sensor GEELY CK 2008 Repair Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 296 of 392

289III. ABS System CheckIte mIgnition

Switch ShiftTe rminal Pole Standard Unit

Battery Voltage OFF 25-8 10.1~

14.5 V

Battery Voltage

(

s ole noid va lve)OFF 9-24 10.1~

14.5 V

P owe r supply

in s ula t ionOFF 8-4 0.00~

0.5 V

Ground insula tion OFF 8-24 0.00~

0.5 V

P owe r supply

volta geON 8-4 10.1~

14.5 V

OFF Warning light goe s off Visua l inspec tion

ON Wa rning light goes on Visua l inspec tion

OFF Warning light goe s off Visua l inspec tion

ONWa rning light goes on

for a bout 1.7 se c onds

then goes offVisual inspection

B r a ke light s w it c h

peda l not de presse dON 8-18 0. 0~

0.5 V

B r a ke light s w it c h

peda l de pre sse dON 8-18 10. 0~

14.5 V

Diagnostic interface OFFDia gnostic inte rfa c e

K & 70.0~

0.5Ω

LF Wheel Speed

Sensor ResistanceOFF 1-20 1.2~

1.3 KΩ

RF Wheel Speed

Sensor ResistanceOFF 19-20 1.2~

1.3 KΩ

LR Wheel Speed

Sensor ResistanceOFF 5-6 1.0~

1.3 KΩ

RR Wheel Speed

Sensor ResistanceOFF 22-23 1.0~

1.3 KΩ

LF Whe e l Se nsor

Output VoltageOFF 1-2 3.4~

14.8 MV/Hz

RF Whe e l Se nsor

Output VoltageOFF 19-20 3.4~

14.8 MV/Hz

LR Whe e l Se nsor

Output VoltageOFF 5-6 >12.2 MV/Hz

RR Wheel Sensor

Output VoltageOFF 22-23 >12.2 MV/Hz

Spee d Se nsor Output

Voltage RatioABS Warning LightECU not connected

Connect ECUMaximum peak voltage

Minimum peak voltage≦2

Page 298 of 392

291IV. ABS Operation Inspection1. Check the Wheel Speed Sensor Output Voltage

1Check whether the clearance between the wheel speed sensor and the ring gear is within the specification

For front wheel standard value, refer to "Front Wheel Sensor Installation Drawing"

For rear wheel standard value, refer to "Rear Wheel Sensor Installation Drawing"

3Jack up the wheel and release the manual brake

2Remove the ABS wire harness, measure at the wire harness connector

4Rotate the wheel at the speed of 1/2 turn/second, and use the multimeter or oscilloscope to measure the

output voltage

Terminal 1-2

Terminal 19-20

Terminal 5-6

Terminal 22-23

Output Voltage

�zWhen use the multimeter to measure

For front wheel, refer to "Front Wheel Sensor Drawing".

For rear wheel, refer to "Rear Wheel Sensor Drawing".

�zWhen use the oscilloscope to measure

For front wheel, refer to the related standard.

For rear wheel, refer to the related standard.

5The fact that the output voltage is not within the above range may result from the following causes:

�zExcessive clearance between the sensor and the ring gear.

�zSensor fault.

�zCheck the sensor resistance£¨1.0 - 1.3k¦¸£©.

�zSelect the 4 points on the ring gear to check the clearance (ring gear distortion) between the ring

gear and the wheel speed sensor.

2.Check the Hydraulic Control Unit (HCU).

1Jack up the vehicle, make sure the wheel can rotate freely.

2Release the manual brake.

3Turn the ignition switch to ON after connecting the scan meter, do not start the engine this time.

4Refer to the HCU Diagnosis for inspection.

Note: when connecting or removing the scan meter, the ignition switch must be turned to OFF.

