GREAT WALL HOVER 2006 Service Repair Manual

Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 311 of 425

Brake-25

1. Install the clearance-adjusting device assembly

Insert the clearance-adjusting shaft head into the clearance-adjusting

wheel; screw the clearance-adjusting screw rod into the clearance

adjusting wheel.

Remarks:The screw direction of left clearance-adjusting screw

rod is the left hand.

The screw direction of right clearance-adjusting

screw rod is the right hand.

2. Coat the following components with the proper anti-high tem

perature grease :

a. Contact position of brake soleplate and brake shoe.

b. Contacting surface of push plate and shoe plate; contacting sur-

face of clearance-adjusting device assembly and shoe plate.

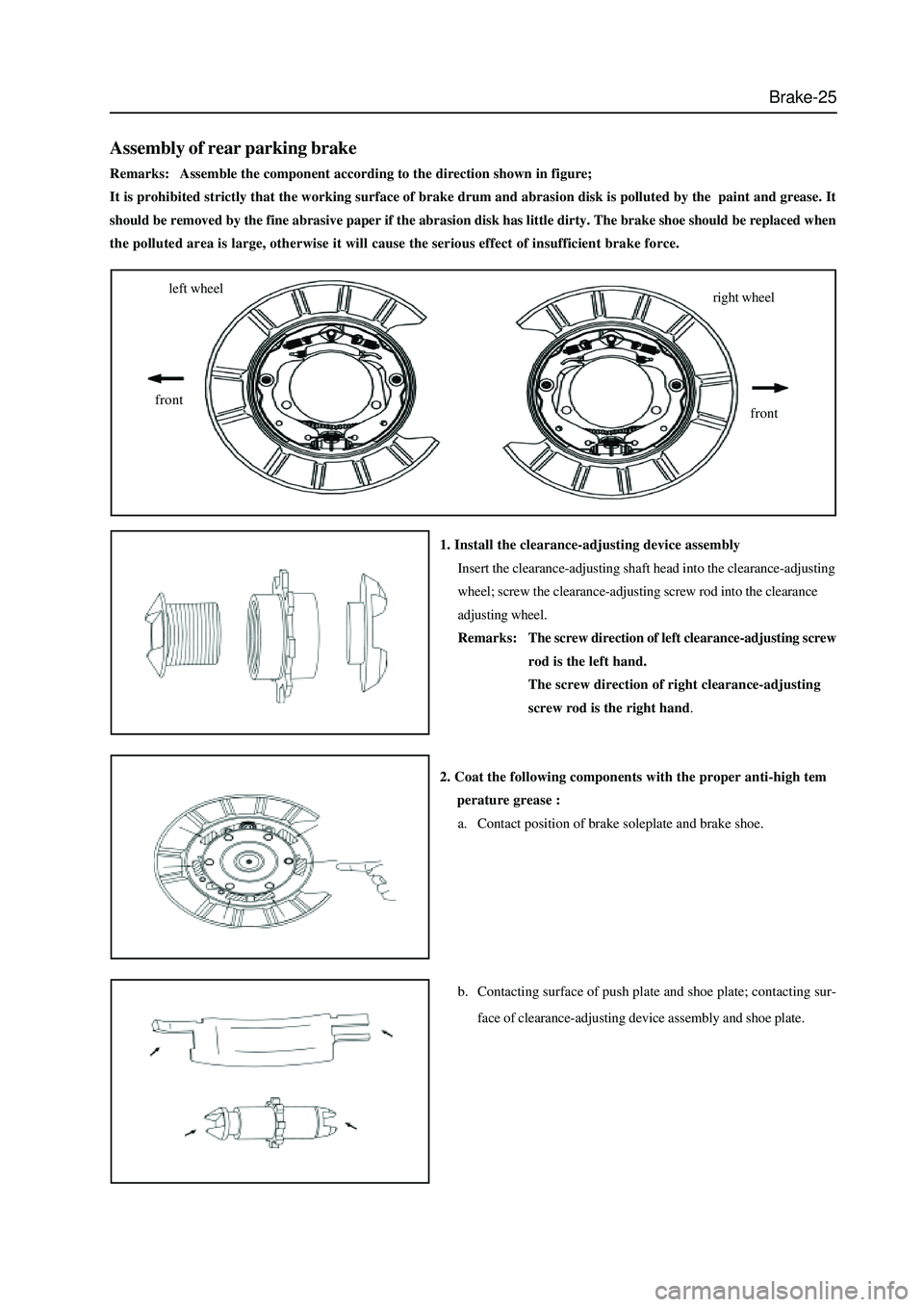

Assembly of rear parking brake

Remarks: Assemble the component according to the direction shown in figure;

