stop start FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 354 of 413

07-03-14

FMX Transmission

07-03-14

REMOVAL AND INSTALLATION

An oil impregnated plastic grommet

is incorporated in the end of the man-

ual shift linkage lever arm on all col-

umn shift vehicles. A special tool

T67P-7341-A is required to install the

grommet in the manual lever, and to

install the manual linkage rod into the

grommet. Refer to Part 7-1, Section

2,

for the grommet replacement pro-

cedures.

TRANSMISSION AND

CONVERTER REPLACEMENT—

FORD-METEOR

REMOVAL

1.

Drive the vehicle on a hoist, but

do not raise at this time.

2.

Remove the two upper bolts and

lock washers which attach the con-

verter housing to the engine.

3.

Raise the vehicle and remove the

cover from the lower front side of the

converter housing. Drain the fluid

from the transmission.

4.

Remove one of the converter

drain plugs. Then rotate the converter

180 degrees and remove the other

plug. Do not attempt to turn the con-

verter with a wrench on the converter

stud nuts. If desired, the converter

may be drained after the unit has been

removed from the vehicle.

5.

Disconnect the fluid filler tube

from the transmission case. Discon-

nect the vacuum hose from the vacu-

um diaphragm unit and the tube from

the extension housing clip.

6. When the fluid has stopped

draining from the transmission and

converter, remove the flywheel to con-

verter nuts and flat washers. Install

the drain plugs in the converter and

torque to specifications. Install the

converter housing front plate to hold

the converter in place when the trans-

mission is removed.

7.

Disconnect the starter cables

from the starter and remove the start-

er.

8. Disconnect the oil cooler lines

from the transmission. Remove the

transmission vent tube.

9. Disconnect the downshift linkage

from the transmission.

10.

Disconnect the selector rod from

the transmission manual lever with

T67P-7341-A.

11.

Disconnect the speedometer

cable from the extension housing, and

remove the driveshaft.

12.

Support the transmission on a

stand. Remove the engine rear support

to transmission bolts, and raise the

transmission slightly to take the

weight off the cross member. Remove

the cross member. Support the rear

part of the engine.

13.

Remove the remaining convert-

er housing to engine attaching bolts.

Move the assembly to the rear and

down to remove it.

INSTALLATION

1.

If the converter has been re-

moved from the converter housing,

carefully position the converter in the

housing, and then install the housing

lower front cover plate to prevent the

converter from slipping out of the

housing.

2.

Install the transmission vent

tube.

Rotate the converter until the

studs adjacent to the drain plugs are

in a vertical position.

3.

Rotate the flywheel as required

to align the drain plug holes with the

drain plugs in the converter. With the

transmission mounted on a support

stand, move the converter and trans-

mission assembly forward into posi-

tion, using care not to damage the fly-

wheel and the converter pilot.

4.

Install the converter lower

housing-to-engine bolts, then torque

the bolts to specification.

5.

Install the cross member.

6. Lower the transmission until the

extension housing rests on the cross

member, and then install the extension

housing-to-cross member bolts.

7.

The converter must rest squarely

against the flywheel. This indicates

that the converter pilot is not binding

in the engine crankshaft.

8. Install the converter attaching

nuts and flat washers. Install the ac-

cess plates.

9. Connect the oil cooler inlet and

outlet lines to the transmission case.

10.

Coat the front universal joint

yoke seal and spline with B8A-

19589-A lubricant, and install the

drive shaft.

11.

Connect the speedometer cable

at the transmission.

12.

Using tool T67P-7341-A install

a new grommet in the manual lever.

Then secure the manual selector rod

to the lever.

13.

Connect the downshift linkage

and bushing at the transmission

throttle lever.

14.

Install the starter motor.

15.

Connect the fluid filter tube to

the transmission case. Connect the

vacuum hose to the vacuum dia-

phragm unit and the tube to its clip.

16.

Lower the transmission support

stand. Then install the upper two con-

verter housing-to-engine bolts and

tighten them to specification.

17.

Lower the vehicle and fill the

transmission with transmission fluid,

following the recommended procedure.

18.

Check the transmission, con-

verter assembly, and fluid cooler lines

for fluid leaks, and then adjust the

manual and downshift linkages.

TRANSMISSION REPLACEMENT

WITHOUT CONVERTER—

FORD-METEOR

The frame construction of the con-

vertible will not permit the transmis-

sion to be moved rearward enough to

clear the turbine shaft from the con-

verter. For this reason, the converter

and transmission must be removed as

a unit from this model.

REMOVAL

1.

Raise the vehicle on a hoist.

2.

Drain the fluid from the trans-

mission.

3.

Disconnect the hose from the

vacuum diaphragm unit and the tube

from its clip. Disconnect the fluid fill-

er tube from the case.

4.

Remove the cover from the lower

front side of the converter housing.

5.

Remove one of the converter

drain plugs. Then rotate the converter

180 degrees and remove the other

plug. Do not attempt to turn the con-

verter with a wrench on the converter

stud nuts.

6. Disconnect the drive shaft from

the rear axle, and remove the drive

shaft.

7.

Disconnect the fluid cooler lines

from the transmission. Remove the

vent tube.

8. Disconnect the downshift linkage

at the transmission.

