clutch GEELY CK 2008 Workshop Manual

[x] Cancel search | Manufacturer: GEELY, Model Year: 2008, Model line: CK, Model: GEELY CK 2008Pages: 392, PDF Size: 38.86 MB

Page 3 of 392

Chapter 6 Cooling System Inspection

(MR7131A, MR7151A, MR7161A).................................................................52Section 1 System Check

Section 2 Water Pump, Thermostat and Radiator Replacement.................................... 54Chapter 7 Clutch (MR7131A, MR7151A, MR7161A)....................................56Section 1 Clutch Replacement...................................................................................57Chapter 8 Maunal Transaxle Assembly

(MR7131A, MR7151A, MR7161A)................................................................59Section 1 Manual Transaxle Replacement..................................................................60

Section 2 Vehicle Speed Sensor Replacement

Section 3 Transmission Case Oil Seal..........................................................................62

Section 4 Transaxle Case Oil Seal Replacement........................................................63Chapter 9 General Engine Troubles and Their Troubleshooting....................64Section 1 Overview........................................................................................................64

Section 2 General Engine Fault and Troubleshooting.......................................................64

Section 3 Engine Noise Diagnosis and Troubleshooting................................................77Chapter 10 Engine Management Unit..............................................................81Section 1 System Description.........................................................................................81

Section 2 System Component and Working Principle......................................................82Part II Chassis............................................................................85Chapter 1 Transmission Control Device.........................................................85Section 1 Transmission Control Device.........................................................................85

Section 2 Lever Type Transmission Control Device......................................................85

Section 3 Cable Type Transmission Control Module......................................................87Chapter 2 Accelerator Pedal............................................................................90Section 1 Accelerator Pedal..........................................................................................90Chapter 3 Clutch Control System....................................................................91Section 1 Clutch Control System....................................................................................91

Section 2 Clutch Cable Control Mechanism.....................................................................91

Section 3 Clutch hydraulic Control Device.......................................................................94Chapter 4 Propeller Shaft...............................................................................97...............................................................................................52

..............................................................61

Page 17 of 392

10Chapter 2 Engine Components Replacement

(MR479Q, MR479QA, MR481QA)Section 1 Engine ComponentsComponent 1Air Filter Assembly W/ Hose

Accelerator Control

Cable Assembly

Heater Inlet Hose

Heater Outlet Hose

Fuel Sub-Assembly

Efi Fuel Pipe Clamp

MT:

Transmission

Control Cable

Assembly

AT :

Transmission Control Cable Assembly MT:

Clutch Release

Cylinder Assembly

Radiator Outlet Pipe Radiator Inlet Pipe

Starter AssemblyAT: Oil Cooler Outlet Pipe

AT: Oil Cooler Inlet Pipe

Radiator Assembly

BatteryFront Exhaust

Pipe Assy.3-way catalytic

converterMufflerTail PipeFigure 20

Page 19 of 392

12Component 3Figure 22Flywheel

Clutch Disc

Clutch Cover

Clutch Release Bearing

Clutch Release Fork

Release Fork Support

Release Fork Boot

Page 20 of 392

13Section 2 Engine Components Replacement1. Avoid gasoline ejection when work.

2. Drain the coolant to empty.

3. Remove air filter assembly with hose. See (Figure 23)

4. Remove battery

5. Remove fuel delivery pipe sub-assembly

6. Disconnect water hoses, disconnect heater outlet hose

from A/C hose.

7. Loose nut, remove accelerator control cable

8. Remove throttle body assembly

9. Remove power steering pump reservoir assembly

10. Remove front exhaust pipe assembly

11. Remove steering gear boot

12. Seperate steering column assembly. See (Figure 24)

13. Remove front wheel hub nut

14. Disconnect front wheel vehicle speed sensor (with ABS)

15. Detach steering tie rod ball stud pin assembly

16. Detach front lower swing arm sub-assembly

17. Detach front propeller assembly. See (Figure 25)

Detach front propeller from the shaft hub with plastic hammer.

