

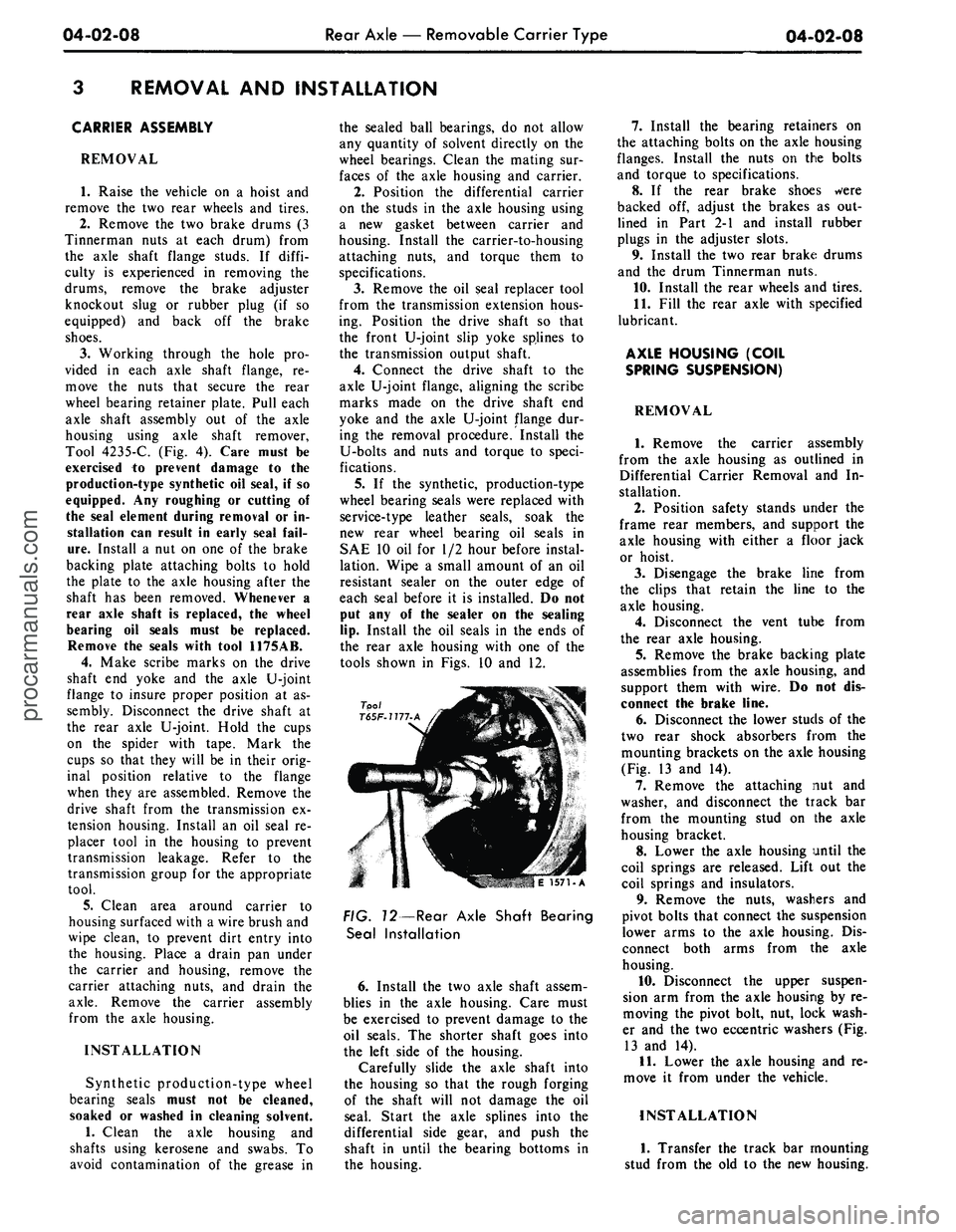

E 1195-C

FIG. 41—Removing

or

Installing

Pinion

and

Retainer Assembly

10.

Hold

the

flange with

the

tool

shown

in Fig. 22

(Ford)

or Fig. 23

(Mercury),

and

torque

the

pinion shaft

nut

to 175

ft-lbs.

Do not

exceed

175

ft-Ibs

at

this time.

11.

Check

the

pinion bearing

pre-

load

as

shown

in Fig. 42.

