GREAT WALL HOVER 2006 Service Repair Manual

Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 301 of 425

Brake-15

Installation of brake caliper

1. Install the brake block

2. Install the brake pump

a. Install the brake pump.

b. Install and tighten the hexagon flange bolt.

Tightening force: 25

35Nm

3. Connect the brake pipeline

Connect the brake oil pipe to the tong body.

Tightening force: 50

5Nm

4. Fill up the brake liquid reservoir with the brake fluid and dis

charge the air in brake system.

5. Check for the leakage of brake fluid.

Caution: Discharge the air after the completion of replacement.

Page 302 of 425

Brake-16

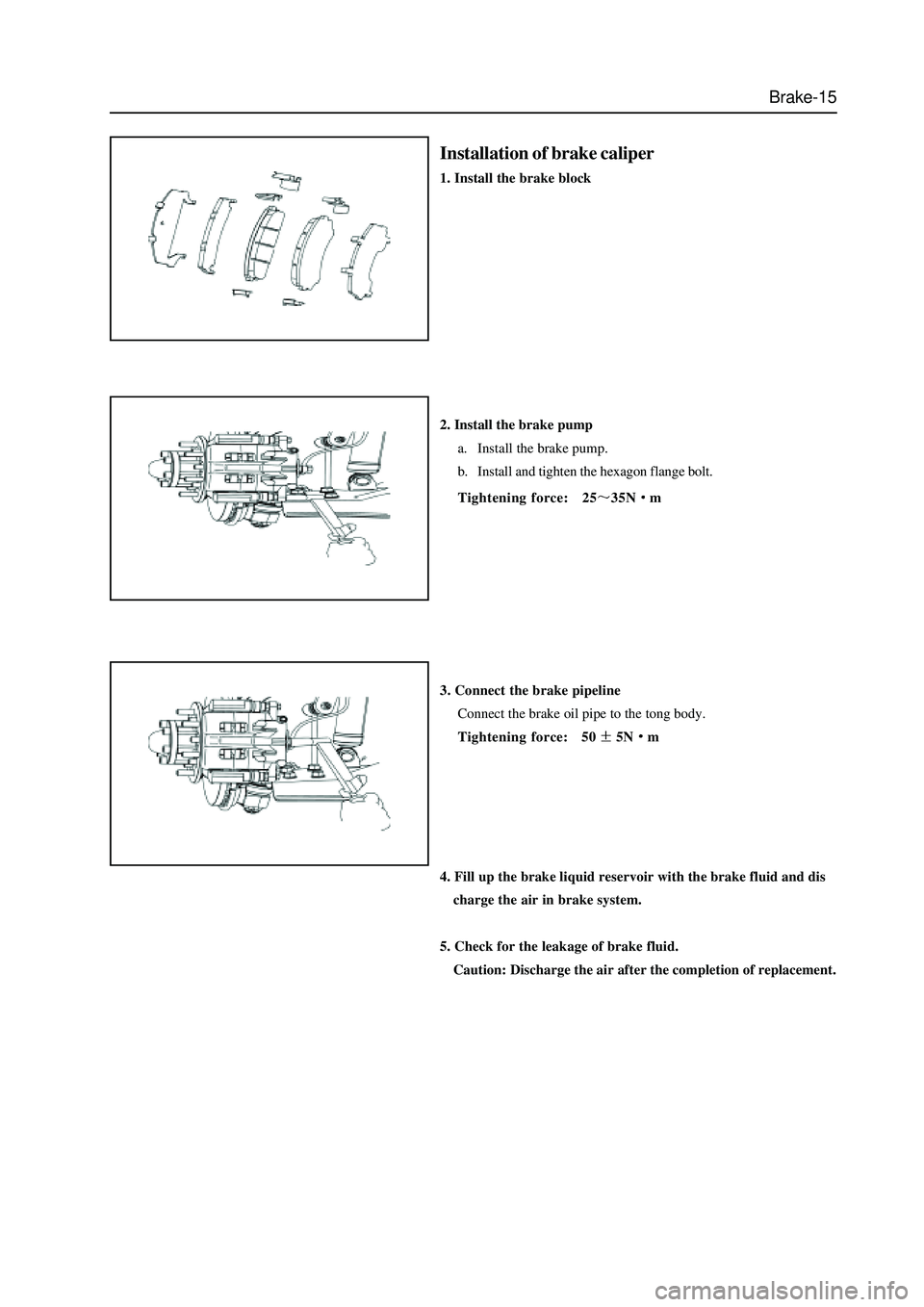

Rear brake (Disk-and-drum type)

tong bracket

pin rubber cover

brake caliper locking bolt 100

silencing plate

combination

outside brake block

inside brake block

brake block wearing

indication plate

cylinder hole

dustproof cover

wire clip

rectangle seal ring

piston

tong body (left)

