ECU GEELY CK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 11 of 392

4Table 3

CO HC Problems Causes

1. Fa ult

. Inc orre c t ignition timing

. Fouled, shorted or imprope rly cle aranc e of spa rk plug

2. Incorrect valve clearance

3. Le a ky inta ke & e xha ust valve s

4. Leaky cylinders

1. Air leaks

. PCV hoses, intake manifold

. Throttle body

. Brake booster circuit

2. Le a n mixture ga s c a using misfire

1. Clogged air filter

2. Clogge d P CV valve

. Faulty ECU

. Fa ulty fue l pre ssure regula tor

. Faulty water temperature sensor

. Faulty air compressor

. Faulty injectors

. Faulty throttle position sensor Normal

Low High

High HighRough idle

(Black smoke

from exhaust

pipe ) Rough idle Rough idle High

Page 48 of 392

41Chapter 4 Fuel System

(MR7131A, MR7151A, MR7161A)Section 1 Check Fuel System Pressure1. Remove the fuel tank from the vehicle

2. Check the fuel pump running

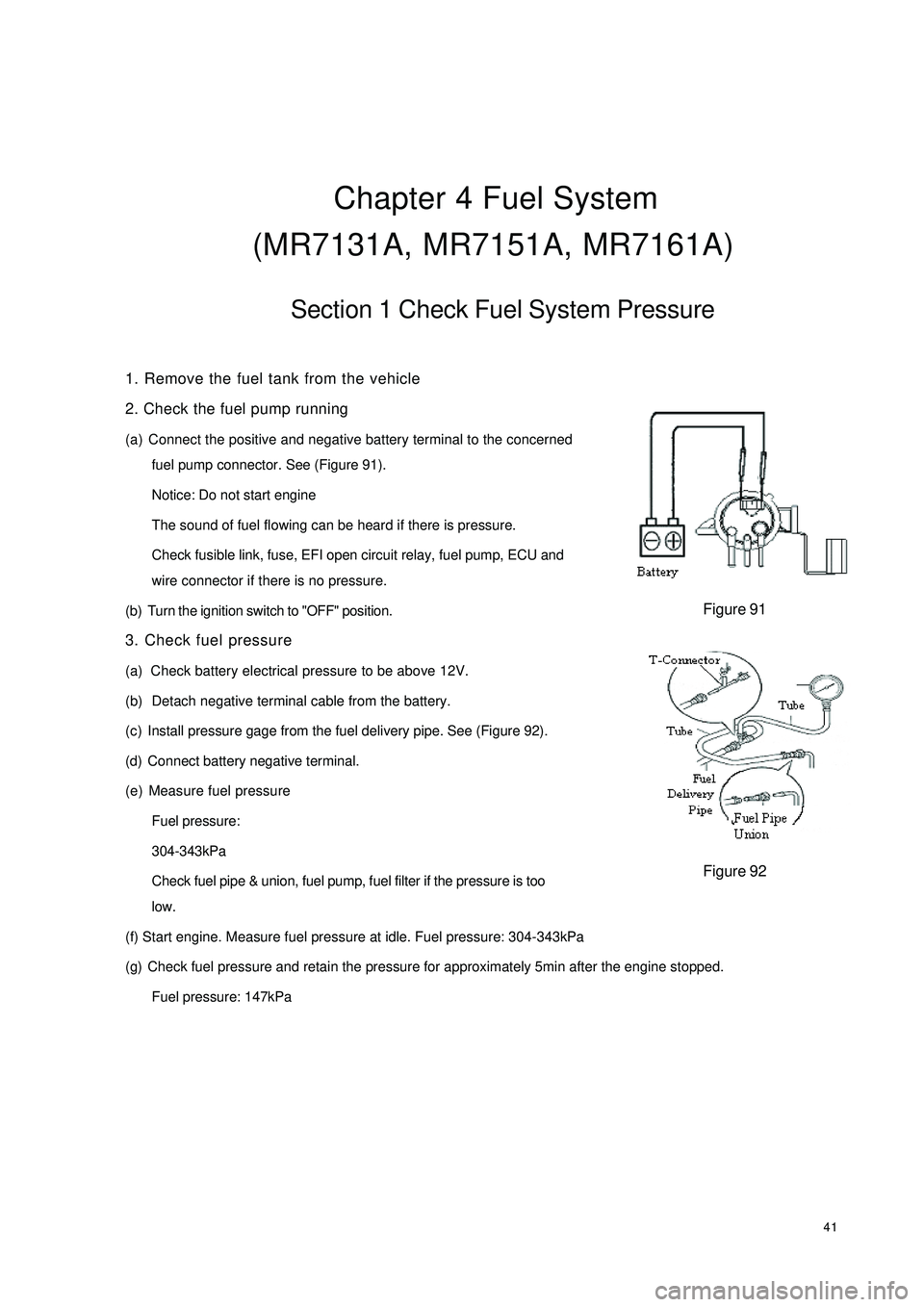

(a) Connect the positive and negative battery terminal to the concerned

fuel pump connector. See (Figure 91).