Page 309 of 392

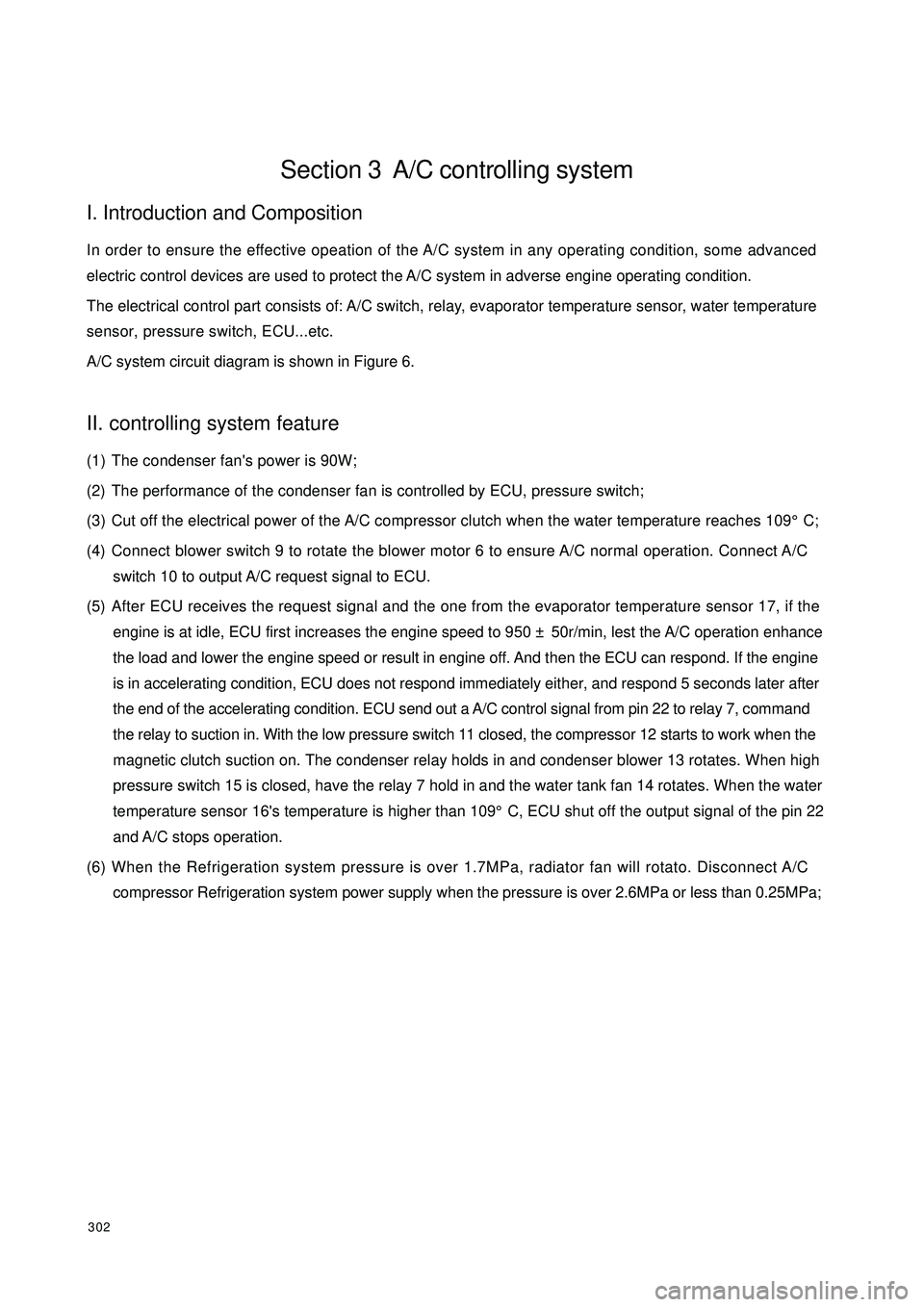

302Section 3 A/C controlling systemI. Introduction and CompositionIn order to ensure the effective opeation of the A/C system in any operating condition, some advanced

electric control devices are used to protect the A/C system in adverse engine operating condition.

The electrical control part consists of: A/C switch, relay, evaporator temperature sensor, water temperature

sensor, pressure switch, ECU...etc.

A/C system circuit diagram is shown in Figure 6.II. controlling system feature(1) The condenser fan's power is 90W;

(2) The performance of the condenser fan is controlled by ECU, pressure switch;

(3) Cut off the electrical power of the A/C compressor clutch when the water temperature reaches 109°C;

(4) Connect blower switch 9 to rotate the blower motor 6 to ensure A/C normal operation. Connect A/C

switch 10 to output A/C request signal to ECU.

