lock GMC TERRAIN 2010 Manual PDF

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: TERRAIN, Model: GMC TERRAIN 2010Pages: 410, PDF Size: 2.55 MB

Page 281 of 410

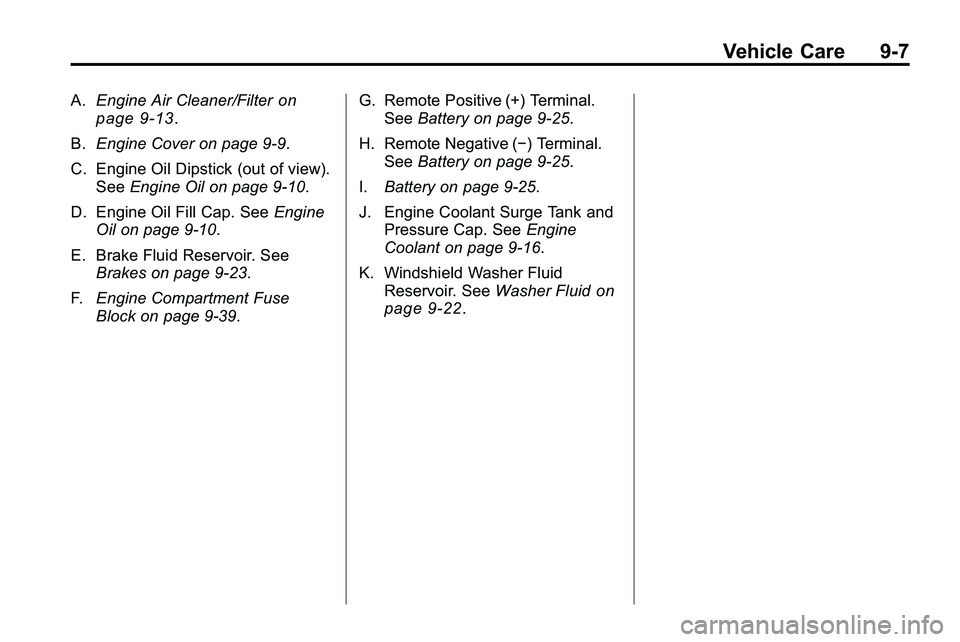

Vehicle Care 9-7

A.Engine Air Cleaner/Filteron

page 9‑13.

B. Engine Cover on page 9‑9.

C. Engine Oil Dipstick (out of view). See Engine Oil on page 9‑10.

D. Engine Oil Fill Cap. See Engine

Oil on page 9‑10.

E. Brake Fluid Reservoir. See Brakes on page 9‑23.

F. Engine Compartment Fuse

Block on page 9‑39. G. Remote Positive (+) Terminal.

See Battery on page 9‑25.

H. Remote Negative (−) Terminal. See Battery on page 9‑25.

I. Battery on page 9‑25.

J. Engine Coolant Surge Tank and Pressure Cap. See Engine

Coolant on page 9‑16.

K. Windshield Washer Fluid Reservoir. See Washer Fluid

on

page 9‑22.

Page 283 of 410

Vehicle Care 9-9

A.Engine Air Cleaner/Filteron

page 9‑13.

B. Power Steering Fluid

(2.4L L4 Engine)

on page 9‑21orPower Steering Fluid

(3.0L V6 Engine) on page 9‑21.

C. Engine Oil Fill Cap. See Engine

Oil on page 9‑10.

D. Engine Cover on page 9‑9.

E. Engine Oil Dipstick (out of view). See Engine Oil on page 9‑10.

F. Brake Fluid Reservoir. See Brakes on page 9‑23. G.

Engine Compartment Fuse

Block on page 9‑39.

H. Remote Positive (+) Terminal. See Battery on page 9‑25.

I. Remote Negative (−) Terminal. See Battery on page 9‑25.

J. Battery on page 9‑25.

K. Engine Coolant Surge Tank and Pressure Cap. See Engine

Coolant on page 9‑16.