copper washer

brake oil pipe fastening blot 55

location pin 2530

bleed screw

bleed screw dustproof cover

guide pin 2530

rear brake oil pipeline

N

m: specified torque

peepholesilencing

plate

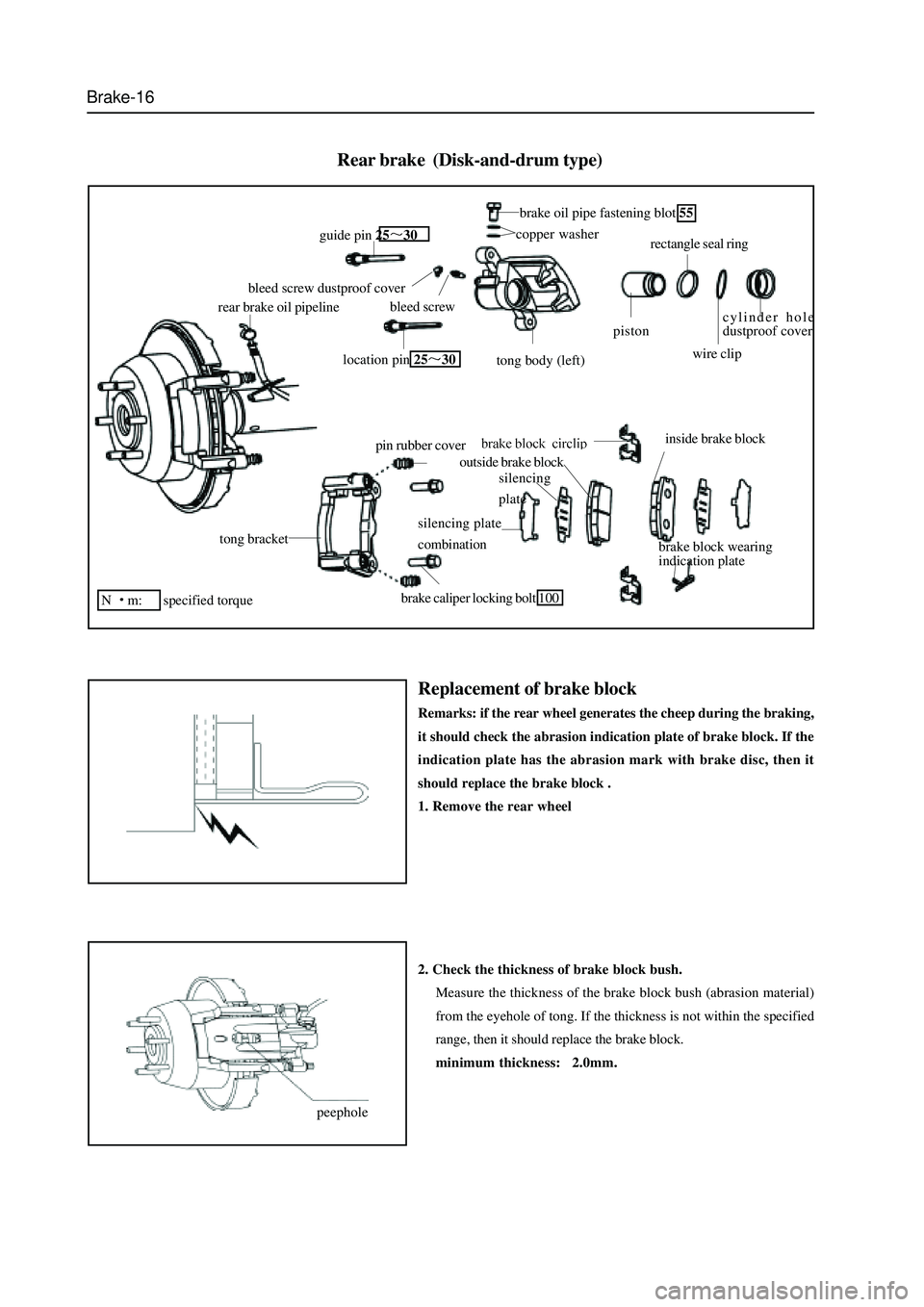

Replacement of brake block

Remarks: if the rear wheel generates the cheep during the braking,

it should check the abrasion indication plate of brake block. If the

indication plate has the abrasion mark with brake disc, then it

should replace the brake block .

1. Remove the rear wheel

2. Check the thickness of brake block bush.

Measure the thickness of the brake block bush (abrasion material)

from the eyehole of tong. If the thickness is not within the specified

range, then it should replace the brake block.

minimum thickness: 2.0mm.

