lock HONDA CIVIC 2002 7.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 424 of 1139

Manual Transmission

Transmission Disassembly

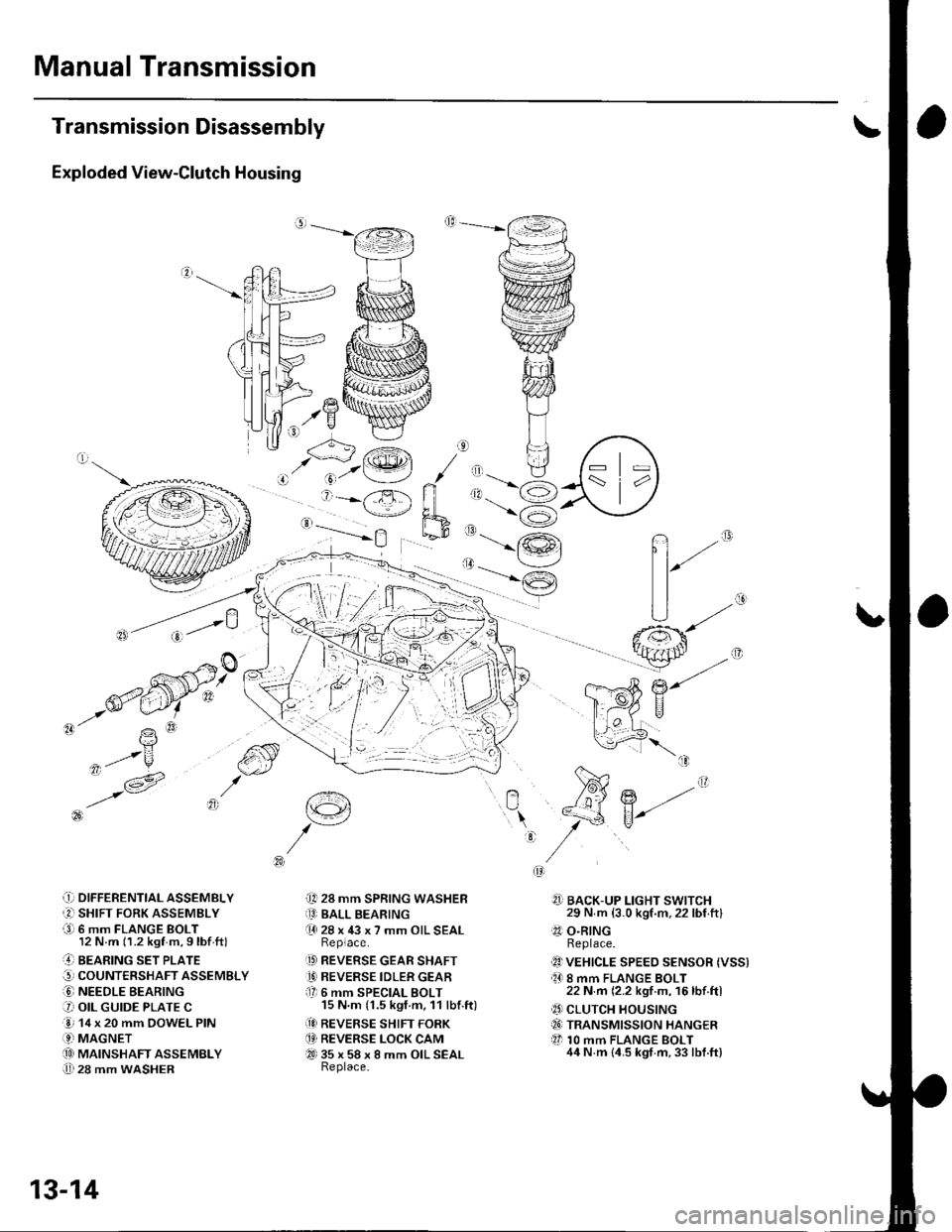

Exploded View-Clutch Housing

,.Y

-'- R

,ot/u

,t- v -1A' i6 t3l

\?

q'/V^

.!) DIFFERENTTAL ASSEMBLY

r2l SHIFT FORK ASSEMBLY

a9l 6 mm FLANGE BOLT12 N.m (1.2 kgf m,9lbf ftl

..4] BEARING sET PLATE

G, COUNTERSHAFT ASSEMBLY

O NEEDLE BEARING

3 OIL GUIDE PLATE C

e 14 x 20 mm DOWEL PIN

.9-i MAGNETi.!! MAINSHAFT ASSEMBLY

U 28 mm WASHER

t€4

i[, 28 mm SPRING WASHERiO BALL BEARING(l 28 x 43 x 7 mm OIL SEALReplace.

