GEELY MK 2008 Workshop Manual

Manufacturer: GEELY, Model Year: 2008, Model line: MK, Model: GEELY MK 2008Pages: 416, PDF Size: 25.19 MB

Page 261 of 416

Air Conditioning System -General Information5-74Symptom

No air temperature control

Compressor does not work

Insufficient refrigeration

No engine idle speed when air conditioning

switch is ON (switch on)

No air input control

No mode control

Condenser fan does not workSuspected Area

1. Engine coolant quantity

2. Air conditioning control mechanism assembly.

1. Refrigerant quantity

2. Compressor fuse

3. Centralized controller fuse

4. Magnetic clutch relay

5. Pressure switch

6. Magnetic clutch assembly

7. Air conditioning compressor assembly

8. Integrated control panel assembly (air conditioner switch)

9. Air conditioner thermistor

10. Engine ECU

11. Wiring harness

1. Refrigerant quantity

2. Refrigerant pressure

3. Driving belt

4. Air conditioner thermistor

5. Integrated control panel assembly (air conditioner switch)

6. Magnetic clutch assembly

7. Air conditioning compressor assembly

8. Condenser

9. Accumulator-drier

10. Expansion valve

11. Evaporator

12. Refrigerant line

13. Pressure switch

14. Air conditioner control mechanism assembly

15. Wiring harness

1. Idle speed control system

2. Wiring harness

3. ECM

1.Air conditioner control mechanism assembly

1.Air conditioner control mechanism assembly

1. MAIN fuse

2. Condenser fan fuse

3. Condenser fan relay

4. Condenser fan motor

5. Wiring harness

Page 262 of 416

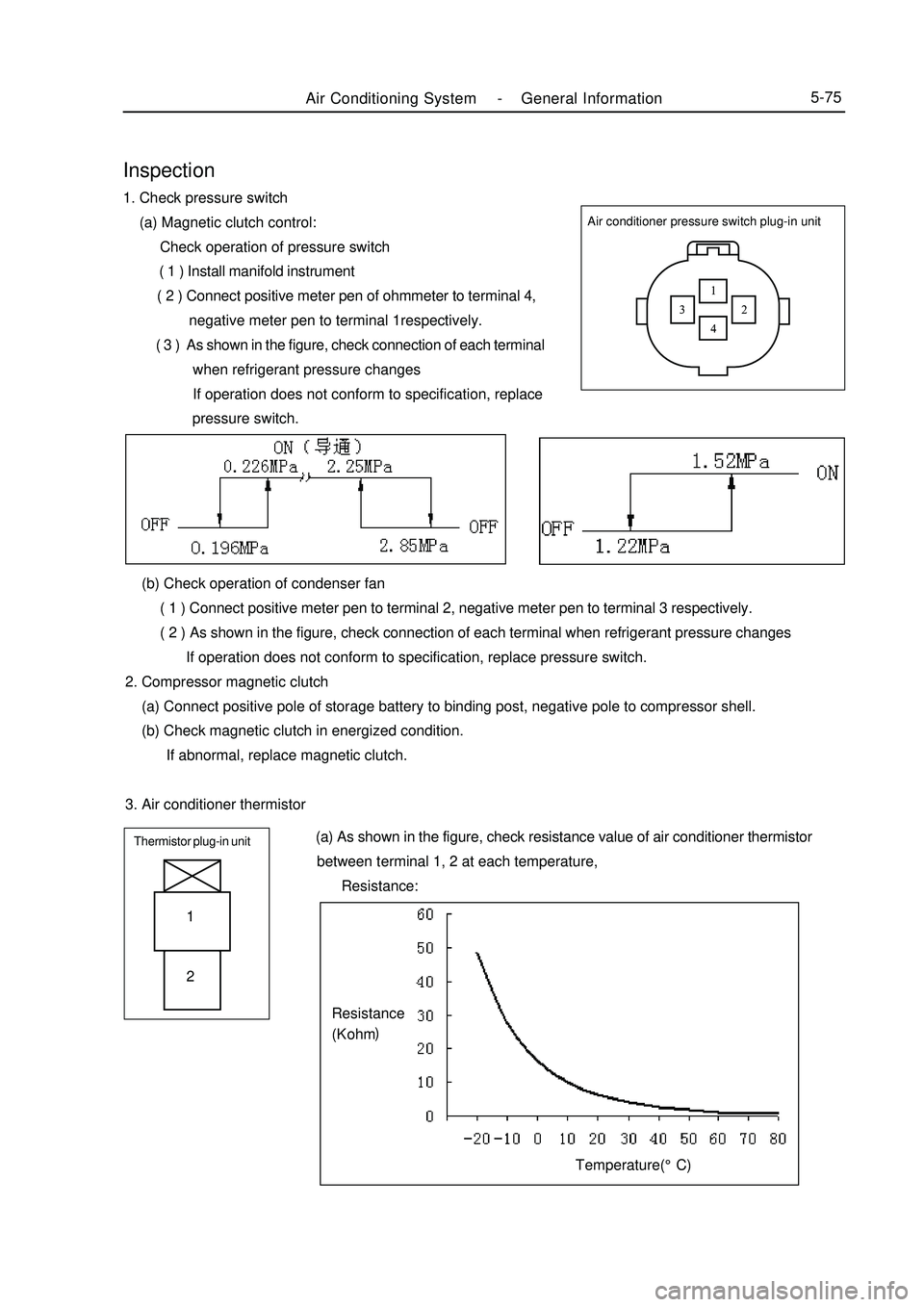

Air Conditioning System -General Information5-75Air conditioner pressure switch plug-in unitInspection1. Check pressure switch

(a) Magnetic clutch control:

Check operation of pressure switch

( 1 ) Install manifold instrument

( 2 ) Connect positive meter pen of ohmmeter to terminal 4,

negative meter pen to terminal 1respectively.

( 3 ) As shown in the figure, check connection of each terminal

when refrigerant pressure changes

If operation does not conform to specification, replace

pressure switch.

(b) Check operation of condenser fan

( 1 ) Connect positive meter pen to terminal 2, negative meter pen to terminal 3 respectively.