It is prohibited strictly that the working surface of brake drum and abrasion disk is polluted by the paint and grease. It

should be removed by the fine abrasive paper if the abrasion disk has little dirty. The brake shoe should be replaced when

the polluted area is large, otherwise it will cause the serious effect of insufficient brake force.

left wheel

frontright wheel

front

Page 312 of 425

Brake-26

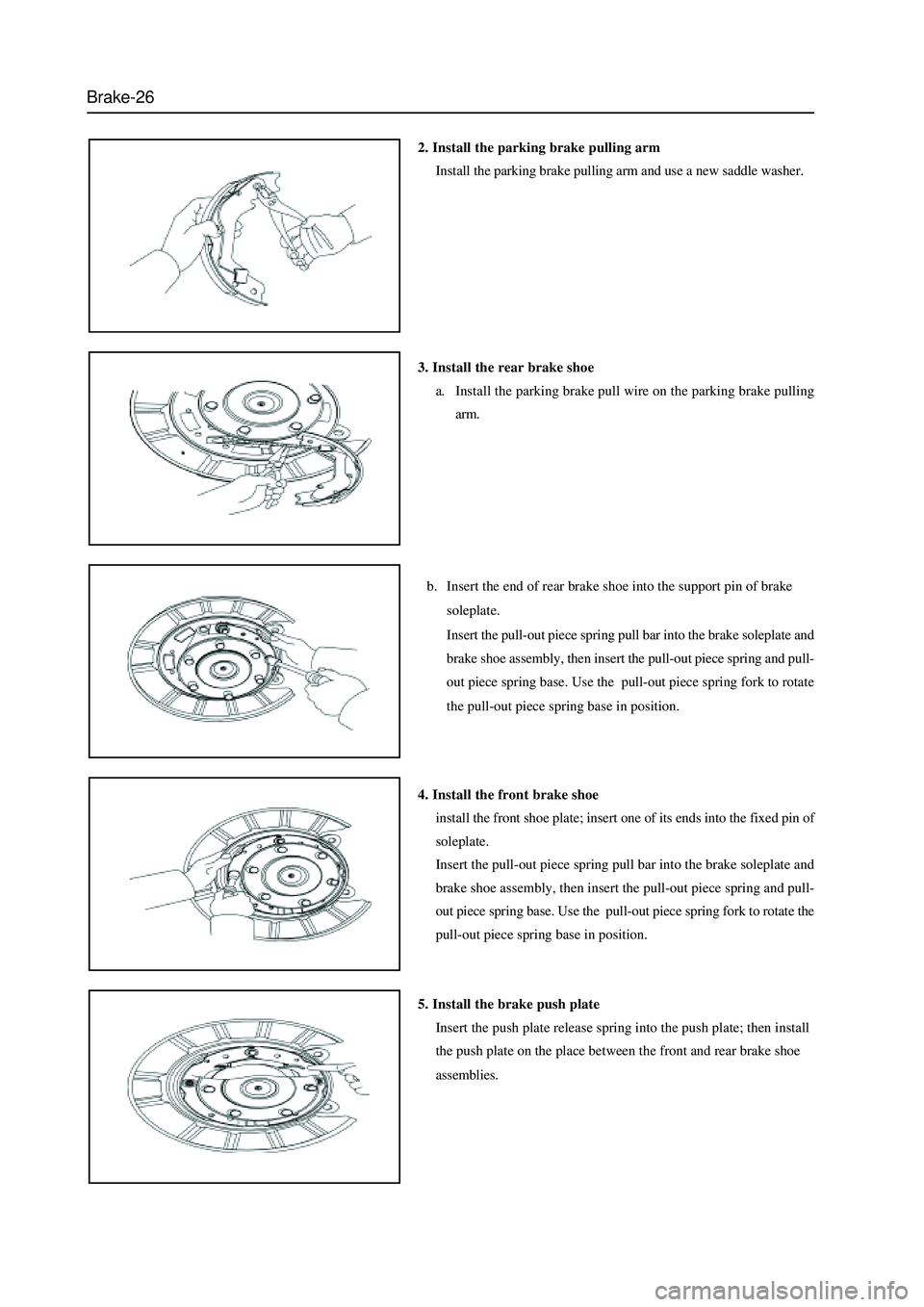

2. Install the parking brake pulling arm

Install the parking brake pulling arm and use a new saddle washer.

