lock GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 246 of 425

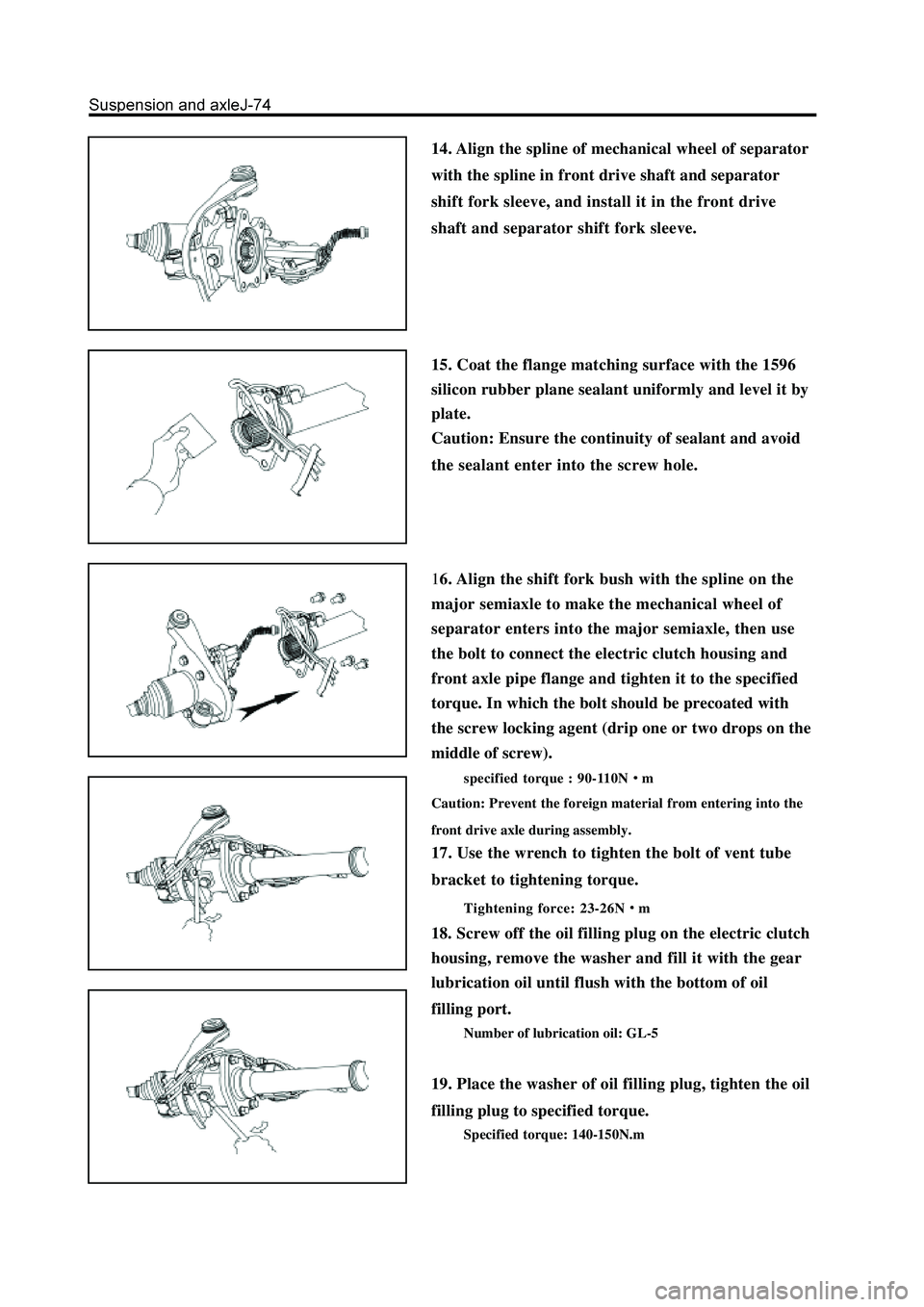

14. Align the spline of mechanical wheel of separator

with the spline in front drive shaft and separator

shift fork sleeve, and install it in the front drive

shaft and separator shift fork sleeve.

15. Coat the flange matching surface with the 1596

silicon rubber plane sealant uniformly and level it by

plate.

Caution: Ensure the continuity of sealant and avoid

the sealant enter into the screw hole.

16. Align the shift fork bush with the spline on the

major semiaxle to make the mechanical wheel of

separator enters into the major semiaxle, then use

the bolt to connect the electric clutch housing and

front axle pipe flange and tighten it to the specified

torque. In which the bolt should be precoated with

the screw locking agent (drip one or two drops on the

middle of screw).

specified torque : 90-110Nm

Caution: Prevent the foreign material from entering into the

front drive axle during assembly.

17. Use the wrench to tighten the bolt of vent tube

bracket to tightening torque.

Tightening force: 23-26Nm

18. Screw off the oil filling plug on the electric clutch

housing, remove the washer and fill it with the gear

lubrication oil until flush with the bottom of oil

filling port.

Number of lubrication oil: GL-5

19. Place the washer of oil filling plug, tighten the oil

filling plug to specified torque.

