sensor GEELY CK 2008 Owner's Guide

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 106 of 392

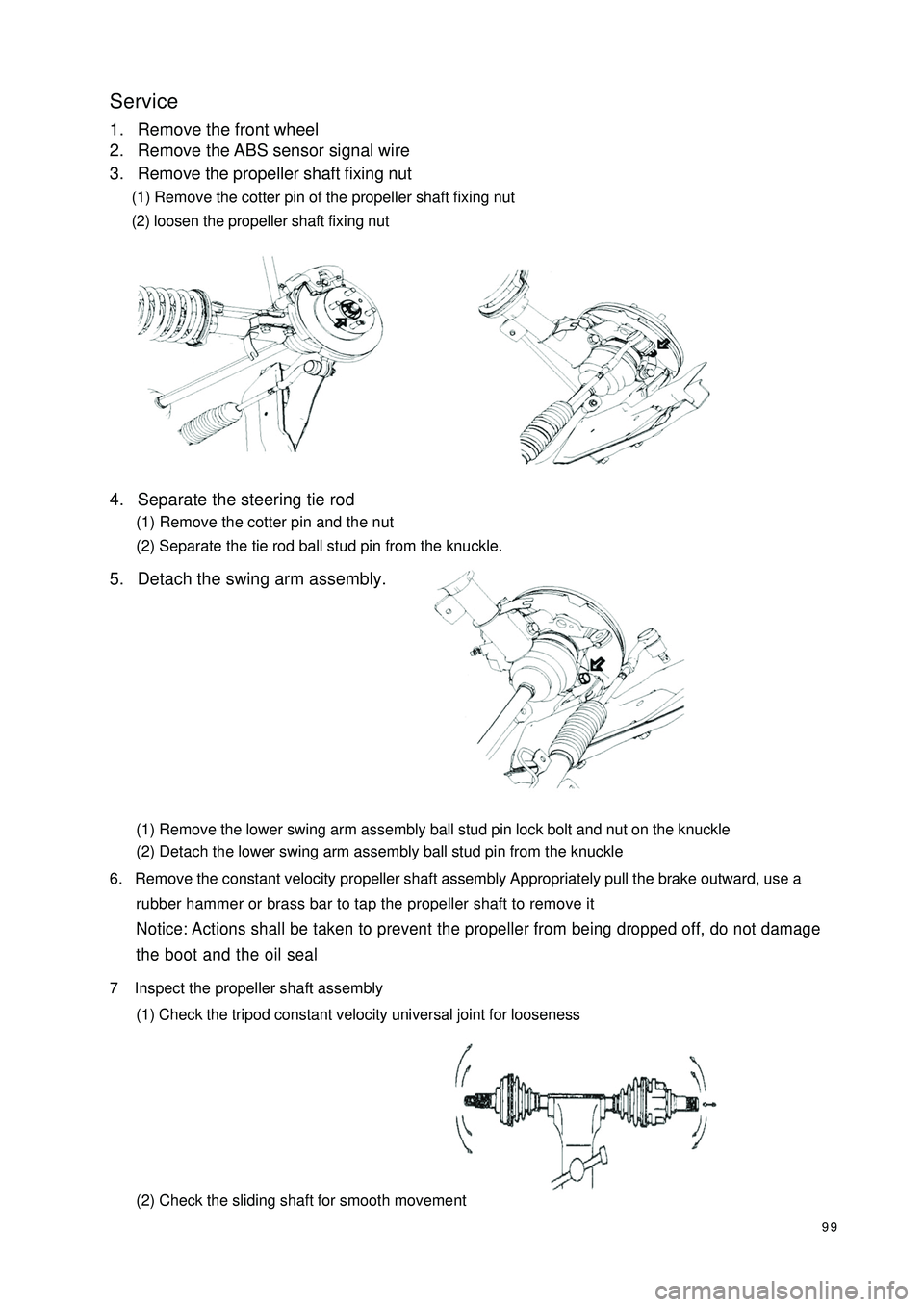

99Service1. Remove the front wheel

2. Remove the ABS sensor signal wire

3. Remove the propeller shaft fixing nut

(1) Remove the cotter pin of the propeller shaft fixing nut

(2) loosen the propeller shaft fixing nut

4. Separate the steering tie rod

(1) Remove the cotter pin and the nut

(2) Separate the tie rod ball stud pin from the knuckle.