3. Install the rear brake shoe

a. Install the parking brake pull wire on the parking brake pulling

arm.

b. Insert the end of rear brake shoe into the support pin of brake

soleplate.

Insert the pull-out piece spring pull bar into the brake soleplate and

brake shoe assembly, then insert the pull-out piece spring and pull-

out piece spring base. Use the pull-out piece spring fork to rotate

the pull-out piece spring base in position.

4. Install the front brake shoe

install the front shoe plate; insert one of its ends into the fixed pin of

soleplate.

Insert the pull-out piece spring pull bar into the brake soleplate and

brake shoe assembly, then insert the pull-out piece spring and pull-

out piece spring base. Use the pull-out piece spring fork to rotate the

pull-out piece spring base in position.

5. Install the brake push plate

Insert the push plate release spring into the push plate; then install

the push plate on the place between the front and rear brake shoe

assemblies.

Page 313 of 425

Brake-27

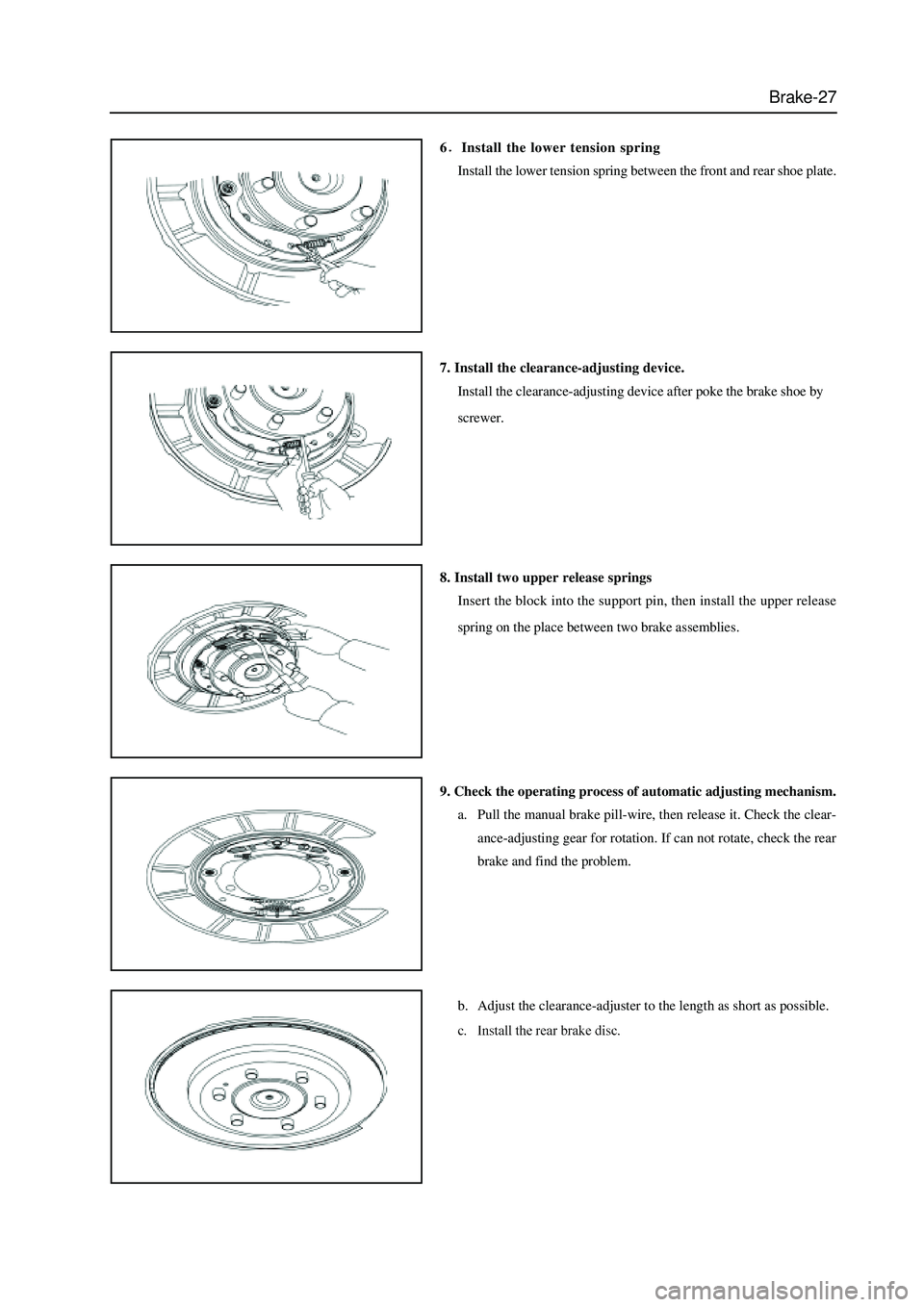

6Install the lower tension spring

Install the lower tension spring between the front and rear shoe plate.

