mat HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1140 of 2189

Front Suspension

L

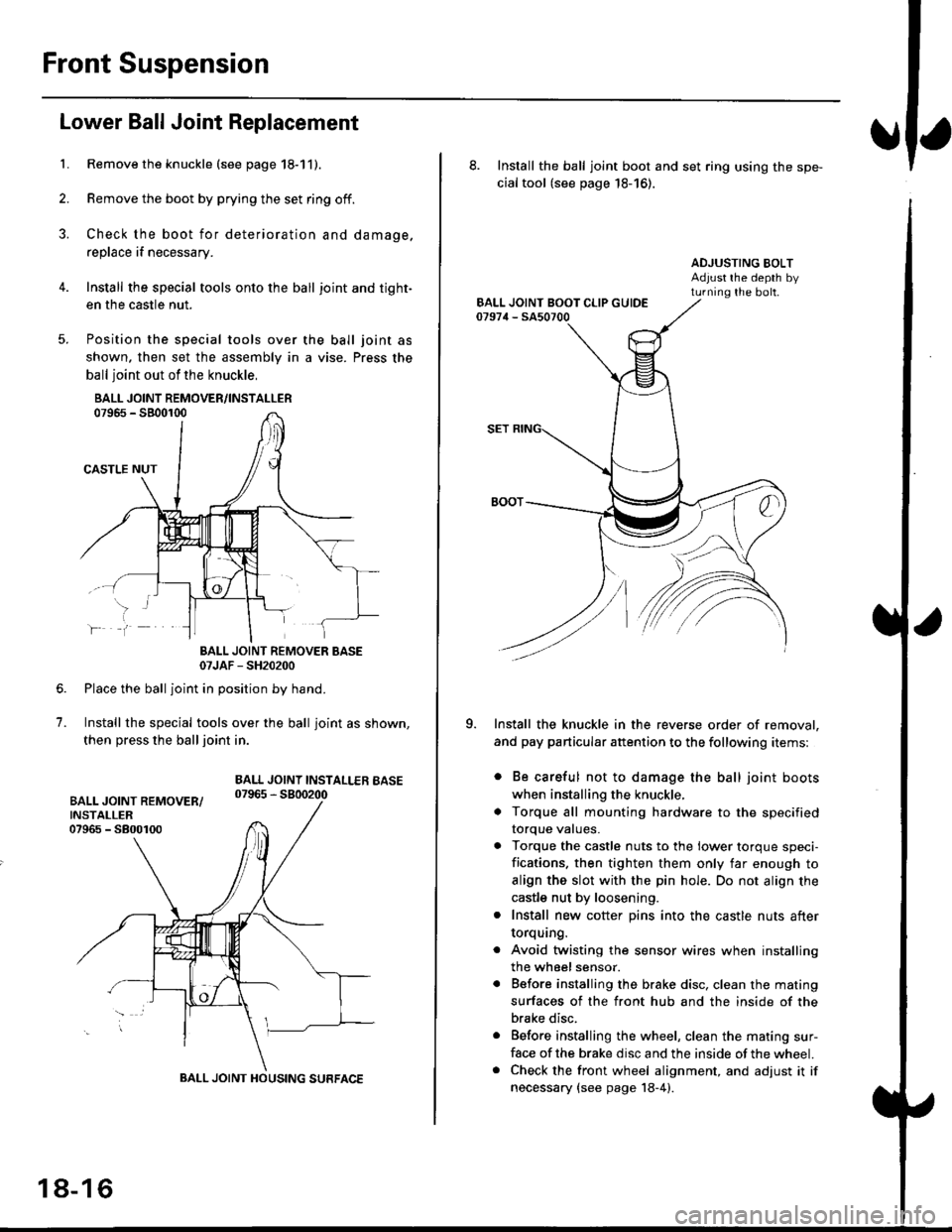

Lower Ball Joint Replacement

Remove the knuckle (see page 18-11).

Remove the boot by prying the set ring off.

Check the boot for deterioration and damage.

replace if necessary.

Install the special tools onto the ball joint and tight-

en the casfle nut.

Position the special tools over

shown. then set the assembly in

ball joint out of the knuckle,

BALL JOINT REMOVER/INSTALLER07965 - SB00r00

CASTLE NUT

the ball joint as

a vise. Press the

lf

7.

BALL JOINT REMOVER BASE07JAF - SH20200

Place the ball joint in position by hand.

Install the special tools over the ball joint as shown,

then press the ball joint in.

BALL JOINT INSTALLEB BASE07965 - 5800200

BALL JOINT HOUSING SURFACE

18-16

8. Install the ball joint boot and set ring using the spe-

cial tool (see page 18-16).

ADJUSTING BOLTAdjust rhe depth byturning the bolt.

Install the knuckle in the reverse order of removal,

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle,

. Torque all mounting hardware to the specified

torque values.

. Torque the castle nuts to the lower torque speci-

fications. then tighten them only far enough to

align the slot with the pin hole. Do not align the

castle nut by loosening.

. Install new cotter pins into the castle nuts after

torquang.

. Avoid twisting the sensor wires when installing

the wheel sensor.

. Before installing the brake disc. clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the wheel, clean the mating sur-

face of the brake disc and the inside of the wheel.. Check the front wheel alignment, and adjust it if

necessary {see page 18-4).

