light GMC TERRAIN 2010 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: TERRAIN, Model: GMC TERRAIN 2010Pages: 410, PDF Size: 2.55 MB

Page 298 of 410

9-24 Vehicle Care

Brake Fluid

The brake master cylinder reservoir

is filled with DOT 3 brake fluid as

indicated on the reservoir cap. See

Engine Compartment Overview

on

page 9‑6for the location of the

reservoir.

There are only two reasons why the

brake fluid level in the reservoir

might go down:

.The brake fluid level goes down

because of normal brake lining

wear. When new linings are

installed, the fluid level goes

back up.

.A fluid leak in the brake

hydraulic system can also cause

a low fluid level. Have the brake

hydraulic system fixed, since a

leak means that sooner or later

the brakes will not work well.

Do not top off the brake fluid.

Adding fluid does not correct a leak.

If fluid is added when the linings are

worn, there will be too much fluid

when new brake linings are

installed. Add or remove brake fluid,

as necessary, only when work is

done on the brake hydraulic system.

{WARNING

If too much brake fluid is added, it

can spill on the engine and burn,

if the engine is hot enough. You

or others could be burned, and

the vehicle could be damaged.

Add brake fluid only when work is

done on the brake hydraulic

system. When the brake fluid falls to a low

level, the brake warning light comes

on. See

Brake System Warning

Light on page 4‑19.

What to Add

Use only new DOT 3 brake fluid

from a sealed container. See

Recommended Fluids and

Lubricants on page 10‑7.

Always clean the brake fluid

reservoir cap and the area around

the cap before removing it. This

helps keep dirt from entering the

reservoir.{WARNING

With the wrong kind of fluid in the

brake hydraulic system, the

brakes might not work well. This

could cause a crash. Always use

the proper brake fluid.

Page 304 of 410

9-30 Vehicle Care

5. Align the wiper blade with thearm and hold both ends of the

arm while gently squeezing until

the blade snaps into place.

Do not apply excessive force

during this operation.

Reposition the blade in the arm

and repeat, if blade is not

correctly positioned.

6. Place the wiper arm with the wiper blade attached back on

the liftgate glass.Headlamp Aiming

The headlamp aiming system has

been preset at the factory.

If the vehicle is damaged in an

accident, the aim of the headlamps

may be affected and adjustment

may be necessary.

It is recommended that a dealer/

retailer adjust the headlamps. To

re-aim the headlamps yourself, use

the following procedure.

The vehicle should be properly

prepared as follows. The vehicle:

.Should be placed so the

headlamps are 7.6 m (25 ft) from

a light colored wall.

.Must have all four tires on a

level surface which is level all

the way to the wall.

.Should be placed so it is

perpendicular to the wall or other

flat surface.

.Should not have any snow, ice,

or mud on it.

.Should be fully assembled and

all other work stopped while

headlamp aiming is being

performed.

.Should be normally loaded with

a full tank of fuel and one person

or 75 kg (160 lbs) sitting in the

driver's seat.

.Tires should be properly inflated.

Headlamp aiming is done with the

vehicle's low-beam headlamps. The

high-beam headlamps will be

correctly aimed if the low-beam

headlamps are aimed properly.