Notice: Do not start engine

The sound of fuel flowing can be heard if there is pressure.

Check fusible link, fuse, EFI open circuit relay, fuel pump, ECU and

wire connector if there is no pressure.

(b) Turn the ignition switch to "OFF" position.

3. Check fuel pressure

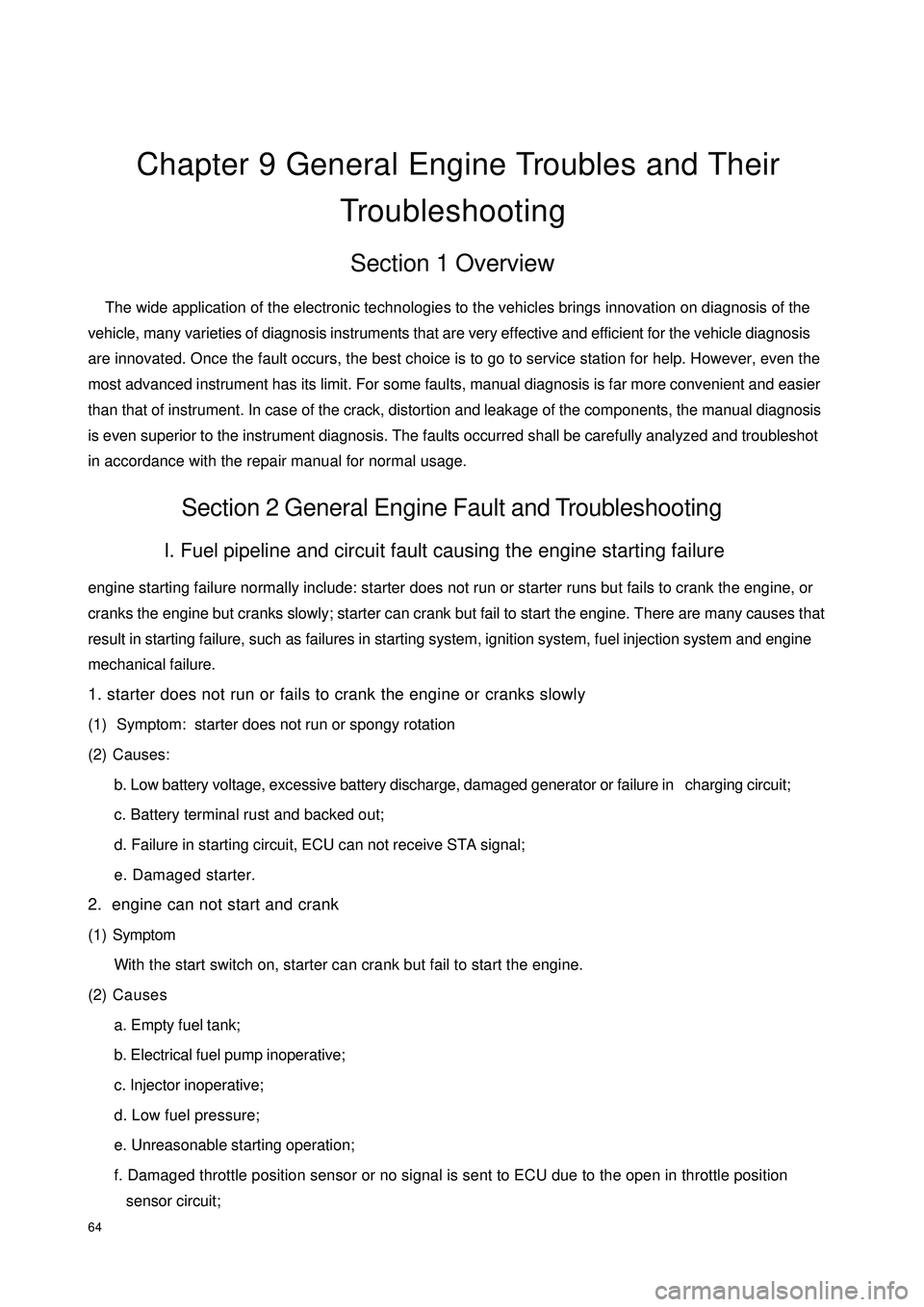

(a) Check battery electrical pressure to be above 12V.

(b) Detach negative terminal cable from the battery.

(c) Install pressure gage from the fuel delivery pipe. See (Figure 92).

(d) Connect battery negative terminal.

(e) Measure fuel pressure

Fuel pressure:

304-343kPa

Check fuel pipe & union, fuel pump, fuel filter if the pressure is too

low.

(f) Start engine. Measure fuel pressure at idle. Fuel pressure: 304-343kPa

(g) Check fuel pressure and retain the pressure for approximately 5min after the engine stopped.

