battery GEELY CK 2008 User Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 49 of 392

42Section 2 Fuel Pump Inspection1. Fuel pump

(a) Check fuel pump resistance, 0.2~3.0 at 20°. Replace fuel pump if the resistance is not as specified.

See (Figure 93)

(b) Fuel pump running:

Check fuel pump by connecting with battery. Replace fuel pump or wire if the running is not as specified.

See (Figure 94).

The test should be conducted within 10s to prevent coil from damage.

2. Fuel injector assembly

Injection Volume: 40~50cm3/s

Error between each injector: less than 10 cm3Replace injector if the injection volume is not as specified.

(a) Check for leakage: Disconnect the cable from the battery. The fuel drop/min is no more than 1 drop.

Figure 93 Figure 94 Ohmmeter

Battery Ω

Page 60 of 392

536. Fan

(1) Check the cooling fan operation with low temperature (Lower than

83°C)

(a) Turn the ignition switch to “ON” position.

(b) Check that the cooling fan stops.

(c) Pull out the water temperature sensor connector. See (Figure

122)

(d) Connect the water temperature sensor to car body with the

wire and ground the wire.

(e) Check the cooling fan operation.

(f) Insert water temperature sensor connector.> 93°C

See (Figure 123)

(a) Start engine and make the coolant temp. higher than 93°C.

(b) Check that the cooling fan turns.

Replace it with water temperature switch if it doesn't run)

(3) Check the cooling fan. See (Figure 124)

(a) Disconnect the cooling fan connector.

(b) Connect the battery and ammeter to the connector.

(c) Check that the cooling fan rotates smoothly and check

the reading on the ammeter.

Standard amperage: 5.7 - 7.7A

(d) Reconnect the cooling fan connector.Disconnest

Figure 123

Figure 124 Figure 122

(2) Check the cooling fan operation with high temperature (over 93°C)Battery Amperometer

Page 67 of 392

60Section 1 Manual Transaxle Replacement1. Open the engine hood

2. Remove the battery

3. Remove clutch cylinder sub-assembly. See (Figure 140)

4. Detach transmission shift cable assembly. See (Figure 141)

5. Remove the connector and turn on the back-up lamp switch connector.

6. Disconnect vehicle speed sensor

Disconnect vehicle speed sensor connector.

7. Detach the front exhaust pipe

8. Drain transmission oil

9. Detach left & right front wheel hub nut

10. Detach left & right front wheel speed sensor (ABS)

11. Detach front balance rod

12. Detach left & right tie-rod with ball stud pin

13. Detach front balance rod

14. Detach left & right lower swing arm

15. Detach left & right front propeller assembly

16. Hoist the engine from compartment. See "Provision 20, Section 2, Chapter 2"

17. Detach starter assembly

18. Detach engine mounting bracket

19. Detach manual transaxle assembly

20. Install engine mounting bracket

21. Install manual transaxle assembly

22. Connect engine vibration insulating cushions

23. Install starter assembly

24. Install left & right front propeller assembly

25. Connect left & right lower swing arm

26. Connect left & right tie-rod with ball stud pin

27. Connect front balance rod

28. Connect left & right front speed sensor (ABS)

29. Installleft & right front shaft nut

30. Install front exhaust pipe

31. Connect speedometer sensor connector.

32. Connect back-up lamp switch connector.

33. Connect transmission shift cable assembly. See (Figure 141)

34. Install clutch sub-pump assembly. See (Figure 140)Figure 140

Figure 141

Page 71 of 392

64Chapter 9 General Engine Troubles and Their

TroubleshootingSection 1 Overview The wide application of the electronic technologies to the vehicles brings innovation on diagnosis of the

vehicle, many varieties of diagnosis instruments that are very effective and efficient for the vehicle diagnosis

are innovated. Once the fault occurs, the best choice is to go to service station for help. However, even the

most advanced instrument has its limit. For some faults, manual diagnosis is far more convenient and easier

than that of instrument. In case of the crack, distortion and leakage of the components, the manual diagnosis

is even superior to the instrument diagnosis. The faults occurred shall be carefully analyzed and troubleshot

in accordance with the repair manual for normal usage.Section 2 General Engine Fault and TroubleshootingI. Fuel pipeline and circuit fault causing the engine starting failureengine starting failure normally include: starter does not run or starter runs but fails to crank the engine, or

cranks the engine but cranks slowly; starter can crank but fail to start the engine. There are many causes that

result in starting failure, such as failures in starting system, ignition system, fuel injection system and engine

mechanical failure.