7. Install the clearance-adjusting device.

Install the clearance-adjusting device after poke the brake shoe by

screwer.

8. Install two upper release springs

Insert the block into the support pin, then install the upper release

spring on the place between two brake assemblies.

9. Check the operating process of automatic adjusting mechanism.

a. Pull the manual brake pill-wire, then release it. Check the clear-

ance-adjusting gear for rotation. If can not rotate, check the rear

brake and find the problem.

b. Adjust the clearance-adjuster to the length as short as possible.

Page 314 of 425

Brake-28

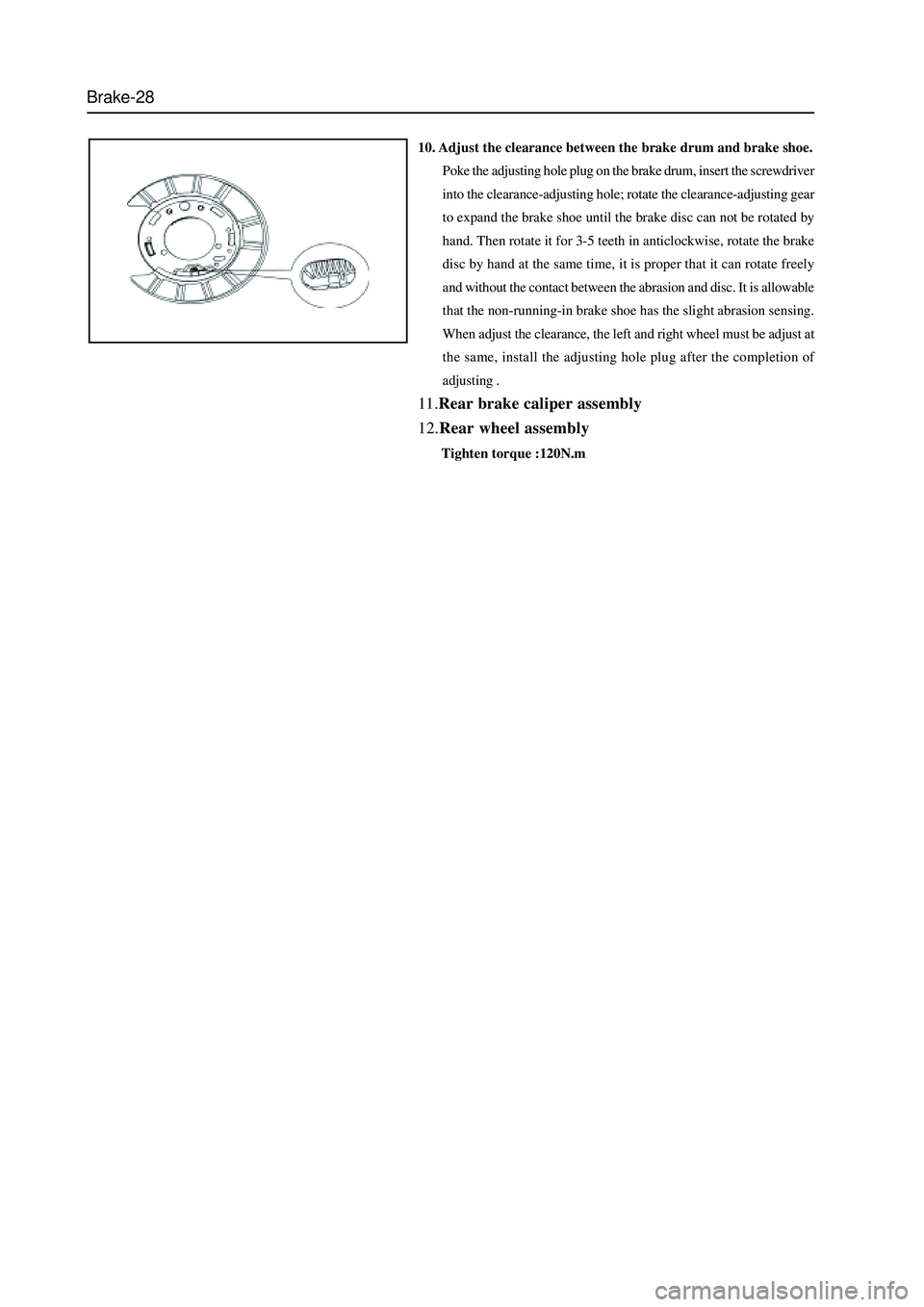

10. Adjust the clearance between the brake drum and brake shoe.

Poke the adjusting hole plug on the brake drum, insert the screwdriver

into the clearance-adjusting hole; rotate the clearance-adjusting gear

to expand the brake shoe until the brake disc can not be rotated by

hand. Then rotate it for 3-5 teeth in anticlockwise, rotate the brake

disc by hand at the same time, it is proper that it can rotate freely

and without the contact between the abrasion and disc. It is allowable

that the non-running-in brake shoe has the slight abrasion sensing.

When adjust the clearance, the left and right wheel must be adjust at

the same, install the adjusting hole plug after the completion of

adjusting .