Page 1141 of 2189

Front Damper

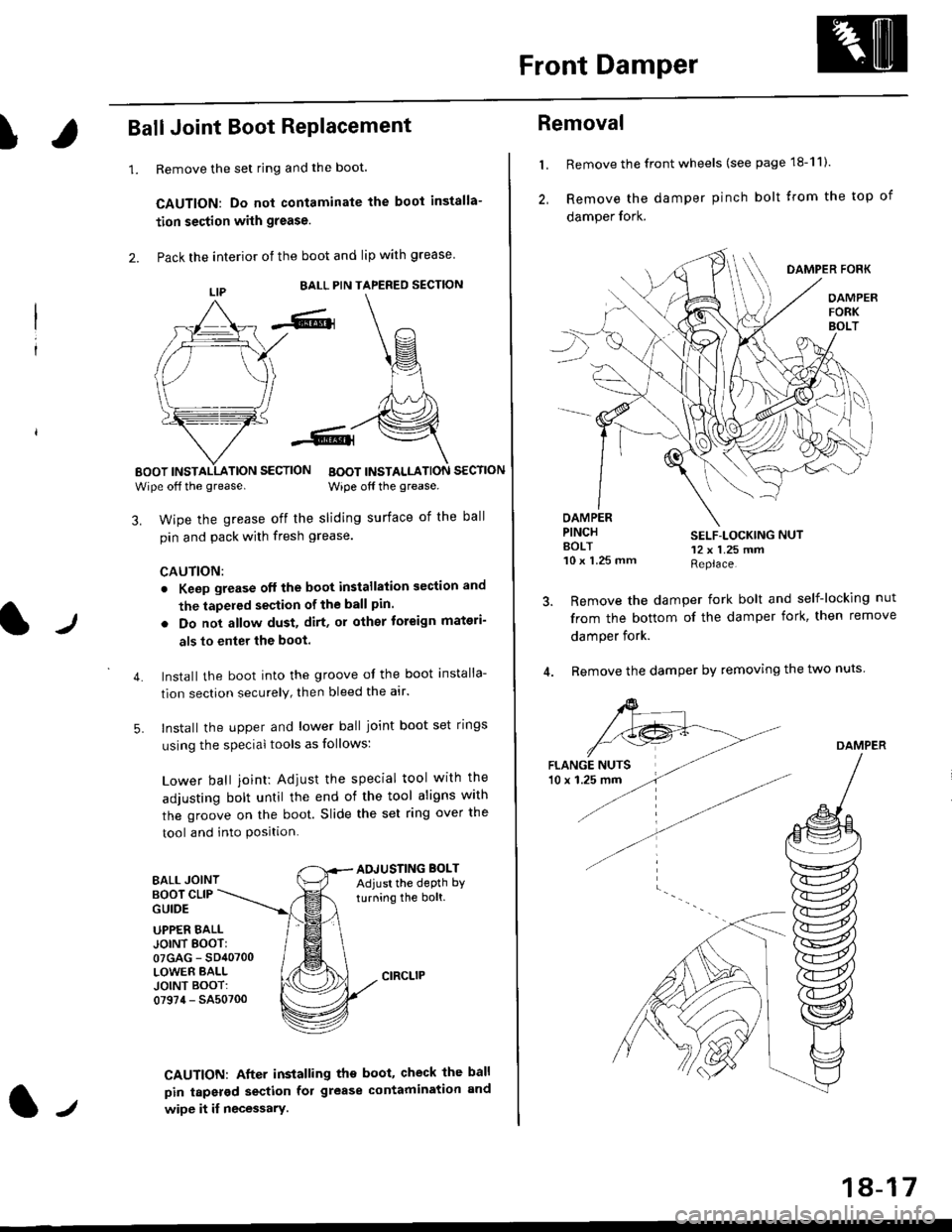

!Ball Joint Boot RePlacement

1.Remove the set ring and the boot.

CAUTION: Do not contaminate the boot installa-

tion section with grease.

Pack the interior of the boot and lip with grease

EALL PIN TAPERED SECTION

EOOT INSTALLATION SECTION

Wipe off the grease.BOOT INSTALLATION SECTION

Wipe off the grease.

lJ

3. Wipe the grease off the sliding surface of the ball

pin and pack with fresh grease.

CAUTION:

. Keep grease off the boot installation section and

the tapeled section of the ball pin.

5.

. Do not allow dust, dirt, or other toreign materi-

als to enter the boot.

Install the boot into the groove of the boot installa-

tion section securely, then bleed the atr.

Install the upper and lower ball joint boot set rings

using the special tools as follows:

Lower ball joint: Adiust the special tool with the

adjusting bolt until the end of the tool aligns with

the groove on the boot. Slide the set ring over the

tool and into Position.

BALL JOINTAOJUSTING BOLTAdjust the depth by

turning the bolt.BOOT CLIPGUIDE

4.

UPPER EALLJOINT EOOT:07GAG - SD40700LOWER BALLJOINT BOOT:07974 - SA50700

CAUTION: After installing the boot, check the ball

pin tapsrod section fol grease contamination and

wipe it if necessary.lt

18-17

Removal

l. Remove the front wheels (see page 18-11).

2, Remove the damper pinch bolt trom the top of

damper fork.

DAMPER FORK

OAMPERFORKBOLT

OAMPERPINCHAOLT10 x 1.25 mm

SELF-LOCKING NUT12 x 1.25 mmReplace.

Remove the damper fork bolt and self-locking nut

from the bottom of the damper fork, then remove

damper fork.

Remove the damper by removing the two nuts

DAMPER

Page 1147 of 2189

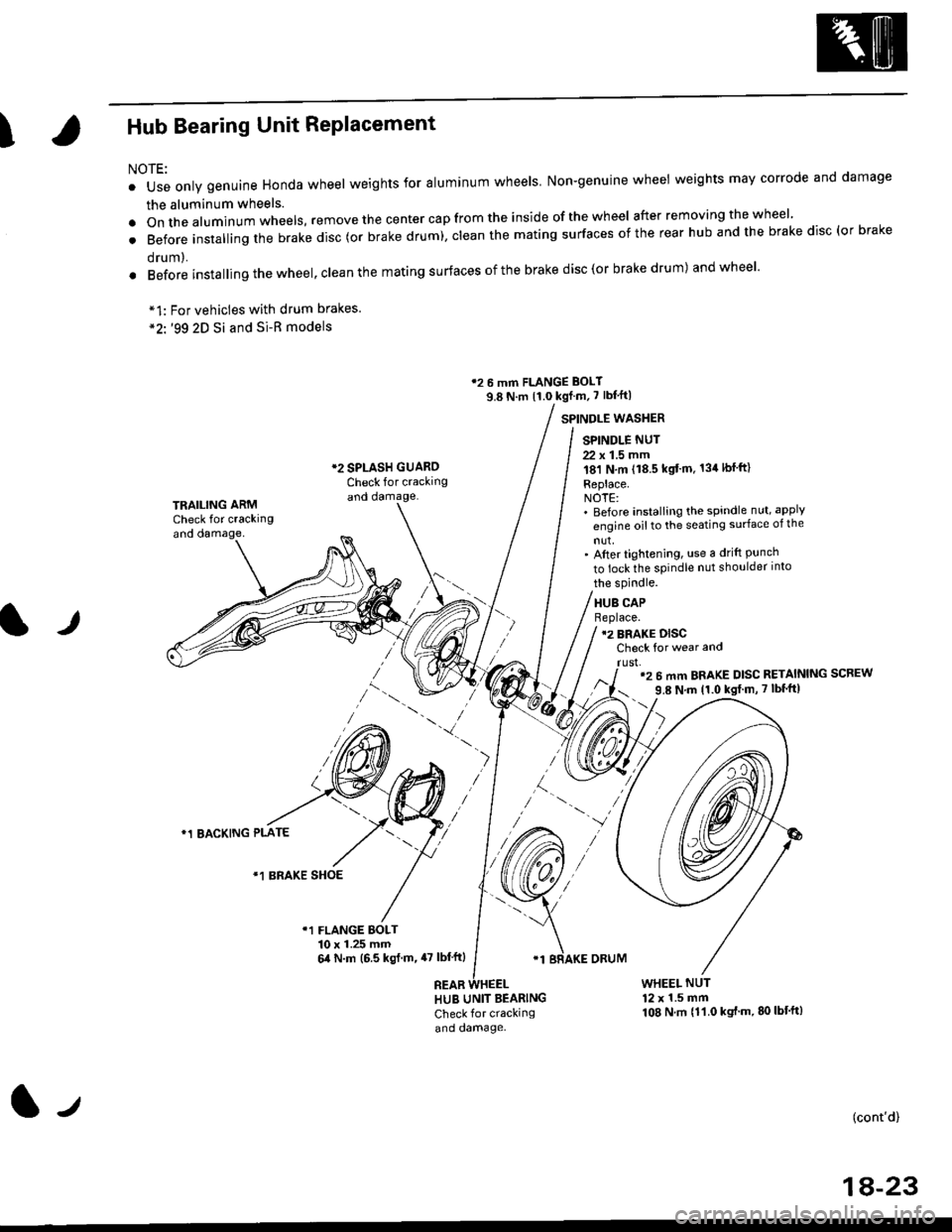

IHub Bearing Unit RePlacement

For vehicles with drum brakes.'99 2D Si and Si-B models

NOTE:

o Use only genuine Honda wheel weights for aluminum wheels Non-genuine wheel weights may corrode and damage

the aluminum wheels.