Fuel pressure: 147kPaFigure 91Figure 92

Page 71 of 392

64Chapter 9 General Engine Troubles and Their

TroubleshootingSection 1 Overview The wide application of the electronic technologies to the vehicles brings innovation on diagnosis of the

vehicle, many varieties of diagnosis instruments that are very effective and efficient for the vehicle diagnosis

are innovated. Once the fault occurs, the best choice is to go to service station for help. However, even the

most advanced instrument has its limit. For some faults, manual diagnosis is far more convenient and easier

than that of instrument. In case of the crack, distortion and leakage of the components, the manual diagnosis

is even superior to the instrument diagnosis. The faults occurred shall be carefully analyzed and troubleshot

in accordance with the repair manual for normal usage.Section 2 General Engine Fault and TroubleshootingI. Fuel pipeline and circuit fault causing the engine starting failureengine starting failure normally include: starter does not run or starter runs but fails to crank the engine, or

cranks the engine but cranks slowly; starter can crank but fail to start the engine. There are many causes that

result in starting failure, such as failures in starting system, ignition system, fuel injection system and engine

mechanical failure.

1. starter does not run or fails to crank the engine or cranks slowly

(1) Symptom: starter does not run or spongy rotation

(2) Causes:

b. Low battery voltage, excessive battery discharge, damaged generator or failure in charging circuit;

c. Battery terminal rust and backed out;

d. Failure in starting circuit, ECU can not receive STA signal;

e. Damaged starter.

2. engine can not start and crank

(1) Symptom

With the start switch on, starter can crank but fail to start the engine.

(2) Causes

a. Empty fuel tank;

b. Electrical fuel pump inoperative;

c. Injector inoperative;

d. Low fuel pressure;

e. Unreasonable starting operation;

f. Damaged throttle position sensor or no signal is sent to ECU due to the open in throttle position

sensor circuit;

Page 72 of 392

65g. Ignition system failure;

h. Low engine compression pressure.

(3) Diagnosis and Troubleshooting

a. First, check the fuel tank for fuel level, turn on the ignition switch, if fuel gauge pointer does not

move or fuel level warning lamp lights, then the fuel tank is empty, fuel shall be filled at this time.

b. Check that the electrical fuel pump for operation. Remove the fuel tank, you may use a wire to

connect the two jacks of the fuel pump for short, then turn on the ignition switch. The fuel pump

operation sound shall be able to be heard from the fuel tank nozzle or fuel flow can be felt with hand

pinching the tube; or remove the return hose on the fuel pressure regulator, check that the fuel

flows out; Direct judgment can be made if it is equipped with fuel pressure gage.

If electrical fuel pump is inoperative, check whether the main fuse, main relay, fuel pump relay,

fuel pump control circuit and ECU are OK. If all of them are OK, check fuel pump circuit for open,

short or damaged check valve. Repair or replacement shall be made when problems are found.

c. If there is no injection sound in injector, check injector control circuit for fault. You may use a

testing lamp with big resistance to be connected to the injector wiring connector, turn on the ignition

switch. If the testing lamp lights up, it indicates that the injector has been damaged and shall be

replaced; if the testing lamp does not light up, check whether the main fuse, EFI relay, fuse, ignition

switch and ECU terminal are OK, repair or replace them if they are not OK.

d. If there is low fuel pressure, the injection amount would be small and the engine won't start, you

should check the fuel filter for block and fuel pump safety valve for damage and check whether the

fuel pressure regulator is within the normal range, otherwise those components shall be repaired or

replaced.

e. Electric injection engine normally spot contact start the engine.

f. Check for open in the throttle position sensor (TPS) circuit.

g. Check whether there is Diagnostic Trouble Code (DTC), if there is, check it by the DTC; if there

is not, check the high voltage spark for intensity, if it is too weak, check spark plug, high voltage

wire, high voltage coil, distributor cover for faults, if there are faults, repair or replace them.

h. Check the compression pressure in the cylinder, insert the compression pressure gauge into the

spark plug hole, completely open the throttle, measure the compression pressure while starting the

engine. If the compression pressure is less than 980kPa when engine speed is more than 250r/min,

remove and inspect the engine and troubleshoot it.

3. The engine cranks but can not start

(1) Symptom

When starting the engine, starter can crank the engine but fail to start the engine.