1. starter does not run or fails to crank the engine or cranks slowly

(1) Symptom: starter does not run or spongy rotation

(2) Causes:

b. Low battery voltage, excessive battery discharge, damaged generator or failure in charging circuit;

c. Battery terminal rust and backed out;

d. Failure in starting circuit, ECU can not receive STA signal;

e. Damaged starter.

2. engine can not start and crank

(1) Symptom

With the start switch on, starter can crank but fail to start the engine.

(2) Causes

a. Empty fuel tank;

b. Electrical fuel pump inoperative;

c. Injector inoperative;

d. Low fuel pressure;

e. Unreasonable starting operation;

f. Damaged throttle position sensor or no signal is sent to ECU due to the open in throttle position

sensor circuit;

Page 73 of 392

66f. The idle control valve is faulty;

g. The water temperature sensor is damaged;

h. The vacuum pressure sensor is damaged;

i. The air filter is blocked;

j. The injector leaks;

k. The compression pressure in the cylinder is too low;

l. The intake temperature sensor is damaged.

(3) Diagnosis and Troubleshooting

a. Check high pressure spark, check whether the high pressure spark on the ignition coil high pressure

bus and extension are OK, if the bus spark is week, replace the ignition coil, if the bus spark is OK

while the extension spark is too week, replace the ignition coil also; In addition, excessive spark

plug clearance will influence the starting feature, the clearance of the spark plug shall be adjusted

to normal value (0.8±0.1mm);

b. If there is low fuel pressure, check whether the battery voltage is OK, otherwise it shall be

troubleshot or replaced; check fuel pump check valve for leakage, check fuel filter and fuel pipe for

block, if there are leakage or block, replace or troubleshoot them;

c. If there is leakage for fuel pressure regulator, intake manifold is likely to be mixed with gasoline and

it is hard to start, troubleshoot or replace them;

d. Idle control valve can not be opened to maximum position due to mechanical wear, aging or control

circuit failure, the idle control valve shall be replaced and the control circuit failure shall be troubleshot;

e. If the water temperature sensor data is not accurate, it may cause small injection, check the water

temperature sensor based on the standard data and calibrate the data;

f. There is big time lag for intake pressure temperature sensor that makes it somewhat insensitive at

low speed and result in inaccurate injection, adjustment or replacement shall be made;

g. If the air cleaner filter is too dirty, the air flow resistance is excessively big, resulting in hard start,

as a result of it, the filter shall be replaced.

In a word, there are many factors causing the starting failure of the engine, analysis shall be made based on

the severe conditions of the faults. Generally speaking, check the ignition system first, then check intake

system, fuel system, control system, at last check the cylinder pressure, check the DTC before checking the

trouble. The diagnosis and troubleshooting procedures for starting failure of the engine are shown in (Figure

148).

Page 90 of 392

83ECU microcomputer consists of microprocessor, memory, clock generator, timer, I/O interface and input

level A/D converter that are integrated in a large scale integrated circuit chip, that is SCM (Single Chip

Microcomputer).

1. Input level

The input signals from the sensor are pre-processed by the input level. The input signals are sent to protected

circuit first, sometimes through the signal converter and amplifier, and then sent to microcomputer.

The sensor signal is separated into switch type and analog type. Ignition on/off signal, camshaft position

signal, vehicle speed signal and A/C signal are switch type; Signals such as battery voltage, engine temperature,

intake temperature, airflow, intake manifold absolute pressure, throttle opening, excessive air coefficient,

knock, A/C refrigerant pressure are analog type. Analogy signal can only be processed by the digital micro-

computer after being converted into digital signal by A/D converter. Hence, data collection shall be made

first for analog signal, and the sampling shall be maintained also.

Speed and crankshaft position reference signal from the sensor is processed in a dedicated circuit to restrain

the interference pulse.

2. Microcomputer

The microcomputer of the engine electronic control unit is integrated in a single chip microcomputer, consist-

ing of the following:

(1) Microprocessor, microprocessor is also called as central processing unit (CPU), consisting of the following

three parts:

Arithmetic logic unit.