.onthea|uminumwhee|s,removethecentercapfromtheinsideoftheWhee|afterremovingthewhee|'

. Before insta||ing the brake disc (or brake drum), c|ean the mating surfaces of the rear hub and the brake disc (or brake

orum,.

. Before installing the wheel, clean the mating surfaces ofthe brake disc(or brake drum) andwheel'

*1:

*2'.

12 6 mm FLANGE BOLT

9.8 N.m {1.0 kgf m, 7 lbf'ft|

*2 SPLASH GUAROCheck for crackingand damage.

SPINDLE WASTIER

SPINDLE NUT

22 x 1.5 mm181 N,m (18.5 kgt'm. 134lbfft)

Replace.NOTE:' Before installing the spindle nut, apply

engine oil to the seating surface of the

nut,' After tightening, use a drift Punchto lock the spindle nut shoulder into

TRAILING ARMCheck for crackingand oamage,

lr

the spindle.

HUB CAPBeplace.12 BRAKE DISCCheck for wear and

rust,'2 6 mm BRAKE DISC RETAINING SCREW

9.8 N'm 11.0 kgt m, 7 lbf'ft|

)

*1 BACKING PLATE

/\*1 BRAKE SHOE

r1 FLANGE BOLT10 x 1.25 mm6,0 N.m (6.5 ksl.m,47 lbl'ftl

REAB

'1 BRAKE ORUM

HUB UNIT BEARING

Check for crackingand damage.

WHEEL NUT12 x 1.5 mm108 N.m {11.0 kgt'm.80lbt'ft)

(cont'd)

1A-23

l-t

Page 1161 of 2189

I

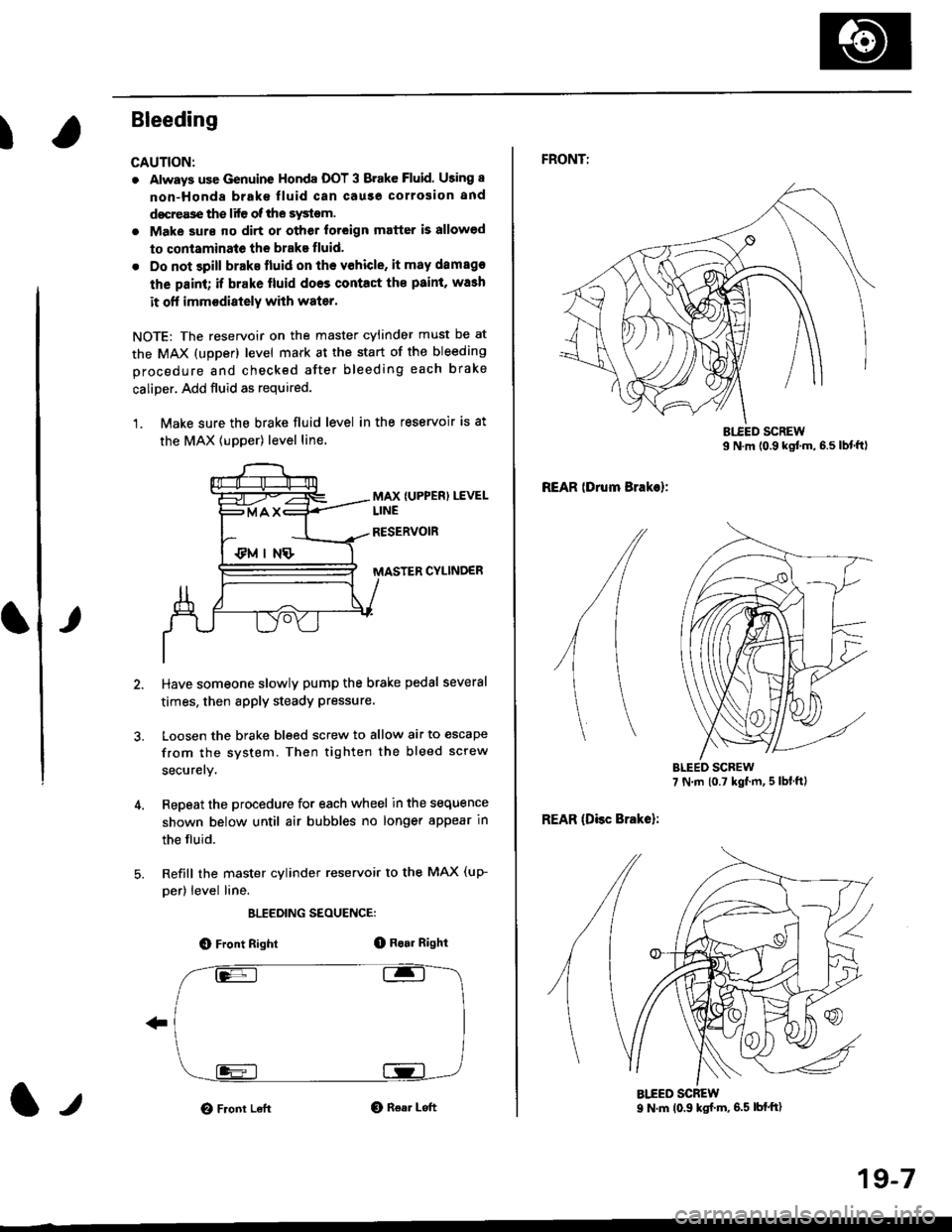

Bleeding

CAUTION:

. Always use Genuine Honda DOT 3 Brake Fluid. Using 8

non-Honda brak€ fluid can cause corrosion and

docrea3e the life of the system.

. Make surs ||o dirt or other foteign matter is allowed

to contaminate the brake fluid,

. Do not spill brake lluid on the vehicle, it may damago

the paint; if brake lluid doos contac{ the paint, wash

it ofl imm€diately with water.

NOTE: The reservoir on the master cylinder must be at

the MAX (upper) level mark at the start of the bleeding

procedure and checked after bleeding each brake

caliper. Add fluid as required.

1. Make sure the brake fluid level in the reservoir is at

the MAX lupper) level line.

