brake GREAT WALL FLORID 2008 User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 44 of 281

Downloaded from www.Manualslib.com manuals search engine 37Clutch Operational System

Areas of Importance

1. Clutch Rigid Pipe Installation

Before installing, check to make sure that the rigid pipe flare contact area is in good condition, the pipeline is

clean, and that there is no foreign materials.

2. Clutch Hose Installation

Check the surface of the clutch hose to make sure that there is no scuffing and that the pipeline is clean.

3. Coat grease on the U-joint of the pedal and the master cylinder.

4. Strictly adhere to the set torque guidelines when tightening the pipe fittings.

Rigid pipe and the master cylinder: M10 16±2 N·m

Clutch rigid pipe and hose: M10 16±2 N·m

5. While the clutch system is undergoing the exhausting process, make sure that all the air bubbles in

the pipeline are cleared out. Then check the brake fluid level in the reservoir, it should be between

MIN and MAX.

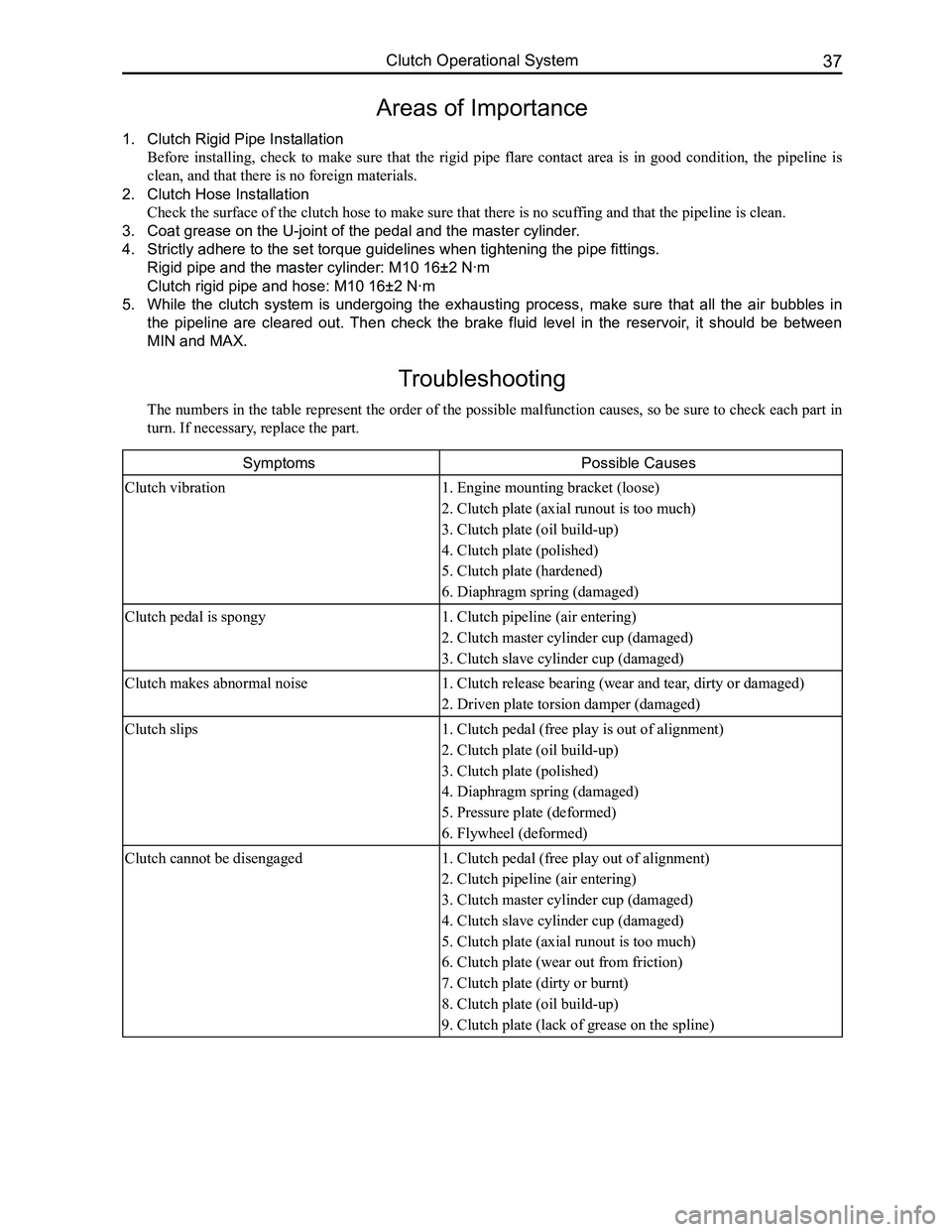

Troubleshooting

The numbers in the table represent the order of the possible malfunction causes, so be sure to check each part in

turn. If necessary, replace the part.

SymptomsPossible Causes

Clutch vibration1. Engine mounting bracket (loose)

2. Clutch plate (axial runout is too much)

3. Clutch plate (oil build-up)

4. Clutch plate (polished)

5. Clutch plate (hardened)

6. Diaphragm spring (damaged)

Clutch pedal is spongy1. Clutch pipeline (air entering)

2. Clutch master cylinder cup (damaged)

3. Clutch slave cylinder cup (damaged)

Clutch makes abnormal noise1. Clutch release bearing (wear and tear, dirty or damaged)

2. Driven plate torsion damper (damaged)

Clutch slips1. Clutch pedal (free play is out of alignment)

2. Clutch plate (oil build-up)

3. Clutch plate (polished)

4. Diaphragm spring (damaged)

5. Pressure plate (deformed)

6. Flywheel (deformed)

Clutch cannot be disengaged1. Clutch pedal (free play out of alignment)