Correct

pre-load will

be

obtained when

the

torque required

to

rotate

the

pinion

in

the retainer

is as

specified

in

Part

4-3.

If

the

torque required

to

rotate

the pin-

ion

is

less than specified, tighten

the

pinion shaft

nut a

little

at a

time until

Inch-Pound

Torque Wrench

E1899A

FIG. 42—Checking Pinion Bearing

Preload

the proper preload

is

established.

Do

not overtighten

the nut. If

excessive

preload

is

obtained

as a

result

of

over-

tightening, replace

the

collapsible

bearing spacer.

Do

not

back

off the

pinion shaft

nut

to establish pinion bearing preload.

If

the torque

on the

pinion shaft

nut is

less than

175

ft-lbs after bearing

pre-

load

is

established,

a new

collapsible

spacer must

be

used.

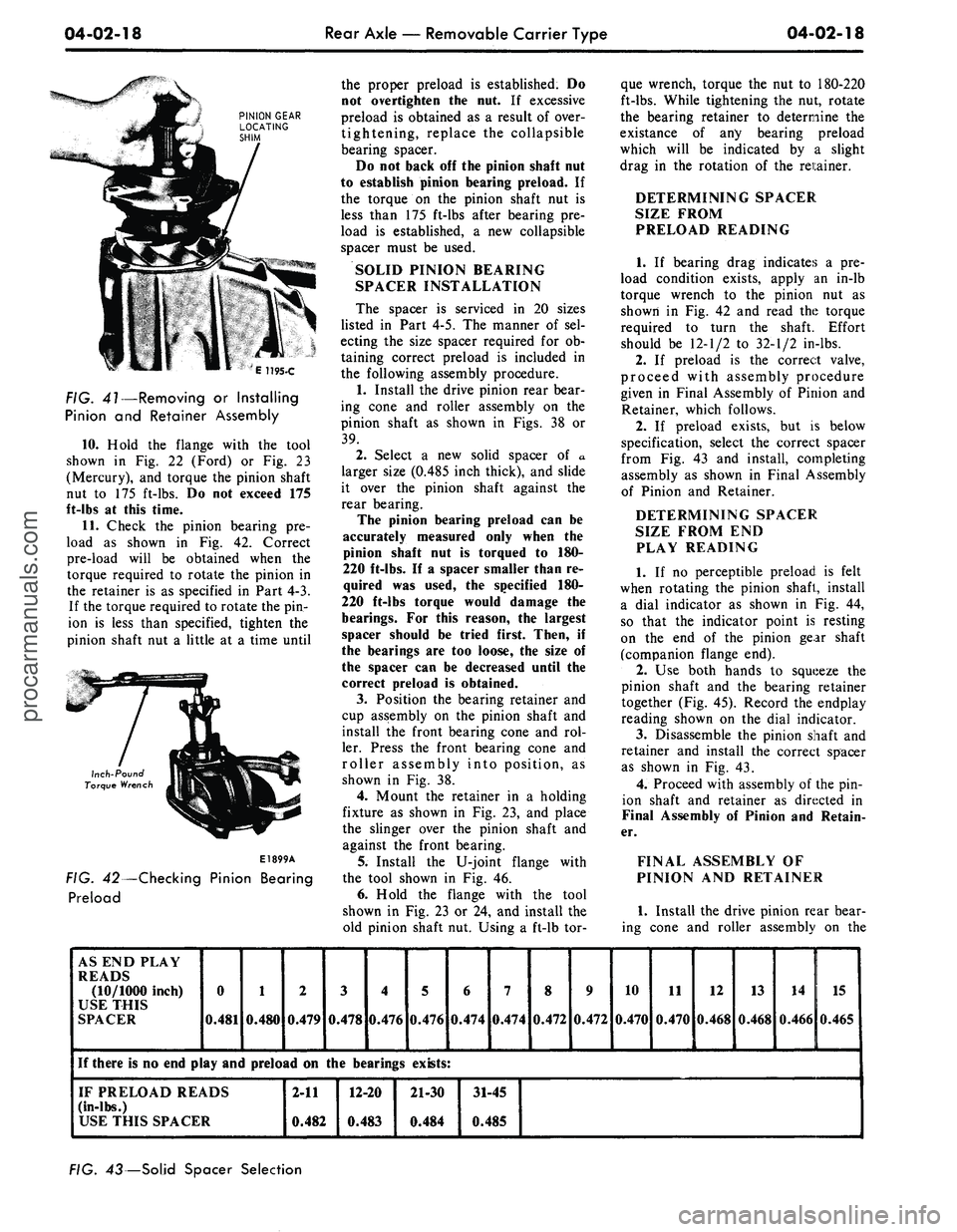

SOLID PINION BEARING

SPACER INSTALLATION

The spacer

is

serviced

in 20

sizes

listed

in

Part

4-5. The

manner

of sel-

ecting

the

size spacer required

for ob-

taining correct preload

is

included

in

the following assembly procedure.