Page 303 of 425

Brake-17

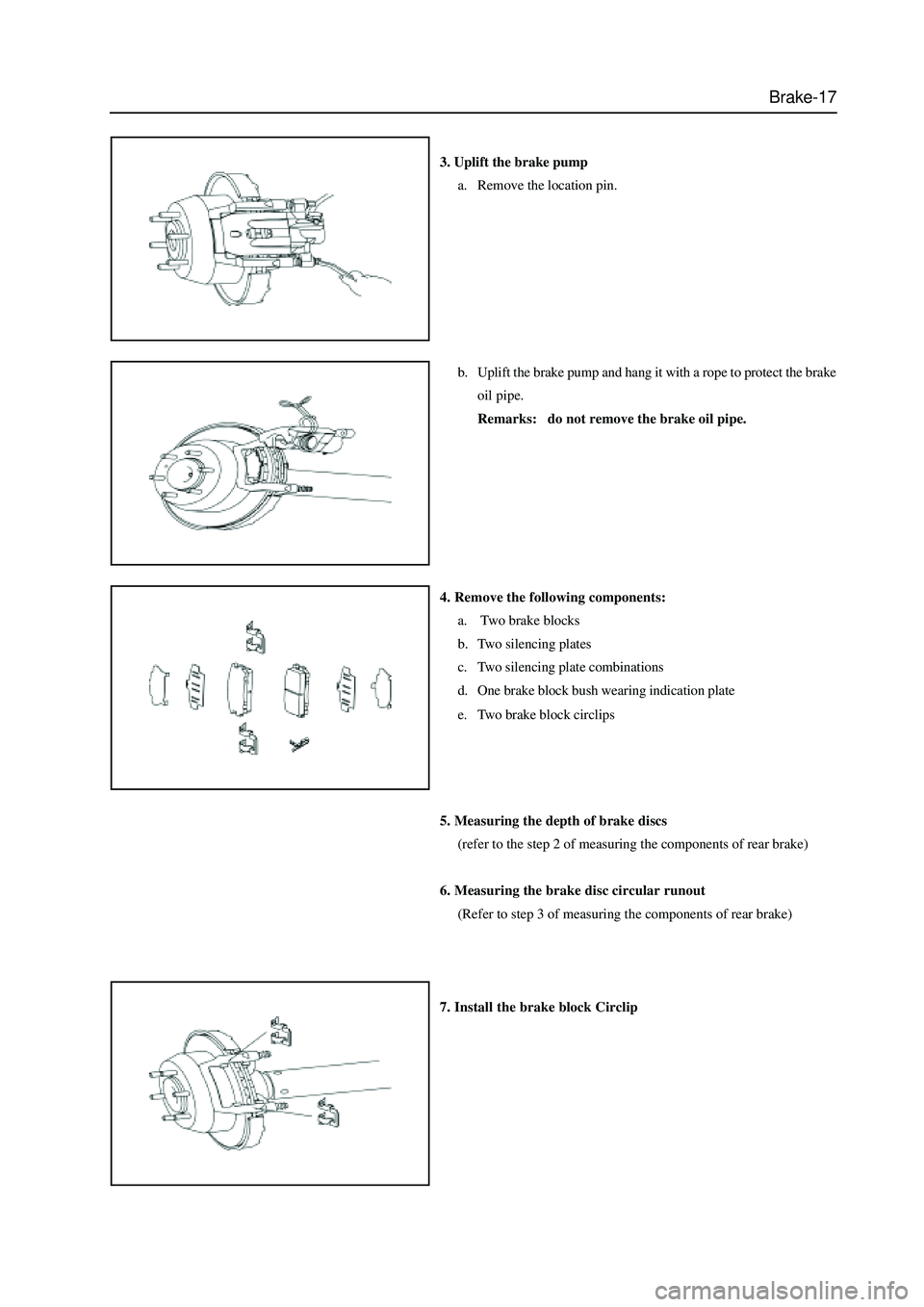

3. Uplift the brake pump

a. Remove the location pin.

b. Uplift the brake pump and hang it with a rope to protect the brake

oil pipe.

Remarks: do not remove the brake oil pipe.

4. Remove the following components:

a. Two brake blocks

b. Two silencing plates

c. Two silencing plate combinations

d. One brake block bush wearing indication plate

e. Two brake block circlips

5. Measuring the depth of brake discs

(refer to the step 2 of measuring the components of rear brake)

6. Measuring the brake disc circular runout

(Refer to step 3 of measuring the components of rear brake)

7. Install the brake block Circlip

Page 304 of 425

Brake-18

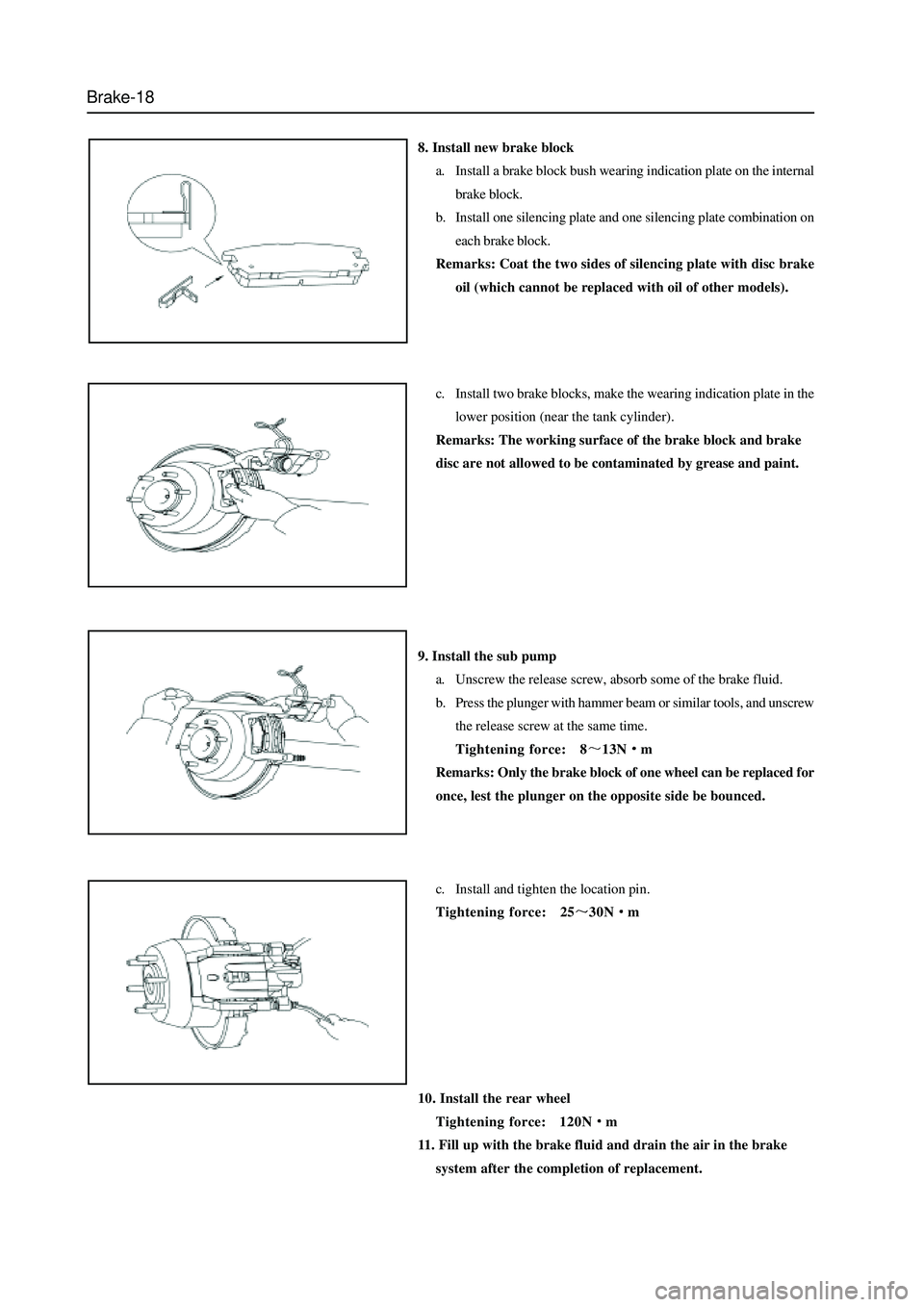

8. Install new brake block

a. Install a brake block bush wearing indication plate on the internal

brake block.

b. Install one silencing plate and one silencing plate combination on

each brake block.

