battery GEELY CK 2008 Owner's Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 171 of 392

164Section 2 Charging System

(MR479Q, MR479QA, MR481QA)I. BATTERYMaintenance-free battery is applied in this vehicle. Its termination voltage is 12V. It is connected inline by six

2V single cell in tandem with walls between every pole.

1. BATTERY WARNING SIGNS

1 -- Danger of corrosion

The battery electrolyte is very corrosive. DO NOT overturn the battery.

2 -- Read the instructions for battery

3 -- Children are forbidden to touch the battery

4 -- Avoid fire, electromagnetic wave and strong light.

Avoid electric spark while repair; avoid short.

5 -- Wear protecting glasses

6 -- Danger of explosion

The explosive mixed gas will be produced while charging.

7 -- How to deal with a scrapped battery

The scrapped battery should be delivered to the collection station.1234567

Page 172 of 392

1652. BATTERY REMOVAL AND INSTALLATION

HINT:

(1) The battery is not allowed to contact lubricating grease.

(2) The battery terminal is only allowed to be softly pulled out, in order to void damaging the battery.REMOVAL(1) Remove the negative (-) ground cable

(2) Remove the battery positive (+) cable

(3) Loosen the fixing clamp on the battery.INSTALLATIONInstall according to the inverted order of removal.

Tighten the torque

Tighten the battery cable clip to 6N.m (61kgf.cm, 4ft.lbf)

Tighten the fixing clamp to 12N.m (123kgf.cm, 8.6ft.lbf)