Page 305 of 410

Vehicle Care 9-31

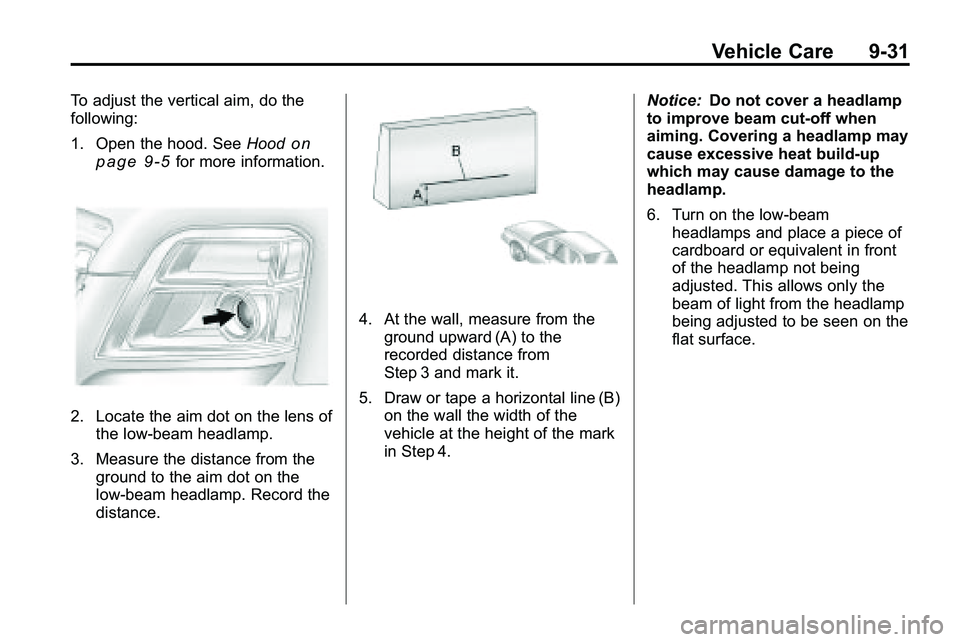

To adjust the vertical aim, do the

following:

1. Open the hood. SeeHood

on

page 9‑5for more information.

2. Locate the aim dot on the lens of the low‐beam headlamp.

3. Measure the distance from the ground to the aim dot on the

low‐beam headlamp. Record the

distance.

4. At the wall, measure from the

ground upward (A) to the

recorded distance from

Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the width of the

vehicle at the height of the mark

in Step 4. Notice:

Do not cover a headlamp

to improve beam cut-off when

aiming. Covering a headlamp may

cause excessive heat build-up

which may cause damage to the

headlamp.

6. Turn on the low-beam

headlamps and place a piece of

cardboard or equivalent in front

of the headlamp not being

adjusted. This allows only the

beam of light from the headlamp

being adjusted to be seen on the

flat surface.

Page 306 of 410

9-32 Vehicle Care

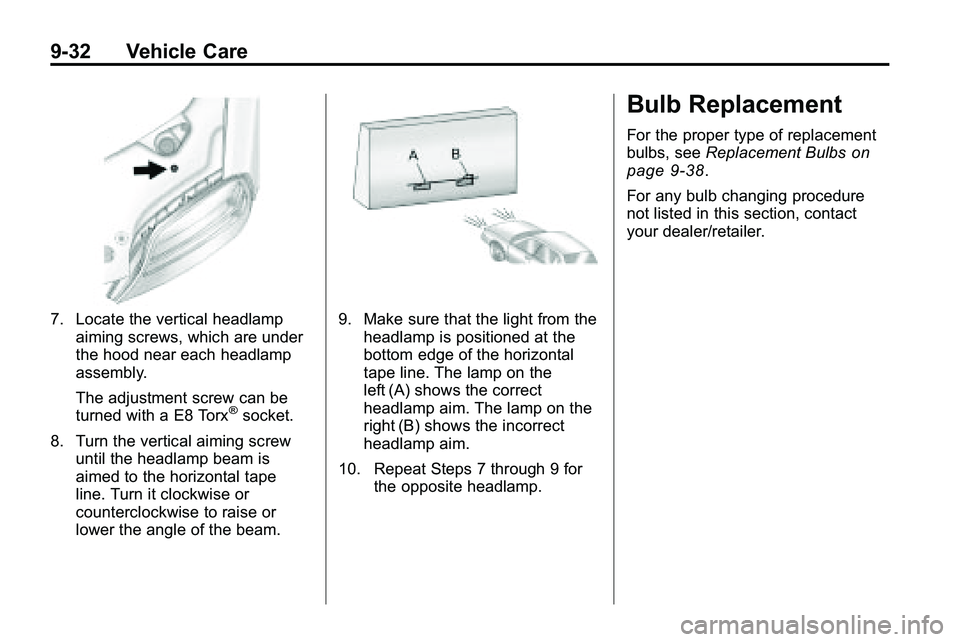

7. Locate the vertical headlampaiming screws, which are under

the hood near each headlamp

assembly.

The adjustment screw can be

turned with a E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam is

aimed to the horizontal tape

line. Turn it clockwise or

counterclockwise to raise or

lower the angle of the beam.