2. Clutch pipeline (air entering)

3. Clutch master cylinder cup (damaged)

4. Clutch slave cylinder cup (damaged)

5. Clutch plate (axial runout is too much)

6. Clutch plate (wear out from friction)

7. Clutch plate (dirty or burnt)

8. Clutch plate (oil build-up)

9. Clutch plate (lack of grease on the spline)

Page 45 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual38

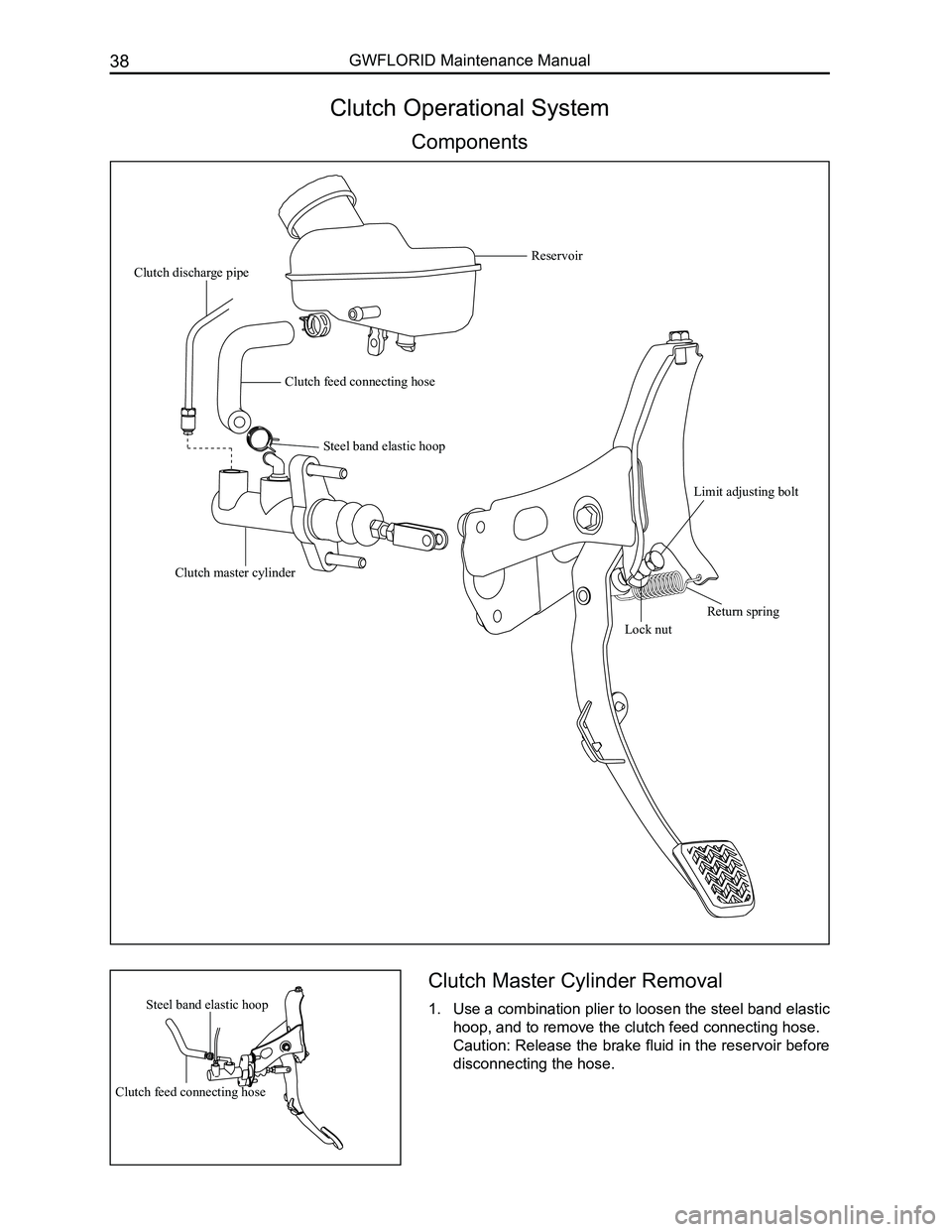

Clutch Operational System

Components

Clutch Master Cylinder Removal

1. Use a combination plier to loosen the steel band elastic

hoop, and to remove the clutch feed connecting hose.

Caution: Release the brake fluid in the reservoir before

disconnecting the hose.

