mat HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1471 of 2189

l'f .

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.

Page 1475 of 2189

t

Five-step Troubleshooting

2.

1.Verify The Complaint

Turn on all the components in the problem circuit to

verify the customer complaint. Note the symptoms.

Do not begin disassembly or testing until you have

narrowed down the problem area.

Analyze The Schematic

Look up the schematic for the problem circuit.

Determine how the circuit is supposed to work by

tracing the current paths from the power feed

through the circuit components to ground. lf several

circuits fail at the same time, the fuse or ground is a

likely cause.

Based on the symptoms and your understanding of

the circult operation, identify one or more possible

causes of the problem.

lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made

in step 2. Keep in mind that a logical, simple proce-

dure is the key to efficient troubleshooting. Test for

the most likely cause of failure first. Try to make

tests at points that are easily accessible.

Fix The Problem

Once the specific problem is identified, make the

repair. Be sure to use proper tools and safe proce-

dures.

Make Sure The Circuit Works

Turn on all components in the repaired circuit in all

modes to make sure you've fixed the entire prob-

lem. lf the problem was a blown fuse, be sure to

test all of the circuits on the fuse, Make sure no new

problems turn up and the original problem does not

recur.

3.

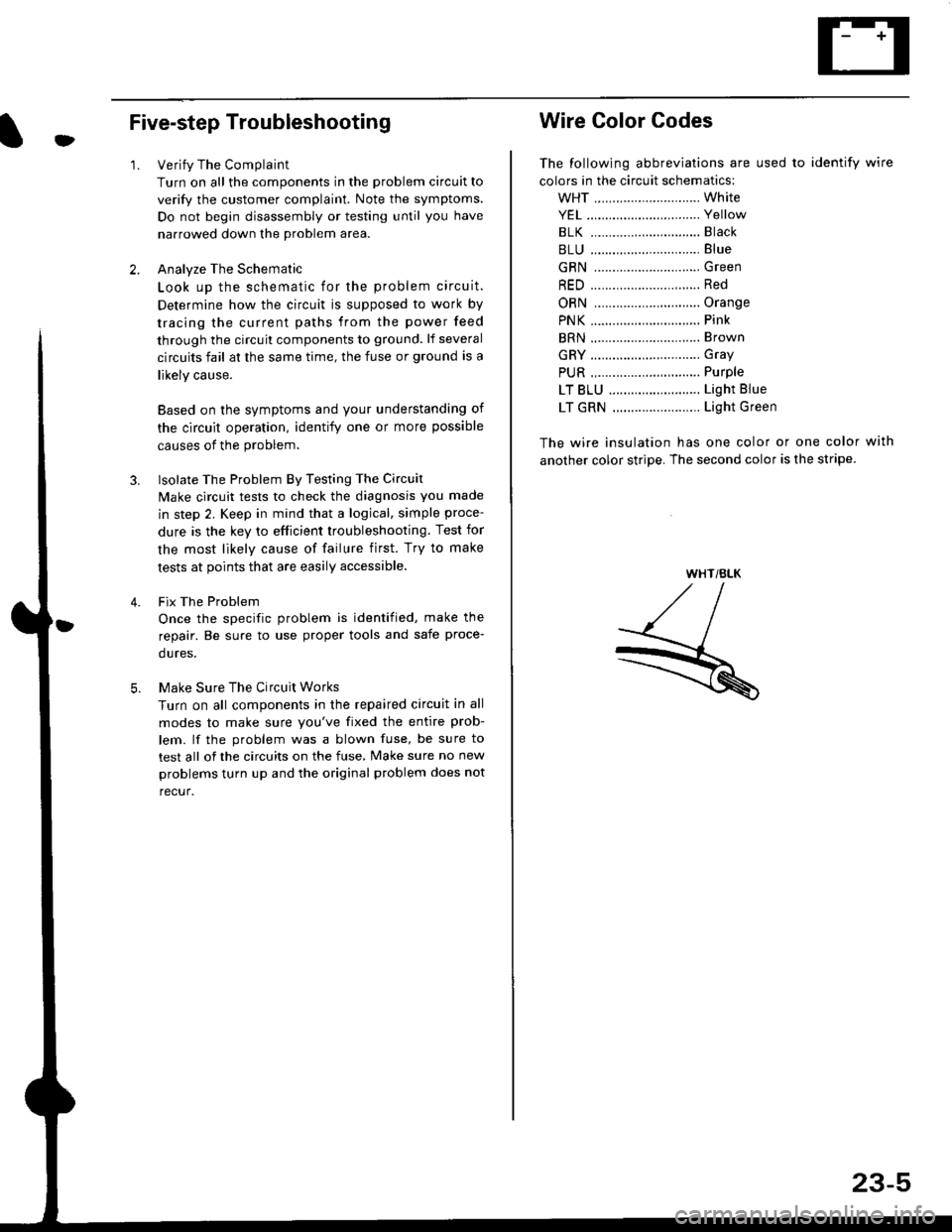

Wire Color Codes

The following abbreviations are used to identify wire

colors in the circuit schematics:

wHT ............................. White

YEL ............................... Yellow

BLK ............,.,...............81ack

BLU .............................. Blue

GRN .............................Green

RED .......................,...... Red

ORN ............................. Orange

PNK .............................. Pink

BRN .............................. Brown

GRY .............................. Gray

PUR .,.................,.,........ Purple

LT BLU ......................... Light Blue

LT GRN ........................ Light Green

The wire insulation has one color or one color with

another color stripe. The second color is the stripe.

