engine FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 61 of 234

2.5 Driveshaft

2.5.1 Power Take Off

Gear Box add-on - Auxiliary

Propeller Drive Shaft

CAUTIONS:

Make sure that an inhibitor is fitted

to any modified vehicle that uses

the prop-shaft to power auxillary

equipment.

The only modification to the engine

control system (throttle, powertrain

control module and fuel pump)

recommended by the manufacturer

is the addition of an engine (RPM)

controller.

Do not weld or join onto any part of

the axle assembley.

The transmission oil temperature

must not exceed 130° during

operation of the Power Take Off

Where power is to be taken from the prop-shaft

for accessory drive, the engine controller can be

used in the same way as for the Front End

Accessory Drive (FEAD).

Refer to: 3.3 Accessory Drive (page 77).

Exceeding the recommended power take off

ratings may result in the engine over heating.

If the driveshaft is modified, it must be balanced

to a limit of 80gmm at 5000rpm and the

installation must not have universal joint angles

exceeding 4°. The gearbox output included angle

must be no more than 1°.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

2 Chassis

61

Page 66 of 234

3.1 Engine

CAUTION: Make sure to follow the

equipment suppliers instructions for

safety, warranty and sometimes

legal compliance

For electrical supply to auxiliary equipment.

Refer to: 4.3 Charging System (page 95).

3.1.1 Engine Power Curves

The torque and power curves of the following

engines are shown in this section

•Common Rail 2.2L TCI 62.5kW (85HP) Diesel

Engine

•Common Rail 2.2L TCI 81kW (110HP) Diesel

Engine

•Common Rail 2.2L TCI 96kW (130HP) Diesel

Engine

•Common Rail 2.4L TCI 74kW (100HP) Diesel

Engine

•Common Rail 2.4L TCI 85kW (115HP) Diesel

Engine

•Common Rail 2.4L TCI 103kW (140HP) Diesel

Engine

•2.3L Gasoline engine 107kW (145HP)