Steel band elastic hoop

Clutch feed connecting hose

Reservoir

Steel band elastic hoop

Clutch feed connecting hose

Clutch discharge pipe

Clutch master cylinder

Limit adjusting bolt

Return spring

Lock nut

Page 47 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual40

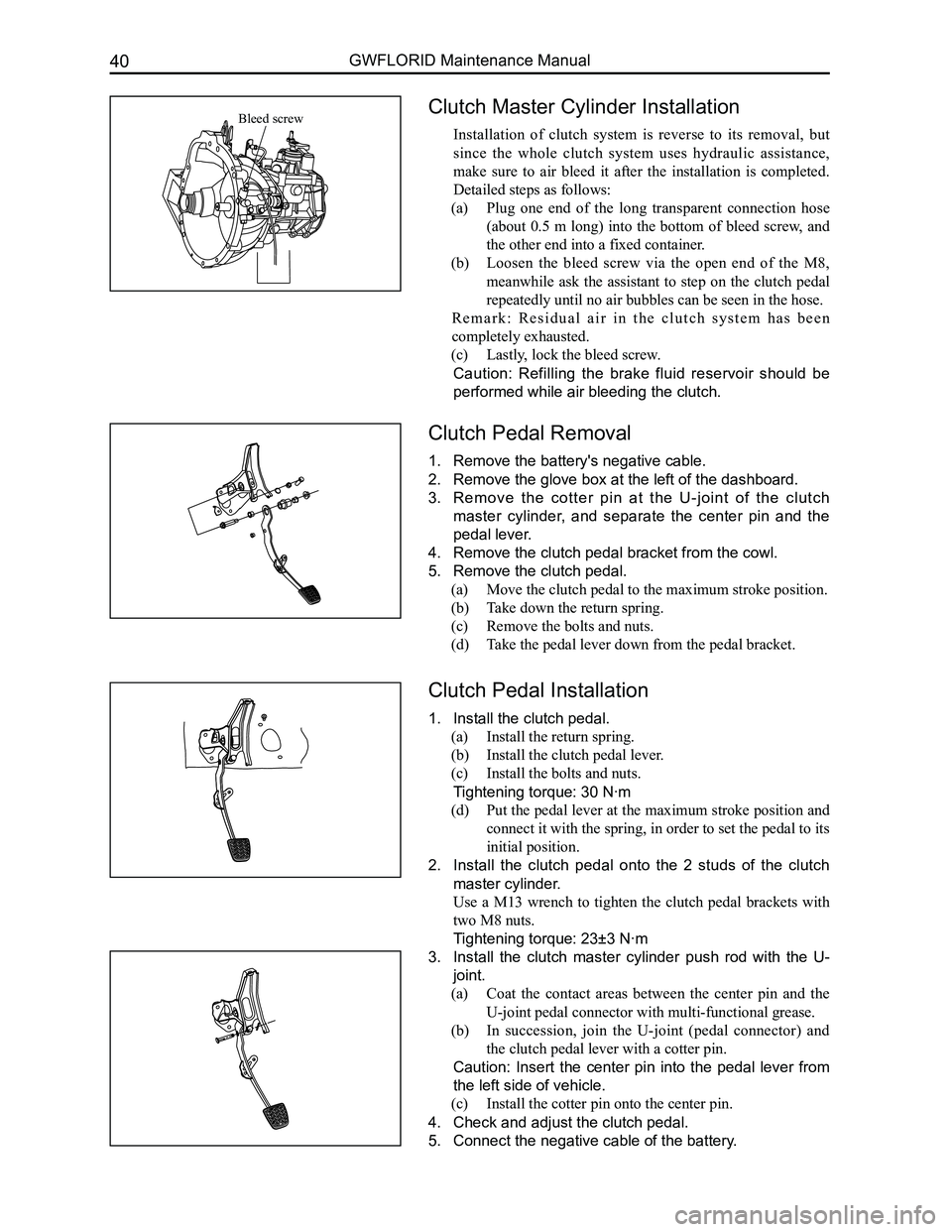

Clutch Master Cylinder Installation

Installation of clutch system is reverse to its removal, but

since the whole clutch system uses hydraulic assistance,

make sure to air bleed it after the installation is completed.

Detailed steps as follows:

(a) Plug one end of the long transparent connection hose

(about 0.5 m long) into the bottom of bleed screw, and

the other end into a fixed container.

(b) Loosen the bleed screw via the open end of the M8,

meanwhile ask the assistant to step on the clutch pedal

repeatedly until no air bubbles can be seen in the hose.

R e m a r k : R e s i d u a l a i r i n t h e c l u t c h s y s t e m h a s b e e n

completely exhausted.

(c) Lastly, lock the bleed screw.

Caution: Refilling the brake fluid reservoir should be

performed while air bleeding the clutch.

Clutch Pedal Removal

1. Remove the battery's negative cable.

2. Remove the glove box at the left of the dashboard.

3. Remove the cotter pin at the U-joint of the clutch

master cylinder, and separate the center pin and the

pedal lever.

4. Remove the clutch pedal bracket from the cowl.

5. Remove the clutch pedal.

(a) Move the clutch pedal to the maximum stroke position.

(b) Take down the return spring.

(c) Remove the bolts and nuts.

(d) Take the pedal lever down from the pedal bracket.

Clutch Pedal Installation

1. Install the clutch pedal.

(a) Install the return spring.

(b) Install the clutch pedal lever.

(c) Install the bolts and nuts.

Tightening torque: 30 N·m

(d) Put the pedal lever at the maximum stroke position and

connect it with the spring, in order to set the pedal to its

initial position.

2. Install the clutch pedal onto the 2 studs of the clutch

master cylinder.

Use a M13 wrench to tighten the clutch pedal brackets with

two M8 nuts.

Tightening torque: 23±3 N·m

3. Install the clutch master cylinder push rod with the U-

joint.

(a) Coat the contact areas between the center pin and the

U-joint pedal connector with multi-functional grease.

(b) In succession, join the U-joint (pedal connector) and

the clutch pedal lever with a cotter pin.

Caution: Insert the center pin into the pedal lever from

the left side of vehicle.

(c) Install the cotter pin onto the center pin.

