stop start FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 146 of 413

03-08-02

Ford Design Integral Power Steering Gear

03-08-02

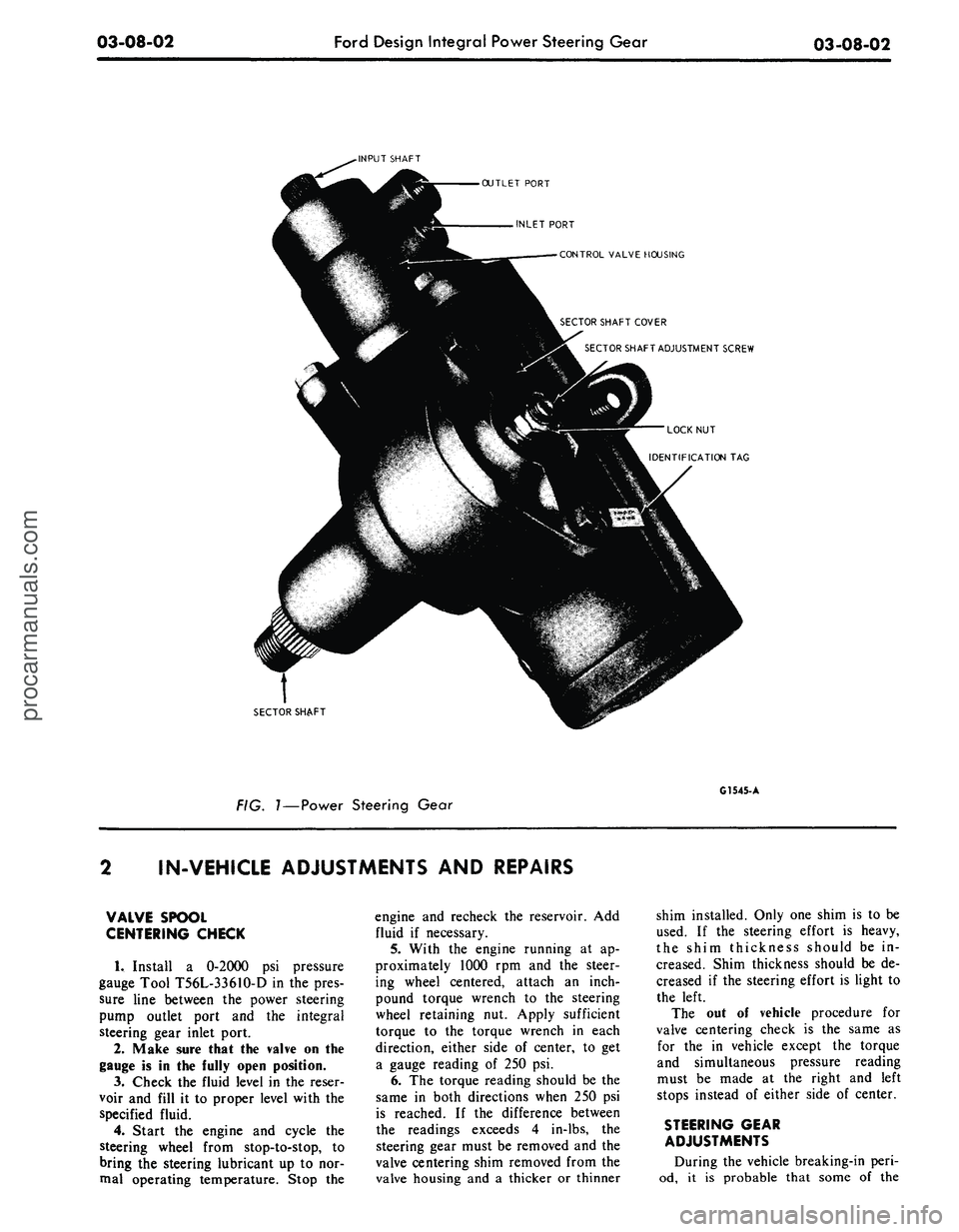

-INPUT SHAFT

OUTLET PORT

INLET PORT

CONTROL VALVE HOUSING

SECTOR SHAFT COVER

SECTOR SHAFT ADJUSTMENT SCREW

LOCK NUT

IDENTIFICATION TAG

SECTOR SHAFT

FIG.

1—Power

Steering Gear

G1545- A

IN-VEH1CLE ADJUSTMENTS AND REPAIRS

VALVE SPOOL

CENTERING CHECK

1.

Install a 0-2000 psi pressure

gauge Tool T56L-33610-D in the pres-

sure line between the power steering

pump outlet port and the integral

steering gear inlet port.

2.

Make sure that the valve on the

gauge is in the fully open position.

3.

Check the fluid level in the reser-

voir and fill it to proper level with the

specified fluid.

4.

Start the engine and cycle the

steering wheel from stop-to-stop, to

bring the steering lubricant up to nor-

mal operating temperature. Stop the

engine and recheck the reservoir. Add

fluid if necessary.

5.

With the engine running at ap-

proximately 1000 rpm and the steer-

ing wheel centered, attach an inch-

pound torque wrench to the steering

wheel retaining nut. Apply sufficient

torque to the torque wrench in each

direction, either side of center, to get

a gauge reading of 250 psi.

6. The torque reading should be the

same in both directions when 250 psi

is reached. If the difference between

the readings exceeds 4 in-lbs, the

steering gear must be removed and the

valve centering shim removed from the

valve housing and a thicker or thinner

shim installed. Only one shim is to be

used. If the steering effort is heavy,

the shim thickness should be in-

creased. Shim thickness should be de-

creased if the steering effort is light to

the left.

The out of vehicle procedure for

valve centering check is the same as

for the in vehicle except the torque

and simultaneous pressure reading

must be made at the right and left

stops instead of either side of center.

STEERING GEAR

ADJUSTMENTS

During the vehicle breaking-in peri-

od, it is probable that some of theprocarmanuals.com

Page 295 of 413

07-01-04

General Transmission Service

07-01-04

taching bolts to the proper torque. If

necessary, replace the gasket.

Check the fluid filler tube connec-

tion at the transmission case or pan.

If leakage is found here, install a new

O-ring or tighten the fitting to the

specified torque.

Check the fluid lines and fittings

between the transmission and the

cooler in the radiator tank for loose-

ness,

wear, or damage. If leakage can-

not be stopped by tightening a fitting,

replace the damaged parts.

Check the engine coolant in the ra-

diator. If transmission fluid is present

in the coolant, the cooler in the radia-

tor is probably leaking.

The cooler can be further checked

for leaks by disconnecting the lines

from the cooler fittings and applying

50-75 psi air pressure to the fittings.

Remove the radiator cap to relieve the

pressure build at the exterior of the oil

cooler tank. If the cooler is leaking

and will not hold this pressure the

cooler must be replaced. Cooler re-

placement is described in the Cooling

System Section of Group 11.

If leakage is found at either the

downshift control lever shaft or the

manual lever shaft, replace either or

both seals.

Inspect the pipe plug on the left

side of the transmission case at the

front. If the plug shows leakage, tor-

que the plug to specifications. If tight-

ening does not stop the leaks, replace

the plug. On a C6 transmission, a TV

pressure plug is also provided on the

right rear side of the case.

When converter drain plugs leak,

remove drain plugs with a six-point

wrench. Coat the threads with FoMo-

Co Perfect Seal Sealing Compound or

its equivalent, and install the plugs.

Torque the drain plugs to specifica-

tion. Fluid leakage from the converter

housing may be caused by engine oil

leaking past the rear main bearing or

from oil gallery plugs, or power steer-

ing oil leakage from steering system.

Be sure to determine the exact cause

of the leak before repair procedures

are started.

Oil-soluble aniline or fluorescent dyes

premixed at the rate of 1/2 teaspoon

of dye powder to 1/2 pint of transmis-

sion fluid have proved helpful in locat-

ing the source of the fluid leakage.

Such dyes may be used to determine

whether an engine oil or transmission

fluid leak is present or if the fluid in

the oil cooler leaks into the engine

coolant system. A black light, how-

ever, must be used with the fluorescent

dye solution.

DISHED OR

FLAT WASHER

" O.D.,

a" STEEL PLATE

5/8"X \W,

DRILL TO SUIT

HEX. HEAD SCREW

3/8"-24 X Vl

HEX. NUT W—

24

WELD

TOGETHER

WING

NUT

>/2"_13

THREAD

CHAIN,

10"

LONG

RUBBER PLUG

1

Vi" DIA. X 2"

LONG Vl"

HOLE THRU

APPROXIMATELY

40 DUROMETER

FLAT WASHER

Vs" O.D.