WHT/BLK

23-5

Page 1476 of 2189

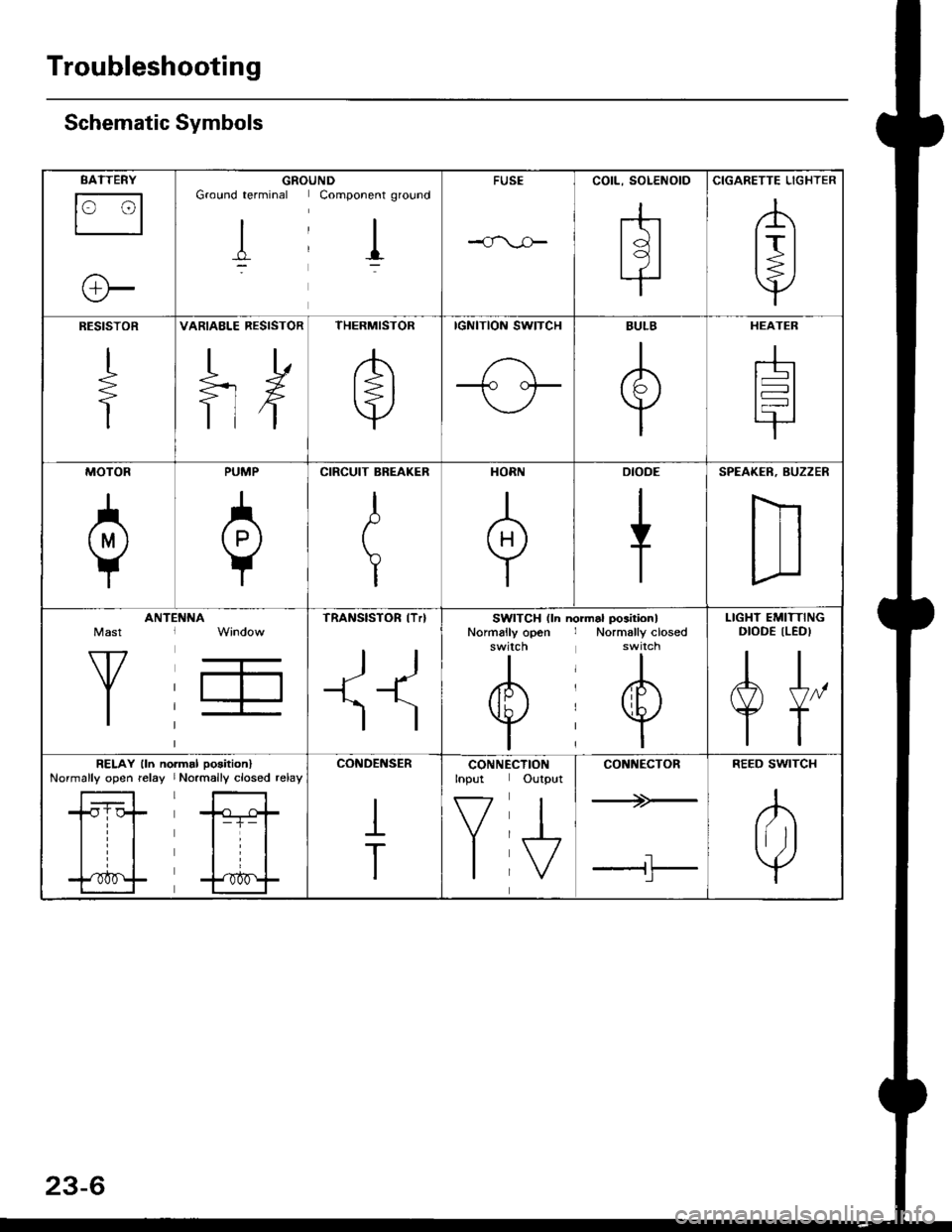

Troubleshooting

Schematic Symbols

BATTERY

E

@

GROGroLrnd terminal

II_d:

UNDComponent ground

II_..'-

FUSE

--cn-.e

COIL, SOLENOID

r{r

tql'|

CIGARETTE LIGHTER

A

lrl

P

RESISTOR

I

f

VARIAELE RESISTOR

ilH

THERMISTOR

c

IGNITION SWITCH

-fo o.t-

BULB

+

HEATEB

At-l

F

MOTOR

0

PUMP

H

CIRCUIT BREAKER

I

r

Yr

T

HORN

+

DIODE

+

SPEAKER, BUZZER

D

Mast

Y

ANTt:f\,NATRANSISTOR lTrl

II

SWITCH (ln niNormally open

I

/F\t tL I\Y/

I

rrdal positionlNormally closed'*i."n

@

I

LIGHT EMITTINGDIODE ILEDI

A+,

TT

RELAY lln noNormally opon relay

| ....--1'rl*r

til

t "t^f

fmal poaitionlNormally closed relay

ffl-+- |

lrl

lrl

fff

CONDENSER

I

T

CONNTInput

V

I

:CTIONOutput

J

CONNECTOR

*>-

'l!

