light FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 86 of 413

03-02-10

Suspension

03-02-10

lower

arm

free

to

drop

as

coil spring

tension

is

eased.

If a

chain hoist

or a

jack that

has

a

narrow contact

pad is

to

be

used

on the

bumper

to

raise

the

car, distribute

the

load along

the

bumper

by

using

a

steel plate

3 or 4

inches long

as a

contact

pad to pre-

vent damaging

the

bumper.

2.

If the

ball joint

is

riveted

to the

arm, drill

a

1/8-inch

pilot hole

com-

pletely through each rivet. Then drill

off

the

rivet head through

the

pilot

hole with

a

3/8-inch drill,

and

drive

out both rivets.

3.

Position

a

jack

or

safety stand

under

the

lower

arm, and

lower

the

vehicle about

6

inches

to

offset

the

coil spring tension.

4.

Remove

the

cotter

pin

from

the

ball joint stud,

and

remove

the nut.

5.

Place

a box

wrench over

the

lower

end

of the

tool shown

in

Fig.

7,

and position

the

tool.

The

tool should

seat firmly against

the end of

both

studs,

and

not

against

the

upper stud

nut.

6. Turn

the

wrench until both studs

are under tension,

and

then, with

a

hammer,

tap the

spindle near

the

lower stud

to

loosen

the

stud from

the

spindle.

Do not

loosen

the

stud with

tool pressure alone. Remove

the

ball

joint.

7.

Clean

the end of the arm, and

remove

all

burrs from

the

hole edges.

Check

for

cracks

in the

metal

at the

holes,

and

replace

the arm if it is

cracked.

8. Position

the

stud

of

the

ball joint

to

the

spindle bore,

and

install

the at-

taching

nut

finger-tight.

9. Attach

the

ball joint

to

the

lower

arm.

Use

only

the

specified bolts

and

nuts.

Do not

rivet

the new

ball joint

to

the

arm.

Torque nuts

to

specification.

10.

Torque

the

ball joint stud

nut

to specification,

and

install

a

new cot-

ter

pin.

11.

Remove

the

jack.

12.

Check

and, if

necessary, adjust

caster, camber,

and

toe-in. Whenever

any part

of the

front suspension

has

been removed

and

installed, front

wheel alignment must

be

checked.

BALL JOINT REPLACEMENT

LINCOLN CONTINENTAL

The lower ball joint

is

riveted

to

the

lower

arm

wheras

the

upper ball joint

is bolted

to the

upper

arm.

When

re-

placing

a

ball joint,

use all the

parts

supplied

in the kit.

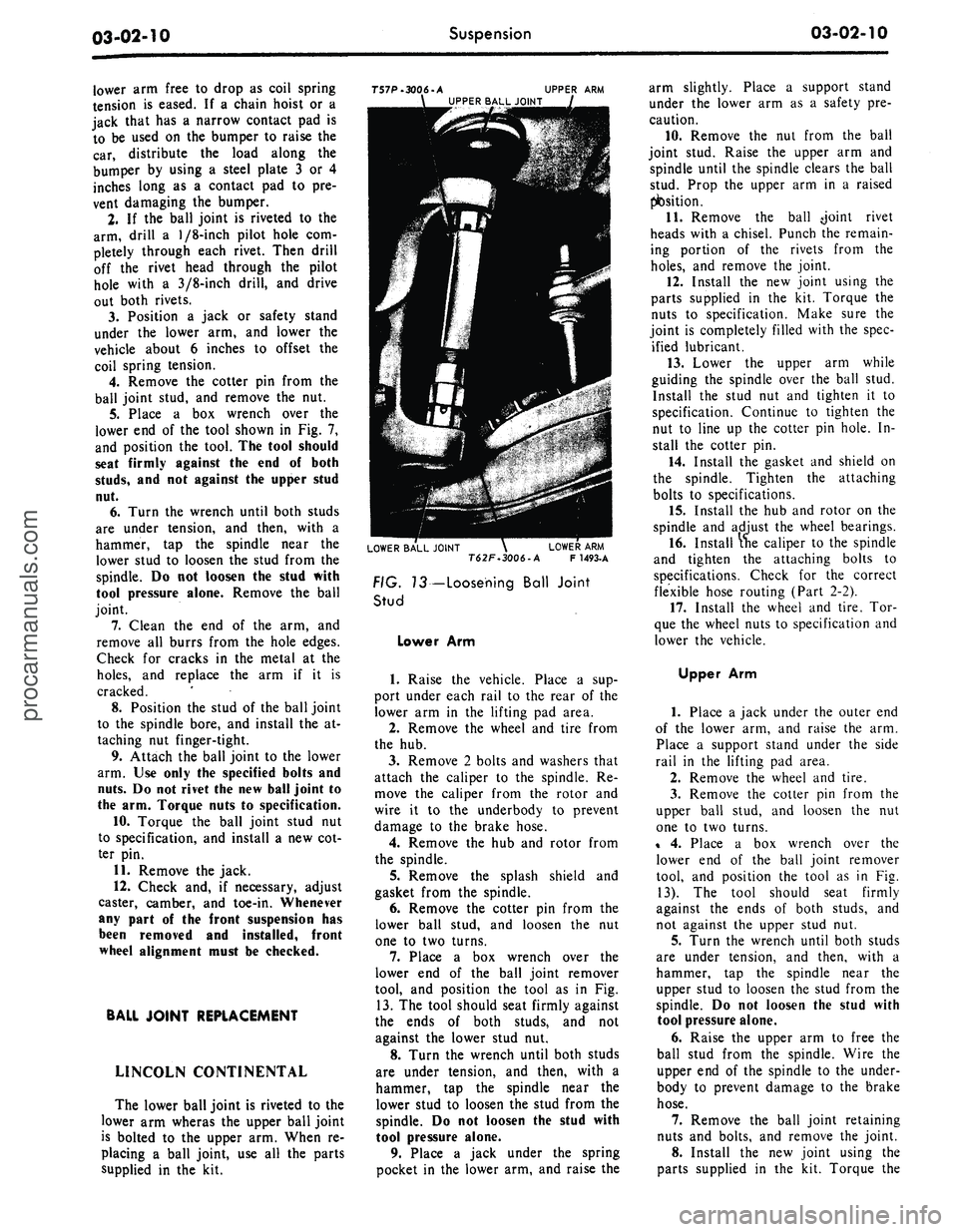

T57P-3006-A

UPPER

ARM

UPPER BALL JOINT

LOWER BALL JOINT

\

LOWER

ARM

T62F.3006-A

F

1493-A

FIG. 13— Loosening Ball Joint

Stud

Lower

Arm

1.

Raise

the

vehicle. Place

a sup-

port under each rail

to the

rear

of

the

lower

arm in the

lifting

pad

area.

2.

Remove

the

wheel

and

tire from

the

hub.

3.

Remove

2

bolts

and

washers that

attach

the

caliper

to the

spindle.

Re-

move

the

caliper from

the

rotor

and

wire

it to the

underbody

to

prevent

damage

to the

brake hose.

4.

Remove

the hub and

rotor from

the spindle.

5.

Remove

the

splash shield

and

gasket from

the

spindle.

6. Remove

the

cotter

pin

from

the

lower ball stud,

and

loosen

the nut

one

to two

turns.

7.

Place

a box

wrench over

the

lower

end of the

ball joint remover

tool,

and

position

the

tool

as in Fig.

13.

The

tool should seat firmly against

the ends

of

both studs,

and not

against

the

lower stud

nut.

8. Turn

the

wrench until both studs

are under tension,

and

then, with

a

hammer,

tap the

spindle near

the

lower stud

to

loosen

the

stud from

the

spindle.

Do not

loosen

the

stud with

tool pressure alone.

9. Place

a

jack under

the

spring

pocket

in the

lower

arm, and

raise

the

arm slightly. Place

a

support stand

under

the

lower

arm as a

safety

pre-

caution.

10.

Remove

the nut

from

the

ball

joint stud. Raise

the

upper

arm and

spindle until

the

spindle clears

the

ball

stud. Prop

the

upper

arm in a

raised

position.

11.

Remove

the

ball -joint rivet

heads with

a

chisel. Punch

the

remain-

ing portion

of the

rivets from

the

holes,

and

remove

the

joint.

12.

Install

the

new

joint using

the

parts supplied

in the kit.

Torque

the

nuts

to

specification. Make sure

the

joint

is

completely filled with

the

spec-

ified lubricant.

13.

Lower

the

upper

arm

while

guiding

the

spindle over

the

ball stud.

Install

the

stud

nut and

tighten

it to

specification. Continue

to

tighten

the

nut

to

line

up the

cotter

pin

hole.

In-

stall

the

cotter

pin.

14.

Install

the

gasket

and

shield

on

the spindle. Tighten

the

attaching

bolts

to

specifications.

15.

Install

the

hub and

rotor

on the

spindle

and

adjust

the

wheel bearings.

16.

Install

the

caliper

to

the

spindle

and tighten

the

attaching bolts

to

specifications. Check

for the

correct

flexible hose routing (Part

2-2).

17.

Install

the

wheel

and

tire.

Tor-

que

the

wheel nuts

to

specification

and

lower

the

vehicle.

Upper

Arm

1.

Place

a

jack under

the

outer

end

of

the

lower

arm,

and

raise

the arm.

Place

a

support stand under

the

side

rail

in the

lifting

pad

area.

2.

Remove

the

wheel

and

tire.

3.

Remove

the

cotter

pin

from

the

upper ball stud,

and

loosen

the nut

one

to two

turns.

%

4.

Place

a box

wrench over

the

lower

end of the

ball joint remover

tool,

and

position

the

tool

as in Fig.

13).

The

tool should seat firmly

against

the

ends

of

both studs,

and

not against

the

upper stud

nut.

5.

Turn

the

wrench until both studs

are under tension,

and

then, with

a

hammer,

tap the

spindle near

the

upper stud

to

loosen

the

stud from

the

spindle.

Do not

loosen

the

stud with

tool pressure alone.

6. Raise

the

upper

arm to

free

the

ball stud from

the

spindle. Wire

the

upper

end

of

the

spindle

to the

under-

body

to

prevent damage

to the

brake

hose.