L. Windshield Washer Fluid Reservoir. See Washer Fluid

on

page 9‑22.

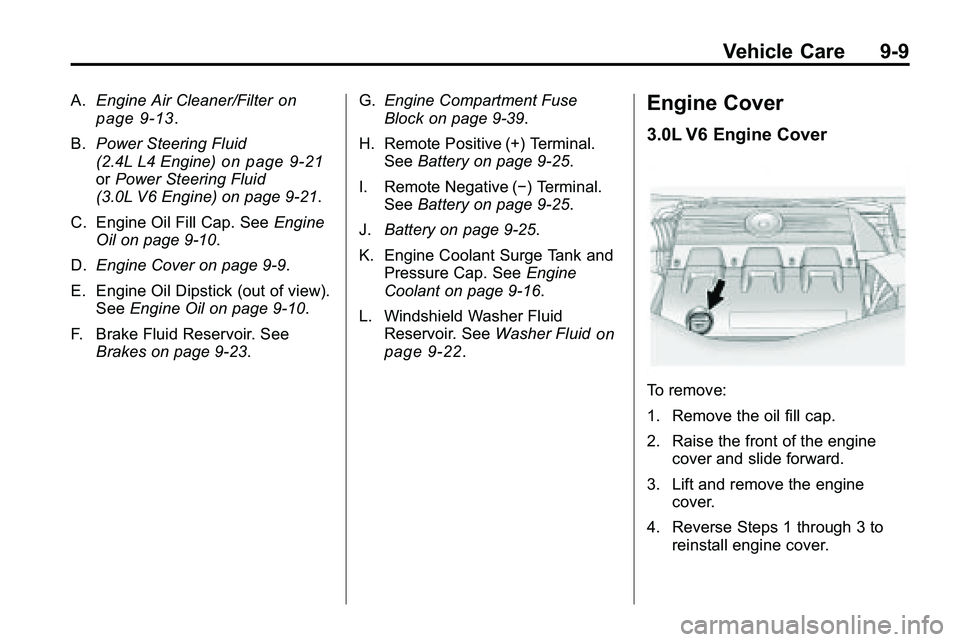

Engine Cover

3.0L V6 Engine Cover

To remove:

1. Remove the oil fill cap.

2. Raise the front of the engine

cover and slide forward.

3. Lift and remove the engine cover.

4. Reverse Steps 1 through 3 to reinstall engine cover.

Page 286 of 410

9-12 Vehicle Care

Engine Oil Life System

When to Change Engine Oil

This vehicle has a computer system

that indicates when to change the

engine oil and filter. This is based

on engine revolutions and engine

temperature, and not on mileage.

Based on driving conditions, the

mileage at which an oil change is

indicated can vary considerably. For

the oil life system to work properly,

the system must be reset every time

the oil is changed.

When the system has calculated

that oil life has been diminished, it

indicates that an oil change is

necessary. A“Change Engine Oil

Soon” message comes on.

See Engine Oil Messages

on

page 4‑31. Change the oil as soon as possible within the next 1 000 km

(600 miles). It is possible that,

if driving under the best conditions,

the oil life system might not indicate

that an oil change is necessary for

over a year. However, the engine oil

and filter must be changed at least

once a year and at this time the

system must be reset. Your dealer/

retailer has trained service people

who will perform this work using

genuine parts and reset the system.

It is also important to check the oil

regularly and keep it at the proper

level.

If the system is ever reset

accidentally, the oil must be

changed at 5 000 km (3,000 miles)

since the last oil change.

Remember to reset the oil life

system whenever the oil is changed.

How to Reset the Engine Oil

Life System

Reset the system whenever the

engine oil is changed so that the

system can calculate the next

engine oil change. To reset the

system:

1. Turn the ignition to ON/RUN with

the engine off.

2. Fully press and release the accelerator pedal three times

within five seconds.