PLUG

VALVE

STANDARD BOLT

W-13

X 4Vl"

LONG SQUARE

THREAD

END

REMOVE HEAD

AND WELD

TO

WASHER

STANDARD 1/8" FITTING-87971-S FOR

RETAPPED DRAIN PLUG THREADS-USE

1/4" OVERSIZE FITTING-87973-S

D 1067-B

WELD TOGETHER

SECURELY—MUST

NOT LEAK

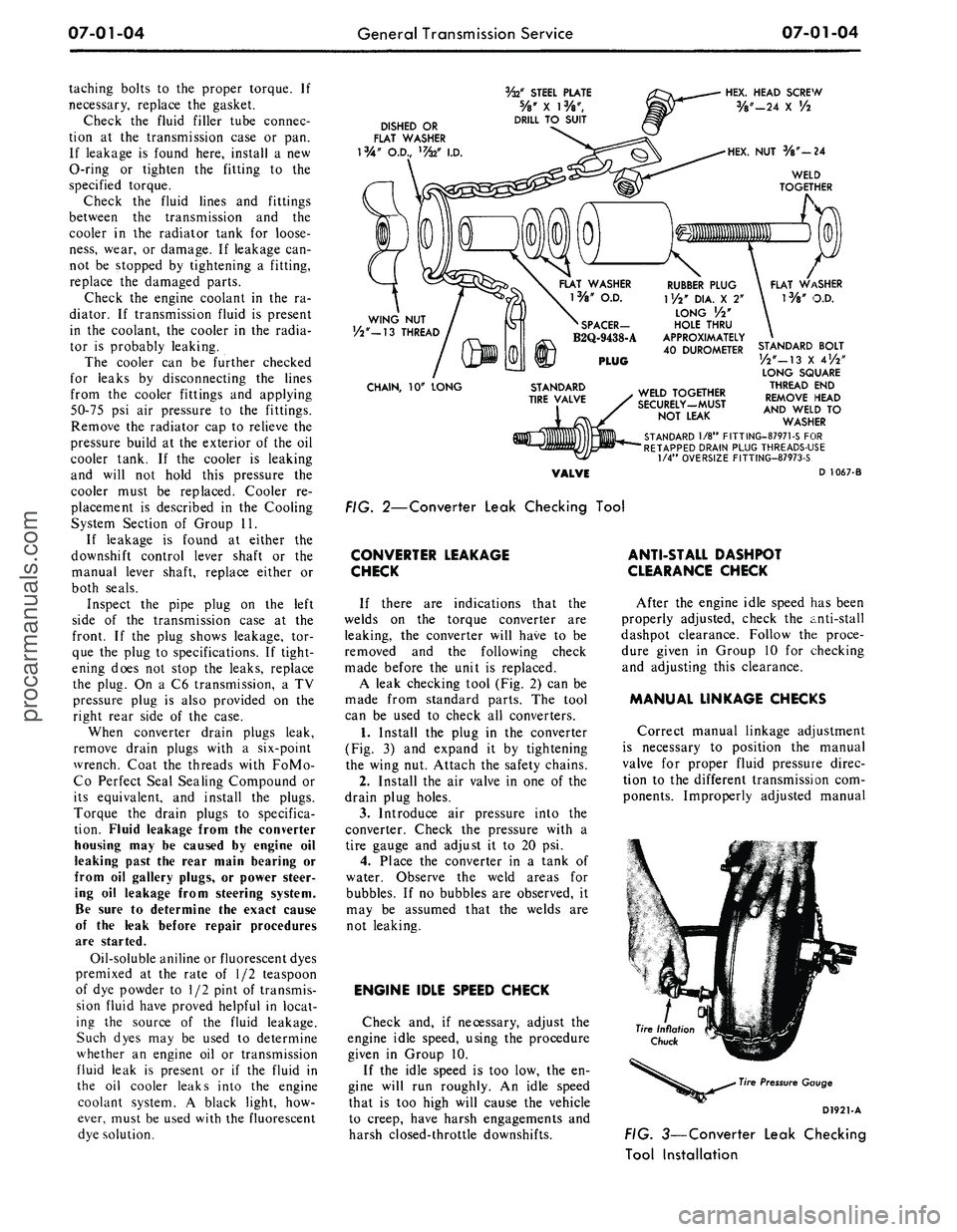

FIG. 2—Converter Leak Checking Tool

CONVERTER LEAKAGE

CHECK

If there are indications that the

welds on the torque converter are

leaking, the converter will have to be

removed and the following check

made before the unit is replaced.

A leak checking tool (Fig. 2) can be

made from standard parts. The tool

can be used to check all converters.

1.

Install the plug in the converter

(Fig. 3) and expand it by tightening

the wing nut. Attach the safety chains.

2.

Install the air valve in one of the

drain plug holes.

3.

Introduce air pressure into the

converter. Check the pressure with a

tire gauge and adjust it to 20 psi.

4.

Place the converter in a tank of

water. Observe the weld areas for

bubbles. If no bubbles are observed, it

may be assumed that the welds are

not leaking.

ENGINE IDLE SPEED CHECK

Check and, if necessary, adjust the

engine idle speed, using the procedure

given in Group 10.

If the idle speed is too low, the en-

gine will run roughly. An idle speed

that is too high will cause the vehicle

to creep, have harsh engagements and

harsh closed-throttle downshifts.

ANTI-STALL DASHPOT

CLEARANCE CHECK

After the engine idle speed has been

properly adjusted, check the anti-stall

dashpot clearance. Follow the proce-

dure given in Group 10 for checking

and adjusting this clearance.

MANUAL LINKAGE CHECKS

Correct manual linkage adjustment

is necessary to position the manual

valve for proper fluid pressure direc-

tion to the different transmission com-

ponents. Improperly adjusted manual

Tire Pressure Gauge

D1921-A

FIG. 3—Converter Leak Checking

Tool Installationprocarmanuals.com

Page 299 of 413

07-01-08

General Transmission Service

07-01-08

3.

Install the bench testing tool on

the transmission.

4.

Remove the

1/8-inch

pipe plug

at the transmission case. Turn the

front pump in a clockwise direction at

75-100 rpm until a regular flow of

transmission fluid leaves the hole in

the transmission case. This operation

bleeds the air from the pump.

5.

Install the pressure gauge (77820

or T57L-77820-A) as shown in Fig.

13.

PRESSURE TESTS

Turn the front pump at 75-100 rpm

and note the gauge readings. The

pressure readings on the bench test

must be within the limits as outlined

in Figure 13, for the engine idle check.

If pressure gauge readings are with-

in limits in all selector lever positions,

install the vacuum diaphragm control

rod unit.

COMMON ADJUSTMENTS AND REPAIRS

TRANSMISSION FLUID DRAIN

AND REFILL

Normal maintenance and lubrica-

tion requirements do not necessitate

periodic automatic transmission fluid

changes.

If a major repair, such as a clutch

band, bearing, etc., is required in the

transmission, it will have to be re-

moved for service. At this time the

converter, transmission cooler and

cooler lines must be thoroughly

flushed to remove any dirt.

When filling a dry transmission and

converter, install five quarts of fluid.

Start the engine, shift the selector

lever as outlined below, and check and

add fluid as necessary.

Following are the procedures for

partial drain and refill due to in-

vehicle repair operation.

C4 TRANSMISSION

1.

On PEA models, disconnect the

fluid filler tube from the transmission

oil pan to drain the fluid.

On PEB and PEE models, loosen

the pan attaching bolts to drain the

fluid from the transmission.

2.

When the fluid has stopped

draining from the transmission, re-

move and thoroughly clean the pan

and the screen. Discard the pan gas-

ket.

3.

Place a new gasket on the pan,

and install the pan on the transmis-

sion.

4.

On PEA models, connect the

filler tube to the pan and tighten the

fitting securely.

5.

Add three quarts of fluid to the

transmission through the filler tube.

6. Run the engine at idle speed for

about two minutes, and then run it at

fast idle speed (about 1200 rpm) until

it reaches it's normal operating temp-

erature. Do not race the engine.

7.

Shift the selector lever through

all the positions, place it at P, and

check the fluid level. The fluid level

should be above the ADD mark. If

necessary, add enough fluid io the

transmission to bring the level be-

tween the ADD and FULL marks on

che dipstick. Do not overfill the trans-

mission.

FMX OK C6

TRANSMISSION

1.

Raise the vehicle on a hoist or

jack stands.

2.

Place a drain pan under the

transmission.

3.

Loosen the pan attaching bolts

to drain the fluid from the transmis-

sion.

4.

After the fluid has drained to the

level of the pan flange, remove the

rest of the pan bolts working from the

rear and both sides of the pan to

allow it to drop and drain slowly.

5.

When the fluid has stopped

draining from the transmission, re-

move and thoroughly clean the pan

and the screen. Discard the pan gas-

ket.

6. Place a new gasket on the pan,

and install the pan on the transmis-

sion.

7.

Add three quarts of fluid to the

transmission through the filler tube.

8. Run the engine at idle speed for

about two minutes, and then run it at

fast idle speed (about 1200 rpm) until

it reaches normal operating tempera-

ture.

Do not race the engine.

9. Shift the selector lever through

all the positions, place it at P, and

check the fluid level. The fluid level

should be above the ADD mark. If

necessary, add enough fluid to the

transmission to bring the level be-

tween the ADD and FULL marks on

the dipstick. Do not overfill the trans-

mission.

OIL COOLER TUBE

REMOVAL AND INSTALLATION

When fluid leakage is found at the

oil cooler, the cooler must be re-

placed. Cooler replacement is de-

scribed in the Cooling System Section

of Group 11.

When one or more of the fluid

cooler steel tubes must be replaced,

each replacement tube must be fabri-

cated from the same size steel tubing

as the original line.

Using the old tube as a guide, bend

the new tube as required. Add the

necessary fittings, and install the tube.

After the fittings have been tight-

ened, add fluid as needed, and check

for fluid leaks.