Page 173 of 392

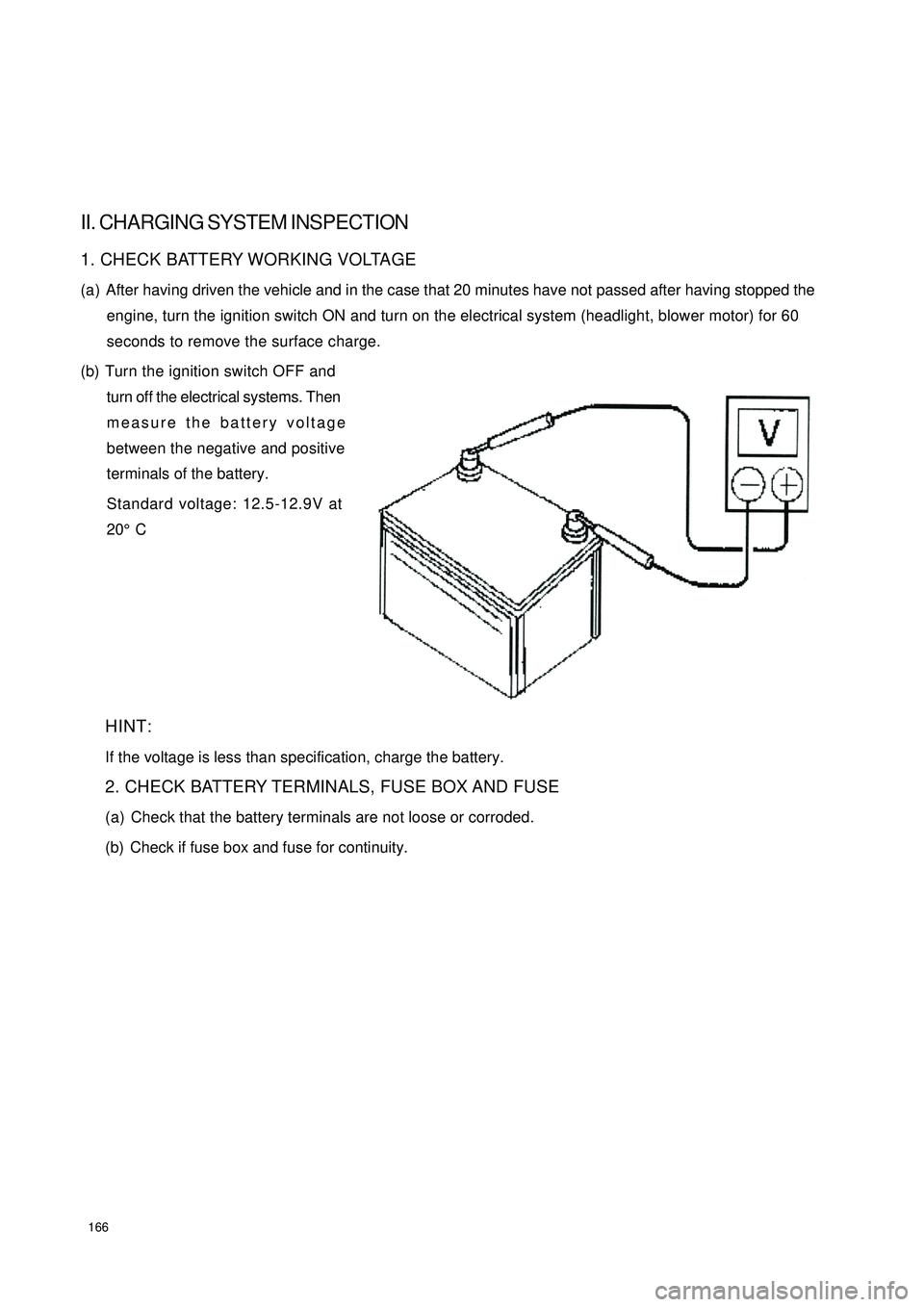

166II. CHARGING SYSTEM INSPECTION1. CHECK BATTERY WORKING VOLTAGE

(a) After having driven the vehicle and in the case that 20 minutes have not passed after having stopped the

engine, turn the ignition switch ON and turn on the electrical system (headlight, blower motor) for 60

seconds to remove the surface charge.

(b) Turn the ignition switch OFF and

turn off the electrical systems. Then

measure the battery voltage

between the negative and positive

terminals of the battery.

Standard voltage: 12.5-12.9V at

20°C

HINT:

If the voltage is less than specification, charge the battery.

2. CHECK BATTERY TERMINALS, FUSE BOX AND FUSE

(a) Check that the battery terminals are not loose or corroded.

(b) Check if fuse box and fuse for continuity.

