light FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 144 of 413

03-07-06

Ford Design Non-Integral Power Steering System

03-07-06

VALVE HOUSING

VALVE SPOOL

G

1659-

A

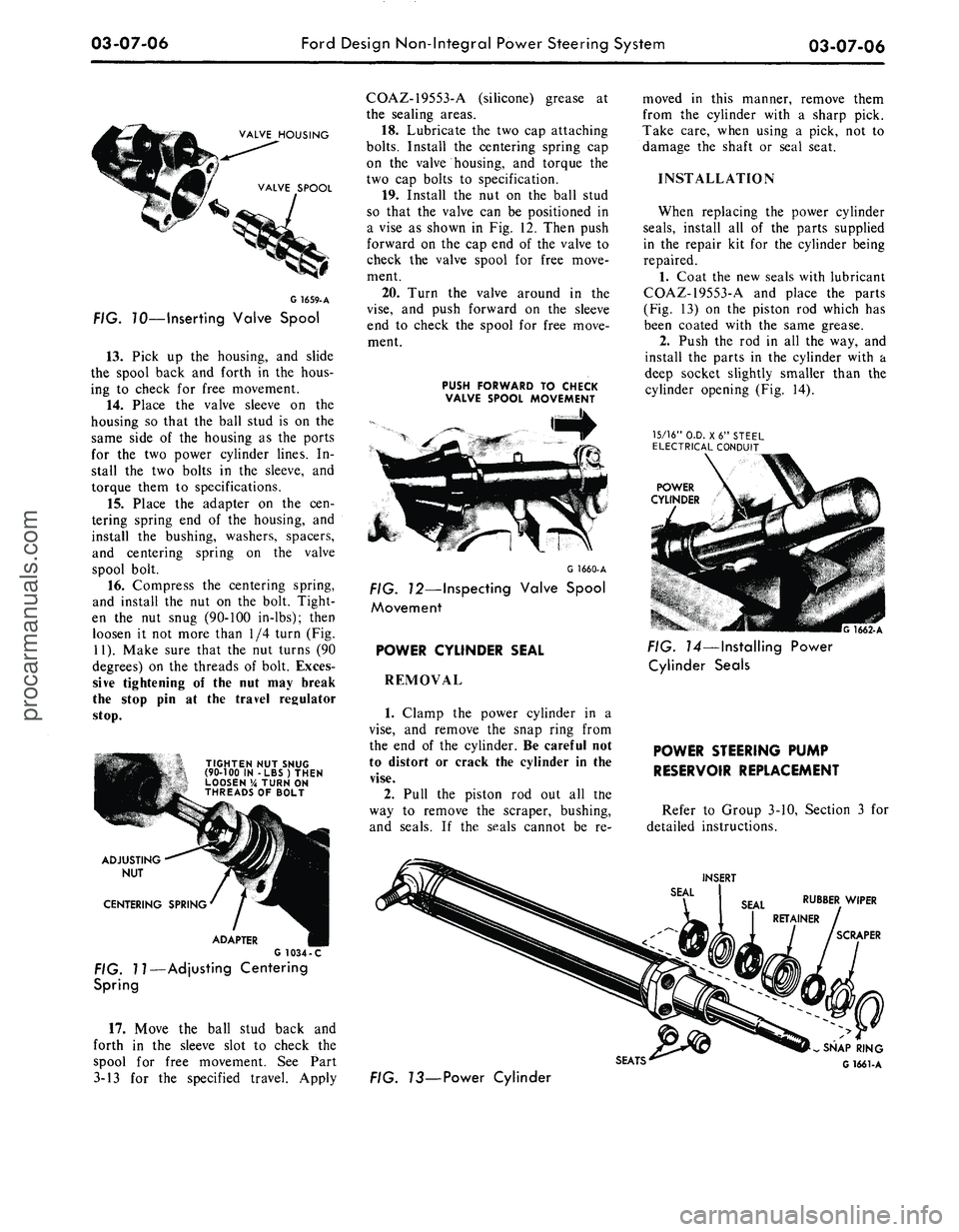

FIG. 70—Inserting Valve Spool

13.

Pick up the housing, and slide

the spool back and forth in the hous-

ing to check for free movement.

14.

Place the valve sleeve on the

housing so that the ball stud is on the

same side of the housing as the ports

for the two power cylinder lines. In-

stall the two bolts in the sleeve, and

torque them to specifications.

15.

Place the adapter on the cen-

tering spring end of the housing, and

install the bushing, washers, spacers,

and centering spring on the valve

spool bolt.

16.

Compress the centering spring,

and install the nut on the bolt. Tight-

en the nut snug (90-100 in-lbs); then

loosen it not more than 1/4 turn (Fig.

11).

Make sure that the nut turns (90

degrees) on the threads of bolt. Exces-

sive tightening of the nut may break

the stop pin at the travel regulator

stop.

TIGHTEN NUT SNUG

(90-100 IN -LBS) THEN

LOOSEN % TURN ON

THREADS OF BOLT

ADJUSTING

NUT

CENTERING SPRING

ADAPTER

G 1034 -C

FIG. 11—Adjusting Centering

Spring

17.

Move the ball stud back and

forth in the sleeve slot to check the

spool for free movement. See Part

3-13 for the specified travel. Apply

COAZ-19553-A (silicone) grease at

the sealing areas.

18.

Lubricate the two cap attaching

bolts.

Install the centering spring cap

on the valve housing, and torque the

two cap bolts to specification.

19.

Install the nut on the ball stud

so that the valve can be positioned in

a vise as shown in Fig. 12. Then push

forward on the cap end of the valve to

check the valve spool for free move-

ment.

20.

Turn the valve around in the

vise,

and push forward on the sleeve

end to check the spool for free move-

ment.

PUSH FORWARD TO CHECK

VALVE SPOOL MOVEMENT

G 1660-A

FIG. 12—Inspecting Valve Spool

Movement

POWER CYLINDER SEAL

REMOVAL

1.

Clamp the power cylinder in a

vise,

and remove the snap ring from

the end of the cylinder. Be careful not

to distort or crack the cylinder in the

vise.

2.

Pull the piston rod out all the

way to remove the scraper, bushing,

and seals. If the seals cannot be re-

moved in this manner, remove them

from the cylinder with a sharp pick.

Take care, when using a pick, not to

damage the shaft or seal seat.

INSTALLATION

When replacing the power cylinder

seals,

install all of the parts supplied

in the repair kit for the cylinder being

repaired.

1.

Coat the new seals with lubricant

COAZ-19553-A and place the parts

(Fig. 13) on the piston rod which has

been coated with the same grease.

2.

Push the rod in all the way, and

install the parts in the cylinder with a

deep socket slightly smaller than the

cylinder opening (Fig. 14).

15/16"

O.D. X6" STEEL

ELECTRICAL CONDUIT

POWER

CYLINDER

G 1662-A

FIG. 14—Installing Power

Cylinder Seals

POWER STEERING PUMP

RESERVOIR REPLACEMENT

Refer to Group 3-10, Section 3 for

detailed instructions.