9. Disconnect the selector rod from

the transmission manual lever with

tool T67P-7341-A.

10.

Disconnect the speedometer

cable at the extension housing.

11.

Remove the two engine rear

support to transmission bolts.

12.

Position a transmission jack

under the transmission and raise it

slightly to take the weight off the

cross member.procarmanuals.com

Page 374 of 413

07-04-05

C-6 Automatic Transmission

07-04-05

IN-VEHICLE ADJUSTMENTS AND REPAIRS

CONTROL LINKAGE

ADJUSTMENTS

The transmission control linkage

adjustments should be performed in

the order in which they appear in this

section of the manual.

THROTTLE AND

DOWNSHIFT LINKAGE

ADJUSTMENTS

Adjusting the throttle linkage is im-

portant to be certain the throttle and

kickdown systems are properly adjust-

ed. The kickdown system should come

in when the accelerator is pressed

through detent, and not before detent.

Refer to Group 10 for detailed

throttle and downshift linkage adjust-

ment procedures.

MANUAL LINKAGE

ADJUSTMENT

Column Shift

1.

Place the selector lever in the D

position tight against the stop.

2.

Loosen the shift rod adjusting

nut at point A (Fig. 4, 5, 6 or 7).

3.

Shift the manual lever at the

transmission into the D detent posi-

tion, third from the rear.

4.

Make sure that the selector lever

has not moved from the D stop; then,

tighten the nut at point A to 10-20 ft-

lbs.

5.

Check the transmission operation

for all selector lever detent positions.

Console Shift

1.

Position the transmission selec-

tor lever in the D position.

2.

Raise the vehicle and loosen the

manual lever shift rod retaining nut

(Fig. 8, 9 or 10). Move the transmis-

sion manual lever to the D position,

fourth detent position from the back

of the transmission.

3.

With the transmission selector

lever and manual lever in the D posi-

tions,

torque the retaining nut 10 to

20 ft-lbs.

4.

Check the operation of the trans-

mission in each selector lever position.

