battery GREAT WALL FLORID 2008 Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 200 of 281

Downloaded from www.Manualslib.com manuals search engine 193Electrical Accessories

SymptomsCausesSolutions

Cannot start

Burnt fuseReplace with a new fuse of the same

specification

Vehicle supply battery fuse is burntReplace the vehicle supply battery fuse

Illegal operation and other factorsPress the reset button to reset the system

No sound or sound is too low

The volume of the head unit or the

connected component is too low

Raise the volume of the head unit or the

connected component

Speaker possibly damagedCheck the speaker

The sound balance settings lean to one

side

Adjust the sound balance

Speaker's connection wire touches the

vehicle body

Use insulated conductor to connect the

speaker and use insulating cement to cover

the exposed connections

Disc is not genuineUse a genuine disc

Speaker is incorrectly connectedPlease refer to the "Electrical connection

diagram" to correct the connection

Common faults and solutions

General problems

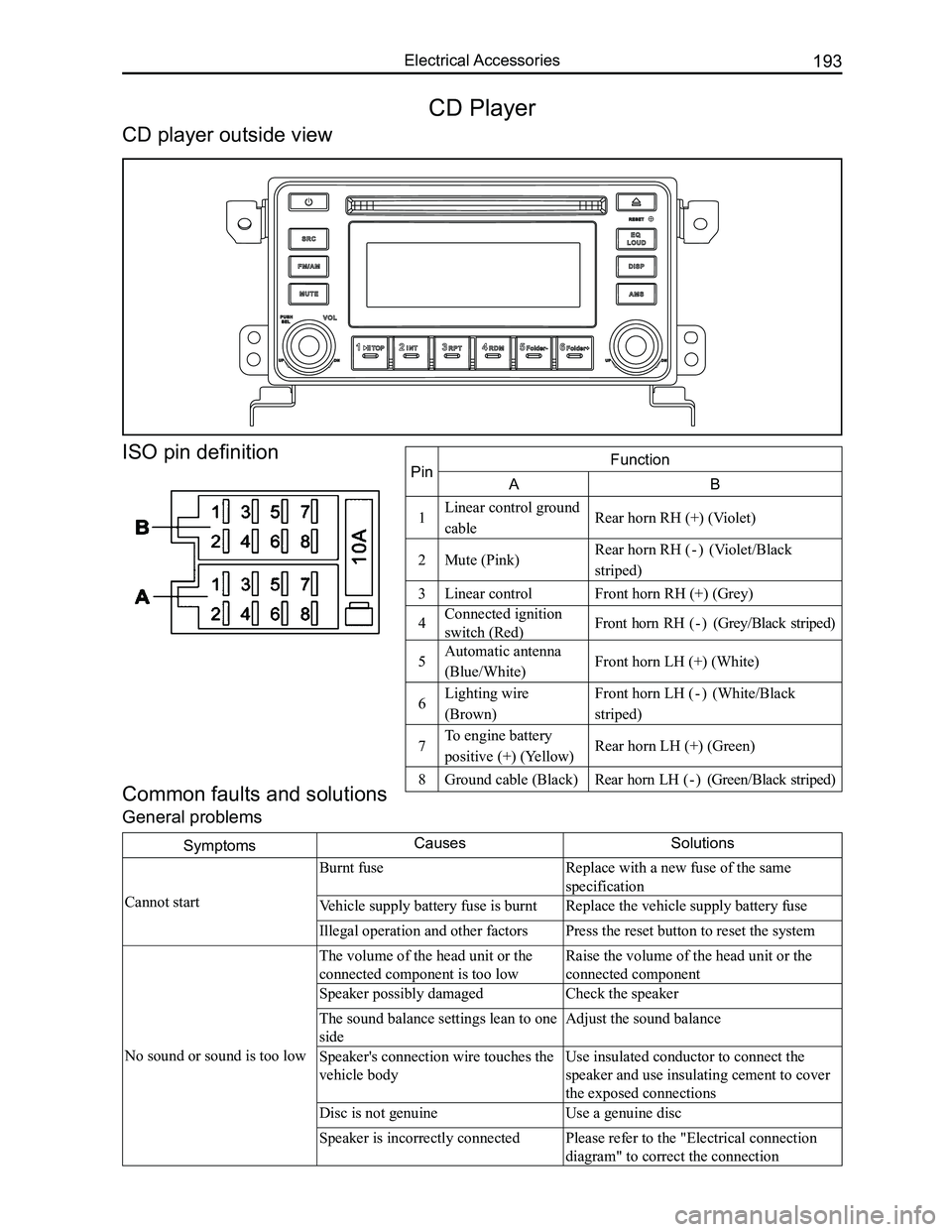

CD Player

CD player outside view

ISO pin definition

PinFunction

AB

1Linear control ground

cableRear horn RH (+) (Violet)

2Mute (Pink)Rear horn RH ( - ) (Violet/Black

striped)

3Linear controlFront horn RH (+) (Grey)

4Connected ignition

switch (Red)Front horn RH ( - ) (Grey/Black striped)

5Automatic antenna

(Blue/White)Front horn LH (+) (White)

6Lighting wire

(Brown)

Front horn LH ( - ) (White/Black

striped)

7To engine battery

positive (+) (Yellow)Rear horn LH (+) (Green)

8Ground cable (Black)Rear horn LH ( - ) (Green/Black striped)