Specified torque: 140-150N.m

Page 251 of 425

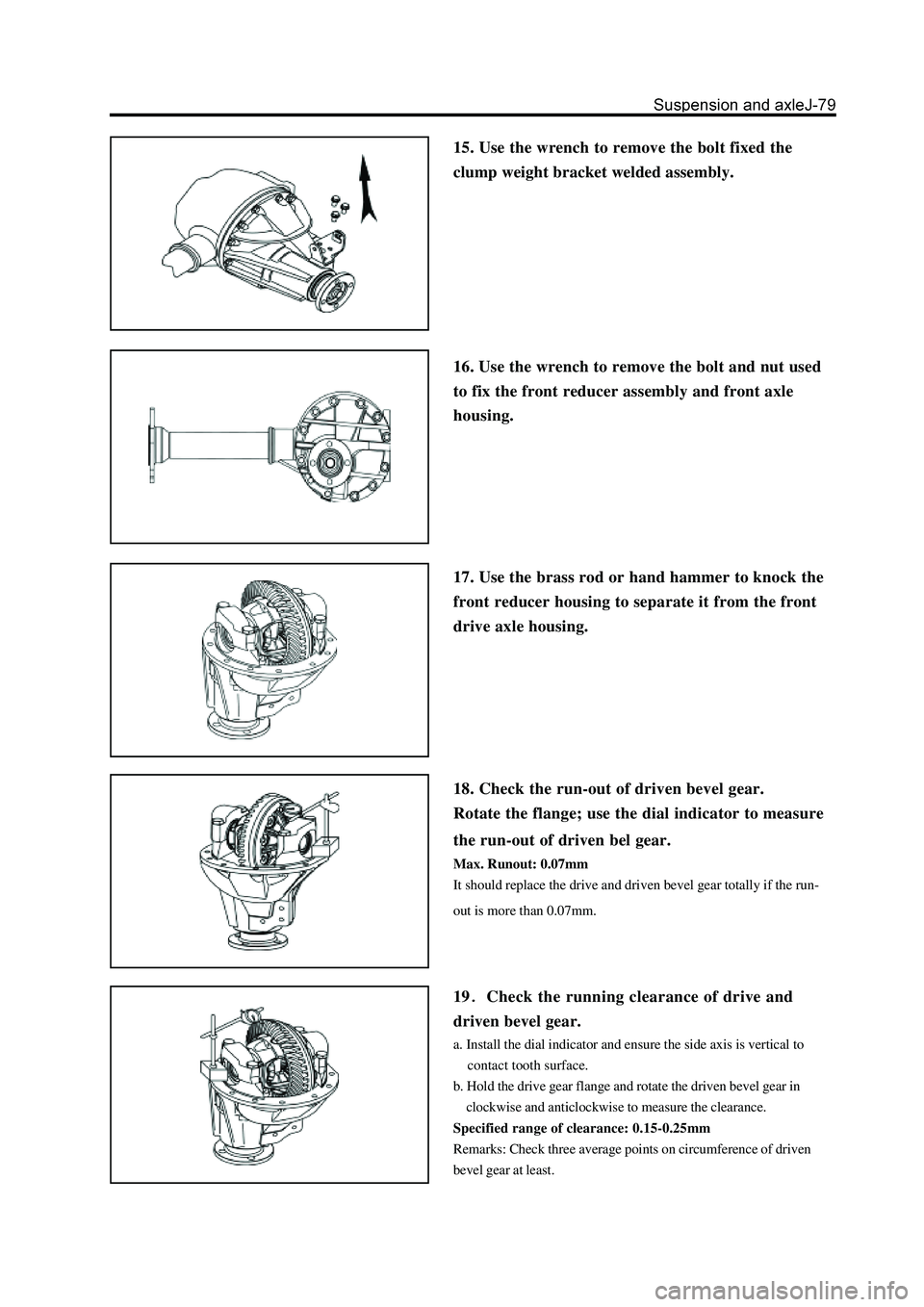

15. Use the wrench to remove the bolt fixed the

clump weight bracket welded assembly.

16. Use the wrench to remove the bolt and nut used

to fix the front reducer assembly and front axle

housing.

17. Use the brass rod or hand hammer to knock the

front reducer housing to separate it from the front

drive axle housing.

18. Check the run-out of driven bevel gear.

Rotate the flange; use the dial indicator to measure

the run-out of driven bel gear.

Max. Runout: 0.07mm

It should replace the drive and driven bevel gear totally if the run-

out is more than 0.07mm.

19Check the running clearance of drive and

driven bevel gear.

a. Install the dial indicator and ensure the side axis is vertical to

contact tooth surface.

b. Hold the drive gear flange and rotate the driven bevel gear in

clockwise and anticlockwise to measure the clearance.

Specified range of clearance: 0.15-0.25mm

Remarks: Check three average points on circumference of driven

bevel gear at least.