If the vehicle has Driver Information

Center (DIC) buttons:

1. Turn the ignition to ON/RUN, with the engine off.

2. Press the DIC menu button until “Remaining Oil Life” displays.

3. Press and hold the set/clear button until “100%”is displayed.

4. Turn the key to LOCK/OFF.

The system is reset when the

“Change Engine Oil Soon” message

goes off.

Page 293 of 410

Vehicle Care 9-19

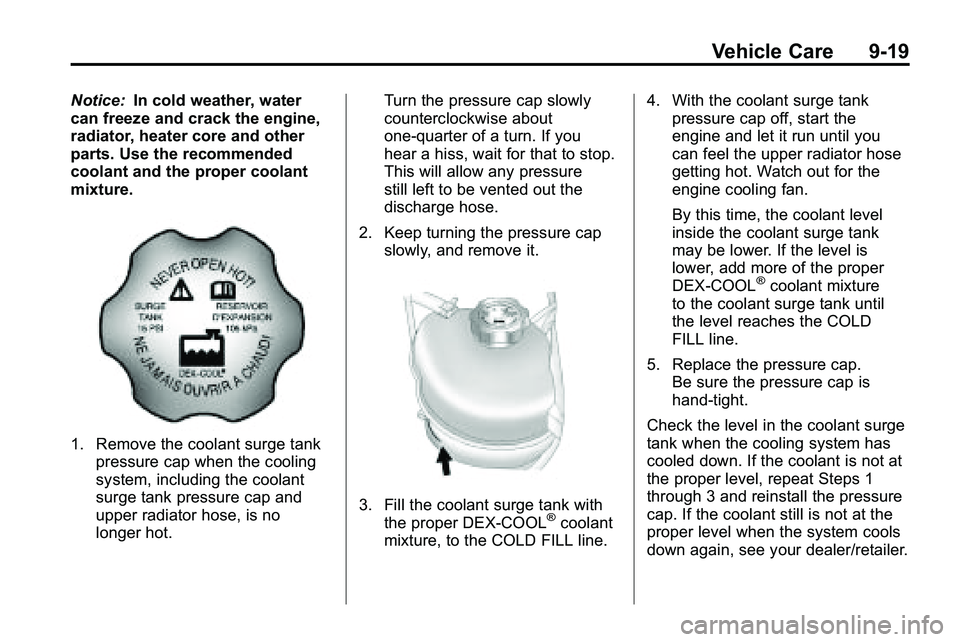

Notice:In cold weather, water

can freeze and crack the engine,

radiator, heater core and other

parts. Use the recommended

coolant and the proper coolant

mixture.

1. Remove the coolant surge tank pressure cap when the cooling

system, including the coolant

surge tank pressure cap and

upper radiator hose, is no

longer hot. Turn the pressure cap slowly

counterclockwise about

one-quarter of a turn. If you

hear a hiss, wait for that to stop.

This will allow any pressure

still left to be vented out the

discharge hose.

2. Keep turning the pressure cap slowly, and remove it.

3. Fill the coolant surge tank with

the proper DEX-COOL®coolant

mixture, to the COLD FILL line. 4. With the coolant surge tank

pressure cap off, start the

engine and let it run until you

can feel the upper radiator hose

getting hot. Watch out for the

engine cooling fan.

By this time, the coolant level

inside the coolant surge tank

may be lower. If the level is

lower, add more of the proper

DEX-COOL

®coolant mixture

to the coolant surge tank until

the level reaches the COLD

FILL line.

5. Replace the pressure cap. Be sure the pressure cap is

hand-tight.

Check the level in the coolant surge

tank when the cooling system has

cooled down. If the coolant is not at

the proper level, repeat Steps 1

through 3 and reinstall the pressure

cap. If the coolant still is not at the

proper level when the system cools

down again, see your dealer/retailer.

Page 301 of 410

Vehicle Care 9-27

3. Try to start the engine in eachgear. The vehicle should start

only in P (Park) or N (Neutral).

If the vehicle starts in any other

position, contact your dealer/

retailer for service.