(5) After ECU receives the request signal and the one from the evaporator temperature sensor 17, if the

engine is at idle, ECU first increases the engine speed to 950 ± 50r/min, lest the A/C operation enhance

the load and lower the engine speed or result in engine off. And then the ECU can respond. If the engine

is in accelerating condition, ECU does not respond immediately either, and respond 5 seconds later after

the end of the accelerating condition. ECU send out a A/C control signal from pin 22 to relay 7, command

the relay to suction in. With the low pressure switch 11 closed, the compressor 12 starts to work when the

magnetic clutch suction on. The condenser relay holds in and condenser blower 13 rotates. When high

pressure switch 15 is closed, have the relay 7 hold in and the water tank fan 14 rotates. When the water

temperature sensor 16's temperature is higher than 109°C, ECU shut off the output signal of the pin 22

and A/C stops operation.

(6) When the Refrigeration system pressure is over 1.7MPa, radiator fan will rotato. Disconnect A/C

compressor Refrigeration system power supply when the pressure is over 2.6MPa or less than 0.25MPa;

Page 310 of 392

303Figure 6 A/C System Electrical Appliance DiagramIII. Protecting Device1. Low temperature protection

Evaporator temperature sensor, when the sensed temperature is lower than 3°C, the compressor clutch

is de-energized and stops operation.

2. High temperature protection

Water temperature sensor, when the sensed water temperature reaches 109°C, the compressor clutch is

de-energized and stops operation.

3. Low pressure protection

When pressure sensed by the pressure switch is lower than 0.25MPa, the compressor clutch is de-

energized and stops operation.

4. Voltage protection

When the pressure sensed by the pressure switch reaches 1.7MPa, radiator fan rotates.

5. High pressure protection

When the pressure sensed by the pressure switch reaches 2.6MPa, the compressor clutch is de-energized

and stops operation.

6. Normal pressure

When system pressure reaches 0.25MPa~2.4MPa, control the A/C idle speed. Color of wire:R-Red Bl-Blue Y-Yellow Lg-Light green Br-Brown B-Black P-Pink G-Green W-White Gr-Gray