Page 201 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual194

Display characterMalfunctionSolutions

ERR3Disc is placed upside downEject the disc and reload

ERR4Incompatible disc file or formatCheck the disc format

ERR1

ERR1Disc structure errorEject the disc and replay

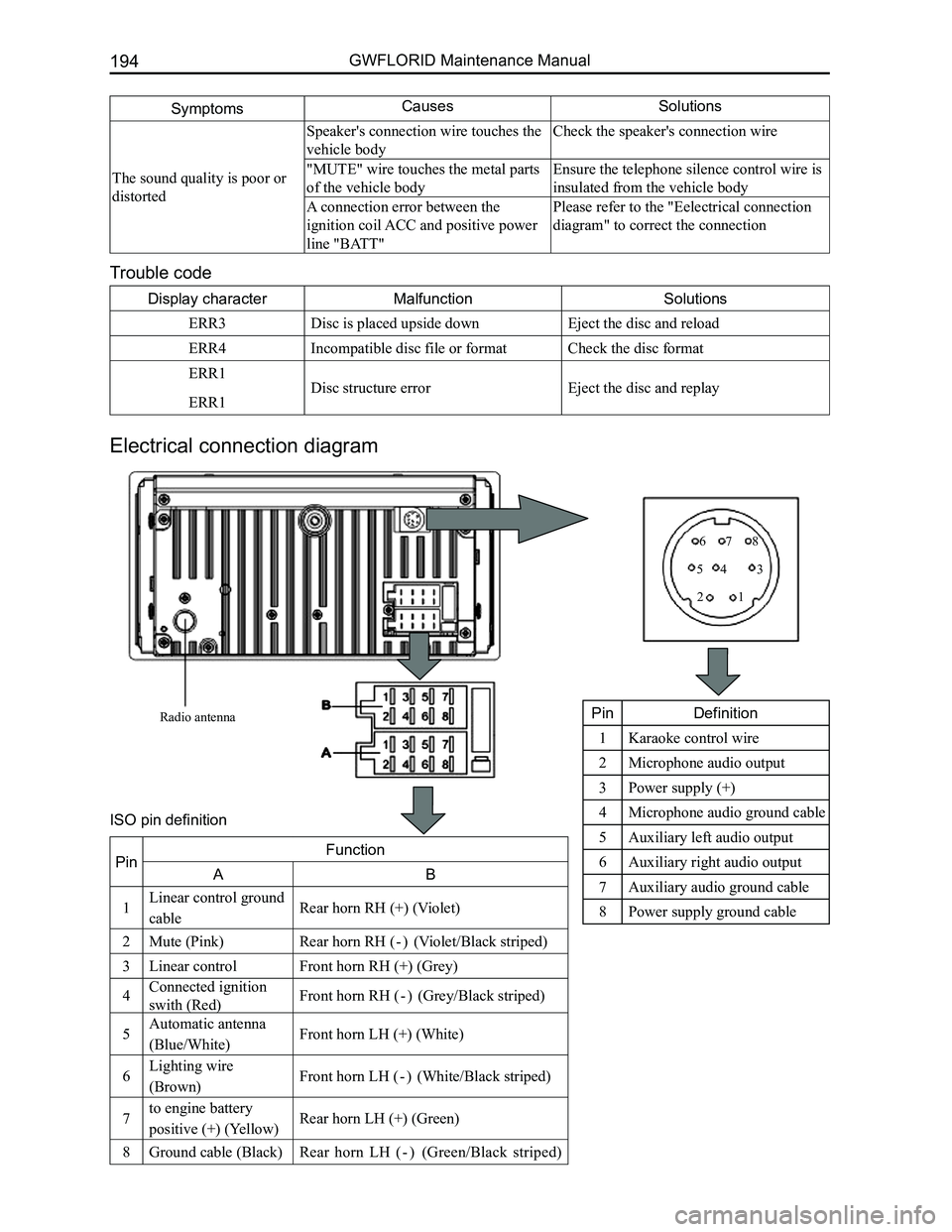

Trouble code

Electrical connection diagram

SymptomsCausesSolutions

The sound quality is poor or

distorted

Speaker's connection wire touches the

vehicle body

Check the speaker's connection wire

"MUTE" wire touches the metal parts

of the vehicle body

Ensure the telephone silence control wire is

insulated from the vehicle body

A connection error between the

ignition coil ACC and positive power

line "BATT"

Please refer to the "Eelectrical connection

diagram" to correct the connection

Radio antenna

12

345

678

PinDefinition

1Karaoke control wire

2Microphone audio output

3Power supply (+)

4Microphone audio ground cable

5Auxiliary left audio output

6Auxiliary right audio output

7Auxiliary audio ground cable

8Power supply ground cable

PinFunction

AB

1Linear control ground

cableRear horn RH (+) (Violet)

2Mute (Pink)Rear horn RH ( - ) (Violet/Black striped)

3Linear controlFront horn RH (+) (Grey)

4Connected ignition

swith (Red)Front horn RH ( - ) (Grey/Black striped)

5Automatic antenna

(Blue/White)Front horn LH (+) (White)

6Lighting wire

(Brown)Front horn LH ( - ) (White/Black striped)

7to engine battery

positive (+) (Yellow)Rear horn LH (+) (Green)

8Ground cable (Black)Rear horn LH ( - ) (Green/Black striped)

ISO pin definition

Page 204 of 281

Downloaded from www.Manualslib.com manuals search engine 197Electrical Accessories