Page 175 of 392

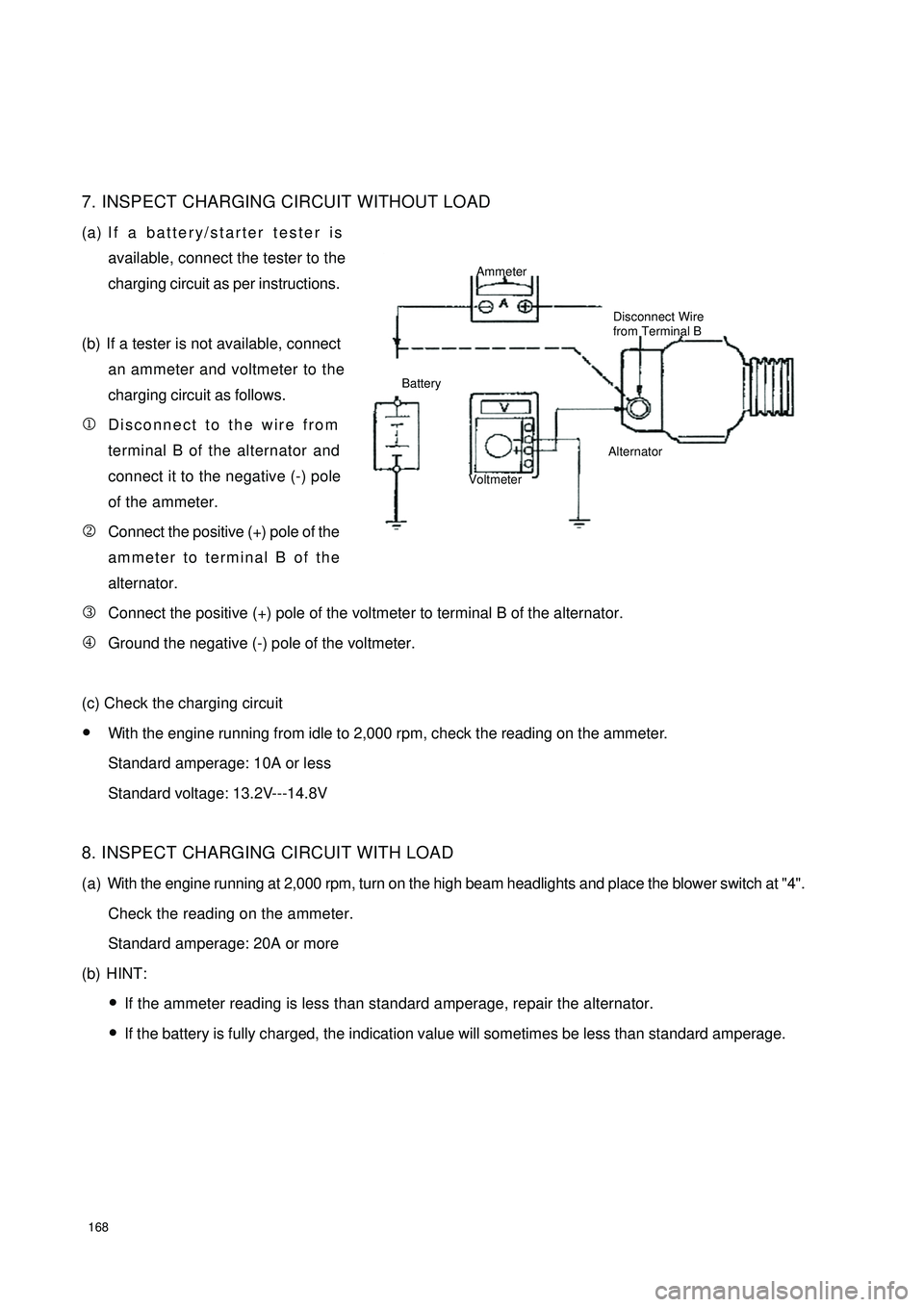

1687. INSPECT CHARGING CIRCUIT WITHOUT LOAD

(a) If a battery/starter tester is

available, connect the tester to the

charging circuit as per instructions.

(b) If a tester is not available, connect

an ammeter and voltmeter to the

charging circuit as follows.

1Disconnect to the wire from

terminal B of the alternator and

connect it to the negative (-) pole

of the ammeter.

2Connect the positive (+) pole of the

ammeter to terminal B of the

alternator.

3Connect the positive (+) pole of the voltmeter to terminal B of the alternator.

4Ground the negative (-) pole of the voltmeter.

(c) Check the charging circuit

�yWith the engine running from idle to 2,000 rpm, check the reading on the ammeter.

Standard amperage: 10A or less

Standard voltage: 13.2V---14.8V

8. INSPECT CHARGING CIRCUIT WITH LOAD

(a) With the engine running at 2,000 rpm, turn on the high beam headlights and place the blower switch at "4".

Check the reading on the ammeter.

Standard amperage: 20A or more

(b) HINT:

�yIf the ammeter reading is less than standard amperage, repair the alternator.

�yIf the battery is fully charged, the indication value will sometimes be less than standard amperage.Ammeter