REED SWITCH

A

tftl

Y

Page 1546 of 2189

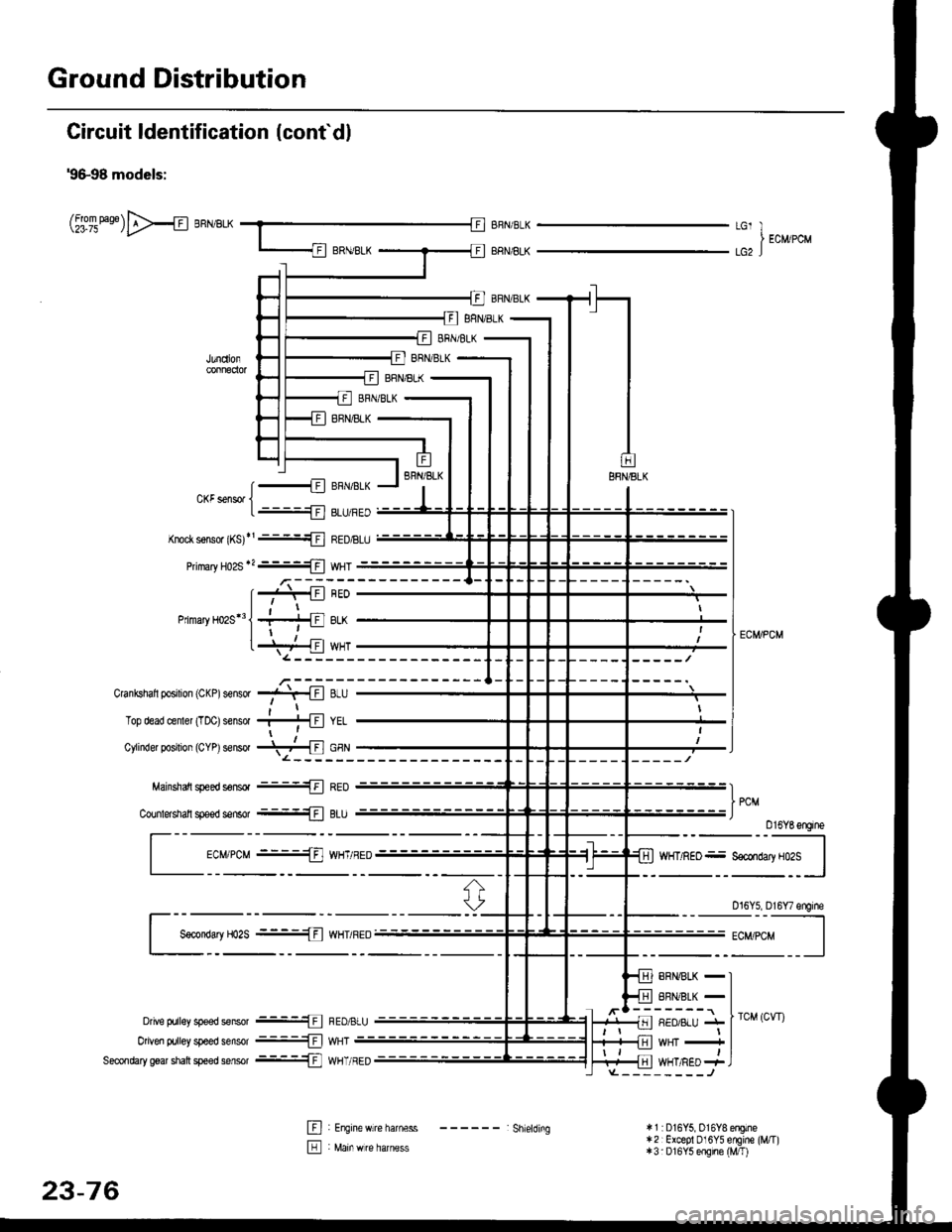

Ground Distribution

Circuit ldentification (conf dl

'9&98 models:

(t[oileas6)>{ BRN/BLKLGl II EcM/PcMlcz J

[..........{ BFNaLKCKF sensor jL .-!l 8LU/FED

Knoct s€rlsor (KS)r' ::{ REDtsLU

PimaryH02S*?- wHT

Matnsnafi g]€eo sdnsoa -'1 t I HEL)

Counlersiall speed sensor --={Fl BIU

Ecr#PcM ----Tal WHT/BED

Dive trjiley speed seftsor -1ll FED,ALU

0 ven pulley speed sensor .-lJ WHT

Seconftry gear shalt speed sansor .-!.1 WHT/RED

44:lil

ECIVPCM

)*"Dl6YBengine

Dl6Y5, D16Y7 sngine

vtl

8BM/BLK - IBBi1/BLK _ I^l^1ll'. I rcu rcwr

**' -i IWHT/RED + ]

El , Engln" *lr" h"rn""" - - - - - - : Shietorns

E : Main *re harness

23-76

* 1 :D16Y5,016Y8 engino* 2 : Excepl Dl 6Y5 engine (i//T)+3: D16Y5 engine (Mfi)

Page 1562 of 2189

Battery

Test (cont'd)

