light GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 82 of 425

Automatic transmission-6

Selection of drive mode

The selection of drive mode includes a mode selection switch and indicator lamp. The drive mode selection switch is located

on the operating panel. It can provide the different mode selection according to the different type of car.

It has the optimal fuel economy when select the “normal” mode. At this time, the indicator lamp is not light. When select the

“dynamic” mode, the car will have the maximum dynamic performance and the “dynamic” mode indicator lamp is light. When select

the “snowland” mode, it will realize the starting of “2

nd-Gear”, the “snowland” mode indicator lamp is light, meanwhile the

“dynamic” mode indicator lamp will be closed. When select the manual mode, press down the “snowland” switch firstly, the

“manual” light will be light when the gear is in 3, 2, 1. When in manual mode, 1-2, 2-3, 3-4, 3-2, 2-1, 1-3, 3-1 is shifted by driver

manually and can not be shifted automatically. It can be used in car-racing etc. for the special mode of each model of car refers to

operation manual of user.

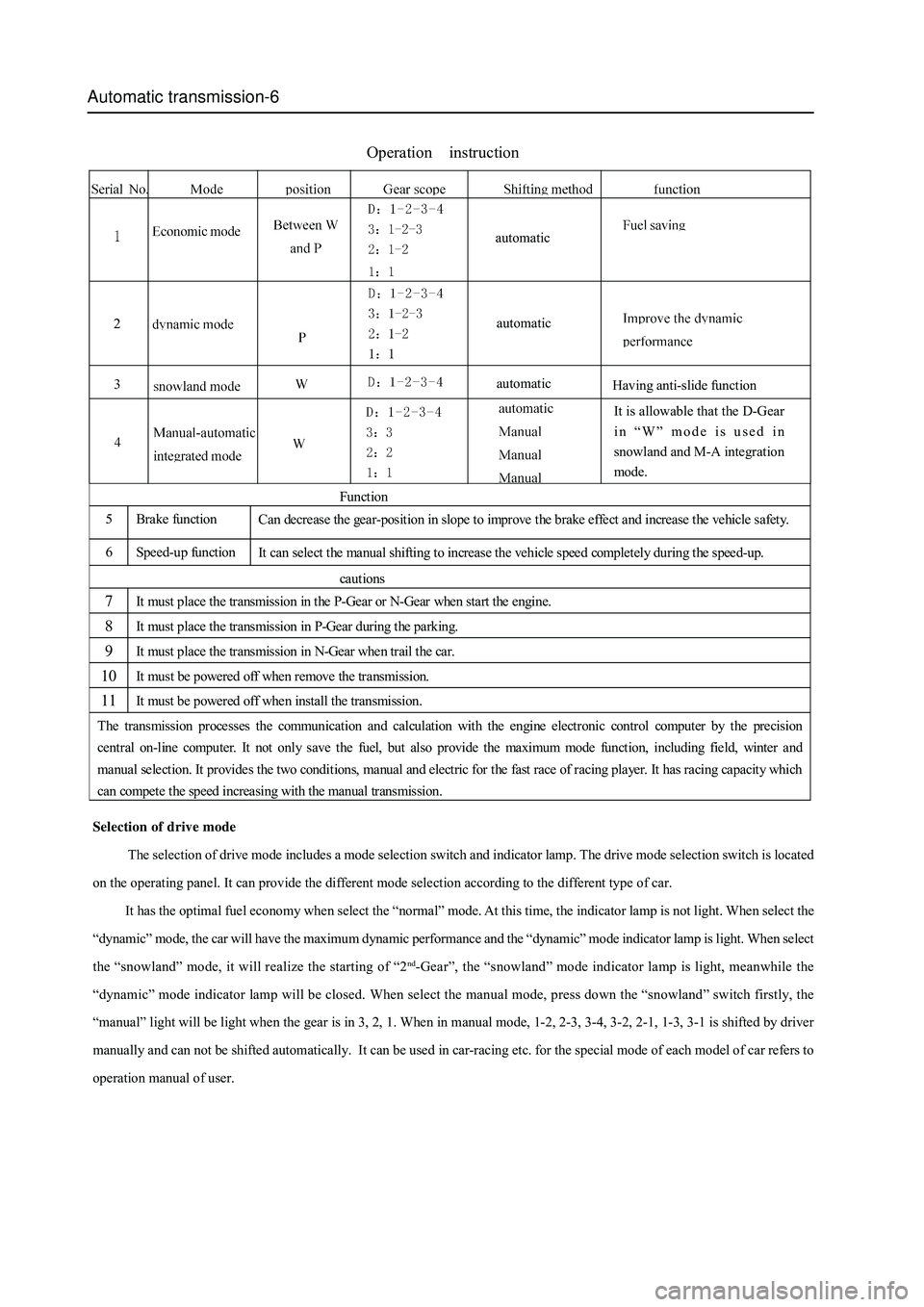

Operation instruction

Function

5 Brake function

Can decrease the gear-position in slope to improve the brake effect and increase the vehicle safety.

6 Speed-up function

It can select the manual shifting to increase the vehicle speed completely during the speed-up.

cautions

7 It must place the transmission in the P-Gear or N-Gear when start the engine.

8 It must place the transmission in P-Gear during the parking.

9 It must place the transmission in N-Gear when trail the car.

10 It must be powered off when remove the transmission.

11 It must be powered off when install the transmission.

The transmission processes the communication and calculation with the engine electronic control computer by the precision

central on-line computer. It not only save the fuel, but also provide the maximum mode function, including field, winter and

manual selection. It provides the two conditions, manual and electric for the fast race of racing player. It has racing capacity wh i ch

can compete the speed increasing with the manual transmission.