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

66

Page 67 of 234

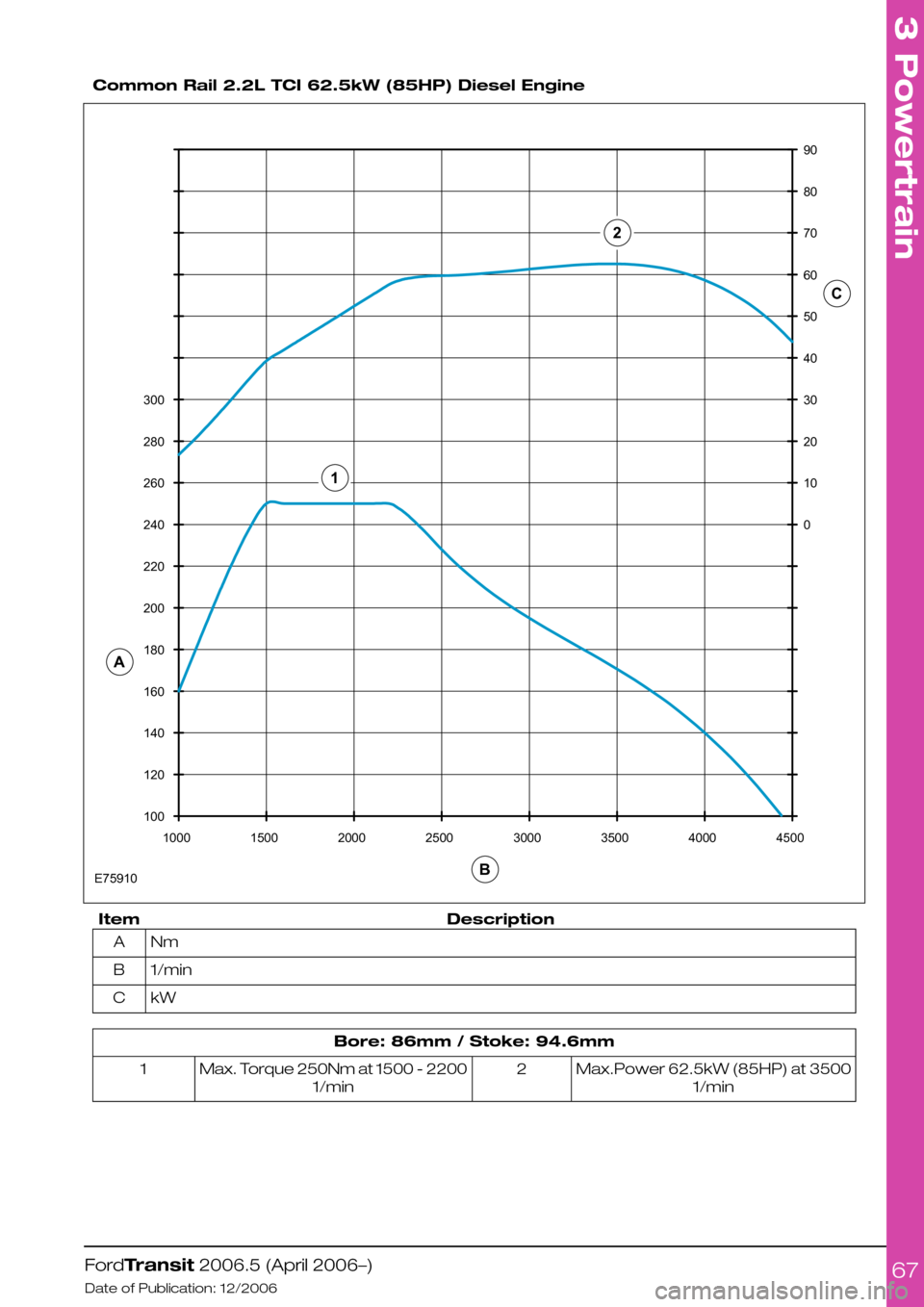

Common Rail 2.2L TCI 62.5kW (85HP) Diesel Engine

DescriptionItem

NmA

1/minB

kWC

Bore: 86mm / Stoke: 94.6mm

Max.Power 62.5kW (85HP) at 3500

1/min

2Max. Torque 250Nm at 1500 - 2200

1/min

1

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

6710012014016018020022024026028030010001500200025003000350040004500010203040506070809021ACBE75910

Page 68 of 234

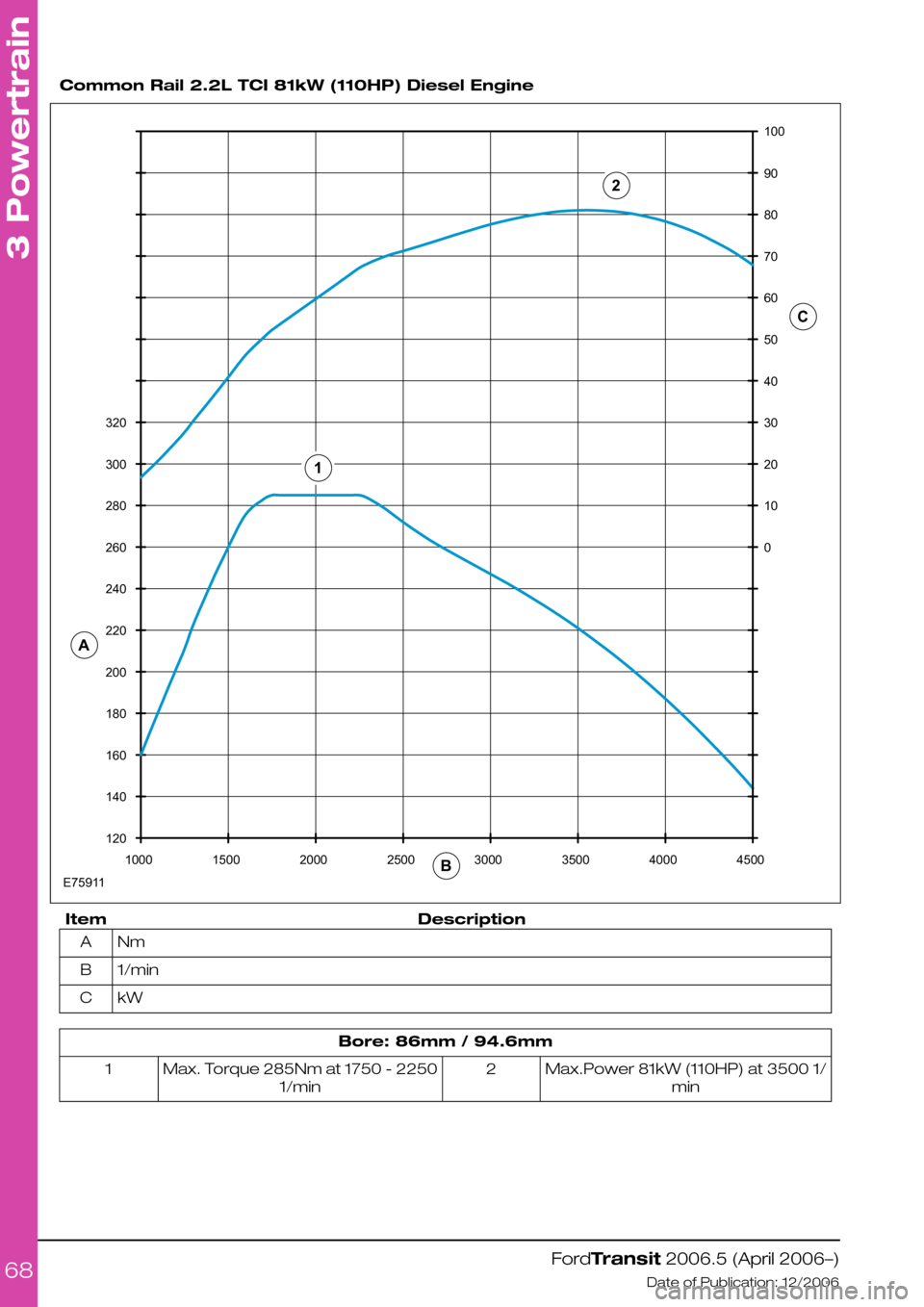

Common Rail 2.2L TCI 81kW (110HP) Diesel Engine

DescriptionItem

NmA

1/minB

kWC

Bore: 86mm / 94.6mm

Max.Power 81kW (110HP) at 3500 1/

min

2Max. Torque 285Nm at 1750 - 2250