18. Disconnect transmission shift cable or gear shift level assembly

19. Disconnect clutch cylinder assembly or disconnect clutch cable

20. Detach engine assembly and transaxle

(a) Hoisting engine ;

(b) Remove 3 bolts. Detach the right engine mounting bracket. See (Figure 26) ;

(c) Remove 1 bolt. Detach the left engine mounting bracket;

(d) Remove 1 bolt. Detach the rear engine mounting bracket;

(e) Remove engine and transaxle and put them on the pallet;

(f) Jack up the boday.Figure 23

Figure 24

Figure 25 Figure 26

Page 21 of 392

1421. Remove radiator assembly

22. Remove engine V-belt

23. Remove No. 1 V- belt (A/C compressor to crankshaft pulley)

24. Remove generator assembly

25. Remove A/C compressor

26. Remove compressor installing No. 1 bracket. Remove 4 bolts and compressor installing No.

1 bracket.

27. Remove starter assembly

28. Remove power steering pump V- belt

29. Detach power steering pump assembly

30. Remove power steering pump, adjust the bracket

31. Detach manual transaxle assembly (Separate automatic transaxle assembly)

32. Detach clutch cover panel assembly.

33. Detach clutch pressure plate assembly.

34. Detach flywheel sub-assembly.

35. Remove engine rear end cover.

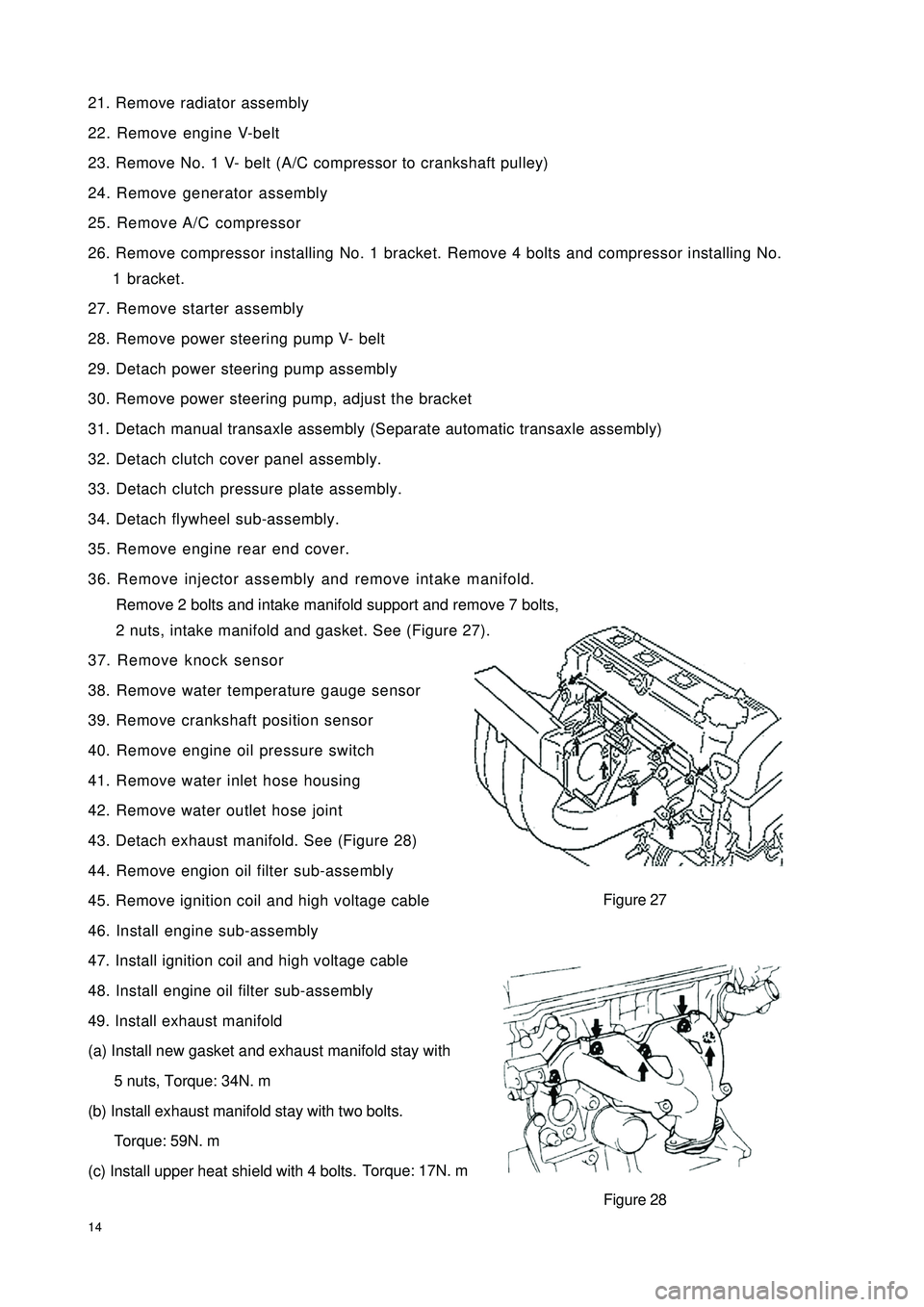

36. Remove injector assembly and remove intake manifold.

Remove 2 bolts and intake manifold support and remove 7 bolts,

2 nuts, intake manifold and gasket. See (Figure 27).

37. Remove knock sensor

38. Remove water temperature gauge sensor

39. Remove crankshaft position sensor

40. Remove engine oil pressure switch

41. Remove water inlet hose housing

42. Remove water outlet hose joint

43. Detach exhaust manifold. See (Figure 28)

44. Remove engion oil filter sub-assembly

45. Remove ignition coil and high voltage cable

46. Install engine sub-assembly

47. Install ignition coil and high voltage cable

48. Install engine oil filter sub-assembly

49. Install exhaust manifold

(a) Install new gasket and exhaust manifold stay with

5 nuts, Torque: 34N. m

(b) Install exhaust manifold stay with two bolts.