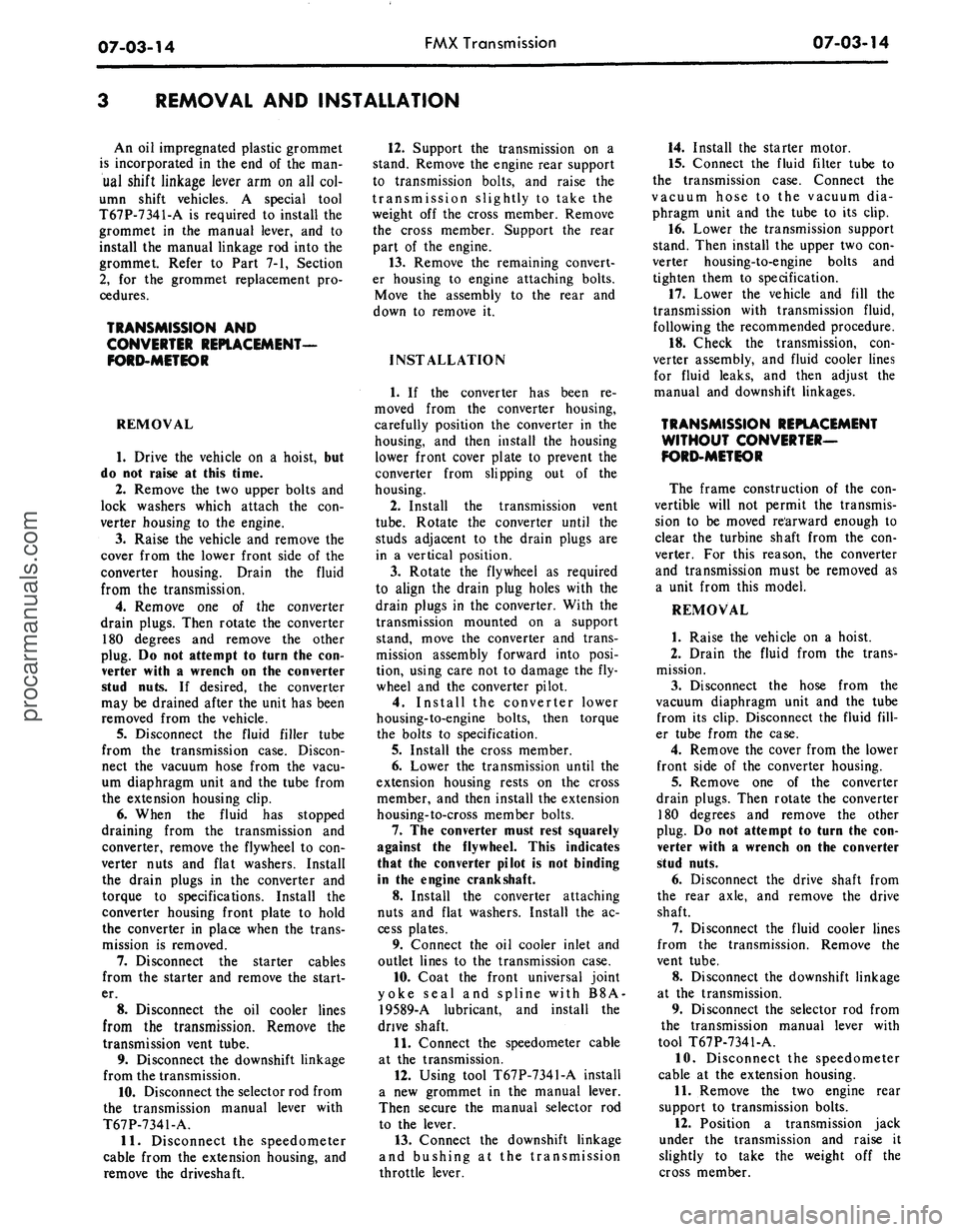

COLUMN SHIFT LEVER

SHIFT ROD

TRANSMISSION

MANUAL LEVER

D2031-A

FIG. 4—Manual Linkage—Column Shift—Ford-Mercury-Meteor

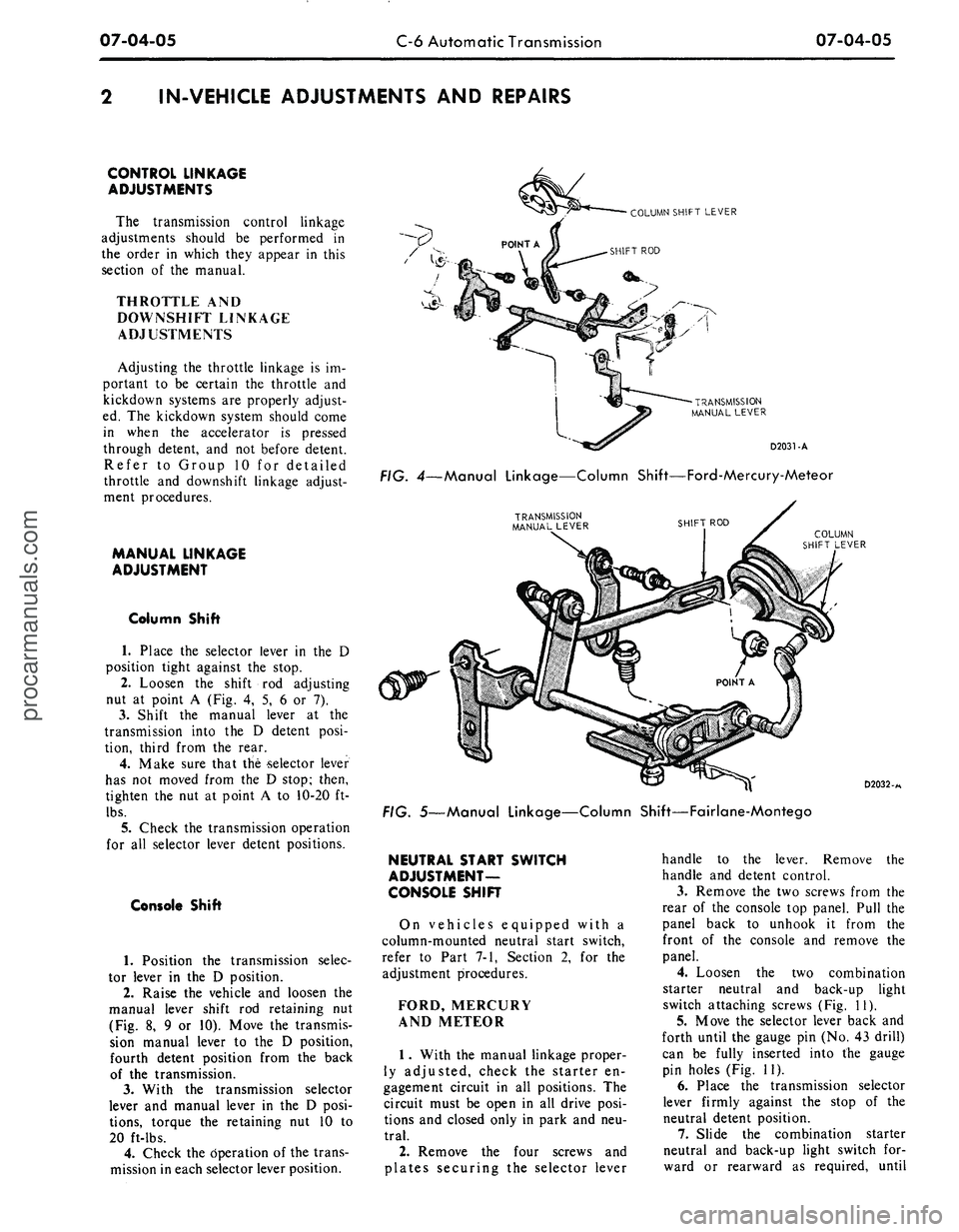

TRANSMISSION

MANUAL LEVER

FIG. 5—Manual Linkage—Column Shift—Fairlane-Montego

NEUTRAL START SWITCH

ADJUSTMENT-

CONSOLE SHIFT

On vehicles equipped with a

column-mounted neutral start switch,

refer to Part 7-1, Section 2, for the

adjustment procedures.

FORD, MERCURY

AND METEOR

1.

With the manual linkage proper-

ly adjusted, check the starter en-

gagement circuit in all positions. The

circuit must be open in all drive posi-

tions and closed only in park and neu-

tral.