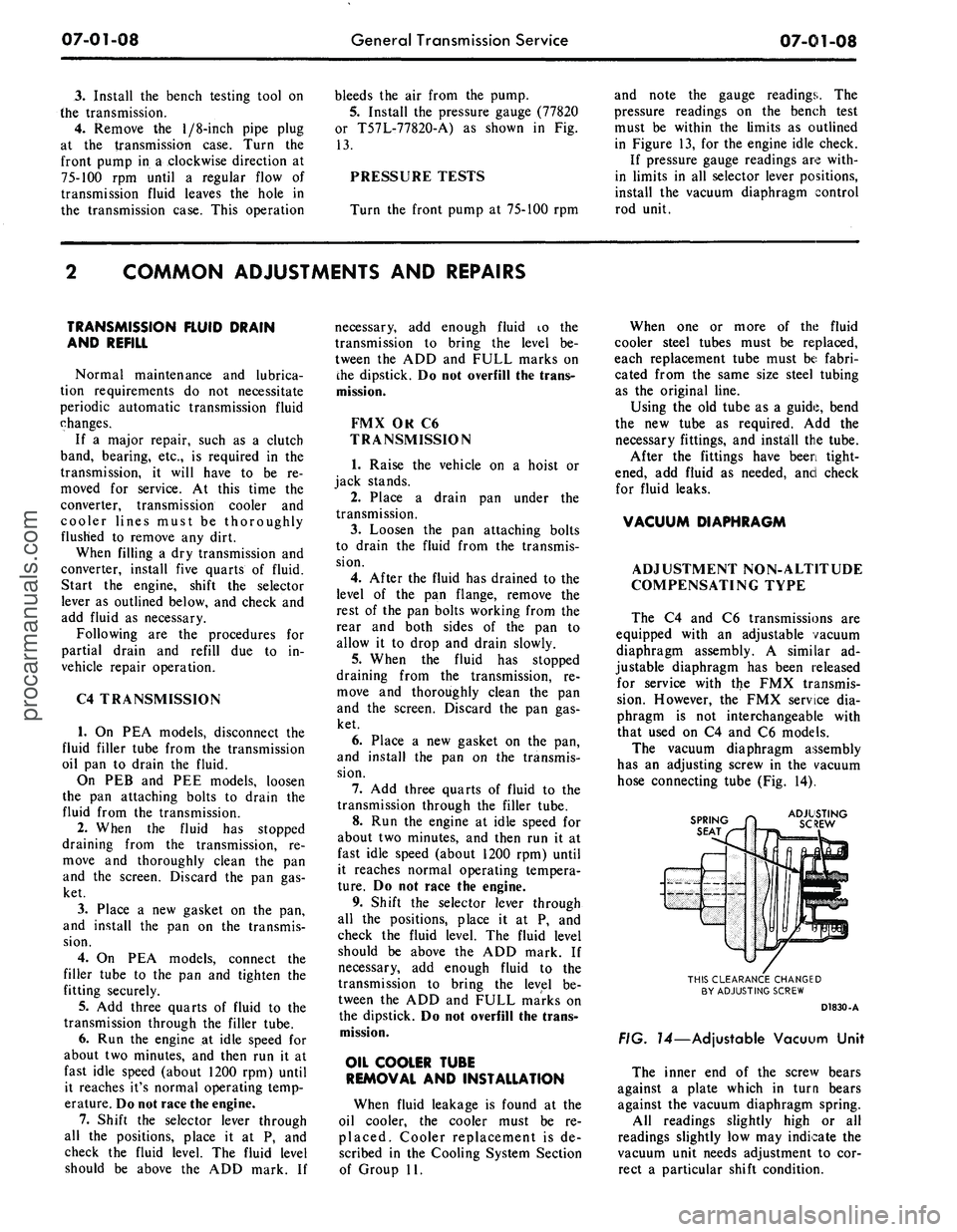

VACUUM DIAPHRAGM

ADJUSTMENT NON-ALTITUDE

COMPENSATING TYPE

The C4 and C6 transmissions are

equipped with an adjustable vacuum

diaphragm assembly. A similar ad-

justable diaphragm has been released

for service with the FMX transmis-

sion. However, the FMX service dia-

phragm is not interchangeable with

that used on C4 and C6 models.

The vacuum diaphragm assembly

has an adjusting screw in the vacuum

hose connecting tube (Fig. 14).

SPRING

SEAT

THIS CLEARANCE CHANGED

BY ADJUSTING SCREW

D1830-A

FIG. 14—Adjustable Vacuum Unit

The inner end of the screw bears

against a plate which in turn bears

against the vacuum diaphragm spring.

All readings slightly high or all

readings slightly low may indicate the

vacuum unit needs adjustment to cor-

rect a particular shift condition.procarmanuals.com

Page 300 of 413

07-01-09

General Transmission Service

07-01-09

For example, on a C4 transmission,

if the pressure at 10 inches of vacuum

was 120 psi and the pressure at 1.0

inch of vacuum was 170 psi, and up-

shifts and downshifts were harsh, a di-

aphragm adjustment to reduce the di-

aphragm assembly spring force would

be required.

If the pressure readings are low, an

adjustment to increase diaphragm

spring force is required.

To increase control pressure, turn

the adjusting screw in clockwise to re-

duce control pressure, back the adjust-

ing screw out by turning it counte-

rclockwise. One complete turn of the

adjusting screw (360 degrees) will

change idle line control pressure ap-

proximately 2-3 psi. After the adjust-

ment is made, install the vacuum line

and make all the pressure checks as

outlined in the Specification Section.

The diaphragm should not be ad-

justed to provide pressure below the

ranges shown in the Specification Sec-

tion in order to change shift feel. To

do so could result in soft or slipping

shift points and damage to the trans-

mission.

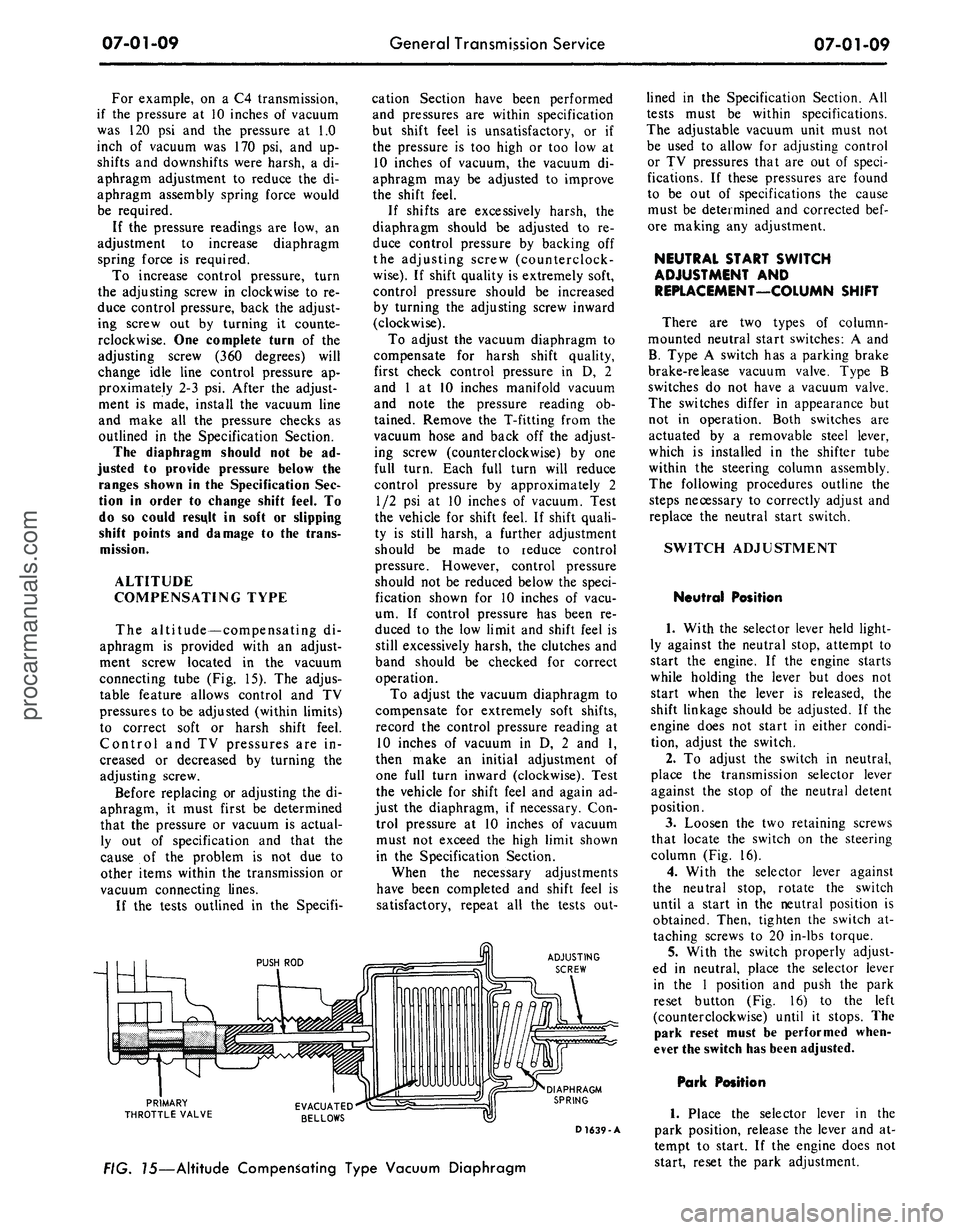

ALTITUDE

COMPENSATING TYPE

The altitude—compensating di-

aphragm is provided with an adjust-

ment screw located in the vacuum

connecting tube (Fig. 15). The adjus-

table feature allows control and TV

pressures to be adjusted (within limits)

to correct soft or harsh shift feel.