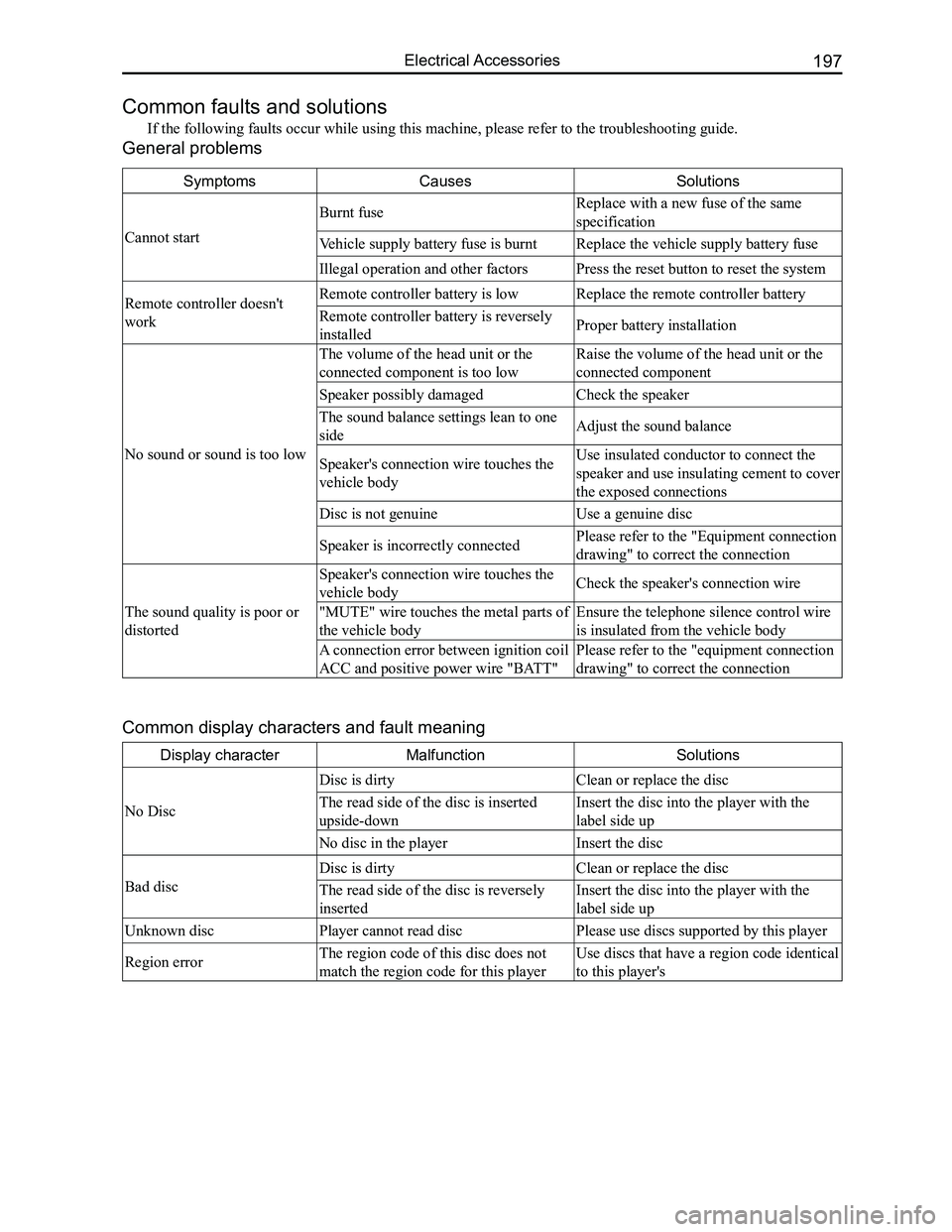

Common faults and solutions

If the following faults occur while using this machine, please refer to \

the troubleshooting guide.

General problems

SymptomsCausesSolutions

Cannot start

Burnt fuseReplace with a new fuse of the same

specification

Vehicle supply battery fuse is burntReplace the vehicle supply battery fuse

Illegal operation and other factorsPress the reset button to reset the system

Remote controller doesn't

work

Remote controller battery is lowReplace the remote controller battery

Remote controller battery is reversely

installedProper battery installation

No sound or sound is too low

The volume of the head unit or the

connected component is too low

Raise the volume of the head unit or the

connected component

Speaker possibly damagedCheck the speaker

The sound balance settings lean to one

sideAdjust the sound balance

Speaker's connection wire touches the

vehicle body

Use insulated conductor to connect the

speaker and use insulating cement to cover

the exposed connections

Disc is not genuineUse a genuine disc

Speaker is incorrectly connectedPlease refer to the "Equipment connection

drawing" to correct the connection

The sound quality is poor or

distorted

Speaker's connection wire touches the

vehicle bodyCheck the speaker's connection wire

"MUTE" wire touches the metal parts of

the vehicle body

Ensure the telephone silence control wire

is insulated from the vehicle body

A connection error between ignition coil

ACC and positive power wire "BATT"

Please refer to the "equipment connection

drawing" to correct the connection

Common display characters and fault meaning

Display characterMalfunctionSolutions

No Disc

Disc is dirtyClean or replace the disc

The read side of the disc is inserted

upside-down

Insert the disc into the player with the

label side up

No disc in the playerInsert the disc

Bad disc

Disc is dirtyClean or replace the disc

The read side of the disc is reversely

inserted

Insert the disc into the player with the

label side up

Unknown disc Player cannot read discPlease use discs supported by this player

Region error The region code of this disc does not

match the region code for this player

Use discs that have a region code identical

to this player's

Page 208 of 281

Downloaded from www.Manualslib.com manuals search engine 201Electrical Accessories

1. This player is used on vehicles with a 12 V battery and negative ground. If this player is to be installed

on a vehicle with a 24 V battery, please install voltage reduction equipment.

2. To avoid short circuiting the electrical system, cut off the battery negative end's connection wire before

installation.

3. Please arrange the connection wires at fixed locations, as to make sure they will not make contact

with any portable parts, such as the parking brake control mechanism assembly, gear lever, the seat's

fixed track, and so on. Please do not arrange the wires in a heat source area, like near the discharge

outlet of the heater, etc. Otherwise the heat source will cause the insulating layer to melt or wear out,

and then lead to a short circuit between the connection wire and the veh\

icle body.

4. Do not put the power cord through the mounting hole into the engine box and then connect it to the

battery. Otherwise it might damage the power cord and then lead to a short circuit between the power

cord and the vehicle body.

5. When changing the fuse, please use the specified 15 A fuse. Fuses with an unmatched size will lead

to abnormal operation, and even damage the player or cause a fire hazard\

.

6. Please do not share the player's power supply with other equipment, otherwise it might lead to a

malfunction due to overloading.

7. Please wrap up the exposed places of the wire with insulating cement to \

avoid short circuiting.

8. Bind up all the connection wires well to avoid any connecting term inal touching the player or other

mental parts of the vehicle body and leading to a short circuit.

9. When switching the player's power on, the external connection amplifier's controlling signal will output

through the lead wire P.CONT. If the player is connected with an external connection amplifier, please

do not connect the lead wire P.CONT to the amplifier's supply terminal, otherwise it will cause a

malfunction.

10. The player's outputting terminal must not be grounded, otherwise the amplifier may burn out. Please

do not use a 3-wire type speaker system which shares the ground cable. Please do not connect the

speaker wire to the vehicle body.