( 2 ) As shown in the figure, check connection of each terminal when refrigerant pressure changes

If operation does not conform to specification, replace pressure switch.

2. Compressor magnetic clutch

(a) Connect positive pole of storage battery to binding post, negative pole to compressor shell.

(b) Check magnetic clutch in energized condition.

If abnormal, replace magnetic clutch.

3. Air conditioner thermistorThermistor plug-in unit (a) As shown in the figure, check resistance value of air conditioner thermistor

between terminal 1, 2 at each temperature,

Resistance:1

2Temperature(°C)Resistance

(K ohm)

Page 263 of 416

Condition/ circuit Tester connection Specification

OFF OFF

LO E D1 ON

ML E D1 D2 ON

MH E D1 D4 ON

HI E D1 D5 ONBlower switch connector unitD2 D4 D5

D1 D6 E4. Integrated control panel assembly

(a) Check connection of blower switch. If connection does not conform to specification, replace integrated control panel assembly.

(b) Check lighting operation

Connect positive wire of storage battery to terminal D6, negative wire to terminal E, then check whether

illuminating lamp illuminates. If bulb does not illuminate, replace the bulb.

(c) Check connection of air conditioning switch

As shown in the table, check connection of terminal when switch is pressedA/C switch connectorTester connection Specification

2 5 ON If connection does not conform to specification, replace air

conditioning switch.

(d) Check indicator work

Connect positive wire of storage battery to terminal 1, negative

wire to terminal 3, then check whether illuminating lamp

illuminates.

If connection does not conform to specification, replace

integrated control panel assembly.

4. Blower adjustment resistor

(a) Measure resistance between terminals, as shown in the table

Tester connection Specification

1-2 About 0. 38 Ohm

2-3 About 1. 47 Ohm

1-4 About 2. 71 OhmSpeed regulating resistance connector unit If resistance does not conform to specification, replace blower

resistance.

5. Blower assembly

(a) Connect positive wire of storage battery to terminal 2, negative

wire to terminal 1, check work smoothness of motor.