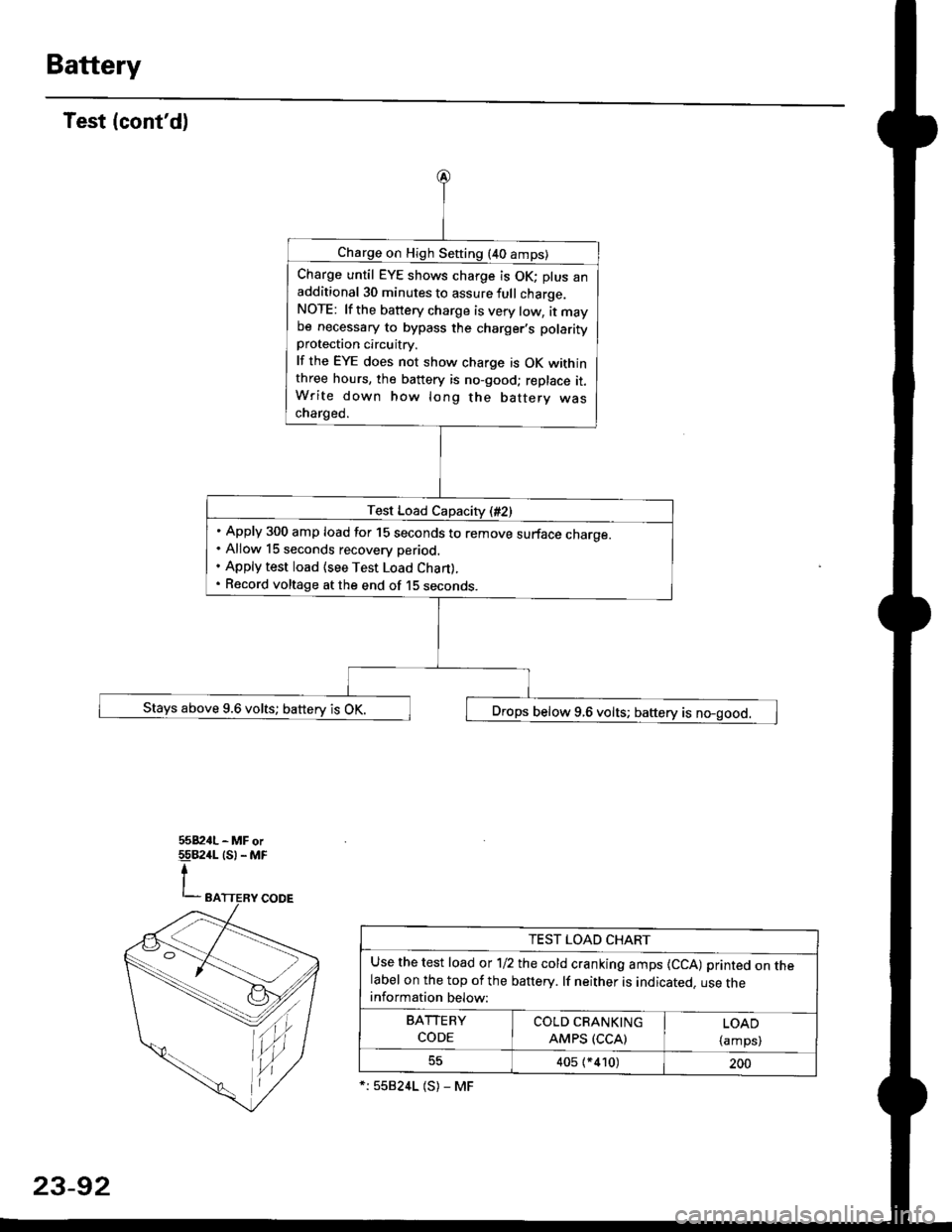

Charge on High Sefting (40 amps)

Charge until EYE shows charge is OK; plus anadditional 30 minutes to assure full charge.NOTE: lf the battery charge is very tow, it maybe necessary to bypass the charger,s polarityprotection circuitry.

lf the EYE does not show charge is OK withinthree hours, the battery is no-good; replace it.Write down how long the battery wascharged.

Test Load Capacity (#2)

Apply 300 amp load for 15 seconds to remove surface charoe.Allow 15 seconds recovery period.

Apply test load {see Test Load Chan).

Record voltage at the end of 15 seconos.

Stays above 9.6 volts; battery is OK. ,] Drops below 9.6 volts; baftery is no-good.

tu,

TEST LOAD CHART

Use the test load or 1/2 the cold cranking amps {CCA) printed on thelabel on the top of the banery. lf neither is indicated. use theinformation below:

BArrERy coLb@

coDE I AMps (ccAl | {amps)

405 (*410)200

*:558241 (S) - MF

23-92

Page 1566 of 2189

Starting System

Starter Test lcont'dl

Ch€ck tor Wear and Damage

The starter should crank the engine smoothly and

steadily, lf the starter engages. but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter or flywheel ring gear for damage.

. Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held,- lf damaged. replace the gears.

Check Cranking Voltsge and Curr€nt Draw

Cranking voltage should be no less than 8.5 volts.

Current draw should be no more than 350 amperes.

lf cranking voltage is too low, or current draw too high,

check for;

. dead or low batterv.

. open circuit in starter armature commutator seg-

ments,

. starter armature dragging.

. shorted armature winding.

o excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm,

lf speed is too low, check for:

. loose battery or stanerterminals.

. excessively worn starter brushes,

. open circuit in commutator segments.

o dirty or damaged helical spline or drive gear.

. defective drive gear overrunning clutch.

Check Siarter Disengag€ment

With the shift lever in El or @ position (A/T) or with the

clutch pedal depressed (M/T), turn the ignition switch to

START (lll), and release to ON (ll).

The starter drive gear should disengage from the torque

converter or flywheel ring gear when you release the

Key.

lf the drive gear hangs up on the torque converter or fly-

wheel ring gear, check for:

. solenoid plunger and switch malfunction,

. dirty drive gear assembly or damaged overrunning

clutch.