Control and TV pressures are in-

creased or decreased by turning the

adjusting screw.

Before replacing or adjusting the di-

aphragm, it must first be determined

that the pressure or vacuum is actual-

ly out of specification and that the

cause of the problem is not due to

other items within the transmission or

vacuum connecting lines.

If the tests outlined in the Specifi-

cation Section have been performed

and pressures are within specification

but shift feel is unsatisfactory, or if

the pressure is too high or too low at

10 inches of vacuum, the vacuum di-

aphragm may be adjusted to improve

the shift feel.

If shifts are excessively harsh, the

diaphragm should be adjusted to re-

duce control pressure by backing off

the adjusting screw (counterclock-

wise).

If shift quality is extremely soft,

control pressure should be increased

by turning the adjusting screw inward

(clockwise).

To adjust the vacuum diaphragm to

compensate for harsh shift quality,

first check control pressure in D, 2

and 1 at 10 inches manifold vacuum

and note the pressure reading ob-

tained. Remove the T-fitting from the

vacuum hose and back off the adjust-

ing screw (counterclockwise) by one

full turn. Each full turn will reduce

control pressure by approximately 2

1/2 psi at 10 inches of vacuum. Test

the vehicle for shift feel. If shift quali-

ty is still harsh, a further adjustment

should be made to reduce control

pressure. However, control pressure

should not be reduced below the speci-

fication shown for 10 inches of vacu-

um. If control pressure has been re-

duced to the low limit and shift feel is

still excessively harsh, the clutches and

band should be checked for correct

operation.

To adjust the vacuum diaphragm to

compensate for extremely soft shifts,

record the control pressure reading at

10 inches of vacuum in D, 2 and 1,

then make an initial adjustment of

one full turn inward (clockwise). Test

the vehicle for shift feel and again ad-

just the diaphragm, if necessary. Con-

trol pressure at 10 inches of vacuum

must not exceed the high limit shown

in the Specification Section.

When the necessary adjustments

have been completed and shift feel is

satisfactory, repeat all the tests out-

ADJUSTING

SCREW

PRIMARY

THROTTLE VALVE

DIAPHRAGM

SPRING

D 1639-A

FIG. 15—Altitude Compensating Type Vacuum Diaphragm

lined in the Specification Section. All

tests must be within specifications.

The adjustable vacuum unit must not

be used to allow for adjusting control

or TV pressures that are out of speci-

fications. If these pressures are found

to be out of specifications the cause

must be determined and corrected bef-

ore making any adjustment.

NEUTRAL START SWITCH

ADJUSTMENT AND

REPLACEMENT—COLUMN SHIFT

There are two types of column-

mounted neutral start switches: A and

B.

Type A switch has a parking brake

brake-release vacuum valve. Type B

switches do not have a vacuum valve.

The switches differ in appearance but

not in operation. Both switches are

actuated by a removable steel lever,

which is installed in the shifter tube

within the steering column assembly.

The following procedures outline the

steps necessary to correctly adjust and

replace the neutral start switch.

SWITCH ADJUSTMENT

Neutral Position

1.

With the selector lever held light-

ly against the neutral stop, attempt to

start the engine. If the engine starts

while holding the lever but does not

start when the lever is released, the

shift linkage should be adjusted. If the

engine does not start in either condi-

tion, adjust the switch.

2.

To adjust the switch in neutral,

place the transmission selector lever

against the stop of the neutral detent

position.

3.

Loosen the two retaining screws

that locate the switch on the steering

column (Fig. 16).

4.

With the selector lever against

the neutral stop, rotate the switch

until a start in the neutral position is

obtained. Then, tighten the switch at-

taching screws to 20 in-lbs torque.

5.

With the switch properly adjust-

ed in neutral, place the selector lever

in the 1 position and push the park

reset button (Fig. 16) to the left

(counterclockwise) until it stops. The

park reset must be performed when-

ever the switch has been adjusted.

Park Position

1.

Place the selector lever in the

park position, release the lever and at-

tempt to start. If the engine does not

start, reset the park adjustment.procarmanuals.com

Page 301 of 413

07-01-10

General Transmission Service

07-01-10

2.

To adjust the switch for the park

position, place the transmission selec-

tor lever in 1 and push the park reset

button (Fig. 16) to the left (counter-

clockwise) until it stops.

3.

Check the operation of the

switch in each selector lever position.

The starter should engage in only the

neutral and park positions. Be sure to

perform

the

park reset

if for any rea-

son

the

neutral switch

is

adjusted.

If,

after performing

the

switch

ad-

justments,

the

starter still will

not en-

gage

in the

neutral

or

park positions,

replace

the

switch. Never replace

the

neutral switch until

the

switch adjust-

ments have been made.

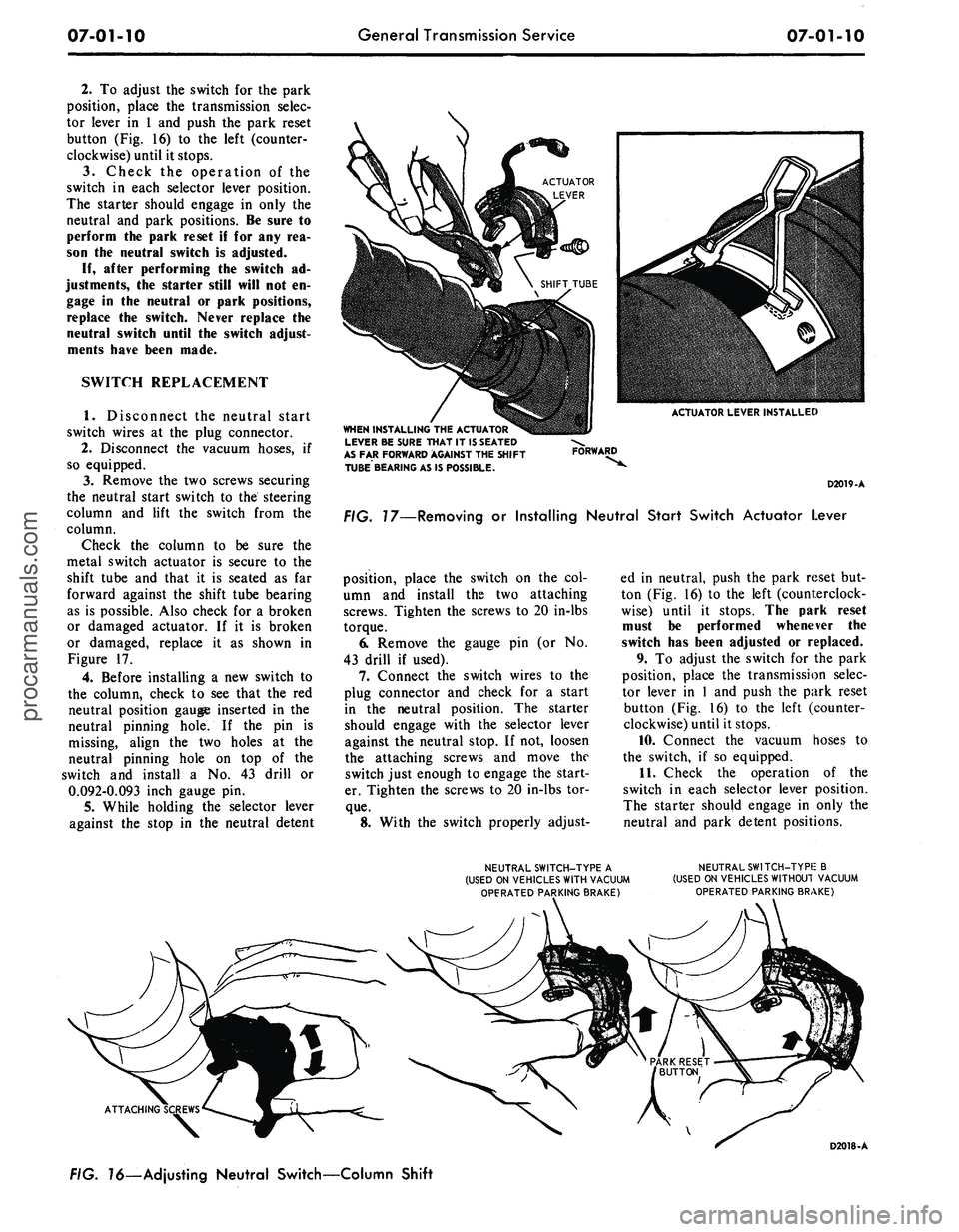

SWITCH REPLACEMENT

1.

Disconnect the neutral start

switch wires at the plug connector.

2.

Disconnect the vacuum hoses, if

so equipped.

3.

Remove the two screws securing

the neutral start switch to the steering

column and lift the switch from the

column.

Check the column to be sure the

metal switch actuator is secure to the

shift tube and that it is seated as far

forward against the shift tube bearing

as is possible. Also check for a broken

or damaged actuator. If it is broken

or damaged, replace it as shown in

Figure 17.

4.

Before installing a new switch to

the column, check to see that the red

neutral position gauge inserted in the

neutral pinning hole. If the pin is

missing, align the two holes at the

neutral pinning hole on top of the

switch and install a No. 43 drill or

0.092-0.093 inch gauge pin.

5.