.D REVERSE GEAR SHAFT

1' REVERSE IDLER GEARf lr 6 mm SPECIAL BOLT15 N.m (1.5 kgt.m, 11 lbf.ft)

(!I REVERSE SHIFT FORK

.4' REVERSE LOCK CAMQ-t 35 x 58 x 8 mm OIL SEALReplace.

n""

?]] BACK-UP LIGHT SWITCH29 N m (3.0 kgf.m,22 lbf ftl.?1 O.RINGReplace.

1!) VEHICLE SPEEo sENsoR (Vss).O 8 mm FLANGE BOLT22 N.m (2.2 kgf m, 16lbf.ftl

.' CLUTCH HOUSINGiI6) TRANSMISSION HANGER

tl 10 mm FLANGE BOLT44 N.m {4.5 kgt.m,33 lbf.ft}

:

r'<__J'.@t / ,, tl

' j=-X ri ,1.-6

'-==-Yh,_-9

13-14

Page 425 of 1139

o,. @\

'\b

e

P\B

z-W

-

€:

iq { "

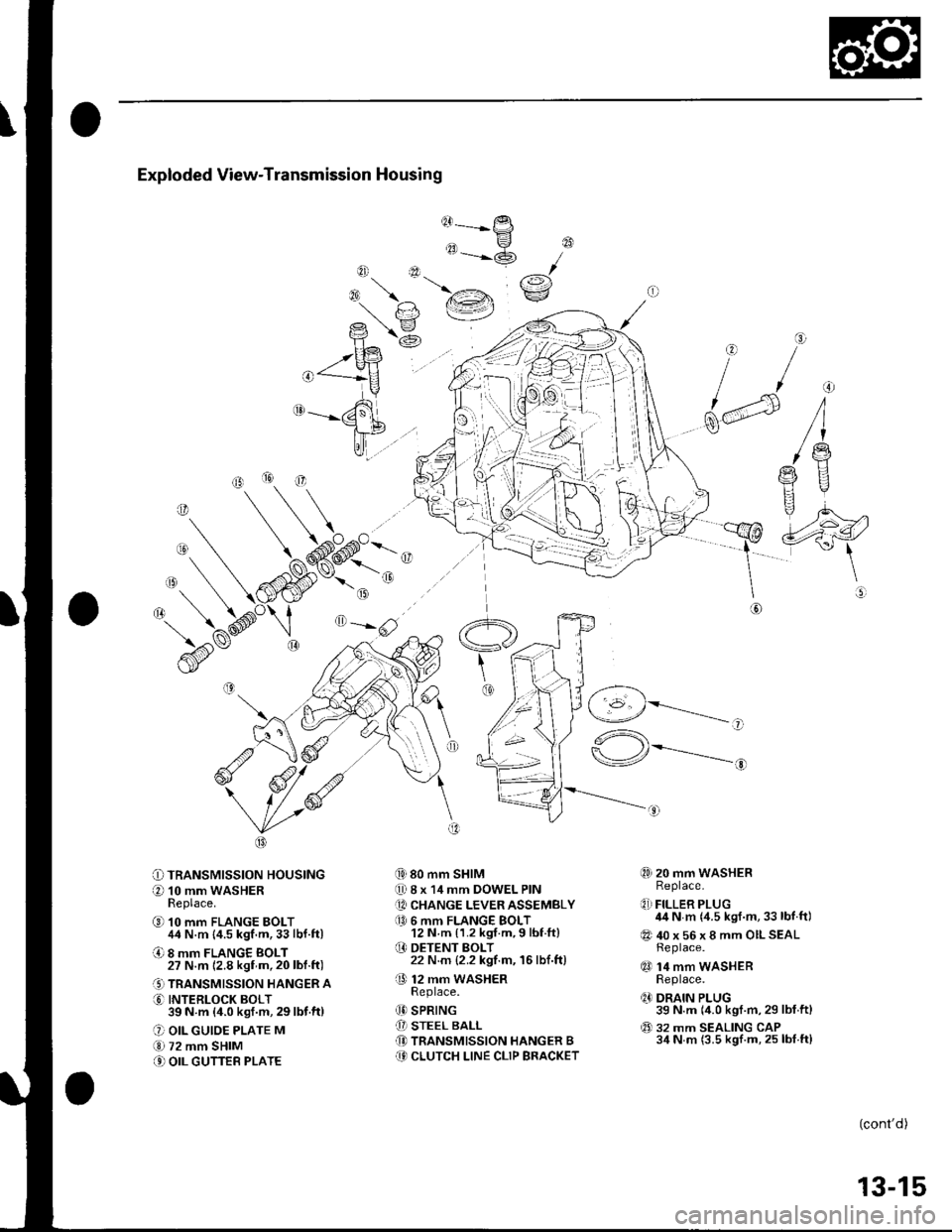

Exploded View-Transmission Housing

@------

tt-P

"=-@

{i) 80 mm SHIM

0 8 x 14 mm DOWEL PIN

[A CHANGE LEVER ASSEMBLY

a0 6 mm FLANGE BOLT12 N m {1.2 kgf.m,9 lbf ft}

O DETENT BOLT22 N.m {2.2 kgf.m, 16lbf.ft)