9. Make sure that the light from theheadlamp is positioned at the

bottom edge of the horizontal

tape line. The lamp on the

left (A) shows the correct

headlamp aim. The lamp on the

right (B) shows the incorrect

headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

Bulb Replacement

For the proper type of replacement

bulbs, see Replacement Bulbson

page 9‑38.

For any bulb changing procedure

not listed in this section, contact

your dealer/retailer.

Page 314 of 410

9-40 Vehicle Care

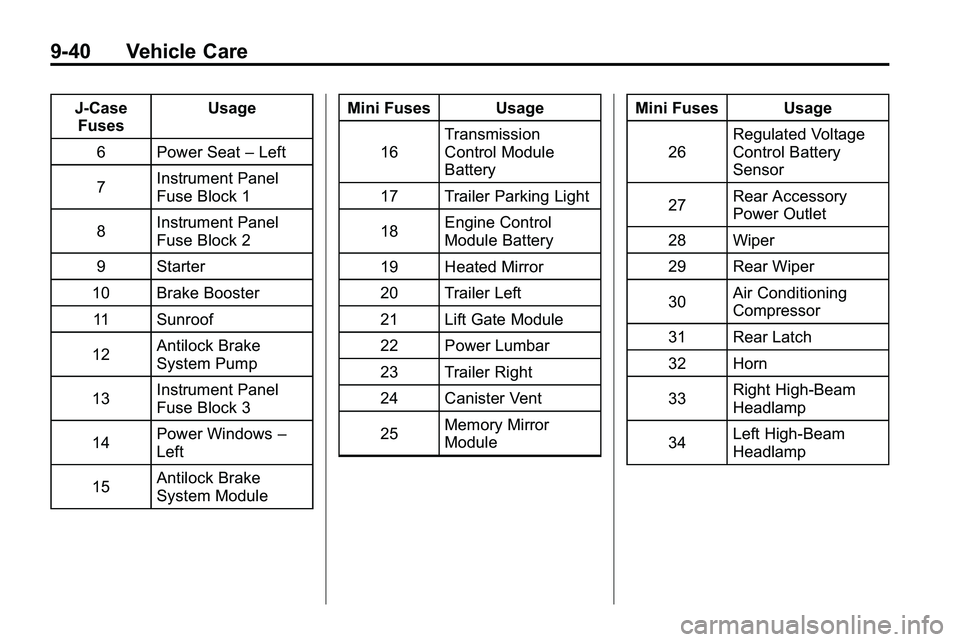

J-CaseFuses Usage

6 Power Seat –Left

7 Instrument Panel

Fuse Block 1

8 Instrument Panel

Fuse Block 2

9 Starter

10 Brake Booster 11 Sunroof

12 Antilock Brake

System Pump

13 Instrument Panel

Fuse Block 3

14 Power Windows

–

Left

15 Antilock Brake

System Module Mini Fuses Usage

16 Transmission

Control Module

Battery

17 Trailer Parking Light

18 Engine Control

Module Battery

19 Heated Mirror

20 Trailer Left

21 Lift Gate Module

22 Power Lumbar

23 Trailer Right

24 Canister Vent

25 Memory Mirror

Module Mini Fuses Usage

26 Regulated Voltage

Control Battery

Sensor

27 Rear Accessory

Power Outlet

28 Wiper

29 Rear Wiper

30 Air Conditioning

Compressor

31 Rear Latch

32 Horn

33 Right High‐Beam

Headlamp

34 Left High‐Beam

Headlamp

Page 324 of 410

9-50 Vehicle Care

GAWR FRT:Gross Axle Weight

Rating for the front axle. See

Vehicle Load Limits

on

page 8‑22

.

GAWR RR

:Gross Axle Weight

Rating for the rear axle. See

Vehicle Load Limits

on

page 8‑22

.

Intended Outboard Sidewall

:

The side of an asymmetrical tire,

that must always face outward

when mounted on a vehicle.

Kilopascal (kPa)

:The metric

unit for air pressure.

Light Truck (LT‐Metric) Tire

:A

tire used on light duty trucks and

some multipurpose passenger

vehicles.