While holding the selector lever

against the stop in the neutral detent

ACTUATOR LEVER INSTALLED

WHEN INSTALLING

THE

ACTUATOR

LEVER

BE

SURE THAT

IT

1$ SEATED

AS

FAR

FORWARD AGAINST

THE

SHIFT

TUBE BEARING

AS IS

POSSIBLE.

FORWARD

D2019-A

FIG. 17—Removing

or

Installing Neutral Start Switch Actuator Lever

position, place the switch on the col-

umn and install the two attaching

screws. Tighten the screws to 20 in-lbs

torque.

6. Remove the gauge pin (or No.

43 drill if used).

7.

Connect the switch wires to the

plug connector and check for a start

in the neutral position. The starter

should engage with the selector lever

against the neutral stop. If not, loosen

the attaching screws and move the

switch just enough to engage the start-

er. Tighten the screws to 20 in-lbs tor-

que.

8. With the switch properly adjust-

ed in neutral, push the park reset but-

ton (Fig. 16) to the left (counterclock-

wise) until it stops. The park reset

must be performed whenever the

switch has been adjusted or replaced.

9. To adjust the switch for the park

position, place the transmission selec-

tor lever in 1 and push the park reset

button (Fig. 16) to the left (counter-

clockwise) until it stops.

10.

Connect the vacuum hoses to

the switch, if so equipped.

11.

Check the operation of the

switch in each selector lever position.

The starter should engage in only the

neutral and park detent positions.

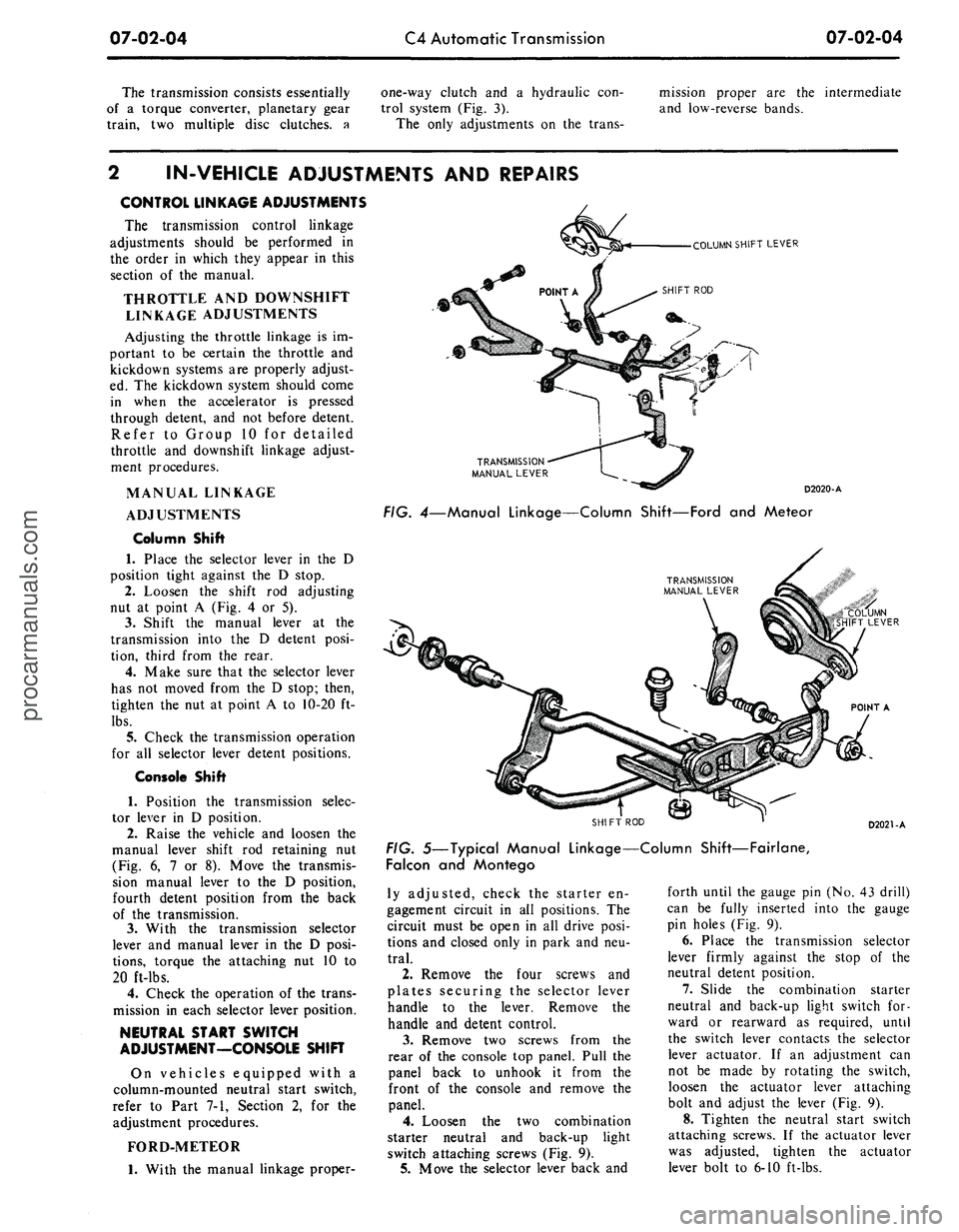

NEUTRAL SWITCH-TYPE

A

(USED

ON

VEHICLES WITH VACUUM

OPFRATED PARKING BRAKE)

NEUTRAL SWITCH-TYPIE

B

(USED

ON

VEHICLES WITHOUT VACUUM

OPERATED PARKING BRAKE)

ATTACHING

FIG.

16—Ad

justing Neutral Switch—Column Shift

D2018-Aprocarmanuals.com

Page 312 of 413

07-02-04

C4 Automatic Transmission

07-02-04

The transmission consists essentially

of a torque converter, planetary gear

train, two multiple disc clutches, a

one-way clutch and a hydraulic con-

trol system (Fig. 3).

The only adjustments on the trans-

mission proper are the intermediate

and low-reverse bands.

TRANSMISSION

MANUAL LEVER

2 IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

CONTROL LINKAGE ADJUSTMENTS

The transmission control linkage

adjustments should be performed in

the order in which they appear in this

section of the manual.

THROTTLE AND DOWNSHIFT

LINKAGE ADJUSTMENTS

Adjusting the throttle linkage is im-

portant to be certain the throttle and

kickdown systems are properly adjust-

ed. The kickdown system should come

in when the accelerator is pressed

through detent, and not before detent.

Refer to Group 10 for detailed

throttle and downshift linkage adjust-

ment procedures.

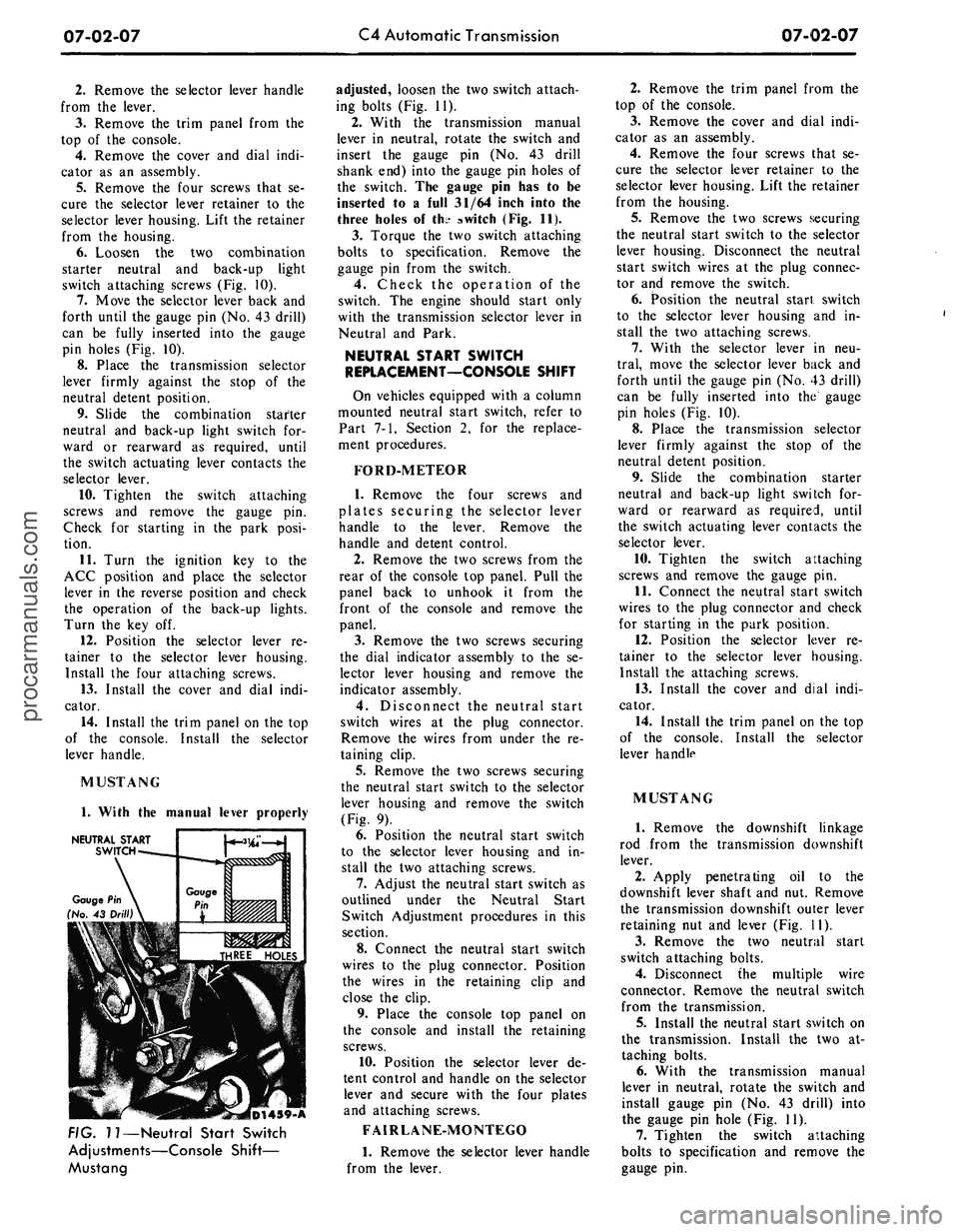

MANUAL LINKAGE

ADJUSTMENTS

Column Shift

1.