2.

Remove the four screws and

plates securing the selector lever

D2032-M

the

handle to the lever. Remove

handle and detent control.

3.

Remove the two screws from the

rear of the console top panel. Pull the

panel back to unhook it from the

front of the console and remove the

panel.

4.

Loosen the two combination

starter neutral and back-up light

switch attaching screws (Fig. 11).

5.

Move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 11).

6. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

7.

Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, untilprocarmanuals.com

Page 375 of 413

07-04-06

C-6 Automatic Transmission

0704-06

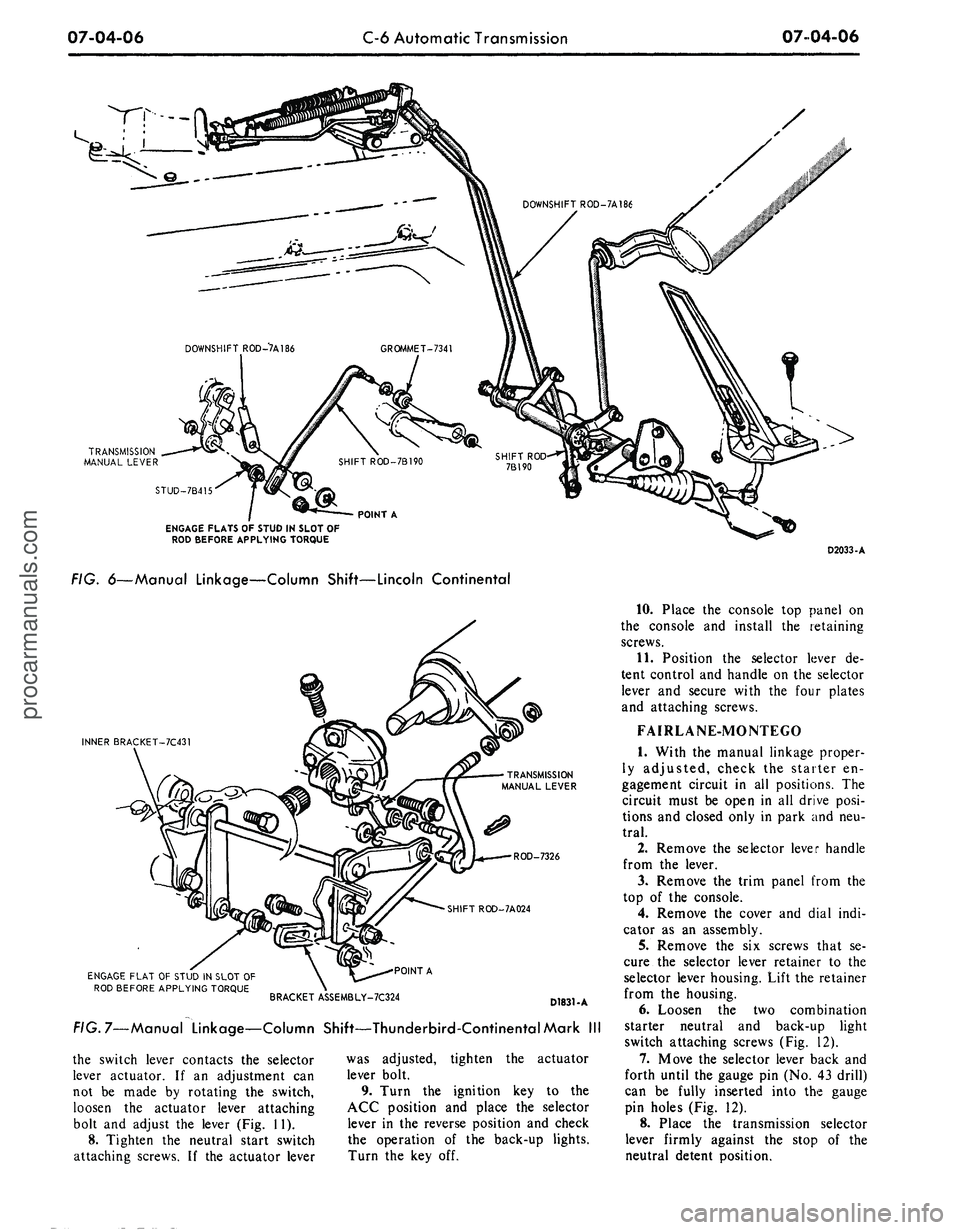

TRANSMISSION

MANUAL LEVER

STUD-7B415

ENGAGE FLATS OF STUD IN SLOT OF

ROD BEFORE APPLYING TORQUE

FIG. 6—Manual Linkage—Column Shift—Lincoln Continental

INNER BRACKET-7C431

TRANSMISSION

MANUAL LEVER

ROD-7326

SHIFT ROD-7A024

ENGAGE FLAT OF STUD IN SLOT

OF

ROD BEFORE APPLYING TORQUE

POINT A

BRACKET ASSEMBLY-7C324

D1831-A

FIG.

7—Manual

Linkage—Column Shift—Thunderbird-Continental Mark

III

the switch lever contacts

the

selector

lever actuator.

If an

adjustment

can

not

be

made

by

rotating

the

switch,

loosen

the

actuator lever attaching

bolt

and

adjust

the

lever (Fig.