INSERT

RUBBER WIPER

SCRAPER

SEATS'

FIG. 73—Power Cylinder

SNAP RING

G 1661-Aprocarmanuals.com

Page 145 of 413

03-08-01

Ford Design Integral Power Steering Gear

03-08-01

PART

3-8

Ford Design Integral Power

Steering Gear

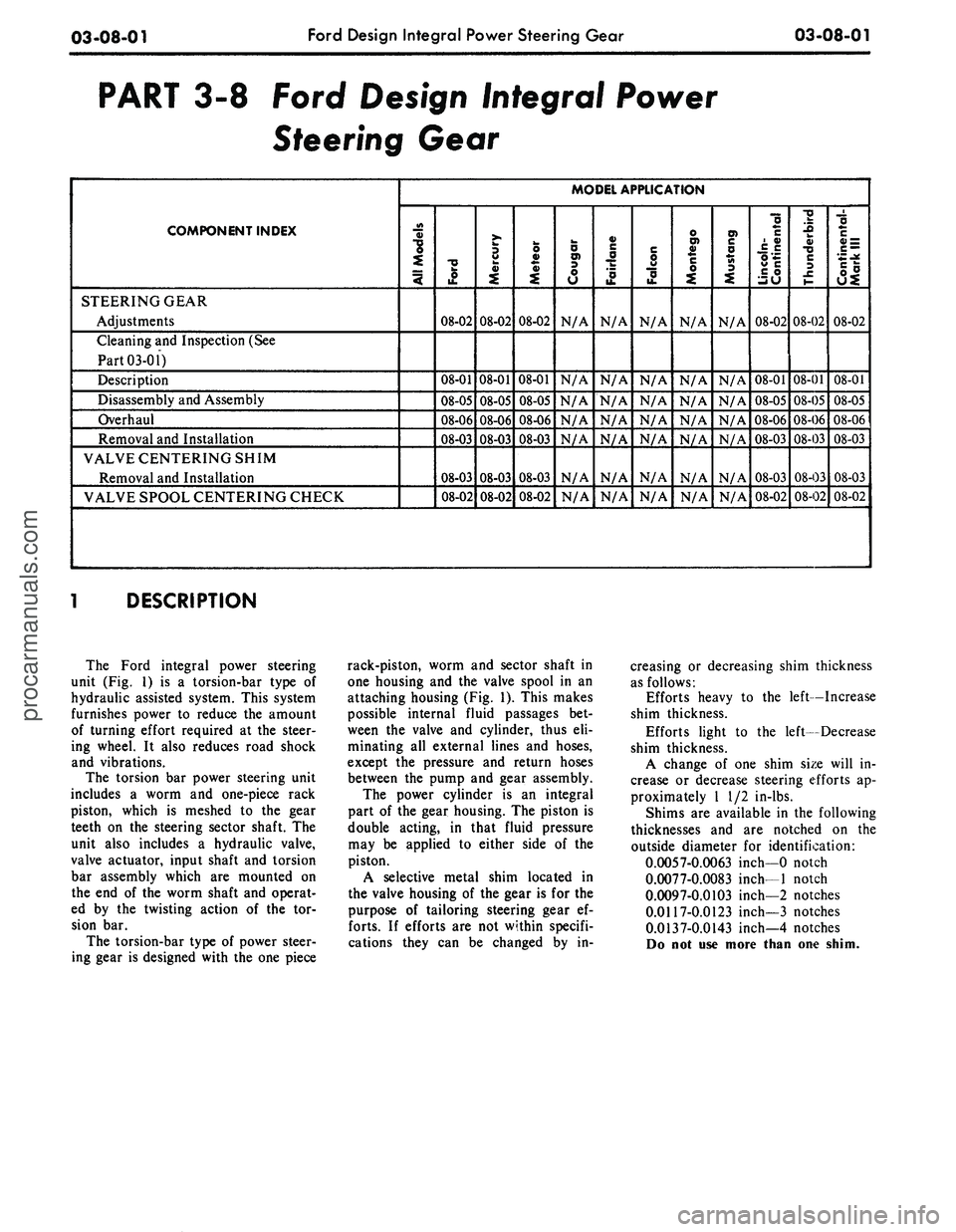

COMPONENT INDEX

STEERING GEAR

Adjustments

Cleaning

and

Inspection

(See

Part 03-01)

Description

Disassembly

and

Assembly

Overhaul

Removal

and

Installation

VALVE CENTERING SHIM

Removal

and

Installation

VALVE SPOOL CENTERING CHECK

MODEL APPLICATION

All Models

Ford

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Mercury

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Meteor

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Cougar

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Fairlane

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Falcon

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Montego

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Mustang

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Lincoln-

Continental

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Thunderbird

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Continental-

Mark

III

08-02

08-01

08-05

08-06

08-03

08-03

08-02

DESCRIPTION

The Ford integral power steering

unit

(Fig. 1) is a

torsion-bar type

of

hydraulic assisted system. This system

furnishes power

to

reduce

the

amount

of turning effort required

at the

steer-

ing wheel.

It

also reduces road shock

and vibrations.

The torsion

bar

power steering unit

includes

a

worm

and

one-piece rack

piston, which

is

meshed

to the

gear

teeth

on the

steering sector shaft.

The

unit also includes

a

hydraulic valve,

valve actuator, input shaft

and

torsion

bar assembly which

are

mounted

on

the

end of the

worm shaft

and

operat-

ed

by the

twisting action

of the tor-

sion

bar.

The torsion-bar type

of

power steer-

ing gear

is

designed with

the one

piece

rack-piston, worm

and

sector shaft

in

one housing

and the

valve spool

in an

attaching housing

(Fig. 1).

This makes

possible internal fluid passages

bet-

ween

the

valve

and

cylinder, thus

eli-

minating

all

external lines

and

hoses,

except

the

pressure

and

return hoses

between

the

pump

and

gear assembly.

The power cylinder

is an

integral

part

of the

gear housing.

The

piston

is

double acting,

in

that fluid pressure

may

be

applied

to

either side

of the

piston.

A selective metal shim located

in

the valve housing

of the

gear

is for the

purpose

of

tailoring steering gear

ef-

forts.

If

efforts

are not

within specifi-

cations they

can be

changed

by in-

creasing

or

decreasing shim thickness

as follows:

Efforts heavy

to the

left—Increase

shim thickness.

Efforts light

to the

left—Decrease

shim thickness.

A change

of one

shim size will

in-

crease

or

decrease steering efforts

ap-

proximately

1 1/2

in-lbs.

Shims

are

available

in the

following

thicknesses

and are

notched

on the

outside diameter

for

identification:

0.0057-0.0063 inch—0 notch

0.0077-0.0083 inch—1 notch

0.0097-0.0103 inch—2 notches

0.0117-0.0123 inch—3 notches

0.0137-0.0143 inch—4 notches

Do

not use

more than

one

shim.

procarmanuals.com

Page 146 of 413

03-08-02

Ford Design Integral Power Steering Gear

03-08-02

-INPUT SHAFT

OUTLET PORT

INLET PORT

CONTROL VALVE HOUSING

SECTOR SHAFT COVER

SECTOR SHAFT ADJUSTMENT SCREW

LOCK NUT

IDENTIFICATION TAG

SECTOR SHAFT

FIG.