automatic

Having anti-slide function

It is allowable that the D-Gear

in “W” mode is used in

snowland and M-A integration

mode. automatic

automatic

Page 96 of 425

Automatic transmission-20

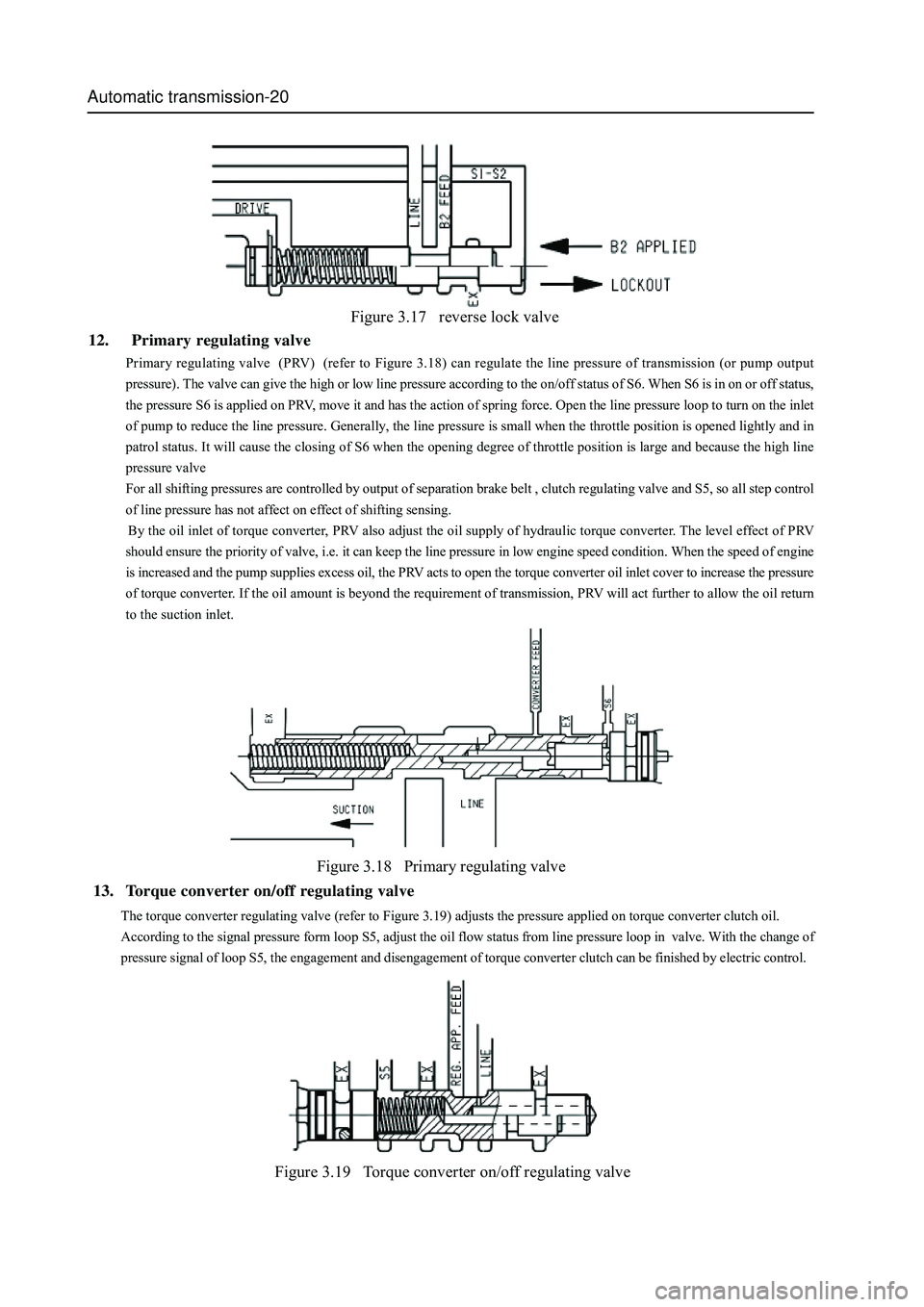

Figure 3.17 reverse lock valve

12. Primary regulating valve

Primary regulating valve (PRV) (refer to Figure 3.18) can regulate the line pressure of transmission (or pump output

pressure). The valve can give the high or low line pressure according to the on/off status of S6. When S6 is in on or off status,

the pressure S6 is applied on PRV, move it and has the action of spring force. Open the line pressure loop to turn on the inlet

of pump to reduce the line pressure. Generally, the line pressure is small when the throttle position is opened lightly and in

patrol status. It will cause the closing of S6 when the opening degree of throttle position is large and because the high line

pressure valve

For all shifting pressures are controlled by output of separation brake belt , clutch regulating valve and S5, so all step control

of line pressure has not affect on effect of shifting sensing.

By the oil inlet of torque converter, PRV also adjust the oil supply of hydraulic torque converter. The level effect of PRV

should ensure the priority of valve, i.e. it can keep the line pressure in low engine speed condition. When the speed of engine

is increased and the pump supplies excess oil, the PRV acts to open the torque converter oil inlet cover to increase the pressure

of torque converter. If the oil amount is beyond the requirement of transmission, PRV will act further to allow the oil return

to the suction inlet.

Figure 3.18 Primary regulating valve

Figure 3.19 Torque converter on/off regulating valve

The torque converter regulating valve (refer to Figure 3.19) adjusts the pressure applied on torque converter clutch oil.

According to the signal pressure form loop S5, adjust the oil flow status from line pressure loop in valve. With the change of

pressure signal of loop S5, the engagement and disengagement of torque converter clutch can be finished by electric control.

13. Torque converter on/off regulating valve

Page 130 of 425

3. Oil filling of service after sales

Set the liquid level position correctly; the procedure is shown as follows:

a. Shut down the engine; place the gear-position in the P-Gear.

b . Lift the vehicle (or place it above the trench).

c. Clean the around of plug before remove it. Remove the oil plug and check the O-ring for damage, finally connect the oil filling

pump to the oil filling hole.

d. Lower the vehicle and oil filling pump to the ground; fill with the transmission fluid partially. The general oil filling amount

is shown as follows:

If in the status of transmission hydraulic torque converter is empty: 8.0 L

If in the status of transmission hydraulic torque converter is full: 3.8 L

e. When start the vehicle in P-Gear, rotate the engine in idle speed. Step down the foot brake, pull the shifting lever in each gear-

position in circulation and add the transmission fluid until the action of each gear-position can be sensed.

f. Then fill with 0.5L transmission fluid (ATF) additionally.

g. Shut off the engine, lift the vehicle; take off the pump and replace the plug. Ensure the plug is tightened according to the

specification.

h. Then pull the vehicle throttle position for slight opening to make the vehicle runs for 3.5

4.5km; the rotary speed of engine

is no more than 2500r/min; then the transmission fluid temperature will in the scope of 50

60.

i. The engine is in idle-speed; pull the hand brake to make the shifting lever circuits in each gear-position horizontal status.

k. Remove the filling plug 3 minutes after the engine is shut off, but must be no more than1 hour. At this time, the correct

level position should be in the bottom of oil filling hole. If does not reach the liquid level position, then fill with few

transmission fluid (ATF) to meet the requirement.

l. Reinsert the transmission fluid plug, remove the residual transmission fluid around the vehicle and transmission; tighten the

plug to the specified torque.