Register group.

Controller.

(2) System assembly, The data transferred among the internal sections of the single chip microcomputer

(SCM) is performed on the internal bus, while that between the SCM and other components is performed

on the external bus. The external bus is also called system bus. It is separated into data bus, address bus

and control bus.

(3) Memory, the memory is designed to store the binary data. The primary components of the memory are:

Memory.

Data register.

Address register, address decoder.

a. Memory controller

(4) A/D converter

(5) I/O interface.

(6) Clock generator.

(7) Timer

(8) CAPCOM unit.

(9) Watchdog timer.

(10) Interrupt system.

Page 138 of 392

131Replacement1. Cautions (refer to Steering System Cautions)

2. Make sure the wheels are placed straight ahead

3. disconnect the battery negative terminals

4. Remove the air bag assembly

Remove two screws on both sides and pull out the wiring harness connector

Notice: Do not pull air bag wire harness when removing the air bag assembly!

Warning:

�‹ �‹�‹ �‹

�‹Make sure the upper surface of the air bag assembly is kept upward when placing it!

�‹ �‹�‹ �‹

�‹Do not disassemble the air bag assembly!

5. Remove steering wheel assembly

(1) Remove the nut.

(2) Remove the steering wheel cover set bolt.

(3) place the matchmarks on the steering wheel and main shaft assembly.

(4) Use special tool to remove the steering wheel assembly.

6. Remove the steering column upper and lower cover

(1) Remove 3 screws.

(2) Remove the steering column upper and lower cover.Use Inner

Hex Socket

Wrench

Page 164 of 392

157Part III Electrical EquipmentChapter 1 SurveyThis part refers to the electrical repair of the Free Cruiser, and analyzes the faults from every system. Then

some practicable diagnosis procedure and repair ways are given.I. HAND-HELD TESTER1. Before the tester is used, a through reading of the Tester Operation Manual is commended.

2. Connect the tester to the diagnosis interface with a wire. Turn the ignition switch ON. At this time, if the

tester and ECU control system cannot communicate, the vehicle or the tester may have faults.

(1) Connect the tester lead wire to another vehicle. If the communication is normal, inspect the vehicle

diagnosis Busline or power supply circuit.

(2) If it still cannot communicate when connecting to the other vehicles, it may have faults on tester itself.

Consult the self-inspecting procedure described on the Tester Operation ManualII. HOW TO PROCEED WITH TROUBLESHOOTINGThe basic operation procedure for troubleshooting is as follows.

1. Customer fault analysis

(a) Ask the customer for the conditions and environment when faults happen.

2. Confirm the fault symptoms, and check the DTCs and storage data.

(a) Check the battery positive voltage (Voltage: 10 - 14V when the engine is stopped.)

(b) Inspect the harness, connector and fuse for open and short, etc. by their appearance.

(c) Warm up the engine temperature to the normal operation temperature.

(d) Confirm the fault symptoms and check the DTCs.

(e) Confirm the test procedure for the parts or systems that need checking.

3. Circuit or part inspection

4. Repair

5. Test for checking

(a) After the repair is completed, verify if the fault has been removed.

(If the fault has not appeared yet, a verifying test should be done under the same conditions and environment

when the fault first occurred.)

Page 168 of 392

161Chapter 2 Starting and Charging SystemSection 1 Starting System

(MR479Q MR479QA MR481QA)I. STARTER INSPECTIONNOTICE:

These tests must be done within 5 seconds to avoid burning out the coil.