1—Power

Steering Gear

G1545- A

IN-VEH1CLE ADJUSTMENTS AND REPAIRS

VALVE SPOOL

CENTERING CHECK

1.

Install a 0-2000 psi pressure

gauge Tool T56L-33610-D in the pres-

sure line between the power steering

pump outlet port and the integral

steering gear inlet port.

2.

Make sure that the valve on the

gauge is in the fully open position.

3.

Check the fluid level in the reser-

voir and fill it to proper level with the

specified fluid.

4.

Start the engine and cycle the

steering wheel from stop-to-stop, to

bring the steering lubricant up to nor-

mal operating temperature. Stop the

engine and recheck the reservoir. Add

fluid if necessary.

5.

With the engine running at ap-

proximately 1000 rpm and the steer-

ing wheel centered, attach an inch-

pound torque wrench to the steering

wheel retaining nut. Apply sufficient

torque to the torque wrench in each

direction, either side of center, to get

a gauge reading of 250 psi.

6. The torque reading should be the

same in both directions when 250 psi

is reached. If the difference between

the readings exceeds 4 in-lbs, the

steering gear must be removed and the

valve centering shim removed from the

valve housing and a thicker or thinner

shim installed. Only one shim is to be

used. If the steering effort is heavy,

the shim thickness should be in-

creased. Shim thickness should be de-

creased if the steering effort is light to

the left.

The out of vehicle procedure for

valve centering check is the same as

for the in vehicle except the torque

and simultaneous pressure reading

must be made at the right and left

stops instead of either side of center.

STEERING GEAR

ADJUSTMENTS

During the vehicle breaking-in peri-

od, it is probable that some of theprocarmanuals.com

Page 150 of 413

03-08-06

Ford Design Integral Power Steering Gear

03-08-06

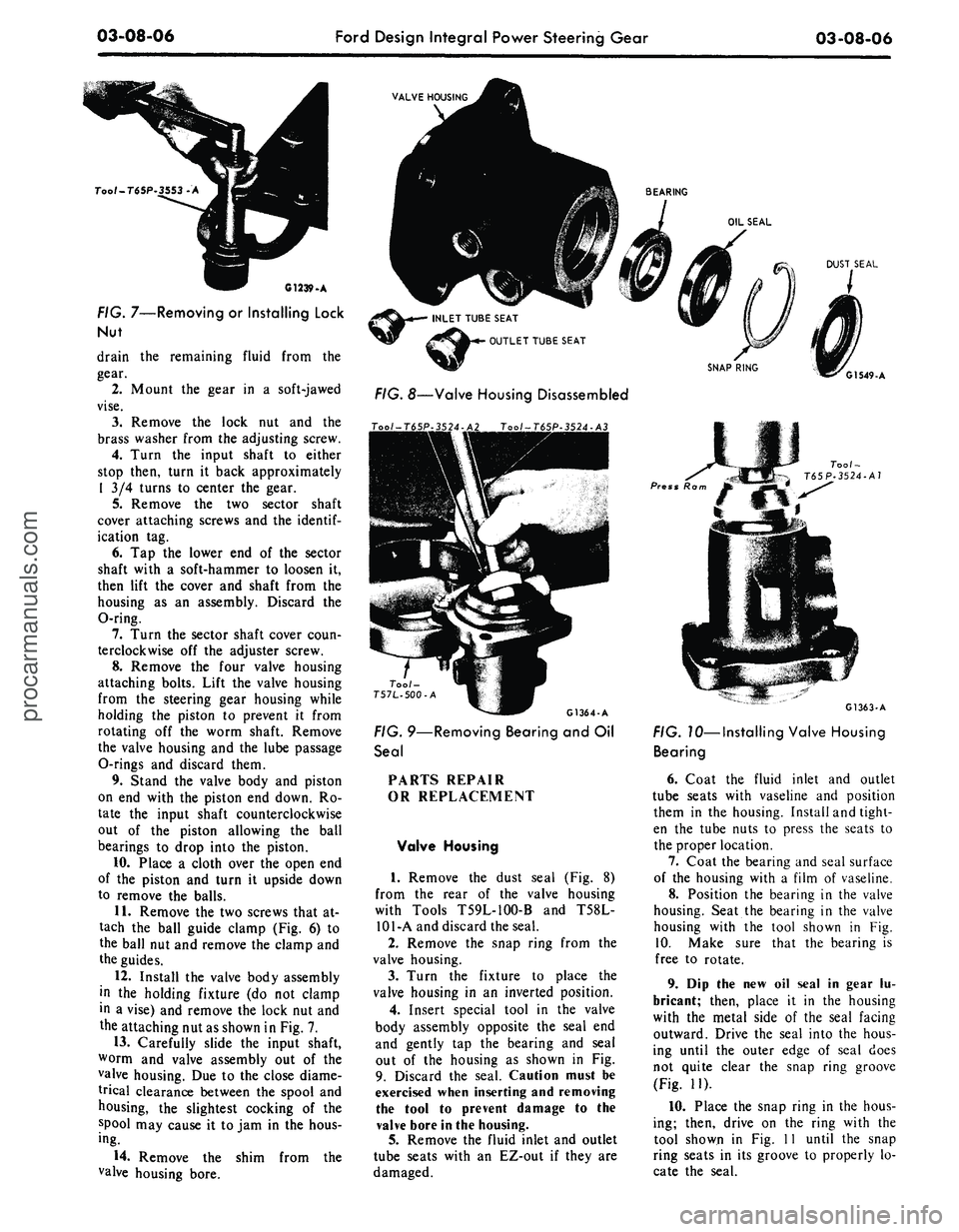

VALVE HOUSING

7W-T65P

C1239 -A

FIG. 7—Removing or Installing Lock

Nut

drain the remaining fluid from the

gear.

2.

Mount the gear in a soft-jawed

vise.

3.

Remove the lock nut and the

brass washer from the adjusting screw.

4.

Turn the input shaft to either

stop then, turn it back approximately

1 3/4 turns to center the gear.

5.

Remove the two sector shaft

cover attaching screws and the

identif-

ication tag.

6. Tap the lower end of the sector

shaft with a soft-hammer to loosen it,

then lift the cover and shaft from the

housing as an assembly. Discard the

O-ring.

7.

Turn the sector shaft cover coun-

terclockwise off the adjuster screw.

8. Remove the four valve housing

attaching bolts. Lift the valve housing

from the steering gear housing while

holding the piston to prevent it from

rotating off the worm shaft. Remove

the valve housing and the lube passage

O-rings and discard them.

9. Stand the valve body and piston

on end with the piston end down. Ro-

tate the input shaft counterclockwise

out of the piston allowing the ball

bearings to drop into the piston.

10.

Place a cloth over the open end

of the piston and turn it upside down

to remove the balls.

11.

Remove the two screws that at-

tach the ball guide clamp (Fig. 6) to

the ball nut and remove the clamp and

the guides.

12.

Install the valve body assembly

in the holding fixture (do not clamp

in a vise) and remove the lock nut and

the attaching nut as shown in Fig. 7.

13.