4. Replace the ATF

Please notice that the color of TQ95 automatic transmission oil will be faded in the normal operation of transmission; it will be

turn into the deep brown or even in black. It will not affect the performance of ATF. It means that the fading of transmission

fluid not always means to replace the transmission fluid.

If the transmission temperature is raised, the ATF will be burnt. In this condition, ATF will change into black and with special

sulfur smell. The smell of the ATF means the oil is burnt.

If the ATF is burnt, it will cause the damage of transmission (the clutch assembly is damaged at least).At this time, it should

disassembly the transmission and process the necessary detection.

Electronic calibration

1. Idle-speed calibration

The idle-speed calibration is introduced in detail in the vehicle factory manual.

2 Calibration of position of throttle position

If the throttle position information stored in TCU is lost or not in application scope. It can be reestablished according to the

following program as the diagnosis error information.

a. Check whether the engine idle speed is in required range.

b. In the status of shutting off of air-condition, make the engine is in “D” –Gear for 60s,then the reference point with opening

degree of 0

of throttle position is reset in TCU.

Shut off the engine; switch on the ignition device, step the accelerator pedal to bottom for 60s, then the reference point with opening

degree of 100

of throttle position is reset in TCU.

3. Clear of throttle position

The clear process set by learning throttle position is necessary for M88 transmission TCU.

4. Car code

For M88 transmission, the car code is unnecessary.

Page 183 of 425

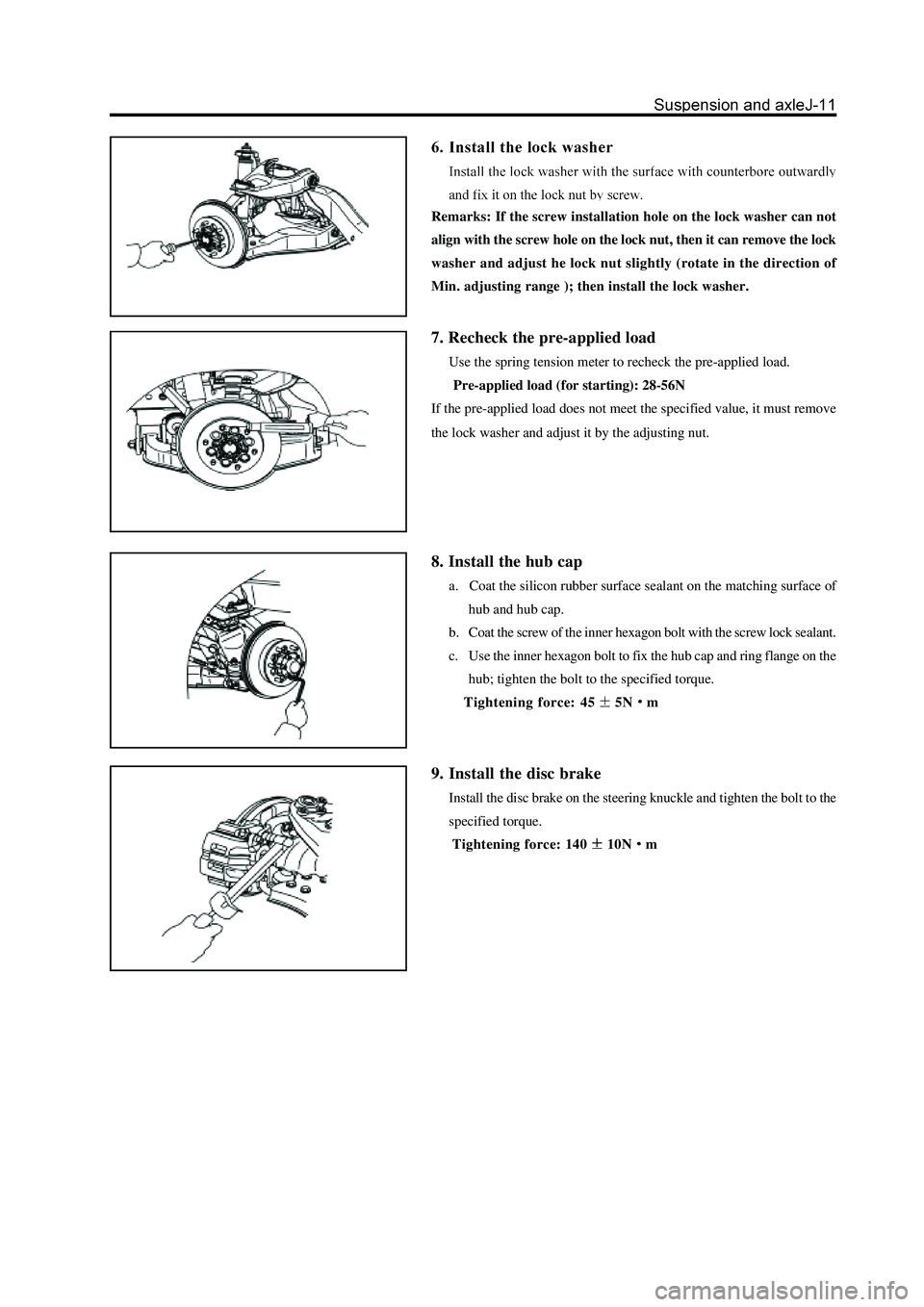

Remarks: If the screw installation hole on the lock washer can not

align with the screw hole on the lock nut, then it can remove the lock

washer and adjust he lock nut slightly (rotate in the direction of

Min. adjusting range ); then install the lock washer.

7. Recheck the pre-applied load

Use the spring tension meter to recheck the pre-applied load.

Pre-applied load (for starting): 28-56N

If the pre-applied load does not meet the specified value, it must remove

the lock washer and adjust it by the adjusting nut.