Torque: 59N. m

(c) Install upper heat shield with 4 bolts.Torque: 17N. mFigure 27

Figure 28

Page 22 of 392

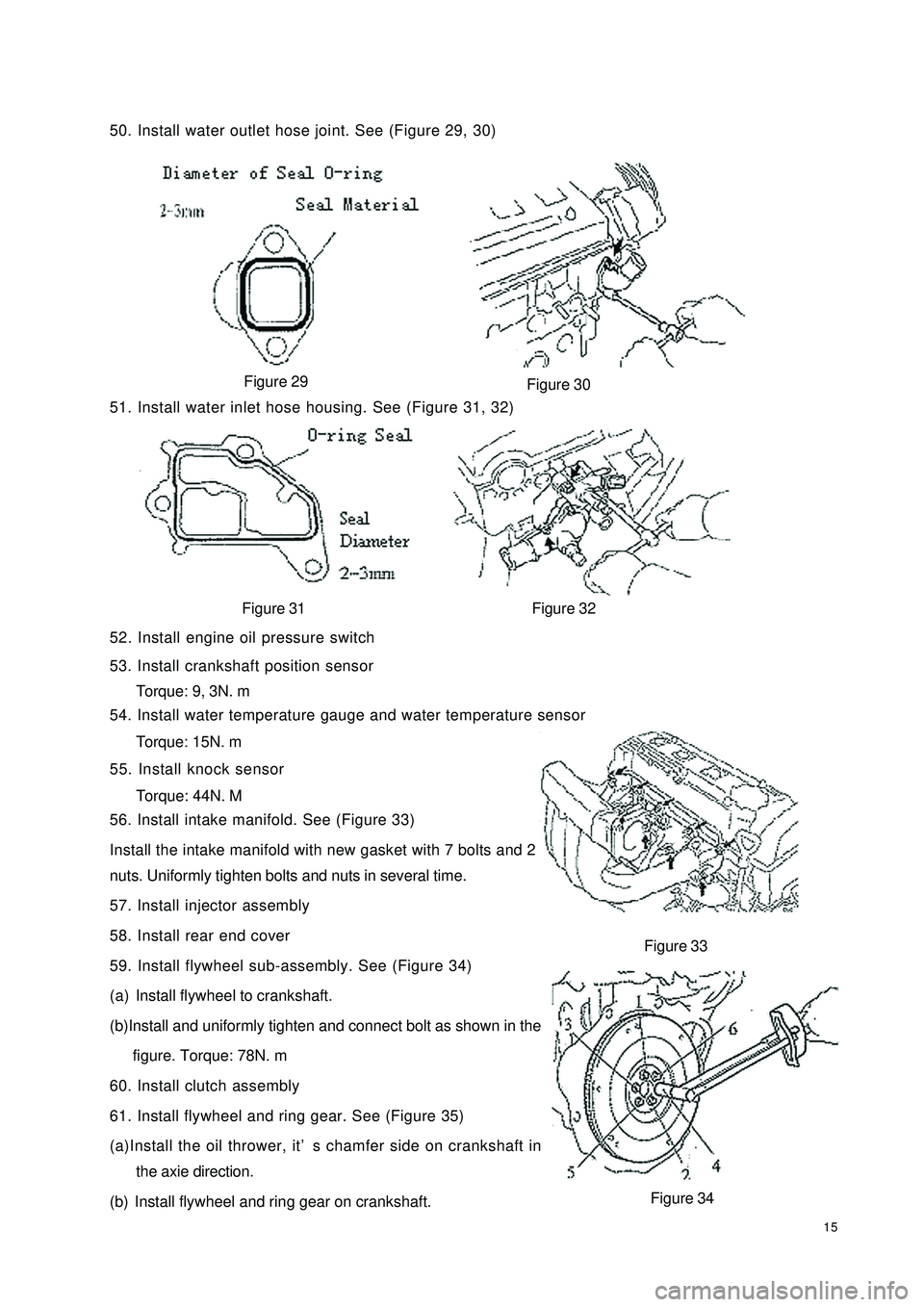

1550. Install water outlet hose joint. See (Figure 29, 30)

Figure 29

51. Install water inlet hose housing. See (Figure 31, 32)

Figure 31 Figure 32

52. Install engine oil pressure switch

53. Install crankshaft position sensor

Torque: 9, 3N. m

54. Install water temperature gauge and water temperature sensor

Torque: 15N. m

55. Install knock sensor

Torque: 44N. M

56. Install intake manifold. See (Figure 33)

Install the intake manifold with new gasket with 7 bolts and 2

nuts. Uniformly tighten bolts and nuts in several time.

57. Install injector assembly

58. Install rear end cover

59. Install flywheel sub-assembly. See (Figure 34)

(a) Install flywheel to crankshaft.

(b)Install and uniformly tighten and connect bolt as shown in the

figure. Torque: 78N. m

60. Install clutch assembly

61. Install flywheel and ring gear. See (Figure 35)

(a)Install the oil thrower, it’s chamfer side on crankshaft in

the axie direction.