Remarks: Coat the two sides of silencing plate with disc brake

oil (which cannot be replaced with oil of other models).

c. Install two brake blocks, make the wearing indication plate in the

lower position (near the tank cylinder).

Remarks: The working surface of the brake block and brake

disc are not allowed to be contaminated by grease and paint.

9. Install the sub pump

a. Unscrew the release screw, absorb some of the brake fluid.

b. Press the plunger with hammer beam or similar tools, and unscrew

the release screw at the same time.

Tightening force: 8

13Nm

Remarks: Only the brake block of one wheel can be replaced for

once, lest the plunger on the opposite side be bounced.

c. Install and tighten the location pin.

Tightening force: 25

30Nm

10. Install the rear wheel

Tightening force: 120N

m

11. Fill up with the brake fluid and drain the air in the brake

system after the completion of replacement.

Page 305 of 425

Brake-19

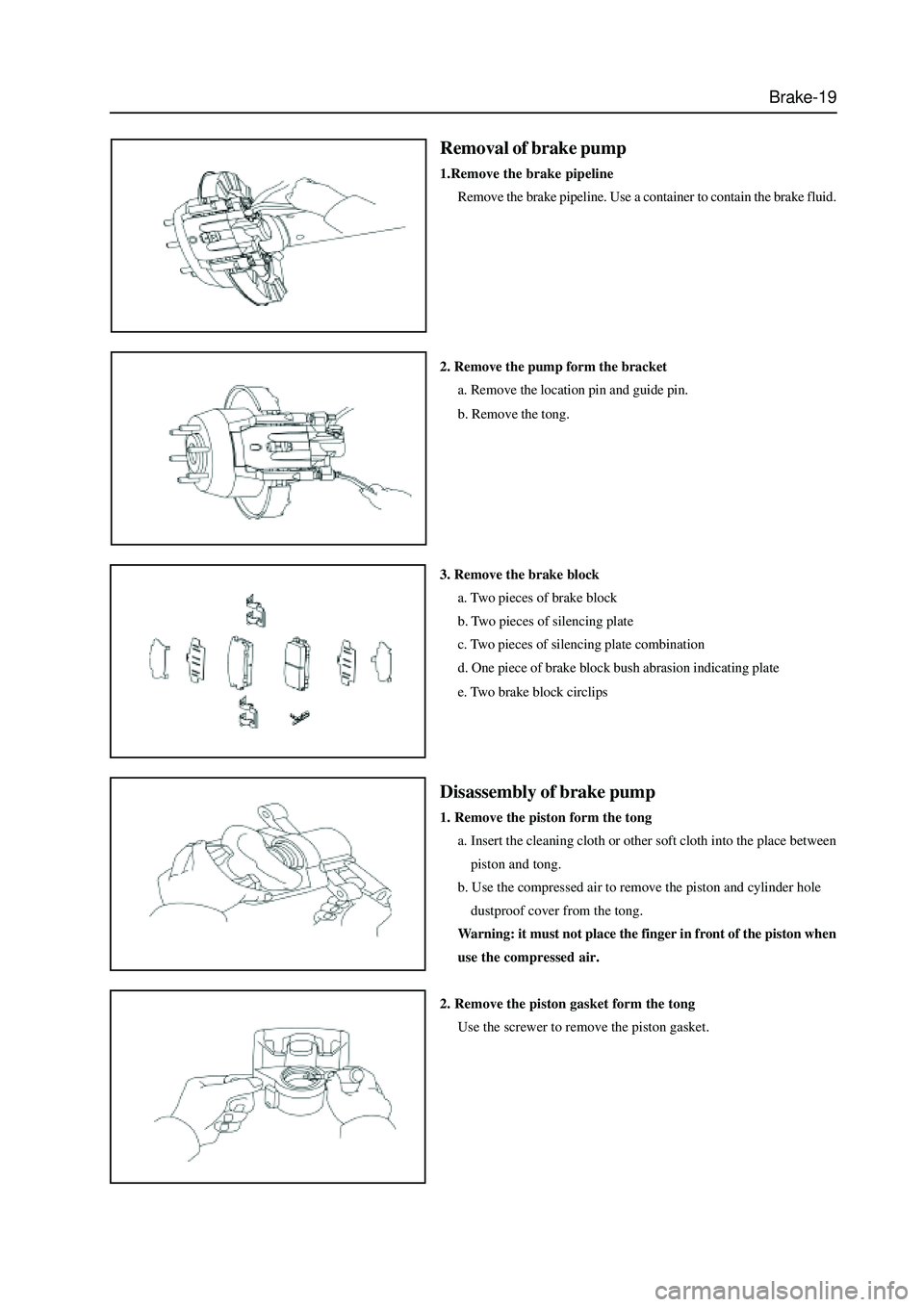

Removal of brake pump

1.Remove the brake pipeline

Remove the brake pipeline. Use a container to contain the brake fluid.

2. Remove the pump form the bracket

a. Remove the location pin and guide pin.

b. Remove the tong.

3. Remove the brake block

a. Two pieces of brake block

b. Two pieces of silencing plate

c. Two pieces of silencing plate combination

d. One piece of brake block bush abrasion indicating plate

e. Two brake block circlips

Disassembly of brake pump

1. Remove the piston form the tong

a. Insert the cleaning cloth or other soft cloth into the place between

piston and tong.

b. Use the compressed air to remove the piston and cylinder hole

dustproof cover from the tong.

Warning: it must not place the finger in front of the piston when

use the compressed air.

2. Remove the piston gasket form the tong

Use the screwer to remove the piston gasket.