Automatic Transmission

Shift Lock Control

System Check

{WARNING

When you are doing this

inspection, the vehicle could

move suddenly. If the vehicle

moves, you or others could be

injured.

1. Before starting this check, be sure there is enough room

around the vehicle. It should be

parked on a level surface. 2. Firmly apply the parking brake.

See Parking Brake

on

page 8‑40.

Be ready to apply the regular

brake immediately if the vehicle

begins to move.

3. With the engine off, turn the ignition to ON/RUN, but do not

start the engine. Without

applying the regular brake, try to

move the shift lever out of

P (Park) with normal effort. If the

shift lever moves out of P (Park),

contact your dealer/retailer for

service.

Ignition Transmission

Lock Check

While parked, and with the parking

brake set, try to turn the ignition to

LOCK/OFF in each shift lever

position.

.The ignition should turn to

LOCK/OFF only when the shift

lever is in P (Park).

.The ignition key should come

out only in LOCK/OFF.

Contact your dealer/retailer if

service is required.

Page 306 of 410

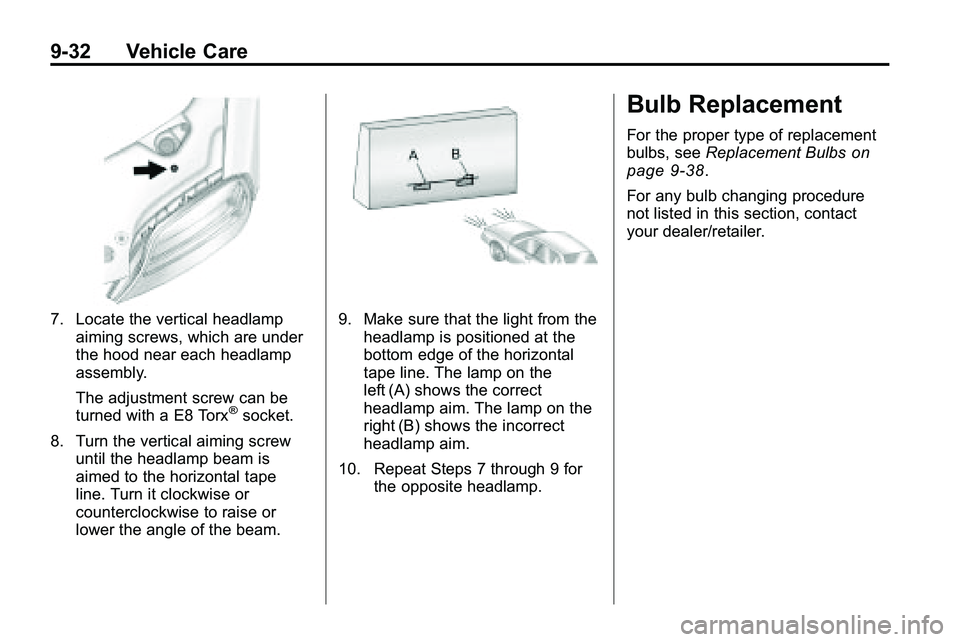

9-32 Vehicle Care

7. Locate the vertical headlampaiming screws, which are under

the hood near each headlamp

assembly.

The adjustment screw can be

turned with a E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam is

aimed to the horizontal tape

line. Turn it clockwise or

counterclockwise to raise or

lower the angle of the beam.

9. Make sure that the light from theheadlamp is positioned at the

bottom edge of the horizontal

tape line. The lamp on the

left (A) shows the correct

headlamp aim. The lamp on the

right (B) shows the incorrect

headlamp aim.

10. Repeat Steps 7 through 9 for the opposite headlamp.

Bulb Replacement

For the proper type of replacement

bulbs, see Replacement Bulbson

page 9‑38.

For any bulb changing procedure

not listed in this section, contact

your dealer/retailer.