O 12 mm waSHERReDlace.

(D SPRING

[I STEEL BALL(D TRANSMISSION HANGER B(9 CLUTCH LINE CLIP BRACKET

@

rai\€:/

o

f/

dd

\@

O=-rlF,z

O TRANSMISSION HOUSING

O 10 mm WASHERReplace.

@ 10 mm FLANGE BOLT44 N.m {4.5 kgf.m,33lbf.ft)

O 8 mm FLANGE BOLT27 N.m 12.8 kgf m,20lbl.ft)

.' TRANSMISSION HANGER A

O INTERLOCK BOLT39N m (4.0ksf.m,29lbf.ft)

O OIL GUIOE PLATE M

€.1 72 mm SHIM

.' OIL GUTTEB PLATE

,-1 _\(g/----------__-

"^\

\-/r*---------..-,

@) 20 mm WASHERReplace.

q,] FILLER PLUG44 N m {4.5 kgf.m,33 lbf.ft)

@ 40 x 56 x 8 mm OILSEALReplace.

qO 14 mm WASHERReplace.

q' DRAIN PLUG39 N.m (4.0 kgf.m,29 lbf.ftl

@ 32 mm SEALING CAP34 N m (3.5 kgf.m, 25 lbf.ft)

o

(cont'd)

13-15

Page 426 of 1139

Manual Transmission

Transmission Disassembly (cont'd)