MAX {UPPER) LEVEL

CYLINDER

Have someone slowly pump the brake pedsl several

times, then apply steady Pressure.

Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

Repeat the procedure for each wheel in the sequence

shown below until air bubbles no longer appear in

the fluid.

Refill the master cylinder reservoir to the MAX (up-

per) level line.

ELEEDING SEOUENCE:

O Front Right(D Bo.r Right

O Front LeftO Rear Left1,,

19-7

FRONTT

REAR lDrum Brakel:

REAR (Disc Brake):

AIEED SCREW9 N.m (0.9 ksf m, 6.5 lbf'ft)

Page 1166 of 2189

Front Brake Disc

Disc Runout Inspection

L

2.

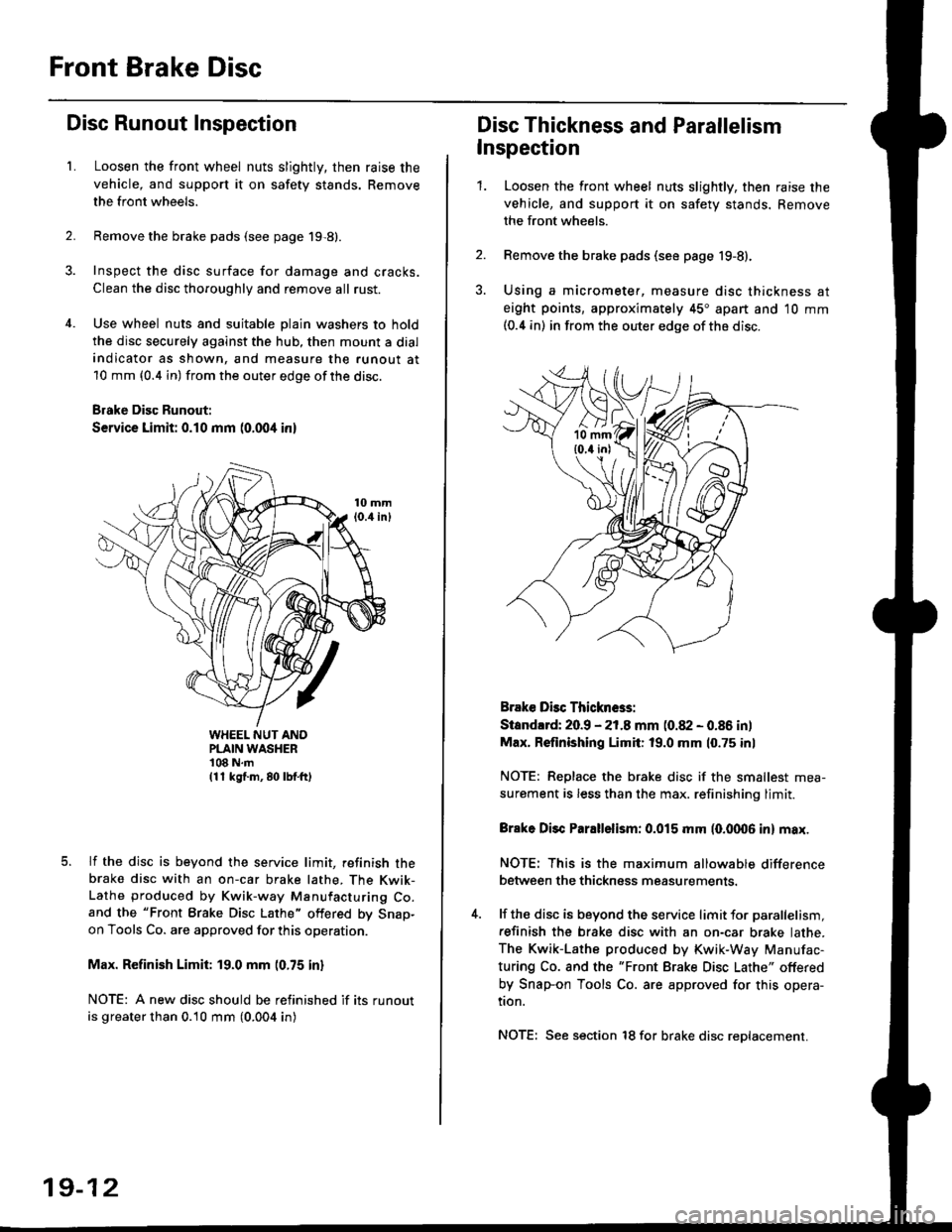

Loosen the front wheel nuts slightly, then raise the

vehicle, and support it on safety stands. Remove

the front wheels.

Remove the brake pads (see page 19,8).

Inspect the disc surface for damage and cracks.

Clean the disc thoroughly and remove all rust.

Use wheel nuts and suitable plain washers to hold

the disc securely against the hub, then mount a dial

indicator as shown, and measure the runout at

10 mm (0.4 in) from the outer edge of the disc.

Brake Disc Runout:

Service Limit: 0.10 mm (0.004 inl

WHEEL NUT ANOPLAIN WASHER'108 N.m(11 kg{.m, 80 lbf.ft)

lf the disc is beyond the service limit, refinish thebrake disc with an on-car brake lathe, The Kwik-Lathe produced by Kwik-way Manufacturing Co.and the "Front Brake Disc Lathe" offered by Snap-on Tools Co. are approved for this operation.

Max. Refinish Limit: 19.0 mm (0.75 in)

NOTE: A new disc should be refinished if its runout

is greater than 0.10 mm (0.004 in)

19-12

Disc Thickness and Parallelism

Inspection

1.Loosen the front wheel nuts slightly, then raise the

vehicle, and support it on safety stands. Remove

the front wheels.

Remove the brake pads (see page 19-8).

Using a micrometer, measure disc thickness at

eight points, approximately 45" apart and 10 mm(0.4 in) in from the outer edge of the disc.

Brake Dbc Thickn6s:

Standlrd: 20.9 - 21.8 mm (0.82 - 0.86 in)

Max. Refinishing Limit: 19.0 mm 10.75 inl

NOTE: Replace the brake disc if the smallest mea-

surement is less than the max. refinishinq limit.

Brake Disc Parallelism: 0.015 mm (0.fit06 in) max.

NOTE: This is the maximum allowable difference

between the thickness measurements.

lf the disc is beyond the service limit for parallelism,

refinish the brake disc with an on-car brake lathe.

The Kwik-Lathe produced by Kwik-Way Manufac-

turing Co. and the "Front Brake Disc Lathe" offered

by Snap-on Tools Co. are approved for this opera-

tion.

NOTE: See section 18 for brake disc reDlacement.