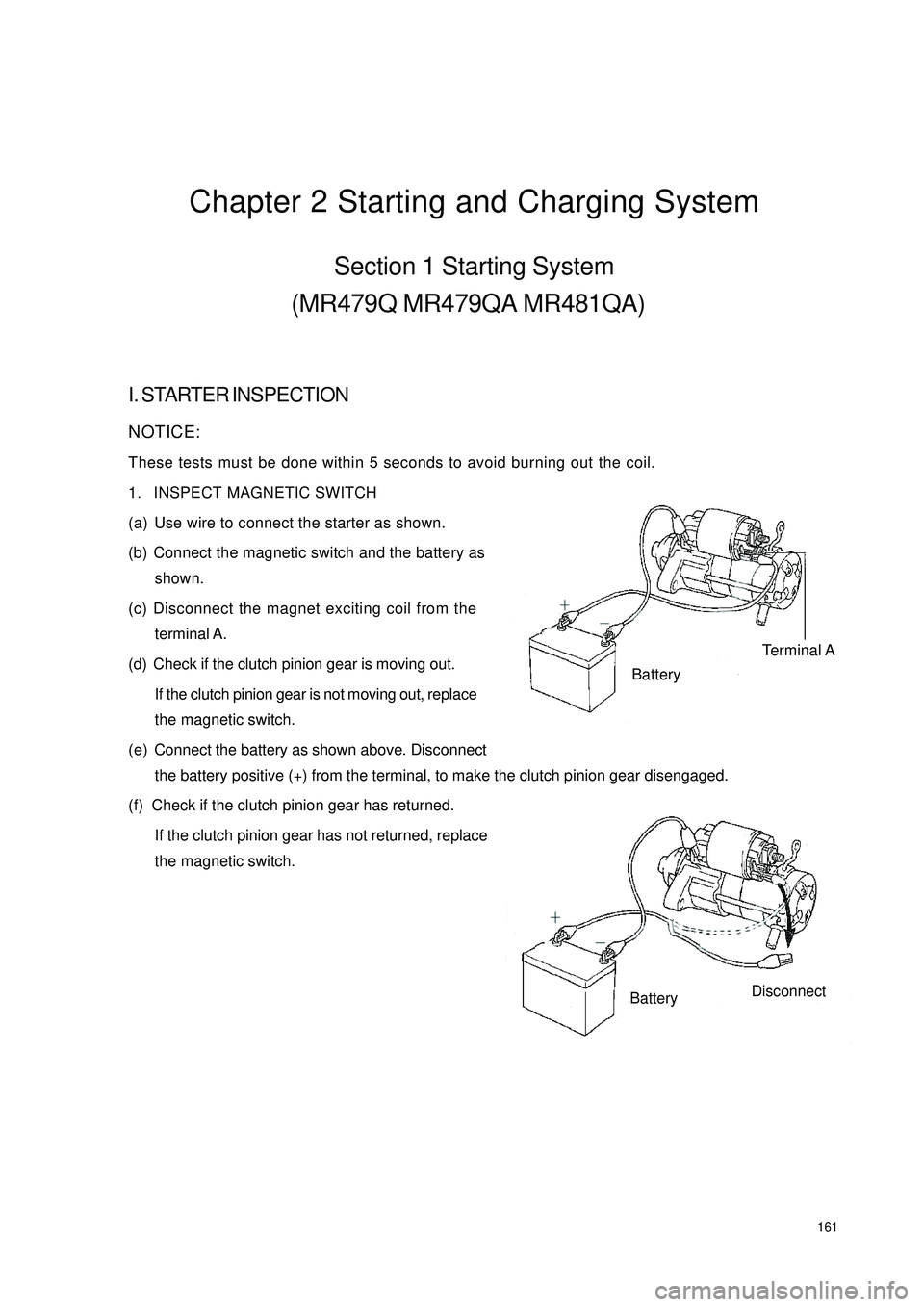

1. INSPECT MAGNETIC SWITCH

(a) Use wire to connect the starter as shown.

(b) Connect the magnetic switch and the battery as

shown.

(c) Disconnect the magnet exciting coil from the

terminal A.

(d) Check if the clutch pinion gear is moving out.

If the clutch pinion gear is not moving out, replace

the magnetic switch.

(e) Connect the battery as shown above. Disconnect

the battery positive (+) from the terminal, to make the clutch pinion gear disengaged.

(f) Check if the clutch pinion gear has returned.