7.

Remove

the

ball joint retaining

nuts

and

bolts,

and

remove

the

joint.

8. Install

the new

joint using

the

parts supplied

in the kit.

Torque

theprocarmanuals.com

Page 94 of 413

03-02-18

Suspension

03-02-18

5.

Remove the cotter pin from the

upper ball joint stud nut.

6. Loosen the upper ball joint stud

nut one or two turns. Do not remove

the nut from the stud at this time.

7.

Install tool T57P-3006-A be-

tween the upper and lower ball joint

studs with the adapter screw on top

(Fig. 13). The tool should be seated

firmly against the ends of both studs

and not against the nuts or lower stud

cotter pin.

8. With a wrench, turn the adapter

screw until the tool places the stua

under tension. Tap the spindle near

the upper stud with a hammer to loos-

en the stud in the spindle. Do not

loosen the stud from the spindle with

tool pressure only.

9. Remove the tool from between

the ball joint studs and place a floor

jack under the lower arm.

10.

Raise the floor jack to relieve

the pressure from the upper ball joint

stud nut and remove the nut.

11.

Remove the upper arm inner

shaft attaching bolts. Remove the

upper arm and inner shaft as an as-

sembly (Fig. 1).

12.

Remove the bumpei from the

upper arm.

Installation

1.

Position the bumper to the upper

arm and install the nut and washer.

Torque the nut to specifications.

2.

Position the upper arm inner

shaft to the frame side rail and install

the 2 attaching bolts and washers

snug.

3.

Connect the upper ball joint stud

to the spindle and install the attaching

nut. Torque the nut to specification

and continue to tighten the nut until

the cotter pin hole in the stud is in

line with the nut slots. Then, install

the cotter pin.

4.

If equipped with drum type bra-

kes—Adjust the brakes as outlined in

Part 2-2. Install the wheel, tire, and

drum to the spindle and adjust the

wheel bearings as outlined in Part

3-12.

5.

If equipped with disc brak-

es—Install the wheel and tire on the

hub and adjust the wheel bearings as

outlined in Part 3-12.

6. Install the hub cap or wheel

cover.

7.

Remove the safety stands and

lower the front of the vehicle.

8. Check caster, camber, and toe-in

and adjust as required (Section 2, Part

3-D.

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1.

Raise the front of the vehicle,

position safety stands under the

frame, and lower the vehicle slightly.

2.

Remove the wheel and tire.

3.

Remove the shock absorber

lower attaching nuts and washers.

4.

Remove the shock absorber

upper mounting bracket attaching

nuts,

and remove the shock absorber

and bracket as an assembly (Fig. 26).

On all 8-cylinder vehicles, remove

the air cleaner to obtain access for

tool installation.

5.

Install the spring compressor

tool and compress the spring (Figs.

19,

20 and 21).

6. Position a safety stand under the

lower arm.

7.

Remove the cotter pin from the

nut on the upper ball joint stud, and

loosen the nut one or two turns. Do

not remove the nut from the stud at

this time.

8. Position the ball joint remover

tool between the upper and lower ball

joint studs as shown in Fig. 10. The

tool should seat firmly against the

ends of both studs and not against the

stud nuts.

9. Turn the tool with a wrench until

the tool places the studs under consid-

erable tension; then, hit the spindle

smartly near the upper stud with a

hammer to break the stud loose in the

spindle. Do not loosen the stud in the

spindle with tool pressure only. If

both arms are being removed, loosen

the lower stud in the same manner as

the upper stud.

10.

Remove the nut from the upper

stud and lift the stud out of the

spindle.

11.

Remove the upper arm inner

shaft attaching nuts from the engine

compartment, and remove the upper

arm.

12.

Wipe off all loose dirt from the

upper arm parts. Do not wash the ball

joint with a solvent.

Installation

1.

Position the upper arm on the

underbody mounting bracket, and in-

stall the nuts and lock washers on the

two inner shaft attaching bolts. The

specified keystone-type lock washers

must be used. Torque the nuts to

soecification.

2.

Position the upper ball joint stud

in the top of the wheel spindle, and in-

stall the stud nut. Torque the nut to

specification, and continue to tighten

it until the cotter pin hole and slots

line up. Install a new cotter pin.

3.

Release the coil spring, remove

the tool, and install the front shock

absorber and the wheel and tire.

LINCOLN CONTINENTAL

Removal

1.

Place a jack under the outer end

of the suspension lower arm and raise

the arm. Refer to Fig. 22.

2.

Remove the wheel and tire.

3.

Remove the cotter pin from the

upper ball joint stud. Loosen the nut

one or two turns.

4.

Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig.

13.

The tool should seat firmly against

the ends of both studs, and not

against the upper stud nut.

5.

Turn the wrench until both studs

are under tension, and then, tap the

spindle with a hammer near the upper

stud to loosen it from the spindle. Do

not loosen the stud with tool pressure

alone. Remove the nut.