5. Detach the swing arm assembly.

(1) Remove the lower swing arm assembly ball stud pin lock bolt and nut on the knuckle

(2) Detach the lower swing arm assembly ball stud pin from the knuckle

6. Remove the constant velocity propeller shaft assembly Appropriately pull the brake outward, use a

rubber hammer or brass bar to tap the propeller shaft to remove itNotice: Actions shall be taken to prevent the propeller from being dropped off, do not damage

the boot and the oil seal7 Inspect the propeller shaft assembly

(1) Check the tripod constant velocity universal joint for looseness

(2) Check the sliding shaft for smooth movement

Page 109 of 392

102(7) Install front wheel, wheel nut torque: 95~115N.m

(8) Make sure that the propeller shafts for 1.3L engine and 1.5L engine are not interchanged

at the time of replacement

(9) Check the ABS sensor signal, check and adjust the front wheel alignment if necessary.

Page 112 of 392

105Section 2 Front SuspensionComponents

LF Strut Assembly

Front

Brake Hose Clip

Connected to Brake

Connected

to Brake

LF Brake Assembly

Stabilizer Bar

Left Link Rod

Assembly

Left lower Swing

Arm Assembly

Lower Swing

Arm LF Bracket

Lower Swing Arm

RF Bracket

Front Stabilizer Bar Assembly

Stabilizer Bar

Right Link Rod Assembly

RF Brake Assembly

Connected to Brake

Clip

Front Brake Hose

RF Strut Assembly

Connected

to Brake

BodyBody

Right Lower

Swing Arm

Assembly

Lower Trailing

Arm Rear Elastic Hinge

Fixed to Shock

Absorber

ABS Sensor Wire Harness

Shock Absorber

Page 114 of 392

107Section 4 Front Strut AssemblyComponents:WasherMount CoverShock Absorber Mount SupportBig WasherThrust Ball BearingSpring Upper SeatFront Coil Spring

Upper InsulatorFront Coil SpringLeft Brake Assembly ABS Sensor Wire HarnessFront Brake Hose Stabilizer Bar Left

Link Rod AssemblyLF Shock Absorber AssemblyFront Coil Spring Lower InsulatorFront BumperFront Shock Absorber

Protecting Sleeve

Page 115 of 392

108Replacement1. Remove the front wheel.

2. Remove the ABS sensor from the steering knuckle. Separate the sensor and signal wire from the wire

harness bracket on the front shock absorber.

3. Separate the front brake hose

Remove 2 clips and separate the front brake hose from the front shock absorber bracket.

4. Remove the stabilizer bar link rod assembly

Remove the nut connecting the stabilizer bar link rod assembly and the shock absorber.

5. Remove the front shock absorber with the coil spring

(1) Remove the nuts and bolts connecting the shock absorber and brake.

(2) Remove the 4 nuts connecting the front shock absorber and vehicle body.

Notice: reliable object shall be used to support the brake assembly!