(2) Causes:

a. Ignition advance angle is unfavorable;

b. Ignition is out of sequence, there is misfire;

c. High voltage spark is too weak;

d. The fuel pressure is too low;

e. fuel pressure regulator leakage;

Page 74 of 392

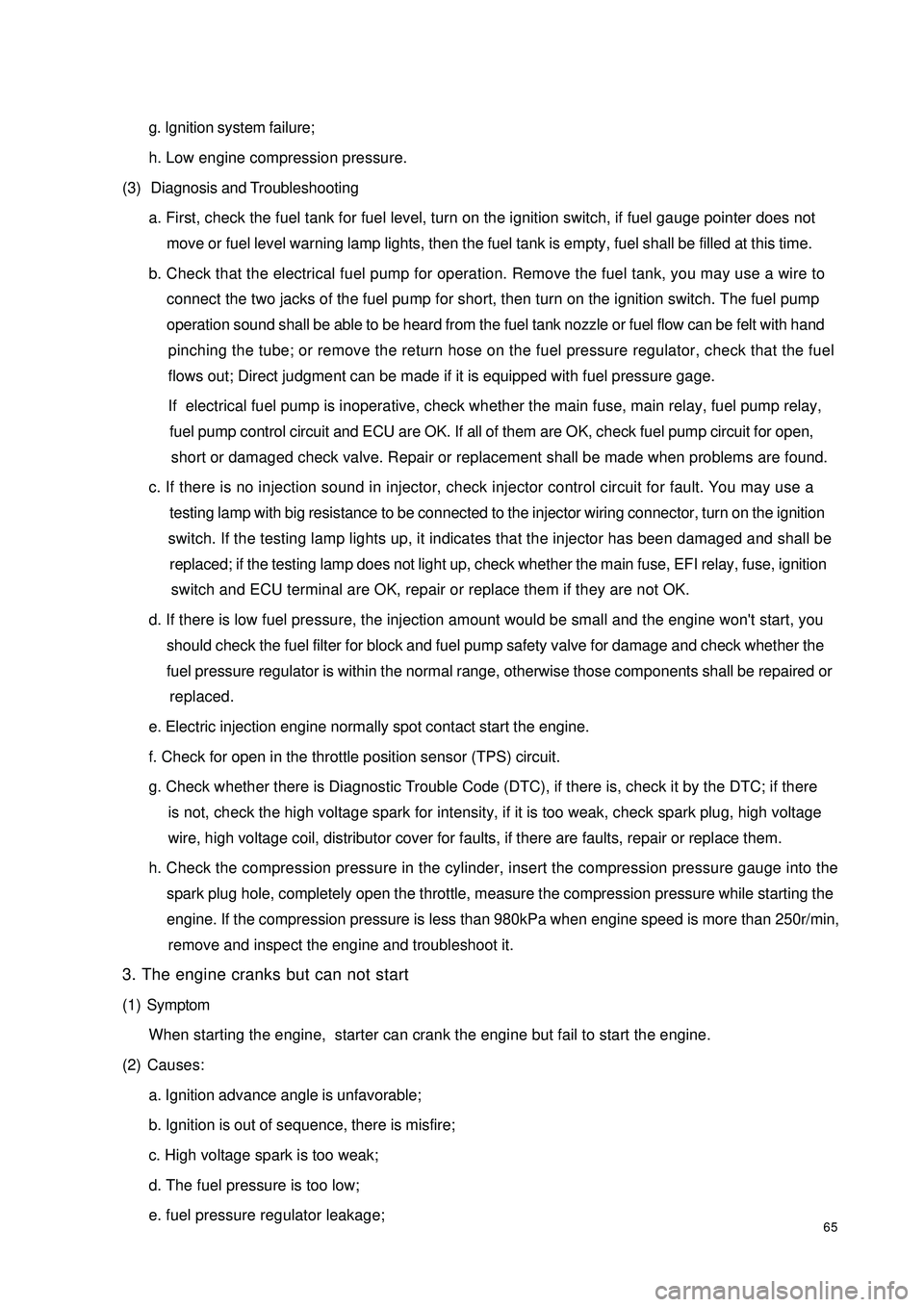

67Figure 148II. Fuel pipeline and Circuit Fault for Hard Engine StartingHard engine starting indicates that starter can crank but fail to start the engine, or it may take multiple

consecutive starting efforts or long time rotation to successfully start the engine. For hard start fault, make

sure whether it occurs at cold or hot status or regardless of the cold or hot status.

1. Symptom

When starting, engine cranks at normal speed, but it takes longer to start or fails to start although cranks.

2. Causes:

a. Air cleaner is clogged;

b. Intake temperature sensor fault;

c. Water temperature sensor fault; Engine can not start

Check the starting system Repair or replace the part if it is faulty

Check the high voltage spark

No high voltage spark or weak spark OK

Check the ignition system Is there any sign of cranking

No sign of cranking There is sign of cranking

Check the electric fuel pump for operation Check the air cleaner filter

Operative Inoperative OK Clogged

Check the injector Check the electric fuel Check the Replaced

pump and its control circuit spark clearance

Operative Inoperative

Measure the fuel pressure

Measure the fuel pressure Check the injector

Measure the vapor pressure,

water temperature and intake

Excessively low OK Check the control circuit air temperature sensor

Check the fuel Check thecylinder pressure Check the cylinder pressure

pressure regulator

Page 76 of 392

69j. Poor intake and exhaust valve seal, failed piston ring, low compression pressure;

h. Too many carbon deposit in spark plug and combustion chamber;

k. Water temperature switch and thermostat fault;

l. Aging of Oxygon sensor;

m. Incorrect ignition timing;

n. Check valve fault.