8. Install the hub cap

a. Coat the silicon rubber surface sealant on the matching surface of

hub and hub cap.

b. Coat the screw of the inner hexagon bolt with the screw lock sealant.

c. Use the inner hexagon bolt to fix the hub cap and ring flange on the

hub; tighten the bolt to the specified torque.

Tightening force: 45

5Nm

9. Install the disc brake

Install the disc brake on the steering knuckle and tighten the bolt to the

specified torque.

Tightening force: 140

10Nm

Page 205 of 425

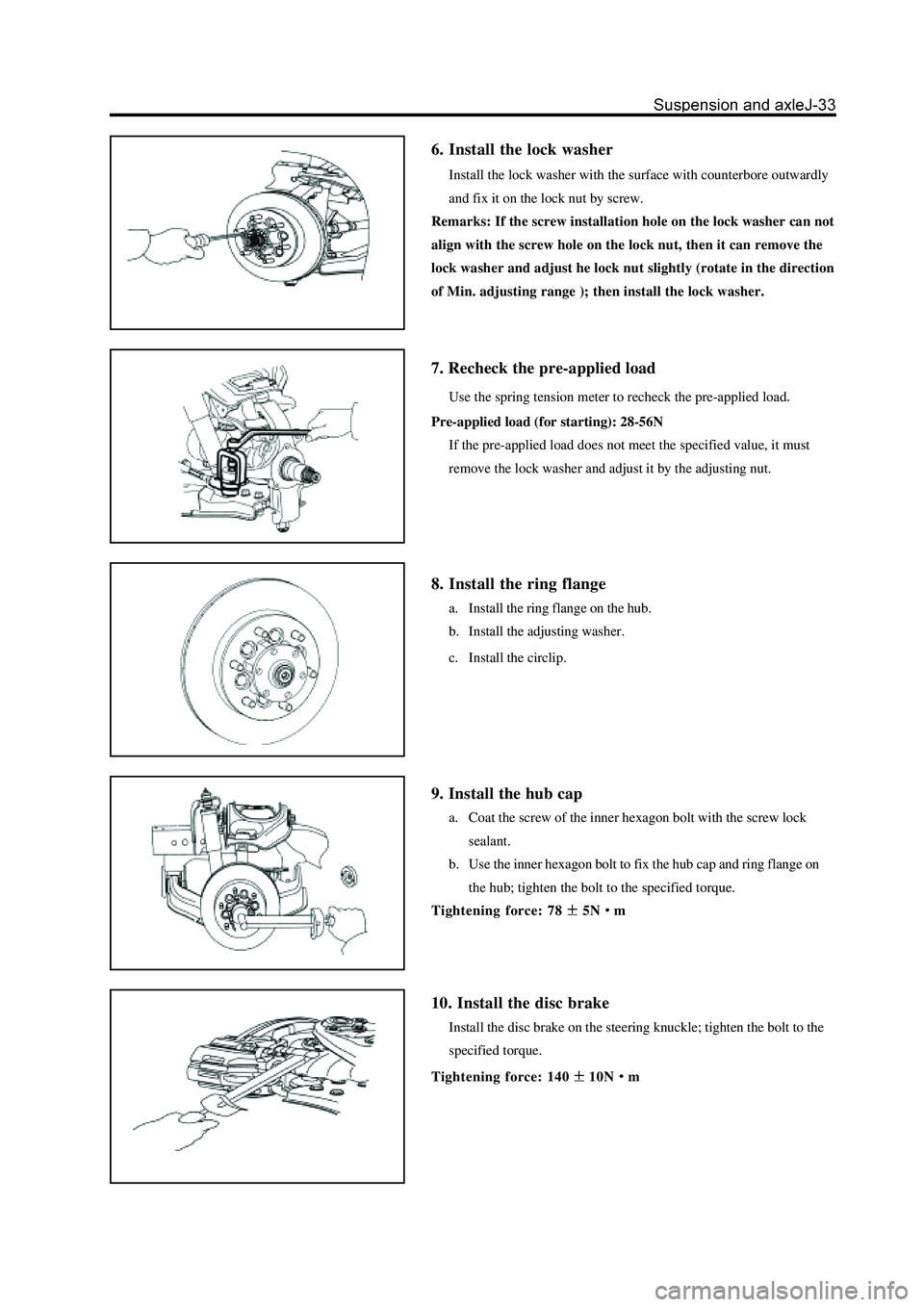

6. Install the lock washer

Install the lock washer with the surface with counterbore outwardly

and fix it on the lock nut by screw.

Remarks: If the screw installation hole on the lock washer can not

align with the screw hole on the lock nut, then it can remove the

lock washer and adjust he lock nut slightly (rotate in the direction

of Min. adjusting range ); then install the lock washer.

7. Recheck the pre-applied load

Use the spring tension meter to recheck the pre-applied load

Pre-applied load (for starting): 28-56N

If the pre-applied load does not meet the specified value, it must

remove the lock washer and adjust it by the adjusting nut.

8. Install the ring flange

a. Install the ring flange on the hub.

b. Install the adjusting washer.

c. Install the circlip.

9. Install the hub cap

a. Coat the screw of the inner hexagon bolt with the screw lock

sealant.

b. Use the inner hexagon bolt to fix the hub cap and ring flange on

the hub; tighten the bolt to the specified torque.

Tightening force: 78

5Nm

10. Install the disc brake

Install the disc brake on the steering knuckle; tighten the bolt to the

specified torque.