Load Index

:An assigned

number ranging from 1 to 279

that corresponds to the load

carrying capacity of a tire. Maximum Inflation Pressure

:

The maximum air pressure to

which a cold tire can be inflated.

The maximum air pressure is

molded onto the sidewall.

Maximum Load Rating

:The

load rating for a tire at the

maximum permissible inflation

pressure for that tire.

Maximum Loaded Vehicle

Weight

:The sum of curb

weight, accessory weight,

vehicle capacity weight, and

production options weight.

Normal Occupant Weight

:The

number of occupants a vehicle

is designed to seat multiplied by

68 kg (150 lbs). See Vehicle

Load Limits

on page 8‑22.

Occupant Distribution

:

Designated seating positions. Outward Facing Sidewall

:The

side of an asymmetrical tire that

has a particular side that faces

outward when mounted on a

vehicle. The side of the tire that

contains a whitewall, bears

white lettering, or bears

manufacturer, brand, and/or

model name molding that is

higher or deeper than the same

moldings on the other sidewall

of the tire.

Passenger (P-Metric) Tire

:

A tire used on passenger cars

and some light duty trucks and

multipurpose vehicles.

Recommended Inflation

Pressure

:Vehicle

manufacturer's recommended

tire inflation pressure as shown

on the tire placard. See Tire

Pressure

on page 9‑52and

Vehicle Load Limits

on

page 8‑22

.

Page 329 of 410

Vehicle Care 9-55

Tire Pressure Monitor

Operation

This vehicle may have a Tire

Pressure Monitor System (TPMS).

The TPMS is designed to warn the

driver when a low tire pressure

condition exists. TPMS sensors are

mounted onto each tire and wheel

assembly, excluding the spare tire

and wheel assembly. The TPMS

sensors monitor the air pressure in

the vehicle's tires and transmit the

tire pressure readings to a receiver

located in the vehicle.

When a low tire pressure condition

is detected, the TPMS illuminates

the low tire pressure warning light

located on the instrument panel

cluster. If the warning light comes

on, stop as soon as possible andinflate the tires to the recommended

pressure shown on the tire loading

information label. See

Vehicle Load

Limits on page 8‑22.

At the same time a message to

check the pressure in a specific tire

appears on the Driver Information

Center (DIC) display. The low tire

pressure warning light and the DIC

warning message come on at each

ignition cycle until the tires are

inflated to the correct inflation

pressure. Using the DIC, tire

pressure levels can be viewed by

the driver. For additional information

and details about the DIC operation

and displays see Driver Information

Center (DIC) on page 4‑25.

The low tire pressure warning light

may come on in cool weather when

the vehicle is first started, and then

turn off as you start to drive. This

could be an early indicator that the

air pressure in the tire(s) are getting

low and need to be inflated to the

proper pressure. A Tire and Loading Information

label, attached to your vehicle,

shows the size of your vehicle's

original equipment tires and the

correct inflation pressure for your

vehicle's tires when they are cold.

See

Vehicle Load Limits

on

page 8‑22, for an example of the

Tire and Loading Information label

and its location on your vehicle.

Also see Tire Pressure

on

page 9‑52.

Your vehicle's TPMS can warn you

about a low tire pressure condition

but it does not replace normal tire

maintenance. See Tire Inspection

on page 9‑58,Tire Rotationon

page 9‑58and Tires on page 9‑45.

Notice: Liquid tire sealants could

damage the Tire Pressure Monitor

System (TPMS) sensors. Sensor

damage caused by using a tire

sealant is not covered by your

warranty. Do not use liquid tire

sealants.

Page 330 of 410

9-56 Vehicle Care

TPMS Malfunction Light and

Message

The TPMS will not function properly

if one or more of the TPMS sensors

are missing or inoperable. When the

system detects a malfunction, the

low tire warning light flashes for

about one minute and then stays on

for the remainder of the ignition

cycle. A DIC warning message is

also displayed. The low tire warning

light and DIC warning message

come on at each ignition cycle until

the problem is corrected. Some of

the conditions that can cause the

malfunction light and DIC message

to come on are:

.One of the road tires has been

replaced with the spare tire. The

spare tire does not have a

TPMS sensor. The TPMS

malfunction light and DIC

message should go off once you

re‐install the road tire containing

the TPMS sensor.