Page 116 of 392

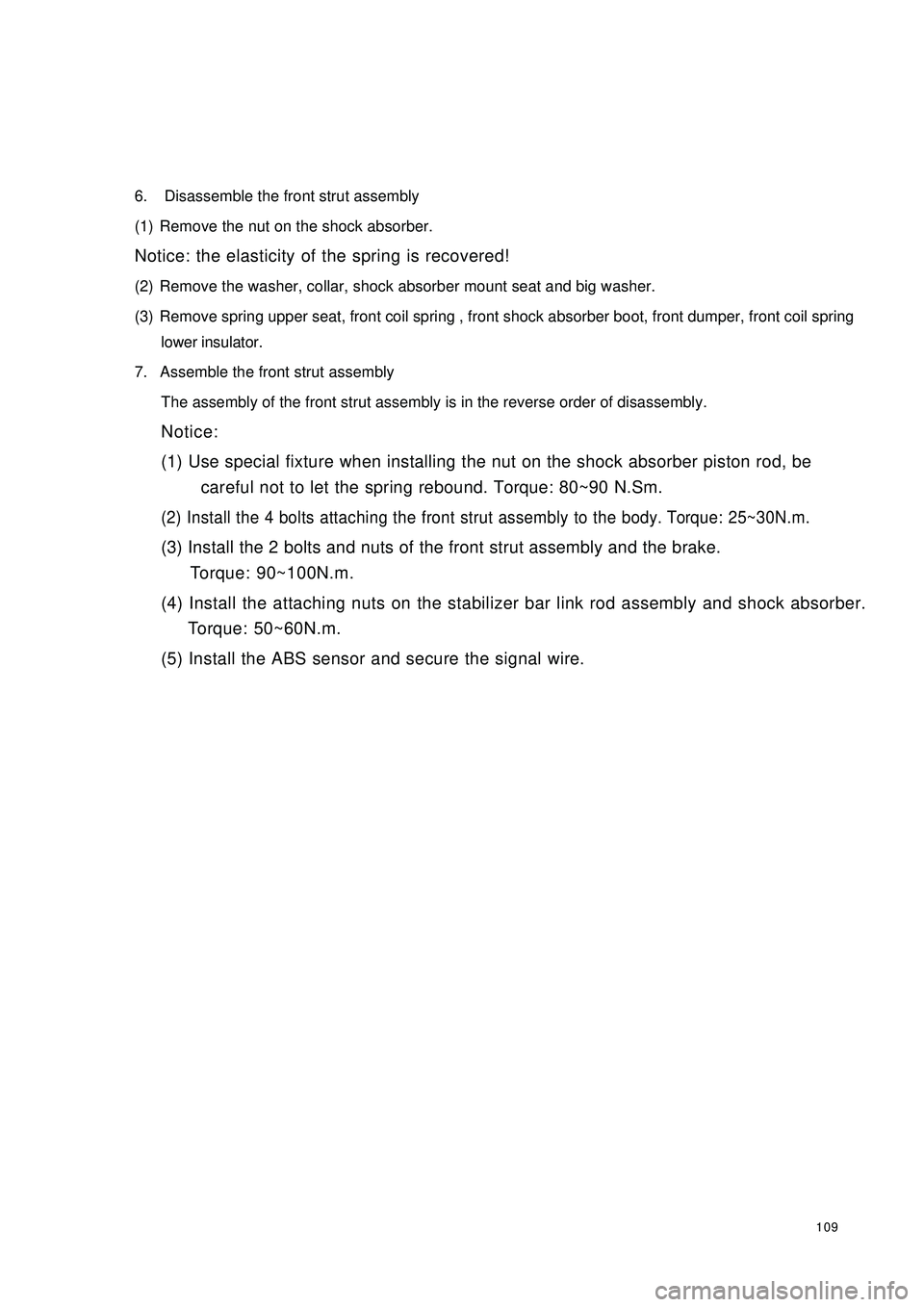

1096. Disassemble the front strut assembly

(1) Remove the nut on the shock absorber.

Notice: the elasticity of the spring is recovered!

(2) Remove the washer, collar, shock absorber mount seat and big washer.

(3) Remove spring upper seat, front coil spring , front shock absorber boot, front dumper, front coil spring

lower insulator.

7. Assemble the front strut assembly

The assembly of the front strut assembly is in the reverse order of disassembly.

Notice:

(1) Use special fixture when installing the nut on the shock absorber piston rod, be

careful not to let the spring rebound. Torque: 80~90 N.Sm.(2) Install the 4 bolts attaching the front strut assembly to the body. Torque: 25~30N.m.(3) Install the 2 bolts and nuts of the front strut assembly and the brake.

Torque: 90~100N.m.

(4) Install the attaching nuts on the stabilizer bar link rod assembly and shock absorber.

Torque: 50~60N.m.

(5) Install the ABS sensor and secure the signal wire.