4. Check and adjust the clutch pedal.

5. Connect the negative cable of the battery.

Bleed screw

Page 80 of 281

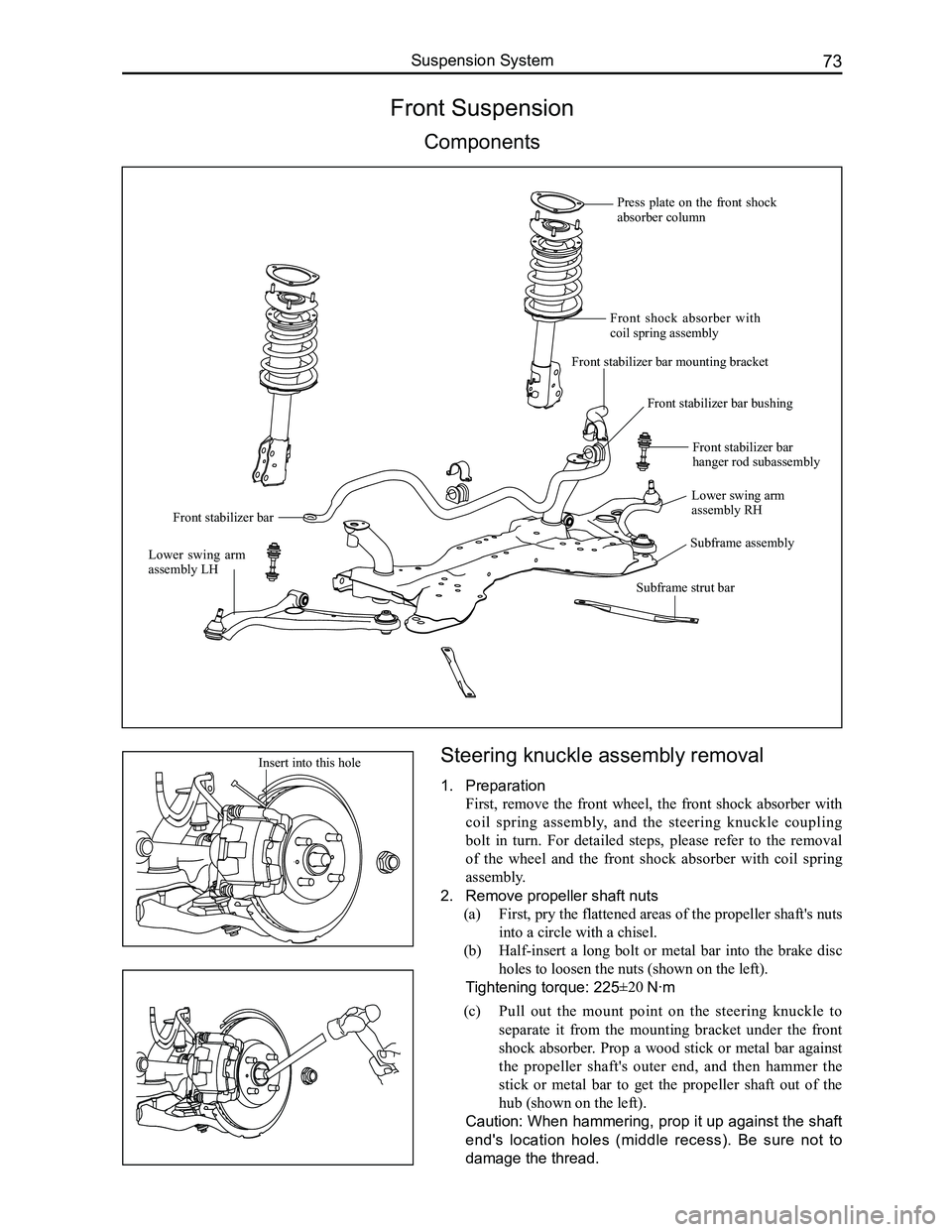

Downloaded from www.Manualslib.com manuals search engine 73Suspension System

Steering knuckle assembly removal

1. Preparation

First, remove the front wheel, the front shock absorber with

coil spring assembly, and the steering knuckle coupling

bolt in turn. For detailed steps, please refer to the removal

of the wheel and the front shock absorber with coil spring

assembly.

2. Remove propeller shaft nuts

(a) First, pry the flattened areas of the propeller shaft's nuts

into a circle with a chisel.

(b) Half-insert a long bolt or metal bar into the brake disc

holes to loosen the nuts (shown on the left).

Tightening torque: 225±20 N·m

Front Suspension

Components

(c) Pull out the mount point on the steering knuckle to

separate it from the mounting bracket under the front

shock absorber. Prop a wood stick or metal bar against

the propeller shaft's outer end, and then hammer the

stick or metal bar to get the propeller shaft out of the

hub (shown on the left).

Caution: When hammering, prop it up against the shaft

end's location holes (middle recess). Be sure not to

damage the thread.

Insert into this hole

Press plate on the front shock absorber column

Front shock absorber with coil spring assembly

Front stabilizer bar mounting bracket

Front stabilizer bar bushing

Front stabilizer bar

Lower swing arm assembly RH

Lower swing arm assembly LH

Subframe assembly

Front stabilizer bar hanger rod subassembly

Subframe strut bar

Page 81 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual74

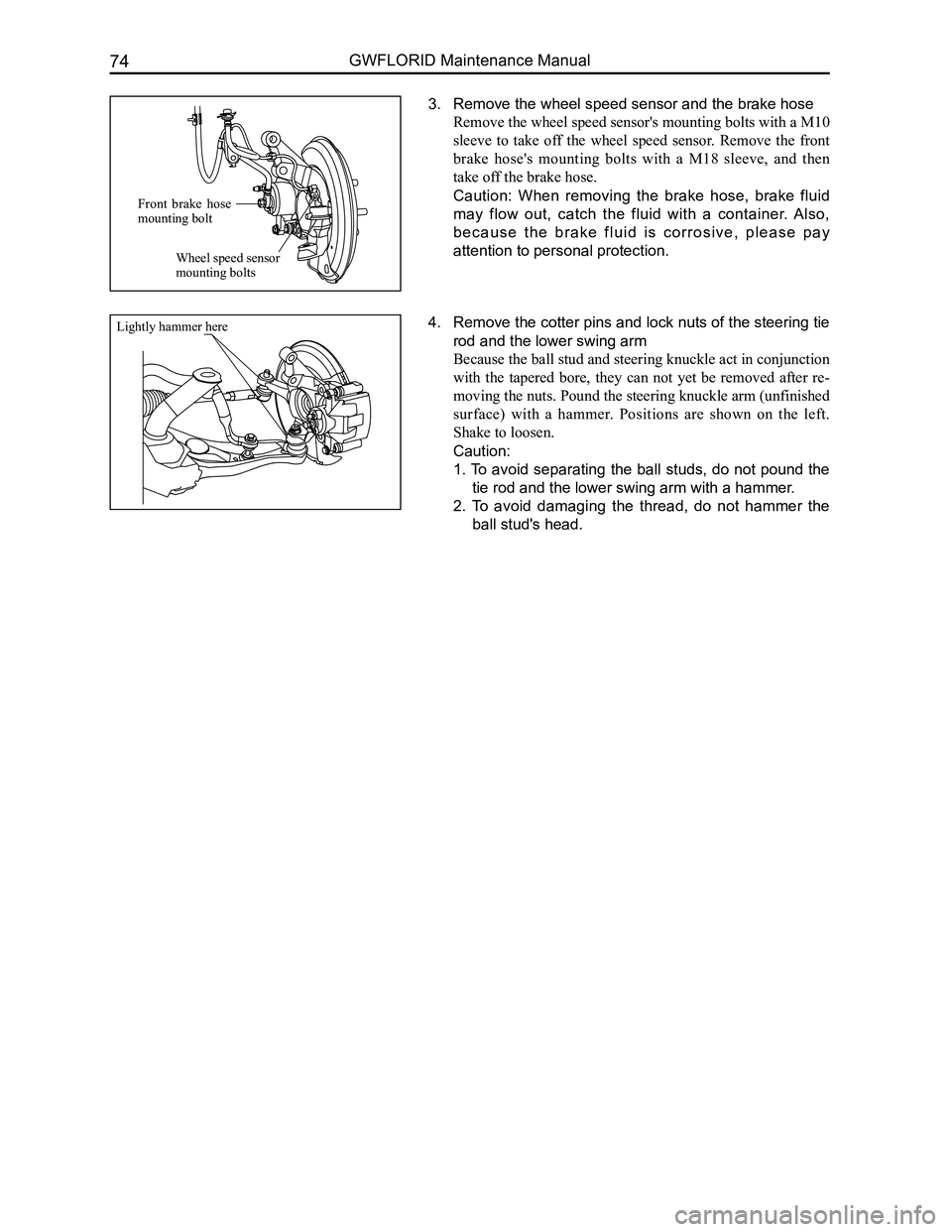

3. Remove the wheel speed sensor and the brake hose

Remove the wheel speed sensor's mounting bolts with a M10

sleeve to take off the wheel speed sensor. Remove the front

brake hose's mounting bolts with a M18 sleeve, and then

take off the brake hose.