Tightening force: 140

10Nm

Page 208 of 425

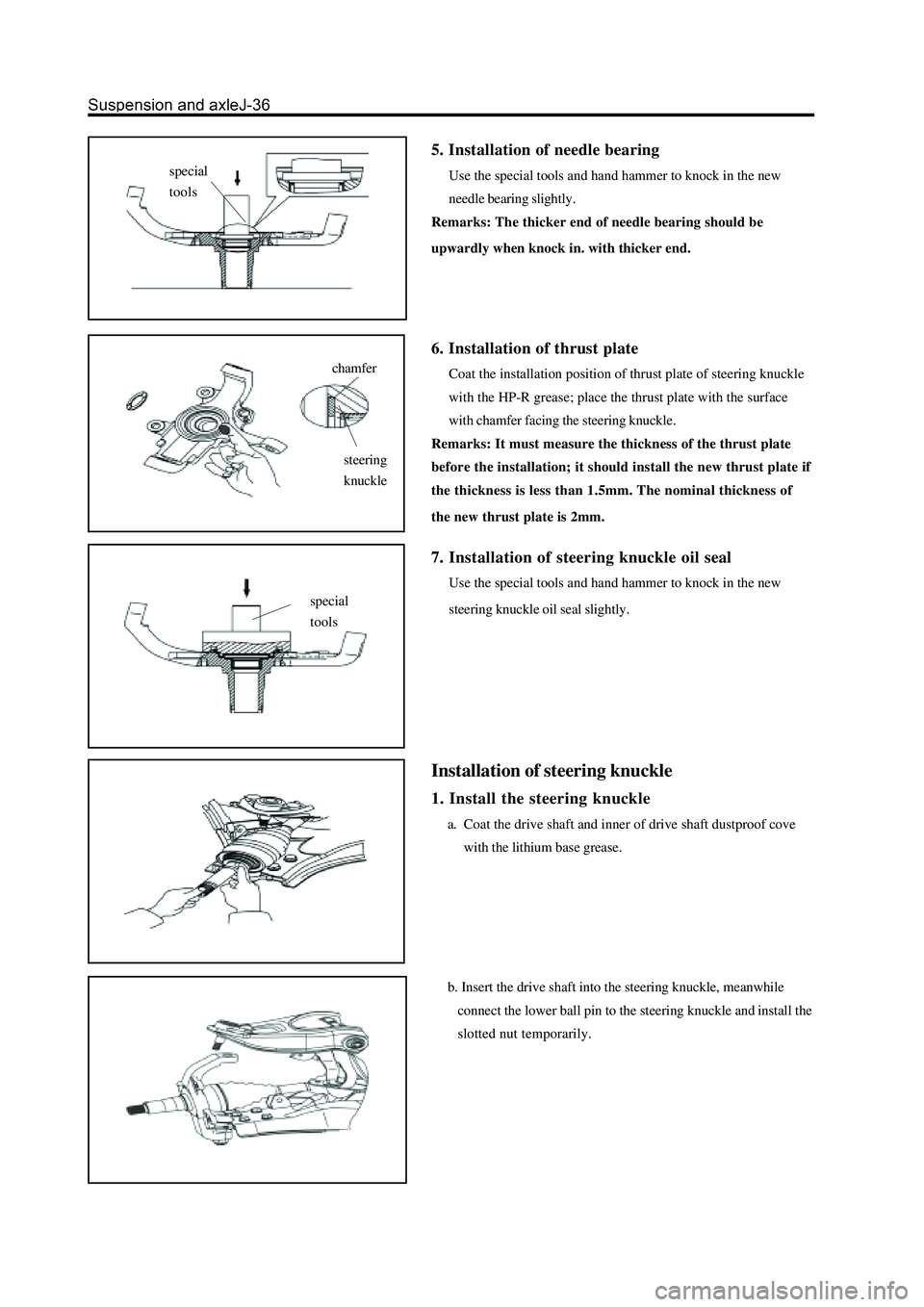

5. Installation of needle bearing

Use the special tools and hand hammer to knock in the new

needle bearing slightly.

Remarks: The thicker end of needle bearing should be

upwardly when knock in. with thicker end.

chamfer

steering

knuckle

6. Installation of thrust plate

Coat the installation position of thrust plate of steering knuckle

with the HP-R grease; place the thrust plate with the surface

with chamfer facing the steering knuckle.

Remarks: It must measure the thickness of the thrust plate

before the installation; it should install the new thrust plate if

the thickness is less than 1.5mm. The nominal thickness of

the new thrust plate is 2mm.

7. Installation of steering knuckle oil seal

Use the special tools and hand hammer to knock in the new

steering knuckle oil seal slightly.

Installation of steering knuckle

1. Install the steering knuckle

a. Coat the drive shaft and inner of drive shaft dustproof cove

with the lithium base grease.

b. Insert the drive shaft into the steering knuckle, meanwhile

connect the lower ball pin to the steering knuckle and install the

slotted nut temporarily.