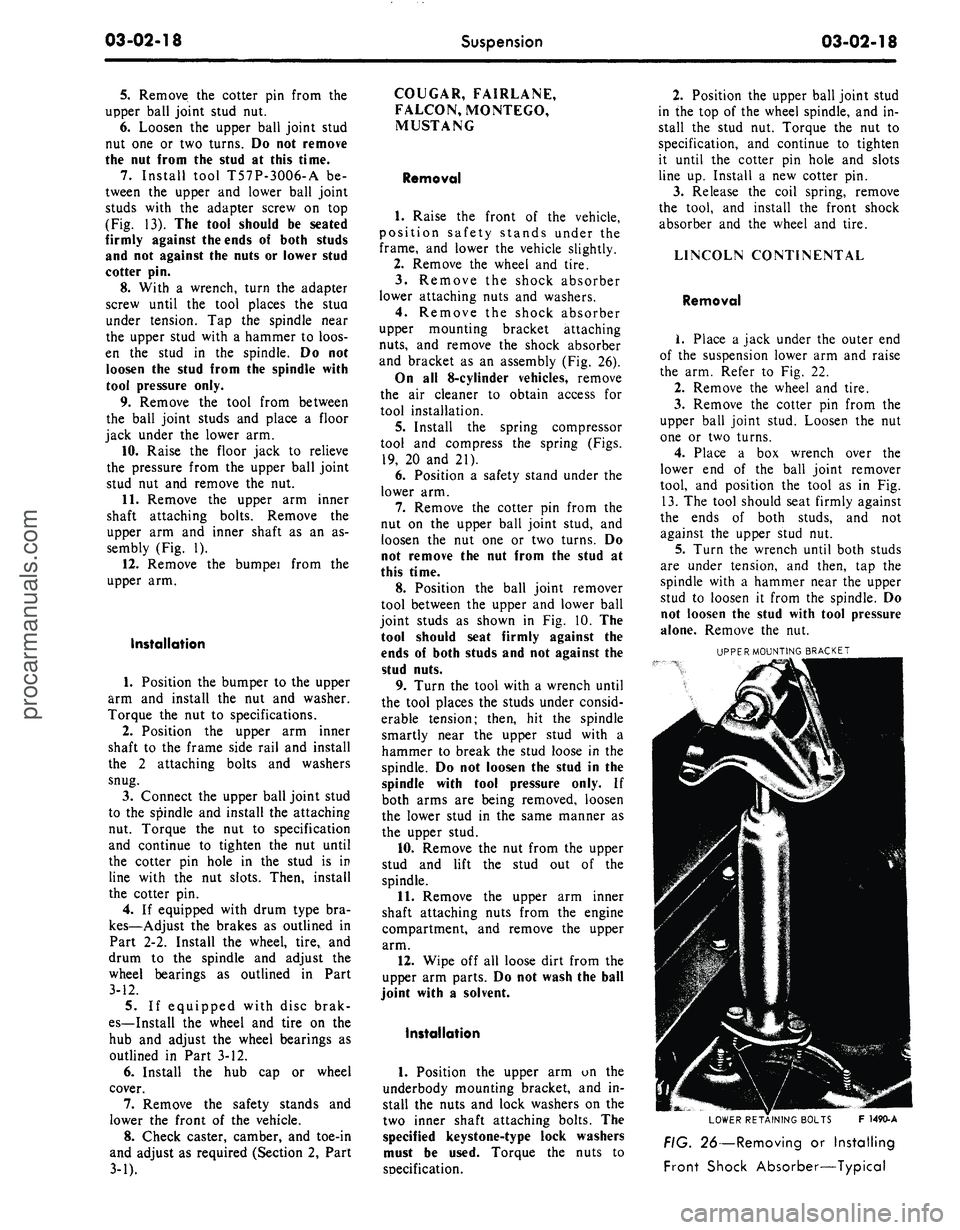

UPPER MOUNTING BRACKET

LOWER RETAINING BOLTS F 1490-A

FIG. 26—Removing or Installing

Front Shock Absorber—Typicalprocarmanuals.com

Page 102 of 413

03-02-26

Suspension

03-02-26

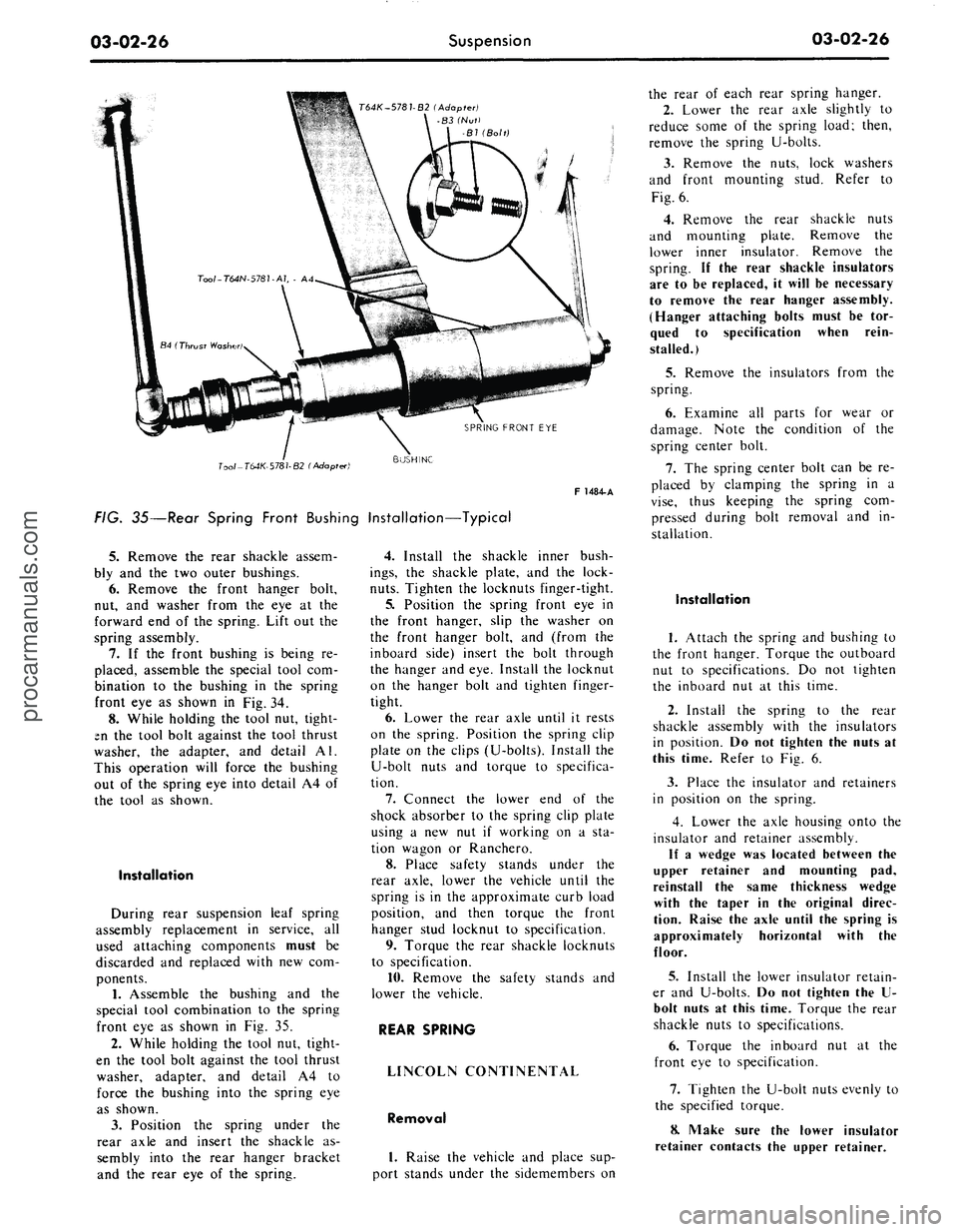

T64K-578 7-B2 (Adapter)

-83 (Nut)

(Bolt)

SPRING FRONT

EYE

Tool-T64K-5781-B2 (Adapter)

BUSHING

F 1484-A

FIG. 35—Rear Spring Front Bushing Installation—Typical

5.

Remove

the

rear shackle assem-

bly

and the two

outer bushings.

6. Remove

the

front hanger bolt,

nut,

and

washer from

the eye at the

forward

end of the

spring. Lift

out the

spring assembly.

7.

If the

front bushing

is

being

re-

placed, assemble

the

special tool

com-

bination

to the

bushing

in the

spring

front

eye as

shown

in

Fig.

34.

8. While holding

the

tool

nut,

tight-

en

the

tool bolt against

the

tool thrust

washer,

the

adapter,

and

detail

Al.

This operation will force

the

bushing

out

of the

spring

eye

into detail

A4 of

the tool

as

shown.

Installation

During rear suspension leaf spring

assembly replacement

in

service,

all

used attaching components must

be

discarded

and

replaced with

new com-

ponents.

1.

Assemble

the

bushing

and the

special tool combination

to the

spring

front

eye as

shown

in Fig. 35.

2.

While holding

the

tool

nut,

tight-

en

the

tool bolt against

the

tool thrust

washer, adapter,

and

detail

A4 to

force

the

bushing into

the

spring

eye

as shown.

3.

Position

the

spring under

the

rear axle

and

insert

the

shackle

as-

sembly into

the

rear hanger bracket

and

the

rear

eye of the

spring.

4.

Install

the

shackle inner bush-

ings,

the

shackle plate,

and the

lock-

nuts.

Tighten

the

locknuts finger-tight.

5.

Position

the

spring front

eye in

the front hanger, slip

the

washer

on

the front hanger bolt,

and

(from

the

inboard side) insert

the

bolt through

the hanger

and

eye. Install

the

locknut

on

the

hanger bolt

and

tighten finger-

tight.

6. Lower

the

rear axle until

it

rests

on

the

spring. Position

the

spring clip

plate

on the

clips (U-bolts). Install

the

U-bolt nuts

and

torque

to

specifica-

tion.

7.

Connect

the

lower

end of the

shock absorber

to the

spring clip plate

using

a new nut if

working

on a sta-

tion wagon

or

Ranchero.

8. Place safety stands under

the

rear axle, lower

the

vehicle until

the

spring

is in the

approximate curb load

position,

and

then torque

the

front

hanger stud locknut

to

specification.

9. Torque

the

rear shackle locknuts

to specification.

10.

Remove

the

safety stands

and

lower

the

vehicle.

REAR SPRING

LINCOLN CONTINENTAL

Removal

1.

Raise

the

vehicle

and

place

sup-

port stands under

the

sidemembers

on

the rear

of

each rear spring hanger.

2.

Lower

the

rear axle slightly

to

reduce some

of the

spring load; then,

remove

the

spring U-bolts.

3.

Remove

the

nuts, lock washers

and front mounting stud. Refer

to

Fig.

6.

4.

Remove

the

rear shackle nuts

and mounting plate. Remove

the

lower inner insulator. Remove

the

spring.

If the

rear shackle insulators

are

to be

replaced,

it

will

be

necessary

to remove

the

rear hanger assembly.

(Hanger attaching bolts must

be tor-

qued

to

specification when rein-

stalled.)

5.

Remove

the

insulators from

the

spring.

6. Examine

all

parts

for

wear

or

damage. Note

the

condition

of the

spring center bolt.

7.

The

spring center bolt

can be re-

placed

by

clamping

the

spring

in a

vise,

thus keeping

the

spring

com-

pressed during bolt removal

and in-

stallation.

Installation

1.

Attach

the

spring

and

bushing

to

the front hanger. Torque

the

outboard

nut

to

specifications.

Do not

tighten

the inboard

nut at

this time.

2.

Install

the

spring

to the

rear

shackle assembly with

the

insulators

in position.

Do not

tighten

the

nuts

at

this time. Refer

to Fig. 6.

3.

Place

the

insulator

and

retainers

in position

on the

spring.

4.

Lower

the

axle housing onto

the

insulator

and

retainer assembly.

If

a

wedge

was

located between

the

upper retainer

and

mounting

pad,

reinstall

the

same thickness wedge

with

the

taper

in the

original direc-

tion. Raise

the

axle until

the

spring

is

approximately horizontal with

the

floor.

5.

Install

the

lower insulator retain-

er

and

U-bolts.

Do not

tighten

the U-

bolt nuts

at

this time. Torque

the

rear

shackle nuts

to

specifications.

6. Torque

the

inboard

nut at the

front

eye to

specification.

7.

Tighten

the

U-bolt nuts evenly

to

the specified torque.

8. Make sure

the

lower insulator

retainer contacts

the

upper retainer.procarmanuals.com

Page 112 of 413

03-04-03

Automatic Air Leveling System — Lincoln Continental

03-04-03

outlet lines to their respective parts.

3.

Adjust the trim height as de-

tailed in Section 4.

4.

Connect the link to the arm.

5.

Remove the jack stands and

lower the vehicle.

SUPER LIFT SHOCK ABSORBER

REMOVAL

1.

Raise the vehicle and place jack

stands under the axle to compress the

super lift.

2.

Loosen the air line or lines (right

super lift) slowly to release the air

from the system. Then, disconnect the

line or lines.

3.

Remove the three mounting plate

attaching screws from the upper end

of the super lift.

4.

Remove the attaching nut and

washer from the lower end of the

super lift and remove it from the vehi-

cle.

5.

Remove the nut, outer washer

and the insulator that attach the super

lift to the mounting plate. Remove the

plate, remaining insulator and washer.

INSTALLATION

1.

Position a washer, insulator,

mounting plate, insulator, washer and

nut on the stud at the upper end of

the super lift. Torque the nut to speci-

fication.

2.

Install the mounting plate, outer

insulator, washer and nut on the stud.

Torque the nut to specification.

3.

Attach the mounting plate and

shock absorber to the crossmember

with the attaching screws to specifica-

tions.

4.

Connect the lower end of the

super lift to the mounting stud with

the washers and attaching nut. Torque

the nut to specification.

5.

Connect the air line or lines

(right super lift) to the super lift.

6. Start the engine and check for

leaks.