Page 253 of 425

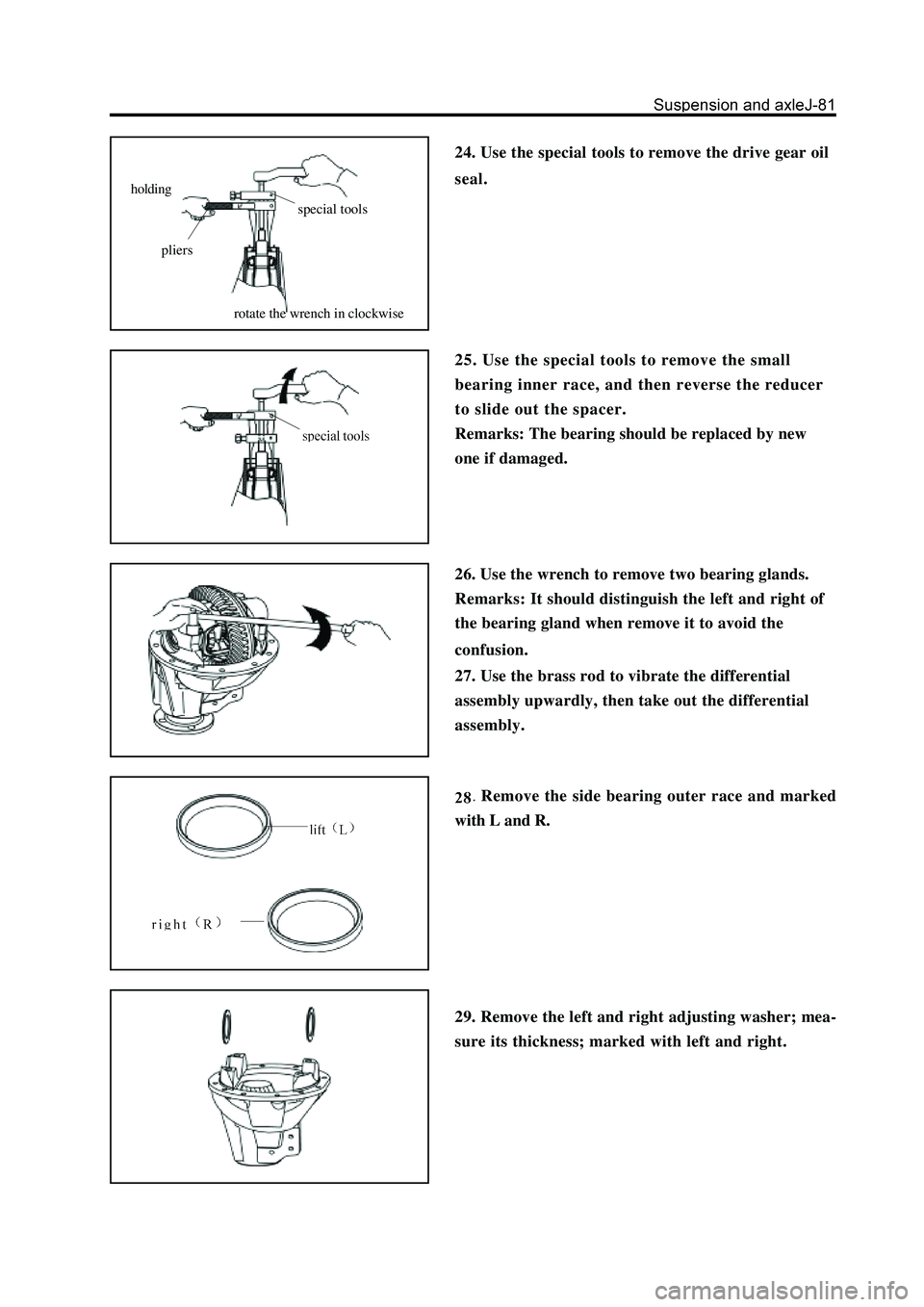

25. Use the special tools to remove the small

bearing inner race, and then reverse the reducer

to slide out the spacer.

Remarks: The bearing should be replaced by new

one if damaged.

26. Use the wrench to remove two bearing glands.

Remarks: It should distinguish the left and right of

the bearing gland when remove it to avoid the

confusion.

Remove the side bearing outer race and marked

with L and R.

29. Remove the left and right adjusting washer; mea-

sure its thickness; marked with left and right. 27. Use the brass rod to vibrate the differential

assembly upwardly, then take out the differential

assembly.

holding

pliers

special tools

rotate the wrench in clockwise

24. Use the special tools to remove the drive gear oil

seal.

Page 256 of 425

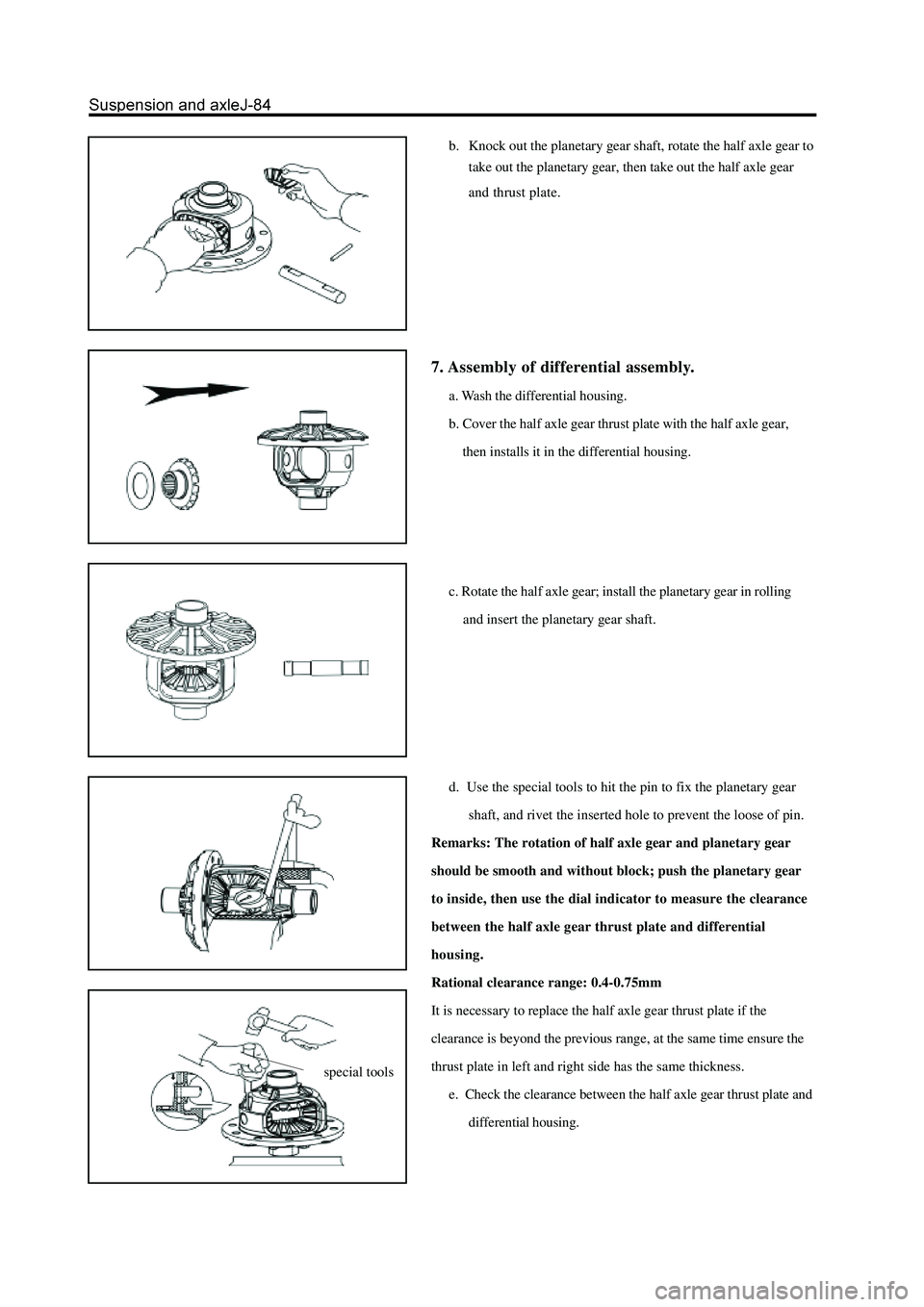

b. Knock out the planetary gear shaft, rotate the half axle gear to

take out the planetary gear, then take out the half axle gear

and thrust plate.

7. Assembly of differential assembly.

a. Wash the differential housing.

b. Cover the half axle gear thrust plate with the half axle gear,

then installs it in the differential housing.

c. Rotate the half axle gear; install the planetary gear in rolling

and insert the planetary gear shaft.

d. Use the special tools to hit the pin to fix the planetary gear

shaft, and rivet the inserted hole to prevent the loose of pin.

Remarks: The rotation of half axle gear and planetary gear

should be smooth and without block; push the planetary gear

to inside, then use the dial indicator to measure the clearance

between the half axle gear thrust plate and differential

housing.