1.

Install

the

drive pinion rear bear-

ing cone

and

roller assembly

on the

pinion shaft

as

shown

in

Figs.

38 or

39.

2.

Select

a new

solid spacer

of a

larger size (0.485 inch thick),

and

slide

it over

the

pinion shaft against

the

rear bearing.

The pinion bearing preload

can be

accurately measured only when

the

pinion shaft

nut is

torqued

to 180-

220 ft-lbs.

If a

spacer smaller than

re-

quired

was

used,

the

specified

180-

220 ft-lbs torque would damage

the

bearings.

For

this reason,

the

largest

spacer should

be

tried first. Then,

if

the bearings

are too

loose,

the

size

of

the spacer

can be

decreased until

the

correct preload

is

obtained.

3.

Position

the

bearing retainer

and

cup assembly

on the

pinion shaft

and

install

the

front bearing cone

and rol-

ler. Press

the

front bearing cone

and

roller assembly into position,

as

shown

in Fig. 38.

4.

Mount

the

retainer

in a

holding

fixture

as

shown

in Fig. 23, and

place

the slinger over

the

pinion shaft

and

against

the

front bearing.

5.

Install

the

U-joint flange with

the tool shown

in Fig. 46.

6. Hold

the

flange with

the

tool

shown

in Fig. 23 or 24, and

install

the

old pinion shaft

nut.

Using

a

ft-lb

tor-

que wrench, torque

the nut to

180-220

ft-lbs.

While tightening

the nut,

rotate

the bearing retainer

to

determine

the

existance

of any

bearing preload

which will

be

indicated

by a

slight

drag

in the

rotation

of the

retainer.

DETERMINING SPACER

SIZE FROM

PRELOAD READING

1.

If

bearing drag indicates

a pre-

load condition exists, apply

an

in-lb

torque wrench

to the

pinion

nut as

shown

in Fig. 42 and

read

the

torque

required

to

turn

the

shaft. Effort

should

be

12-1/2

to

32-1/2 in-lbs.

2.

If

preload

is the

correct valve,

proceed with assembly procedure

given

in

Final Assembly

of

Pinion

and

Retainer, which follows.

2.

If

preload exists,

but is

below

specification, select

the

correct spacer

from

Fig. 43 and

install, completing

assembly

as

shown

in

Final Assembly

of Pinion

and

Retainer.

DETERMINING SPACER

SIZE FROM

END

PLAY READING

1.

If no

perceptible preload

is

felt

when rotating

the

pinion shaft, install

a dial indicator

as

shown

in Fig. 44,

so that

the

indicator point

is

resting

on

the end of the

pinion gear shaft

(companion flange

end).

2.

Use

both hands

to

squeeze

the

pinion shaft

and the

bearing retainer

together

(Fig. 45).

Record

the

endplay

reading shown

on the

dial indicator.

3.

Disassemble

the

pinion shaft

and

retainer

and

install

the

correct spacer

as shown

in Fig. 43.

4.

Proceed with assembly

of the pin-

ion shaft

and

retainer

as

directed

in

Final Assembly

of

Pinion

and

Retain-

er.

FINAL ASSEMBLY

OF

PINION

AND

RETAINER

1.

Install

the

drive pinion rear bear-

ing cone

and

roller assembly

on the

AS

END

PLAY

READS

(10/1000 inch)

USE THIS

SPACER

0

0.481

1

0.480

2

0.479

3

0.478

4

0.476

If there

is no end

play

and

preload

on the

bearings

IF PRELOAD READS

(in-lbs.)