11).

8. Tighten

the

neutral start switch

attaching screws.

If the

actuator lever

was adjusted, tighten

the

actuator

lever bolt.

9. Turn

the

ignition

key to the

ACC position

and

place

the

selector

lever

in the

reverse position

and

check

the operation

of the

back-up lights.

Turn

the key off.

D2033-A

10.

Place

the

console

top

panel

on

the console

and

install

the

retaining

screws.

11.

Position

the

selector lever

de-

tent control

and

handle

on the

selector

lever

and

secure with

the

four plates

and attaching screws.

FAIRLANE-MONTEGO

1.

With

the

manual linkage proper-

ly adjusted, check

the

starter

en-

gagement circuit

in all

positions.

The

circuit must

be

open

in all

drive posi-

tions

and

closed only

in

park

and neu-

tral.

2.

Remove

the

selector lever handle

from

the

lever.

3.

Remove

the

trim panel from

the

top

of the

console.

4.

Remove

the

cover

and

dial indi-

cator

as an

assembly.

5.

Remove

the six

screws that

se-

cure

the

selector lever retainer

to the

selector lever housing. Lift

the

retainer

from

the

housing.

6. Loosen

the two

combination

starter neutral

and

back-up light

switch attaching screws (Fig.

12).

7.

Move

the

selector lever back

and

forth until

the

gauge

pin

(No.

43

drill)

can

be

fully inserted into

the

gauge

pin holes (Fig.

12).

8. Place

the

transmission selector

lever firmly against

the

stop

of the

neutral detent position.procarmanuals.com

Page 378 of 413

07-04-09

C-6 Automatic Transmission

07-04-09

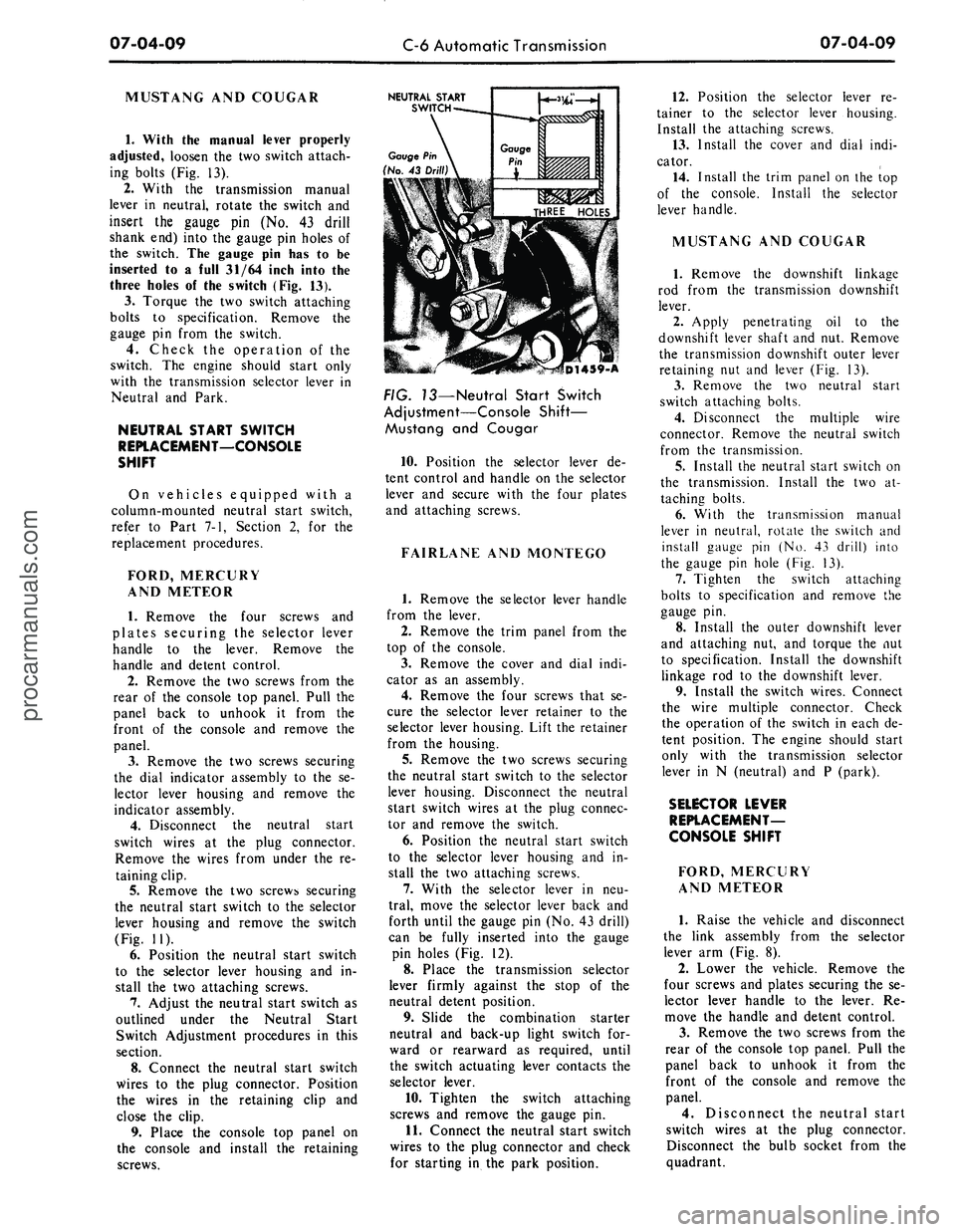

MUSTANG AND COUGAR

1.