(b) Install flywheel and ring gear on crankshaft.Figure 33

Figure 34 Figure 30

Page 41 of 392

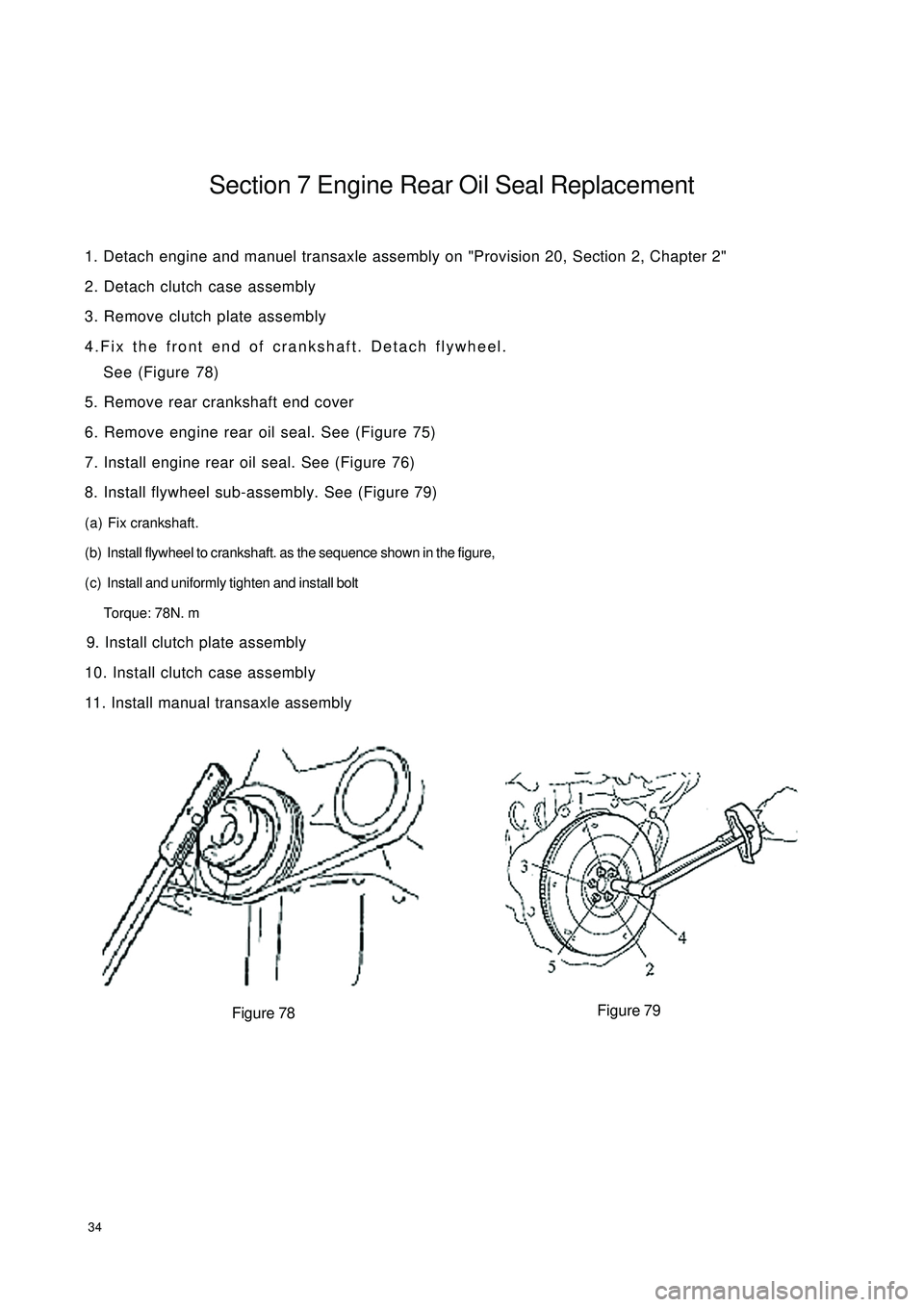

34Section 7 Engine Rear Oil Seal Replacement1. Detach engine and manuel transaxle assembly on "Provision 20, Section 2, Chapter 2"

2. Detach clutch case assembly

3. Remove clutch plate assembly

4.Fix the front end of crankshaft. Detach flywheel.

See (Figure 78)

5. Remove rear crankshaft end cover

6. Remove engine rear oil seal. See (Figure 75)

7. Install engine rear oil seal. See (Figure 76)

8. Install flywheel sub-assembly. See (Figure 79)

(a) Fix crankshaft.

(b) Install flywheel to crankshaft. as the sequence shown in the figure,

(c) Install and uniformly tighten and install bolt

Torque: 78N. m

9. Install clutch plate assembly

10. Install clutch case assembly

11. Install manual transaxle assembly

Figure 78Figure 79

Page 63 of 392

56Chapter 7 Clutch

(MR7131A, MR7151A, MR7161A)Component 1 (Hydraulic Manipulation)Figure 131

Page 64 of 392

57Section 1 Clutch ReplacementHoist the engine from the compartment. See "Provison 20, Section 2, Chapter 2".

1. Remove manual transaxle assembly

2. Remove the clutch release fork. See (Figure 132)

3. Detach clutch release fork boot.

4. Detach clutch release bearing

5. Detach clutch release bearing fixed clamp

6. Remove clutch fork pivot pin

7. Align the clutch cover to the mark on the flywheel. Detach clutch cover. See (Figure 133)

8. Remove clutch plate

9. Check and remove clutch plate assembly. See (Figure 134)

10. Check clutch cover. See (Figure 135)

Depth wear: A: 0.6mm

Width wear: B: 5mm

Figure 132 Figure 133

Figure 134 Figure 135

Page 65 of 392

5811. Using the dial gauge, check the flywheel runout. See

(Figure 136).

The maximum runout: 0.3mm

12. Check clutch release bearing

The bearing is permanently lubricated. There is no need to

lubricate or clean.