Caution: When removing the brake hose, brake fluid

may flow out, catch the fluid with a container. Also,

b e c a u s e t h e b r a k e f l u i d i s c o r r o s i v e , p l e a s e p a y

attention to personal protection.

4. Remove the cotter pins and lock nuts of the steering tie

rod and the lower swing arm

Because the ball stud and steering knuckle act in conjunction

with the tapered bore, they can not yet be removed after re-

moving the nuts. Pound the steering knuckle arm (unfinished

surface) with a hammer. Positions are shown on the left.

Shake to loosen.

Caution:

1. To avoid separating the ball studs, do not pound the

tie rod and the lower swing arm with a hammer.

2. To avoid damaging the thread, do not hammer the

ball stud's head.

Front brake hose mounting bolt

Wheel speed sensor mounting bolts

Lightly hammer here

Page 82 of 281

Downloaded from www.Manualslib.com manuals search engine 75Suspension System

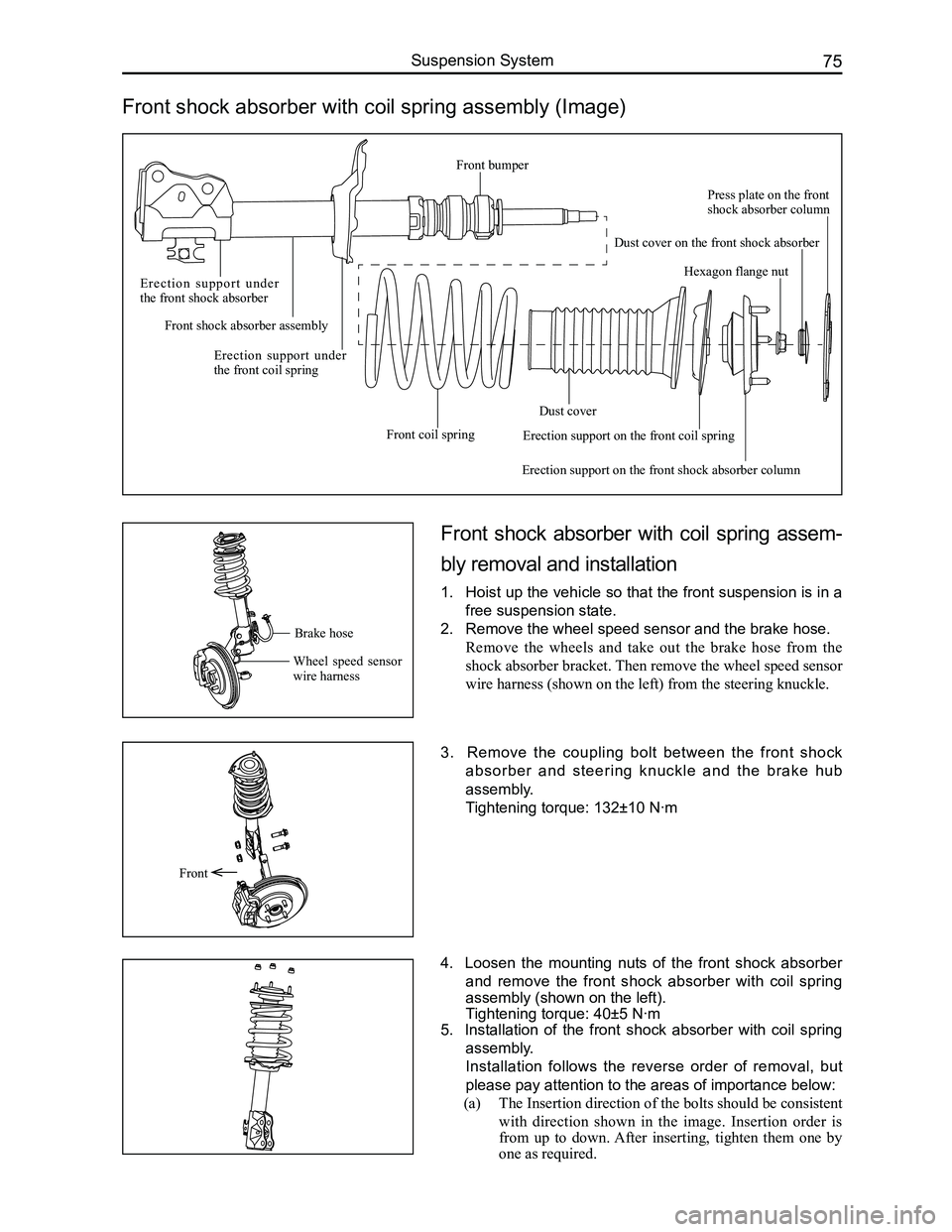

Front shock absorber with coil spring assembly (Image)

Front shock absorber with coil spring assem-

bly removal and installation

1. Hoist up the vehicle so that the front suspension is in a

free suspension state.

2. Remove the wheel speed sensor and the brake hose.

Remove the wheels and take out the brake hose from the

shock absorber bracket. Then remove the wheel speed sensor

wire harness (shown on the left) from the steering knuckle.

3. Remove the coupling bolt between the front shock

absorber and steering knuckle and the brake hub

assembly.

Tightening torque: 132±10 N·m

4. Loosen the mounting nuts of the front shock absorber

and remove the front shock absorber with coil spring

assembly (shown on the left).

Tightening torque: 40±5 N·m

5. Installation of the front shock absorber with coil spring

assembly.

Installation follows the reverse order of removal, but

please pay attention to the areas of importance below:

(a) The Insertion direction of the bolts should be consistent

with direction shown in the image. Insertion order is

from up to down. After inserting, tighten them one by

one as required.