special

tools

special

tools

Page 233 of 425

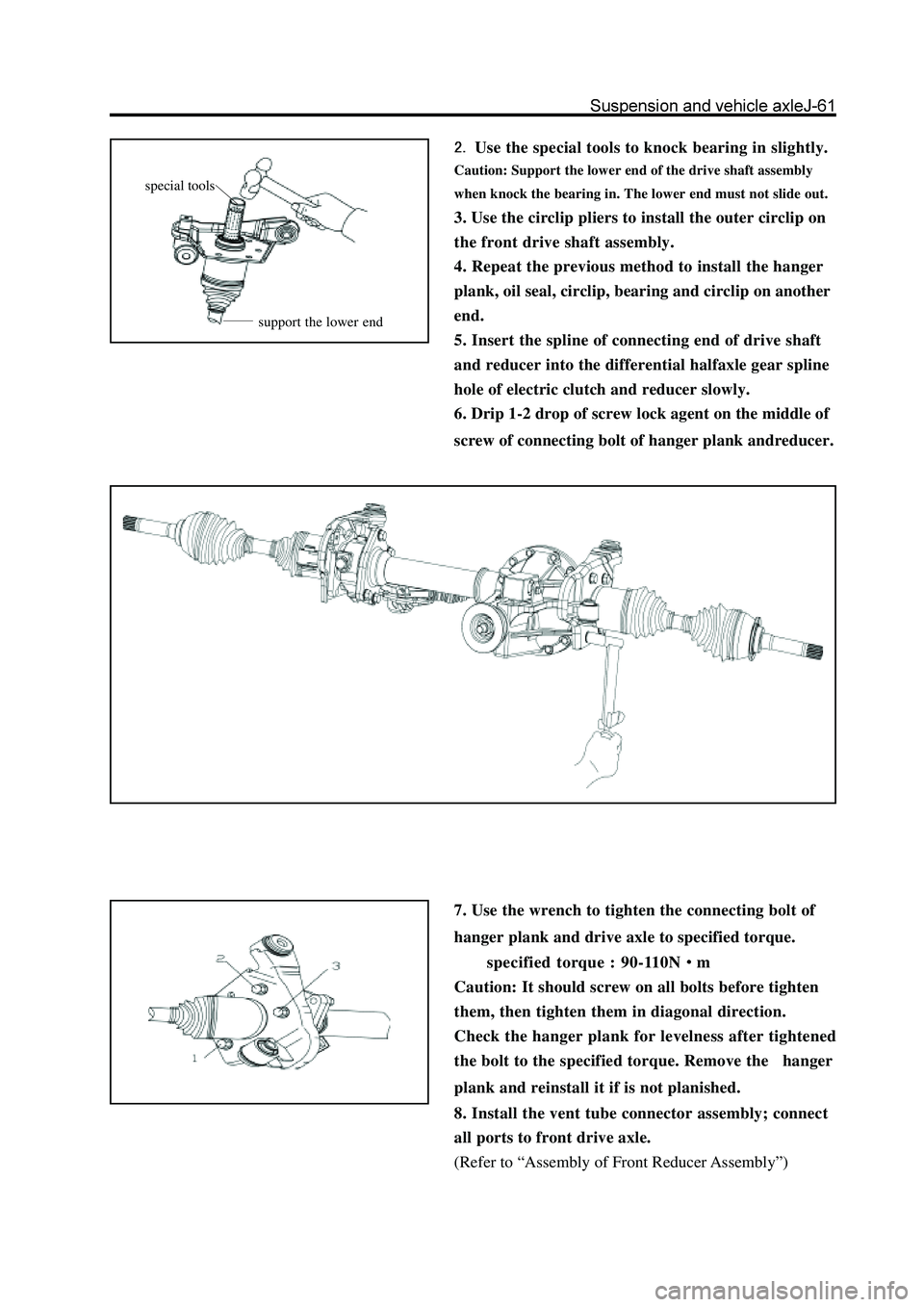

Use the special tools to knock bearing in slightly.

Caution: Support the lower end of the drive shaft assembly

when knock the bearing in. The lower end must not slide out.

3. Use the circlip pliers to install the outer circlip on

the front drive shaft assembly.

4. Repeat the previous method to install the hanger

plank, oil seal, circlip, bearing and circlip on another

end.

5. Insert the spline of connecting end of drive shaft

and reducer into the differential halfaxle gear spline

hole of electric clutch and reducer slowly.

6. Drip 1-2 drop of screw lock agent on the middle of

screw of connecting bolt of hanger plank andreducer.

7. Use the wrench to tighten the connecting bolt of

hanger plank and drive axle to specified torque.

specified torque : 90-110N

m

Caution: It should screw on all bolts before tighten

them, then tighten them in diagonal direction.

Check the hanger plank for levelness after tightened

the bolt to the specified torque. Remove the hanger

plank and reinstall it if is not planished.

8. Install the vent tube connector assembly; connect

all ports to front drive axle.

(Refer to “Assembly of Front Reducer Assembly”)

special tools

support the lower end

Page 245 of 425

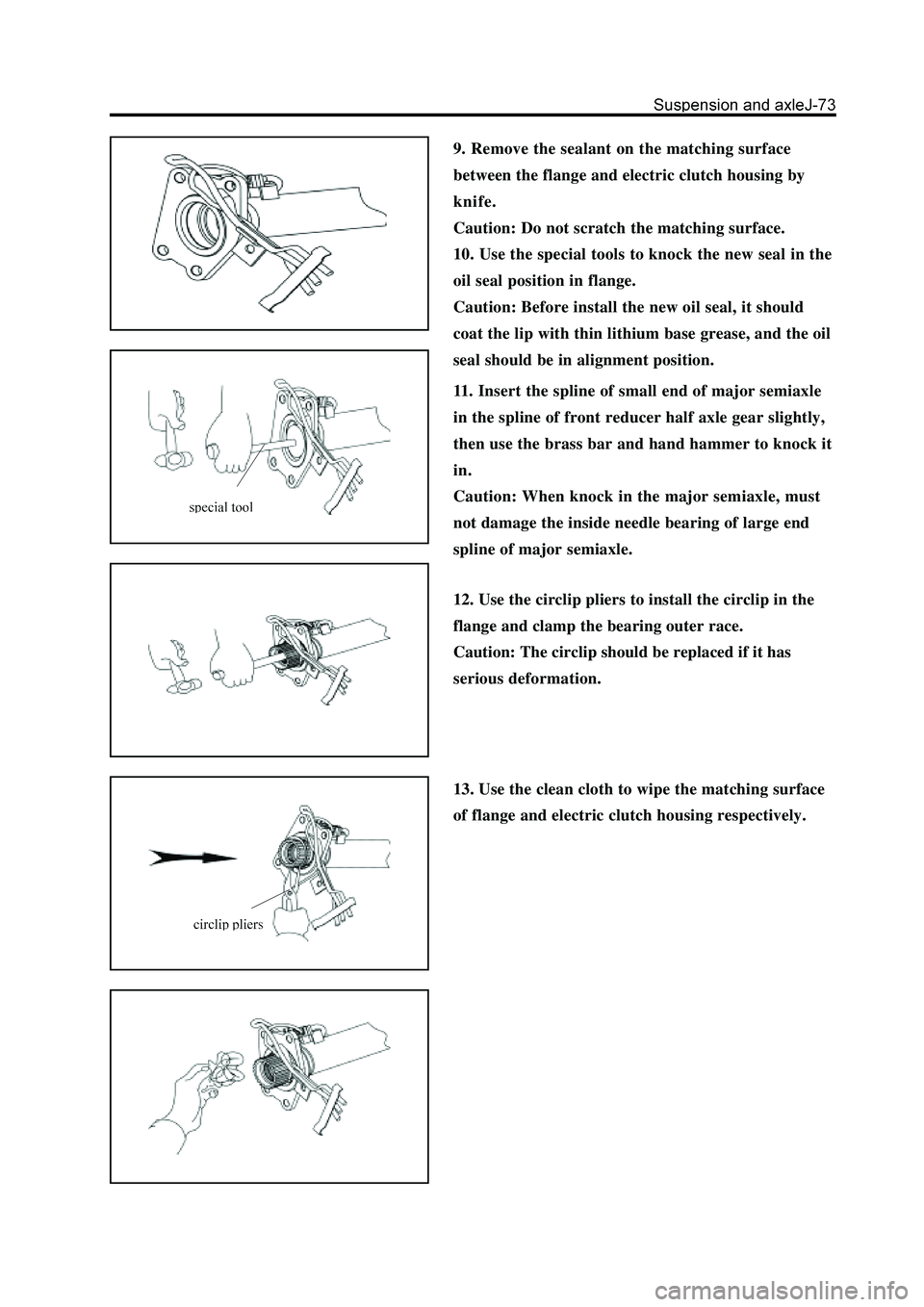

9. Remove the sealant on the matching surface

between the flange and electric clutch housing by

knife.