Carefully slide the input shaft,

worm and valve assembly out of the

valve housing. Due to the close diame-

trical clearance between the spool and

housing, the slightest cocking of the

spool may cause it to jam in the hous-

ing.

14.

Remove the shim from the

valve housing bore.

OIL SEAL

INLET TUBE SEAT

OUTLET TUBE SEAT

DUST SEAL

G1549-A

FIG.

8—Valve Housing Disassembled

Too/-T<

Tool-

T57L-500-A ,^^^

G1364-A

FIG. 9—Removing Bearing and Oil

Seal

PARTS REPAIR

OR REPLACEMENT

Valve Housing

1.

Remove the dust seal (Fig. 8)

from the rear of the valve housing

with Tools T59L-100-B and T58L-

101-A and discard the seal.

2.

Remove the snap ring from the

valve housing.

3.

Turn the fixture to place the

valve housing in an inverted position.

4.

Insert special tool in the valve

body assembly opposite the seal end

and gently tap the bearing and seal

out of the housing as shown in Fig.

9. Discard the seal. Caution must be

exercised when inserting and removing

the tool to prevent damage to the

valve bore in the housing.

5.

Remove the fluid inlet and outlet

tube seats with an EZ-out if they are

damaged.

Press Ra

Tool-

T65P-3524-A7

G1363-A

FIG. 10—Installing Valve Housing

Bearing

6. Coat the fluid inlet and outlet

tube seats with vaseline and position

them in the housing. Install and tight-

en the tube nuts to press the seats to

the proper location.

7.

Coat the bearing and seal surface

of the housing with a film of vaseline.

8. Position the bearing in the valve

housing. Seat the bearing in the valve

housing with the tool shown in Fig.

10.

Make sure that the bearing is

free to rotate.

9. Dip the new oil seal in gear lu-

bricant; then, place it in the housing

with the metal side of the seal facing

outward. Drive the seal into the hous-

ing until the outer edge of seal does

not quite clear the snap ring groove

(Fig. 11).

10.

Place the snap ring in the hous-

ing; then, drive on the ring with the

tool shown in Fig. 11 until the snap

ring seats in its groove to properly lo-

cate the seal.procarmanuals.com

Page 151 of 413

03-08-07

Ford Design Integral Power Steering Gear

03-08-07

Press Ram

Tool-

T65P.3524-A1

G1362-A

FIG.

17—Installing

Oil Seal in

Valve Housing

11.

Place the dust seal in the hous-

ing with the dished side (rubber side)

facing out. Drive the dust seal into

place with the tool shown in Fig. 11.

the seal must be located behind the

undercut in the input shaft when it is

installed.

Worm and Valve

1.

Remove the snap ring from the

end of the actuator.

2.

Slide the control valve spool

(Fig. 6) off the actuator.

3.

Install the valve spool evenly and

slowly with a slight oscillating motion

into the flanged end of valve housing

with the Valve identification groove

between the valve spool lands out-

ward, checking for freedom of valve

movement within the housing working

area. The valve spool should enter the

housing bore freely and fall by its own

weight.

4.

If the valve spool is not free,

check for burrs at the outward edges

of the working lands in the housing

and remove with a hard stone.

5.

Check the valve for burrs and if

burrs are found, stone the valve in a

radial direction only. Check for free-

dom of the valve again.

6. Remove the valve spool from the

housing.

7.

Slide the spool onto the actuator

making, sure that the groove in the

spool annulus is toward the worm.

8. Install the snap ring to retain the

spool.

9. Check the clearance between the

spool and the snap ring. The clearance

should be between 0.002-0.005 inch. If

the clearance is not within these lim-

its,

select a snap ring that will allow a

clearance of 0.003 inch.

STEERING GEAR HOUSING

J

UPPER SEAL

I LOWER SEAL

SNAP RING

SPACER WASHER

FIG. 12—Steering Gear Housing Disassembled

Tool - T59L - 100-B

Tool T57L-500 - A

G1551-A

FIG. 13—Removing Lower Seal

Piston and Ball Nut

1.

Remove the teflon ring and the

O-ring (Fig. 7) from the piston and

ball nut.

2.

Dip a new O-ring in gear lubri-

cant and install it on the piston and

ball nut.

3.

Install a new teflon ring on the

piston and ball nut being careful not

to stretch it any more than necessary.

Steering Gear Housing

1.

Remove the snap ring and the

spacer washer (Fig. 12) from the

lower end of the steering gear housing.

2.

Remove the lower seal from the

housing as shown in Fig. 13. Lift the

spacer washer from the housing.

3.

Remove the upper seal in the

same manner as the lower seal.

4.

Dip both sector shaft seals in

gear lubricant.

SHORT END

AWAY

FROM SEAL

G1550-A

Press Rom

G1374-A

FIG. 14—Installing Sector Shaft

Inner Seal

5. Apply Lubricant to the sector

shaft seal bore of the housing and

position the sector shaft inner seal

into the housing with the lip facing in-

ward. Press the seal into place with

the tool shown in Fig. 14. Place a spa-

cer washer (0.090 inch) on top of the

seal and apply more Lubricant to the

housing bore.

6. Place the outer seal in the hous-

ing with the lip facing inward and

press it into place as shown in Fig. 15.

Then, place a 0.090 inch spacer wash-

er on top of the seal.

7.

Position the snap ring in the

housing. Press the snap ring into the

housing with the tool shown in Fig. 15

to properly locate the seals and en-

gage the snap ring in the groove.

