check oil GEELY CK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 28 of 392

2139. Install oil pipe and water hose

40. Install left & right propeller shaft

41. Install left & right front wheel

42. Check engine oil for leakage

43. Install all connected wire harnesses and the cables on engine and vehicle body

Page 30 of 392

231. Disconnect all connected wire harnesses and the cable on the engine and the vehicle body

2. Remove air filter assembly with hose

3. Disconnect oil pipe and water hose

4. Loose positive and negative cables of the battery

5. Detach propeller shaft

6. Loose left & right rear engine mounting bracket after hoisting the engine.

7. Disconnect all other connectors between the engine and the vehicle body.

8. Remove engine per "Provison 20, Section 2, Chapter 2"

9. Remove A/C compressor to crankshaft pulleyV-belt

10. Remove power steering pump V- belt

11. Remove water pump fan pulley

12. Disconnect ignition coil and high voltage cables

13. Remove cylinder head cover sub-assembly

14. Remove generator assembly

15. Remove cylinder head cover sub-assembly

(a) Disconnect generator wire joint.

(b) Disconnect generator circuit

(c) Disconnect A/C compressor switch connector.

(e) Open wires clips.

(f) Disconnect wire harness from the cylinder head cover.

(g) Disconnect 2 ventilation PCV hoses from cylinder head cover.

(h) Remove 4 screws, 4 seal gaskets, cylinder head and gasket.

16. Remove generator assembly. See (Figure 50)

17. Remove timing belt cover

18. Remove crankshaft gear or pulley cover sub-assembly

19. Put the piston on Cylinder 1 to TDC compression position.

(a) Turn crankshaft pulley. Align its notch to the timing mark "O" on the

timing belt cover.

(b) Check if the mark "K" on camshaft timing pulley is aligned to the

timing mark on the bearing cap. Turn crankshaft 360° if not.

20. Remove ignition coil assembly

21. Remove timing belt. See (Figure 51)

(a) Mark on the timing belt and the camshaft pulley. The mark on the

timing belt to the timing belt cover No. 1 should match.

(b) Remove rubber gasket from timing belt cover.Figure 50

Figure 51

Page 34 of 392

2731. Install timing belt cover

Torque: 9.3N. m

32. Install generator assembly

33. Install right engine mounting bracket. See (Figure 67)

34. Install cylinder head cover sub-assembly

(a) Install 2 ventilation PCV hoses to the cylinder head cover.

(b) Connect the generator wire.

(c) Install the wire clip.

(d) Connect A/C compressor switch connector.

35. Install water pump pulley

36. Install power steering pump V-belt

37. Install A/C compressor to crankshaft pulleyV-belt

38. Install generator V-belt

39. Install left & right rear mounting bracket of engine.

40. Install ignition coil and high voltage cable

41. Hoist the engine back into the compartment

42. Install propeller shaft

43. Install air filter assembly with hose

44. Install oil pipe and water hoses

45. Install left and right front tires.

46. Check engine oil for leakage

47. Install all the wire harnesses and the cables on the engine connected to car bodyFigure 67

Page 39 of 392

3228. Install power steering adjusting pole

29. Install power steering pump assembly

30. Install wire harness.

31. Install No. 1 fuel delivery pipe

32. Set the new gasket on cylinder head with flange upward. Install water inlet hose. See

(Figure 73)

33. Install manifold stay No. 2

34. Connect front exhaust pipe assembly

35. Install throttle body assembly

36. Install camshaft

37. Install engine cylinder head cover

38. Hoist the engine back to the compartment.

39. Install engine right left and rear brackets

40. Install propeller shaft

41. Install ignition coil and high pressure cables. Install air filter assembly with hose

42. Install oil pipe and water hose

43. Install left & right front tire

44. Install all the wire harnesses and cables on the engine connected to car body

45. Check compression pressure

46. Check CO/HC. Check idle and ignition timingFigure 73

Page 40 of 392

33Section 6 Oil Pump Oil Seal Replacement1. Pry with 2 screwdrivers. Detach crankshaft timing pulley.