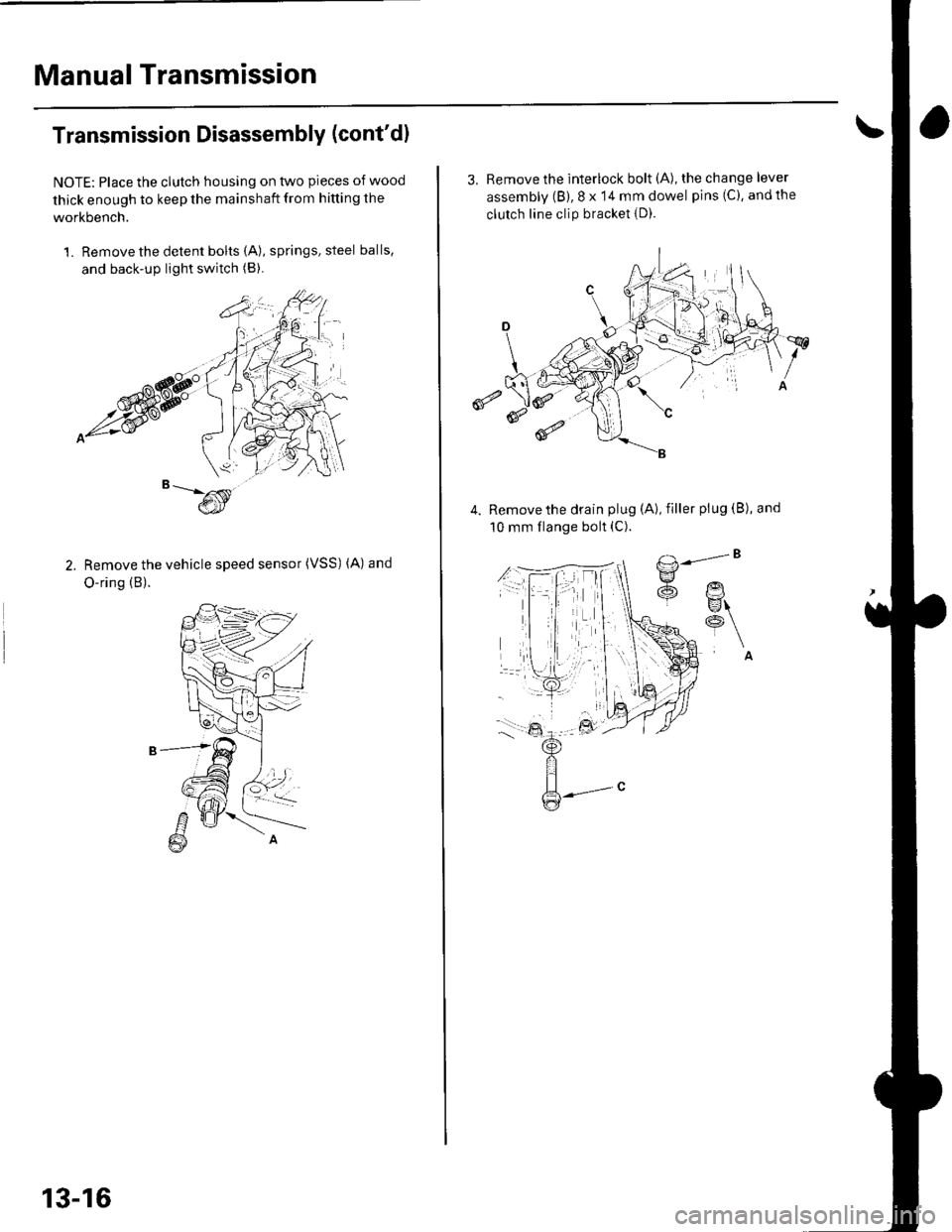

NOTE: Place the clutch housing on two pieces of wood

thick enough to keep the mainshaft from hitting the

workbench.

1. Remove the detent bolts (A), springs, steel balls,

and back-up light switch (B).

Remove the vehicle speed sensor (VSS) (A) and

O-ring (B).

13-16

3, Remove the interlock bolt (A), the change lever

assembly (B), 8 x 14 mm dowel pins (C), andthe

clutch line clip bracket {D).

€

Remove the drain plug (A), filler plug (B), and

10 mm flange bolt (C).

Page 427 of 1139

6.