3 IN-VEHICLE ADJUSTMENTS AND REPAIRS

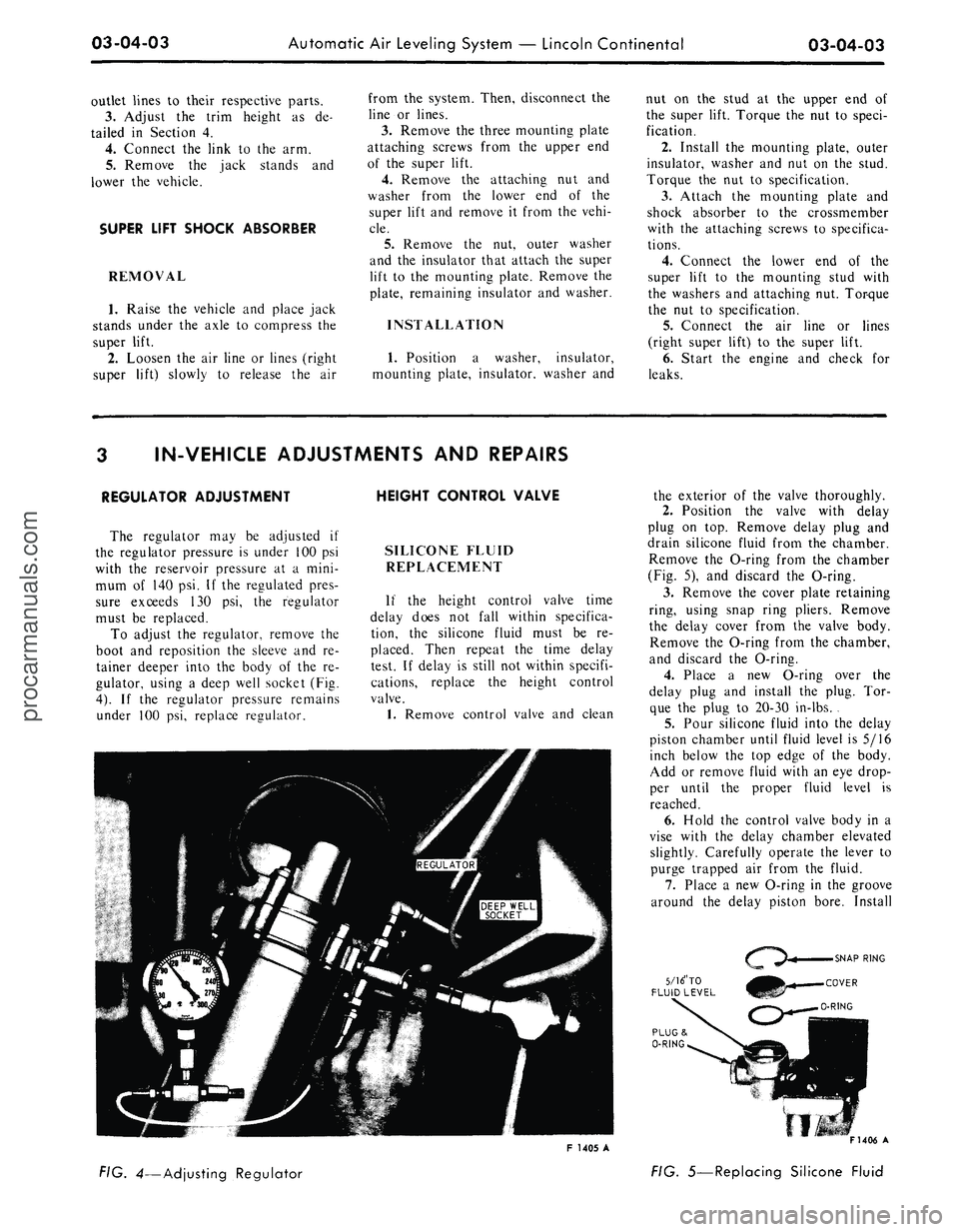

REGULATOR ADJUSTMENT HEIGHT CONTROL VALVE

The regulator may be adjusted if

the regulator pressure is under 100 psi

with the reservoir pressure at a mini-

mum of 140 psi. If the regulated pres-

sure exceeds 130 psi, the regulator

must be replaced.

To adjust the regulator, remove the

boot and reposition the sleeve and re-

tainer deeper into the body of the re-

gulator, using a deep well socket (Fig.

4).

If the regulator pressure remains

under 100 psi, replace regulator.

SILICONE FLUID

REPLACEMENT

If the height control valve time

delay does not fall within specifica-

tion, the silicone fluid must be re-

placed. Then repeat the time delay

test. If delay is still not within specifi-

cations, replace the height control

valve.

1.

Remove control valve and clean

the exterior of the valve thoroughly.

2.

Position the valve with delay

plug on top. Remove delay plug and

drain silicone fluid from the chamber.

Remove the O-ring from the chamber

(Fig. 5), and discard the O-ring.

3.

Remove the cover plate retaining

ring, using snap ring pliers. Remove

the delay cover from the valve body.

Remove the O-ring from the chamber,

and discard the O-ring.

4.

Place a new O-ring over the

delay plug and install the plug. Tor-

que the plug to 20-30 in-lbs. .

5.

Pour silicone fluid into the delay

piston chamber until fluid level is 5/16

inch below the top edge of the body.

Add or remove fluid with an eye drop-

per until the proper fluid level is

reached.

6. Hold the control valve body in a

vise with the delay chamber elevated

slightly. Carefully operate the lever to

purge trapped air from the fluid.

7.

Place a new O-ring in the groove

around the delay piston bore. Install

5/16" TO

FLUID LEVEL

F 1405 A

FIG. 4—Adjusting Regulator

F1406 A

FIG. 5—Replacing Silicone Fluidprocarmanuals.com

Page 116 of 413

03-05-03

Steering Columns And Linkage

03-05-03

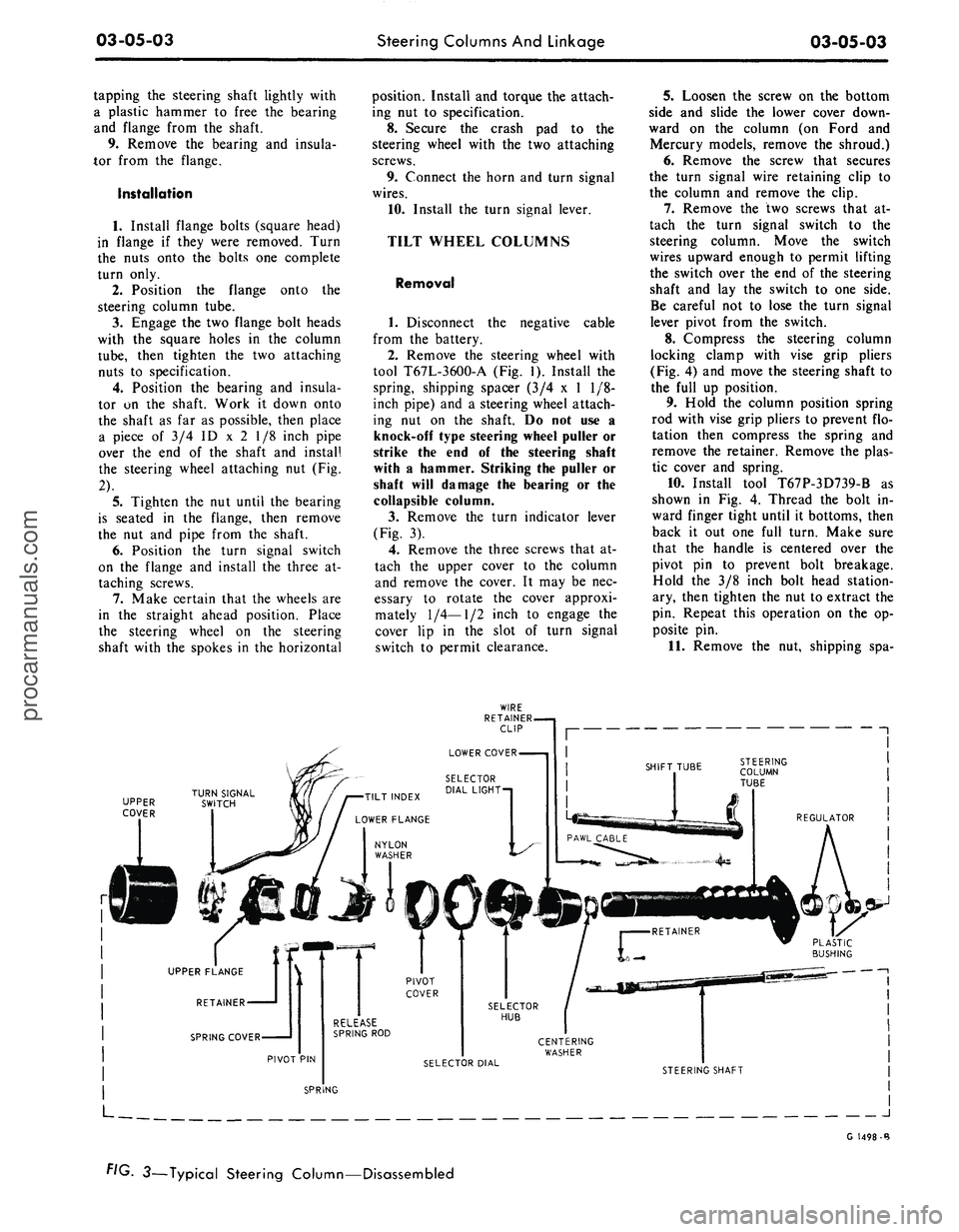

tapping the steering shaft lightly with

a plastic hammer to free the bearing

and flange from the shaft.

9. Remove the bearing and insula-

tor from the flange.

Installation

1.

Install flange bolts (square head)

in flange if they were removed. Turn

the nuts onto the bolts one complete

turn only.

2.

Position the flange onto the

steering column tube.

3.

Engage the two flange bolt heads

with the square holes in the column

tube,

then tighten the two attaching

nuts to specification.

4.

Position the bearing and insula-

tor on the shaft. Work it down onto

the shaft as far as possible, then place

a piece of 3/4 ID x 2 1/8 inch pipe

over the end of the shaft and install

the steering wheel attaching nut (Fig.

2).

5.

Tighten the nut until the bearing

is seated in the flange, then remove

the nut and pipe from the shaft.

6. Position the turn signal switch

on the flange and install the three at-

taching screws.

7.

Make certain that the wheels are

in the straight ahead position. Place

the steering wheel on the steering

shaft with the spokes in the horizontal

position. Install and torque the attach-

ing nut to specification.

8. Secure the crash pad to the

steering wheel with the two attaching

screws.

9. Connect the horn and turn signal

wires.

10.

Install the turn signal lever.

TILT WHEEL COLUMNS

Removal

1.

Disconnect the negative cable

from the battery.

2.

Remove the steering wheel with

tool T67L-3600-A (Fig. 1). Install the

spring, shipping spacer (3/4 x 1 1/8-

inch pipe) and a steering wheel attach-

ing nut on the shaft. Do not use a

knock-off type steering wheel puller or

strike the end of the steering shaft

with a hammer. Striking the puller or

shaft will damage the bearing or the

collapsible column.

3.