See (Figure 74)

2. Remove oil pump oil seal. See (Figure 75)

(a) Using a knife, cut off oil seal lip.

(b) Using a screwdriver, pry out the oil seal.

3. Install oil pump oil seal. See (Figure 76)

(a) Smear grease to a new oil seal lip.

(b) on the oil seal with hammer until the edge of the oil pump

case is filled with the seal packing.

4. Install crankshaft timing pulley. See (Figure 77)

(a) Align pulley set key to the key groove.

(b) Place the flange face inward. Install timing pulley.

5. Install timing belt

6. Check engine oil for leakage

Figure 76 Figure 74

Figure 75

Figure 77

Page 42 of 392

35Chapter 3 Lubrication System

(MR479Q, MR479QA, MR481QA)Section 1 Oil Pressure Gage Sensor Replacement1. Check oil level

Warm up the engine. Check the dipstick to ensure oil level between "L" and "F" after engine stopped

5 minutes. Check for leakage if it is too low. Fill oil to "F.

2. Check oil for deterioration. Water entry, discolor and dilution. Replace oil if it is obviously

deteriorated.

3. Detach oil pressure sensor assembly. See (Figure 80)

4. Install oil pressure gage sensor. See (Figure 81) Start engine to

normal operation temperature.

5. Check for oil pressure

6. Smear adhesive on 2 or 3 threads of the oil pressure sensor.

Install oil pressure sensor. See (Figure 82)

Figure 81

Figure 82Figure 80

Page 44 of 392

3713. Install the dipstick guide. See (Figure 87)

14. Install crankshaft timing pulley. See (Figure 77)

15. Install timing belt idler sub-assembly No.1

16. Install timing belt

17. Fill in engine oil

18. Check oil for leakage

Figure 87

Page 45 of 392

38Section 3 Oil Filter Replacement1. Detach oil filter sub-assembly. See (Figure 88)

2. Install oil filter sub-assembly. See (Figure 89)

Figure 88 Figure 89

3. Install drain plug

Clean and use new washer to install drain plug.

Torque: 54N. m

4. Oil fill

Capacity:

Oil refill amount with the filter replaced: 3.0L

Oil refill amount without the filter dry fill replaced: 2.80L

Dry fill: 3.3L

5. Check oil for leakage

Page 49 of 392

42Section 2 Fuel Pump Inspection1. Fuel pump

(a) Check fuel pump resistance, 0.2~3.0 at 20°. Replace fuel pump if the resistance is not as specified.

See (Figure 93)

(b) Fuel pump running:

Check fuel pump by connecting with battery. Replace fuel pump or wire if the running is not as specified.

See (Figure 94).

The test should be conducted within 10s to prevent coil from damage.

2. Fuel injector assembly

Injection Volume: 40~50cm3/s

Error between each injector: less than 10 cm3Replace injector if the injection volume is not as specified.

(a) Check for leakage: Disconnect the cable from the battery. The fuel drop/min is no more than 1 drop.