With the manual lever properly

adjusted, loosen the two switch attach-

ing bolts (Fig. 13).

2.

With the transmission manual

lever in neutral, rotate the switch and

insert the gauge pin (No. 43 drill

shank end) into the gauge pin holes of

the switch. The gauge pin has to be

inserted to a full 31/64 inch into the

three holes of the switch (Fig. 13).

3.

Torque the two switch attaching

bolts to specification. Remove the

gauge pin from the switch.

4.

Check the operation of the

switch. The engine should start only

with the transmission selector lever in

Neutral and Park.

NEUTRAL START SWITCH

REPLACEMENT—CONSOLE

SHIFT

On vehicles equipped with a

column-mounted neutral start switch,

refer to Part 7-1, Section 2, for the

replacement procedures.

FORD, MERCURY

AND METEOR

1.

Remove the four screws and

plates securing the selector lever

handle to the lever. Remove the

handle and detent control.

2.

Remove the two screws from the

rear of the console top panel. Pull the

panel back to unhook it from the

front of the console and remove the

panel.

3.

Remove the two screws securing

the dial indicator assembly to the se-

lector lever housing and remove the

indicator assembly.

4.

Disconnect the neutral start

switch wires at the plug connector.

Remove the wires from under the re-

taining clip.

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing and remove the switch

(Fig. 11).

6. Position the neutral start switch

to the selector lever housing and in-

stall the two attaching screws.

7.

Adjust the neutral start switch as

outlined under the Neutral Start

Switch Adjustment procedures in this

section.

8. Connect the neutral start switch

Wires to the plug connector. Position

the wires in the retaining clip and

close the clip.

9. Place the console top panel on

the console and install the retaining

screws.

NEUTRAL START

SWITCH

D1459-A

FIG. 73—Neutral Start Switch

Adjustment—Console Shift—

Mustang and Cougar

10.

Position the selector lever de-

tent control and handle on the selector

lever and secure with the four plates

and attaching screws.

FAIRLANE AND MONTEGO

1.

Remove the selector lever handle

from the lever.

2.

Remove the trim panel from the

top of the console.

3.

Remove the cover and dial indi-

cator as an assembly.

4.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing. Disconnect the neutral

start switch wires at the plug connec-

tor and remove the switch.

6. Position the neutral start switch

to the selector lever housing and in-

stall the two attaching screws.

7.

With the selector lever in neu-

tral,

move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 12).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

11.

Connect the neutral start switch

wires to the plug connector and check

for starting in the park position.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the attaching screws.

13.

Install the cover and dial indi-

cator.

14.

Install the trim panel on the top

of the console. Install the selector

lever handle.

MUSTANG AND COUGAR

1.

Remove the downshift linkage

rod from the transmission downshift

lever.

2.

Apply penetrating oil to the

downshift lever shaft and nut. Remove

the transmission downshift outer lever

retaining nut and lever (Fig. 13).

3.

Remove the two neutral start

switch attaching bolts.

4.

Disconnect the multiple wire

connector. Remove the neutral switch

from the transmission.

5.

Install the neutral start switch on

the transmission. Install the two at-

taching bolts.

6. With the transmission manual

lever in neutral, rotate the switch and

install gauge pin (No. 43 drill) into

the gauge pin hole (Fig. 13).

7.

Tighten the switch attaching

bolts to specification and remove the

gauge pin.

8. Install the outer downshift lever

and attaching nut, and torque the nut

to specification. Install the downshift

linkage rod to the downshift lever.

9. Install the switch wires. Connect

the wire multiple connector. Check

the operation of the switch in each de-

tent position. The engine should start

only with the transmission selector

lever in N (neutral) and P (park).

SELECTOR LEVER

REPLACEMENT-

CONSOLE SHIFT

FORD, MERCURY

AND METEOR

1.

Raise the vehicle and disconnect

the link assembly from the selector

lever arm (Fig. 8).

2.

Lower the vehicle. Remove the

four screws and plates securing the se-

lector lever handle to the lever. Re-

move the handle and detent control.

3.

Remove the two screws from the

rear of the console top panel. Pull the

panel back to unhook it from the

front of the console and remove the

panel.

4.

Disconnect the neutral start

switch wires at the plug connector.

Disconnect the bulb socket from the

quadrant.procarmanuals.com

Page 384 of 413

07-04-15

C-6

Automatic Transmission

07-04-15

port attaching nuts and remove the

nuts.

Lift the crossmember from the

frame side supports.

19.

Remove the bolts that attach

the engine rear support to the exten-

sion housing and remove the support.

20.

Lower the transmission, then

disconnect the fluid cooler lines from

the transmission case.

21.

Secure the transmission to the

jack with a chain.

22.

Remove the six bolts that at-

tach the converter housing to the cyl-

inder block.

23.