STEERING GEAR

ASSEMBLY

Do not clean, wash, or soak seals in

cleaning solvent.procarmanuals.com

Page 158 of 413

03-09-06

Saginaw Design Integral Power Steering Gear

03-09-06

ADJUSTER

PLUG

DUST

SEAL

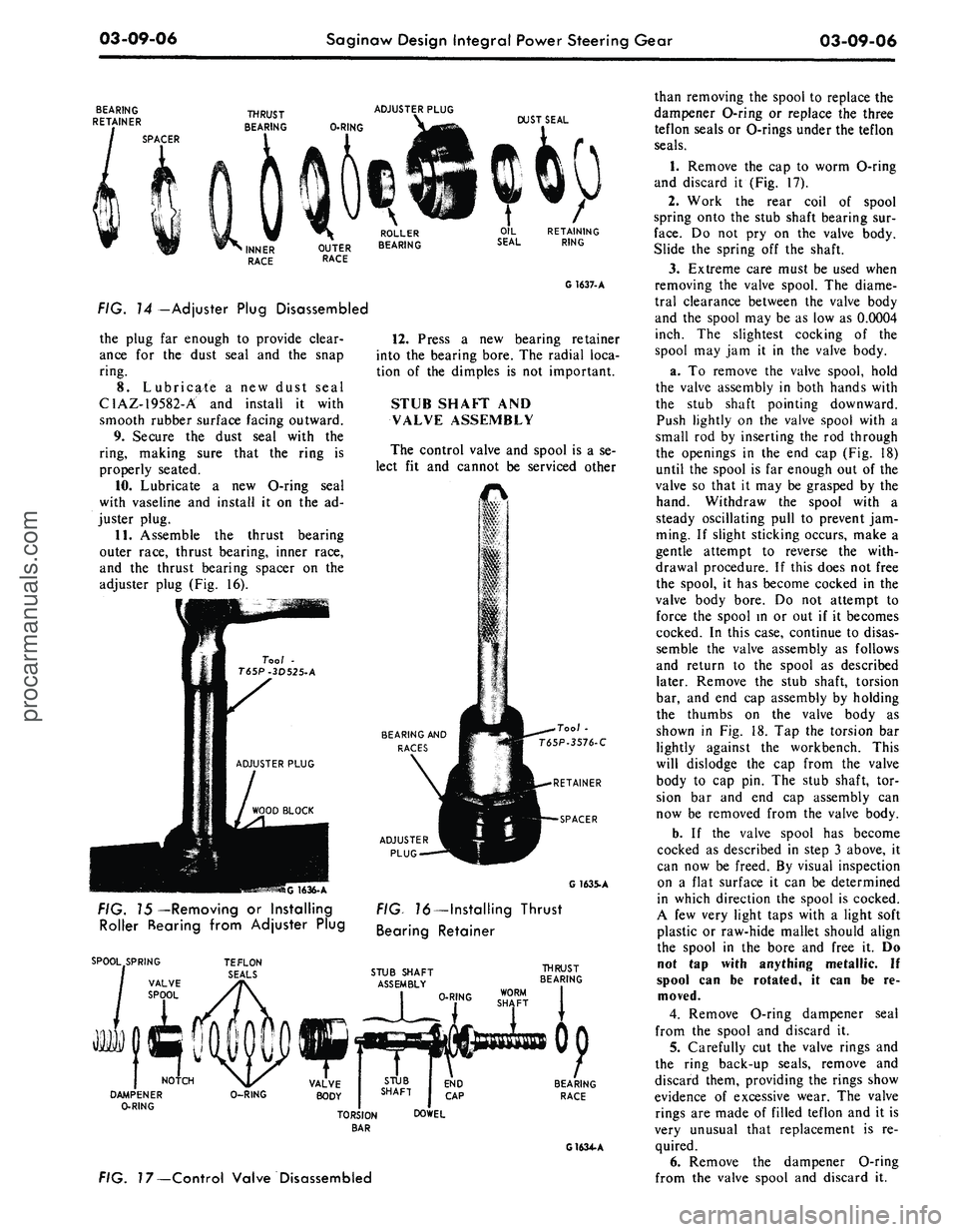

FIG. 14 —Adjuster Plug Disassembled

the plug far enough to provide clear-

ance for the dust seal and the snap

ring.

8. Lubricate a new dust seal

C1AZ-19582-A and install it with

smooth rubber surface facing outward.

9. Secure the dust seal with the

ring, making sure that the ring is

properly seated.

10.

Lubricate a new O-ring seal

with vaseline and install it on the ad-

juster plug.

11.

Assemble the thrust bearing

outer race, thrust bearing, inner race,

and the thrust bearing spacer on the

adjuster plug (Fig. 16).

OIL

RETAINING

SEAL

RING

G

1637-A

12.

Press a new bearing retainer

into the bearing bore. The radial loca-

tion of the dimples is not important.

STUB SHAFT AND

VALVE ASSEMBLY

The control valve and spool is a se-

lect fit and cannot be serviced other

BEARING

AND

RACES

1636-A

FIG. 15 —Removing or Installing

Roller Rearing from Adjuster Plug

G

1635-A

FIG.

76

—Installing Thrust

Bearing Retainer

SPOOL

SPRING

DOWEL

BEARING

RACE

G1634-A

FIG. 77—Control Valve Disassembled

than removing the spool to replace the

dampener O-ring or replace the three

teflon seals or O-rings under the teflon

seals.

1.

Remove the cap to worm O-ring

and discard it (Fig. 17).

2.

Work the rear coil of spool

spring onto the stub shaft bearing sur-

face.

Do not pry on the valve body.

Slide the spring off the shaft.

3.

Extreme care must be used when

removing the valve spool. The diame-

tral clearance between the valve body

and the spool may be as low as 0.0004

inch. The slightest cocking of the

spool may jam it in the valve body.

a. To remove the valve spool, hold

the valve assembly in both hands with

the stub shaft pointing downward.

Push lightly on the valve spool with a

small rod by inserting the rod through

the openings in the end cap (Fig. 18)

until the spool is far enough out of the

valve so that it may be grasped by the

hand. Withdraw the spool with a

steady oscillating pull to prevent jam-

ming. If slight sticking occurs, make a

gentle attempt to reverse the with-

drawal procedure. If this does not free

the spool, it has become cocked in the

valve body bore. Do not attempt to

force the spool in or out if it becomes

cocked. In this case, continue to disas-

semble the valve assembly as follows

and return to the spool as described

later. Remove the stub shaft, torsion

bar, and end cap assembly by holding

the thumbs on the valve body as

shown in Fig. 18. Tap the torsion bar

lightly against the workbench. This

will dislodge the cap from the valve

body to cap pin. The stub shaft, tor-

sion bar and end cap assembly can

now be removed from the valve body.

b.

If the valve spool has become

cocked as described in step 3 above, it

can now be freed. By visual inspection

on a flat surface it can be determined

in which direction the spool is cocked.

A few very light taps with a light soft

plastic or raw-hide mallet should align

the spool in the bore and free it. Do

not tap with anything metallic. If

spool can be rotated, it can be re-

moved.

4.

Remove O-ring dampener seal

from the spool and discard it.

5.

Carefully cut the valve rings and

the ring back-up seals, remove and

discard them, providing the rings show

evidence of excessive wear. The valve

rings are made of filled teflon and it is

very unusual that replacement is re-

quired.