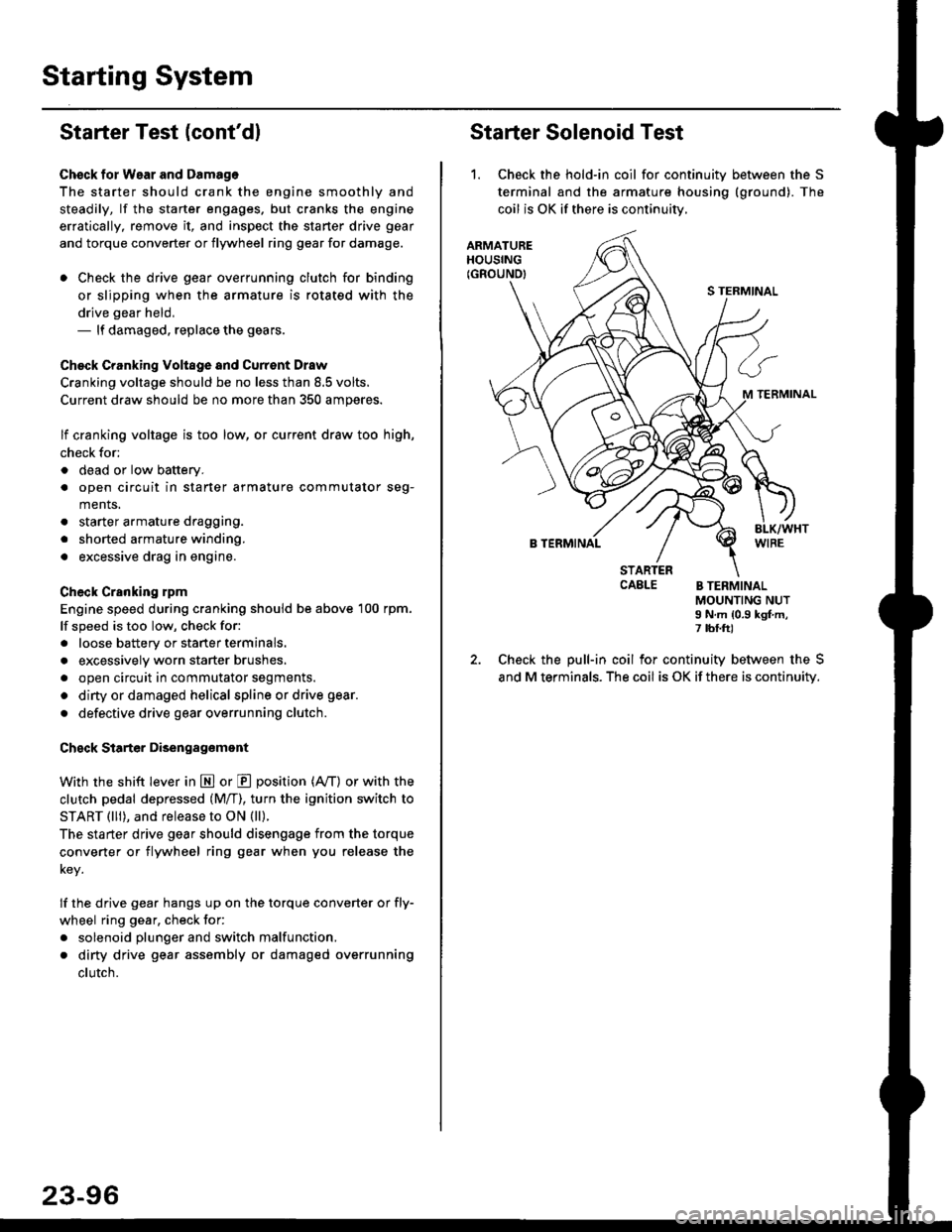

Starter Solenoid Test

1. Check the hold-in coil for continuitv between the S

terminal and the armature housing (ground). The

coil is OK if there is continuitv,

ARMATUREHOUSING(GROUND)

S TERMINAL

M TERMINAL

B TERMINAL

STARTERCAELE B TERMINALMOUNTING NUTI N.m {0.9 kgf.m,7 tbf.ft)