Page 124 of 392

117Section 2 Rear SuspensionComponents

LR Strut Assembly

LR ABS Sensor Wire Harness

LR Brake

LR Brake Pipe

Clip

Clip

RR Strut Assembly

Clip

RR ABS Sensor Wire Harness

RR Brake Hosex2

No. 2 Transverse Arm

Left Trailing Rod Assembly

Body

Body

Body Body

No. 1 Transverse Arm

No. 1 Rocker Arm

Clip

RR Brake Pipe

RR Brake Hose

RR Brake

Right Trailing Rod Assembly

Rear Stabilizer Bar Assembly

No. 2 Transverse Arm

Rear Stabilizer Bar Retainer

Rod Components

Page 126 of 392

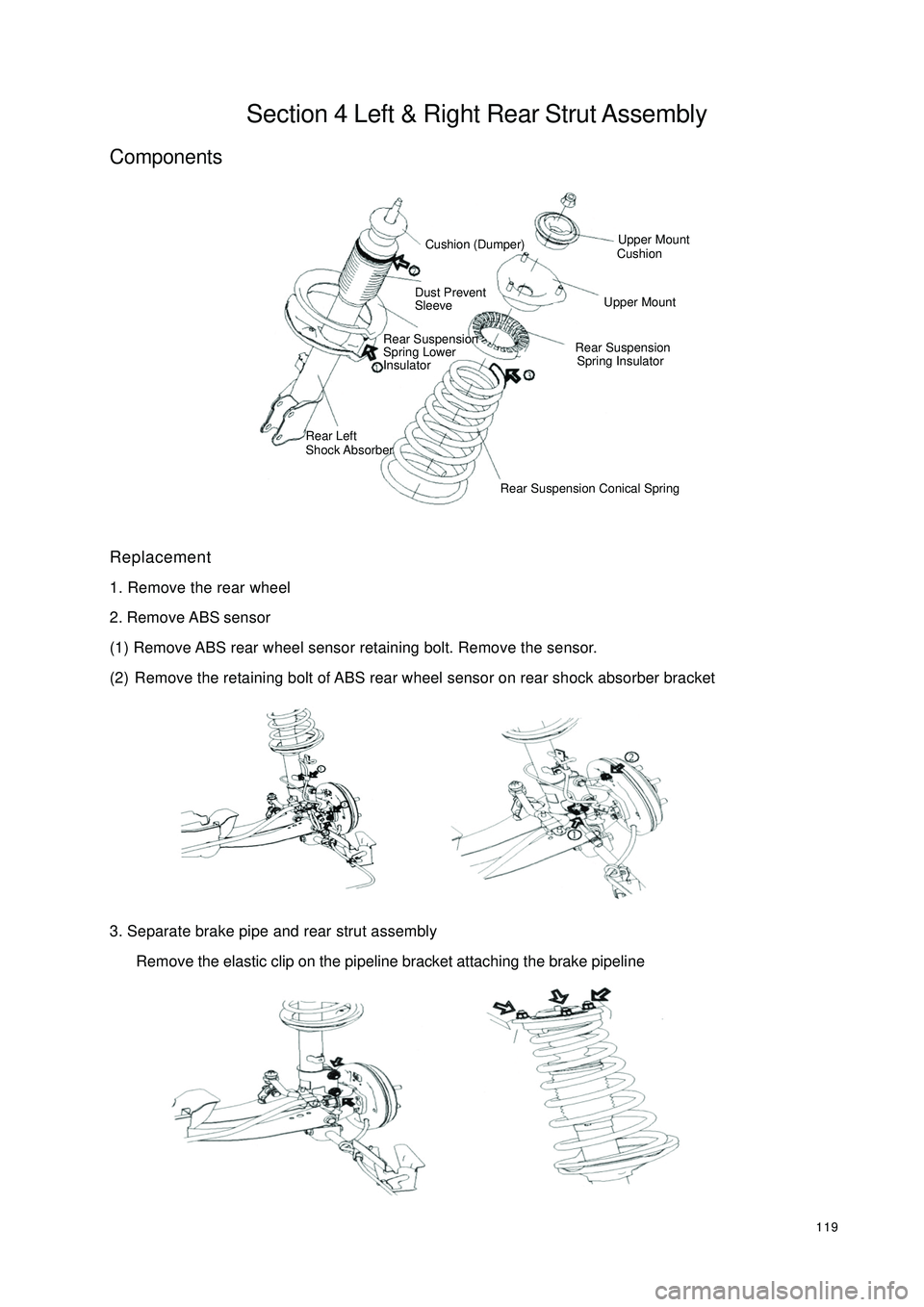

119Section 4 Left & Right Rear Strut AssemblyComponentsReplacement

1. Remove the rear wheel

2. Remove ABS sensor

(1) Remove ABS rear wheel sensor retaining bolt. Remove the sensor.