Front

Brake hose

Wheel speed sensor wire harness

E r e c t i o n s u p p o r t u n d e r the front shock absorber

Front shock absorber assembly

Erection support under the front coil spring

Front coil spring

Dust cover

Erection support on the front shock absorber column

Hexagon flange nut

Press plate on the front shock absorber column

Dust cover on the front shock absorber

Erection support on the front coil spring

Front bumper

Page 99 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual92

Wheel

General tire balancing procedures

Clean out the accumulated dirt and debris from the inside of the rim.

Warning:

The gravel on the tread must be eliminated to avoid flying out and injuring the operator when

undergoing rotational balancing. This is also a good way to acquire better balance. First thoroughly

inspect the tire's damaged condition, then according to the balancing device manufacture's

recommendations, carry out the balancing operation.

Off-vehicle balancing

Most off-vehicle balancers are more accurate and convenient than on-vehicle rotational balancers. They are

also able to perform dynamic (two sided) balancing. Although it does not correct drum brake and brake disc

imbalance like on-vehicle balancing, it achieves the same effect based on its accuracy.

On-vehicle balancing

On-vehicle balancing is different based on equipment and tool manufacturer. Therefore, when performing

balancing operations, be sure to comply to each manufacturer's operating\

instructions.

Warning: Control the wheel rotation speed to make sure the speedometer stays within 55 km/h.

This restriction is necessary because when a driven wheel slides while the other one stays still, the

speedometer will display only half of the actual wheel speed. When a wheel is sliding, be extremely

careful, because sliding wheels can reach very high speeds. This may lead to the tire rubber peeling

or differential damage, which may cause serious personal injury, or damage to the vehicle.

Tire installation and removal

• Install or remove tires with a tire changer. When operating machinery, make sure to comply to the machine

manufacturers operation manual. Please do not change tires merely with manual hand tools or tire installation

crowbars. This will damage the tire chafer or the vehicle wheel's rim.

• Use a wire brush or coarse steel wool to clean off grease and old rubber, as well as light rust or corrosion from

the rim tire bead's tire chafer seat. Before tire installation or removal, first use the indicated tire lubricant to

thoroughly lube the tire chafer portions one time.

• After installing the tire, inflate it to the specified pressure and make\

sure the tire bead is properly seated.

Warning: Do not over-inflate the tire. If the tire bead severally expands and exceeds the safety limit,

it may burst and cause serious personal injury. While inflating, do not exceed the specified pressure.

If the specified pressure does not allow the tire bead to sit properly, deflate the tire, re-lubricate, and

then re-inflate.

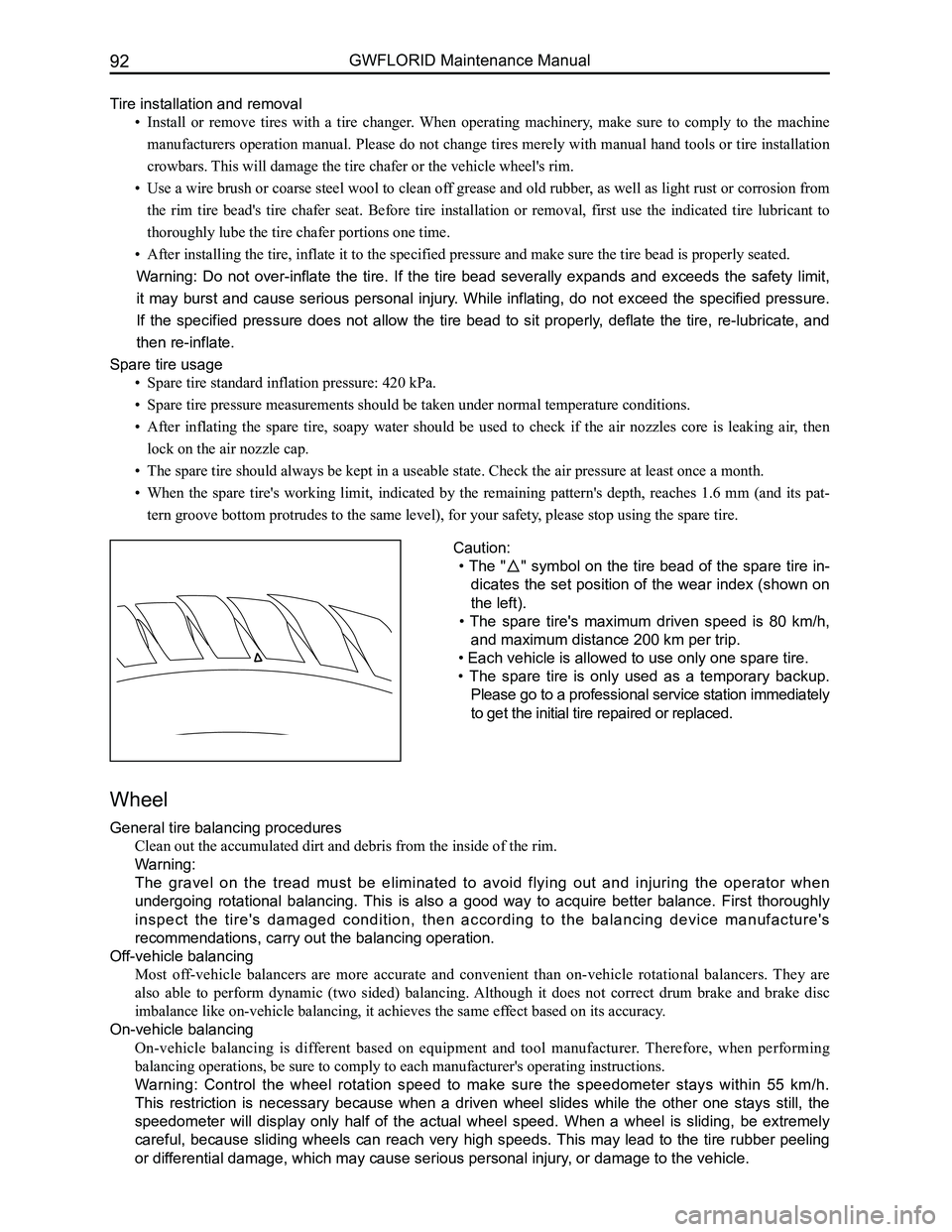

Spare tire usage

• Spare tire standard inflation pressure: 420 kPa.

• Spare tire pressure measurements should be taken under normal temperatur\

e conditions.