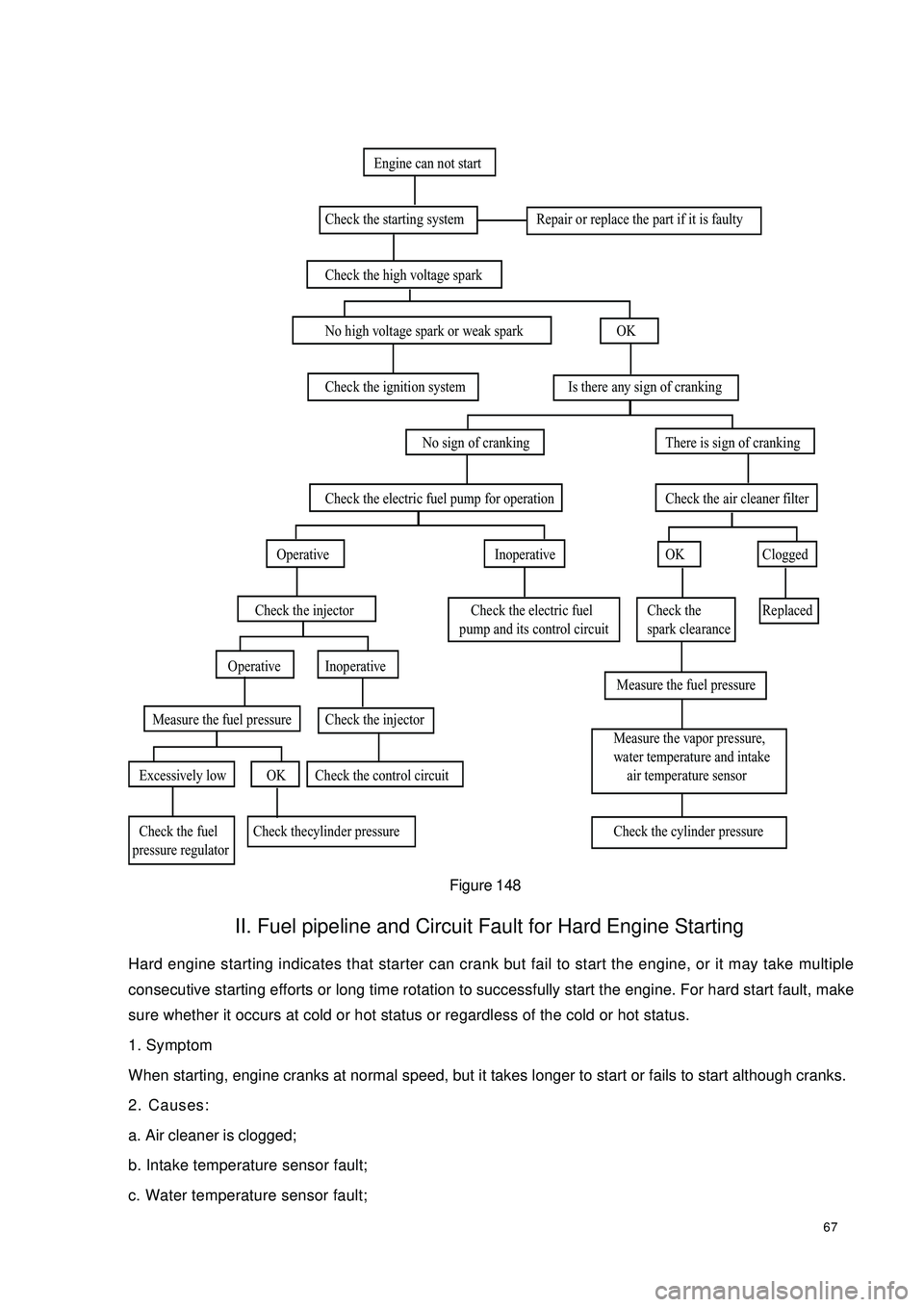

Figure 149Engine is difficult to start

Check whether the air cleaner is clogged Clogged

Troubleshooting

OK

Check the idle control valve NG

Repair or replace

OK

Check the fuel pressure Excessivly low

Service the electric fuel pump,

fuel filter and fuel pressure regulator

OK

Check the vacuum pressure sensor NG

Replace

OK

Check the water temperature sensor and intake air temperature sensor NG

Replace

OK

Check the start switch signal No

Service the start signal wire

OK

Check the ignition timing Misaligned

Adjust