Rational clearance range: 0.4-0.75mm

It is necessary to replace the half axle gear thrust plate if the

clearance is beyond the previous range, at the same time ensure the

thrust plate in left and right side has the same thickness.

e. Check the clearance between the half axle gear thrust plate and

differential housing.

special tools

Page 257 of 425

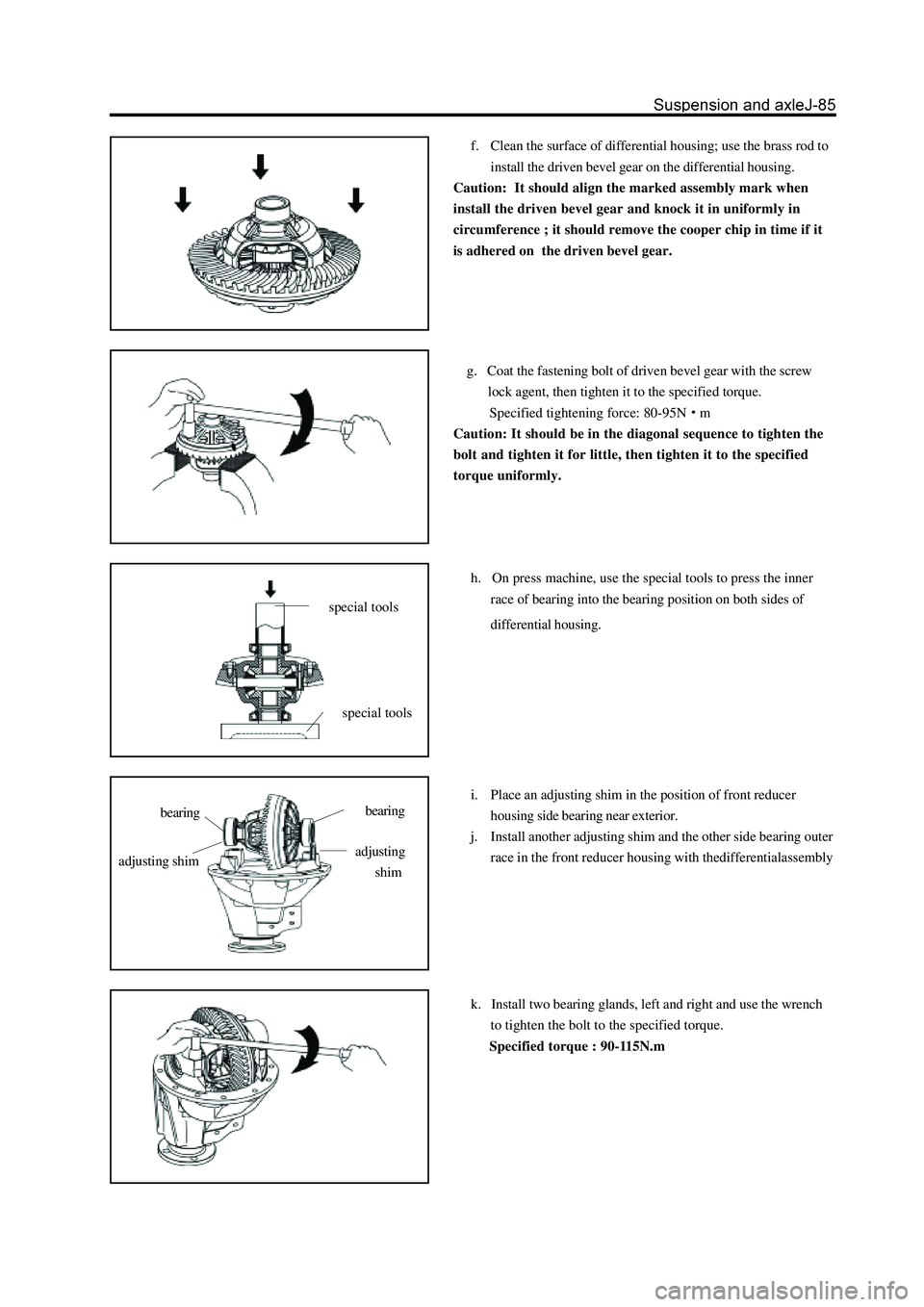

f. Clean the surface of differential housing; use the brass rod to

install the driven bevel gear on the differential housing.

Caution: It should align the marked assembly mark when

install the driven bevel gear and knock it in uniformly in

circumference ; it should remove the cooper chip in time if it

is adhered on the driven bevel gear.

g. Coat the fastening bolt of driven bevel gear with the screw

lock agent, then tighten it to the specified torque.

Specified tightening force: 80-95N

m

Caution: It should be in the diagonal sequence to tighten the

bolt and tighten it for little, then tighten it to the specified

torque uniformly.

h. On press machine, use the special tools to press the inner

race of bearing into the bearing position on both sides of

differential housing.

i. Place an adjusting shim in the position of front reducer

housing side bearing near exterior.

j. Install another adjusting shim and the other side bearing outer

race in the front reducer housing with thedifferentialassembly

k. Install two bearing glands, left and right and use the wrench

to tighten the bolt to the specified torque.