13. Check clutch plate

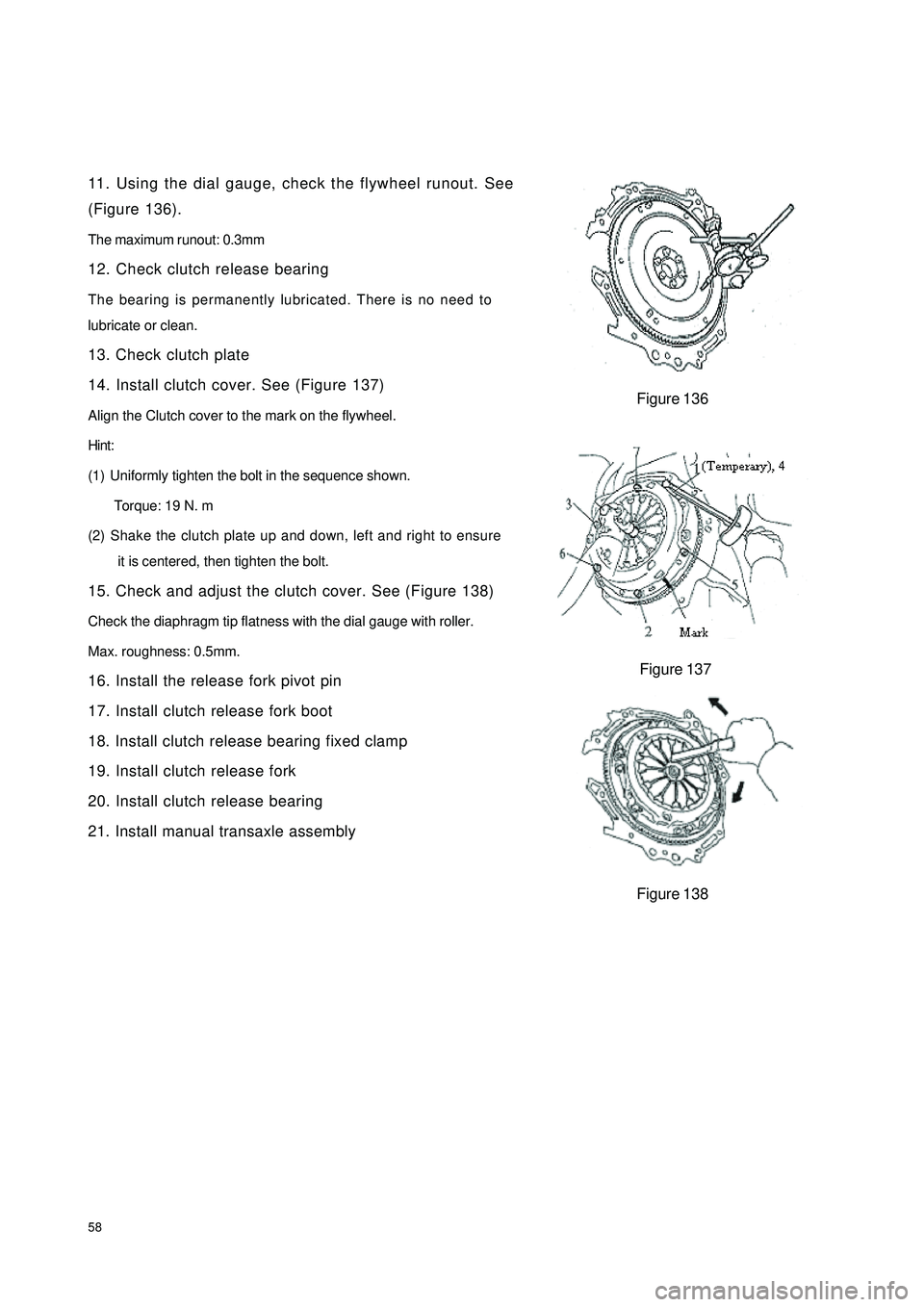

14. Install clutch cover. See (Figure 137)

Align the Clutch cover to the mark on the flywheel.

Hint:

(1) Uniformly tighten the bolt in the sequence shown.

Torque: 19 N. m

(2) Shake the clutch plate up and down, left and right to ensure

it is centered, then tighten the bolt.

15. Check and adjust the clutch cover. See (Figure 138)

Check the diaphragm tip flatness with the dial gauge with roller.

Max. roughness: 0.5mm.

16. Install the release fork pivot pin

17. Install clutch release fork boot

18. Install clutch release bearing fixed clamp

19. Install clutch release fork

20. Install clutch release bearing

21. Install manual transaxle assemblyFigure 136

Figure 137

Figure 138