OK

Check the cylinder pressure NG

Disassemble the engine

OK

Replace the ECU to retry

Page 77 of 392

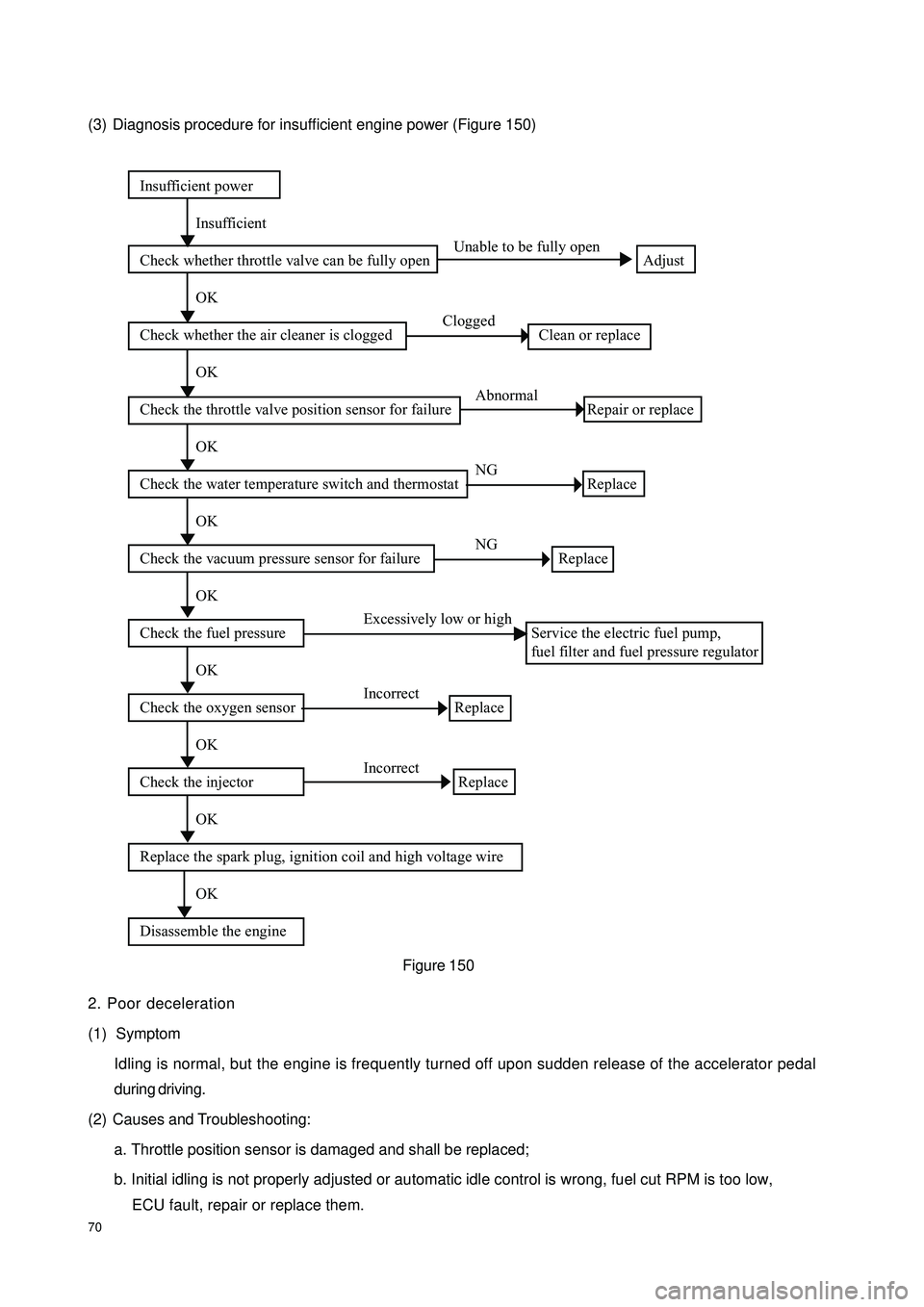

70(3) Diagnosis procedure for insufficient engine power (Figure 150)

2. Poor deceleration

(1) Symptom

Idling is normal, but the engine is frequently turned off upon sudden release of the accelerator pedal

during driving.

(2) Causes and Troubleshooting:

a. Throttle position sensor is damaged and shall be replaced;

b. Initial idling is not properly adjusted or automatic idle control is wrong, fuel cut RPM is too low,