Specified torque : 90-115N.m

special tools

special tools

bearingbearing

adjusting shimadjusting

shim

Page 261 of 425

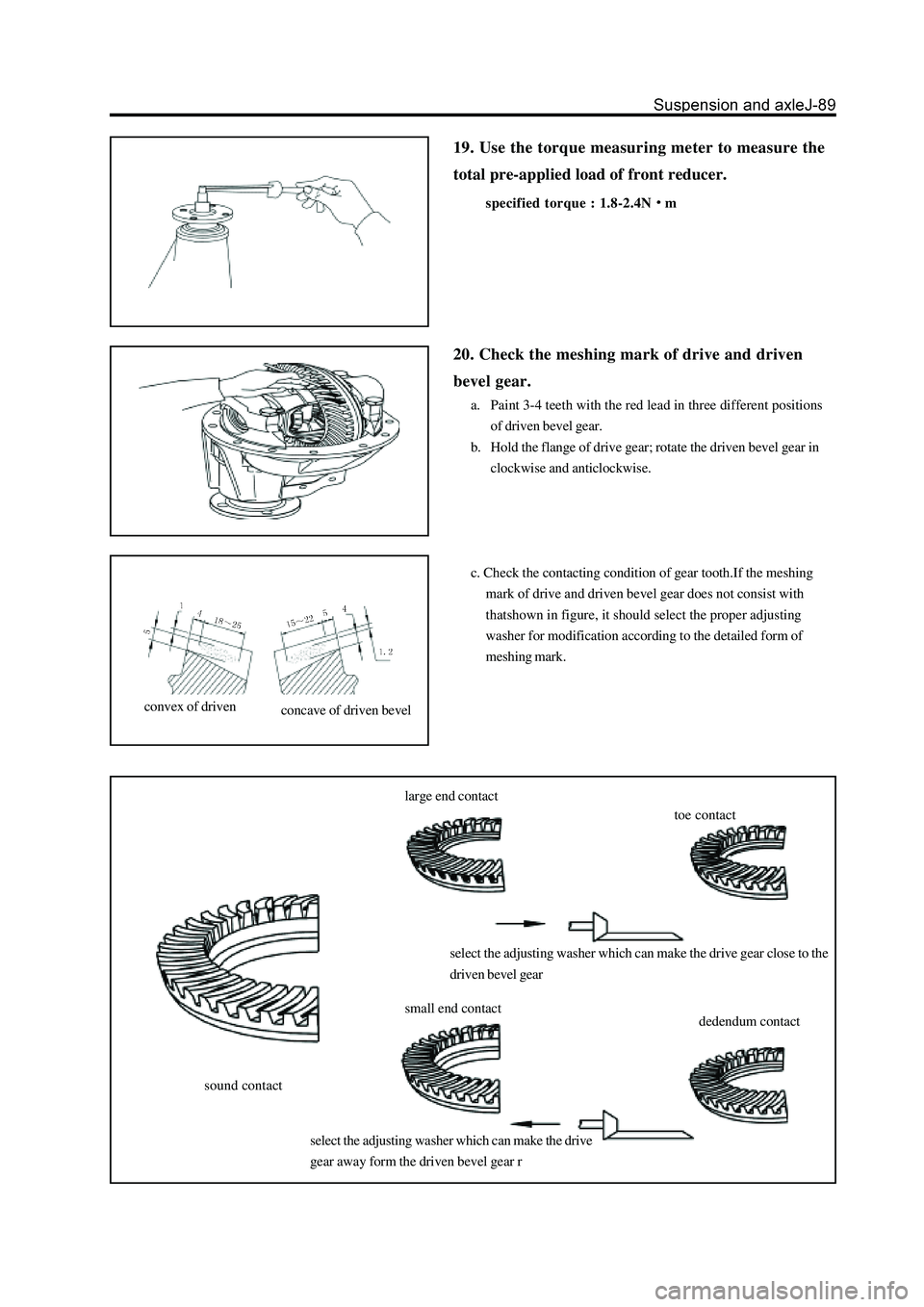

19. Use the torque measuring meter to measure the

total pre-applied load of front reducer.

specified torque : 1.8-2.4Nm

sound contactlarge end contact

toe contact

select the adjusting washer which can make the drive gear close to the

driven bevel gear

select the adjusting washer which can make the drive

gear away form the driven bevel gear rsmall end contact

dedendum contact

20. Check the meshing mark of drive and driven

bevel gear.

a. Paint 3-4 teeth with the red lead in three different positions

of driven bevel gear.

b. Hold the flange of drive gear; rotate the driven bevel gear in

clockwise and anticlockwise.

c. Check the contacting condition of gear tooth.If the meshing

mark of drive and driven bevel gear does not consist with

thatshown in figure, it should select the proper adjusting

washer for modification according to the detailed form of

meshing mark.