If work does not conform to specification, replace blower

assembly5-76Air Conditioning System -General Information

Page 264 of 416

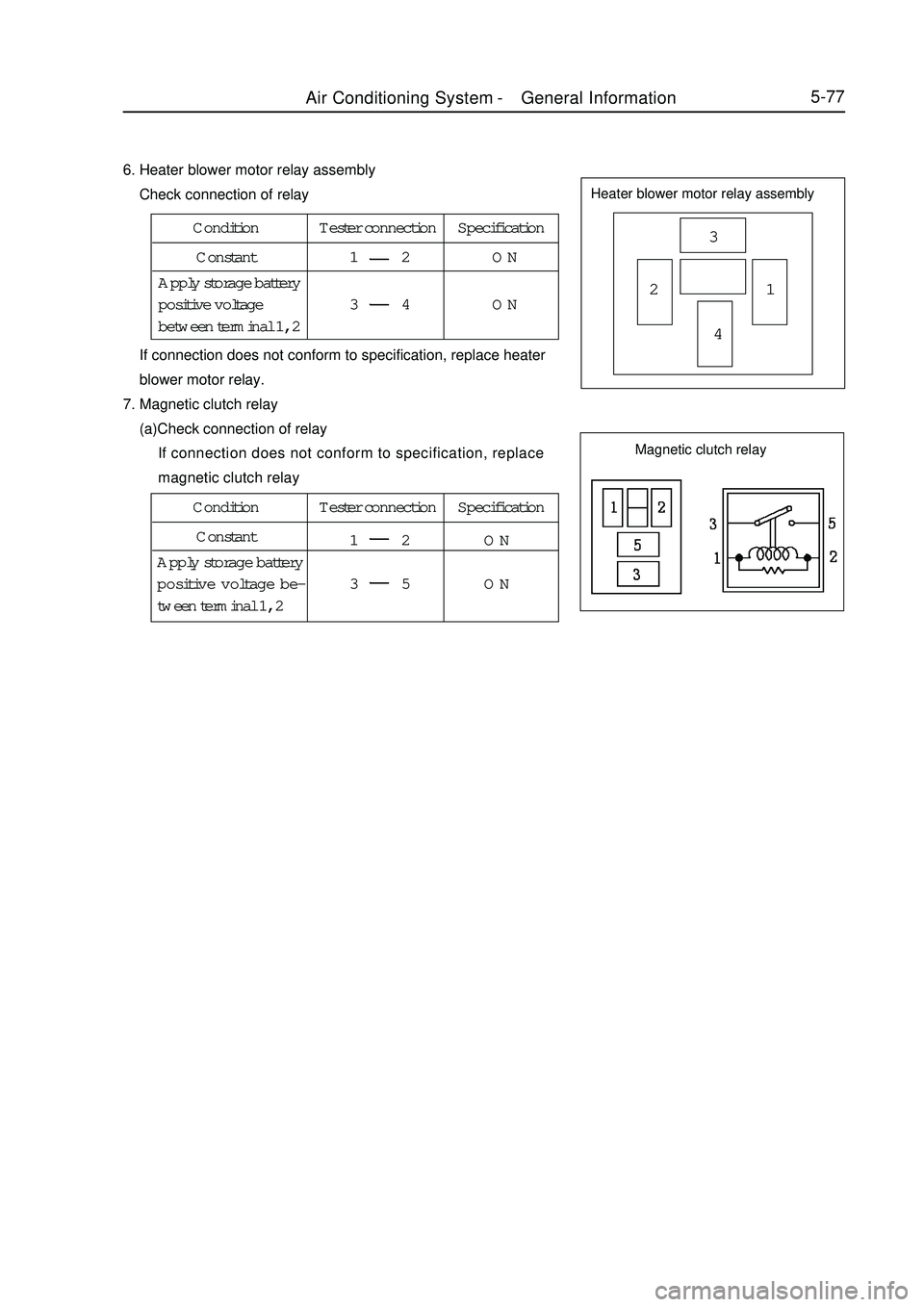

5-776. Heater blower motor relay assembly

Check connection of relayHeater blower motor relay assembly3

21

4 If connection does not conform to specification, replace heater

blower motor relay.