11.Rear brake caliper assembly

12.Rear wheel assembly

Tighten torque :120N.m

Page 315 of 425

Brake-29

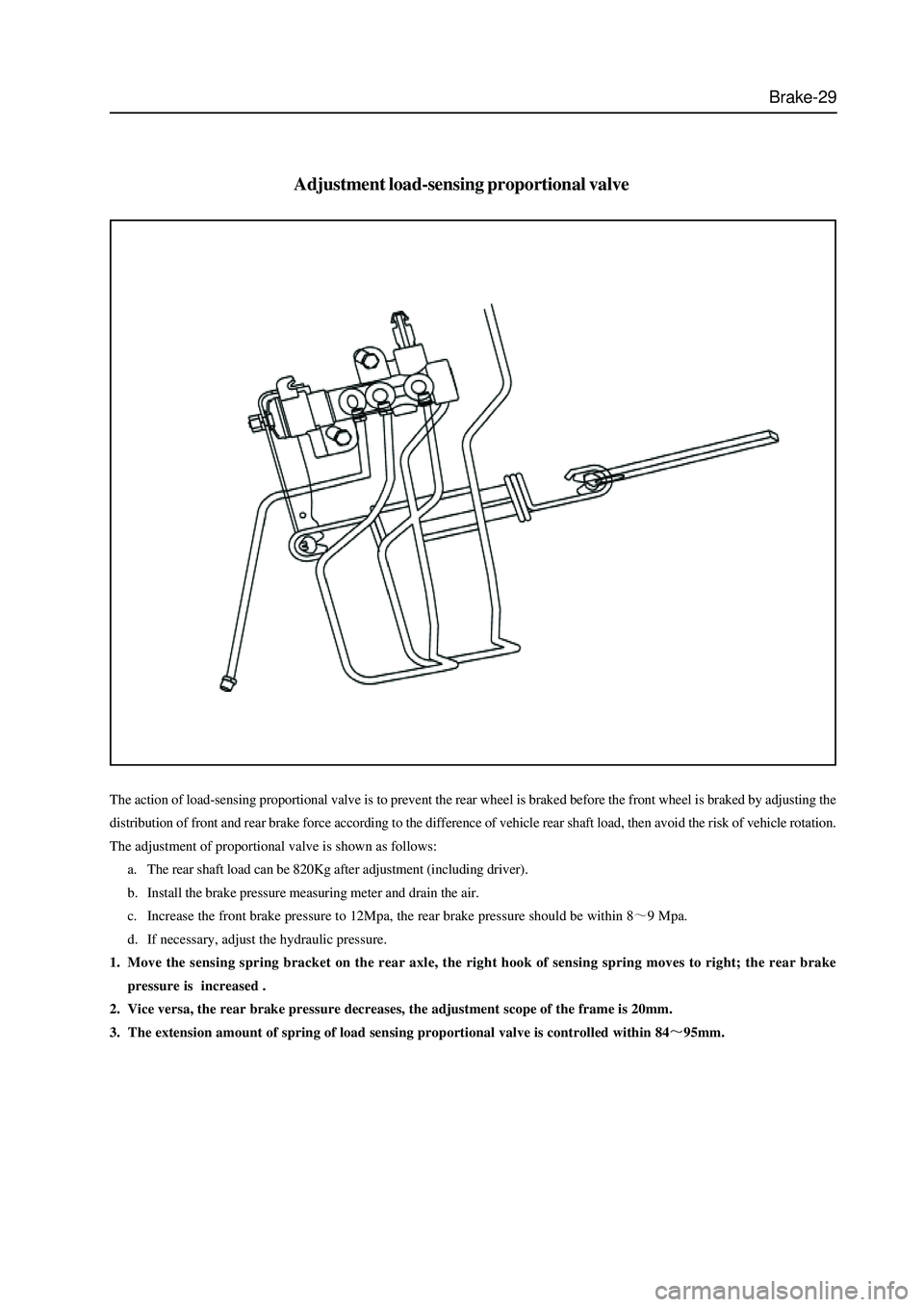

The action of load-sensing proportional valve is to prevent the rear wheel is braked before the front wheel is braked by adjusting the

distribution of front and rear brake force according to the difference of vehicle rear shaft load, then avoid the risk of vehicle rotation.

The adjustment of proportional valve is shown as follows:

a. The rear shaft load can be 820Kg after adjustment (including driver).

b. Install the brake pressure measuring meter and drain the air.

c. Increase the front brake pressure to 12Mpa, the rear brake pressure should be within 8

9 Mpa.

d. If necessary, adjust the hydraulic pressure.

1. Move the sensing spring bracket on the rear axle, the right hook of sensing spring moves to right; the rear brake

pressure is increased .

2. Vice versa, the rear brake pressure decreases, the adjustment scope of the frame is 20mm.

3. The extension amount of spring of load sensing proportional valve is controlled within 84

95mm.