Check the pull-in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

Page 1567 of 2189

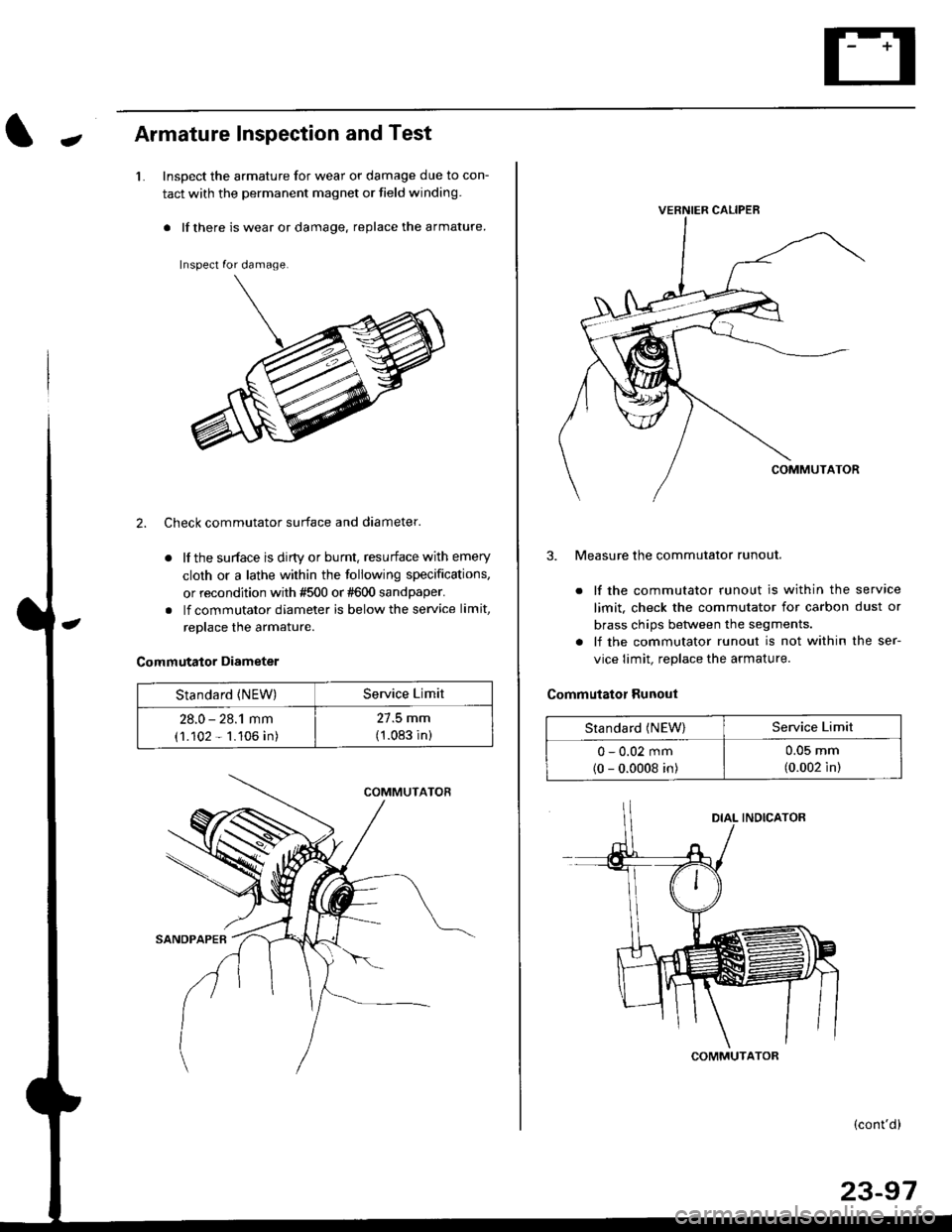

JArmature Inspection and Test

1.Inspect the armature for wear or damage due to con-

tact with the permanent magnet or field winding.

. lf there is wear or damage. replace the armature.

Inspect for damage.

2. Check commutator surface and diameter.

. lf the surface is dirty or burnt. resurface with emery

cloth or a lathe within the following specifications,

or recondition with #500 or #600 sandpaper.

. lf commutator diameter is below the service limit,

replace the armature.

Commutator Diameter

Standard {NEW)Service Limit

28.0 - 28.1 mm

(1.102 - 1.106 in)

27.5 mm

(1.083 in)

VERNIER CALIPEB

3. Measure the commutator runout.

. lf the commutator runout is within the service

limit, check the commutator for carbon dust or

brass chips betlveen the segments.

. lf the commutator runout is not within the ser-

vice limit, replace the armature.

Commutator Runout

Standard (NEW)Service Limit

0 - 0.02 mm(0 - 0.0008 in)

u-u!r mm

(0.002 in)

COMMUTATOR

(cont'd)

23-97

Page 1568 of 2189

Starting System

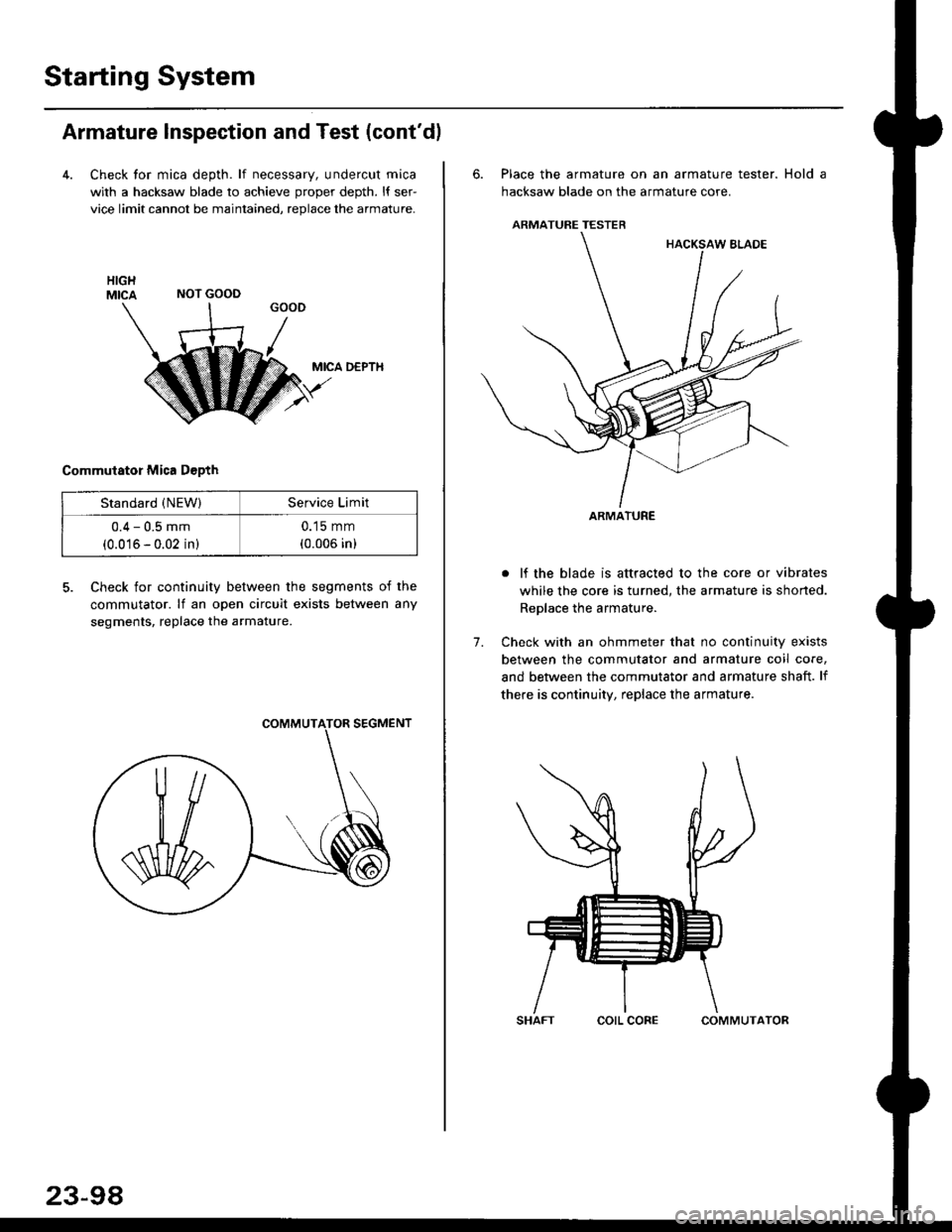

Armature Inspection and Test (cont'dl

4. Check tor mica depth. lf necessary, undercut mica

with a hacksaw blade to achieve proper depth. l{ ser-

vice limit cannot be maintained, replace the armature.