1/min

1

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

68120140160180200220240260280300320100015002000250030003500400045000102030405060708090100ACB12E75911

Page 69 of 234

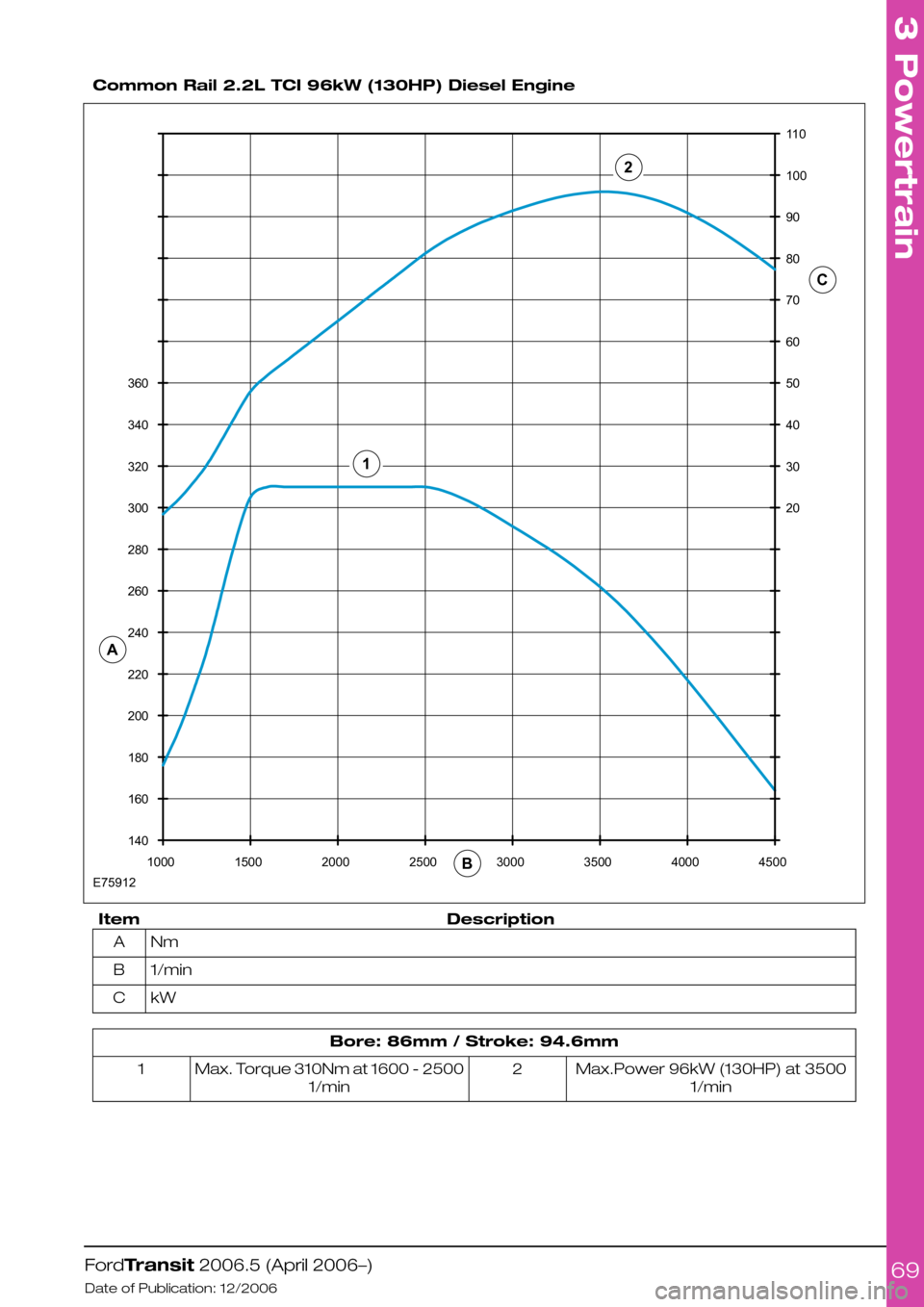

Common Rail 2.2L TCI 96kW (130HP) Diesel Engine

DescriptionItem

NmA

1/minB

kWC

Bore: 86mm / Stroke: 94.6mm

Max.Power 96kW (130HP) at 3500

1/min

2Max. Torque 310Nm at 1600 - 2500

1/min

1

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

69140160180200220240260280300320340360100015002000250030003500400045002030405060708090100110A12BCE75912

Page 70 of 234

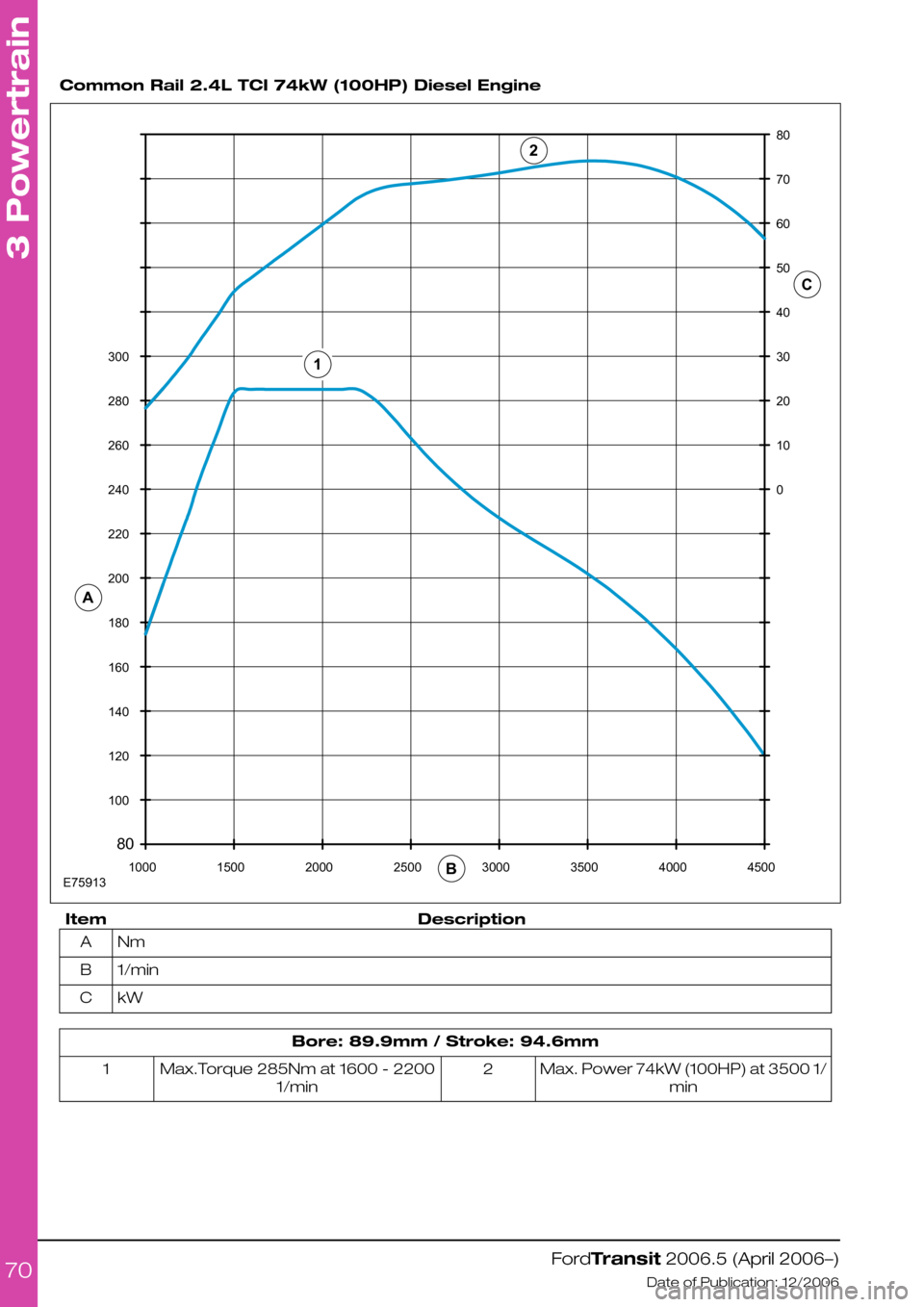

Common Rail 2.4L TCI 74kW (100HP) Diesel Engine

DescriptionItem