7. Magnetic clutch relay

(a)Check connection of relay

If connection does not conform to specification, replace

magnetic clutch relayCondition Tester connection Specification

Constant1 2 ON

3 4 ON Apply storage battery

positive voltage

between terminal 1, 2Condition Tester connection Specification

Constant

1 2 ON

3 5 ON Apply storage battery

positive voltage be-

tween terminal 1, 2Magnetic clutch relayAir Conditioning System -General Information

Page 265 of 416

Section 2 RefrigerantRefrigerant inspection1. Check refrigerant quantity

(a) Observe sight glass on refrigerating liquid pipe.

Test condition:

Engine speed: 1500 rpm

Blower speed control switch: HI "high "

Air conditioning switch: switch on

Temperature setting: maximum refrigeration

Refrigeration runs for 5 minutes

Open door

*: If refrigerating capacity is sufficient, environmental temperature is higher than normal condition, bubble

in sight glass may be deemed as normal.Symptom Refrigerant quantity Correct treatment2. Use manifold meter to check refrigerant pressure

( a ) This method is to utilize installed instrument to determine

where the fault is. Use manifold pressure meter reading to evaluate

fault condition.

Test condition:

Switch sets temperature of cyclical air inlet: 30-35°C

Engine speed: 1500 rpm

Blower speed control switch: high

Temperature control panel: refrigeration5-78With foam

Without foam

No temperature difference be-

tween input and output of

compressor

There is considerable tem-

perature difference between

compressor input and output

After air conditioner is turned

off, refrigerant should be

cleared immediately

After air conditioner is turned

off, refrigerant foams

immediately, then clears 1

2

3

4

5

6Insufficient *

Empty, insufficient or beyond

Empty or nearly full

Proper or beyond

Excess

Appropriate quantity1. Check gas leakage, repair if necessary

2. Add refrigerant until foam disappears

Refer to 3 and 4

1. Use detector to check gas leakage,

repair if necessary

2. Add refrigerant until foam disappears.

Refer to 5 and 6

1. Discharge refrigerant

2. Eliminate air, add appropriate quantity

of pure refrigerantSight glassAir Conditioning System -

Refrigerant

Page 266 of 416

5-79 Air conditioning switch: switch on

So door is completely open

(1) Refrigerating system meter reading during normal work:

Low pressure side: 0. 15-0. 25MPa

High pressure side: 1. 37-1. 57MPa

(2) System contains moistureSymptom Possible cause Diagnosis Correct treatment 1. During work, pressure

on low pressure side some-

times becomes vacuum

2.Intermittent refrigeration,

finally no refrigerationMoisture in the system

freezes at orifice of expan-

sion valve, circulation

suspends, but system re-

stores to normal after ice

thaws1. Drying agent is in satu-

rated state

2.System moisture

freezes at orifice of ex-

pansion valve, obstructs

refrigerant circulation1. Replace stock solution dry-

ing agent

2. By drawing off air repeti-

tively to remove water vapor in

the system, fill in appropriate

quantity of new refrigerant Pressure gauge indication when there is moisture in the system (3) Poor coolingManifold pressure gauge indication in case of poor cooling1. Pressure on high, low

pressure side is a bit low

2. Successive bubble ap-

pears in glass window

3. Refrigeration efficiency

deterioratesRefrigerant leakage

occurs in refrigerat-

ing system1. System refriger-

ant is insufficient

2. Refrigerant leaks1. Use leak detector to check whether

there is gas leakage, repair if there is any.

2. Fill in appropriate quantity of refriger-

ant

3. Connect a pressure gauge, if pressure

is zero, repair leaking part, and vacuumize

the systemSymptom Possible cause Diagnosis Correct treatmentAir Conditioning System -Refrigerant

Page 267 of 416

(4) Poor refrigerant circulation1. Indicates vacuum on low pres-

sure side, indicates too low pres-

sure on high pressure side

2. There is dew or frost on pipe

before and after expansion valve

or stock solution drier1. Pressure on high, low pressure side is a bit low

2. Pipeline from stock solution drier to main set frosts

3. Refrigeration is insufficientDirt in refrigeration

drier obstructs flow

of refrigerantStock solution

drier does not

circulateReplace stock

solution drierManifold pressure gauge indication in case of poor refrigerant circulationaSystem con-

tains moisture

or dirt which

obstructs flow

of refrigerant

Expansion

valve failureRefrigerant

does not cir-

culate1. Check expansion valve

2. Use compressed air to eliminate dirt of expan-

sion valve, but it cannot be eliminated, replace

expansion valve.