MICA D€PTH

Commutator Mica D€pth

5. Check for continuity between the segments of the

commutator. lf an open circuit exists between any

segments, replace the armature.

NOT GOOD

Standard (NEW)Service Limit

0.4 - 0.5 mm

(0.016 - 0.02 in)

0.15 mm

(0.006 in)

23-98

corL coFECOMMUTATOR

6. Place the armature on an armature tester. Hold a

hacksaw blade on the armature core.

ARMATURE TESTER

. lf the blade is attracted to the core or vibrates

while the core is turned, the armature is shorted.

Replace the armature.

7. Check with an ohmmeter that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. lf

there is continuity, replace the armature.

ARMATURE

Page 1569 of 2189

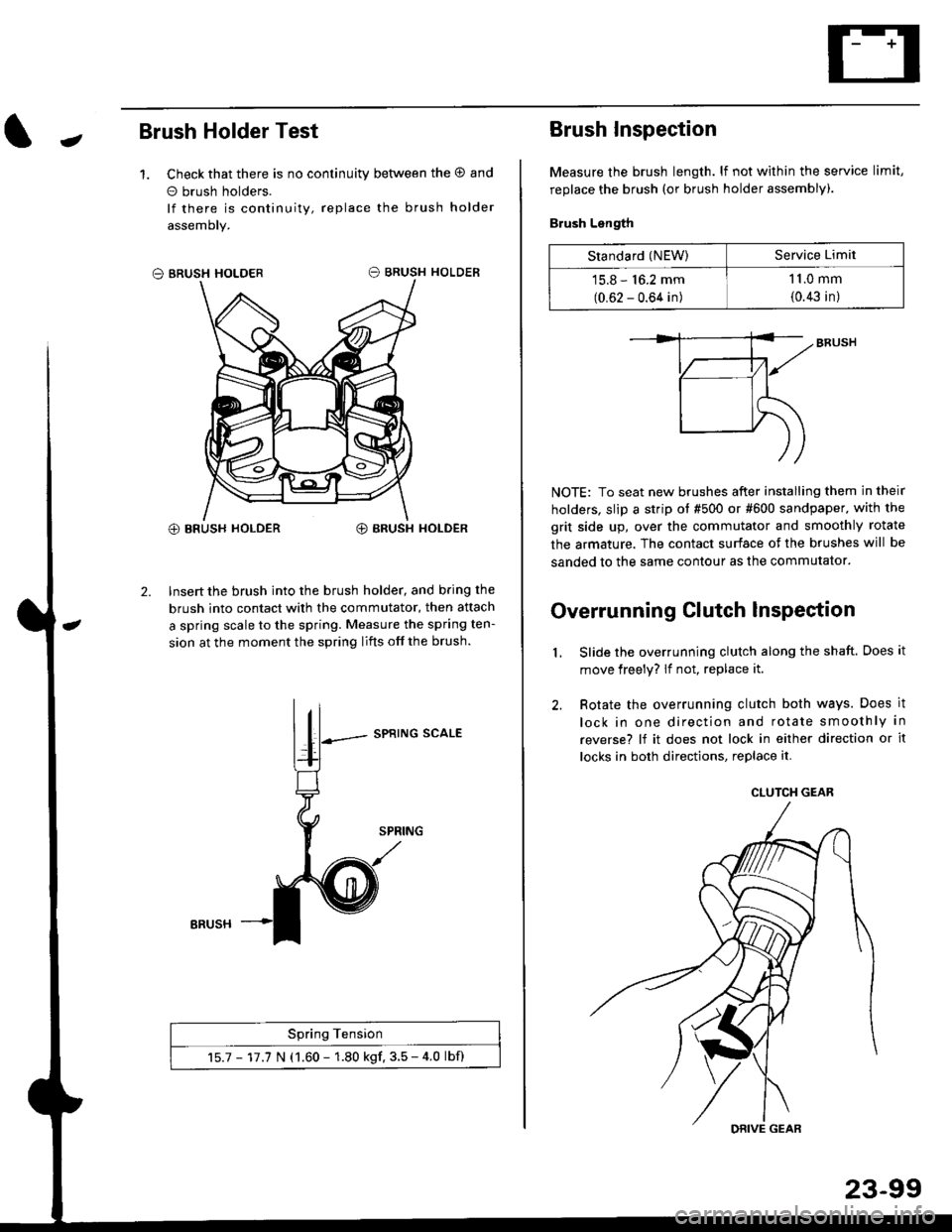

JBrush Holder Test

1. Check that there is no continuity between the O and

o brush holders.

lf there is continuity, replace the brush holder

assemoly.

O BRUSH HOLDER

@ BRUSH HOLDER€) BRUSH HOLDER

2. Insert the brush into the brush holder, and b.ing the

brush into contact with the commutator, then attach

a spring scale to the spring. Measure the spring ten-

sion at the moment the spring lifts off the brush.

SPRING SCALE

Spring Tension

15.7 - 17.7 N (1.60 - 1.80 kgf. 3.5 - 4.0 lbf)

ERUSH

Brush Inspection

Measure the brush length. lf not within the service limit,

replace the brush (or brush holder assembly).