Move the jack rearward until

the transmission clears the engine,

then tip it forward to provide clear-

ance. Lower the transmission and re-

move it from under the vehicle.

24.

Remove the converter from the

transmission. Mount the transmission

in a holding fixture if repairs are nec-

essary.

INSTALLATION—FAIRLANE,

MONTEGO,

MUSTANG

AND COUGAR

1. Mount the transmission in a

transmission jack and secure it with a

safety chain.

2.

Install the converter on the front

pump.

3.

Rotate the flywheel so that the

drain plug holes are in a vertical posi-

tion. Rotate the converter so that the

drain plugs are in the same relative

position as the drain plug holes in the

flywheel.

4.

Roll the transmission into posi-

tion under the vehicle and raise it to

alignment with the engine. Move it

forward until the converter housing

contacts the cylinder block. Install

and torque the converter-to-cylinder

block attaching bolts.

5.

Remove the jack safety chain

from the transmission.

6. Connect the two fluid cooler

lines to the fittings in the transmission

case.

7.

Secure the engine rear support to

the extension housing with the attach-

ing bolts. Torque the bolts to specifi-

cation.

8. Position the crossmember on the

frame side supports and install and

tighten the attaching nuts to specifica-

tion. Install cotter Dins to retain the

nuts.

9. Remove the transmission jack

from under the vehicle. Install and

torque the engine rear support-

to-crossmember attaching nuts.

10.

Install the exhaust system on

Mustang and Cougar.

11.

Install the converter-to-flywheel

attaching nuts and torque them to

specifications. Tighten the drain plugs

to specification.

12.

Secure the converter drain plug

access cover to the lower end of the

converter housing with the attaching

bolts.

13.

Install a new O-ring on the

lower end of the fluid filler tube. Dip

the O-ring in clean automatic trans-

mission fluid and insert the filler tube

in the transmission case.

14.

Secure the starter to the con-

verter housing. Connect the cable to

the terminal on the starter.

15.

Connect the speedometer cable

to the extension housing.

16.

Connect the shift rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

17.

Connect the downshift rod to

the lever on the transmission. Adjust

the rod.

18.

Remove the tool from the ex-

tension housing and install the drive

shaft.

19.

Lower the vehicle.

20.

Working from the engine com-

partment, secure the fluid filler tube

to the rear of the right cylinder head

with the attaching bolt.

21.

On Mustang and Cougar, con-

nect the neutral switch wires to the

harness. Secure the wires to the dash

with the retaining clip.

22.

Fill the transmission with the

specified lubricant as detailed in Part

7-1.

REMOVAL—THUNDERBIRD

1. Working from the engine com-

partment, remove the fluid filler tube

bracket attaching screw that secures it

to the rear of the right cylinder head.

Lift the tube and dipstick from the

transmission.

2.

Remove the starting motor upper

attaching bolt using a long extension.

3.

Remove the two converter hous-

ing upper attaching bolts.

4.

Raise the vehicle on a hoist or

stands.

5.

Remove the dust shield from the

front lower end of the converter hous-

ing.

6. Crank the engine until one of the

converter drain plugs is accessible.

Then, remove the plug.

7.

Crank the engine until the other

plug is at the bottom. Place a drain

pan to catch the fluid, then remove

the pan and allow the fluid to drain.

8. Remove the drive shaft.

9. Remove the frame side rail sup-

port brace attaching bolts and remove

the brace.

10.

After the fluid has been drained

from the converter, install the plug.

11.

Place the drain pan under the

transmission pan and loosen the at-

taching bolts and allow the fluid to

drain. Finally remove all of the pan

attaching bolts except two, to allow

the oil to further drain. After the fluid

has drained, install two bolts on the

opposite side of the pan to temporari-

ly hold it in place.

12.

Remove the converter-

to-flywheel attaching nuts.

13.

Disconnect the downshift link-

age from the transmission downshift

lever.

14.

Using tool T67P-7341-A, re-

move the selector rod from the manu-

al lever.

15.

Remove the two screws that at-

tach the shift rod bellcrank bracket to

the converter housing and remove the

bracket.

16.

Disconnect the vacuum dia-

phragm hose from the upper end of

the vacuum tube.

17.

Disconnect the speedometer

cable from the extension housing and

place it to one side.

18.

Remove the starting motor two

lower attaching bolts and place the

motor to one side.

19.

Disconnect the two oil cooler

lines from the right side of the trans-

mission.

20.

Disconnect the muffler inlet

pipes at the exhaust manifolds and

allow the pipes to hang.

21.

Remove the vibration absorber

from the extension housing.

22.

Remove the two engine rear

support-to-extension housing attaching

bolts.

23.

Place a transmission jack under

the transmission and raise it just

enough to remove the weight from the

support.

24.

Remove the two support attach-

ing bolts and remove the support.

25.

Lower the jack just enough to

remove the weight.

26.

Remove the four remaining

converter housing-to-cylinder block at-

taching bolts and the accelerator link-

age stop from the left side of the

housing.

27.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

28.

Remove the converter and

mount the transmission in a holding

fixture.procarmanuals.com

Page 385 of 413

07-04-16

C-6 Automatic Transmission

07-04-16

INSTALLATION—

THUNDERBIRD

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission on a

transmission jack.

4.