ECU fault, repair or replace them.Insufficient power

Insufficient

Check whether throttle valve can be fully open Unable to be fully open

Adjust

OK

Check whether the air cleaner is clogged Clogged

Clean or replace

OK

Check the throttle valve position sensor for failure Abnormal

Repair or replace

OK

Check the water temperature switch and thermostat NG

Replace

OK

Check the vacuum pressure sensor for failure NG

Replace

OK

Check the fuel pressure Excessively low or high

Service the electric fuel pump,

fuel filter and fuel pressure regulator

OK

Check the oxygen sensor Incorrect

Replace

OK

Check the injector Incorrect

Replace

OK

Replace the spark plug, ignition coil and high voltage wire

OK

Disassemble the engineFigure 150

Page 78 of 392

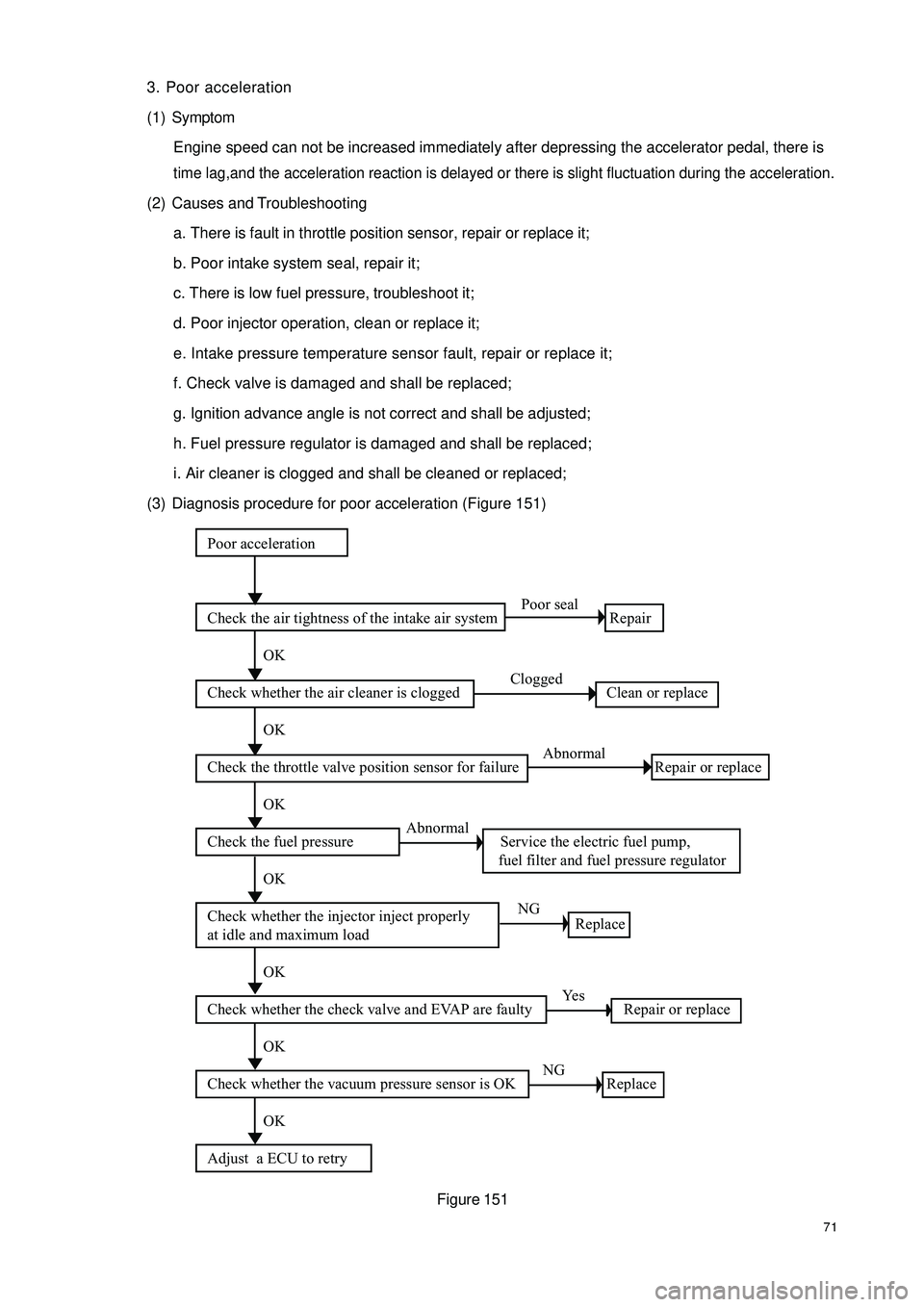

713. Poor acceleration

(1) Symptom

Engine speed can not be increased immediately after depressing the accelerator pedal, there is time lag,and the acceleration reaction is delayed or there is slight fluctuation during the acceleration.(2) Causes and Troubleshooting

a. There is fault in throttle position sensor, repair or replace it;

b. Poor intake system seal, repair it;

c. There is low fuel pressure, troubleshoot it;

d. Poor injector operation, clean or replace it;

e. Intake pressure temperature sensor fault, repair or replace it;

f. Check valve is damaged and shall be replaced;

g. Ignition advance angle is not correct and shall be adjusted;

h. Fuel pressure regulator is damaged and shall be replaced;

i. Air cleaner is clogged and shall be cleaned or replaced;