Page 306 of 425

Brake-20

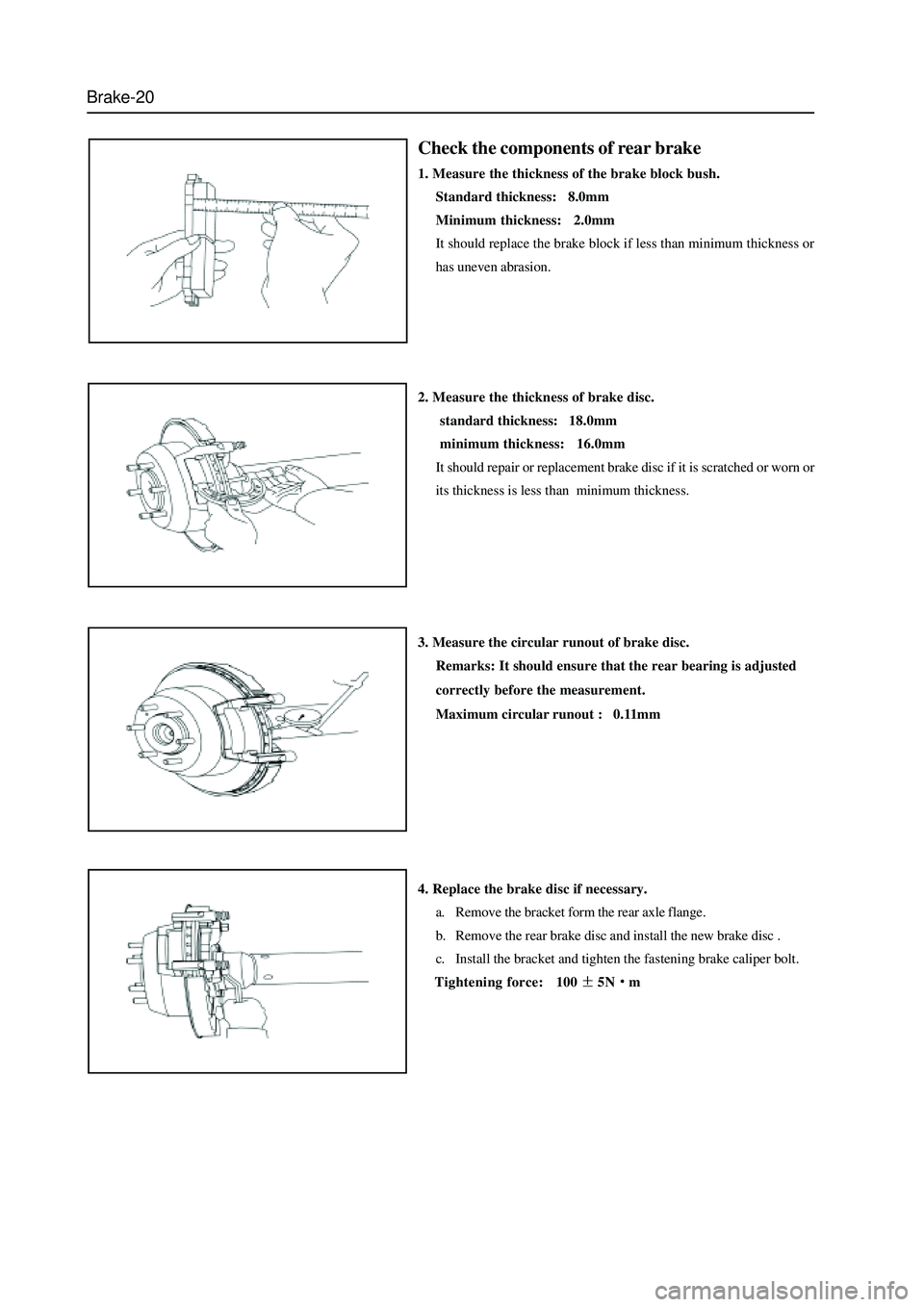

Check the components of rear brake

1. Measure the thickness of the brake block bush.

Standard thickness: 8.0mm

Minimum thickness: 2.0mm

It should replace the brake block if less than minimum thickness or

has uneven abrasion.

2. Measure the thickness of brake disc.

standard thickness: 18.0mm

minimum thickness: 16.0mm

It should repair or replacement brake disc if it is scratched or worn or

its thickness is less than minimum thickness.

3. Measure the circular runout of brake disc.

Remarks: It should ensure that the rear bearing is adjusted

correctly before the measurement.

Maximum circular runout : 0.11mm

4. Replace the brake disc if necessary.

a. Remove the bracket form the rear axle flange.

b. Remove the rear brake disc and install the new brake disc .

c. Install the bracket and tighten the fastening brake caliper bolt.