USE THIS SPACER

2-11

0.482

12-20

0.483

5

0.476

6

0.474

7

0.474

8

0.472

9

0.472

10

0.470

11

0.470

12

0.468

13

0.468

14

0.466

15

0.465

exists:

21-30

0.484

31-45

0.485

FIG. 43— Solid Spacer Selectionprocarmanuals.com

Page 222 of 413

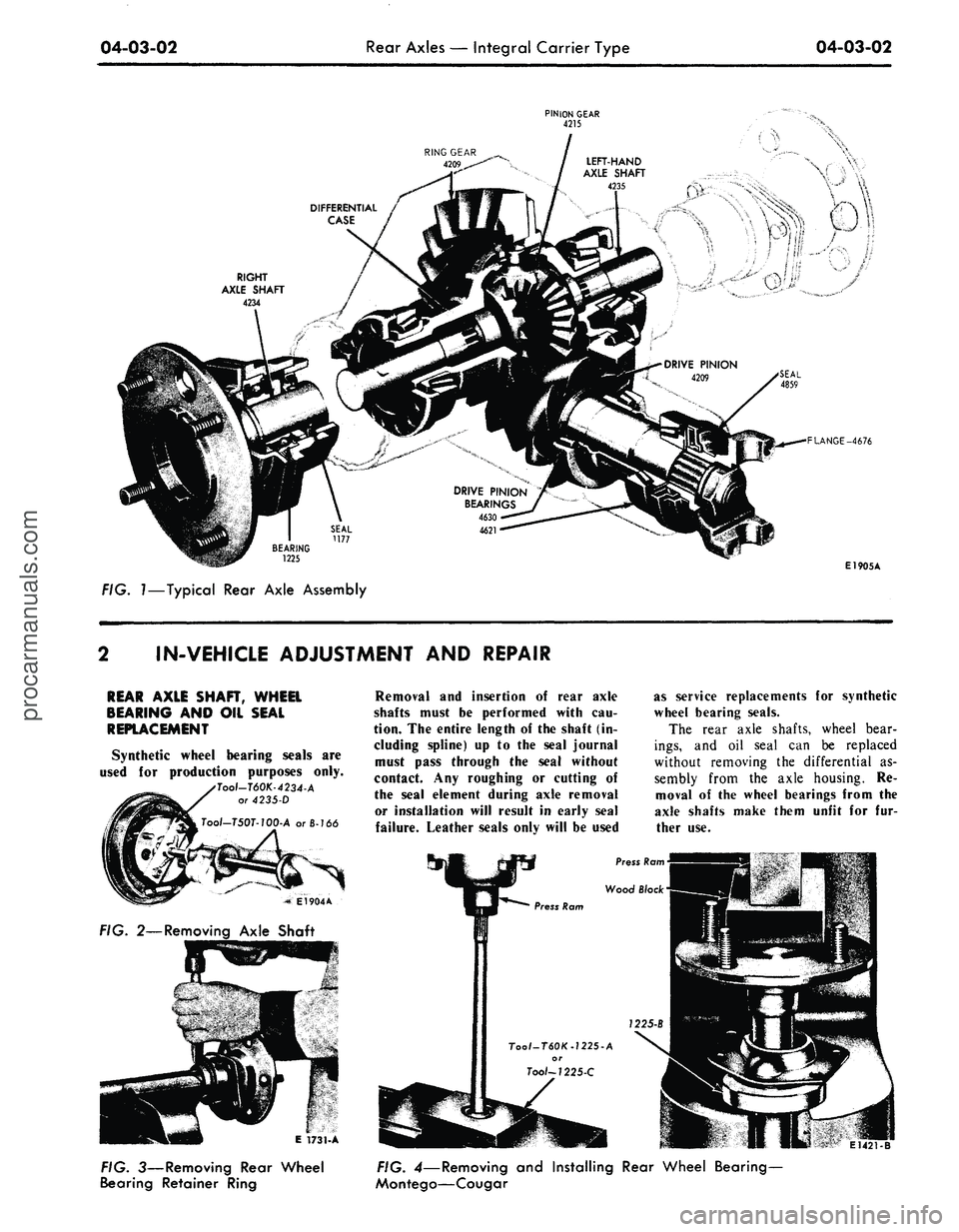

04-03-02

Rear Axles — Integral Carrier Type

04-03-02

RING GEAR

4209

DRIVE PINION

BEARINGS

4630

4621

FLANGE-4676

E1905A

FIG. 7—Typical Rear Axle Assembly

IN-VEHICLE ADJUSTMENT

AND

REPAIR

REAR AXLE SHAFT, WHEEL

BEARING

AND OIL

SEAL

REPLACEMENT

Synthetic wheel bearing seals

are

used

for

production purposes only.