• After inflating the spare tire, soapy water should be used to check if the air nozzles core is leaking air, then

lock on the air nozzle cap.

• The spare tire should always be kept in a useable state. Check the air p\

ressure at least once a month.

• When the spare tire's working limit, indicated by the remaining pattern's depth, reaches 1.6 mm (and its pat-

tern groove bottom protrudes to the same level), for your safety, please stop using the spare tire.

Caution:

• The "" symbol on the tire bead of the spare tire in-

dicates the set position of the wear index (shown on

the left).

• The spare tire's maximum driven speed is 80 km/h,

and maximum distance 200 km per trip.

• Each vehicle is allowed to use only one spare tire.

• The spare tire is only used as a temporary backup.

Please go to a professional service station immediately

to get the initial tire repaired or replaced.

Page 100 of 281

Downloaded from www.Manualslib.com manuals search engine 93Suspension System

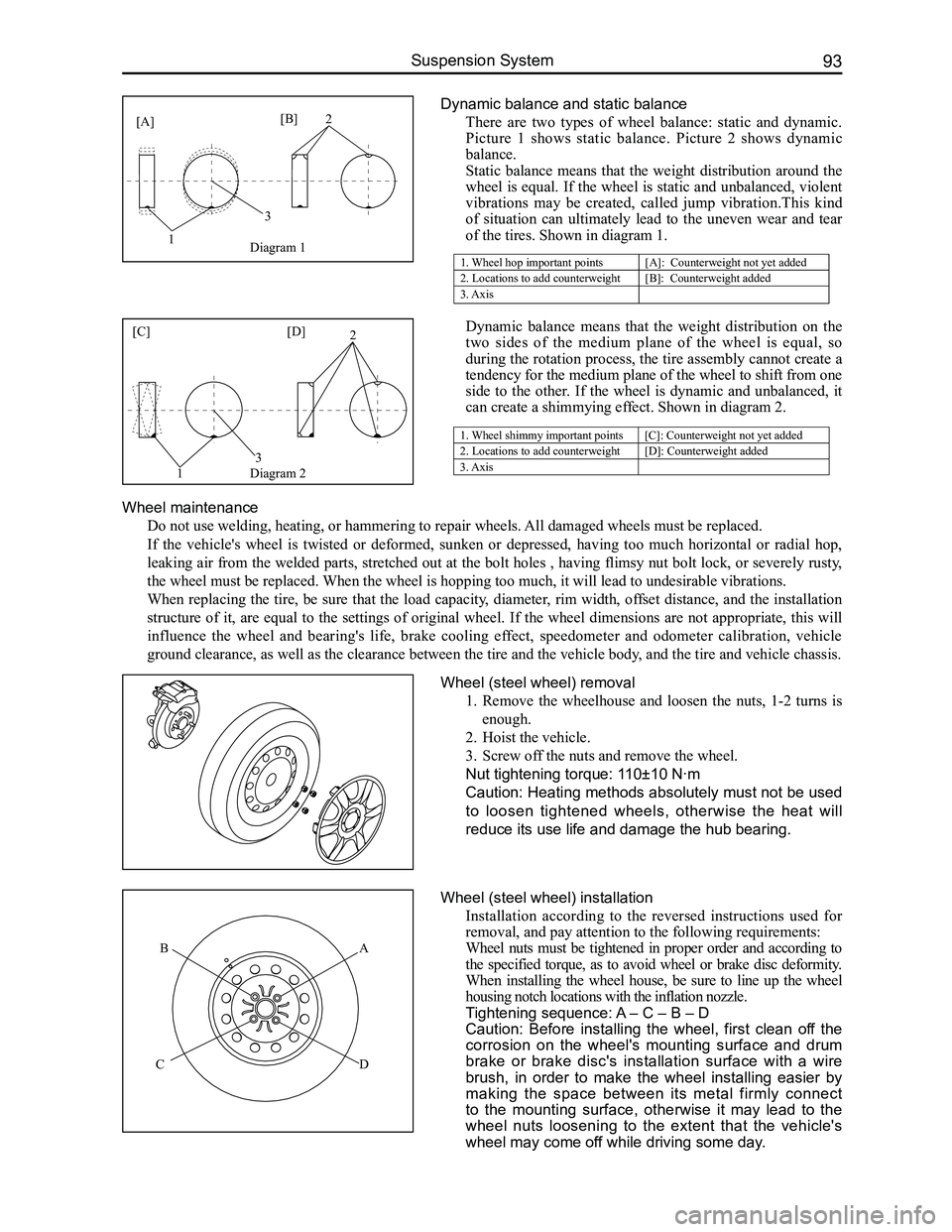

Dynamic balance and static balance

There are two types of wheel balance: static and dynamic.

Picture 1 shows static balance. Picture 2 shows dynamic

balance.

Static balance means that the weight distribution around the

wheel is equal. If the wheel is static and unbalanced, violent

vibrations may be created, called jump vibration.This kind

of situation can ultimately lead to the uneven wear and tear

of the tires. Shown in diagram 1.

Dynamic balance means that the weight distribution on the

two sides of the medium plane of the wheel is equal, so

during the rotation process, the tire assembly cannot create a

tendency for the medium plane of the wheel to shift from one

side to the other. If the wheel is dynamic and unbalanced, it

can create a shimmying effect. Shown in diagram 2.

1. Wheel shimmy important points[C]: Counterweight not yet added

2. Locations to add counterweight[D]: Counterweight added

3. Axis

Wheel maintenance

Do not use welding, heating, or hammering to repair wheels. All damaged wheels must be replaced.

If the vehicle's wheel is twisted or deformed, sunken or depressed, having too much horizontal or radial hop,

leaking air from the welded parts, stretched out at the bolt holes , having flimsy nut bolt lock, or severely rusty,

the wheel must be replaced. When the wheel is hopping too much, it will lead to undesirable vibratio\

ns.

When replacing the tire, be sure that the load capacity, diameter, rim width, offset distance, and the installation

structure of it, are equal to the settings of original wheel. If the wheel dimensions are not appropriate, this will

influence the wheel and bearing's life, brake cooling effect, speedometer and odometer calibration, vehicle

ground clearance, as well as the clearance between the tire and the vehi\

cle body, and the tire and vehicle chassis.