Place the selector lever in the D

position tight against the D stop.

2.

Loosen the shift rod adjusting

nut at point A (Fig. 4 or 5).

3.

Shift the manual lever at the

transmission into the D detent posi-

tion, third from the rear.

4.

Make sure that the selector lever

has not moved from the D stop; then,

tighten the nut at point A to 10-20 ft-

lbs.

5.

Check the transmission operation

for all selector lever detent positions.

Console Shift

1.

Position the transmission selec-

tor lever in D position.

2.

Raise the vehicle and loosen the

manual lever shift rod retaining nut

(Fig. 6, 7 or 8). Move the transmis-

sion manual lever to the D position,

fourth detent position from the back

of the transmission.

3.

With the transmission selector

lever and manual lever in the D posi-

tions,

torque the attaching nut 10 to

20 ft-lbs.

4.

Check the operation of the trans-

mission in each selector lever position.

NEUTRAL START SWITCH

ADJUSTMENT—CONSOLE SHIFT

On vehicles equipped with a

column-mounted neutral start switch,

refer to Part 7-1, Section 2, for the

adjustment procedures.

FORD-METEOR

1.

With the manual linkage proper-

COLUMN SHIFT LEVER

D2020-A

FIG.

4—Manual

Linkage—Column Shift—Ford

and

Meteor

"COLUMN

SHIFT LEVER

POINT

A

SHIFT

ROD

D2021-A

FIG.

5—Typical

Manual Linkage—Column

Shift—Fairlane,

Falcon

and

Montego

ly adjusted, check the starter en-

gagement circuit in all positions. The

circuit must be open in all drive posi-

tions and closed only in park and neu-

tral.

2.

Remove the four screws and

plates securing the selector lever

handle to the lever. Remove the

handle and detent control.

3.

Remove two screws from the

rear of the console top panel. Pull the

panel back to unhook it from the

front of the console and remove the

panel.

4.

Loosen the two combination

starter neutral and back-up light

switch attaching screws (Fig. 9).

5.

Move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 9).

6. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

7.

Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch lever contacts the selector

lever actuator. If an adjustment can

not be made by rotating the switch,

loosen the actuator lever attaching

bolt and adjust the lever (Fig. 9).

8. Tighten the neutral start switch

attaching screws. If the actuator lever

was adjusted, tighten the actuator

lever bolt to 6-10 ft-lbs.procarmanuals.com

Page 315 of 413

07-02-07

C4 Automatic Transmission

07-02-07

2.

Remove the selector lever handle

from the lever.

3.

Remove the trim panel from the

top of the console.

4.

Remove the cover and dial indi-

cator as an assembly.

5.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

6. Loosen the two combination

starter neutral and back-up light

switch attaching screws (Fig. 10).

7.

Move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 10).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

Check for starting in the park posi-

tion.

11.

Turn the ignition key to the

ACC position and place the selector

lever in the reverse position and check

the operation of the back-up lights.

Turn the key off.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the four attaching screws.

13.

Install the cover and dial indi-

cator.

14.

Install the trim panel on the top

of the console. Install the selector

lever handle.

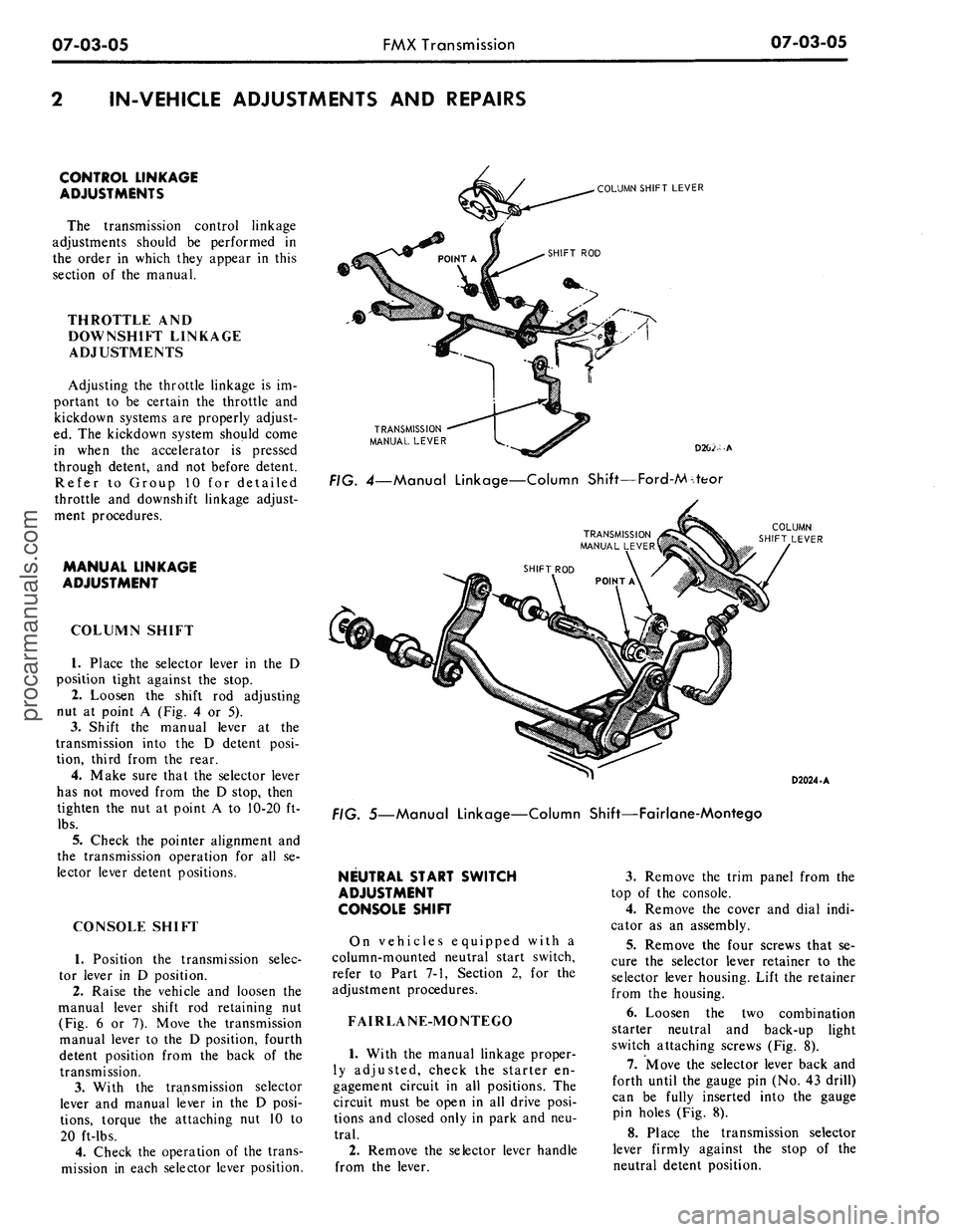

MUSTANG

1.

With the manual lever properly

NEUTRAL

START

SWITCH

(D1439-A

FIG. 11—Neutral Start Switch

Adjustments—Console Shift—

Mustang

adjusted, loosen the two switch attach-

ing bolts (Fig. 11).

2.

With the transmission manual

lever in neutral, rotate the switch and

insert the gauge pin (No. 43 drill

shank end) into the gauge pin holes of

the switch. The gauge pin has to be

inserted to a full 31/64 inch into the

three holes of the switch (Fig. 11).

3.

Torque the two switch attaching

bolts to specification. Remove the

gauge pin from the switch.

4.

Check the operation of the

switch. The engine should start only

with the transmission selector lever in

Neutral and Park.

NEUTRAL START SWITCH

REPLACEMENT—CONSOLE SHIFT

On vehicles equipped with a column

mounted neutral start switch, refer to

Part 7-1, Section 2, for the replace-

ment procedures.

FORD-METEOR

1.

Remove the four screws and

plates securing the selector lever

handle to the lever. Remove the

handle and detent control.

2.

Remove the two screws from the

rear of the console top panel. Pull the

panel back to unhook it from the

front of the console and remove the

panel.

3.

Remove the two screws securing

the dial indicator assembly to the se-

lector lever housing and remove the

indicator assembly.

4.

Disconnect the neutral start

switch wires at the plug connector.

Remove the wires from under the re-

taining clip.

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing and remove the switch

(Fig. 9).

6. Position the neutral start switch

to the selector lever housing and in-

stall the two attaching screws.

7.

Adjust the neutral start switch as

outlined under the Neutral Start

Switch Adjustment procedures in this

section.