Tightening force: 100

5Nm

Page 307 of 425

Brake-21

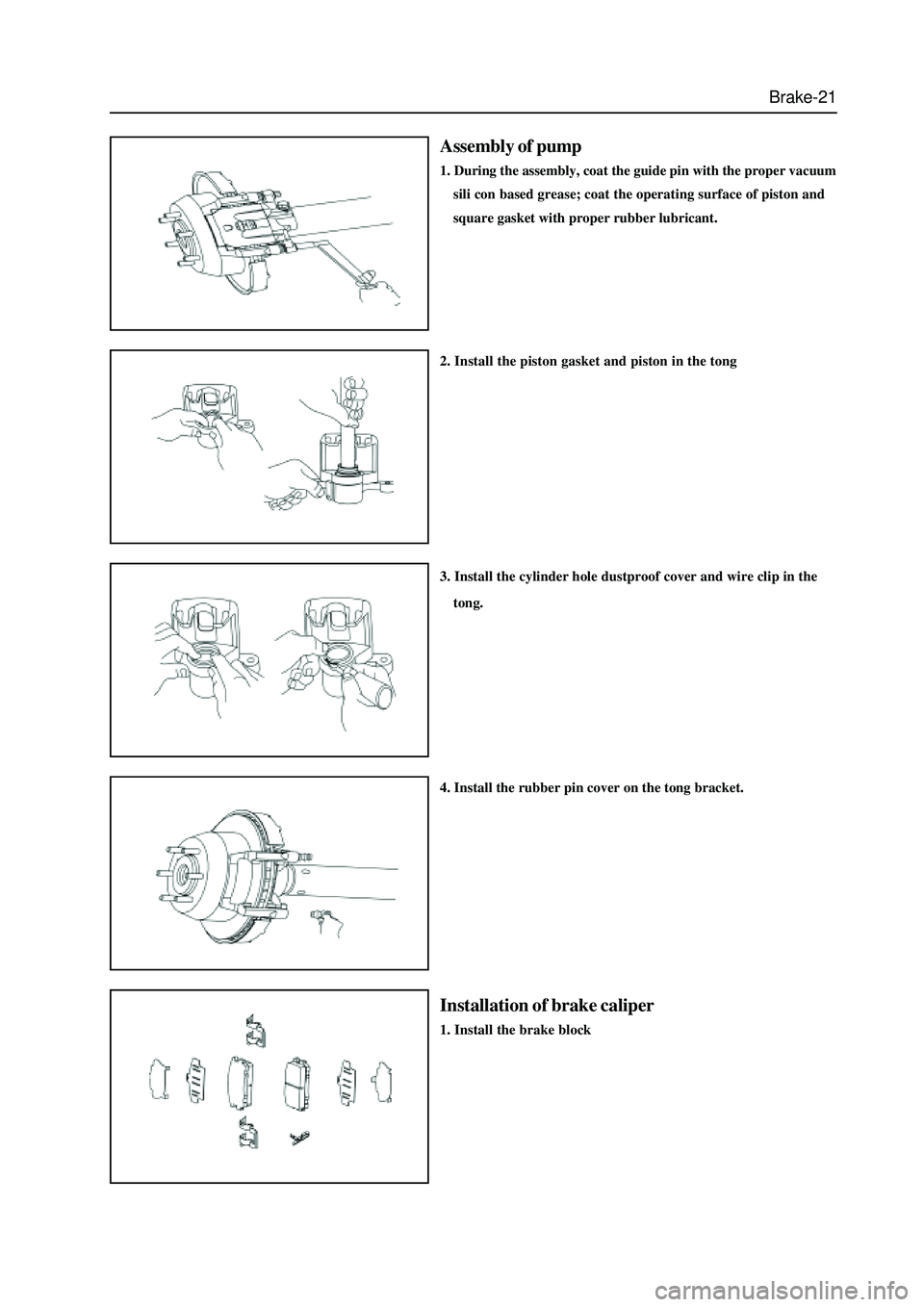

Assembly of pump

1. During the assembly, coat the guide pin with the proper vacuum

sili con based grease; coat the operating surface of piston and

square gasket with proper rubber lubricant.

2. Install the piston gasket and piston in the tong

3. Install the cylinder hole dustproof cover and wire clip in the

tong.

4. Install the rubber pin cover on the tong bracket.

Installation of brake caliper

1. Install the brake block

Page 308 of 425

Brake-22

2. Install the piston gasket in the tong body.

a. Screw the bleed screw into the bleed hole;

b. Install the square gasket in the sealing groove of two cylinders of

pump respectively after coat its working surface with proper

rubber lubricant.

Tightening torque 7

10Nm.

3. Connect the brake pipeline

Connect the brake oil pipe to the tong.

Tightening force: 50

5Nm

4. Fill up the brake system with the brake fluid and drain the air

in the brake system.