convex of drivenconcave of driven bevel

Page 263 of 425

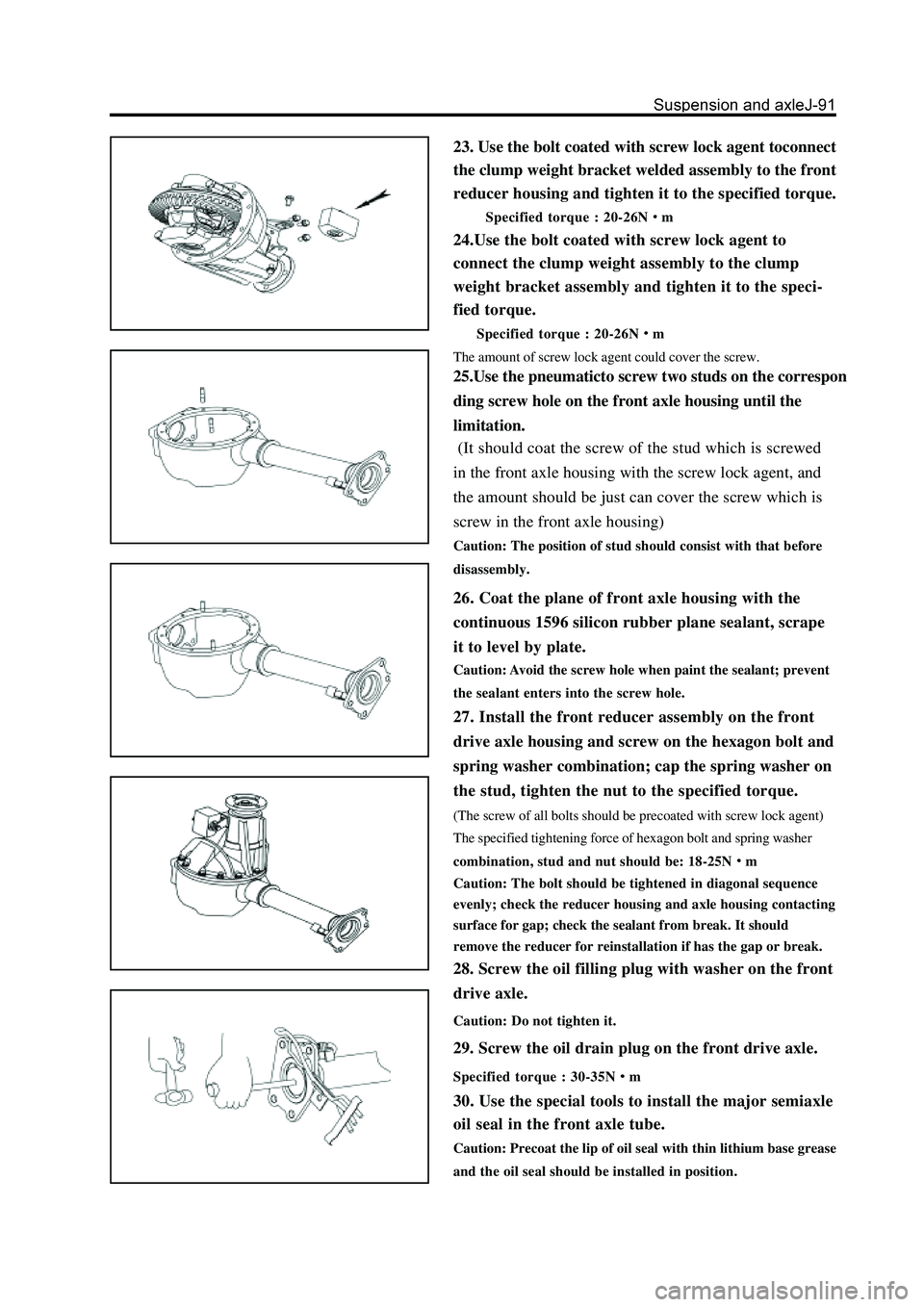

23. Use the bolt coated with screw lock agent toconnect

the clump weight bracket welded assembly to the front

reducer housing and tighten it to the specified torque.

Specified torque : 20-26Nm

24.Use the bolt coated with screw lock agent to

connect the clump weight assembly to the clump

weight bracket assembly and tighten it to the speci-

fied torque.

Specified torque : 20-26Nm

The amount of screw lock agent could cover the screw.

25.Use the pneumaticto screw two studs on the correspon

ding screw hole on the front axle housing until the

limitation.

26. Coat the plane of front axle housing with the

continuous 1596 silicon rubber plane sealant, scrape

it to level by plate.

Caution: Avoid the screw hole when paint the sealant; prevent

the sealant enters into the screw hole.

27. Install the front reducer assembly on the front

drive axle housing and screw on the hexagon bolt and

spring washer combination; cap the spring washer on

the stud, tighten the nut to the specified torque.

(The screw of all bolts should be precoated with screw lock agent)

The specified tightening force of hexagon bolt and spring washer

combination, stud and nut should be: 18-25N

m

Caution: The bolt should be tightened in diagonal sequence

evenly; check the reducer housing and axle housing contacting

surface for gap; check the sealant from break. It should

remove the reducer for reinstallation if has the gap or break.

28. Screw the oil filling plug with washer on the front

drive axle.

Caution: Do not tighten it.

29. Screw the oil drain plug on the front drive axle.

Specified torque : 30-35Nm

30. Use the special tools to install the major semiaxle

oil seal in the front axle tube.

Caution: Precoat the lip of oil seal with thin lithium base grease

and the oil seal should be installed in position.

(It should coat the screw of the stud which is screwed

in the front axle housing with the screw lock agent, and

the amount should be just can cover the screw which is

screw in the front axle housing)

Caution: The position of stud should consist with that before

disassembly.

Page 265 of 425

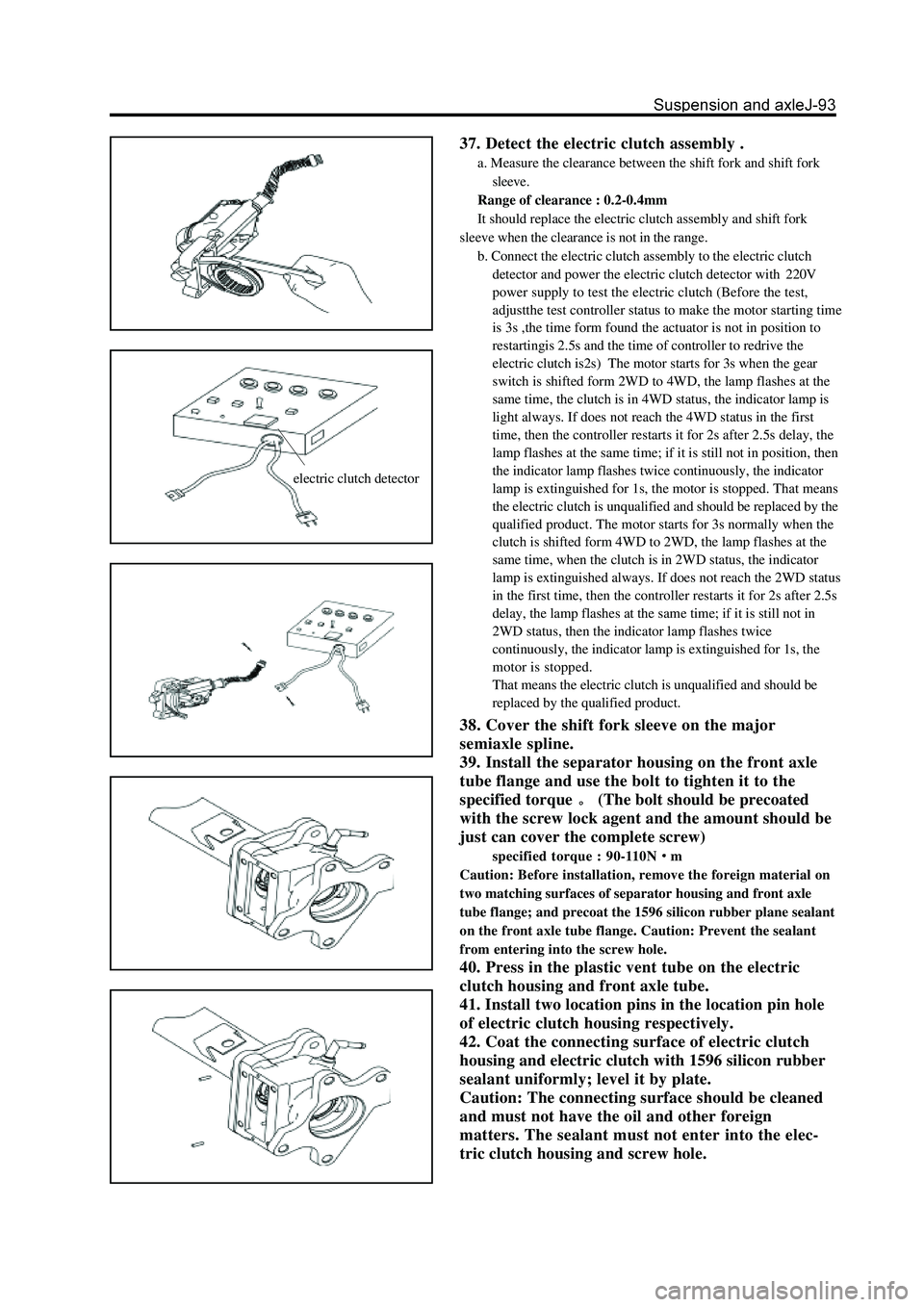

electric clutch detector

37. Detect the electric clutch assembly .

a. Measure the clearance between the shift fork and shift fork

sleeve.