Figure 93 Figure 94 Ohmmeter

Battery Ω

Page 50 of 392

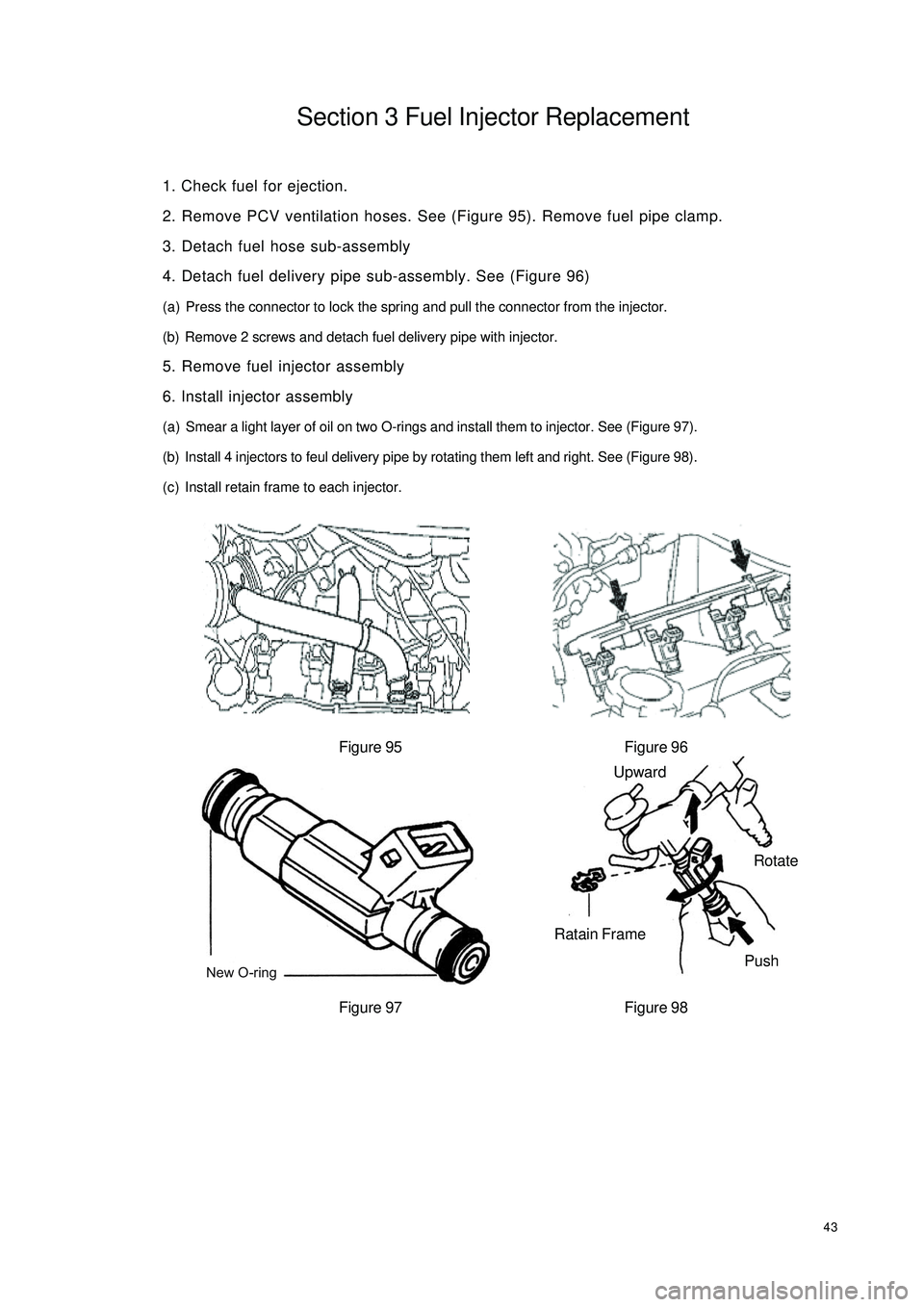

43Section 3 Fuel Injector Replacement1. Check fuel for ejection.

2. Remove PCV ventilation hoses. See (Figure 95). Remove fuel pipe clamp.

3. Detach fuel hose sub-assembly

4. Detach fuel delivery pipe sub-assembly. See (Figure 96)

(a) Press the connector to lock the spring and pull the connector from the injector.

(b) Remove 2 screws and detach fuel delivery pipe with injector.

5. Remove fuel injector assembly

6. Install injector assembly

(a) Smear a light layer of oil on two O-rings and install them to injector. See (Figure 97).

(b) Install 4 injectors to feul delivery pipe by rotating them left and right. See (Figure 98).

(c) Install retain frame to each injector.

Figure 95 Figure 96

Figure 97 Figure 98New O-ringUpward

Ratain Frame

PushRotate