NmA

1/minB

kWC

Bore: 89.9mm / Stroke: 94.6mm

Max. Power 74kW (100HP) at 3500 1/

min

2Max.Torque 285Nm at 1600 - 2200

1/min

1

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

70801001201401601802002202402602803001000150020002500300035004000450001020304050607080A12BCE75913

Page 71 of 234

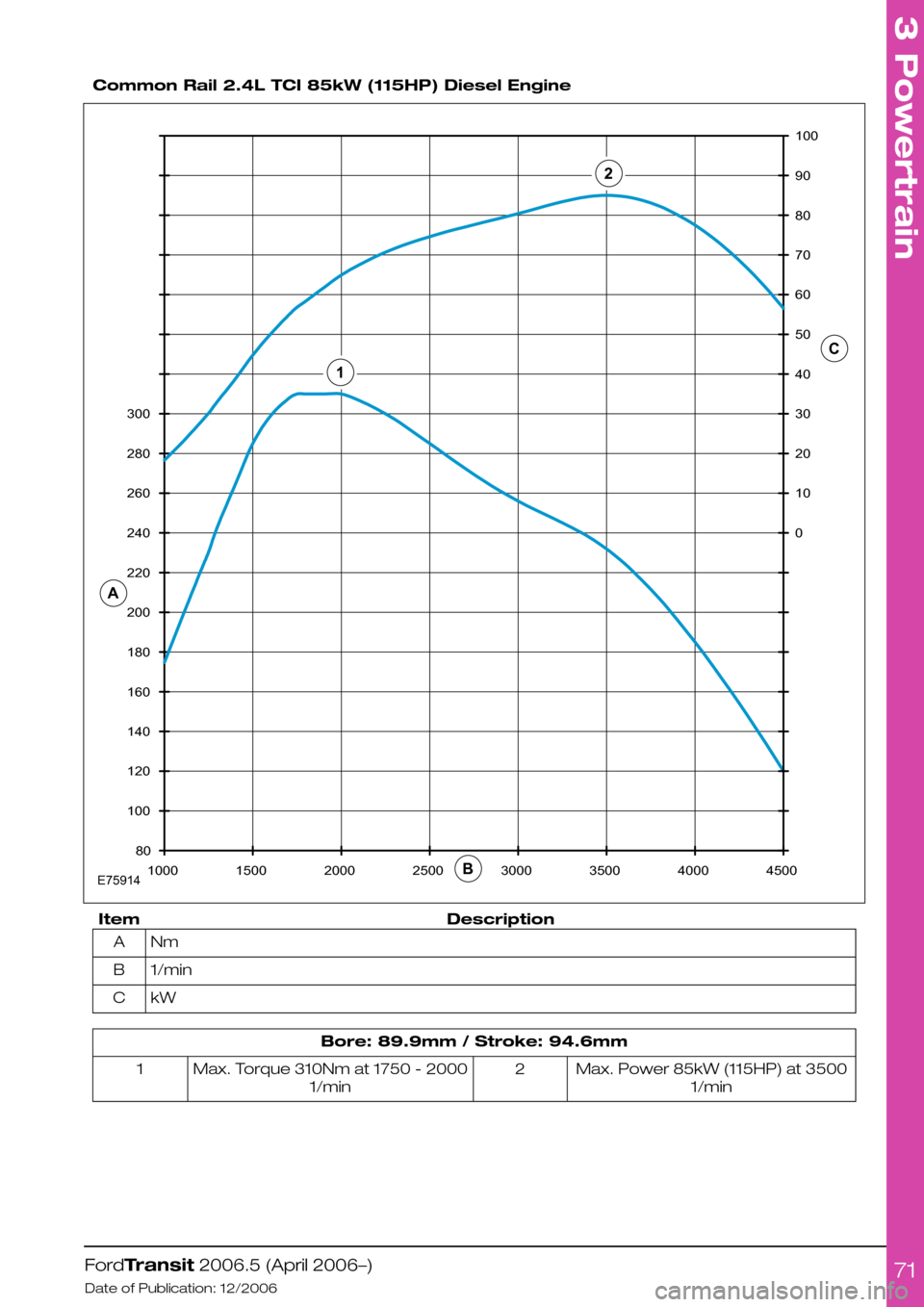

Common Rail 2.4L TCI 85kW (115HP) Diesel Engine

DescriptionItem

NmA

1/minB

kWC

Bore: 89.9mm / Stroke: 94.6mm

Max. Power 85kW (115HP) at 3500

1/min

2Max. Torque 310Nm at 1750 - 2000

1/min

1

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

7180100120140160180200220240260280300100015002000250030003500400045000102030405060708090100ABC21E75914