Wheel (steel wheel) removal

1. Remove the wheelhouse and loosen the nuts, 1-2 turns is

enough.

2. Hoist the vehicle.

3. Screw off the nuts and remove the wheel.

Nut tightening torque: 110±10 N·m

Caution: Heating methods absolutely must not be used

to loosen tightened wheels, otherwise the heat will

reduce its use life and damage the hub bearing.

Wheel (steel wheel) installation

Installation according to the reversed instructions used for

removal, and pay attention to the following requirements:

Wheel nuts must be tightened in proper order and according to

the specified torque, as to avoid wheel or brake disc deformity.

When installing the wheel house, be sure to line up the wheel

housing notch locations with the inflation nozzle.

Tightening sequence: A – C – B – D

Caution: Before installing the wheel, first clean off the

corrosion on the wheel's mounting surface and drum

brake or brake disc's installation surface with a wire

brush, in order to make the wheel installing easier by

making the space between its metal firmly connect

to the mounting surface, otherwise it may lead to the

wheel nuts loosening to the extent that the vehicle's

wheel may come off while driving some day.

1

3

2[A][B]

1. Wheel hop important points[A]: Counterweight not yet added

2. Locations to add counterweight[B]: Counterweight added

3. Axis

Diagram 1

Diagram 2

[C][D]

1

3

2

AB

CD

Page 101 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual94

Brake System

Brake System Components Arrangement Schematics.......95

Brake System Maintenance................................................96

Brake Pedal ........................................................................\

98

Parking Brake Control Mechanism Assembly...................102

Vacuum Booster with Brake Cylinder Assembly ...............103

Anti-lock Brake System ....................................................107

ABS General Problem Maintenance and

Areas of Importance .........................................................109

Steering Knuckle and Hub Brake Assembly .....................112

Front Brake Caliper ..........................................................118

Rear Brake .......................................................................124

Rear Support Axle ............................................................131

Page 102 of 281

Downloaded from www.Manualslib.com manuals search engine 95Brake System

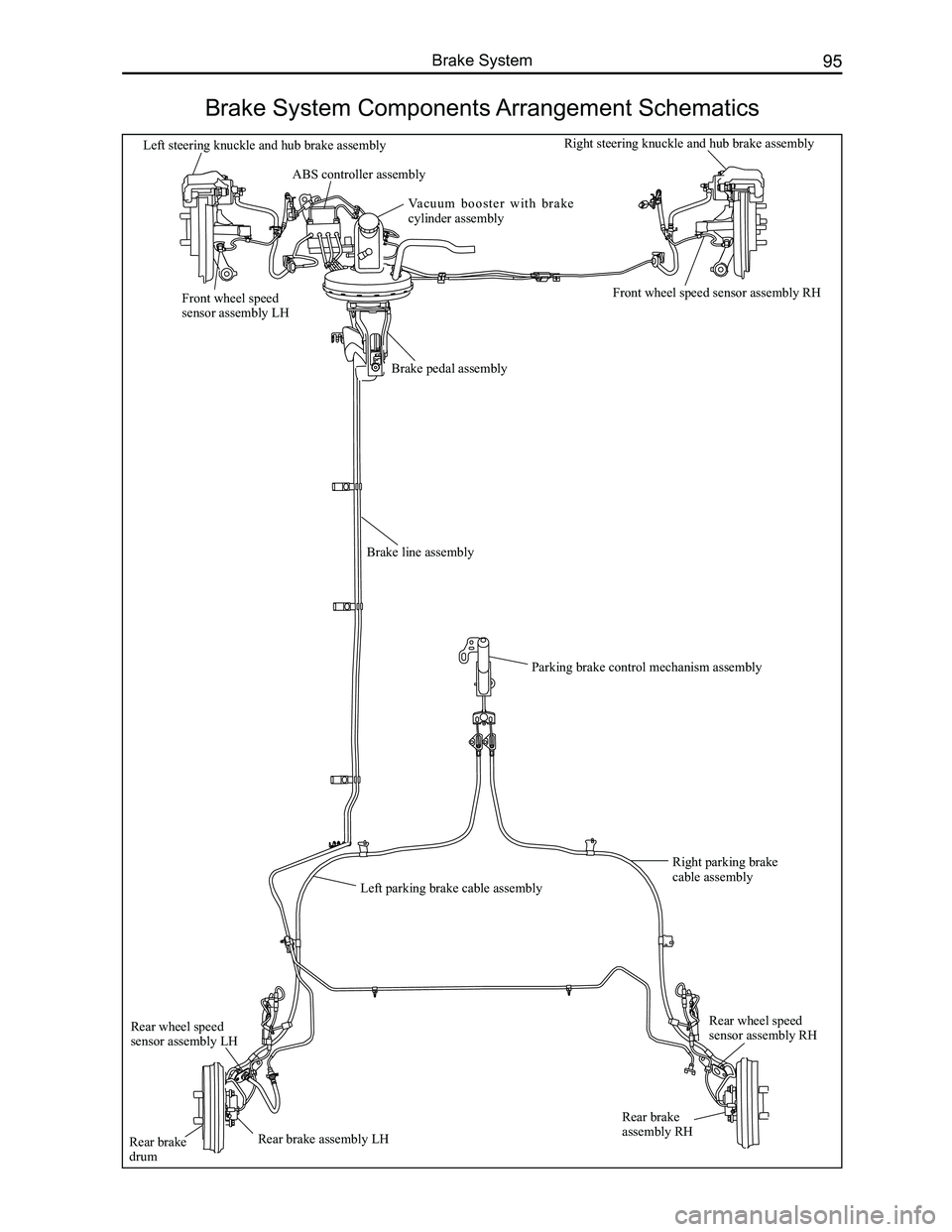

Brake System Components Arrangement Schematics

Brake pedal assembly

Vacuum booster with brake cylinder assembly

Left steering knuckle and hub brake assembly

Left parking brake cable assembly

Rear brake assembly RHRear brake drum

Rear wheel speed sensor assembly RH

Right parking brake cable assembly

ABS controller assembly

Right steering knuckle and hub brake assembly

Brake line assembly

Rear wheel speed

sensor assembly LH

Front wheel speed sensor assembly RHFront wheel speed sensor assembly LH

Rear brake assembly LH

Parking brake control mechanism assembly