Adjustment load-sensing proportional valve

Page 316 of 425

Brake-30

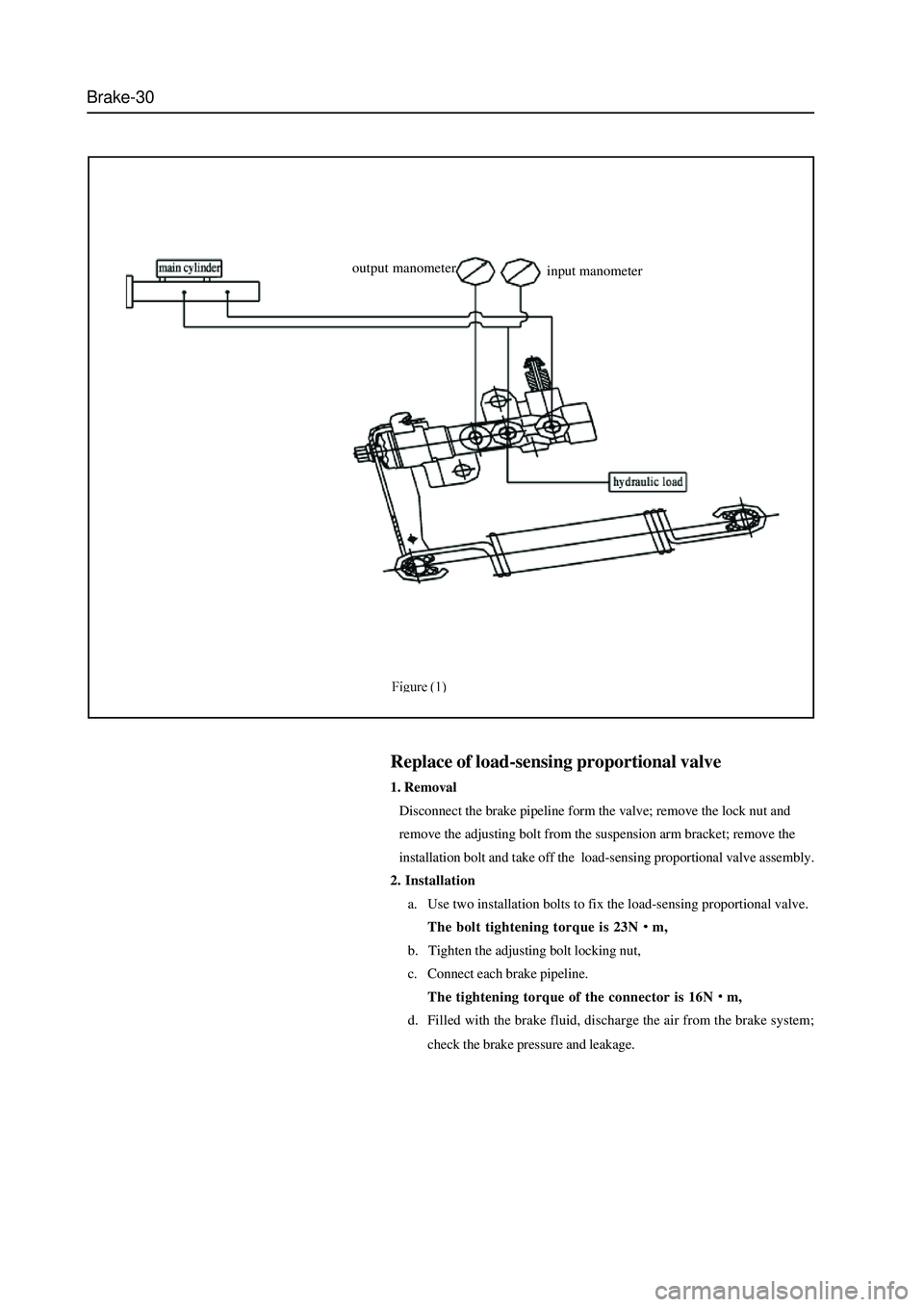

Replace of load-sensing proportional valve

1. Removal

Disconnect the brake pipeline form the valve; remove the lock nut and

remove the adjusting bolt from the suspension arm bracket; remove the

installation bolt and take off the load-sensing proportional valve assembly.

2. Installation

a. Use two installation bolts to fix the load-sensing proportional valve.

The bolt tightening torque is 23N

m,

b. Tighten the adjusting bolt locking nut,

c. Connect each brake pipeline.

The tightening torque of the connector is 16N

m,

d. Filled with the brake fluid, discharge the air from the brake system;

check the brake pressure and leakage. output manometer

input manometer

Page 317 of 425

Brake-31

Antilock Braking System (ABS)

Cautions

1. It must not remove or install the electric elements and wire bunch plug when the ignition switch is in ON to avoid

the damage of ECU. It should turn off the ignition switch if needs disassembly.

2. Pay attention to do not knock or impact the ABS ECU during the maintenance and repair, for it will damage the

ABS ECU easily.

3. The wheel speed sensor and hydraulic unit (integrated with ECU) of BOSCH ABS8.0 can not be repaired, it should

be replaced in integral if damaged.

4. After the brake system is maintained, the brake pedal maybe soft. Discharge the air according to the normal brake

system.

5. It must use the brake fluid from original manufacturer; the brake fluid of different number cannot be used in mixed,

otherwise it will cause the failure of brake system. Select the tyre of original type as most as possible

Repair of Antilock Braking System (ABS)