3. Vacuumize and fill in appropriate quantity of

new refrigerant

4. Expansion valve leaks, replace expansion valve Manifold pressure gauge indication in case of no refrigerant circulationa (5) Refrigerant does not circulateAir Conditioning System -Refrigerant5-80Symptom Possible cause Diagnosis Correct treatment

SymptomPossible cause Diagnosis

Correct treatmentWhen there is too much refrigerant or heat dissipation of condenser is poor (6) Too much refrigerant or heat dissipation of radiator is poor

Page 268 of 416

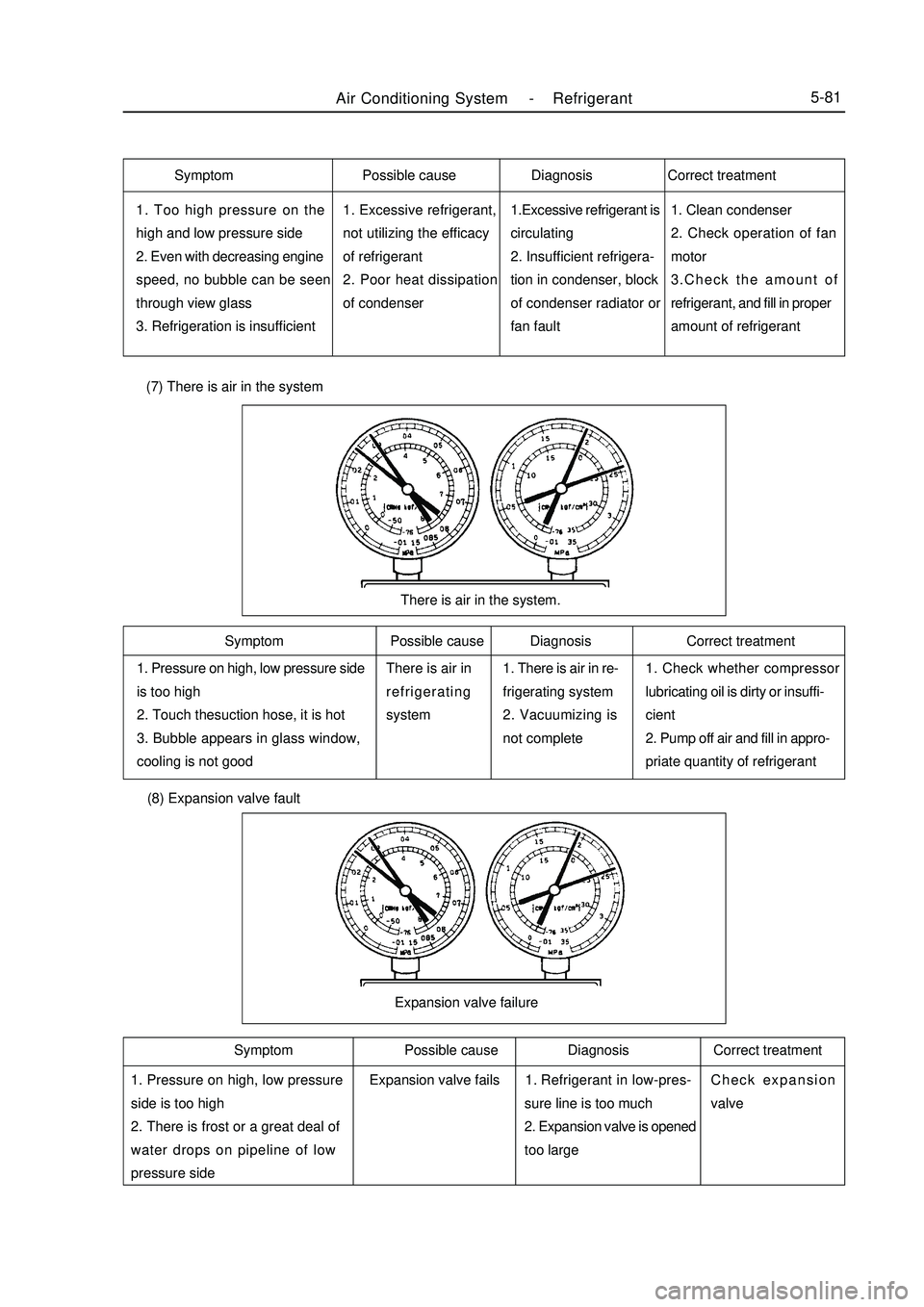

Air Conditioning System -Refrigerant5-811. Too high pressure on the

high and low pressure side

2. Even with decreasing engine

speed, no bubble can be seen

through view glass

3. Refrigeration is insufficient1. Excessive refrigerant,

not utilizing the efficacy

of refrigerant

2. Poor heat dissipation

of condenser1.Excessive refrigerant is

circulating

2. Insufficient refrigera-

tion in condenser, block

of condenser radiator or

fan fault1. Clean condenser

2. Check operation of fan

motor

3.Check the amount of

refrigerant, and fill in proper

amount of refrigerant1. Pressure on high, low pressure side

is too high

2. Touch thesuction hose, it is hot

3. Bubble appears in glass window,

cooling is not goodThere is air in

refrigerating

system1. There is air in re-

frigerating system

2. Vacuumizing is

not complete1. Check whether compressor

lubricating oil is dirty or insuffi-

cient

2. Pump off air and fill in appro-

priate quantity of refrigerantThere is air in the system. (7) There is air in the system (8) Expansion valve fault1. Pressure on high, low pressure

side is too high

2. There is frost or a great deal of

water drops on pipeline of low

pressure sideRefrigerant in low-pres-

sure line is too much

2. Expansion valve is opened

too largeCheck expansion

valveExpansion valve failureSymptom Possible cause Diagnosis Correct treatment

Symptom Possible cause Diagnosis Correct treatment Symptom Possible cause Diagnosis Correct treatment

Expansion valve fails1.

Page 269 of 416

1 pressure is too high on low

pressure side, pressure on high-

pressure side is too low