1. Battery 2. Main Fuse Box 3. Alternator 4. Ignition Switch 5. Idle Rise Valve 6. Blower 7. Relay

8. Blower Regulating Resistance 9. Blower Switch 10. A/C Switch 11. A/C Low Pressure Switch

12. Compressor 13. Condensor Fan 14. Radiator Fan 15. A/C High Pressure Switch

16. Water Temperature Sensor 17. Evaporator Temperature Sensor 18. Electronic Wind Door Actuator Switch

19. Electronic Wind Door Actuator 20. Revolution Sensor 21. Engine ECU

Page 321 of 392

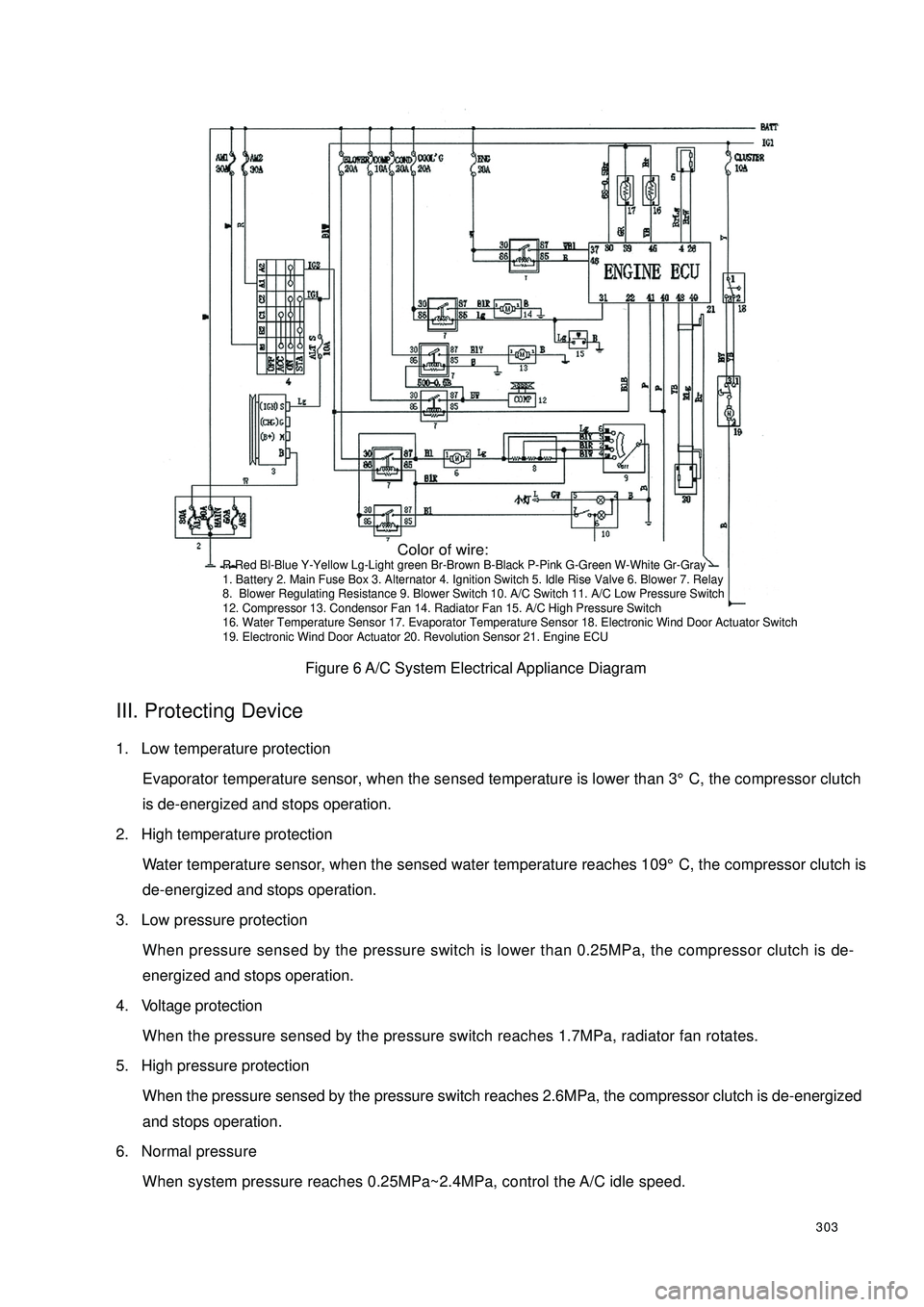

314Have a focus inspection on the following area:

a. Each pipe union joint and valve connection.

b. All hose, especially near the pipe union.

c. Compressor shaft seal, front and rear cover, gasket, oil fill plug.

d. Area on the surface of the condenser and evaporator that is scratched, bruised or damaged.

e. Expansion valve inlet and outlet connection and temperature sensor element and the welding position.

3. Check the Refrigerant

Observing from the sight glass, you may understand the refrigerant status and analyze the possible faults:

4. Check Other Parts

Other parts needed to be checked and their check points:Conditions obse rvedP ossible proble ms

Cle ar, no a ir bubble , A/C e mits c ool wind Re frige ra tion system is normal

Cle ar, no a ir bubble , A/C e mits warm wind Re frige ra nt le a ke d, the re is le aka ge in the syste m

Occ a tiona l a ir bubble . Expa nsion va lve is froste d There is wa te r mixe d in the re frigeration syste m

Occational air bubble. Insufficient refrigerant or air mixed in the system

Cle ar, the re is oil stripe on the gla ss Outle t is not c old, no refrige ra nt

Foamy and turbid Excessive freezing oilChecked PartCheck Points

The re sha ll be no dirt and rust on the radiator tha t hinde r the he at

exchange;

The ra dia tor surfa ce ha s no da mage , fissure a nd hidde n trouble tha t ma y

cause refrigerant leakage.

Elec tromagne tic Clutc hClutc h ope ration is norma l. Whe n switche d on, the c ompre ssor sha ll

operate, clutch can not slip.

Compre ssor Be lt Be lt te nsion of 250N is normal, belt is not broke n and dama ged.

WireThe electromagnetic clutch and blower power cable shall be not damaged

and overheated; the connection shall be reliable, and the protective

gromme t through the me tal plate sha ll be ke pt good a nd without da ma ge .