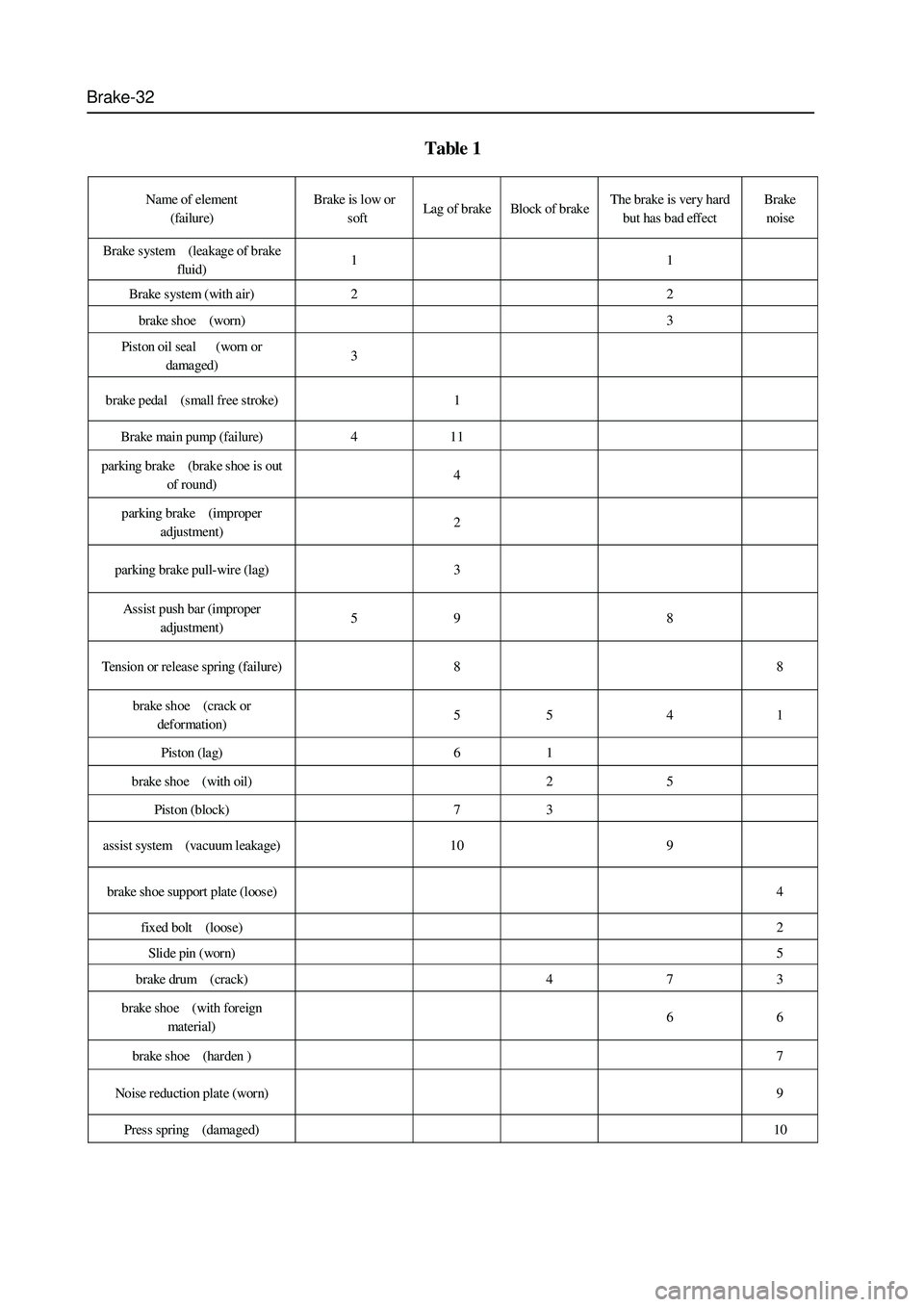

1. It should process the failure diagnosis for the brake system before process the ABS failure diagnosis. It can

diagnose out the failure rapidly by using Table 1. In Table 1, the small number means the failure which occurs most

possibly. Check each element according to the sequence and maintain or replace it if necessary.

2. Check the following elements for normal operation before the diagnosis:

Brake fluid level and brake fluid quality

Pressure of tyre, size of tyre, shape and depth of tyre figure

Other brake component

These components will affect the brake effect of the ABS. Check the system sensor, connecting wire and connector for correct

installation, arrangement and connection. Ensure the completeness of fuse, repair or replace it if necessary.

3. Process the analysis and diagnosis according to the ABS advanced by owner. Use the diagnosis instrument (Annex

1) for final check and confirmation. It must process the run inspection after the competition of all ABS maintenance.

The test condition is shown as follows:

a. Confirm the tyre complies with the requirement, the tyre pressure is normal.

b. The brake system (including brake light ) is normal

c. The brake system is without leakage.

d. The position and installation of wheel speed sensor is correct.

e. All fuses are normal.

4. test method:

Run for 1 min at least when the vehicle speed is beyond 40Km/h, process a proper brake. Then read out the failure code to