Range of clearance : 0.2-0.4mm

It should replace the electric clutch assembly and shift fork

sleeve when the clearance is not in the range.

b. Connect the electric clutch assembly to the electric clutch

detector and power the electric clutch detector with220V

power supply to test the electric clutch (Before the test,

adjustthe test controller status to make the motor starting time

is 3s ,the time form found the actuator is not in position to

restartingis 2.5s and the time of controller to redrive the

electric clutch is2s) The motor starts for 3s when the gear

switch is shifted form 2WD to 4WD, the lamp flashes at the

same time, the clutch is in 4WD status, the indicator lamp is

light always. If does not reach the 4WD status in the first

time, then the controller restarts it for 2s after 2.5s delay, the

lamp flashes at the same time; if it is still not in position, then

the indicator lamp flashes twice continuously, the indicator

lamp is extinguished for 1s, the motor is stopped. That means

the electric clutch is unqualified and should be replaced by the

qualified product. The motor starts for 3s normally when the

clutch is shifted form 4WD to 2WD, the lamp flashes at the

same time, when the clutch is in 2WD status, the indicator

lamp is extinguished always. If does not reach the 2WD status

in the first time, then the controller restarts it for 2s after 2.5s

delay, the lamp flashes at the same time; if it is still not in

2WD status, then the indicator lamp flashes twice

continuously, the indicator lamp is extinguished for 1s, the

motor is stopped.

That means the electric clutch is unqualified and should be

replaced by the qualified product.

38. Cover the shift fork sleeve on the major

semiaxle spline.

39. Install the separator housing on the front axle

tube flange and use the bolt to tighten it to the

specified torque

(The bolt should be precoated

with the screw lock agent and the amount should be

just can cover the complete screw)

specified torque : 90-110Nm

Caution: Before installation, remove the foreign material on

two matching surfaces of separator housing and front axle

tube flange; and precoat the 1596 silicon rubber plane sealant

on the front axle tube flange. Caution: Prevent the sealant

from entering into the screw hole.

40. Press in the plastic vent tube on the electric

clutch housing and front axle tube.

41. Install two location pins in the location pin hole

of electric clutch housing respectively.

42. Coat the connecting surface of electric clutch

housing and electric clutch with 1596 silicon rubber

sealant uniformly; level it by plate.

Caution: The connecting surface should be cleaned

and must not have the oil and other foreign

matters. The sealant must not enter into the elec-

tric clutch housing and screw hole.

Page 266 of 425

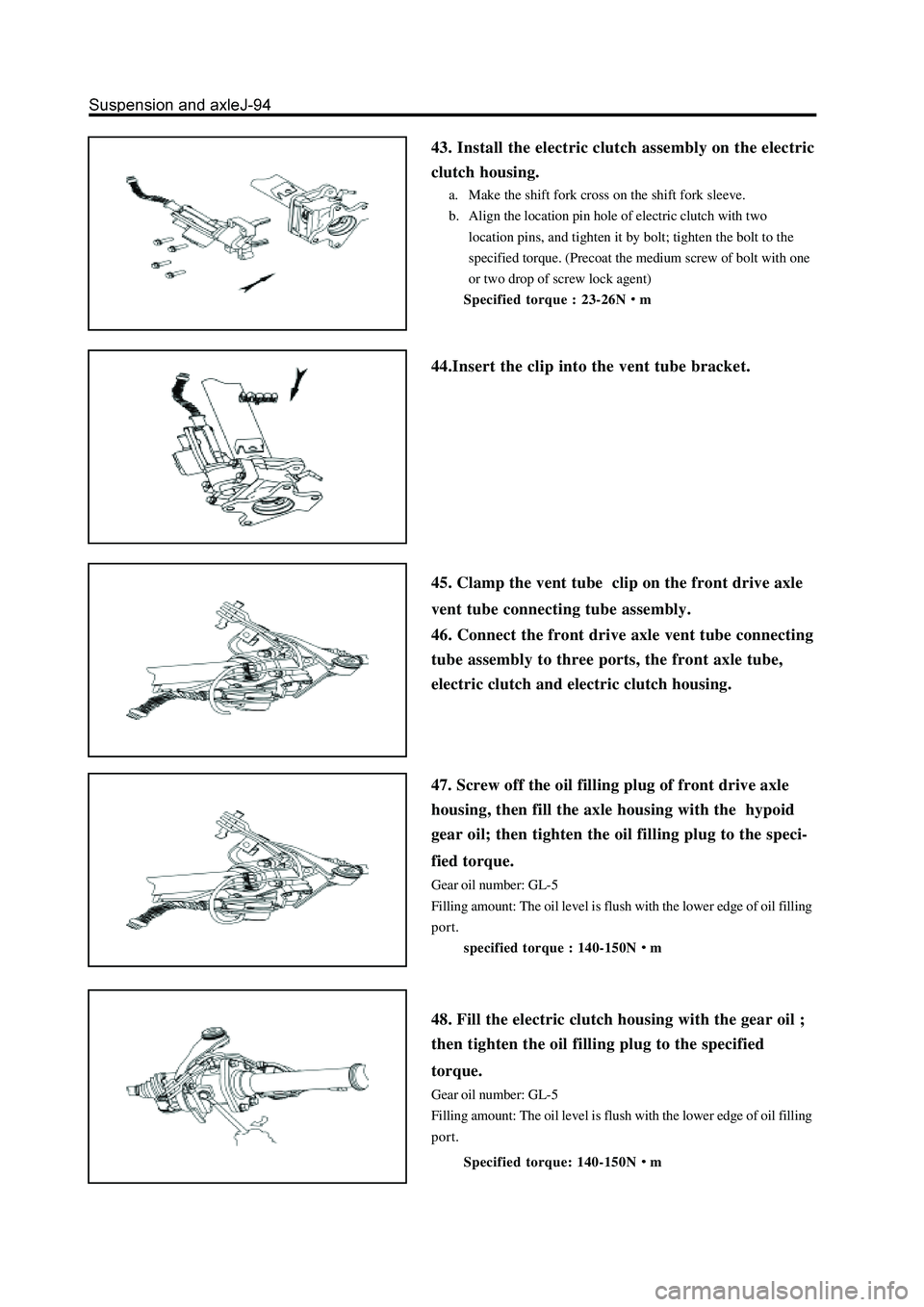

44.Insert the clip into the vent tube bracket.