11. The maximum rated power of the speaker connected to this player is 50 W , resistance value is 4 Ω.

Control wire connection areas of importance

Page 221 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual214

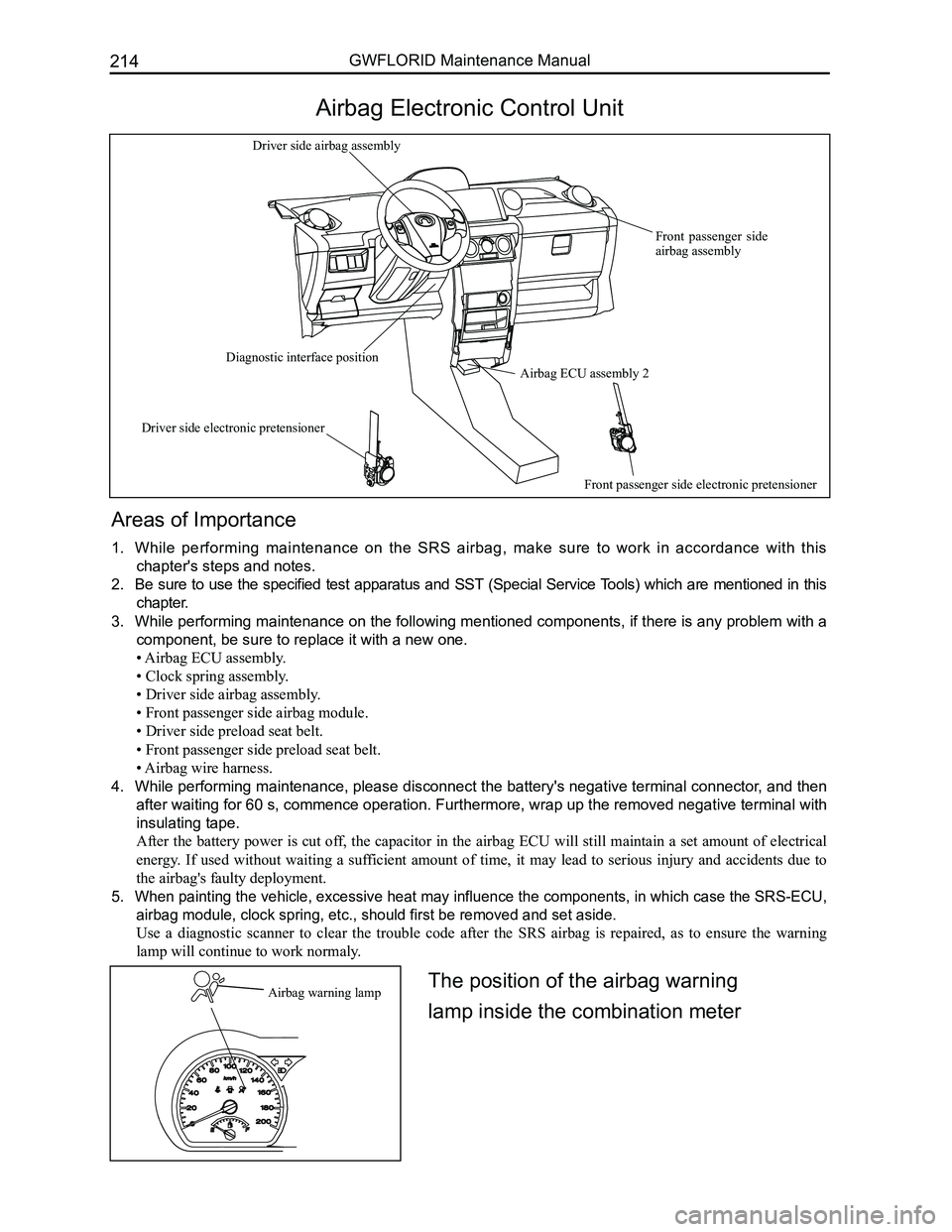

Areas of Importance

1. While performing maintenance on the SRS airbag, make sure to work in accordance with this

chapter's steps and notes.

2. Be sure to use the specified test apparatus and SST (Special Service Tools) which are mentioned in this

chapter.

3. While performing maintenance on the following mentioned components, if there is any problem with a

component, be sure to replace it with a new one.

• Airbag ECU assembly.

• Clock spring assembly.

• Driver side airbag assembly.

• Front passenger side airbag module.

• Driver side preload seat belt.

• Front passenger side preload seat belt.

• Airbag wire harness.

4. While performing maintenance, please disconnect the battery's negative terminal connector, and then

after waiting for 60 s, commence operation. Furthermore, wrap up the removed negative terminal with

insulating tape.

After the battery power is cut off, the capacitor in the airbag ECU will still maintain a set amount of electrical

energy. If used without waiting a sufficient amount of time, it may lead to serious injury and accidents due to

the airbag's faulty deployment.

5. When painting the vehicle, excessive heat may influence the components, in which case the SRS-ECU,

airbag module, clock spring, etc., should first be removed and set aside\

.

Use a diagnostic scanner to clear the trouble code after the SRS airbag is repaired, as to ensure the warning

lamp will continue to work normaly.

Airbag Electronic Control Unit

Airbag warning lamp

Airbag ECU assembly 2

Front passenger side airbag assembly

Driver side airbag assembly

Diagnostic interface position

Driver side electronic pretensioner

Front passenger side electronic pretensioner

The position of the airbag warning

lamp inside the combination meter

Page 225 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual218

detection but also during the diagnostic detection cycle. However, if a short circuit on the power supply causes

a malfunction, and the low-end transistor is opened while malfunctioned, the low-end transistor can only be

detected when starting up detection, as to avoid faulty execution.

(b) Ignition voltage is provided by a pressure increase converter.

(c) Acceleration sensor performs self-detection when starting up detection.

(d) Allowed offset range of the acceleration sensor during a diagnostic cycle.

(e) Microcontroller includes AD converter, ROM, RAM, etc.

(f) Security sensor status.

Caution: There is a short-circuiting bar inside the squib circuit connector. When the connector is not

connected, the short circuit happens between the squib circuit's terminal (+) and terminal (-), as to

avoid faulty deployment caused by static electricity. When the connector is bad and the short-circuiting

bar is connected, the fault symptom may not be eliminated.

4. Clear the trouble code

When the X-431 diagnostic instrument receives the "Clear the trouble code" order sent through the serial inter-

face, the trouble code inside the ECU will be cleared. However, if an internal trouble code is recorded or has a

collision record, it will not carry out this order.

(a) Malfunction status display.