Remove the turn indicator lever

(Fig. 3).

4.

Remove the three screws that at-

tach the upper cover to the column

and remove the cover. It may be nec-

essary to rotate the cover approxi-

mately

1/4—1/2

inch to engage the

cover lip in the slot of turn signal

switch to permit clearance.

5.

Loosen the screw on the bottom

side and slide the lower cover down-

ward on the column (on Ford and

Mercury models, remove the shroud.)

6. Remove the screw that secures

the turn signal wire retaining clip to

the column and remove the clip.

7.

Remove the two screws that at-

tach the turn signal switch to the

steering column. Move the switch

wires upward enough to permit lifting

the switch over the end of the steering

shaft and lay the switch to one side.

Be careful not to lose the turn signal

lever pivot from the switch.

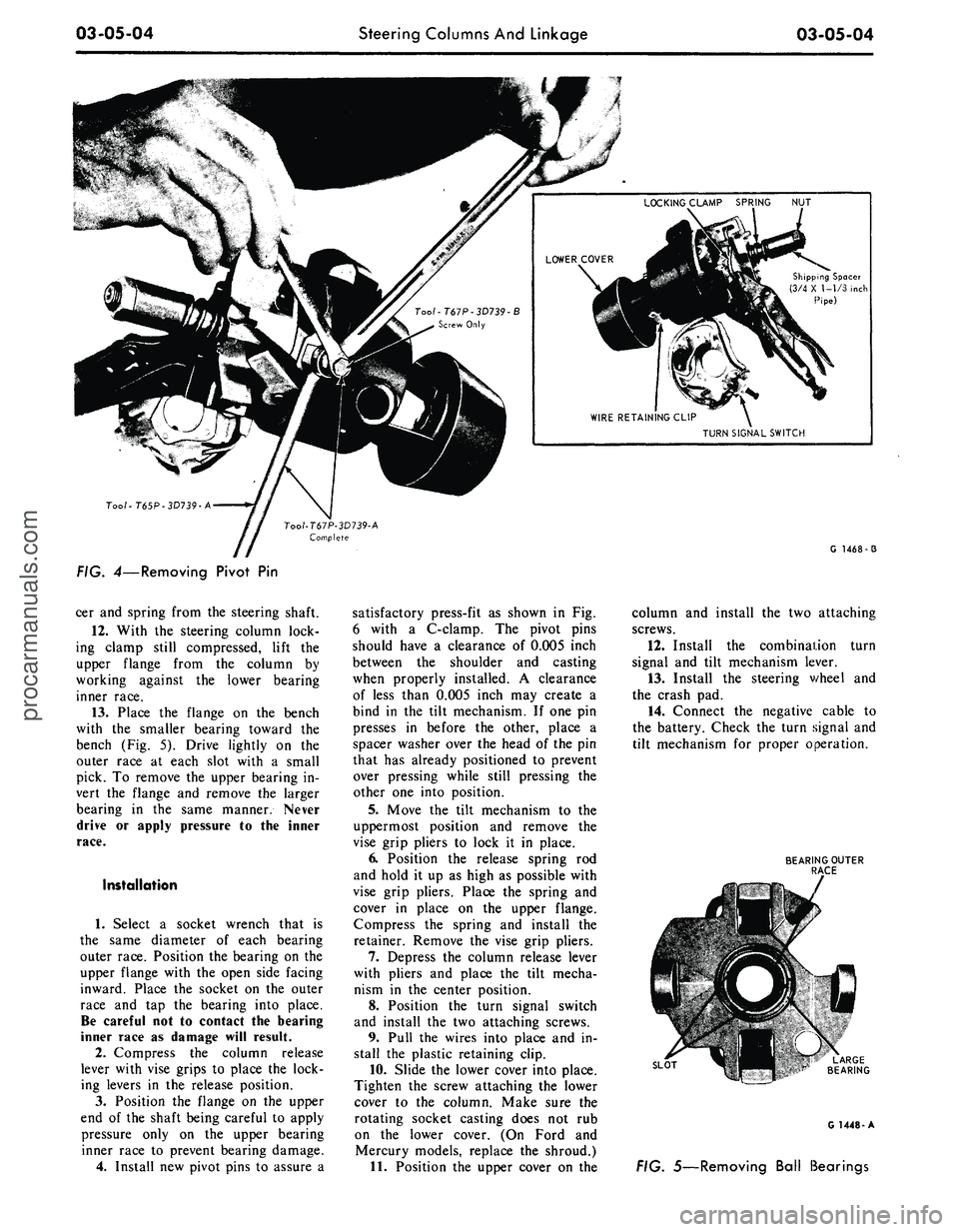

8. Compress the steering column

locking clamp with vise grip pliers

(Fig. 4) and move the steering shaft to

the full up position.

9. Hold the column position spring

rod with vise grip pliers to prevent flo-

tation then compress the spring and

remove the retainer. Remove the plas-

tic cover and spring.

10.

Install tool T67P-3D739-B as

shown in Fig. 4. Thread the bolt in-

ward finger tight until it bottoms, then

back it out one full turn. Make sure

that the handle is centered over the

pivot pin to prevent bolt breakage.

Hold the 3/8 inch bolt head station-

ary, then tighten the nut to extract the

pin. Repeat this operation on the op-

posite pin.

11.

Remove the nut, shipping spa-

UPPER

COVER

J

G 1498-B

FIG. 3—Typical Steering Column—Disassembledprocarmanuals.com

Page 117 of 413

03-05-04

Steering Columns And Linkage

03-05-04

Shipping Spacer

(3/4 X 1-1/3 inch

Pipe)

TURN SIGNAL SWITCH

Too/-T65P-3D739-A

G 1468-3

FIG. 4—Removing Pivot

Pin

cer and spring from the steering shaft.

12.

With

the

steering column lock-

ing clamp still compressed, lift

the

upper flange from

the

column

by

working against

the

lower bearing

inner race.

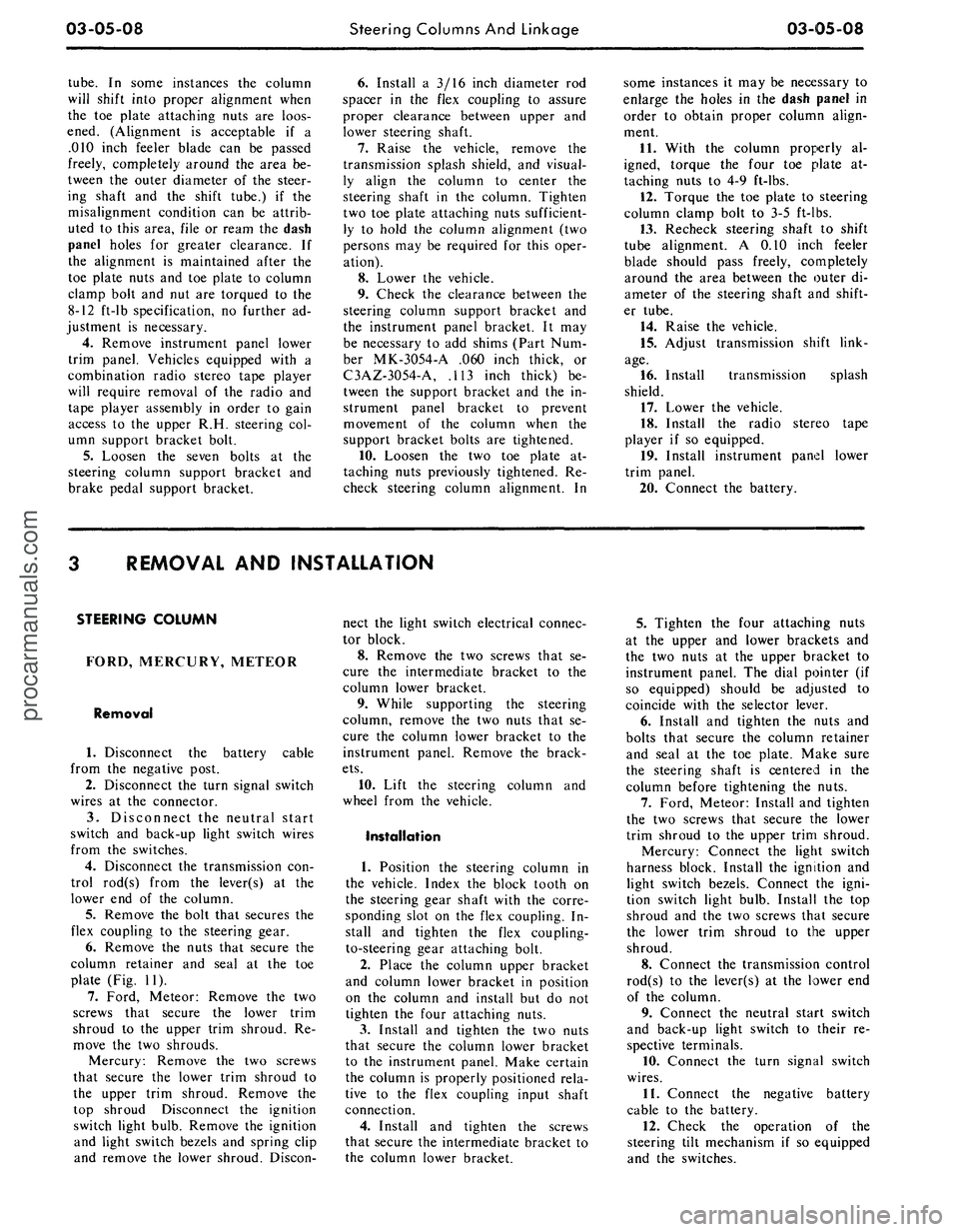

13.

Place

the

flange

on the

bench

with

the

smaller bearing toward

the

bench (Fig.

5).

Drive lightly

on the

outer race

at

each slot with

a

small

pick.

To

remove the upper bearing in-

vert

the

flange

and

remove

the

larger

bearing

in the

same manner. Never

drive

or

apply pressure

to the

inner

race.

Installation

1.

Select

a

socket wrench that

is

the same diameter

of

each bearing

outer race. Position the bearing on the

upper flange with the open side facing

inward. Place

the

socket

on the

outer

race

and tap the

bearing into place.