5. Check for leakage of brake fluid.

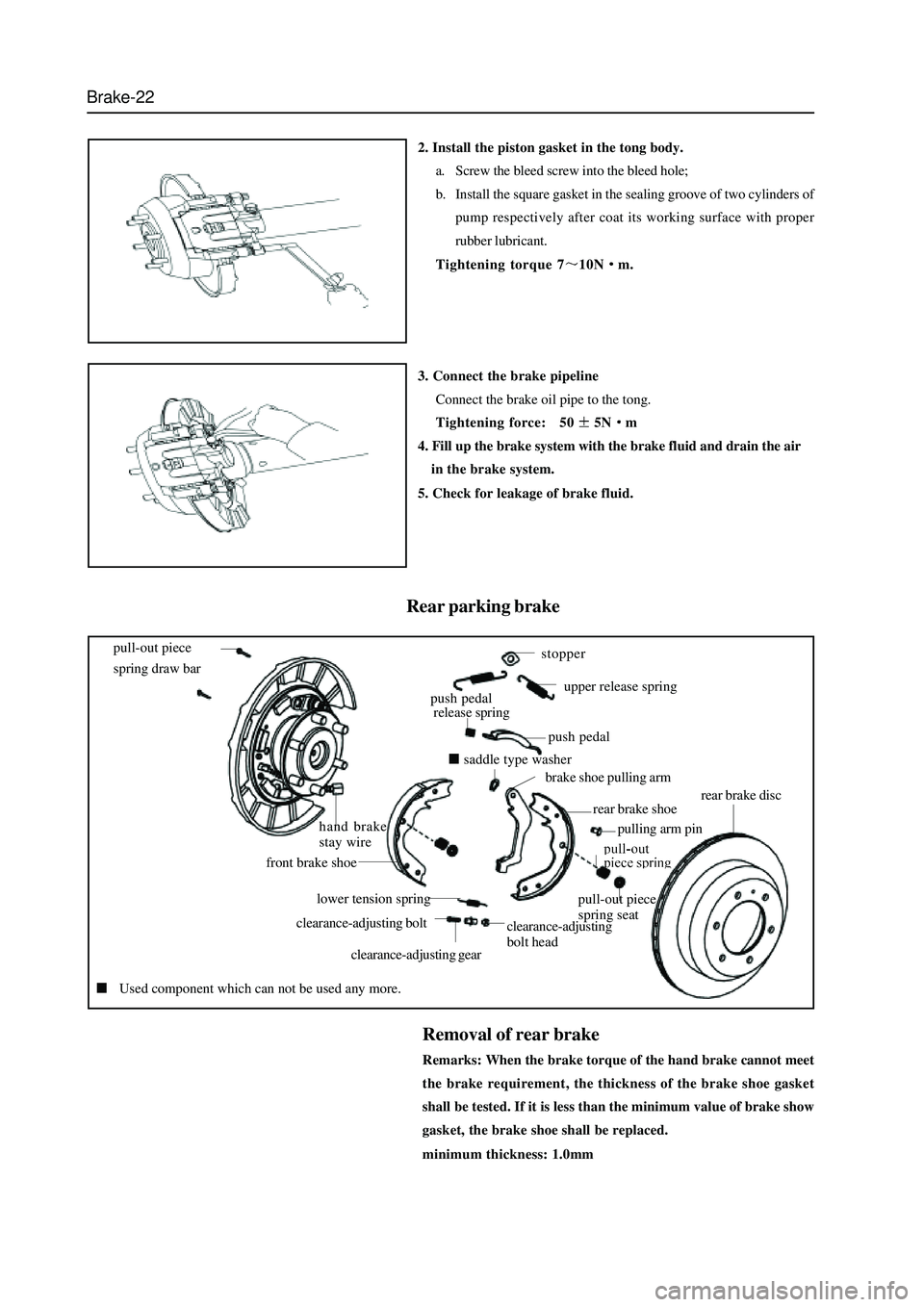

Rear parking brake

pull-out piece

spring draw bar

hand brake

stay wire

front brake shoe

lower tension spring

clearance-adjusting bolt

clearance-adjusting gear

clearance-adjusting

bolt head

pull-out piece

spring seat

pulling arm pin

rear brake shoe

brake shoe pulling arm

saddle type washer

push pedal

push pedal

release spring

stopper

upper release spring

rear brake disc

Used component which can not be used any more.

Removal of rear brake

Remarks: When the brake torque of the hand brake cannot meet

the brake requirement, the thickness of the brake shoe gasket

shall be tested. If it is less than the minimum value of brake show

gasket, the brake shoe shall be replaced.

minimum thickness: 1.0mm

Page 309 of 425

Brake-23

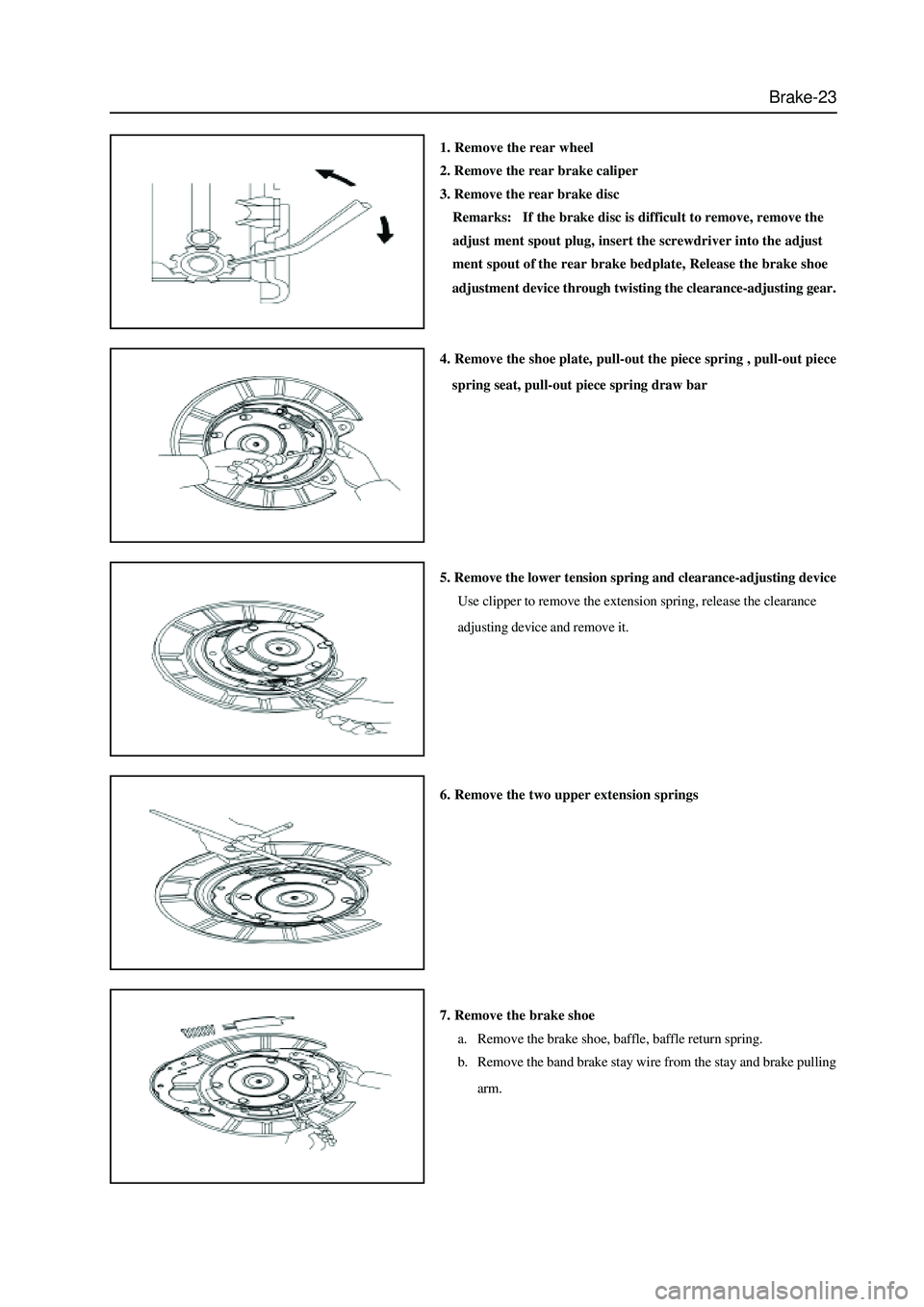

1. Remove the rear wheel

2. Remove the rear brake caliper

3. Remove the rear brake disc

Remarks: If the brake disc is difficult to remove, remove the

adjust ment spout plug, insert the screwdriver into the adjust

ment spout of the rear brake bedplate, Release the brake shoe

adjustment device through twisting the clearance-adjusting gear.