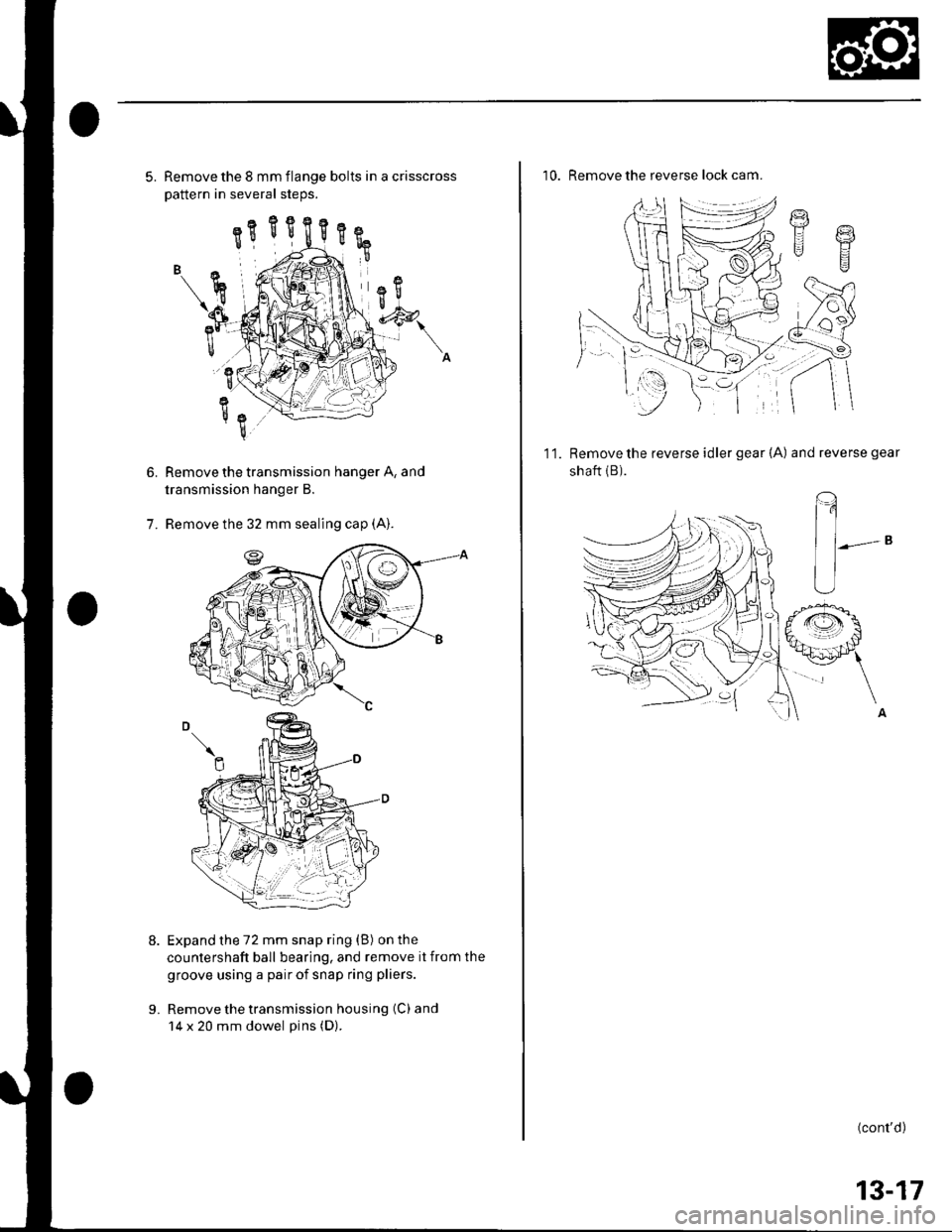

5. Remove the 8 mm flange bolts in a crisscross

Dattern in several steos.

Remove the transmission hanger A, and

transmission hanger B.

Remove the 32 mm sealing cap (A).

Expand the 72 mm snap ring (B) on the

countershaft ball bearing, and remove it from the

groove using a pair of snap ring pliers.

Remove the transmission housing (C) and

14 x 20 mm dowel pins (D).

7.

L

10. Remove the reverse lock cam.

g

t.l Y

g

11.Remove the reverse idler gear {A) and reverse gear

shaft {B).

(,

^A

(cont'd)