When the working voltage is supplied to the SRS-ECU through a battery, the SRS-ECU will light the warning

lamp to inspect the light bulbs. During the initialization stage, the warning lamp will remain on for 6-7 s, and

in order to inform the driver that the system has a malfunction, the warning lamp will continue to remain on

after the working voltage is supplied. If the history trouble code’s quantity is less than 16, the warning lamp

will remain lit for 6-7 s after turning the ignition on and then turn off automatically. If the history trouble code’s

quantity is 16 and the current malfunction appears, it will be recorded and the first history malfunction record

will be automatically removed.

(b) Malfunction indicator.

When the system has malfunctioned, the warning lamp will be always on.

A displayed or history malfunction can only be reset by service personnel. A SRS-ECU internal malfunction or

malfunction’s "collision record" cannot be reset. In this situation, the SRS-ECU mus\

t be replaced.

(c) Microcontroller - independent warning lamp is lit.

The controller has a self-diagnosis function. If the inner controller malfunctions, the warning lamp will always

be on.

(d) If the airbag warning lamp is always on, please inspect it according to the following steps.

The first step of inspecting any of the malfunctions is to detect the malfunction’s position with a scanner. Then

carry out the inspection using the corresponding part’s inspection method. If the scanning result is an internal

malfunction or having to do with airbag execution, the SRS-ECU can be di\

rectly replaced.

Page 226 of 281

Downloaded from www.Manualslib.com manuals search engine 219Airbags

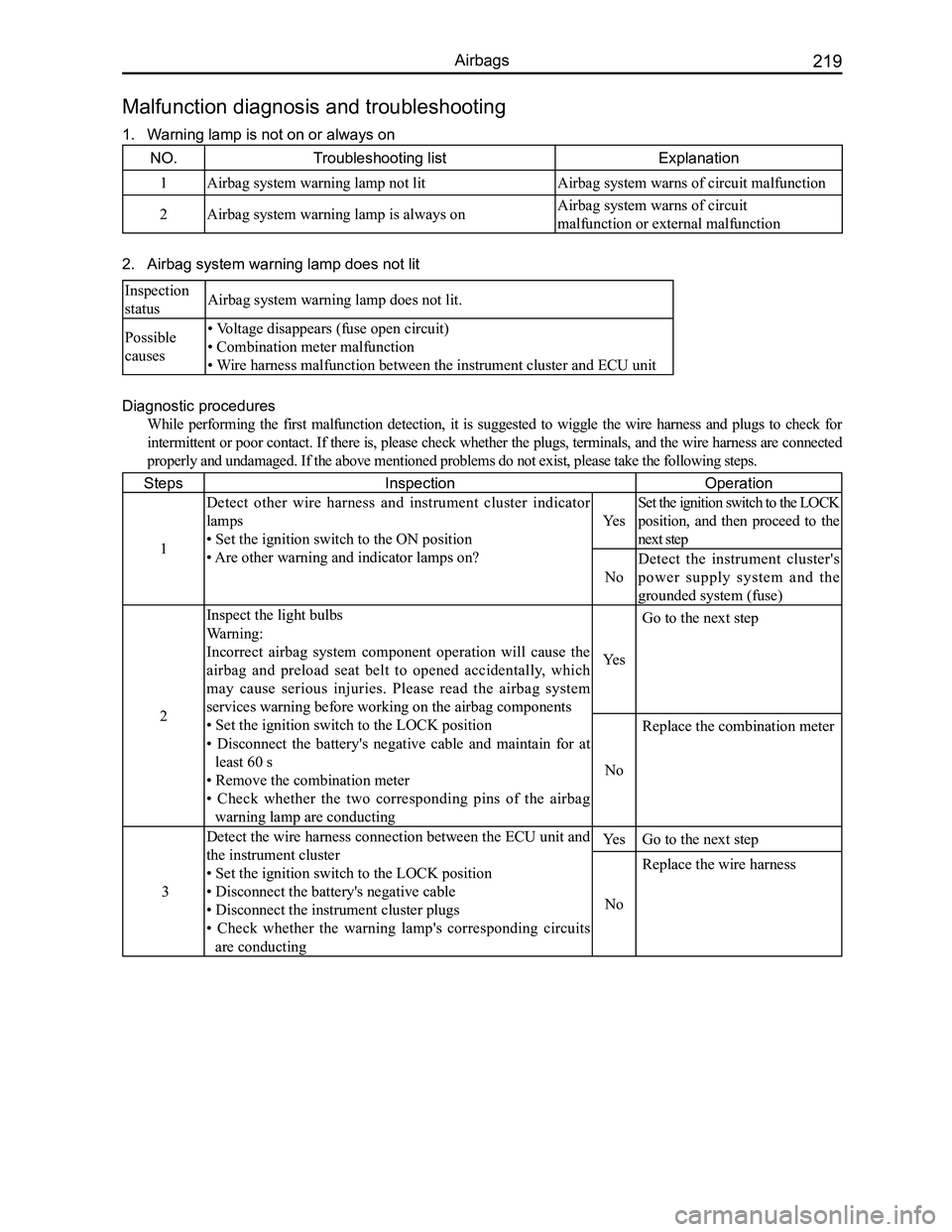

NO.Troubleshooting listExplanation

1Airbag system warning lamp not litAirbag system warns of circuit malfunction

2Airbag system warning lamp is always onAirbag system warns of circuit

malfunction or external malfunction

2. Airbag system warning lamp does not lit

Inspection

statusAirbag system warning lamp does not lit.

Possible

causes

• Voltage disappears (fuse open circuit)

• Combination meter malfunction

• Wire harness malfunction between the instrument cluster and ECU unit

Diagnostic procedures

While performing the first malfunction detection, it is suggested to wiggle the wire harness and plugs to check for

intermittent or poor contact. If there is, please check whether the plugs, terminals, and the wire harness are connected

properly and undamaged. If the above mentioned problems do not exist, pl\

ease take the following steps.

StepsInspectionOperation

1

Detect other wire harness and instrument cluster indicator

lamps

• Set the ignition switch to the ON position

• Are other warning and indicator lamps on?