Rotate the converter so that the

studs and drain plugs are in alignment

with their holes in the flywheel.

5.

Move the transmission toward

the cylinder block until they contact

each other. Install and torque the at-

taching bolts to specification. Before

tightening the center bolt on the left

side,

make sure that the accelerator

linkage stop bracket is properly posi-

tioned so that the left upper bolt may

be installed later.

6. Connect the fluid cooler lines to

their fittings on the right side of the

transmission.

7.

Raise the transmission and in-

stall the engine rear support and tor-

que the bolts to specification. Make

sure that the hand brake equalizer is

positioned properly.

8. Lower the transmission and re-

move the jack.

9. Install the engine rear support-

to-extension housing attaching bolts.

10.

Install the drive shaft.

11.

Connect the speedometer cable

to the extension housing.

12.

Position the starting motor on

the converter housing and secure it

with the two lower bolts.

13.

Install the torque converter-

to-flywheel attaching nuts and torque

them to specification.

14.

Install the converter housing

dust shield.

15.

Secure the frame side rail sup-

port brace with the attaching bolts

and lock washers. Torque the bolts to

specification.

16.

Connect the downshift rod to

the transmission downshift lever.

17.

Connect the vacuum diaphragm

hose to the upper end of the vacuum

tube.

18.

Using Tool T67P-7341-A, in-

stall a new grommet in the manual

lever. Then, secure the manual selec-

tor rod to the lever.

19.

Position the vibration absorber

to the transmission extension housing

and secure it with the three attaching

bolts.

20.

Connect the muffler inlet pipes

to the exhaust manifolds.

21.

Lower the vehicle and install

the two converter housing upper bolts

and torque them to specification.

22.

Install the starting motor upper

bolt.

23.

Place a new O-ring on the end

of the fluid filler tube and insert it in

the transmission case. Secure the tube

to the rear of the right cylinder head

with the attaching screw and lock

washer.

24.

Fill the transmission to the

proper level with the specified fluids.

25.

Adjust the manual and throttle

linkage as required.

REMOVAL-

CONTINENTAL MARK III

1.

Working from the engine com-

partment, lift the fluid filler tube dio-

stick from the transmission.

2.

Raise the vehicle on a hoist or

stands.

3.

Remove the dust shield from the

front lower end of the converter hous-

ing.

4.

Crank the engine until one of the

converter drain plugs is accessible.

Then, remove the plug.

5.

Crank the engine until the other

plug is at the bottom. Place a drain

pan to catch the fluid, then remove

the pan and allow the fluid to drain.

6. Remove the driveshaft.

7.

Remove the frame side rail sup-

port brace attaching bolts and remove

the brace.

8. After the fluid has been drained

from the converter, install the plug.

9. Place the drain pan under the

transmission pan and loosen the at-

taching bolts and allow the fluid to

drain. Finally remove all of the pan

attaching bolts except two, to allow

the oil to further drain. After the fluid

has drained, install two bolts on the

opposite side of the pan to temporari-

ly hold it in place.

10.

Remove the. converter-

to-flywheel attaching nuts.

11.

Disconnect the downshift link-

age from the transmission downshift

lever.

12.

Using tool T67P-7341-A, re-

move the selector rod from the manu-

al lever.

13.

Remove the two screws that at-

tach the shift rod bellcrank bracket to

the converter housing and remove the

bracket.

14.

Disconnect the vacuum dia-

phragm hose at the transmission.

15.

Disconnect the speedometer

cable from the extension housing and

place it to one side.

16.

Remove the two idler arm

bracket retaining bolts at the frame

side rail and allow the linkage to

hang.

17.

Disconnect the starter cable

from the terminal on the starter. Re-

move the starter attaching bolts and

remove it from the housing.

18.

Remove the clip securing the oil

cooler lines to the support bracket.

19.

Disconnect the two oil cooler

lines from the right side of the trans-

mission.

20.

Disconnect the muffler inlet

pipes at the exhaust manifolds and

allow the pipes to hang.

21.

Remove the vibration absorber

from the extension housing.

22.

Remove the engine rear support

to extension housing attaching bolts.

23.

Place a transmission jack under

the transmission and raise it just

enough to remove the weight from the

support.

24.

Remove the two support attach-

ing bolts and remove the support.

25.

Lower the jack and secure the

transmission to the jack with a safety

chain.

26.

Remove the bolt that secures

the filler tube to the rear of the right

cylinder head and lift the tube from

the transmission case.

27.

Remove the six converter

housing-to-cylinder block attaching

bolts.

28.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

29.

Remove the converter and

mount the transmission in a holding

fixture.

INSTALLATION—

CONTINENTAL MARK III

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission on a

transmission jack.

4.

Rotate the converter so that the

studs and drain plugs are in alignment

with their holes in the flywheel.

5.

Move the transmission toward

the cylinder block until they contact

each other. Install and torque the at-

taching bolts to specification

6. Remove the jack safety chain

from the transmission.

7.

Connect the fluid cooler lines to

their fittings on the right side of the

transmission.

8. Install a new O-ring on the lower

end of the fluid filler tube. Dip the

O-ring in clean automatic transmis-

sion fluid and insert the tube in the

transmission case. Install the attach-

ing bolt.procarmanuals.com