>Tool-T60K-4234-A

or 4235-D

Tool-T50T-W0-A

or 8-/66

* El904A

FIG. 2—Removing Axle Shaft

E 1731-A

FIG. 3—Removing Rear Wheel

Bearing Retainer Ring

Removal

and

insertion

of

rear axle

shafts must

be

performed with

cau-

tion.

The

entire length

of the

shaft

(in-

cluding spline)

up to the

seal journal

must pass through

the

seal without

contact.

Any

roughing

or

cutting

of

the seal element during axle removal

or installation will result

in

early seal

failure. Leather seals only will

be

used

as service replacements

for

synthetic

wheel bearing seals.

The rear axle shafts, wheel bear-

ings,

and oil

seal

can be

replaced

without removing

the

differential

as-

sembly from

the

axle housing.

Re-

moval

of the

wheel bearings from

the

axle shafts make them unfit

for fur-

ther

use.

E1421-B

FIG. 4—Removing and Installing Rear Wheel Bearing—

Montego—Cougarprocarmanuals.com

Page 227 of 413

04-03-07

Rear Axles — Integral Carrier Type

04-03-07

junction and install vent hose to vent

tube.

7.

Raise the axle housing and con-

nect the shock absorbers.

8. Connect the rear end of the drive

shaft to the axle U-joint flange, align-

ing the scribe marks made on the

drive shaft end yoke and the axle U-

joint flange (Fig. 14).

9. Fill the axle with the proper

grade and amount of lubricant.

10.

Road test the vehicle.