8. Connect the neutral start switch

wires to the plug connector. Position

the wires in the retaining clip and

close the clip.

9. Place the console top panel on

the console and install the retaining

screws.

10.

Position the selector lever de-

tent control and handle on the selector

lever and secure with the four plates

and attaching screws.

FAIRLANE-MONTEGO

1.

Remove the selector lever handle

from the lever.

2.

Remove the trim panel from the

top of the console.

3.

Remove the cover and dial indi-

cator as an assembly.

4.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing. Disconnect the neutral

start switch wires at the plug connec-

tor and remove the switch.

6. Position the neutral start switch

to the selector lever housing and in-

stall the two attaching screws.

7.

With the selector lever in neu-

tral,

move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 10).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

11.

Connect the neutral start switch

wires to the plug connector and check

for starting in the park position.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the attaching screws.

13.

Install the cover and dial indi-

cator.

14.

Install the trim panel on the top

of the console. Install the selector

lever handle

MUSTANG

1.

Remove the downshift linkage

rod from the transmission downshift

lever.

2.

Apply penetrating oil to the

downshift lever shaft and nut. Remove

the transmission downshift outer lever

retaining nut and lever (Fig. 11).

3.

Remove the two neutral start

switch attaching bolts.

4.

Disconnect the multiple wire

connector. Remove the neutral switch

from the transmission.

5.

Install the neutral start switch on

the transmission. Install the two at-

taching bolts.

6. With the transmission manual

lever in neutral, rotate the switch and

install gauge pin (No. 43 drill) into

the gauge pin hole (Fig. 11).

7.

Tighten the switch attaching

bolts to specification and remove the

gauge pin.procarmanuals.com

Page 345 of 413

07-03-05

FMX Transmission

07-03-05

IN-VEHICLE ADJUSTMENTS AND REPAIRS

CONTROL LINKAGE

ADJUSTMENTS

The transmission control linkage

adjustments should be performed in

the order in which they appear in this

section of the manual.

THROTTLE AND

DOWNSHIFT LINKAGE

ADJUSTMENTS

Adjusting the throttle linkage is im-

portant to be certain the throttle and

kickdown systems are properly adjust-

ed. The kickdown system should come

in when the accelerator is pressed

through detent, and not before detent.

Refer to Group 10 for detailed

throttle and downshift linkage adjust-

ment procedures.

MANUAL LINKAGE

ADJUSTMENT

COLUMN SHIFT

1.

Place the selector lever in the D

position tight against the stop.

2.

Loosen the shift rod adjusting

nut at point A (Fig. 4 or 5).

3.

Shift the manual lever at the

transmission into the D detent posi-

tion, third from the rear.

4.

Make sure that the selector lever

has not moved from the D stop, then

tighten the nut at point A to 10-20 ft-

lbs.

5.

Check the pointer alignment and

the transmission operation for all se-

lector lever detent positions.

CONSOLE SHIFT

1.

Position the transmission selec-

tor lever in D position.

2.

Raise the vehicle and loosen the

manual lever shift rod retaining nut

(Fig. 6 or 7). Move the transmission

manual lever to the D position, fourth

detent position from the back of the

transmission.

3.

With the transmission selector

lever and manual lever in the D posi-

tions,

torque the attaching nut 10 to

20 ft-lbs.

4.

Check the operation of the trans-

mission in each selector lever position.

COLUMN SHIFT LEVER

€>

TRANSMISSION

MANUAL LEVER

FIG. 4—Manual Linkage—Column Shift—Ford-Mteor

D2024-A

FIG. 5—Manual Linkage—Column Shift—Fairlane-Montego

NEUTRAL START SWITCH

ADJUSTMENT

CONSOLE SHIFT

On vehicles equipped with a

column-mounted neutral start switch,

refer to Part 7-1, Section 2, for the

adjustment procedures.

FAIRLANE-MONTEGO

1.

With the manual linkage proper-

ly adjusted, check the starter en-

gagement circuit in all positions. The

circuit must be open in all drive posi-

tions and closed only in park and neu-

tral.

2.

Remove the selector lever handle

from the lever.

3.

Remove the trim panel from the

top of the console.

4.

Remove the cover and dial indi-

cator as an assembly.

5.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

6. Loosen the two combination

starter neutral and back-up light

switch attaching screws (Fig. 8).

7.

Move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 8).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.procarmanuals.com

Page 347 of 413

07-03-07

FMX Transmission

07-03-07

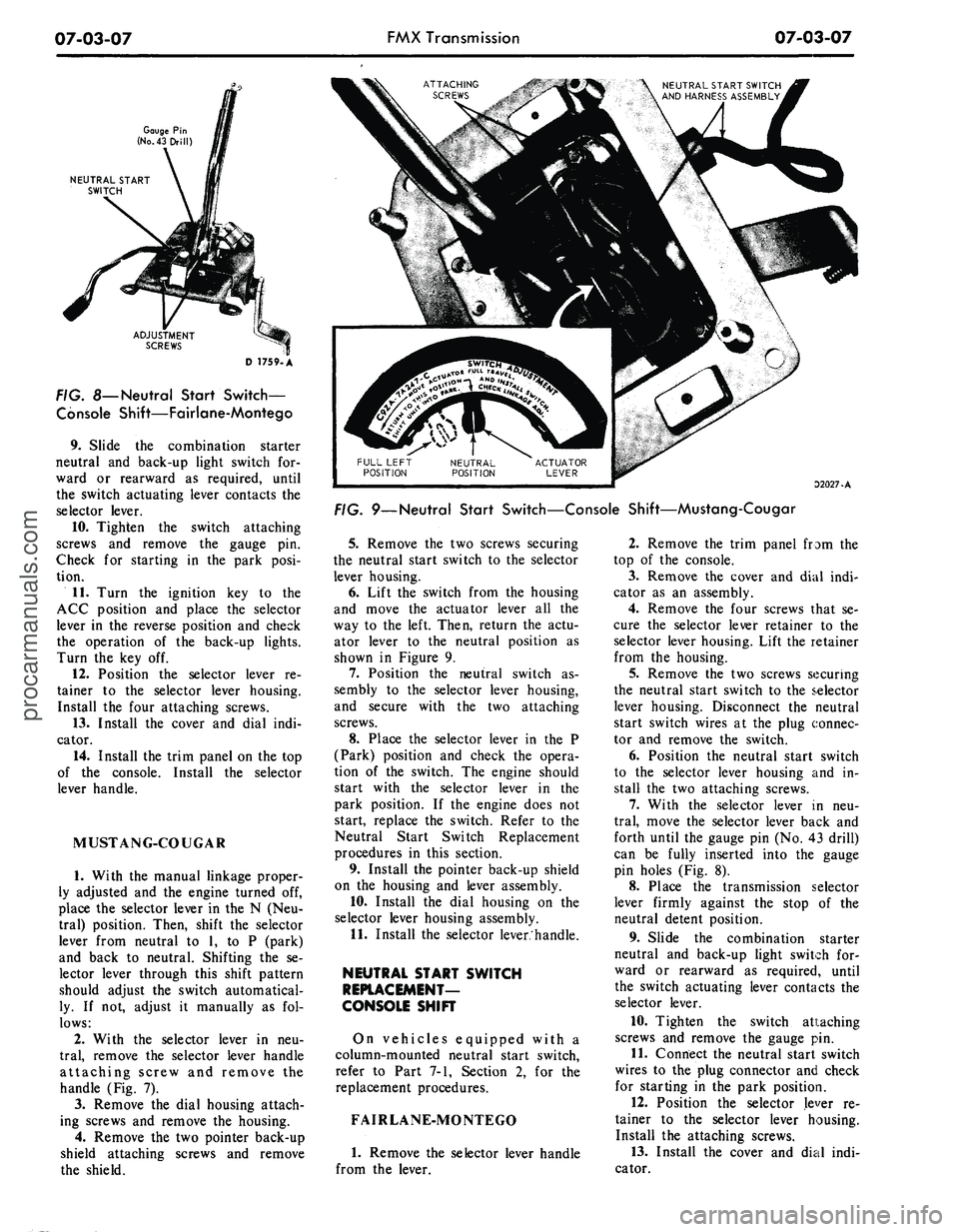

Gauge Pin

(No.

43 Drill)

NEUTRAL START

SWITCH

ADJUSTMENT

SCREWS

D 1759-A

FIG. 8—

Neutral

Start Switch-

Console Shift—Fairlane-Montego

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

Check for starting in the park posi-

tion.

11.

Turn the ignition key to the

ACC position and place the selector

lever in the reverse position and check

the operation of the back-up lights.

Turn the key off.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the four attaching screws.

13.

Install the cover and dial indi-

cator.

14.

Install the trim panel on the top

of the console. Install the selector

lever handle.

MUSTANG-COUGAR

1.

With the manual linkage proper-

ly adjusted and the engine turned off,

place the selector lever in the N (Neu-

tral) position. Then, shift the selector

lever from neutral to 1, to P (park)

and back to neutral. Shifting the se-

lector lever through this shift pattern

should adjust the switch automatical-

ly. If not, adjust it manually as fol-

lows:

2.

With the selector lever in neu-

tral,

remove the selector lever handle

attaching screw and remove the

handle (Fig. 7).

3.

Remove the dial housing attach-

ing screws and remove the housing.

4.

Remove the two pointer back-up

shield attaching screws and remove

the shield.