13-17

Page 430 of 1139

Manual Transmission

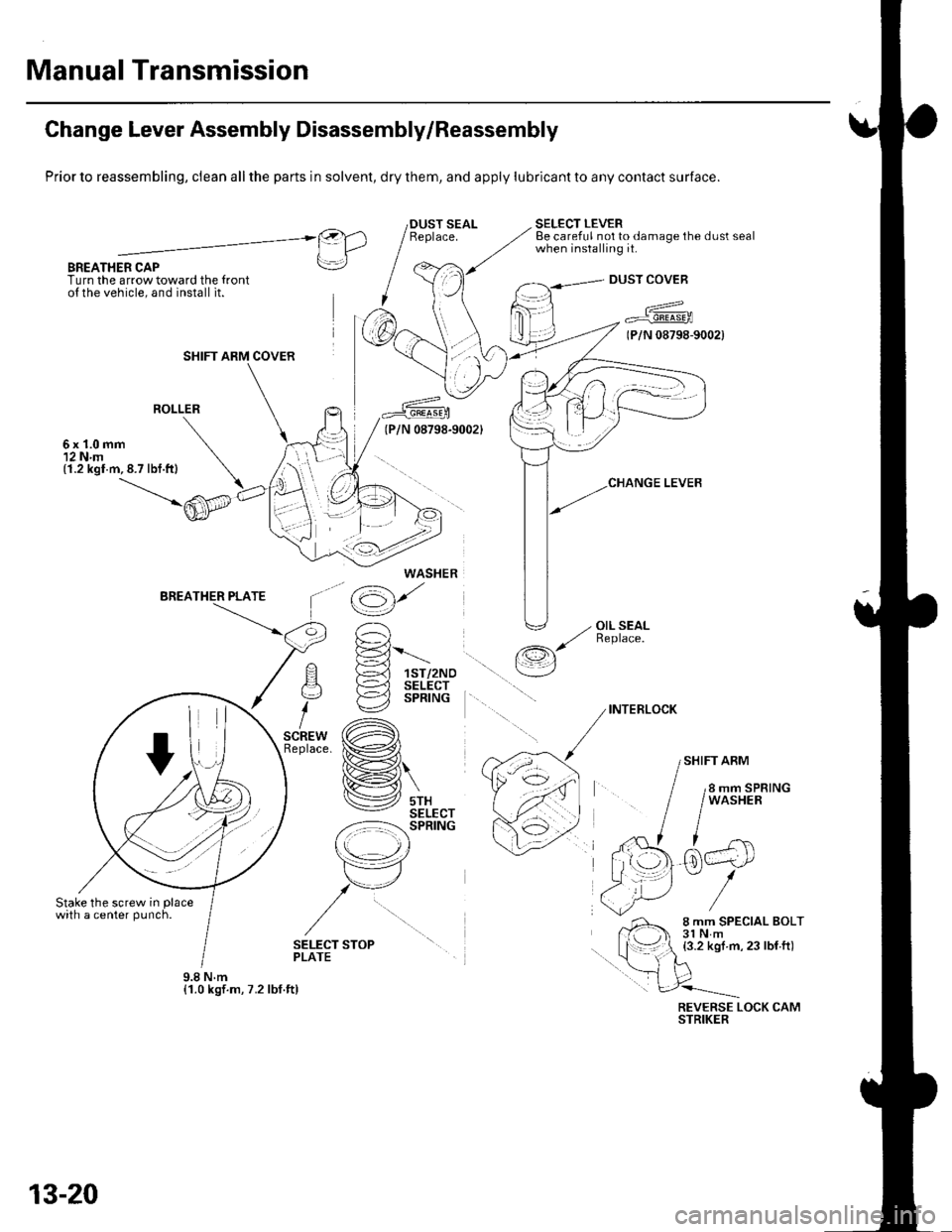

Change Lever Assembly Disassembly/Reassembly

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact surface.

BREATHER CAPTurn the arrow toward the {ronto{ the vehicle, and install it.

SELECT LEVERBe careful not to damage the dust sealwhen installing it.@).1 IlLrl

rrl

I

DUST COVEB

a^^

7 Fr"irr6-rooa

(P/N 08798-9002)

ROLLER

6x1.0mm12 N.m(1.2 kgl.m,8.7 lbf.ft)

'^ E-='-Fl !-d 1sr/2Noq )-=^l sELEcr

i €2 sPntruc

,.* (A)tace. ix�#,,l

H\

lV srxSELECT-z:-=:l-': SPRING

r\

tr7

,/u

/

\op

(g)'

' -, OIL SEAL,/ ReDlace./-r,s

\__/

INTERLOCK

SHIFT ARM

SELECT STOPPLATE

REVERSE LOCK CAMSTRIKER

SHIFT ARM COVER

WASHER

9.8Nm{1.0 kgf.m, 7.2 lbf.ft)