6. Remove the dampener O-ring

from the valve spool and discard it.procarmanuals.com

Page 159 of 413

03-09-07

Saginaw Design Integral Power Steering Gear

03-09-07

VALVE SPOOL

DAMP EN

ERO-RING

TORSION BAR

G 1633-A

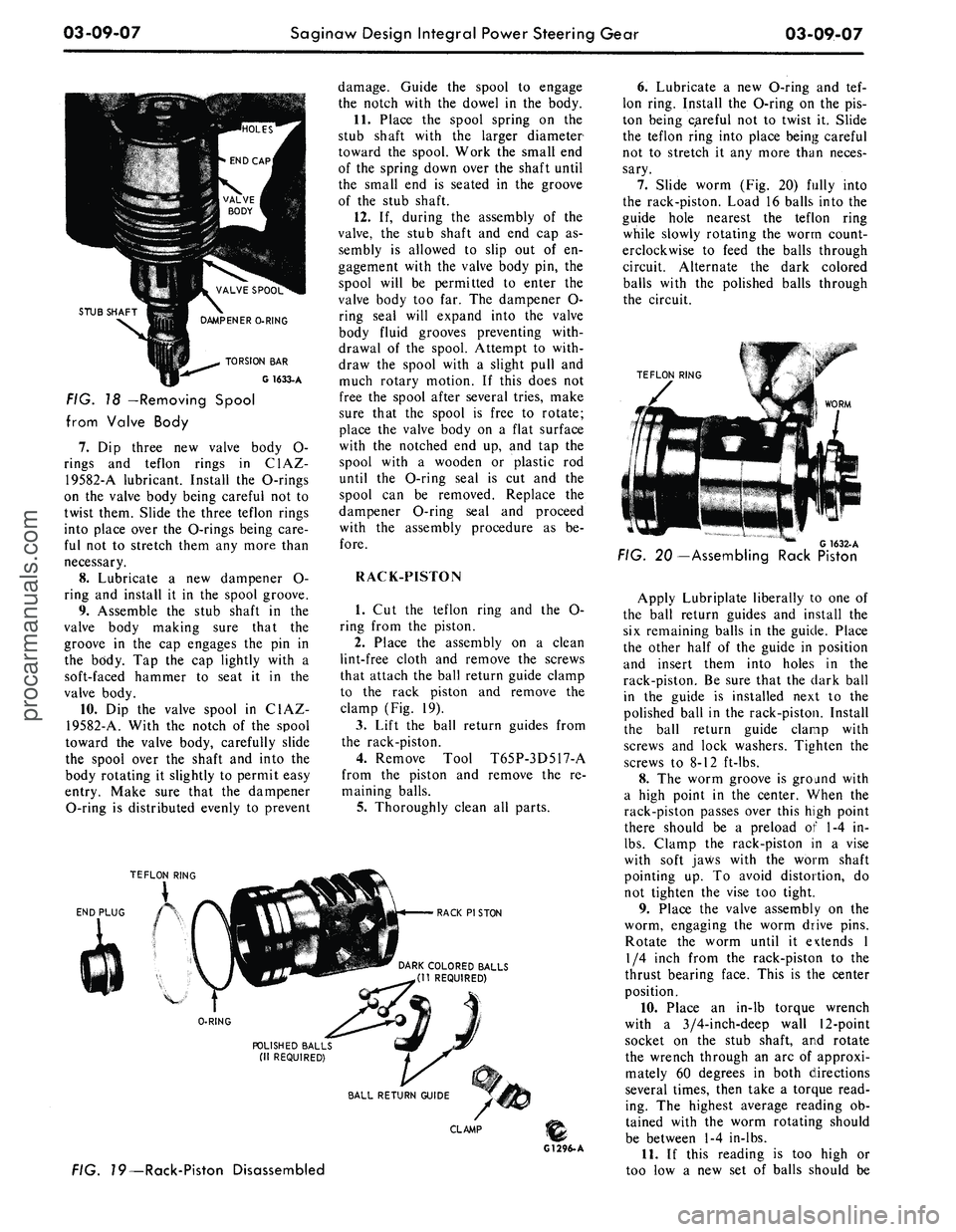

FIG. 18 —Removing Spool

from Valve Body

7.

Dip three new valve body O-

rings and teflon rings in C1AZ-

19582-A lubricant. Install the O-rings

on the valve body being careful not to

twist them. Slide the three teflon rings

into place over the O-rings being care-

ful not to stretch them any more than

necessary.

8. Lubricate a new dampener O-

ring and install it in the spool groove.

9. Assemble the stub shaft in the

valve body making sure that the

groove in the cap engages the pin in

the body. Tap the cap lightly with a

soft-faced hammer to seat it in the

valve body.

10.

Dip the valve spool in C1AZ-

19582-A. With the notch of the spool

toward the valve body, carefully slide

the spooi over the shaft and into the

body rotating it slightly to permit easy

entry. Make sure that the dampener

O-ring is distributed evenly to prevent

TEFLON RING

damage. Guide the spool to engage

the notch with the dowel in the body.

11.

Place the spool spring on the

stub shaft with the larger diameter

toward the spool. Work the small end

of the spring down over the shaft until

the small end is seated in the groove

of the stub shaft.

12.

If, during the assembly of the

valve, the stub shaft and end cap as-

sembly is allowed to slip out of en-

gagement with the valve body pin, the

spool will be permitted to enter the

valve body too far. The dampener O-

ring seal will expand into the valve

body fluid grooves preventing with-

drawal of the spool. Attempt to with-

draw the spool with a slight pull and

much rotary motion. If this does not

free the spool after several tries, make

sure that the spool is free to rotate;

place the valve body on a flat surface

with the notched end up, and tap the

spool with a wooden or plastic rod

until the O-ring seal is cut and the

spool can be removed. Replace the

dampener O-ring seal and proceed

with the assembly procedure as be-

fore.