Yes

Set the ignition switch to the LOCK

position, and then proceed to the

next step

No

Detect the instrument cluster's

power supply system and the

grounded system (fuse)

2

Inspect the light bulbs

Warning:

Incorrect airbag system component operation will cause the

airbag and preload seat belt to opened accidentally, which

may cause serious injuries. Please read the airbag system

services warning before working on the airbag components

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable and maintain for at

least 60 s

• Remove the combination meter

• Check whether the two corresponding pins of the airbag

warning lamp are conducting

Yes

Go to the next step

No

Replace the combination meter

3

Detect the wire harness connection between the ECU unit and

the instrument cluster

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable

• Disconnect the instrument cluster plugs

• Check whether the warning lamp's corresponding circuits

are conducting

YesGo to the next step

No

Replace the wire harness

Malfunction diagnosis and troubleshooting

1. Warning lamp is not on or always on

Page 227 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual220

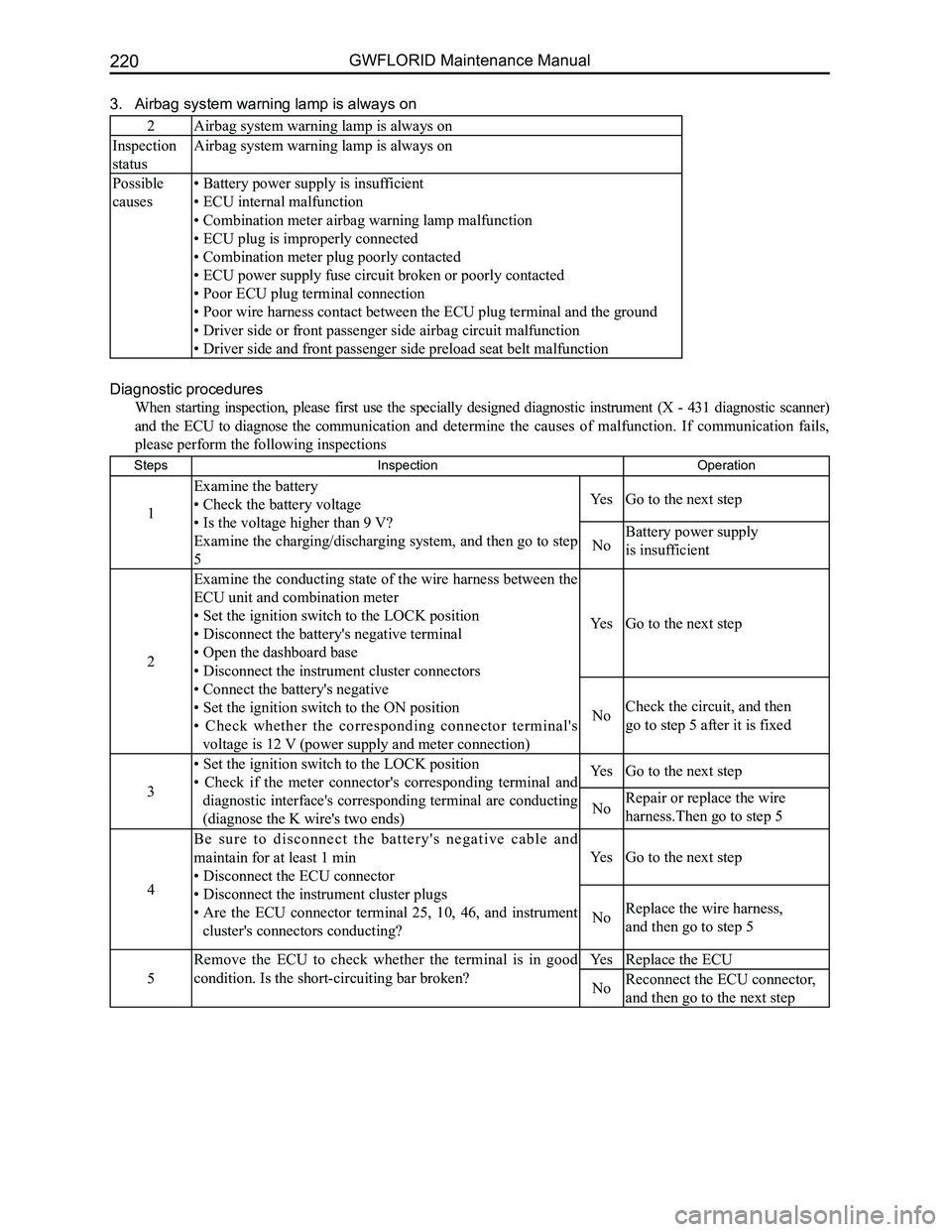

3. Airbag system warning lamp is always on

2Airbag system warning lamp is always on

Inspection

status

Airbag system warning lamp is always on

Possible

causes

• Battery power supply is insufficient

• ECU internal malfunction

• Combination meter airbag warning lamp malfunction

• ECU plug is improperly connected

• Combination meter plug poorly contacted

• ECU power supply fuse circuit broken or poorly contacted

• Poor ECU plug terminal connection

• Poor wire harness contact between the ECU plug terminal and the ground

• Driver side or front passenger side airbag circuit malfunction

• Driver side and front passenger side preload seat belt malfunction

Diagnostic procedures

When starting inspection, please first use the specially designed diagnostic instrument (X - 431 diagnostic scanner)

and the ECU to diagnose the communication and determine the causes of malfunction. If communication fails,

please perform the following inspections

StepsInspection Operation

1

Examine the battery

• Check the battery voltage

• Is the voltage higher than 9 V?

Examine the charging/discharging system, and then go to step

5

YesGo to the next step

NoBattery power supply

is insufficient

2

Examine the conducting state of the wire harness between the

ECU unit and combination meter

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative terminal

• Open the dashboard base

• Disconnect the instrument cluster connectors

• Connect the battery's negative

• Set the ignition switch to the ON position

• Check whether the corresponding connector terminal's

voltage is 12 V (power supply and meter connection)

YesGo to the next step

NoCheck the circuit, and then

go to step 5 after it is fixed

3

• Set the ignition switch to the LOCK position

• Check if the meter connector's corresponding terminal and

diagnostic interface's corresponding terminal are conducting

(diagnose the K wire's two ends)

YesGo to the next step

NoRepair or replace the wire

harness.Then go to step 5

4

B e s u r e t o d i s c o n n e c t t h e b a t t e r y ' s n e g a t i v e c a b l e a n d

maintain for at least 1 min

• Disconnect the ECU connector

• Disconnect the instrument cluster plugs

• Are the ECU connector terminal 25, 10, 46, and instrument

cluster's connectors conducting?