Disconnect Wire

from Terminal B

Battery

VoltmeterAlternator

Page 182 of 392

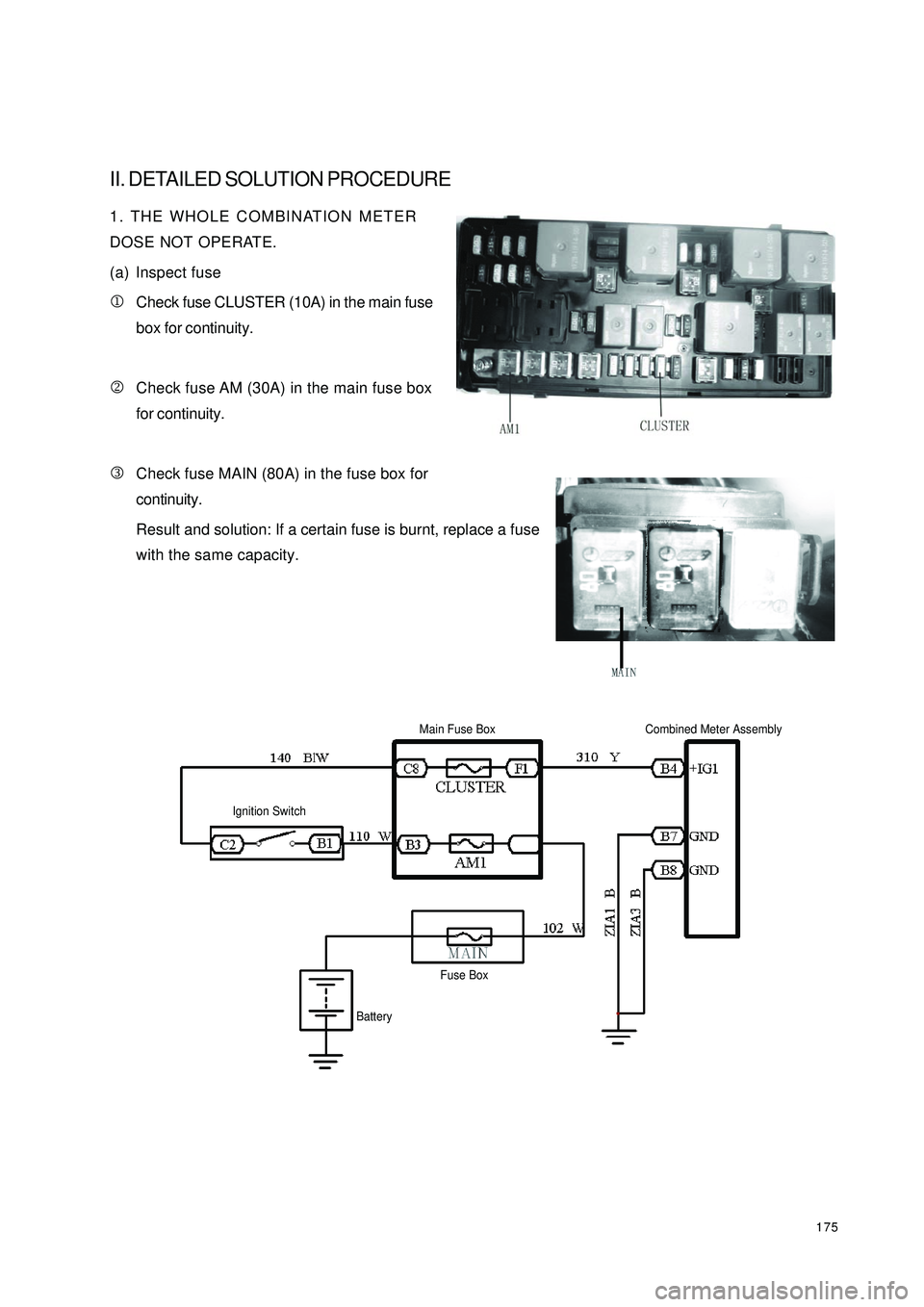

175II. DETAILED SOLUTION PROCEDURE1. THE WHOLE COMBINATION METER

DOSE NOT OPERATE.

(a) Inspect fuse

1Check fuse CLUSTER (10A) in the main fuse

box for continuity.

2Check fuse AM (30A) in the main fuse box

for continuity.

3Check fuse MAIN (80A) in the fuse box for

continuity.

Result and solution: If a certain fuse is burnt, replace a fuse

with the same capacity.Ignition SwitchMain Fuse BoxCombined Meter AssemblyBatteryFuse Box

Page 201 of 392

194II. MALFUNCTION INSPECTION1. WASHER PUMP INSPECTION

(1) Mount washer pump on the can system. Pour washer fluid into the can.

(2) Disconnect the connector of washer pump.

(3) Connect the terminal 1 of washer pump to the battery positive (+) and the terminal 2 to the negative (-),

as shown below. Inspect that the washer fluid flows out of the can.

(4) If not, replace the washer pump.

2. WIPER SWITCH ASSEMBLY

(a) Inspect the continuity

�yInspect each terminal on connector for continuity.

Standard:Switch position Tested terminal Specified condition

MIST 8(

+)

—10(

+)

Continuity

OFF 3(

+)

—10(

+)

Continuity

INT 8(

+)

—6(

+)

3(

+)

—10(

+)

Continuity

LO 8(

+)

—10(

+)

Continuity

HI 8(

+)

—11(

-)

Continuity

Page 202 of 392

195Front washer switch

If no continuity, replace the switch.