4. Remove the shoe plate, pull-out the piece spring , pull-out piece

spring seat, pull-out piece spring draw bar

5. Remove the lower tension spring and clearance-adjusting device

Use clipper to remove the extension spring, release the clearance

adjusting device and remove it.

6. Remove the two upper extension springs

7. Remove the brake shoe

a. Remove the brake shoe, baffle, baffle return spring.

b. Remove the band brake stay wire from the stay and brake pulling

arm.

Page 310 of 425

Brake-24

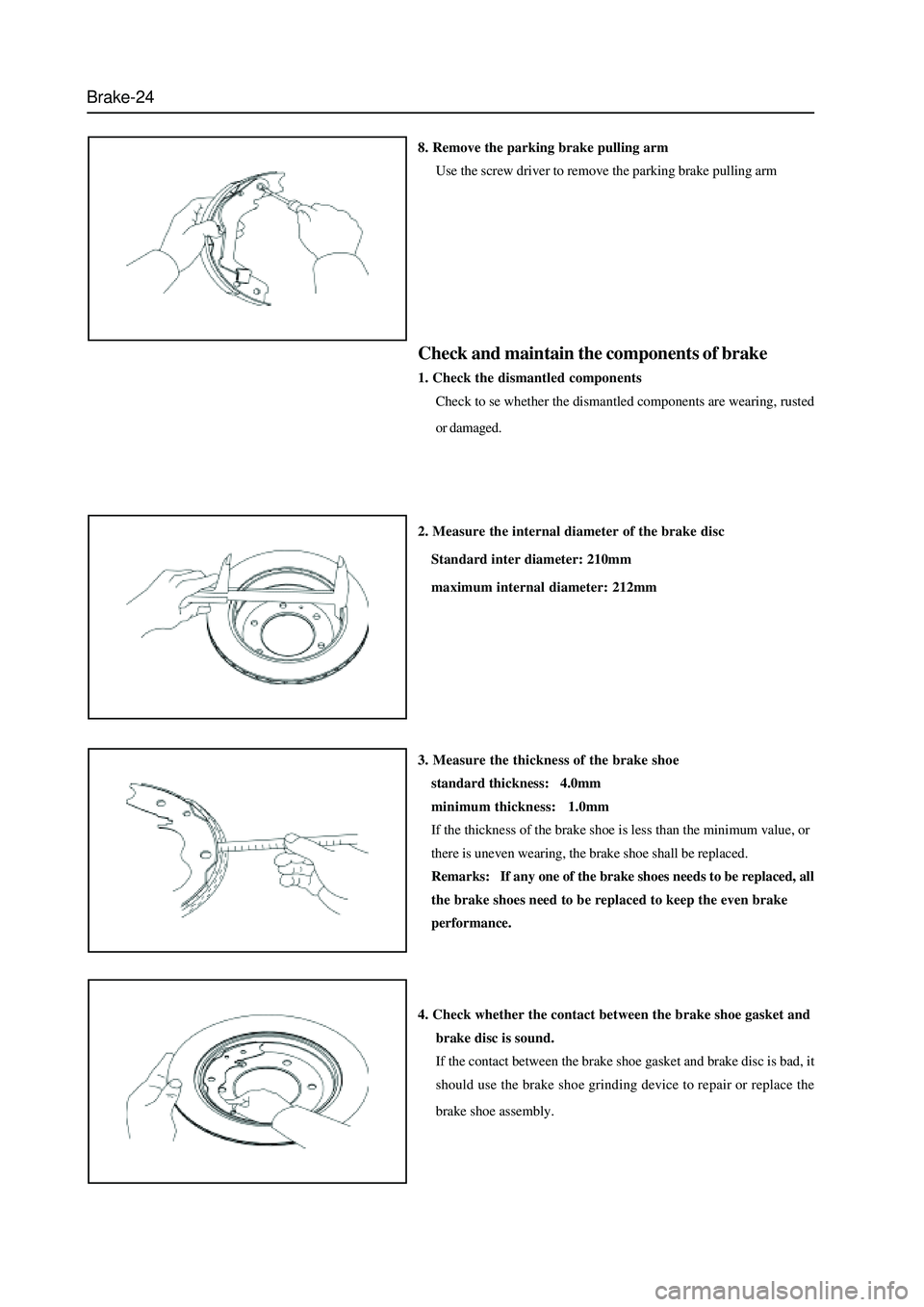

8. Remove the parking brake pulling arm

Use the screw driver to remove the parking brake pulling arm

Check and maintain the components of brake

1. Check the dismantled components

Check to se whether the dismantled components are wearing, rusted

or damaged.

2. Measure the internal diameter of the brake disc

Standard inter diameter: 210mm

maximum internal diameter: 212mm

3. Measure the thickness of the brake shoe

standard thickness: 4.0mm

minimum thickness: 1.0mm

If the thickness of the brake shoe is less than the minimum value, or

there is uneven wearing, the brake shoe shall be replaced.

Remarks: If any one of the brake shoes needs to be replaced, all

the brake shoes need to be replaced to keep the even brake

performance.

4. Check whether the contact between the brake shoe gasket and

brake disc is sound.

If the contact between the brake shoe gasket and brake disc is bad, it

should use the brake shoe grinding device to repair or replace the

brake shoe assembly.