Page 72 of 234

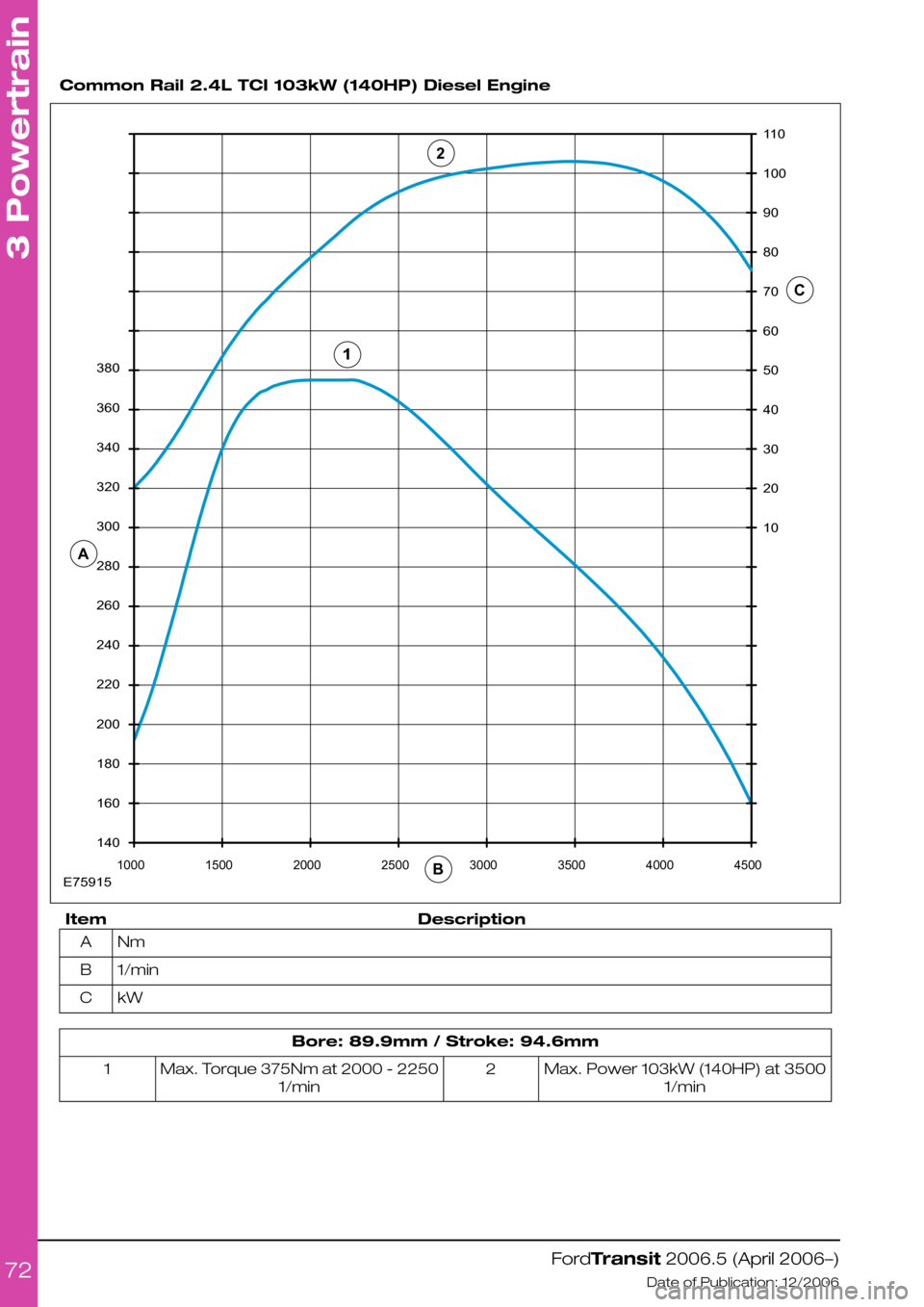

Common Rail 2.4L TCI 103kW (140HP) Diesel Engine

DescriptionItem

NmA

1/minB

kWC

Bore: 89.9mm / Stroke: 94.6mm

Max. Power 103kW (140HP) at 3500

1/min

2Max. Torque 375Nm at 2000 - 2250

1/min

1

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

7214016018020022024026028030032034036038010001500200025003000350040004500102030405060708090100110ABC12E75915

Page 73 of 234

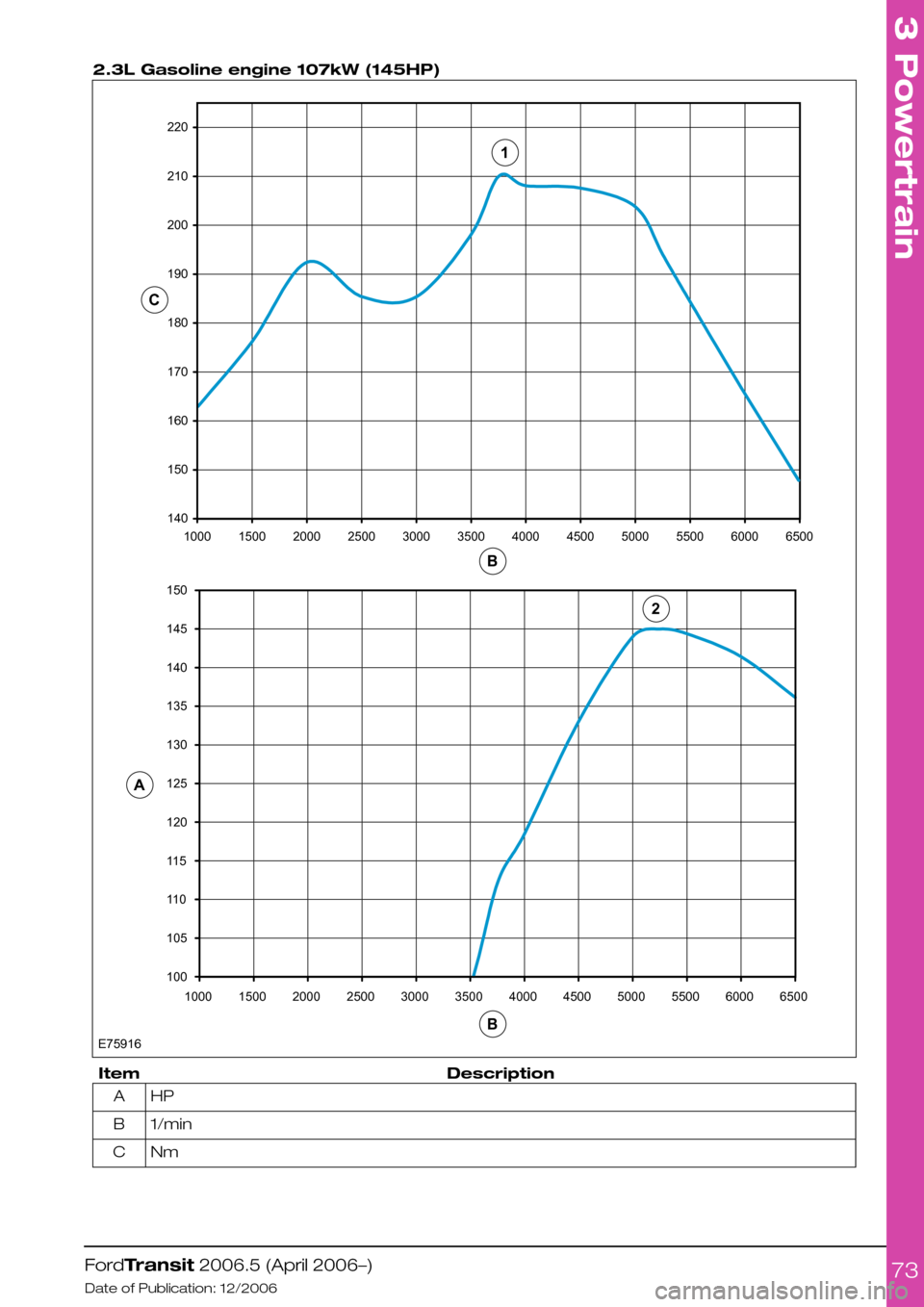

2.3L Gasoline engine 107kW (145HP)

DescriptionItem

HPA

1/minB

NmC

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

731401501601701801902002102201000150020002500300035004000450050005500600065001001051101151201251301351401451501000E7591615002000250030003500400045005000550060006500ACBB12