2. Without cold airInside sealing of compressor

is poorCompressor fails, valve

leaks or is damaged.Repair or replace

compressorCompressor failure (9) Compressor poor compression faultDischarge and fill-up of refrigerantDischarge of refrigerant

In case of depletion, surrounding environment should always be

well-ventilated, do not approach open fire, otherwise toxic gas might

be generated.

(1) Firstly turn off meter valve high low manual valve, connect

pipeline according to the figure below, then adjust air conditioner to

maximum refrigeration operating condition, adjust engine speed to

1000 - 2000 r/min, run for 5 min. Circulate refrigerant and collect

residual oil in parts as far as possible into compressor.Symptom Possible cause Diagnosis Correct treatment (2) Loosen throttle, let engine restore to normal idle speed, turn off engine.

(3) Slowly open high voltage manual valve,cover a white towel on hose outlet,observe whether there is oil stain

on the towel, adjust flow of refrigerant.

(4) When high pressure gauge reading decreases to below 0. 35MPa, slowly open low pressure manual valve.

Close manual valve until reading of high low pressure gauge is zero.Fill-up of refrigerant (1) Use vacuum pump to vacuumize the system

During repair of refrigerating system, once refrigerating system is exposed to air or certain refrigerating

system part is to be replaced, automobile air conditioner must be vacuumized. So as to eliminate air and

water vapour in the system.

(2) Fill in R134 a

Standard: 420 ± 10 g (Dongfeng Painen System)

440 ± 20 g (Tianjing Sando System)Air Conditioning System -Refrigerant5-82Compressor

Gathering tank

Page 270 of 416

Air Conditioning System -A/C Operating Mechanism5-83Section 3 A/C Operating Mechanism1. Remove heater control and attachment assembly

(1) Remove three control knobs.

(2) Remove two screws and middle instrument board

subassembly.

(3) Loosen six lock catches, pull out heater control and attach

ment assembly

2. Remove the operation mechanism

(1) Loosen the fixed clip (air distributor) and remove the air mit

damper conrol cable.

(2) Loosen the fixed clip (air distributor) and remove air inlet

mode selector cable.:clip:clipClamp