NEUTRAL START SWITCH

AND HARNESS ASSEMBLY

32027-A

FIG. 9—Neutral Start Switch—Console Shift—Mustang-Cougar

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing.

6. Lift the switch from the housing

and move the actuator lever all the

way to the left. Then, return the actu-

ator lever to the neutral position as

shown in Figure 9.

7.

Position the neutral switch as-

sembly to the selector lever housing,

and secure with the two attaching

screws.

8. Place the selector lever in the P

(Park) position and check the opera-

tion of the switch. The engine should

start with the selector lever in the

park position. If the engine does not

start, replace the switch. Refer to the

Neutral Start Switch Replacement

procedures in this section.

9. Install the pointer back-up shield

on the housing and lever assembly.

10.

Install the dial housing on the

selector lever housing assembly.

11.

Install the selector lever.'handle.

NEUTRAL START SWITCH

REPLACEMENT-

CONSOLE SHIFT

On vehicles equipped with a

column-mounted neutral start switch,

refer to Part 7-1, Section 2, for the

replacement procedures.

FAIRLANE-MONTEGO

1.

Remove the selector lever handle

from the lever.

2.

Remove the trim panel from the

top of the console.

3.

Remove the cover and dial indi-

cator as an assembly.

4.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing. Disconnect the neutral

start switch wires at the plug connec-

tor and remove the switch.

6. Position the neutral start switch

to the selector lever housing and in-

stall the two attaching screws.

7.

With the selector lever in neu-

tral,

move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 8).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

11.

Connect the neutral start switch

wires to the plug connector and check

for starting in the park position.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the attaching screws.

13.

Install the cover and dial indi-

cator.procarmanuals.com

Page 351 of 413

07-03-11

FMX Transmission

07

03-11

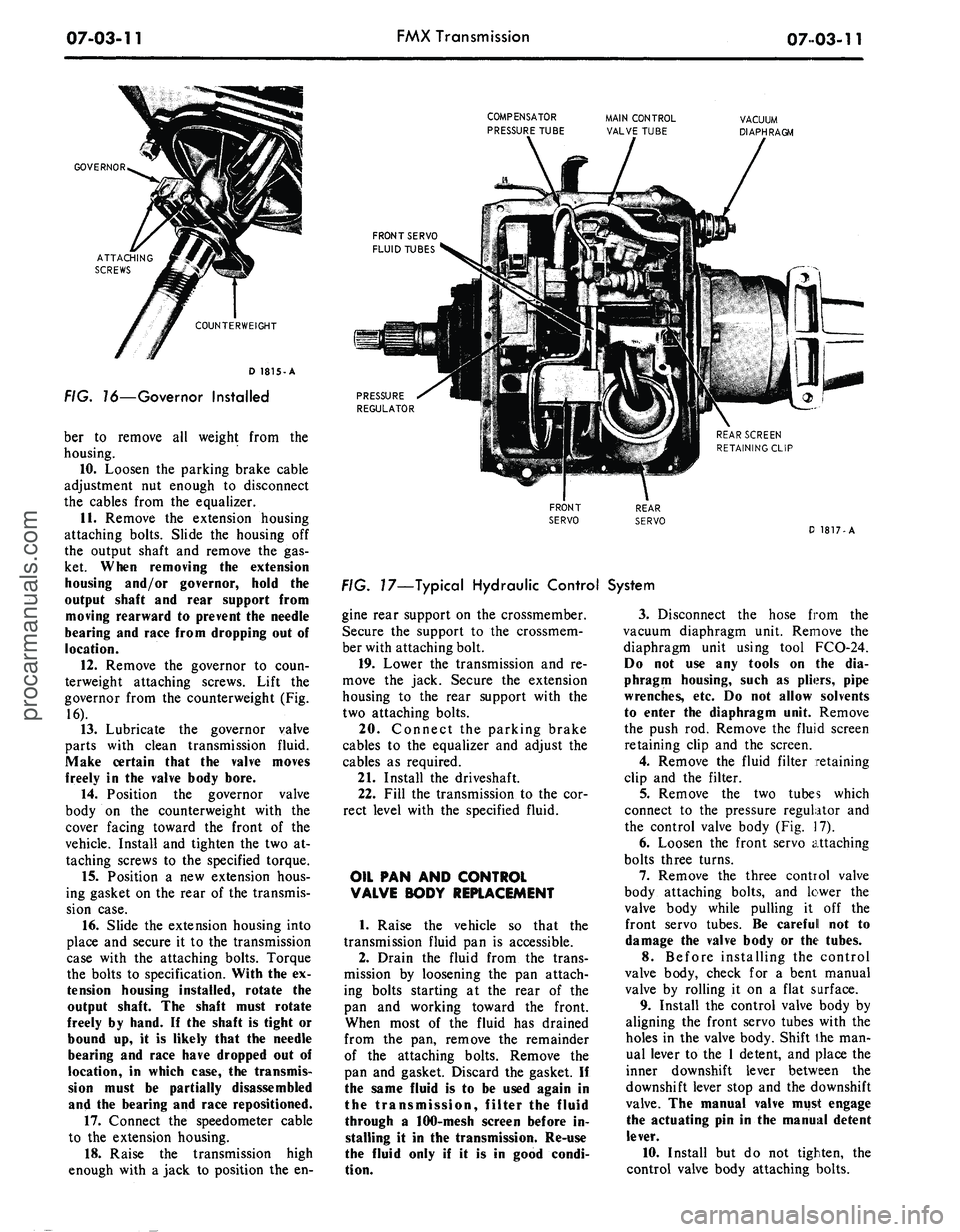

GOVERNOR

COMPENSATOR

PRESSURE TUBE

MAIN CONTROL

VALVE TUBE

COUNTERWEIGHT

D 1815-A

FIG. 16—Governor Installed

ber to remove all weight from the

housing.

10.

Loosen the parking brake cable

adjustment nut enough to disconnect

the cables from the equalizer.

11.

Remove the extension housing

attaching bolts. Slide the housing off

the output shaft and remove the gas-

ket. When removing

the

extension

housing and/or governor, hold

the

output shaft

and

rear support from

moving rearward

to

prevent

the

needle

bearing

and

race from dropping

out of

location.

12.

Remove the governor to coun-

terweight attaching screws. Lift the

governor from the counterweight (Fig.

16).

13.

Lubricate the governor valve

parts with clean transmission fluid.

Make certain that

the

valve moves

freely

in the

valve body bore.

14.

Position the governor valve

body on the counterweight with the

cover facing toward the front of the

vehicle. Install and tighten the two at-

taching screws to the specified torque.

15.

Position a new extension hous-

ing gasket on the rear of the transmis-

sion case.

16.

Slide the extension housing into

place and secure it to the transmission

case with the attaching bolts. Torque

the bolts to specification. With the ex-

tension housing installed, rotate

the

output shaft.

The

shaft must rotate

freely

by

hand.

If the

shaft

is

tight

or

bound

up, it is

likely that

the

needle

bearing

and

race have dropped

out of

location,

in

which case,

the

transmis-

sion must

be

partially disassembled

and

the

bearing

and

race repositioned.

17.

Connect the speedometer cable

to the extension housing.

18.

Raise the transmission high

enough with a jack to position the en-

FRONT SERVO

FLUID TUBES

PRESSURE

REGULATOR

D 1817-A

FIG. 17—Typical Hydraulic Control System

gine rear support on the crossmember.

Secure the support to the crossmem-

ber with attaching bolt.

19.

Lower the transmission and re-

move the jack. Secure the extension

housing to the rear support with the

two attaching bolts.

20.

Connect the parking brake

cables to the equalizer and adjust the

cables as required.

21.

Install the driveshaft.

22.

Fill the transmission to the cor-

rect level with the specified fluid.

OIL

PAN AND

CONTROL

VALVE BODY REPLACEMENT

1. Raise the vehicle so that the

transmission fluid pan is accessible.

2.

Drain the fluid from the trans-

mission by loosening the pan attach-

ing bolts starting at the rear of the

pan and working toward the front.

When most of the fluid has drained

from the pan, remove the remainder

of the attaching bolts. Remove the

pan and gasket. Discard the gasket. If

the same fluid is to be used again in

the transmission, filter the fluid

through a 100-mesh screen before in-

stalling it in the transmission. Re-use

the fluid only if it is in good condi-

tion.

3.

Disconnect the hose from the

vacuum diaphragm unit. Remove the

diaphragm unit using tool FCO-24.

Do

not use any

tools

on the dia-

phragm housing, such

as

pliers, pipe

wrenches,

etc. Do not

allow solvents

to enter

the

diaphragm unit. Remove

the push rod. Remove the fluid screen

retaining clip and the screen.

4.

Remove the fluid filter retaining

clip and the filter.

5.

Remove the two tubes which

connect to the pressure regulator and

the control valve body (Fig. 17).

6. Loosen the front servo attaching

bolts three turns.

7.

Remove the three control valve

body attaching bolts, and lower the

valve body while pulling it off the

front servo tubes. Be carefull not to

damage

the

valve body

or the

tubes.

8.

Before installing the control

valve body, check for a bent manual

valve by rolling it on a flat surface.

9. Install the control valve body by

aligning the front servo tubes with the

holes in the valve body. Shift the man-

ual lever to the 1 detent, and place the

inner downshift lever between the

downshift lever stop and the downshift

valve.

The

manual valve must engage

the actuating

pin in the

manual detent

lever.

10.

Install but do not tighten, the

control valve body attaching bolts.procarmanuals.com