Page 75 of 234

3.2 Engine Cooling

3.2.1 Auxiliary Heater Systems

WARNINGS:

Ford coolant additives are

necessary for the complete function

of the system. Only use ford

approved or equivalent specification

component, to withstand any

detrimental effects on the materials.

Do not mount components in front

of the grille or in an area of air flow

around the engine, which could

affect the engine cooling.

CAUTIONS:

Only make connections into the

heater hose between the front cab

heater and water pump return inlet.

Do not exceed the vehicle's original

coolant volume by more than 10%

Only use the manufactures

recommended (or equivalent

specification) coolant

additives/anti-freeze. Do not mix

coolant types.

•Coolant flow to cab heater must have priority

over flow to auxiliary heater or hand wash

facility.

•Coolant tube routing must be below the base

of the degas bottle.

•Use aluminum or plastic tee junction with

swaged or beaded ends to prevent hose blow

off. Reconnect original coolant tube as shown

in view E74570 (in this section) with standard

Ford water hose clip or suitable equivalent

specification clip. Ensure interference fit

between hose and 'T' joint.

•Tube routing must be secured to the body

structure or suitable brackets avoiding

electrical components or wires, hot or moving

parts and brake or fuel system components

•Hose must be heat sleeved with appropriate

material if within 100mm of exhaust

components (for example, manifold or

exhaust gas recirculating).

•The vertical clearance between the critical

cooling components (radiator, fan shroud and

radiator brackets) and both the hood inner

and outer (assembly) panels at design position

shall not be less than 15mm.

•There shall be a minimum clearance of 7mm

between the engine assembly and flexible

components (for example, hoses or wiring

harnesses) affixed to front end sheet metal

hardware, under a maximum engine torque

roll condition.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

3 Powertrain

75