Page 1170 of 2189

Front Brake Galiper

Reassembly

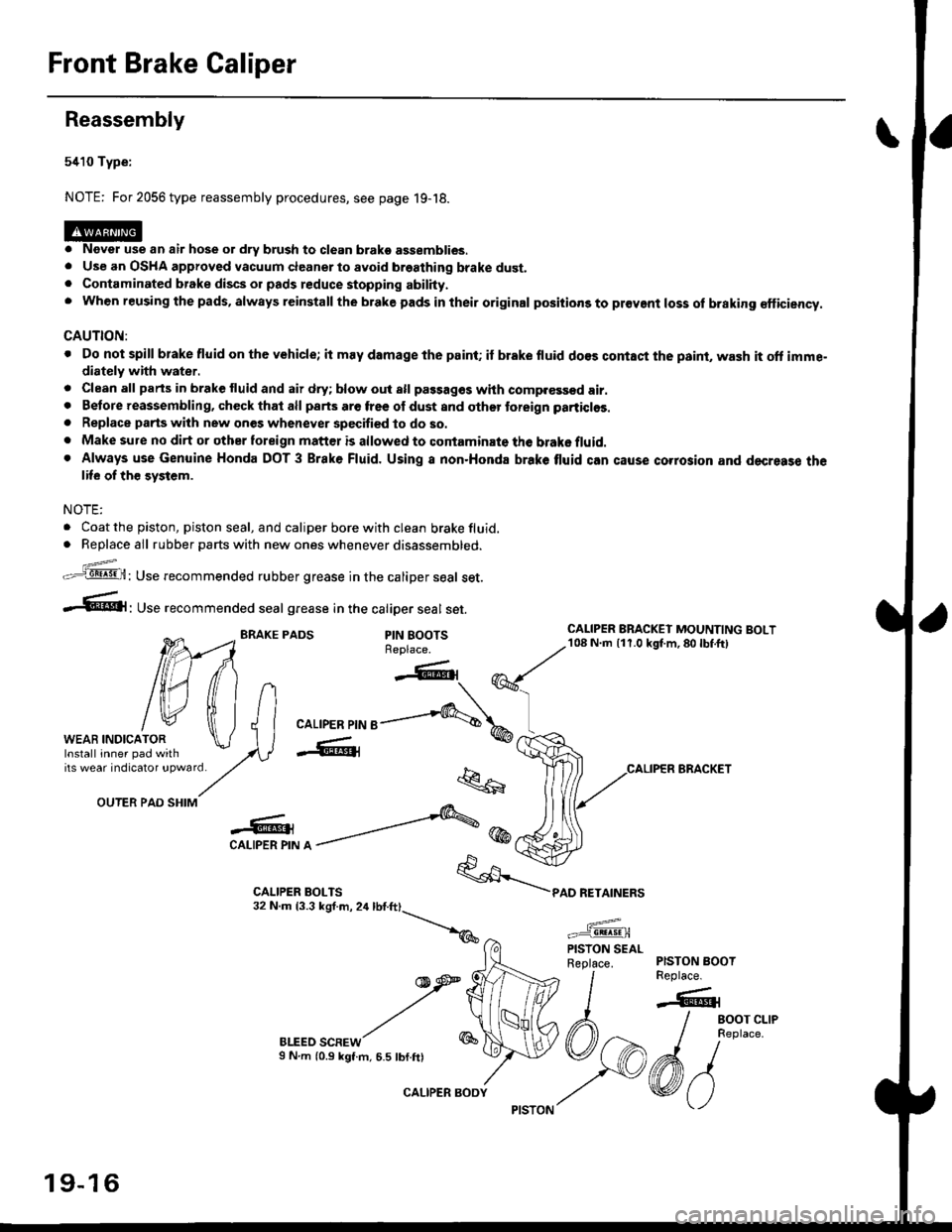

5410 Type:

NOTE: For 2056 type reassembly procedures, see page 19-18.

o Never use an air hose or dry brush to clean brako assemblies.. Use an OSHA approved vacuum cleanerto avoid breathing brake dust.. Contaminated brake discs or pads reduce stopping abilhy.. when reusing the pads, always reinstall the brake pads in their original positions to pr€vent loss of braking €fficiency.

CAUTION:

. Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid do€s contaci the psint, wash it oft imme"diately with water.

. Clean all parts in brake fluid and air dry; blow out all passag€s whh comp.€ssed air.. Betore reassembling, check that all parts are free ol dust and othor toreign particlos.

. Replace parts wilh new ones whenever specified to do so.. Make sure no dirt or other toreign matt€r is allowed to contaminate the brake fluid.. Always use Genuine Honda DOT 3 Brake Fluid. Using a non.Honda brake tluid can cause corrosion and decresse thelife of th€ system.

NOTE:

. Coat the piston, piston seal, and caliper bore with clean brake fluid.. Replace all rubber parts with new ones whenever disassembled.

z_..=-.q8! .9!,H: Use recommended rubber grease in the caliper seal set.

-.61' use recommended seal grease in the catiper seal set.

BRAKE PADSPIN BOOTSReplace.

OUTER PAD SHIM

-o -'''---&@CAI-IPER PIN A -

BLEED SCREWS N.m (0.9 kgt.m, 6.5 tbf.ftl

"k..6

*/\*

car-rpen prr'r e-....,-q\,

-W@{

q

1

PAD RETAINERS

CALIPER BRACKET

WEAB INDICATOR

tilfliltn

tw tfi lJlWEAB rNDrcAroR \J I Ilnsrall inner pad with lAVirs weat indicatot !pwatd/,.

CALIPER BRACKEI MOUNTING BOLT108 N.m {11.0 kgt m,80lbf.ft)

PISTON BOOTReplace.

-6r

/ eoor cr-re

I neptace.

6/vo

PISTON SEALReplace.

19-16

CALIPER BODY

Page 1172 of 2189

Front Brake Caliper

Reassembly (cont'd)