Be careful not

to

contact

the

bearing

inner race

as

damage will result.

2.

Compress

the

column release

lever with vise grips

to

place the lock-

ing levers

in the

release position.

3.

Position

the

flange

on the

upper

end

of

the shaft being careful

to

apply

pressure only

on the

upper bearing

inner race

to

prevent bearing damage.

4.

Install new pivot pins

to

assure

a

satisfactory press-fit

as

shown

in Fig.

6 with

a

C-clamp.

The

pivot pins

should have

a

clearance

of

0.005 inch

between

the

shoulder

and

casting

when properly installed.

A

clearance

of less than 0.005 inch may create

a

bind

in the

tilt mechanism.

If

one pin

presses

in

before

the

other, place

a

spacer washer over the head

of

the pin

that has already positioned

to

prevent

over pressing while still pressing

the

other one into position.

5.

Move

the

tilt mechanism

to the

uppermost position

and

remove

the

vise grip pliers

to

lock

it in

place.

6. Position

the

release spring

rod

and hold

it

up

as

high

as

possible with

vise grip pliers. Place

the

spring

and

cover

in

place

on the

upper flange.

Compress

the

spring

and

install

the

retainer. Remove the vise grip pliers.

7.

Depress

the

column release lever

with pliers

and

place

the

tilt mecha-

nism

in the

center position.

8. Position

the

turn signal switch

and install

the

two attaching screws.

9. Pull

the

wires into place and

in-

stall

the

plastic retaining clip.

10.

Slide the lower cover into place.

Tighten

the

screw attaching the lower

cover

to the

column. Make sure

the

rotating socket casting does

not rub

on

the

lower cover.

(On

Ford

and

Mercury models, replace

the

shroud.)

11.

Position the upper cover

on the

column

and

install

the

two attaching

screws.

12.

Install

the

combination turn

signal

and

tilt mechanism lever.

13.

Install

the

steering v/heel

and

the crash pad.

14.

Connect

the

negative cable

to

the battery. Check the turn signal and

tilt mechanism

for

proper operation.

BEARING OUTER

RACE

SLOT

G 1448-A

FIG. 5—Removing Ball Bearingsprocarmanuals.com

Page 121 of 413

03-05-08

Steering Columns And Linkage

03-05-08

tube.

In some instances the column

will shift into proper alignment when

the toe plate attaching nuts are loos-

ened. (Alignment is acceptable if a

.010 inch feeler blade can be passed

freely, completely around the area be-

tween the outer diameter of the steer-

ing shaft and the shift tube.) if the

misalignment condition can be attrib-

uted to this area, file or ream the dash

panel holes for greater clearance. If

the alignment is maintained after the

toe plate nuts and toe plate to column

clamp bolt and nut are torqued to the

8-12 ft-lb specification, no further ad-

justment is necessary.

4.

Remove instrument panel lower

trim panel. Vehicles equipped with a

combination radio stereo tape player

will require removal of the radio and

tape player assembly in order to gain

access to the upper R.H. steering col-

umn support bracket bolt.

5.

Loosen the seven bolts at the

steering column support bracket and

brake pedal support bracket.

6. Install a 3/16 inch diameter rod

spacer in the flex coupling to assure

proper clearance between upper and

lower steering shaft.

7.

Raise the vehicle, remove the

transmission splash shield, and visual-

ly align the column to center the

steering shaft in the column. Tighten

two toe plate attaching nuts sufficient-

ly to hold the column alignment (two

persons may be required for this oper-

ation).

8. Lower the vehicle.

9. Check the clearance between the

steering column support bracket and

the instrument panel bracket. It may

be necessary to add shims (Part Num-

ber MK-3054-A .060 inch thick, or

C3AZ-3054-A, .113 inch thick) be-

tween the support bracket and the in-

strument panel bracket to prevent

movement of the column when the

support bracket bolts are tightened.

10.

Loosen the two toe plate at-

taching nuts previously tightened. Re-

check steering column alignment. In

some instances it may be necessary to

enlarge the holes in the dash panel in

order to obtain proper column align-

ment.

11.

With the column properly al-

igned, torque the four toe plate at-

taching nuts to 4-9 ft-lbs.

12.

Torque the toe plate to steering

column clamp bolt to 3-5 ft-lbs.

13.

Recheck steering shaft to shift

tube alignment. A 0.10 inch feeler

blade should pass freely, completely

around the area between the outer di-

ameter of the steering shaft and shift-

er tube.

14.

Raise the vehicle.

15.

Adjust transmission shift link-

age.

16.

Install transmission splash

shield.

17.

Lower the vehicle.

18.

Install the radio stereo tape

player if so equipped.

19.

Install instrument panel lower

trim panel.

20.

Connect the battery.

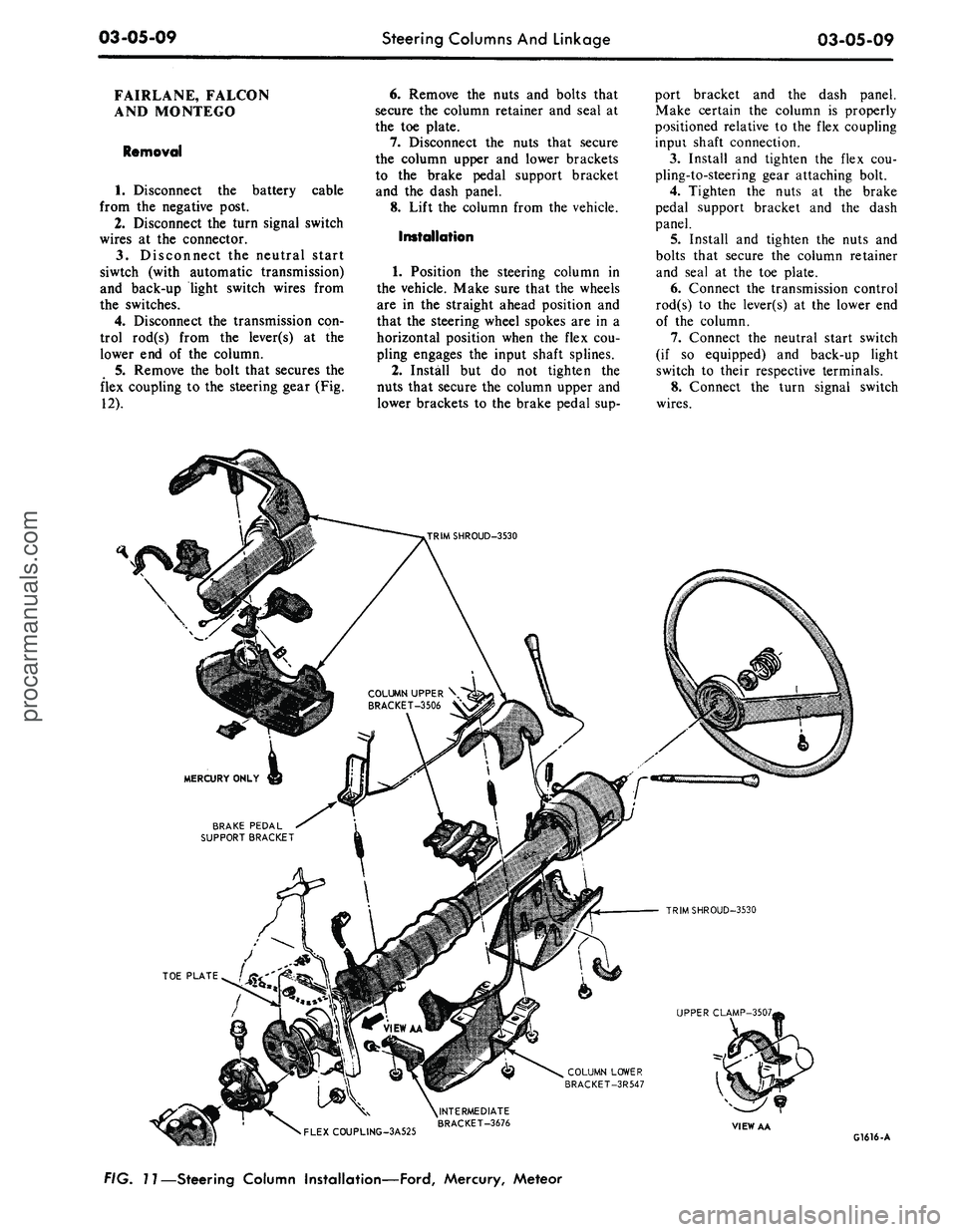

REMOVAL AND INSTALLATION

STEERING COLUMN

FORD, MERCURY, METEOR

Removal

1.

Disconnect the battery cable

from the negative post.

2.

Disconnect the turn signal switch

wires at the connector.

3.

Disconnect the neutral start

switch and back-up light switch wires

from the switches.

4.

Disconnect the transmission con-

trol rod(s) from the lever(s) at the

lower end of the column.

5.

Remove the bolt that secures the

flex coupling to the steering gear.

6. Remove the nuts that secure the

column retainer and seal at the toe

plate (Fig. 11).

7.

Ford, Meteor: Remove the two

screws that secure the lower trim

shroud to the upper trim shroud. Re-

move the two shrouds.

Mercury: Remove the two screws

that secure the lower trim shroud to

the upper trim shroud. Remove the

top shroud Disconnect the ignition

switch light bulb. Remove the ignition

and light switch bezels and spring clip

and remove the lower shroud. Discon-

nect the light switch electrical connec-

tor block.

8. Remove the two screws that se-

cure the intermediate bracket to the

column lower bracket.

9. While supporting the steering

column, remove the two nuts that se-

cure the column lower bracket to the

instrument panel. Remove the brack-

ets.

10.

Lift the steering column and

wheel from the vehicle.

Installation

1.

Position the steering column in

the vehicle. Index the block tooth on

the steering gear shaft with the corre-

sponding slot on the flex coupling. In-

stall and tighten the flex coupling-

to-steering gear attaching bolt.

2.

Place the column upper bracket

and column lower bracket in position

on the column and install but do not

tighten the four attaching nuts.