Caution: Do not scratch the matching surface.

10. Use the special tools to knock the new seal in the

oil seal position in flange.

Caution: Before install the new oil seal, it should

coat the lip with thin lithium base grease, and the oil

seal should be in alignment position.

11. Insert the spline of small end of major semiaxle

in the spline of front reducer half axle gear slightly,

then use the brass bar and hand hammer to knock it

in.

Caution: When knock in the major semiaxle, must

not damage the inside needle bearing of large end

spline of major semiaxle.

12. Use the circlip pliers to install the circlip in the

flange and clamp the bearing outer race.

Caution: The circlip should be replaced if it has

serious deformation.

13. Use the clean cloth to wipe the matching surface

of flange and electric clutch housing respectively.

Page 265 of 425

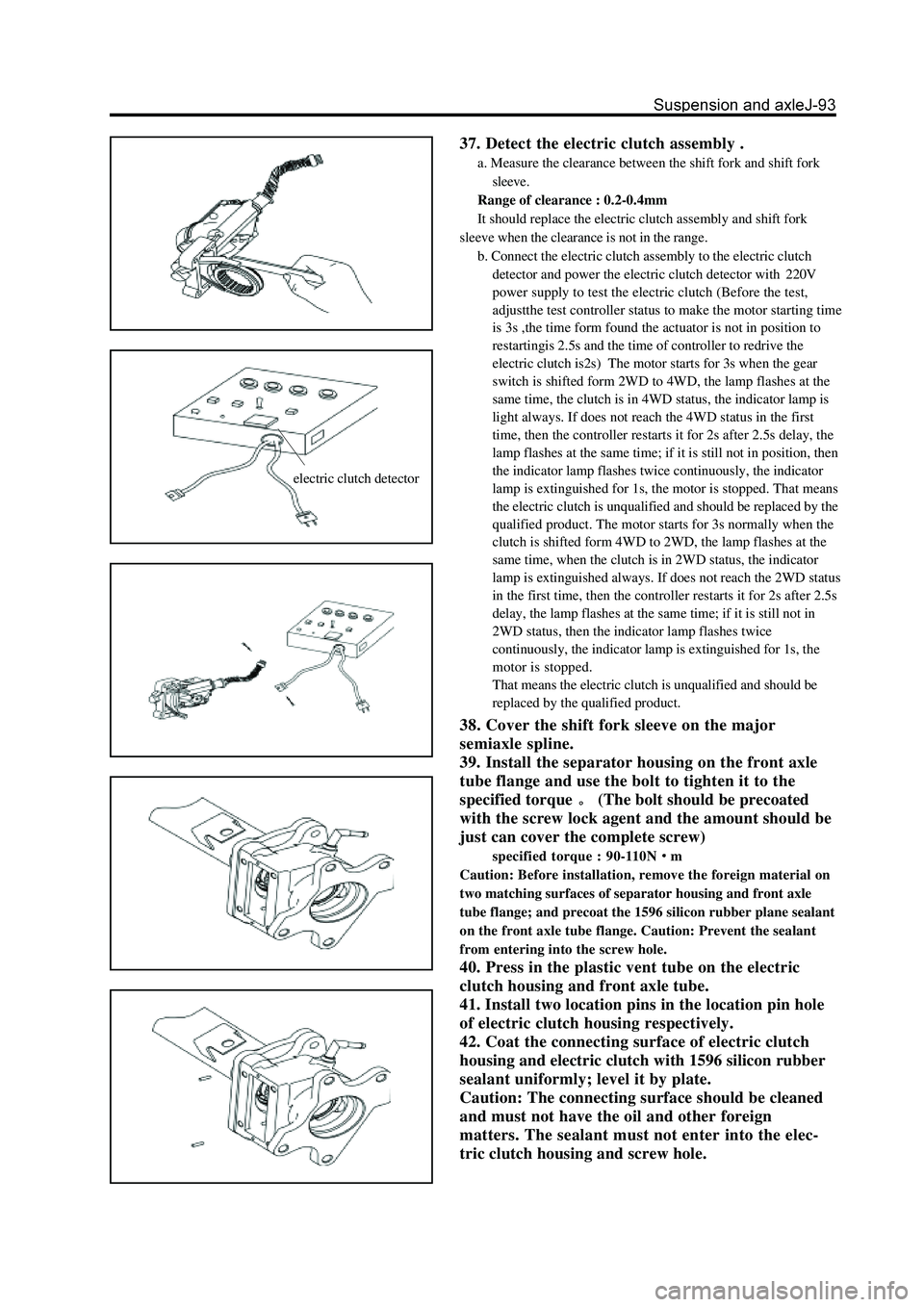

electric clutch detector

37. Detect the electric clutch assembly .

a. Measure the clearance between the shift fork and shift fork

sleeve.

Range of clearance : 0.2-0.4mm

It should replace the electric clutch assembly and shift fork

sleeve when the clearance is not in the range.

b. Connect the electric clutch assembly to the electric clutch

detector and power the electric clutch detector with220V

power supply to test the electric clutch (Before the test,

adjustthe test controller status to make the motor starting time

is 3s ,the time form found the actuator is not in position to

restartingis 2.5s and the time of controller to redrive the

electric clutch is2s) The motor starts for 3s when the gear

switch is shifted form 2WD to 4WD, the lamp flashes at the

same time, the clutch is in 4WD status, the indicator lamp is

light always. If does not reach the 4WD status in the first

time, then the controller restarts it for 2s after 2.5s delay, the

lamp flashes at the same time; if it is still not in position, then

the indicator lamp flashes twice continuously, the indicator

lamp is extinguished for 1s, the motor is stopped. That means

the electric clutch is unqualified and should be replaced by the

qualified product. The motor starts for 3s normally when the

clutch is shifted form 4WD to 2WD, the lamp flashes at the

same time, when the clutch is in 2WD status, the indicator

lamp is extinguished always. If does not reach the 2WD status

in the first time, then the controller restarts it for 2s after 2.5s

delay, the lamp flashes at the same time; if it is still not in

2WD status, then the indicator lamp flashes twice

continuously, the indicator lamp is extinguished for 1s, the

motor is stopped.