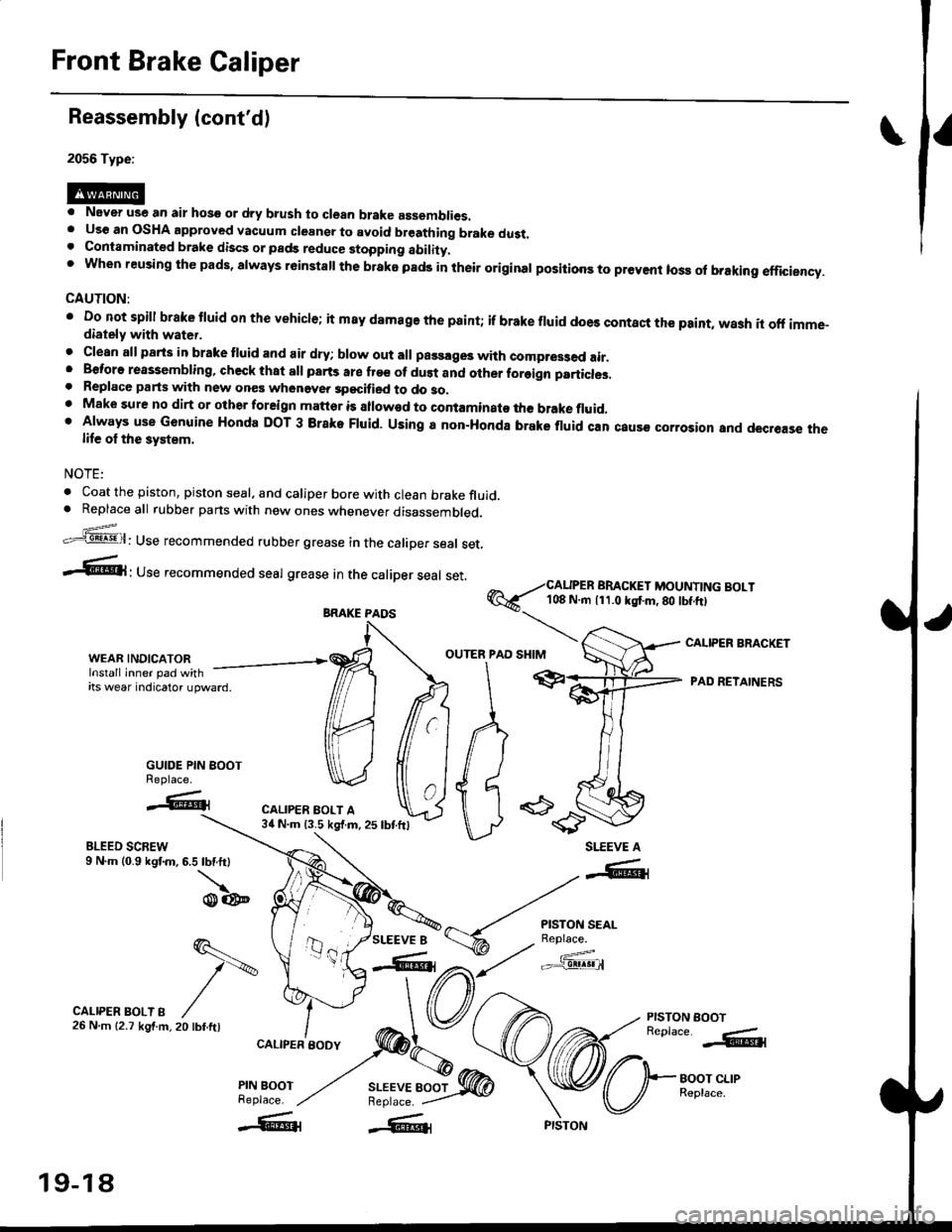

2056 Type:

. Never use an air hose or dry b.ush to clean brake assemblies.. Uso an OSHA approved vacuum cleansr to avoid breathing brake dust.. Contaminated brake discs or pads reduce stopping ability.t when reusing the pads, always r6instsll the brake pads in their original positioos to prevent loss ol braking efficiency.

CAUTION:

' Do not spill brake tluid or th€ vehicle; it m8y damage the paint; if brake fluid does contact the paint, wash it off imme-diately with water.

. Clean all parts in brake tluid and air dry; blow out all passages with compr63ed air.. Beforo reassembling, check that all parts are fr€e of dust and other foreign particles,. Replace parts with new ones whenevea specified to do so.. Make sure no dirt or other foreign matter is allowad to contaminato the brake fluid,' Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can caus€ corrosior and decrease thelife ol the system.

NOTE:

. Coat the piston, piston seal, and caliper bore with clean brake fluid.. Replaceall rubber parts with new ones whenever disassembled.

.'=5@: Use recommended rubber grease in the caliper seal set,

-6l ' Use recommended seal grease In the caliper seal set.

@6--i#i['i,?li"..;:l]l?Y]li"'"'

I

r""'"rr r"""ip"autr, -/ffr

e"6ft 'ADRETATNERSitswearndcatoru'ward

MffiA pr

GUIDE PIN BOOT ) {I I II ) I I

% caL,PER

\I\d/ tt ' id 6

u -es'---r..'.* ".-,."oo*'J.l, ru,oonW U

**=*t

WEAR,INDICAToR. ,ffi OUTERIPAD

BLEED SCREW9 N.m (0.9 kgf.m, 6.5 lbf.ft)

\o@

CALIPER BRACKET

PISTON EOOTReplace. -.&l

BOOT CLIPReplace.

SLEEVE A

SLEEVE 8

-"-41

r{.i'""Jg*'

a,t/ c'f3!@

q.-

t\

20 tbf.ftl

CALIPER BOLT B26Nm{2.7kgf.m,

CALIPER BODY

PIN BOOTReplace.

BRAKE PAOS

19-18

Page 1177 of 2189

Brake Booster InsPection

FunctionalTest

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds lf

the pedal sinks' either the master cYlinder is

bypassing internally, or the brake system (master

cylinder. lines. modulator, proportioning control

valve, or caliPer) is ieaking.

2. Start the engine with the pedal depressed lf the

pedal sinks slightly, the vacuum booster is operating

normally. lf the pedal height does not vary, the

booster or check valve is faultY.

3. With the engine running. depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep. lf the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes,

the master cvlinder is faulty. A slight change in

pedal height when the A'lC compressor cycles on

and off if normal. (The A/C compressor load

changes the vacuum available to the booster')

Leak Test

1. Depress the brake pedal with the engine running.

then stop the engine. lf the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. lf the pedal rises. the booster is

faulty.

2, With the engine stopped, depress the brake pedal

several times using normal pressure When the

Dedal is first depressed, it should be low On con-

secutive applications, the pedal height should grad-

uallv rise. lf the pedal position does not vary, checK

the booster check valve.