3.

Install and tighten the two nuts

that secure the column lower bracket

to the instrument panel. Make certain

the column is properly positioned rela-

tive to the flex coupling input shaft

connection.

4.

Install and tighten the screws

that secure the intermediate bracket to

the column lower bracket.

5.

Tighten the four attaching nuts

at the upper and lower brackets and

the two nuts at the upper bracket to

instrument panel. The dial pointer (if

so equipped) should be adjusted to

coincide with the selector lever.

6. Install and tighten the nuts and

bolts that secure the column retainer

and seal at the toe plate. Make sure

the steering shaft is centered in the

column before tightening the nuts.

7.

Ford, Meteor: Install and tighten

the two screws that secure the lower

trim shroud to the upper trim shroud.

Mercury: Connect the light switch

harness block. Install the ignition and

light switch bezels. Connect the igni-

tion switch light bulb. Install the top

shroud and the two screws that secure

the lower trim shroud to the upper

shroud.

8. Connect the transmission control

rod(s) to the lever(s) at the lower end

of the column.

9. Connect the neutral start switch

and back-up light switch to their re-

spective terminals.

10.

Connect the turn signal switch

wires.

11.

Connect the negative battery

cable to the battery.

12.

Check the operation of the

steering tilt mechanism if so equipped

and the switches.procarmanuals.com

Page 122 of 413

03-05-09

Steering Columns And Linkage

03-05-09

FAIRLANE, FALCON

AND MONTEGO

Removal

1.

Disconnect the battery cable

from the negative post.

2.

Disconnect the turn signal switch

wires at the connector.

3.

Disconnect the neutral start

siwtch (with automatic transmission)

and back-up light switch wires from

the switches.

4.

Disconnect the transmission con-

trol rod(s) from the lever(s) at the

lower end of the column.

5.

Remove the bolt that secures the

flex coupling to the steering gear (Fig.

12).

6. Remove the nuts and bolts that

secure the column retainer and seal at

the toe plate.

7.

Disconnect the nuts that secure

the column upper and lower brackets

to the brake pedal support bracket

and the dash panel.

8. Lift the column from the vehicle.

Installation

1.

Position the steering column in

the vehicle. Make sure that the wheels

are in the straight ahead position and

that the steering wheel spokes are in a

horizontal position when the flex cou-

pling engages the input shaft splines.

2.

Install but do not tighten the

nuts that secure the column upper and

lower brackets to the brake pedal sup-

port bracket and the dash panel.

Make certain the column is properly

positioned relative to the flex coupling

inpui shaft connection.

3.

Install and tighten the flex cou-

pling-to-steering gear attaching bolt.

4.

Tighten the nuts at the brake

pedal support bracket and the dash

panel.

5.

Install and tighten the nuts and

bolts that secure the column retainer

and seal at the toe plate.

6. Connect the transmission control

rod(s) to the lever(s) at the lower end

of the column.

7.

Connect the neutral start switch

(if so equipped) and back-up light

switch to their respective terminals.

8. Connect the turn signal switch

wires.

COLUMN UPPER \

BRACKET-3506 V

BRAKE PEDAL

SUPPORT BRACKET

TRIMSHROUD-3530

UPPER CLAMP-3507,

COLUMN LOWER

BRACKET-3R547

•

FLEXCOUPLING-3A525

^INTERMEDIATE

BRACKET-3676

VIEW AA

G1616-A

FIG. 11—Steering Column Installation—Ford, Mercury, Meteorprocarmanuals.com

Page 127 of 413

03-05-14

Steering Columns And Linkage

03-05-14

8. Connect the turn signal and

emergency flasher switch wires at the

multiple connectors. Connect the wires

to the neutral start switch. Adjust-

ments for the neutral start switch are

detailed in Group 7 of this manual.

9. Connect the tilt-column control

cable to the release cable retainer and

vacuum motor (if so equipped). To re-

move cable slack, loosen the bracket

attaching screw and pull it slightly

toward the column, then tighten the

screw. If difficulty in adjusting this

control is experienced, the retainer

slot may be filed to gain additional

travel.

10.

Install the instrument panel

steering column plate and cover and

the instrument panel lower outer fin-

ish panel.

11.

Connect the negative cable to

the battery.

12.

Start the engine and check the

operation of the steering column and

switches.

LINCOLN CONTINENTAL

Removal

1.

Disconnect the battery.

2.

Disconnect the rod from the

lever at the lower end of the selector

tube.

Loosen the clamp bolt that locks

the flexible coupling to the steering

shaft.

3.

Working from the underside of

the steering wheel spoke, remove the

two screws that secure the crash pad.

Remove the pad. Do not use a ham-

mer or knock-off type wheel puller.

Striking the puller or shaft may cause

damage to the bearings and/or col-

lapsible column. Remove the steering

wheel as shown in Fig. 15.

4.

Remove the instrument panel

steering column finish plate.

5.

Remove the four screws that at-

tach the lower retainer to the dash

panel.

6. Disconnect the turn signal switch

and emergency flasher wires at the

connectors. Disconnect the wires from

the neutral start switch.

7.

While supporting the steering

column, remove the bolts that attach

the lower clamp to the upper bracket

(Fig. 15). Lift the column from the ve-

hicle.

Installation

1.

Position the column in the vehi-

cle,

making sure that the steering

shaft engages the flex coupling.

2.

Install the column retainer-

to-dash panel attaching screws, but do

not tighten them.

3.

Install the lower clamp and the

attaching nuts. Tighten the nuts fing-

ertight.

4.

Move the lower flange as re-

quired to center the steering shaft in

the tube. Aligning procedures are de-

tailed in Part 3-1. Tighten the lower

flange attaching nuts when the shaft is

centered.

5.

Connect the shift rod to the shift

lever at the lower end of the column.

6. Install and tighten the flex cou-

pling attaching bolt.

7.

Tighten the instrument panel-

to-clamp attaching nuts.

8. Connect the turn signal and

emergency flasher switch wirss at the

multiple connectors. Connect the wires

to the neutral start switch. Adjust-

ments for the neutral start switch are

detailed in Group 7 of this manual.

9. Install the instrument panel

steering column finish plate.

10.

Install the steering wheel and

crash pad.

MAJOR REPAIR OPERATIONS

STEERING COLUMN

SHIFT TUBE REPLACEMENT

STATIONARY COLUMN

WITH STANDARD

TRANSMISSION

Removal

1.

Working from the underside of

the steering wheel spoke, remove the

two screws that secure the crash pad.

Remove the pad. (On Continental

Mark III models, pry out the crash

pad insert and remove the two screws

that secure the crash pad. Remove the

crash pad. On models equipped with

steering wheel mounted speed con-

trols,

refer to Group 16 for removal

instructions).

2.

Remove the steering wheel from

the steering shaft with tool T67L-

3600-A (Fig. 1). Then, remove the

tool from the steering wheel. Do not

use a knock-off type steering Wheel

puller or strike the end of the steering

shaft with a hammer. Striking the

puller or shaft will damage the bear-

ing or the collapsible column.

3.

Remove the steering column

from the vehicle.

4.

Remove the selector lever from

the hub (Fig. 16).

5.

Remove the bearing upper snap

ring. It may be necessary to pull the

turn signal switch out to remove the

snap ring.

6. Remove the screws that attach

the shift tube bearing, shift arms, and

shift tube to the lower end of the

steering column.

7.

Slip the shift tube and steering

shaft from the lower end of the steer-

ing column tube. The upper bearing

has a slight press fit on the steering

shaft.

8. Remove the C-washer from the

upper end of the steering shaft, and

pull the shift tube from the steering

shaft.

9. Remove the shift tube bearing

from the lower end of the tube

Installation

1.

Position the shift tube bearing

(Fig. 16) on the tube and insert the

steering shaft in the shift tube.

2.

Install the C-washer on the

upper end of the steering shaft.

3.

Insert the shift tube and steering

shaft into the steerint column tube

and install the three attaching screws

at the lower end of the steering col-

umn tube.

4.

Position the bearing and insula-

tor on the shaft if it was disturbed

during removal. Work it down onto

the shaft as far as possible, then place

a piece of 3/4 ID x 2 1/8 inch pipe

over the end of shaft and install the

steering wheel attaching nut (Fig. 2).

5.

Tighten the nut until the bearing

is seated in the flange, then remove

the nut and pipe from the shaft.

6. Position the turn signal switch

on the flange and install the three at-

taching screws. Install the upper snap

ring.

7.

Install the selector lever and the

turn signal lever in the column.

8. Adjust and install the neutral

start switch as detailed in Group 7.