(b) Operation inspection (washer switch)

1Turn the washer switch on the position OFF.

2Connect the connector terminal 8 to the battery positive (+)

and the terminal 2 of wiper connector to the negative (-). Turn

the washer switch ON and OFF and then measure the battery

voltage between the terminal 8 and terminal 2 of the wiper

motor connector.

Standard: as shown on the left

If it is not as specified, replace the switch.

3. WIPER MOTOR ASSEMBLY

(a) Inspect the low speed shift

�yConnect the connector terminal 3 to the battery positive

(+) and the connector terminal 2 (E) to the negative

(-), check that the motor operates at low speed.

If it is not as specified, replace the motor.

(b) Inspect the high speed shift

�yConnect the connector terminal 3 to the battery positive

(+) and the connector terminal 2 (E) to the negative

(-), check that the motor operates at high speed.

If it is not as specified, replace the motor.

(c) Inspect automatic return

1Connect the connector terminal 5 to the battery positive (+) and the connector terminal 2 (E) to the

negative (-). Let the motor operates at low speed, disconnect terminal 5 (+) to make the motor stop at a

random position.

2Connect the terminal 5 and terminal 3, and connect the terminal 4 to the battery positive (+), make the

motor restart at low speed.

3Check that the automatic return operates in a normal way.

If it is not as specified, replace the motor.Switc h position Te ste d termina l Spe c ifie d c onditionOFFNo c ontinuity

ON 8(+)—7(-)Continuity

Page 205 of 392

198Chapter 5 Light SystemSection 1 Survey of Light SystemI. COMPOSITION1. Front combination lamp assembly: turn signal lamp, high beam, low beam, head lamp, front position lamp.

2. Rear combination lamp: turn signal lamp, back-up lamp, rear fog lamp, tail lamp, brake lamp, retro reflector.

3. Front fog lamp

4. Side turn signal lamp

5. High mounted stop lamp

6. Rear trunk lamp

7. License plate lamp

8. Interior dome lamp

9. Rear row reading lamp

10. Door lampshield and bulb assemblyII. NOTES FOR REPAIR1. NOTES WHEN REPAIRING ELECTRICAL EQUIPMENTS

(a) Disconnect the battery ground cable.

2. Notes when replacing a headlamp bulb

(a) Before replacing a halogen bulb, turn the headlamp OFF to make it cool.

(b) When installing a new halogen bulb, do not touch the glass part of the bulb with bare hands.

(c) If there is oil stain on the surface of halogen bulb (headlamp and front fog lamp) when the lamps are

turned ON, its service life will be shortened.

(d) Halogen bulbs (headlamp and front fog lamp) have pressurized gas inside and require special handling.

They can explode if dropped to ground.The glass fragments will splash up.

(e) When replacing, make sure to use the bulbs with the same power, same model.

(f) After the bulb is installed, make the lamp holder tight.