.The TPMS sensor matching

process was started but not

completed or not completed

successfully after rotating the

vehicle's tires. The DIC message

and TPMS malfunction light

should go off once the TPMS

sensor matching process is

performed successfully. See

“TPMS Sensor Matching

Process”later in this section.

.One or more TPMS sensors are

missing or damaged. The DIC

message and the TPMS

malfunction light should go off

when the TPMS sensors are

installed and the sensor

matching process is performed

successfully. See your dealer/

retailer for service.

.Replacement tires or wheels do

not match your vehicle's original

equipment tires or wheels. Tires

and wheels other than those

recommended for your vehicle

could prevent the TPMS from

functioning properly. See Buying

New Tires on page 9‑60.

.Operating electronic devices or

being near facilities using radio

wave frequencies similar to the

TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning it

cannot detect or signal a low tire

condition. See your dealer/retailer

for service if the TPMS malfunction

light and DIC message comes on

and stays on.

Page 337 of 410

Vehicle Care 9-63

The Uniform Tire Quality

Grading (UTQG) system does

not apply to deep tread,

winter-type snow tires,

space-saver, or temporary use

spare tires, tires with nominal

rim diameters of 10 to 12 inches

(25 to 30 cm), or to some

limited-production tires.

While the tires available on

General Motors passenger cars

and light trucks may vary with

respect to these grades, they

must also conform to federal

safety requirements and

additional General Motors Tire

Performance Criteria (TPC)

standards.

All Passenger Car Tires Must

Conform to Federal Safety

Requirements In Addition To

These Grades.Treadwear

The treadwear grade is a

comparative rating based on the

wear rate of the tire when tested

under controlled conditions on a

specified government test

course. For example, a tire

graded 150 would wear one and

a half (1½) times as well on the

government course as a tire

graded 100. The relative

performance of tires depends

upon the actual conditions of

their use, however, and may

depart significantly from the

norm due to variations in

driving habits, service practices

and differences in road

characteristics and climate.

Traction

–AA, A, B, C

The traction grades, from

highest to lowest, are AA, A, B,

and C. Those grades represent

the tire's ability to stop on wet

pavement as measured under

controlled conditions on

specified government test

surfaces of asphalt and

concrete. A tire marked C may

have poor traction performance.

Warning: The traction grade

assigned to this tire is based on

straight-ahead braking traction

tests, and does not include

acceleration, cornering,

hydroplaning, or peak traction

characteristics.

Page 352 of 410

9-78 Vehicle Care

Jump Starting

Jump starting can be used on

vehicles with run‐down batteries by

using jumper cables and another

vehicle.

{WARNING

Batteries can hurt you. They can

be dangerous because:

.They contain acid that can

burn you.

.They contain gas that can

explode or ignite.

.They contain enough

electricity to burn you.

If you do not follow these steps

exactly, some or all of these

things can hurt you.

{WARNING

Using an open flame near a

battery can cause battery gas to

explode. People have been hurt

doing this, and some have been

blinded. Use a flashlight if you

need more light.

Be sure the battery has enough

water. You do not need to add

water to the battery installed in

your new vehicle. But if a battery

has filler caps, be sure the right

amount of fluid is there. If it is low,

add water to take care of that

first. If you do not, explosive gas

could be present.

Battery fluid contains acid that

can burn you. Do not get it on

you. If you accidentally get it in

your eyes or on your skin, flush

the place with water and get

medical help immediately. Be sure to use the following steps to

do it safely. Ignoring these steps

could result in costly damage to the

vehicle that would not be covered

by the warranty.

Trying to start the vehicle by

pushing or pulling it will not work,

and it could damage the vehicle.

Notice:

If you leave the radio or

other accessories on during the

jump starting procedure, they

could be damaged. The repairs

would not be covered by the

warranty. Always turn off the

radio and other accessories when

jump starting the vehicle.

Notice: If the jumper cables are

connected or removed in the

wrong order, electrical shorting

may occur and damage the

vehicle. The repairs would not be

covered by the vehicle warranty.

Always connect and remove the

jumper cables in the correct

order, making sure that the

cables do not touch each other or

other metal.