9. Install the steering column in the

vehicle.procarmanuals.com

Page 137 of 413

03-06-03

Manual Steering

03-06-03

MAJOR REPAIR OPERATIONS

STEERING GEAR

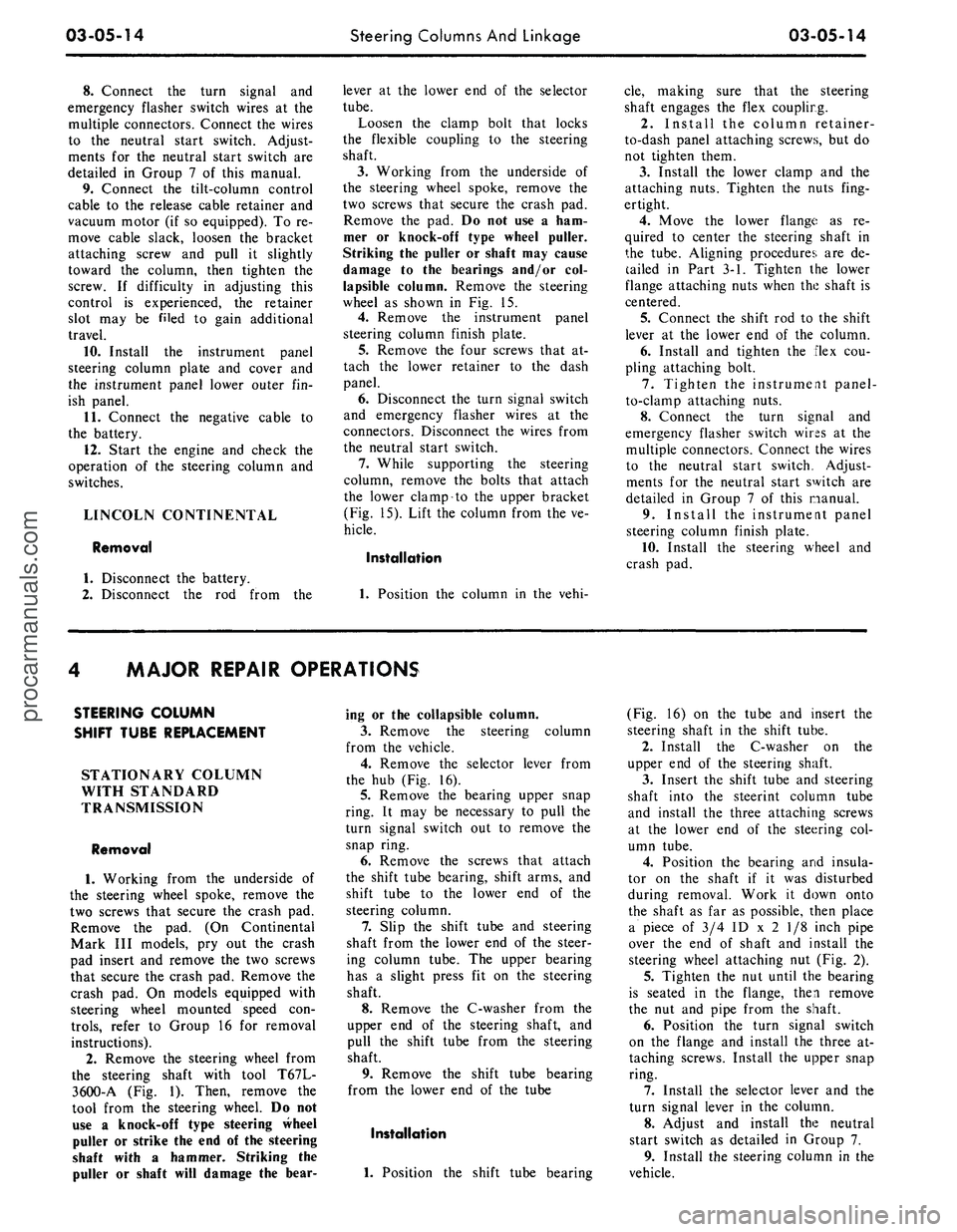

DISASSEMBLY

1. Rotate the steering shaft 3 turns

from either stop.

2.

After removing the sector adjust-

ing screw locknut and the housing

cover bolts (Fig. 6), remove the sector

shaft with the cover. Remove the

cover from the shaft by turning the

screw clockwise. Keep the shim with

the screw.

HOUSING

•

3548

6. Turn the ball nut over, and ro-

tate the worm shaft from side to side

until all 50 balls have dropped out of

the nut into a clean pan. With the

balls removed, the ball nut will slide

off the worm.

7. Remove the upper bearing cup

from the bearing adjuster and the

lower cup from the housing. It may be

necessary to tap the housing or the

adjuster on a block of wood to jar the

bearing cups loose.

8. If the preliminary inspection

GASKET

• 3581

SHIM-3A657 COVER

AND

BUSHING

•

3583

SECTOR SHAFT

ADJUSTING SCREW

.

3577

•BEARING-3576

SEAL

- 3591

G 1623-A

FIG. 6—Sector Shaft

and

Housing Disassembled

-^-HOUSING-3548

BEARING

CUP •

3552

BALL

NUT

BEARING-3571

FILLER PLUG-3556

LOCK NUT-3707

3524 BEARING

CUP \

SEAL-3738

•GUIDE -3523

• BEARINGS

•

3647

.CLAMP-3544

BEARING

• 3571

G 1624-A

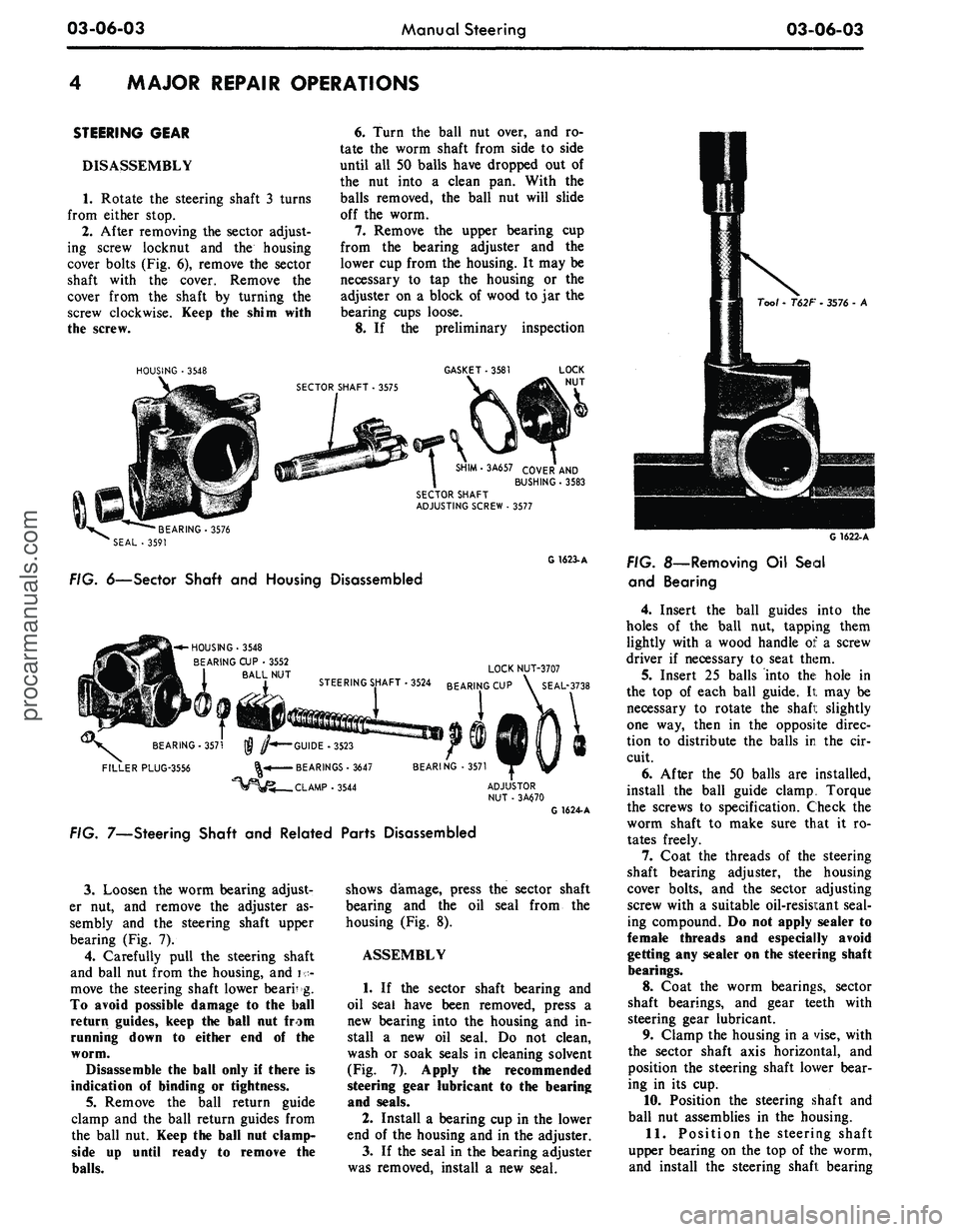

FIG. 7—Steering Shaft

and

Related Parts Disassembled

3.

Loosen the worm bearing adjust-

er nut, and remove the adjuster as-

sembly and the steering shaft upper

bearing (Fig. 7).

4.

Carefully pull the steering shaft

and ball nut from the housing, and i •-

move the steering shaft lower bearr g.

To avoid possible damage to the ball

return guides, keep

the

ball

nut

from

running down

to

either

end of the

worm.

Disassemble

the

ball only

if

there

is

indication

of

binding

or

tightness.

5.

Remove the ball return guide

clamp and the ball return guides from

the ball

nut.

Keep

the

ball

nut

clamp-

side up until ready to remove the

balls.

shows damage, press the sector shaft

bearing and the oil seal from the

housing (Fig. 8).

ASSEMBLY

1. If the sector shaft bearing and

oil seal have been removed, press a

new bearing into the housing and in-

stall a new oil seal. Do not clean,

wash or soak seals in cleaning solvent

(Fig.

7).

Apply

the

recommended

steering gear lubricant

to the

bearing

and seals.

2.

Install a bearing cup in the lower

end of the housing and in the adjuster.

3.

If the seal in the bearing adjuster

was removed, install a new seal.

Tool

-

T62F

•

3576

- A

G 1622-A

FIG.

8—Removing

Oil

Seal

and Bearing

4.

Insert the ball guides into the

holes of the ball nut, tapping them

lightly with a wood handle of a screw

driver if necessary to seat them.

5.

Insert 25 balls into the hole in

the top of each ball guide. It may be

necessary to rotate the shafi: slightly

one way, then in the opposite direc-

tion to distribute the balls in the cir-

cuit.

6. After the 50 balls are installed,

install the ball guide clamp. Torque

the screws to specification. Check the

worm shaft to make sure that it ro-

tates freely.

7. Coat the threads of the steering

shaft bearing adjuster, the housing

cover bolts, and the sector adjusting

screw with a suitable oil-resisi:ant seal-

ing compound. Do not apply sealer to

female threads and especially avoid

getting any sealer on the steering shaft

bearings.

8.

Coat the worm bearings, sector

shaft bearings, and gear teeth with

steering gear lubricant.

9. Clamp the housing in a vise, with

the sector shaft axis horizontal, and

position the steering shaft lower bear-

ing in its cup.

10.

Position the steering shaft and

ball nut assemblies in the housing.

11.

Position the steering shaft

upper bearing on the top of the worm,

and install the steering shaft bearingprocarmanuals.com