If the clutch pinion gear has not returned, replace

the magnetic switch.Terminal ABatteryBatteryDisconnect

Page 169 of 392

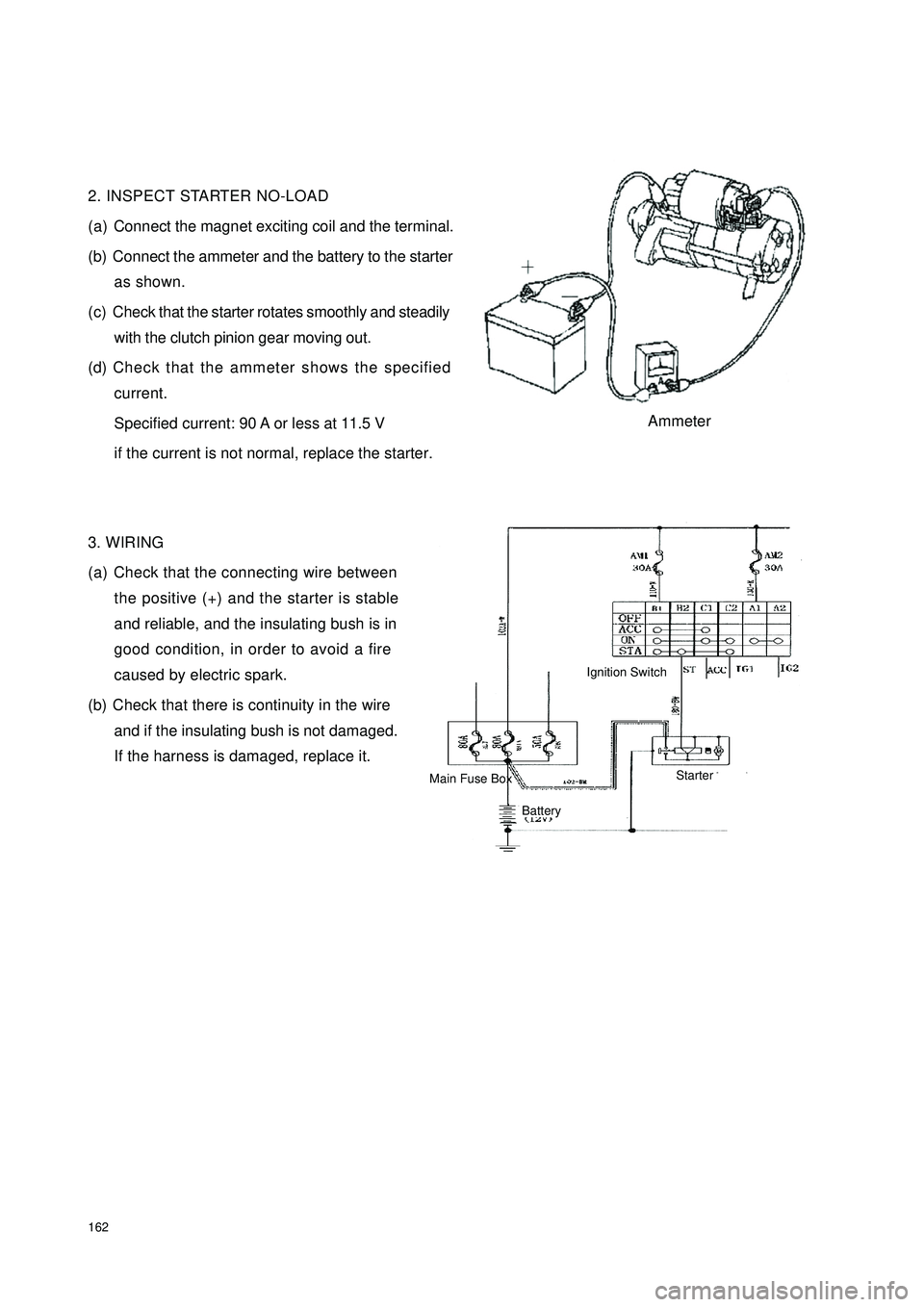

1622. INSPECT STARTER NO-LOAD

(a) Connect the magnet exciting coil and the terminal.

(b) Connect the ammeter and the battery to the starter

as shown.

(c) Check that the starter rotates smoothly and steadily

with the clutch pinion gear moving out.

(d) Check that the ammeter shows the specified

current.

Specified current: 90 A or less at 11.5 V

if the current is not normal, replace the starter.

3. WIRING

(a) Check that the connecting wire between

the positive (+) and the starter is stable

and reliable, and the insulating bush is in

good condition, in order to avoid a fire

caused by electric spark.

(b) Check that there is continuity in the wire

and if the insulating bush is not damaged.

If the harness is damaged, replace it.AmmeterIgnition SwitchBattery Main Fuse BoxStarter