YesGo to the next step

NoReplace the wire harness,

and then go to step 5

5

Remove the ECU to check whether the terminal is in good

condition. Is the short-circuiting bar broken?

YesReplace the ECU

NoReconnect the ECU connector,

and then go to the next step

Page 228 of 281

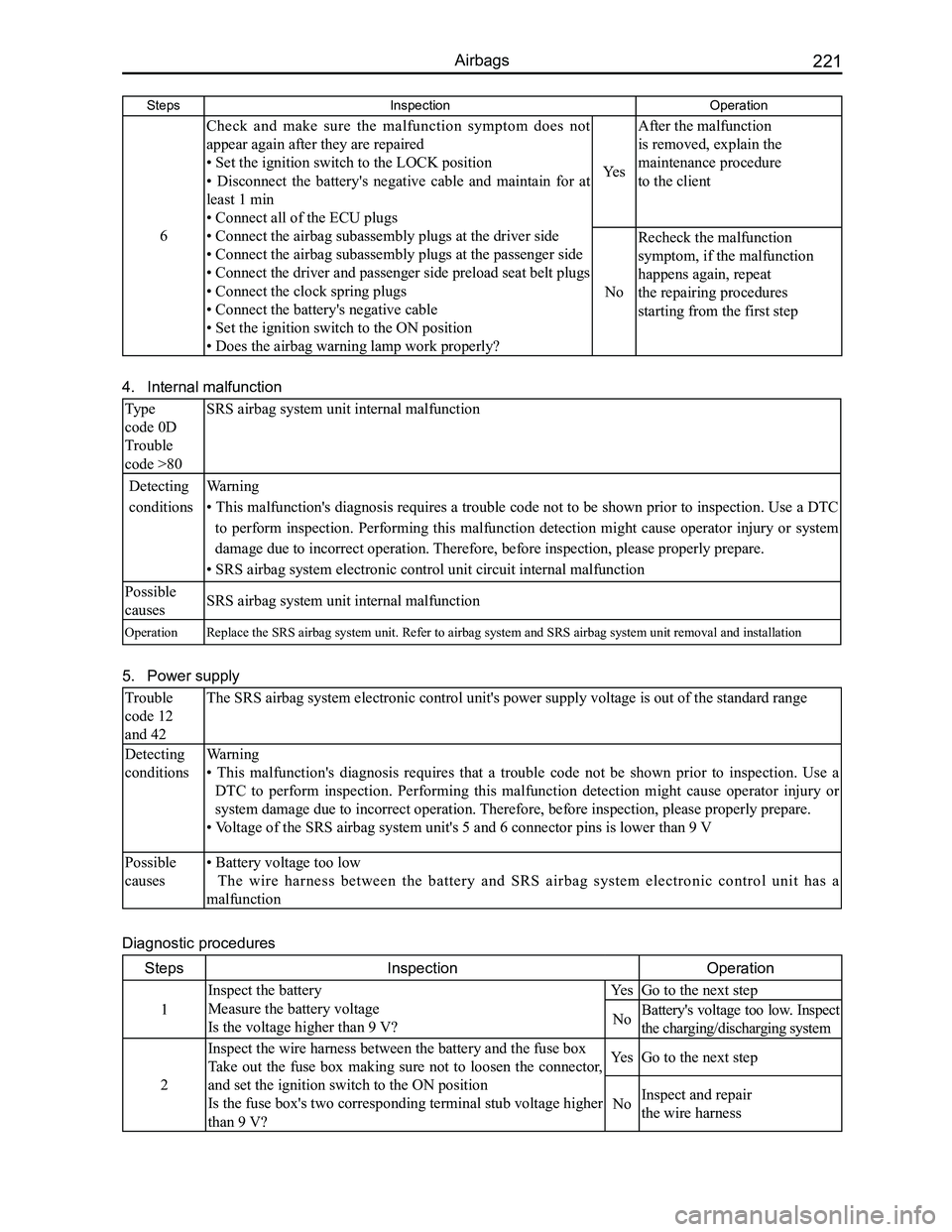

Downloaded from www.Manualslib.com manuals search engine 221Airbags

StepsInspection Operation

6

Check and make sure the malfunction symptom does not

appear again after they are repaired

• Set the ignition switch to the LOCK position

• Disconnect the battery's negative cable and maintain for at

least 1 min

• Connect all of the ECU plugs

• Connect the airbag subassembly plugs at the driver side

• Connect the airbag subassembly plugs at the passenger side

• Connect the driver and passenger side preload seat belt plugs

• Connect the clock spring plugs

• Connect the battery's negative cable

• Set the ignition switch to the ON position

• Does the airbag warning lamp work properly?

Yes

After the malfunction

is removed, explain the

maintenance procedure

to the client

No

Recheck the malfunction

symptom, if the malfunction

happens again, repeat

the repairing procedures

starting from the first step

4. Internal malfunction

Type

code 0D

Trouble

code >80

SRS airbag system unit internal malfunction

Detecting

conditions

Warning

• This malfunction's diagnosis requires a trouble code not to be shown prior to inspection. Use a DTC

to perform inspection. Performing this malfunction detection might cause operator injury or system

damage due to incorrect operation. Therefore, before inspection, please properly prepare.

• SRS airbag system electronic control unit circuit internal malfunction

Possible

causesSRS airbag system unit internal malfunction

OperationReplace the SRS airbag system unit. Refer to airbag system and SRS airba\

g system unit removal and installation

5. Power supply

Trouble

code 12

and 42

The SRS airbag system electronic control unit's power supply voltage is \

out of the standard range

Detecting

conditions

Warning

• This malfunction's diagnosis requires that a trouble code not be shown prior to inspection. Use a

DTC to perform inspection. Performing this malfunction detection might cause operator injury or

system damage due to incorrect operation. Therefore, before inspection, please properly prepare.

• Voltage of the SRS airbag system unit's 5 and 6 connector pins is lower than 9 V

Possible

causes

• Battery voltage too low

The wire harness between the battery and SRS airbag system electronic control unit has a

malfunction

Diagnostic procedures

StepsInspectionOperation

1

Inspect the battery

Measure the battery voltage

Is the voltage higher than 9 V?