l./

19-23

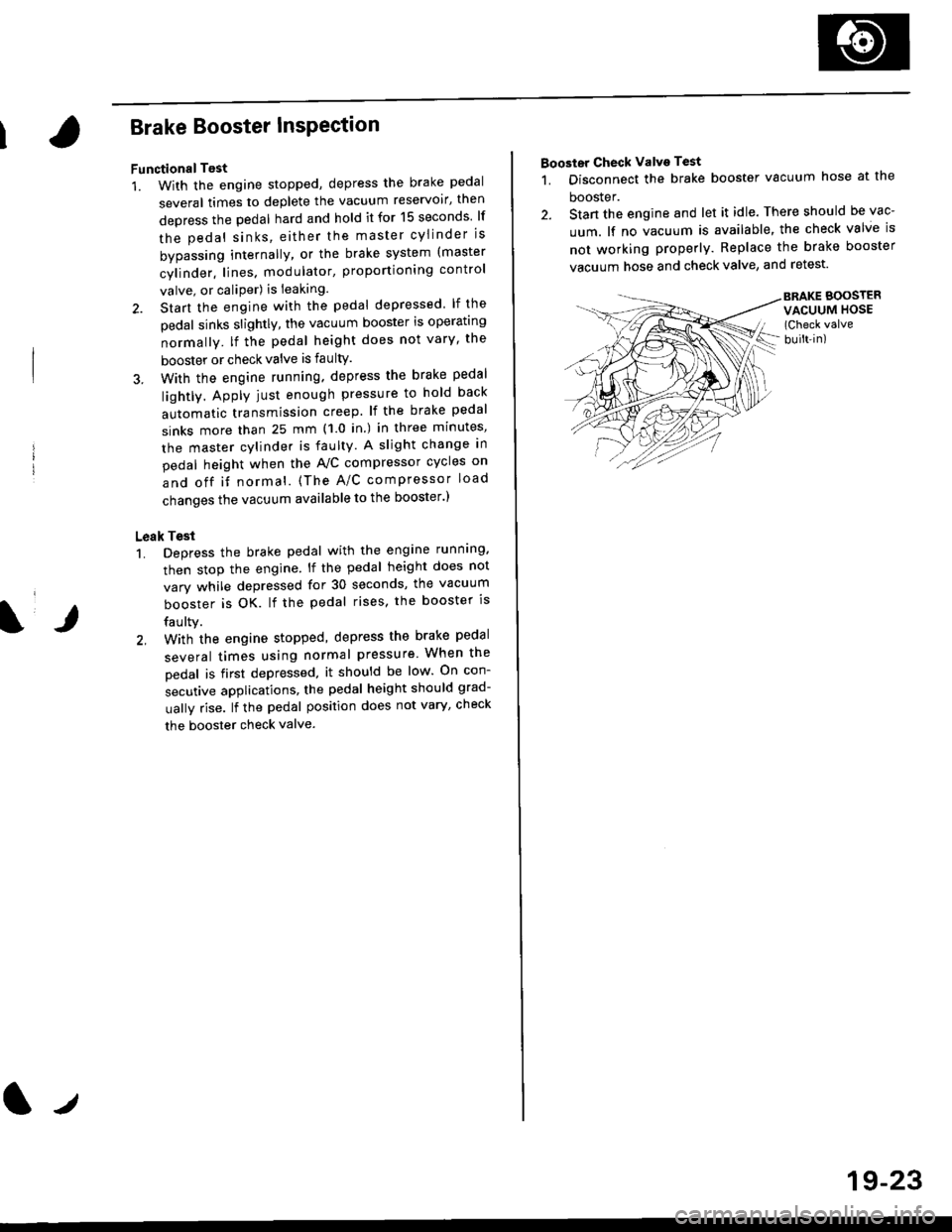

Booster Check Valve Test

1. Disconnect the brake booster vacuum hose at the

booster.

2. Stan the engine and let it idle. There should be vac-

uum. lf no vacuum is available, the check valve is

not working properly. Replace the brake booster

vacuum hose and check valve, and retest.

BRAKE BOOSTERVACUUM HOSE(Check valve

built-in)

Page 1180 of 2189

Rear Brake Disc

Disc Runout Inspection

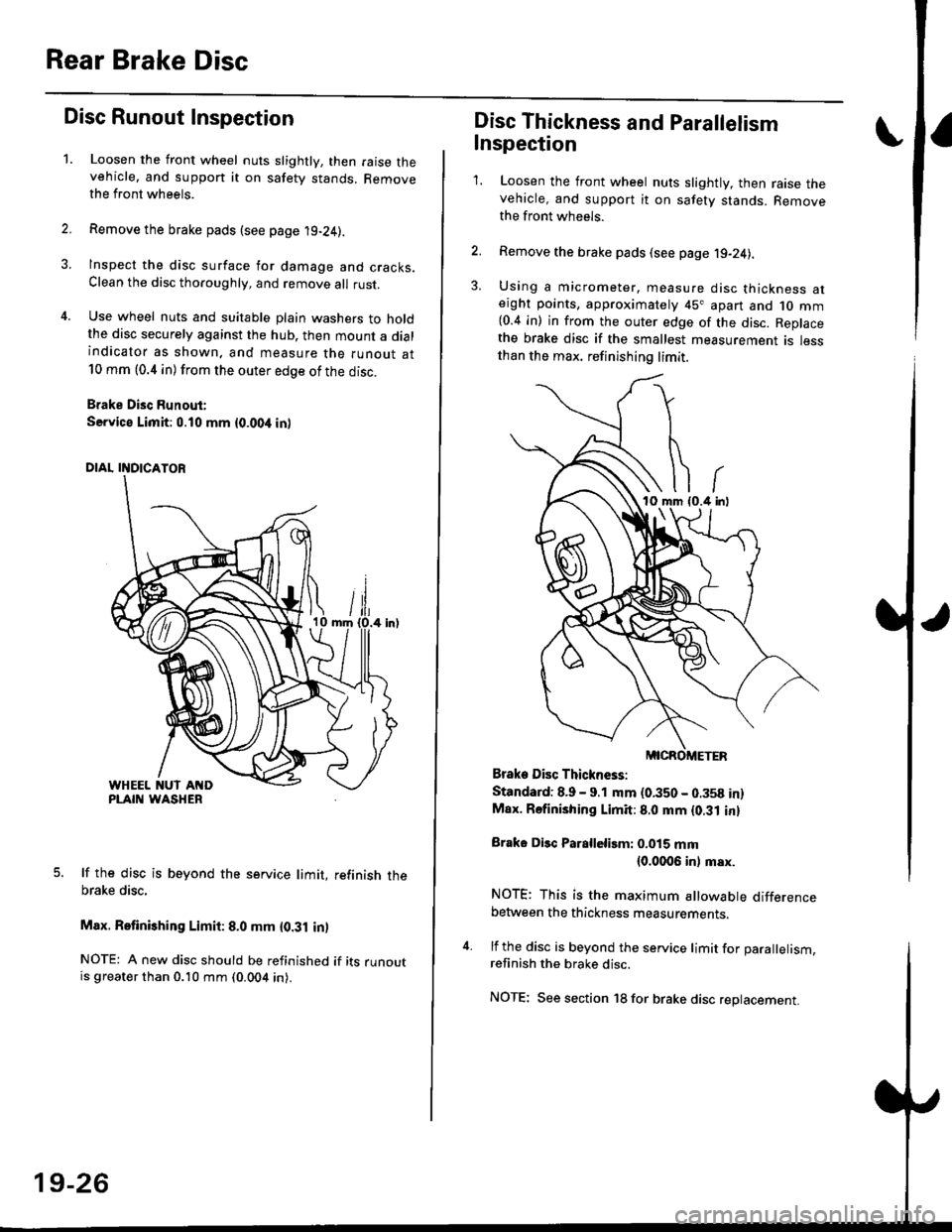

1.Loosen the front wheel nuts slightly, then raise thevehicle, and suppon it on safety stands. Removethe front wheels.

Remove the brake pads (see page 19-24).

Inspect the disc surface for damage and cracks.Clean the disc thoaoughly, and remove a

rust.

Use wheel nuts and suitable plain washers to holdthe disc securely against the hub. then mount a dialindicator as shown. and measure the runout at10 mm (0.4 in) from the outer edge of the disc.