Page 217 of 392

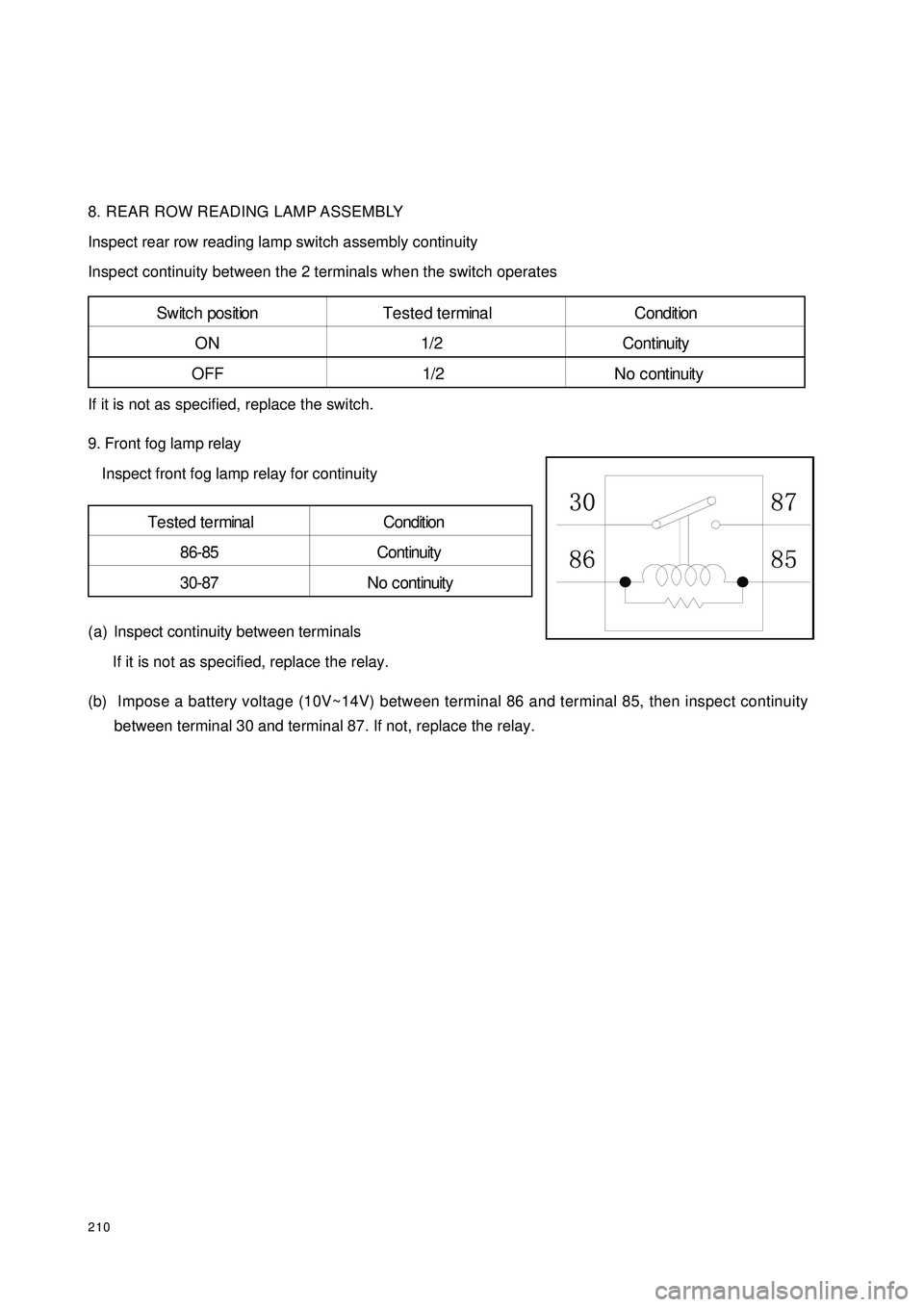

2108. REAR ROW READING LAMP ASSEMBLY

Inspect rear row reading lamp switch assembly continuity

Inspect continuity between the 2 terminals when the switch operates

If it is not as specified, replace the switch.

9. Front fog lamp relay

Inspect front fog lamp relay for continuity

(a) Inspect continuity between terminals

If it is not as specified, replace the relay.

(b) Impose a battery voltage (10V~14V) between terminal 86 and terminal 85, then inspect continuity

between terminal 30 and terminal 87. If not, replace the relay.S w it c h pos it ion T e s t e d t e r mina l C ondit ion

ON 1/2 Continuity

OFF 1/2 No continuityTe ste d te rmina l Condition

86-85 Continuity

30-87 No c ontinuity

Page 233 of 392

226II. Inspection1. Power switch system doesn't work

Wiring Diagram

(1) Check radio assembly (+B, ¬ACC, ¬GND)

1Check the continuity between terminals under each operating condition as shown in the table below

Standard:

2Check the voltage between terminals under each operating condition as shown in the table

Standard:

Normal:Repair or replace wire harness, connector

Abnormal:Check or replace radio assemblyMain Fuse BoxRadio and CD

BatteryFusible Link BoxIgnition SwitchTester connection Condition Standard Status

GND Consta nt Status ContinuityTeste r Connec tion Condition Sta nda rd Sta tus

+B - GND Consta nt Status 10~

14V

ACC - GND Ignition switch ACC or ON 10~

14V