YesGo to the next step

NoBattery's voltage too low. Inspect

the charging/discharging system

2

Inspect the wire harness between the battery and the fuse box

Take out the fuse box making sure not to loosen the connector,

and set the ignition switch to the ON position

Is the fuse box's two corresponding terminal stub voltage higher

than 9 V?

YesGo to the next step

NoInspect and repair

the wire harness

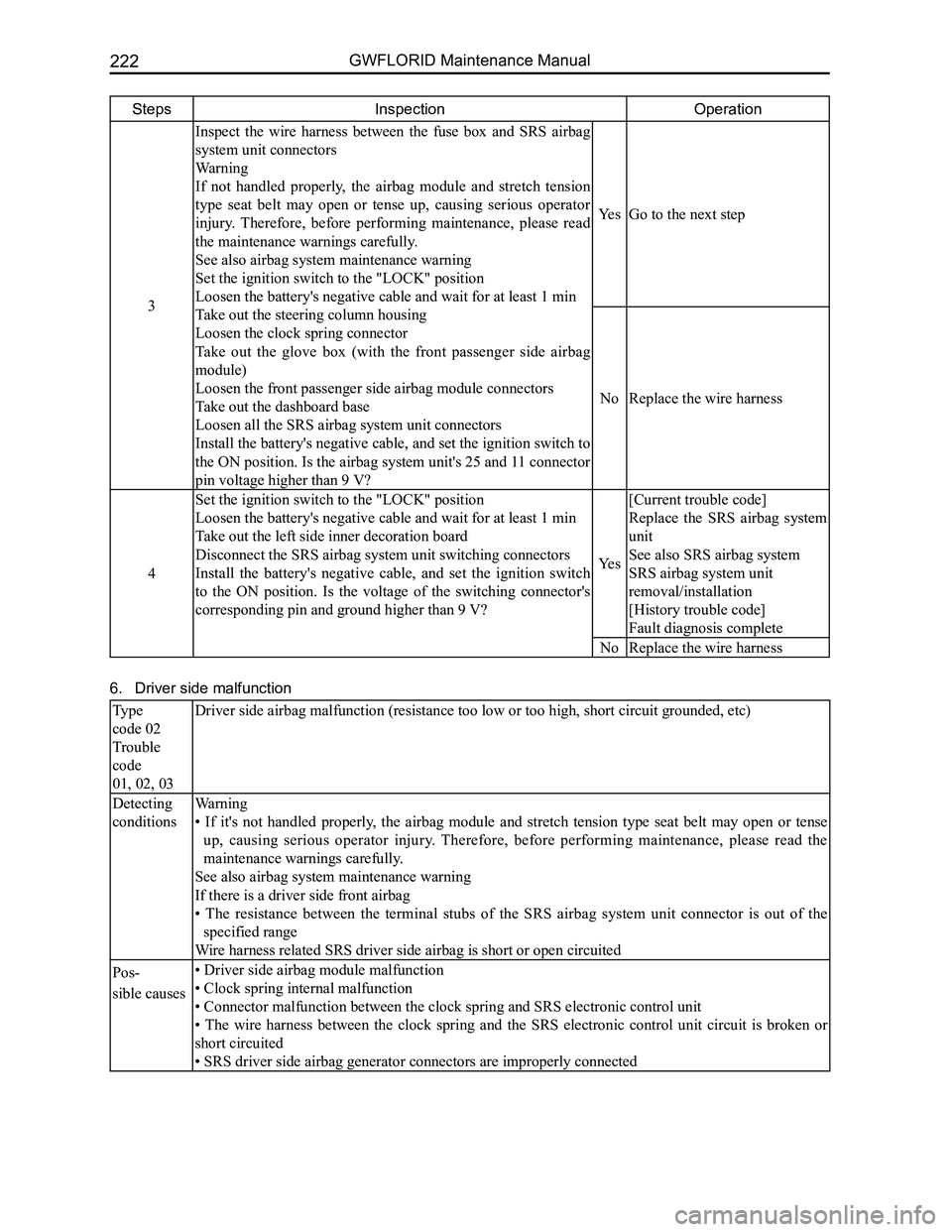

Page 229 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual222

StepsInspectionOperation

3

Inspect the wire harness between the fuse box and SRS airbag

system unit connectors

Warning

If not handled properly, the airbag module and stretch tension

type seat belt may open or tense up, causing serious operator

injury. Therefore, before performing maintenance, please read

the maintenance warnings carefully.

See also airbag system maintenance warning

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least 1 min

Take out the steering column housing

Loosen the clock spring connector

Take out the glove box (with the front passenger side airbag

module)

Loosen the front passenger side airbag module connectors

Take out the dashboard base

Loosen all the SRS airbag system unit connectors

Install the battery's negative cable, and set the ignition switch to

the ON position. Is the airbag system unit's 25 and 11 connector

pin voltage higher than 9 V?

YesGo to the next step

NoReplace the wire harness

4

Set the ignition switch to the "LOCK" position

Loosen the battery's negative cable and wait for at least 1 min

Take out the left side inner decoration board

Disconnect the SRS airbag system unit switching connectors

Install the battery's negative cable, and set the ignition switch

to the ON position. Is the voltage of the switching connector's

corresponding pin and ground higher than 9 V?

Yes

[Current trouble code]

Replace the SRS airbag system

unit

See also SRS airbag system

SRS airbag system unit

removal/installation

[History trouble code]

Fault diagnosis complete

NoReplace the wire harness

6. Driver side malfunction

Type

code 02

Trouble

code

01, 02, 03

Driver side airbag malfunction (resistance too low or too high, short c\

ircuit grounded, etc)

Detecting

conditions

Warning

• If it's not handled properly, the airbag module and stretch tension type seat belt may open or tense

up, causing serious operator injury. Therefore, before performing maintenance, please read the

maintenance warnings carefully.

See also airbag system maintenance warning

If there is a driver side front airbag

• The resistance between the terminal stubs of the SRS airbag system unit connector is out of the

specified range

Wire harness related SRS driver side airbag is short or open circuited

Pos-

sible causes

• Driver side airbag module malfunction

• Clock spring internal malfunction

• Connector malfunction between the clock spring and SRS electronic control unit

• The wire harness between the clock spring and the SRS electronic control unit circuit is broken or

short circuited

• SRS driver side airbag generator connectors are improperly connected