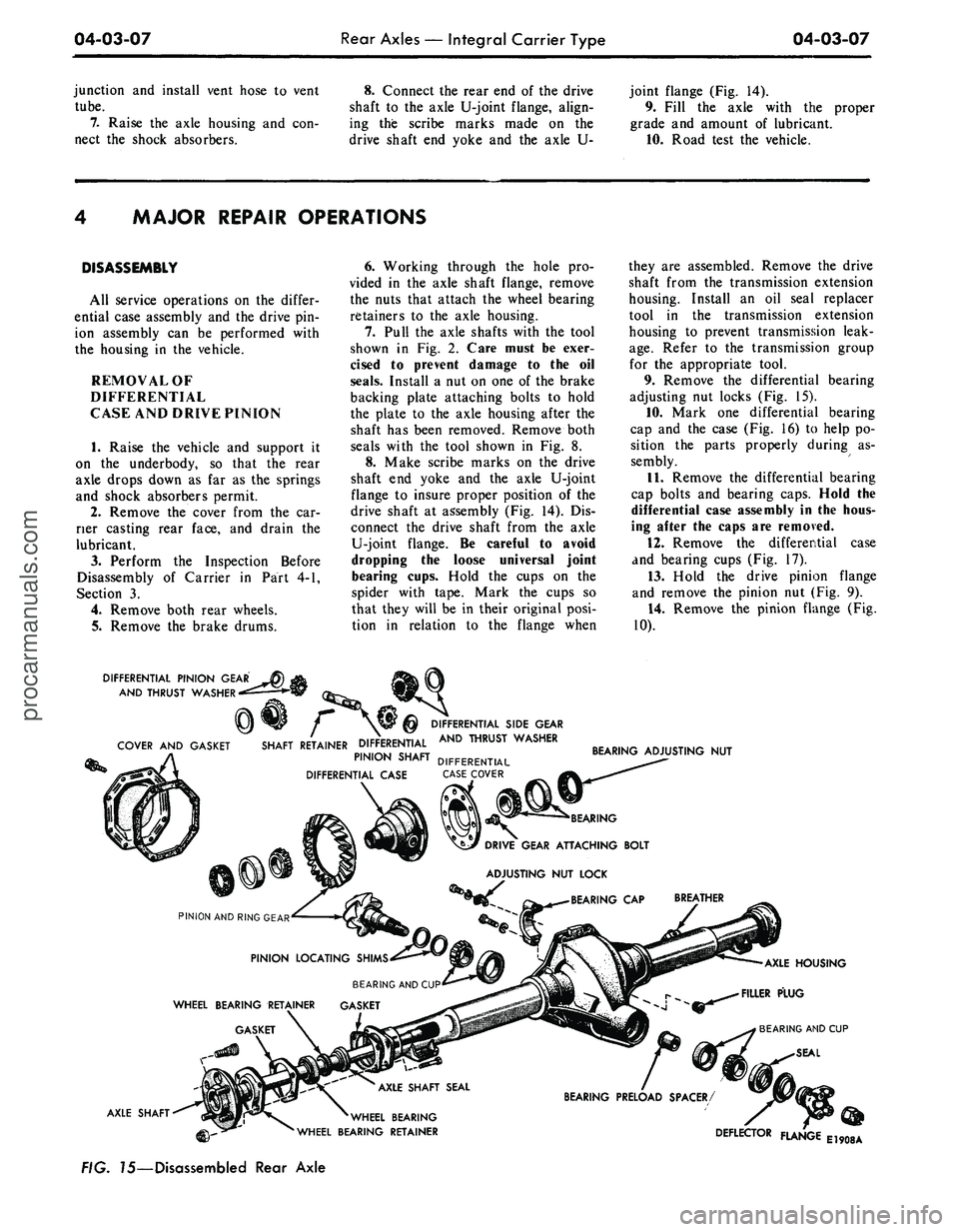

MAJOR REPAIR OPERATIONS

DISASSEMBLY

All service operations on the differ-

ential case assembly and the drive pin-

ion assembly can be performed with

the housing in the vehicle.

REMOVAL OF

DIFFERENTIAL

CASE AND DRIVE PINION

1.

Raise the vehicle and support it

on the underbody, so that the rear

axle drops down as far as the springs

and shock absorbers permit.

2.

Remove the cover from the car-

rier casting rear face, and drain the

lubricant.

3.

Perform the Inspection Before

Disassembly of Carrier in Part 4-1,

Section 3.

4.

Remove both rear wheels.

5.

Remove the brake drums.

6. Working through the hole pro-

vided in the axle shaft flange, remove

the nuts that attach the wheel bearing

retainers to the axle housing.

7.

Pull the axle shafts with the tool

shown in Fig. 2. Care must be exer-

cised to prevent damage to the oil

seals.

Install a nut on one of the brake

backing plate attaching bolts to hold

the plate to the axle housing after the

shaft has been removed. Remove both

seals with the tool shown in Fig. 8.

8. Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly (Fig. 14). Dis-

connect the drive shaft from the axle

U-joint flange. Be careful to avoid

dropping the loose universal joint

bearing cups. Hold the cups on the

spider with tape. Mark the cups so

that they will be in their original posi-

tion in relation to the flange when

they are assembled. Remove the drive

shaft from the transmission extension

housing. Install an oil seal replacer

tool in the transmission extension

housing to prevent transmission leak-

age.

Refer to the transmission group

for the appropriate tool.

9. Remove the differential bearing

adjusting nut locks (Fig. 15).

10.

Mark one differential bearing

cap and the case (Fig. 16) to help po-

sition the parts properly during as-

sembly.

11.

Remove the differential bearing

cap bolts and bearing caps. Hold the

differential case assembly in the hous-

ing after the caps are removed.

12.

Remove the differential case

and bearing cups (Fig. 17).

13.

Hold the drive pinion flange

and remove the pinion nut (Fig. 9).

14.

Remove the pinion flange (Fig.

10).

DIFFERENTIAL PINION GEAR

AND THRUST WASHER

COVER AND GASKET

DIFFERENTIAL SIDE GEAR

AND THRUST WASHER

SHAFT RETAINER DIFFERENTIAL

PINION SHAFT DIFFERENT|AL

DIFFERENTIAL CASE CASE COVER

BEARING ADJUSTING NUT

PINION AND RING GEAR

AXLE SHAFT

BEARING

DRIVE GEAR ATTACHING BOLT

ADJUSTING NUT LOCK

BEARING CAP

PINION LOCATING SHIMS

BEARING AND CUP

WHEEL BEARING RETAINER

GASKET

BEARING AND CUP

SEAL

AXLE SHAFT SEAL

BEARING PRELOAD SPACER/

AXLE HOUSING

FILLER PLUG

'WHEEL BEARING

WHEEL BEARING RETAINER

DEFLECTOR FLANGE

E1908A

FIG. 75—Disassembled Rear Axleprocarmanuals.com