(3) Diagnosis procedure for poor acceleration (Figure 151)

Figure 151Poor acceleration

Check the air tightness of the intake air system Poor seal

Repair

OK

Check whether the air cleaner is clogged Clogged

Clean or replace

OK

Check the throttle valve position sensor for failure Abnormal

Repair or replace

OK

Check the fuel pressure Abnormal

Service the electric fuel pump,

fuel filter and fuel pressure regulator

OK

Check whether the injector inject properly

at idle and maximum load NG

Replace

OK

Check whether the check valve and EVAP are faulty Yes

Repair or replace

OK

Check whether the vacuum pressure sensor is OK NG

Replace

OK

Adjust a ECU to retry

Page 83 of 392

7611. General engine fault symptom and faulty area (Table 7)

Table 7

Unable to explode initially

Unable to explode completely

Difficult for cold start

Difficult for hot start

No fast ilde

Low idle speed

High idle speed

Rough ildling

Idle hunting

At urgent acceleration

When the accelerator pedal is releasec

During idling

Poor acceleration

Hunting during driving

Insufficient power

KnockInta ke a bosolute pre ssure

se nsor

�c�c�c�c�c�c�c �c�c

Water temperature sensor�c�c�c�c �c�c �c �c�c �c

Re volution spee d se nsor

�c

Throttle valve position

se nsor

�c�c�c �c�c�c�c�c

Vehicle speed sensor

�c

Fuel pump system

�c�c �c �c�c �c

Fue l pre ssure regulator

�c�c�c�c�c �c �c�c�c�c

Fue l filte r a nd pipe line

�c�c �c �c�c�c�c

Injector

�c�c�c�c�c �c �c�c�c

Sta rte r signal

�c�c

Ignition c oil

�c�c�c

Spark plug

�c�c�c�c �c �c�c �c

High pre ssure ca ble

�c�c

Ignition timing

�c�c �c �c �c �c�c

Igniter in the ECU

�c �c�c�c

Throttle valve

�c�c�c�c �c

Throttle valve body�c�c �c

Air leakage in the intake

air system�c�c �c�c�c�c�c �c

Air valve

�c�c�c�c�c

ECU powe r supply circuit

�c

Ignition swtich

�c

Ma in re la y

�c

Fuel pump re lay�cPoor driving Difficult to start Poor idling Engine off

Power

supply

system Control

system

Fuel

system

Ignitio n

system

Intake

air

systemSuspect

AreaSymptom

Page 84 of 392

77IV. Exhaust Pipe Discharges Gas with Abnormal Color (or odor)When there is failure in engine combustion system, the exhaust pipe discharges gas with abnormal color.

1. The discharged gas is thickly black

This is caused by incomplete combustion. Since the mixed air is too thick, the combustion is not complete and

part of the fuel is discharged without combustion, leading to decrease of engine power. At this moment, you

should check fuel pressure regulator, throttle position sensor, injector and ECU system and correct the

problems in time.

2. Exhaust is blue and stinks

This is caused by large amount of oil vapor mixed in the exhaust gas that enters in the cylinder and partici-

pates in combustion. One of the primary reasons is that the piston oil ring is dirty and damaged, and shall be

replaced; another reason may be the failure of valve oil seal or excessive clearance between the valve stem

and guide bush hole resulting in oil entering the combustion chamber for combustion, oil seal or valve guide

bush shall be replaced to resume normal condition.

3. Exhaust is white

This is caused by water or fuel vapor mixed in the exhaust. The primary reason is that cylinder head gasket

is damaged, resulting in slow infiltration of coolant into cylinder and the water vapor entry into the exhaust

pipe after combustion, cylinder head gasket shall be replaced to resume the normal condition.Section 3 Engine Noise Diagnosis and TroubleshootingAbnormal sounds generated during engine operation (e.g. knocking sound, chuckle, hiss, rattle) are called

noise.

Engine noise is primarily generated in valve train, connecting rod piston crankshaft components and other

accessory system. The following description discusses the diagnosis and troubleshooting of the noise gener-

ated in valve train and crankshaft connecting rod mechanism.I. Diagnosis and troubleshooting of the noise in valve trainvalve train consists of intake & exhaust camshaft , valve, valve bushing, tappetand counter gear.

1. camshaft noise

(1) camshaft end play is excessively big (normal intake camshaft : 0.030~0.085mm, exhaust camshaft : 0.

035~0.090mm) , when it exceeds 0.11mm and noise is generated, replace it;

(2) Camshaft bend is another cause for noise; it shall be aligned or scraped. ;

(3) Camshaft journal is excessively worn, resulting in big radial clearance between camshaft and bearing and

noise, replace it;

2. Valve group knock noise

(1) Valve noise is caused by excessive valve clearance, the valve spring seat flange is damaged and shall be

replaced;

(2) Valve spring knock noise is caused by broken valve spring. It shall be replaced;