(2) Remove the retaining bolt of ABS rear wheel sensor on rear shock absorber bracket

3. Separate brake pipe and rear strut assembly

Remove the elastic clip on the pipeline bracket attaching the brake pipelineCushion (Dumper)Dust Prevent

SleeveRear Suspension

Spring Lower

InsulatorRear Left

Shock Absorber Upper Mount

CushionUpper MountRear Suspension

Spring Insulator

Rear Suspension Conical Spring

Page 127 of 392

1204. Remove the left and right rear strut assembly

(1) Remove the threaded connect of the rear strut assembly and rear brake assembly

(2) Remove the 3 nuts attaching the rear suspension upper mount to the body

Caution: reliable object shall be used to support the rear brake assembly! Make sure that the

brake pipeline is not affected or damaged!

5. Disassembly the left, right rear strut assembly

(1) Set the rear strut assembly with special tool. Remove the nut on the top of the

rear shock absorber piston

Caution: The spring may rebound!

(2) Remove the rear suspension upper mount, rear suspension upper mount cushion,

rear suspension spring upper insulator, rear suspension spring, rear shock absorber

cushion, rear shock absorber dust preventing sleeve, rear suspension spring lower insulator in order

6. The assembly is in the reverse order of the disassembly.

Caution:

(1) when installing the nut on the shock absorber piston rod upper end, use special fixture

and be careful that the spring may rebound!

Torque : 32~38N.m

(2) Rear strut assembly to body thread torque : 32~38 N.m

(3) Strut assembly to rear brake assembly thread torque : 81~96 N.m

(4) Install the ABS rear wheel sensor and the secure the signal wire

(5) When securing the brake line, make sure that the brake line does not interfere with

other parts

(6) Wheel nut torque : 95~115N.m

(7) Check the brake system for leakage, bleed air in the brake system as necessary

(8) Check whether the ABS signal is normal

(9) Check rear wheel alignment, adjust it as necessary

Page 166 of 392

1594Make a simulation test in a way of symptom simulation

5Inspect DTC

6Confirm symptomV. SYMPTOM SIMULATIONNOTES:

The most difficult conditions to handle in the fault troubleshooting are that the fault symptom dose not appear.

Under the circumstances, make sure first to make a comprehensive analysis to the fault described by the

customer, then to simulate an environment that is similar or the same with the conditions when the fault of the

customer's vehicle occurred. No matter how rich the experience of the technician is and how skillful he is, if

he make a fault troubleshooting analysis without confirm the fault symptom, it is inevitable for him to neglect

some important factors and incorrectly guess, which may cause barriers to repair. For example, if a fault

occurs only when the engine is cool or if a fault occurs only caused by a vibration from pavement and so on,

when the engine is checked in the hot or static state, it is no way to confirm. Because of vibration, high-

temperature or seeping water (Vapor) often causes some faults that are difficult to reappear. So, here are

some effective symptom simulation tests.

KEY POINTS OF SYMPTOM SIMULATION TEST:

In the symptom simulation test, no doubt it is important to confirm the fault symptom, but the fault position or

fault components must be also found out. So, before the test and the pre-inspection of connection, narrow the

range of the circuit where faults may occur according to the fault symptom. Then make a symptom simula-

tion test to see if the circuit measured is normal; the fault symptom is also verified at the same time.

1. Way of Vibration: When vibration may be the major cause of the fault.

For example:

(a) Use your hand to gently vibrate the sensor that is considered the cause of the fault, in order to check if it

is ineffective.

(b) Softly rock the connector and harness in horizontal and vertical direction.

Notes: Hard rock may cause the relay circuit open.

2. Way of Spraying Water: When rainy weather or wet environment may be the major cause of the fault.

(a) Spray water on the vehicle to check if the fault occurs.

NOTES:

�yBe sure not to directly spray water into the engine compartment. Spray the water on the face of the

radiator to change the temperature and humidity indirectly.

�yBe sure not to spray water onto electronic devices and controllers.