45. Clamp the vent tube clip on the front drive axle

vent tube connecting tube assembly.

46. Connect the front drive axle vent tube connecting

tube assembly to three ports, the front axle tube,

electric clutch and electric clutch housing. 43. Install the electric clutch assembly on the electric

clutch housing.

a. Make the shift fork cross on the shift fork sleeve.

b. Align the location pin hole of electric clutch with two

location pins, and tighten it by bolt; tighten the bolt to the

specified torque. (Precoat the medium screw of bolt with one

or two drop of screw lock agent)

Specified torque : 23-26N

m

47. Screw off the oil filling plug of front drive axle

housing, then fill the axle housing with the hypoid

gear oil; then tighten the oil filling plug to the speci-

fied torque.

Gear oil number: GL-5

Filling amount: The oil level is flush with the lower edge of oil filling

port.

specified torque : 140-150N

m

48. Fill the electric clutch housing with the gear oil ;

then tighten the oil filling plug to the specified

torque.

Gear oil number: GL-5

Filling amount: The oil level is flush with the lower edge of oil filling

port.

Specified torque: 140-150N

m

Page 268 of 425

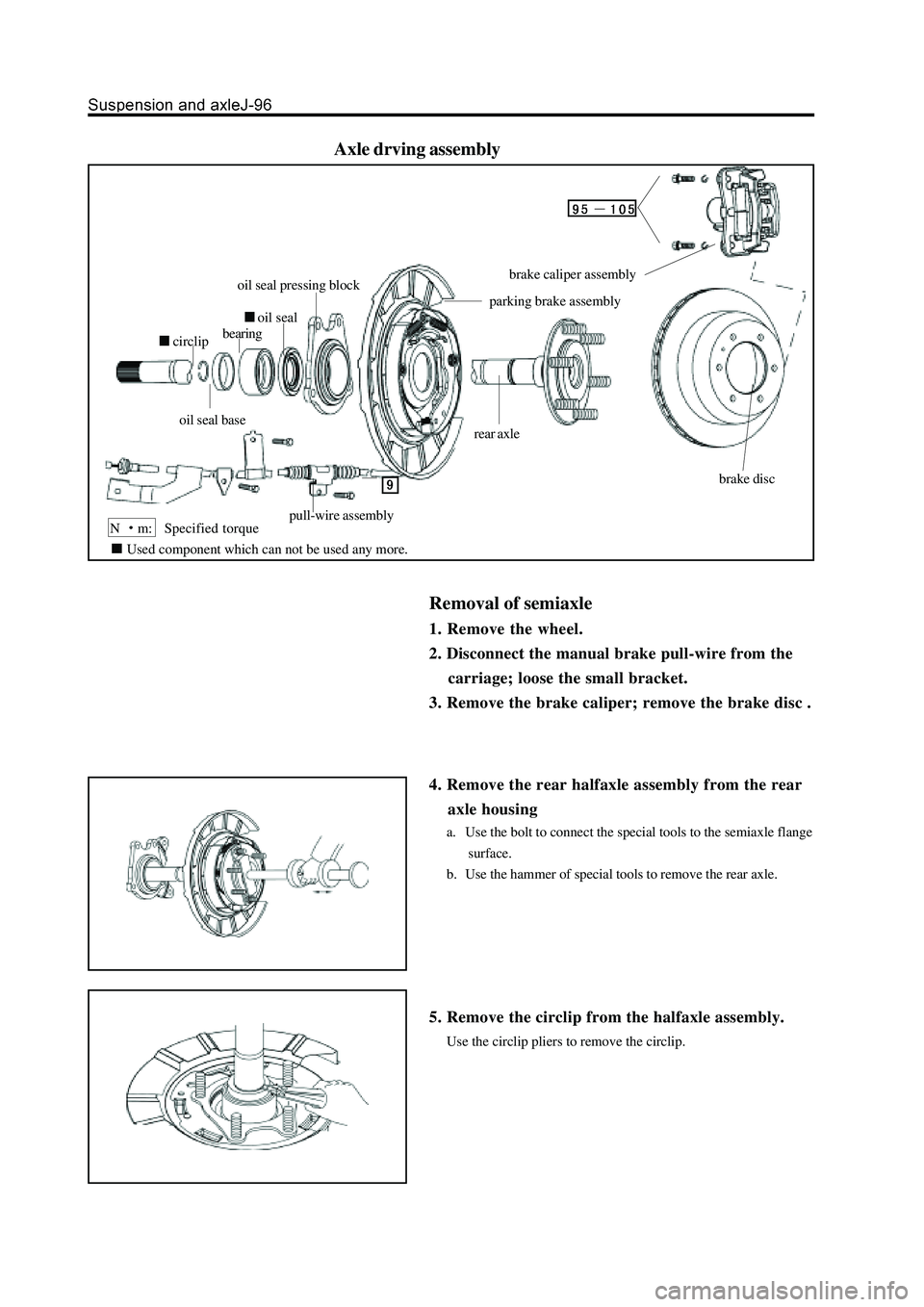

Axle drving assembly

Removal of semiaxle

1. Remove the wheel.

2. Disconnect the manual brake pull-wire from the

carriage; loose the small bracket.

3. Remove the brake caliper; remove the brake disc .

4. Remove the rear halfaxle assembly from the rear

axle housing

a. Use the bolt to connect the special tools to the semiaxle flange

surface.

b. Use the hammer of special tools to remove the rear axle.

brake caliper assembly

brake disc

circlip

oil seal base

bearing

oil seal

oil seal pressing block

parking brake assembly

rear axle

N

m: Specified torque

Used component which can not be used any more.

pull-wire assembly

5. Remove the circlip from the halfaxle assembly.

Use the circlip pliers to remove the circlip.