Page 307 of 410

Vehicle Care 9-33

Headlamps, Front Turn

Signal, Sidemarker, and

Parking Lamps

A. Low-Beam Headlamp

B. High-Beam headlamp

C. Side Marker Lamp

D. Park/Turn Signal LampTo replace:

1. Turn the tire to reach the access

port cap located in the front of

wheel well cover.A. Screw

B. Access Port Cap

2. Remove screw (A) and turn the access port cap (B)

counterclockwise to remove.

3. If replacing a low/high headlamp bulb, remove the dust cover cap

from the back of the headlamp

housing by turning the cap

counterclockwise. 4. Turn the low/high beam or

park/turn signal bulb socket

counterclockwise to remove from

the lamp assembly.

5. Turn the sidemarker bulb socket clockwise to remove from the

lamp assembly.

6. Remove the bulb from the socket or disconnect bulb

assembly from harness

connector.

7. Install new bulb.

8. Reinstall the low/high beam or park/turn signal bulb socket to

the lamp assembly, turning

clockwise.

9. Reinstall the sidemarker bulb socket to the lamp assembly,

turning clockwise.

10. Replace the dust cover cap on headlamps.

11. Reinstall the wheel well cover access port cap and secure by

installing screw.

Page 308 of 410

9-34 Vehicle Care

Fog Lamps

To replace one of these bulbs:

1. Locate the fog lamp assemblyunder the front facia.

2. Disconnect the bulb socket from the electrical connector, turn and

pull out the bulb assembly. 3. Remove the old bulb from the

bulb socket and push the new

bulb straight into the bulb socket

until it connects.

4. Push the bulb socket into the fog lamp assembly and turn

counterclockwise to lock it into

place.