Brake Disc Runout:

Service Limit:0.10 mm {0.00,t in)

5. lf the disc is beyond the service limit, refinish thebrake disc,

Max. Retinishing Limit: 8.0 mm {0.31 in)

NOTE: A new disc should be refinished if its runoutis greater than 0.10 mm (0.004 in).

19-26

Disc Thickness and Parallelism

Inspection

1. Loosen the front wheel nuts slightly, then raise thevehicle, and support it on safety stands. Removethe front wh6els.

2. Remove the brake pads (see page j9-24).

3. Using a micrometer. measure disc thickness aterght points, approximately 45" apart and 1o mm{0.4 in) in from the outer edge of the disc. Replacethe brake disc if the smallest measurement is lessthan the max. refinishing limit.

Brake Disc Thickness:

Standard: 8.9 - 9.1 mm (0.350 - 0.358 in)Max. Rsfinishing Limit: 8.0 mm {0.31 in}

Brake Disc Parallelirm: 0.015 mm(0.0006 inl msx.

NOTE; This is the maximum allowable differencebetween the thickness measurements.

4. lf the disc is beyond the service limit for Darallelism.refinish the brake disc.

NOTE; See section 18 for brake disc replacement.

Page 1185 of 2189

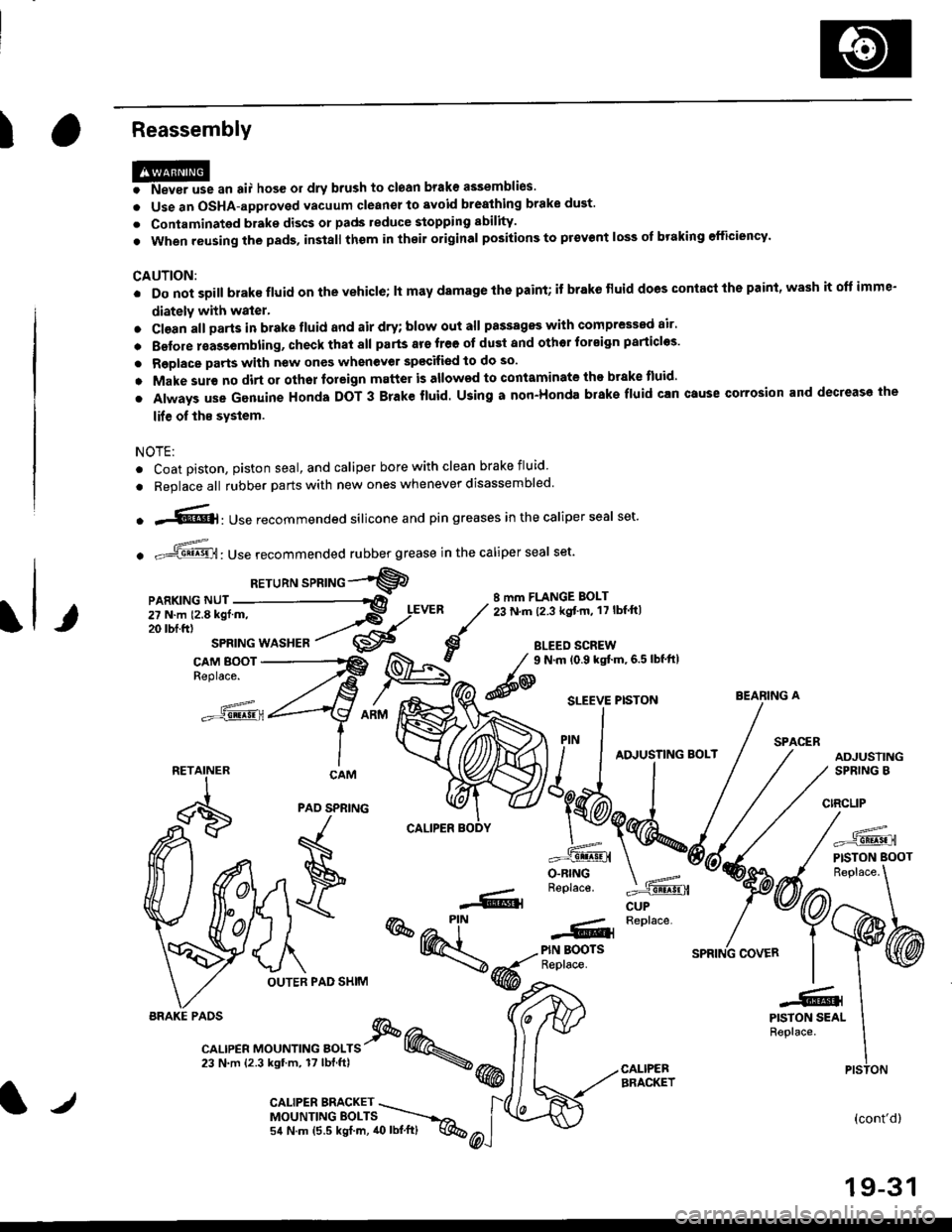

IReassembly

HP* "n ",, hos6 or drv brush to ctoan brake assemblies.

o Use an OSHA-approved vacuum cleanel to avoid brealhing brake dust'

. Contaminated brake discs or pads reduce stopping sbility.

. When reusing the pads, in3tall thom in thoil original positions to prevent loss of braking efficiency'

CAUTION:

. Do not soill brake fluid on the vehicle; lt may damage lhe paint; if brake fluid does contacl the paint' wash it oft imme-

diately with water.

. Cl€an all Darts in brake fluid and air dry; blow out all passagss with comPressed air'

. Belore rsas3embling, check that all parts ars free ot du3t and othor tor€ign particles'

. Replace parts with new ones whenever spscifiod to do so.

o Make sur€ no dirt or othor foreign matter is allowed to contaminate the brake tluid'

. Always use Genuine Honda DOT 3 Brake fluid. Using a non-Honda brake fluid can Gtuse corrosion and decrease the

lif€ of ths system.

NOTE:

. Coat piston, piston seal, and caliper bore with clean brake fluid

. Replace all rubber parts with new ones whenever disassembled.

o .-'{@]: Use recommended silicone and pin greases in the caliper seal set.

. -ffi,Use recommended rubber grease in the caliper seal set.

RETuRN sPRTNG -"'9

8 mm FLANGE BOLT23 N.m (2.3 kgt'm, 17 lbf ftl

BLEED SCREW

@

9 N.m (0.9 kgtm,6.5lbf'ft|

CUP

=^.

PISTON BOOT

(cont'd)

19-31

BEARING A

PAO SPNING

F

\

OUTER PAD SHIM

r--- Replace..ffiPIN BOOTSReplace.

-61

@@-t-.

"l-r,r., "or"'*o " orr" I @.,23 N.m {2.3 kgtm, 17lbf.ftl \@

PISTON SEALReplace.

CALIPEBBRACKET

iiilji:ll;;

__X.,,..".^

BRAKE PAOS

PISTON

l/CALIPER BMCKET \MOUNTINGEOLTS ----.-,o,

54 N.m (5.5 kgf.m, 40lbl.ft) q%