HoseRefrigerant hose and condenser pipe shall be secured and shall not be

dama ged by a pproac hing the othe r ove rhe ate d pa rts, moving pa rts a nd

sha rp parts. Eva pora tor Conde nse r

Page 324 of 392

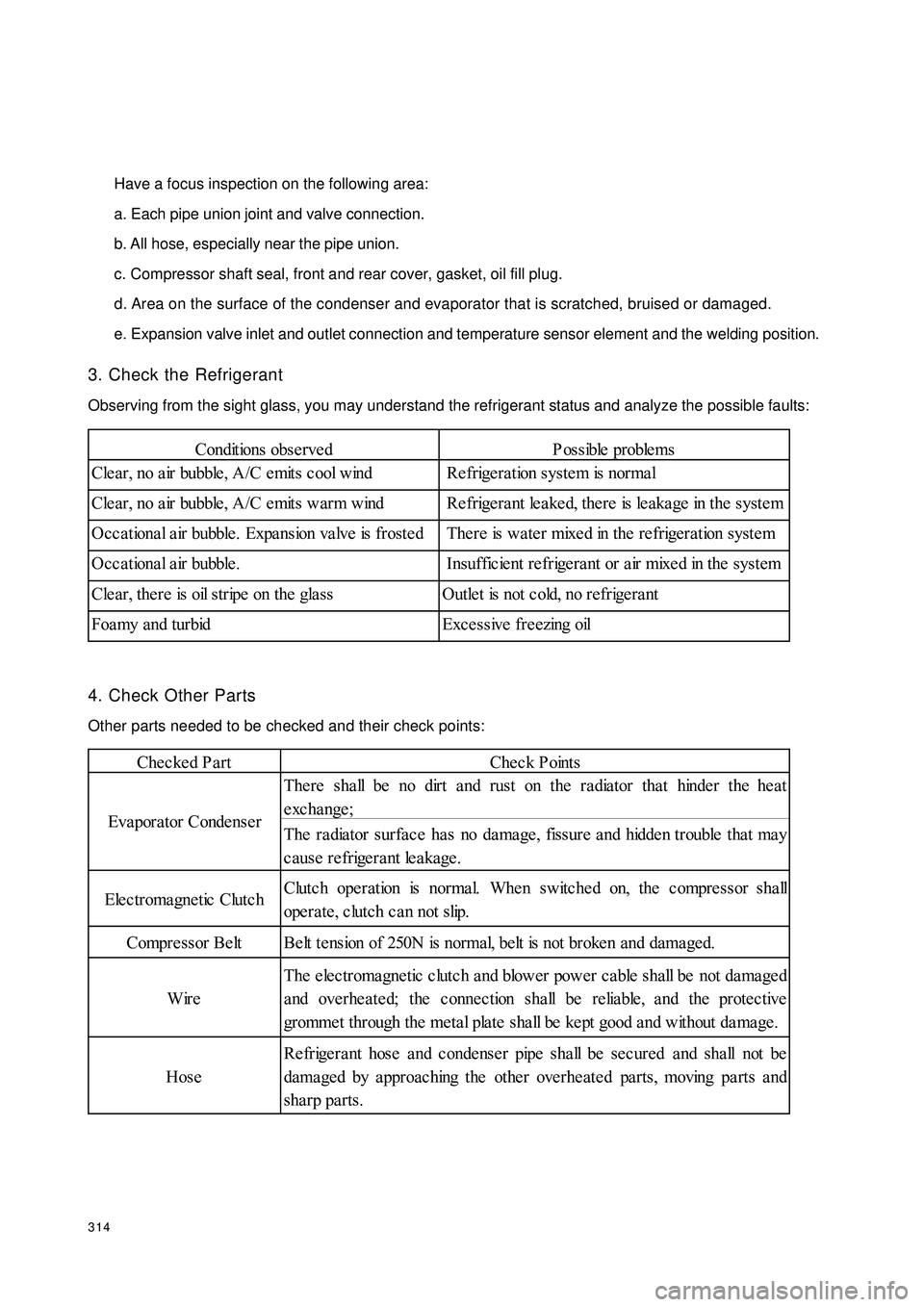

317Table 2. Problem Cause and Troubleshooting of No Heating:Area Problem Cause TroubleshootingH

eat

i

ng

Sy

st

emWater temperature sensor damaged Repair or replac e

Blow er motor does not rotate Repair or replac e

Fan s peed adjus tment sw itc h damaged Replac e

Output air temperature adjustment sw itc h damaged Replac eH

eat

i

ng

Sy

st

emTable 3. Problem Cause and Troubleshooting of Noise:Problem Cause Troubleshooting

Drive belt loose or w orn Replac e the drive belt

Cooling electric fan touc hes other parts Service and eliminate the impac t

Blow er motor mec hanic al fric tion Servic e and fill the oil

N o o il o n t h e m o t o r b e a r in g , d r y f r ic t io n F ill t h e g r e a s e o r r e p la c e t h e b e a r in g

Low battery voltage Charge the battery Ar e a