ensure the ABS is without failure code.

Page 318 of 425

Brake-32

Page 319 of 425

Brake-32

Table 1

Name of element

(failure) Brake is low or

soft Lag of brake Block of brake The brake is very hard

but has bad eff ect Brake

noise

Brake system (leakage of brake

fluid) 1 1

Brake system (with air) 2 2

brake shoe (worn) 3

Piston oil seal (worn or

damaged) 3

brake pedal (small free stroke) 1

Brake mai n p ump (fai lur e) 4 1 1

parking brake (brake shoe is out

of round) 4

parking brake (improper

adjustment) 2

parking brake pull-wire (lag) 3

Assist push bar (improper

adjustment) 5 9 8

Tension or release spring (failure) 8 8

brake shoe (crack or

deformation) 5 5 4 1

Piston (lag) 6 1

brake shoe (with oil) 2 5

Piston (block) 7 3

assist system (vacuum leakage) 10 9

brake shoe support plate (loose) 4

fixed bolt (loose) 2

Slide pin (worn) 5

brake drum (crack) 4 7 3

brake shoe (with foreign

mater ial) 6 6

brake shoe (harden ) 7

Noise reduction plate (worn) 9

Press spring (damaged) 10

Page 320 of 425

Steering-1

Chapter 9

Steering

Precautions...............................................................................2

Troubleshooting........................................................................2

Inspection on vehicle.................................................................3

Steering linkage........................................................................4

Hydraulic power steering system...............................................6