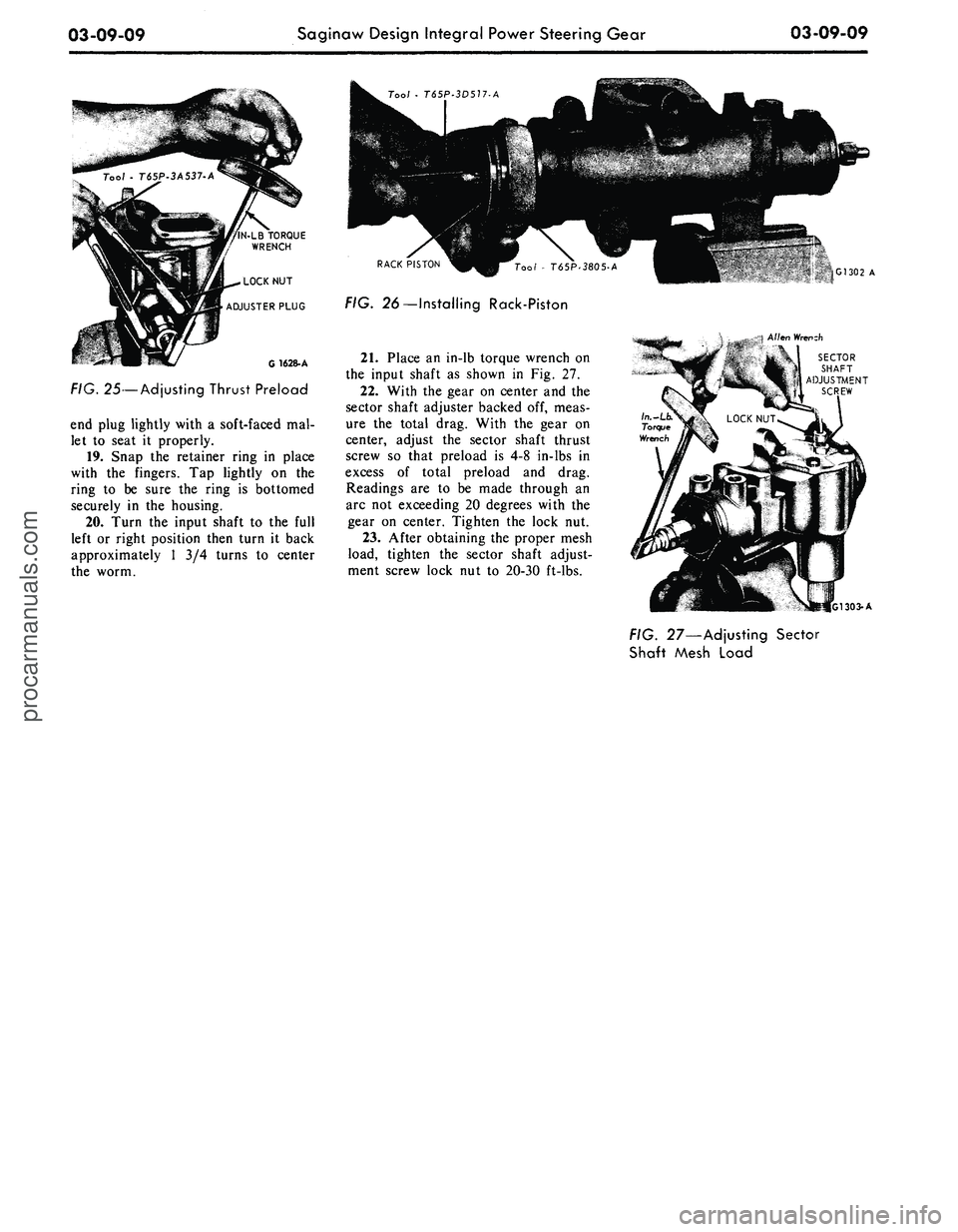

RACK-PISTON

1.

Cut the teflon ring and the O-

ring from the piston.

2.

Place the assembly on a clean

lint-free cloth and remove the screws

that attach the ball return guide clamp

to the rack piston and remove the

clamp (Fig. 19).

3.

Lift the ball return guides from

the rack-piston.

4.

Remove Tool T65P-3D517-A

from the piston and remove the re-

maining balls.

5.

Thoroughly clean all parts.

END PLUG

RACK PI STON

DARK COLORED BALLS

(11 REQUIRED)

V

0-RING

POLISHED BALLS

(II REQUIRED)

BALL RETURN GUIDE

CLAMP

B

G1296. A

6. Lubricate a new O-ring and tef-

lon ring. Install the O-ring on the pis-

ton being qareful not to twist it. Slide

the teflon ring into place being careful

not to stretch it any more than neces-

sary.

7.

Slide worm (Fig. 20) fully into

the rack-piston. Load 16 balls into the

guide hole nearest the teflon ring

while slowly rotating the worm count-

erclockwise to feed the balls through

circuit. Alternate the dark colored

balls with the polished balls through

the circuit.

TEFLON RING

FIG. 19—Rack-Piston Disassembled

G 1632-A

FIG. 20—Assembling Rack Piston

Apply Lubriplate liberally to one of

the ball return guides and install the

six remaining balls in the guide. Place

the other half of the guide in position

and insert them into holes in the

rack-piston. Be sure that the dark ball

in the guide is installed next to the

polished ball in the rack-piston. Install

the ball return guide clamp with

screws and lock washers. Tighten the

screws to 8-12 ft-lbs.

8. The worm groove is ground with

a high point in the center. V/hen the

rack-piston passes over this high point

there should be a preload of 1-4 in-

lbs.

Clamp the rack-piston in a vise

with soft jaws with the worm shaft

pointing up. To avoid distortion, do

not tighten the vise too tight.

9. Place the valve assembly on the

worm, engaging the worm drive pins.

Rotate the worm until it extends 1

1/4 inch from the rack-piston to the

thrust bearing face. This is the center

position.

10.

Place an in-lb torque wrench

with a 3/4-inch-deep wall 12-point

socket on the stub shaft, and rotate

the wrench through an arc of approxi-

mately 60 degrees in both directions

several times, then take a torque read-

ing. The highest average reading ob-

tained with the worm rotating should

be between 1-4 in-lbs.

11.

If this reading is too high or

too low a new set of balls should beprocarmanuals.com

Page 161 of 413

03-09-09

Saginaw Design Integral Power Steering Gear

03-09-09

Tool • T65P-3D517-A

LOCK NUT

ADJUSTER PLUG

G1628-A

FIG. 25

—

Adjusting Thrust Preload

end plug lightly with

a

soft-faced mal-

let

to

seat

it

properly.

19.

Snap

the

retainer ring

in

place

with

the

fingers.

Tap

lightly

on the

ring

to be

sure

the

ring

is

bottomed

securely

in the

housing.

20.

Turn

the

input shaft

to the

full

left

or

right position then turn

it

back

approximately

1 3/4

turns

to

center

the worm.

RACK PISTON

Tool - T65P.3805-A

FIG. 26—Installing Rack-Piston

21.

Place

an

in-lb torque wrench

on

the input shaft

as

shown

in Fig. 27.

22.

With

the

gear

on

center

and the

sector shaft adjuster backed

off,

meas-

ure

the

total drag. With

the

gear

on

center, adjust

the

sector shaft thrust

screw

so

that preload

is 4-8

in-lbs

in

excess

of

total preload

and

drag.

Readings

are to be

made through

an

arc

not

exceeding

20

degrees with

the

gear

on

center. Tighten

the

lock

nut.

23.

After obtaining

the

proper mesh

load, tighten

the

sector shaft adjust-

ment screw lock

nut to

20-30 ft-lbs.