That means the electric clutch is unqualified and should be

replaced by the qualified product.

38. Cover the shift fork sleeve on the major

semiaxle spline.

39. Install the separator housing on the front axle

tube flange and use the bolt to tighten it to the

specified torque

(The bolt should be precoated

with the screw lock agent and the amount should be

just can cover the complete screw)

specified torque : 90-110Nm

Caution: Before installation, remove the foreign material on

two matching surfaces of separator housing and front axle

tube flange; and precoat the 1596 silicon rubber plane sealant

on the front axle tube flange. Caution: Prevent the sealant

from entering into the screw hole.

40. Press in the plastic vent tube on the electric

clutch housing and front axle tube.

41. Install two location pins in the location pin hole

of electric clutch housing respectively.

42. Coat the connecting surface of electric clutch

housing and electric clutch with 1596 silicon rubber

sealant uniformly; level it by plate.

Caution: The connecting surface should be cleaned

and must not have the oil and other foreign

matters. The sealant must not enter into the elec-

tric clutch housing and screw hole.

Page 291 of 425

Brake-5

Check and adjustment

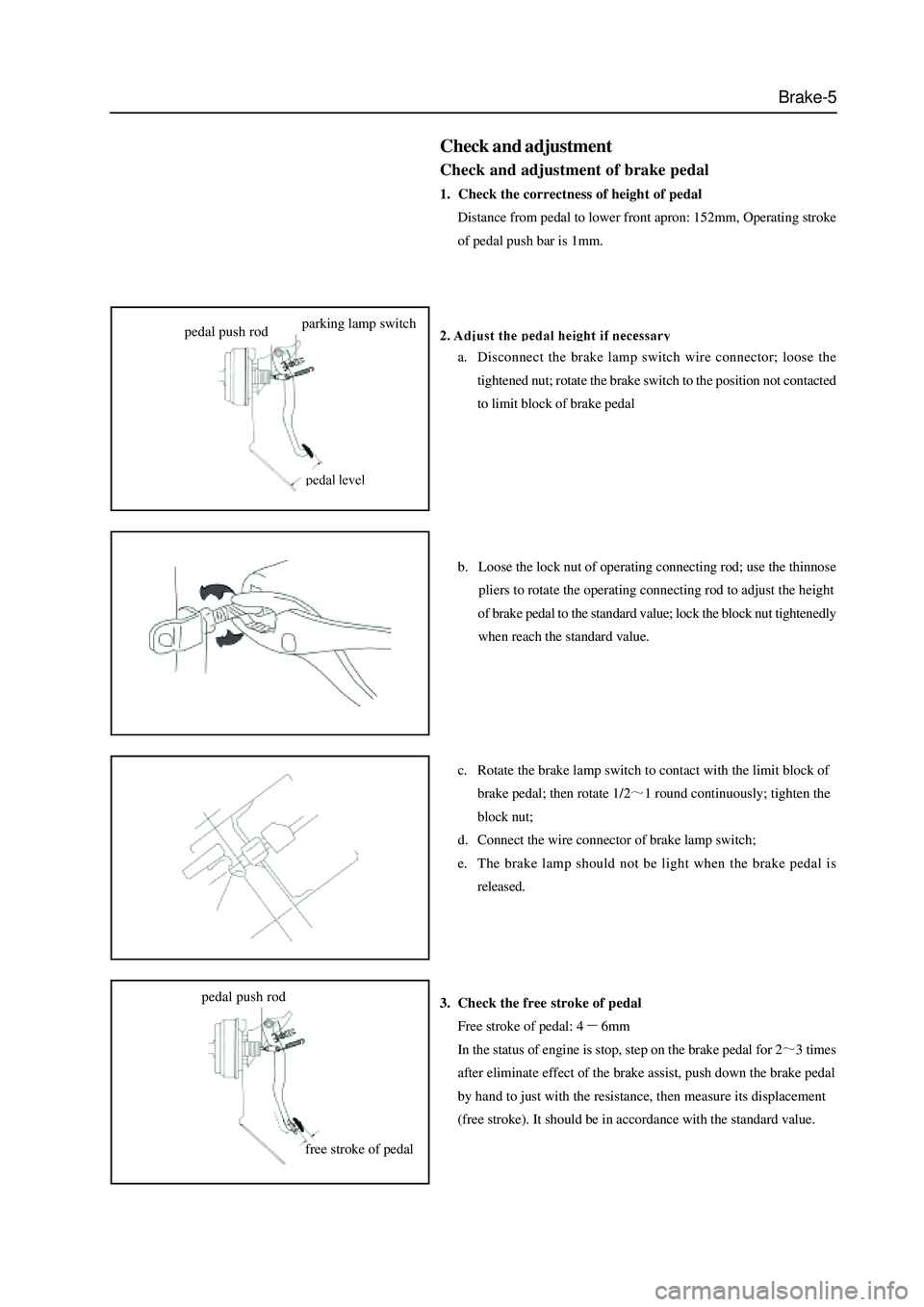

Check and adjustment of brake pedal

1. Check the correctness of height of pedal

Distance from pedal to lower front apron: 152mm, Operating stroke

of pedal push bar is 1mm.

a. Disconnect the brake lamp switch wire connector; loose the

tightened nut; rotate the brake switch to the position not contacted

to limit block of brake pedal

b. Loose the lock nut of operating connecting rod; use the thinnose

pliers to rotate the operating connecting rod to adjust the height

of brake pedal to the standard value; lock the block nut tightenedly

when reach the standard value.

c. Rotate the brake lamp switch to contact with the limit block of

brake pedal; then rotate 1/2

1 round continuously; tighten the

block nut;

d. Connect the wire connector of brake lamp switch;

e. The brake lamp should not be light when the brake pedal is

released.

3. Check the free stroke of pedal

Free stroke of pedal: 4

6mm

In the status of engine is stop, step on the brake pedal for 2

3 times

after eliminate effect of the brake assist, push down the brake pedal

by hand to just with the resistance, then measure its displacement

(free stroke). It should be in accordance with the standard value.

pedal push rodparking lamp switch

free stroke of pedal pedal push rod