Brush Length

NOTE: To seat new brushes after installing them in their

holders, slip a strip ot #500 or #600 sandpaper. with the

grit side up, over the commutator and smoothly rotate

the armature. The contact surface of the brushes will be

sanded to the same contour as the commutator.

Overrunning Clutch lnspection

Slide the overrunning clutch along the shaft. Does it

move freely? lf not, replace it.

Rotate the overrunning clutch both ways. Does it

lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, replace it.

2.

L

Standard (NEW)Service Limit

15.8 - 16.2 mm

(0.62 - 0.64 in)

1 1.0 mm

{0.43 in)

CLUTCH GEAR

DRIVE GEAR

Page 1570 of 2189

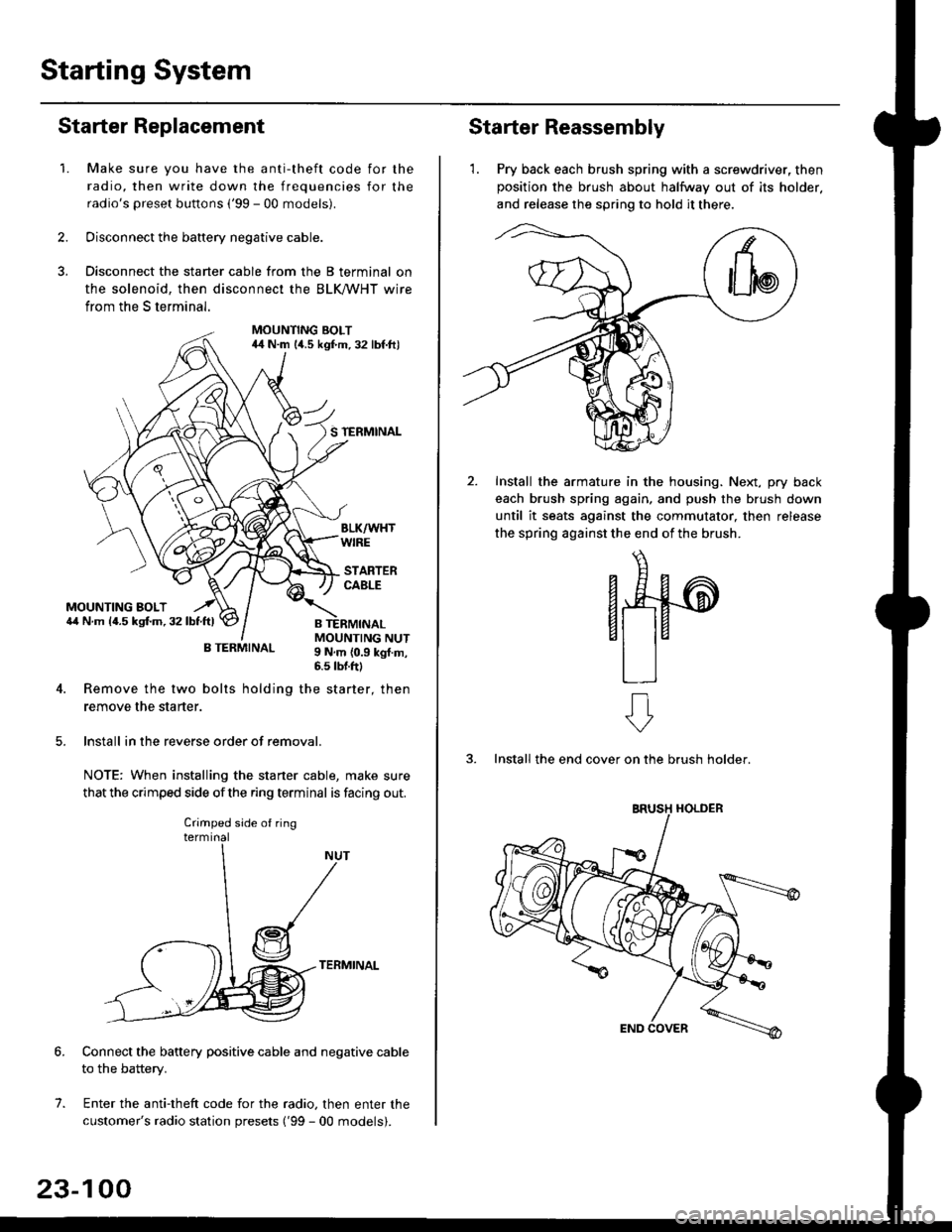

Starting System

Starter Replacement

1.Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable.

Disconnect the starter cable from the B terminal on

the solenoid, then disconnect the BLK trHT wire

from the S terminal.

MOUNTING BOLT44 N.m l/t.s kgf.m. 32 lbf.ft)

S TERMINAL

MOUNTING BOLT6,1 N.m {4.5 kstm.32lbtftl

MOUNTING NUT9 N,m {0.9 kgl.m,6.s lbtftl

B TERMINAL

4. Remove the two bolts holding the starter, then

remove the starter.

lnstall in the reverse order of removal.

NOTE: When installing the staner cable, make sure

that the crimped side ofthe ring terminal is facing out.

TERMINAL

Connect the battery positive cable and negative cable

to the battery.

Enter the anti-theft code for the radio, then enter the

customer's radio station presets ('99 - 00 models).

7.

Crimped side of ring

23-100

Starter Reassembly

'1. Pry back each brush spring with a screwdriver, then

position the brush about halfway out of its holder.

and release the spring to hold it there.

Install the armature in the housing. Next, pry back

each brush spring again, and push the brush down

until it seats against the commutator, then release

the spring against the end of the brush.

aw

3. Install the end cover on the brush holder.

ERUSH HOLDER