5. Reconnect the bulb socket to the electrical connector.

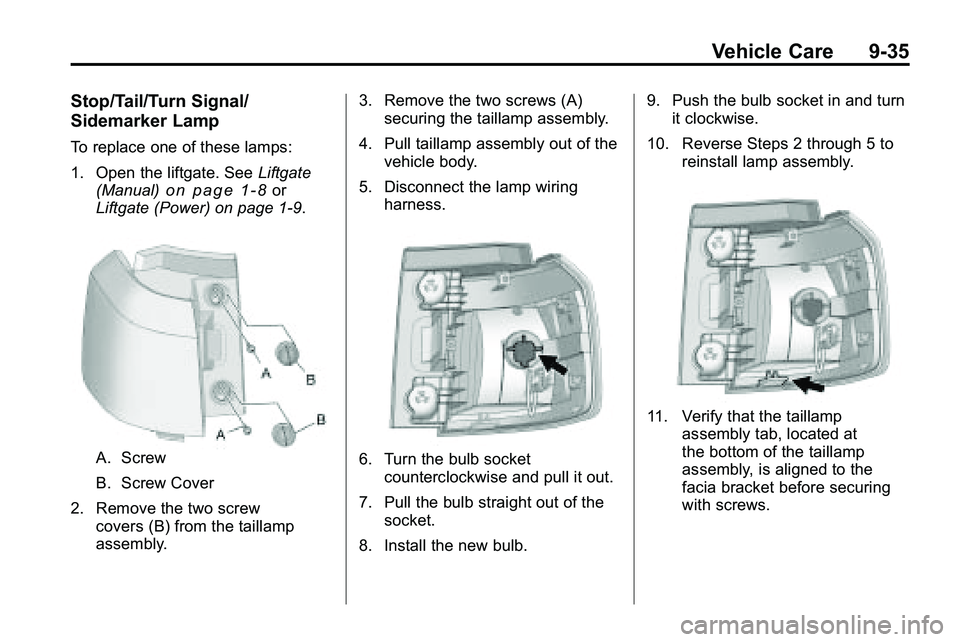

Taillamps, Turn Signal,

Sidemarker, Stoplamps,

and Back-Up Lamps

A. Stop/Tail/Turn Signal/Sidemarker Lamp

B. Auxiliary Taillamp

C. Back-up Lamp

Page 309 of 410

Vehicle Care 9-35

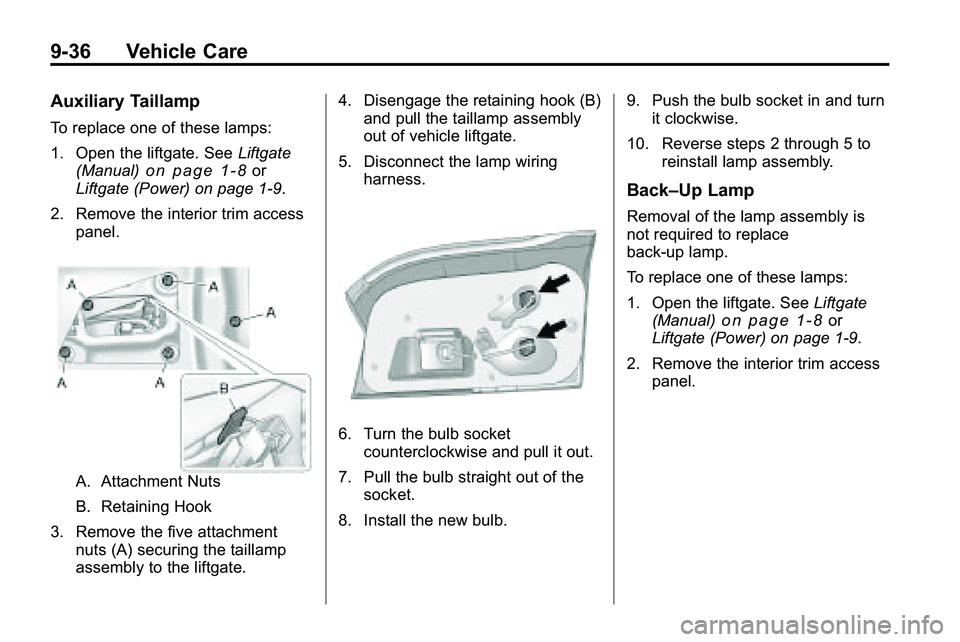

Stop/Tail/Turn Signal/

Sidemarker Lamp

To replace one of these lamps:

1. Open the liftgate. SeeLiftgate

(Manual)

on page 1‑8or

Liftgate (Power) on page 1‑9.

A. Screw

B. Screw Cover

2. Remove the two screw covers (B) from the taillamp

assembly. 3. Remove the two screws (A)

securing the taillamp assembly.

4. Pull taillamp assembly out of the vehicle body.

5. Disconnect the lamp wiring harness.6. Turn the bulb socketcounterclockwise and pull it out.

7. Pull the bulb straight out of the socket.

8. Install the new bulb. 9. Push the bulb socket in and turn

it clockwise.

10. Reverse Steps 2 through 5 to reinstall lamp assembly.

11. Verify that the taillampassembly tab, located at

the bottom of the taillamp

assembly, is aligned to the

facia bracket before securing

with screws.

Page 310 of 410

9-36 Vehicle Care

Auxiliary Taillamp

To replace one of these lamps:

1. Open the liftgate. SeeLiftgate

(Manual)

on page 1‑8or

Liftgate (Power) on page 1‑9.

2. Remove the interior trim access panel.

A. Attachment Nuts

B. Retaining Hook

3. Remove the five attachment nuts (A) securing the taillamp

assembly to the liftgate. 4. Disengage the retaining hook (B)

and pull the taillamp assembly

out of vehicle liftgate.

5. Disconnect the lamp wiring harness.

6. Turn the bulb socketcounterclockwise and pull it out.

7. Pull the bulb straight out of the socket.

8. Install the new bulb. 9. Push the bulb socket in and turn

it clockwise.

10. Reverse steps 2 through 5 to reinstall lamp assembly.

Back–Up Lamp

Removal of the lamp assembly is

not required to replace

back-up lamp.

To replace one of these lamps:

1. Open the liftgate. See Liftgate

(Manual)

on page 1‑8or

Liftgate (Power) on page 1‑9.

2. Remove the interior trim access panel.