jG1302

A

G1303-A

FIG. 27—Adjusting Sector

Shaft Mesh Loadprocarmanuals.com

Page 167 of 413

03-10-06

Ford-Thompson Power Steering Pump

03-10-06

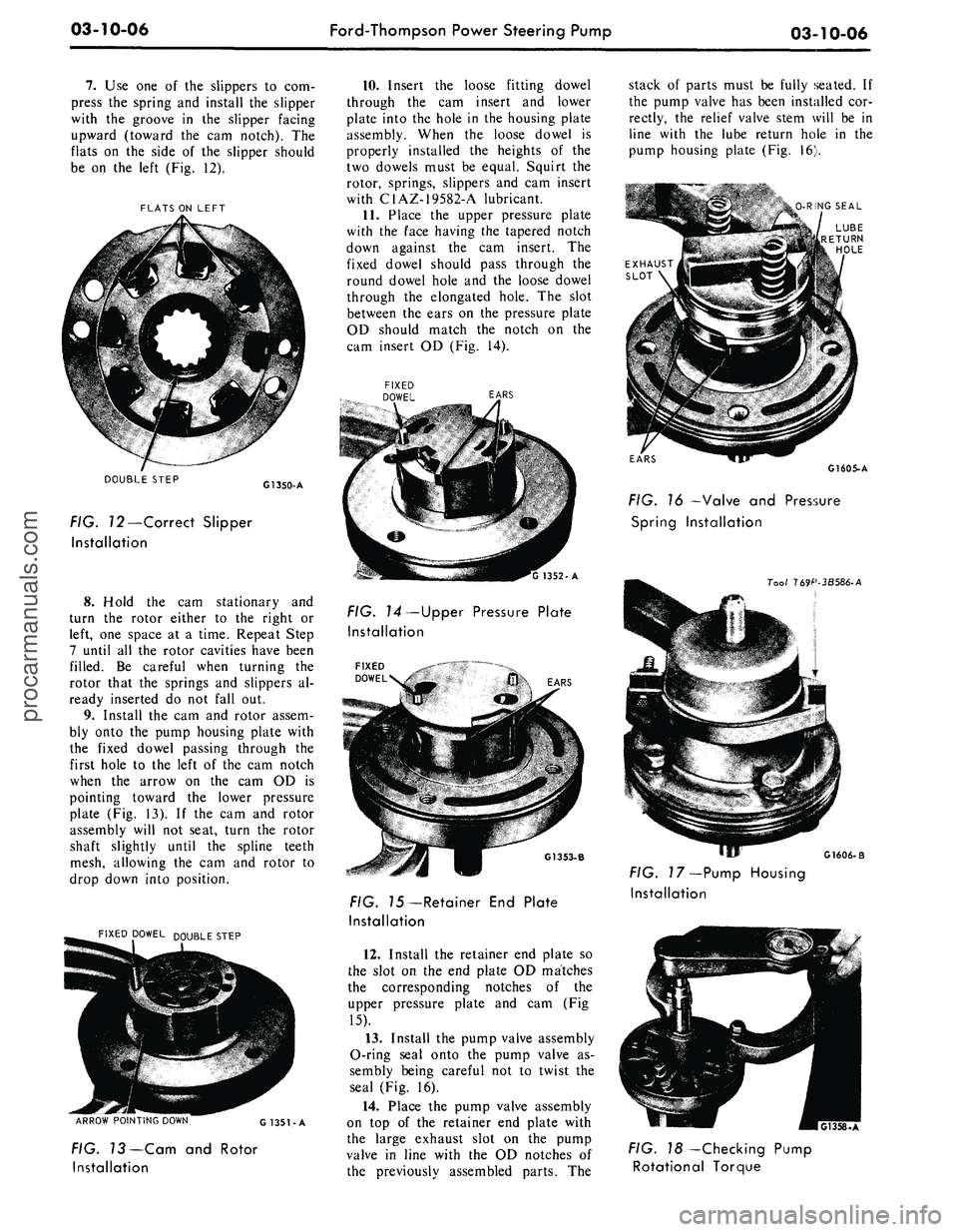

7.

Use one of the slippers to com-

press the spring and install the slipper

with the groove in the slipper facing

upward (toward the cam notch). The

flats on the side of the slipper should

be on the left (Fig. 12).

FLATS ON LEFT

DOUBLE STEP

G1350-A

FIG. 72—Correct Slipper

Installation

8. Hold the cam stationary and

turn the rotor either to the right or

left, one space at a time. Repeat Step

7 until all the rotor cavities have been

filled. Be careful when turning the

rotor that the springs and slippers al-

ready inserted do not fall out.

9. Install the cam and rotor assem-

bly onto the pump housing plate with

the fixed dowel passing through the

first hole to the left of the cam notch

when the arrow on the cam OD is

pointing toward the lower pressure

plate (Fig. 13). If the cam and rotor

assembly will not seat, turn the rotor

shaft slightly until the spline teeth

mesh, allowing the cam and rotor to

drop down into position.

FIXED DOWEL D0|JBLE STEP

ARROW POINTING DOWN

G 1351-A

FIG. 13—Cam and Rotor

Installation

10.

Insert the loose fitting dowel

through the cam insert and lower

plate into the hole in the housing plate

assembly. When the loose dowel is

properly installed the heights of the

two dowels must be equal. Squirt the

rotor, springs, slippers and cam insert

with C1AZ-19582-A lubricant.

11.

Place the upper pressure plate

with the face having the tapered notch

down against the cam insert. The

fixed dowel should pass through the

round dowel hole and the loose dowel

through the elongated hole. The slot

between the ears on the pressure plate

OD should match the notch on the

cam insert OD (Fig. 14).

EARS

'G 1352-A

FIG. 74—Upper Pressure Plate

Installation

\ EARS

G1353-B

FIG. 75—Retainer End Plate

Installation

12.

Install the retainer end plate so

the slot on the end plate OD matches

the corresponding notches of the

upper pressure plate and cam (Fig

15).

13.

Install the pump valve assembly

O-ring seal onto the pump valve as-

sembly being careful not to twist the

seal (Fig. 16).

14.

Place the pump valve assembly

on top of the retainer end plate with

the large exhaust slot on the pump

valve in line with the OD notches of

the previously assembled parts. The

stack of parts must be fully seated. If

the pump valve has been installed cor-

rectly, the relief valve stem will be in

line with the lube return hole in the

pump housing plate (Fig. 16).

O-RING SEAL

EARS

G1605-A

FIG. 16 —Valve and Pressure

Spring Installation

Tool 169P-3B586-A

G1606-B

FIG. 17—Pump Housing

Installation

FIG. 18 -Checking Pump

Rotational Torqueprocarmanuals.com

Page 168 of 413

03-10-07

Ford-Thompson Power Steering Pump

03-10-07

15.

Place small amounts of vaseline

on the pump housing plate to hold the

cover gasket in place. Install the gas-

ket on the pump housing plate.

16.

Insert the pressure plate springs

into the pockets in the pump valve as-

sembly. Vaseline may be placed in the

spring pockets to hold the springs in

position (Fig. 17).

17.

Using Tool T69P-3B586-A,

plug the intake hole in the housing

(Fig. 17).

18.

Lubricate the inside of the

housing and the housing cover seal

with C1AZ-19582-A lubricant. Fabri-

cate two studs (3/8-16x1.55 ) to be

used as positioning guides. Install one

in the housing plate bolt hole closest

to the drain hole and one in the bolt

hole diametrically opposite.

19.

Align the small diameter lube

hole in the housing rim with the lube

hole in the housing plate.

20.

Install the housing, applying an

even, downward pressure. The pres-

sure plate springs must not be jarred

and moved out of position. Remove

the guide studs.

21.

Install the housing retaining

bolts finger tight.

22.

Remove Tool T69P-3B586-A.

23.

Torque the retaining bolts even-

ly to 28-32 ft-lbs until the housing

flange contacts the gasket.

24.

Install a 3/8x16 hex head

screw, finger tight, into the end of the

rotor shaft. Using a torque wrench,

check the input torque of the shaft

(Fig. 18). The torque should not ex-

ceed 15 in-lbs. If it does, loosen the

retaining bolts slightly, rotate the

rotor shaft, retorque the bolts evenly

and again check the shaft torque. The

pump must not be used if the shaft

torque exceeds 15 in-lbs.

25.

Release the pin in the bench

holding fixture and agitate the pump

assembly back and forth. If there is a

rattle, the pressure plate springs have

fallen out of their seats and must be

reinstalled.

26.

Install the reservoir O-ring on

the housing plate being careful not to

twist the O-ring. Apply vaseline to the

seal and to the ID of the reservoir

flange.

27.

Install the reservoir, aligning

the notch in the reservoir flange with

the notch in the OD of the pump

housing plate and bushing assembly.

Using only a plastic or rubber ham-

mer, tap at the rear on the outer cor-

ners of the reservoir to avoid damage.

28.

Inspect the assembly to deter-

mine if the reservoir is seated on the

housing plate.

29.

Install the service identification

tag on the outlet valve fitting.

30.

Install the outlet valve fitting

nut and torque to 43-47 ft-lbs.

31.

Invert the pump assembly.

32.

If the pulley was removed, in-

stall the correct pulley using Tool

T65P-3A733-A.procarmanuals.com