13-20

Page 435 of 1139

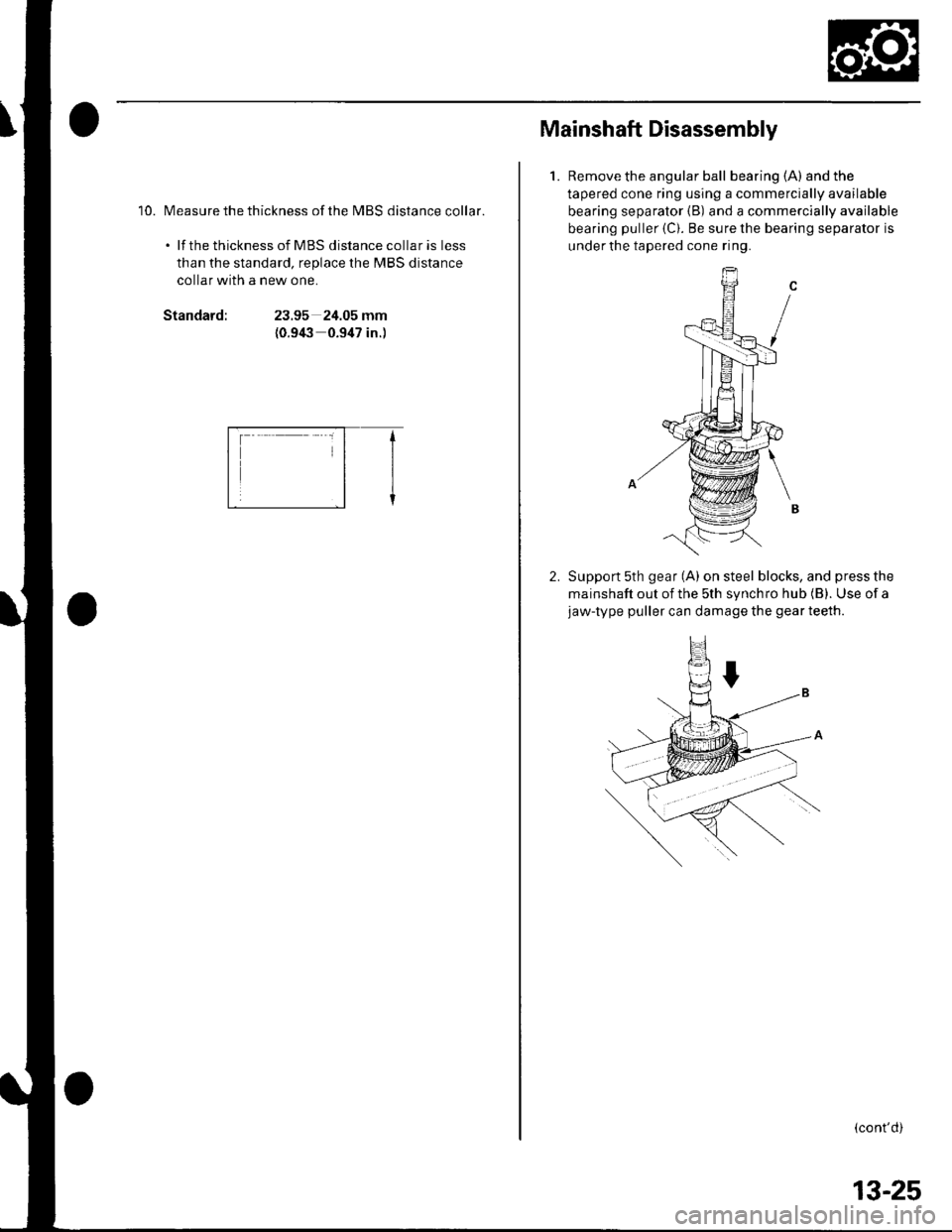

'10. Measure the thickness ofthe MBS distance collar.

. lf the thickness of MBS distance collar is less

than the standard, replace the MBS distance

collar with a new one.

Standard:23.95 24.05 mm

{0.9(3 0.947 in.)

E-f

Mainshaft Disassembly

1.Remove the angular ball bearing (A) and the

tapered cone ring using a commercially available

bearing separator {B) and a commercially available

bearing puller {C). Be sure the bearing separator is

under the tapered cone ring.

Support 5th gear (A) on steel blocks, and press the

mainshaft out of the sth synchro hub (B). Use of ajaw-type puller can damage the gear teeth.

(cont'd)

13-25

Page 436 of 1139

Manual Transmission

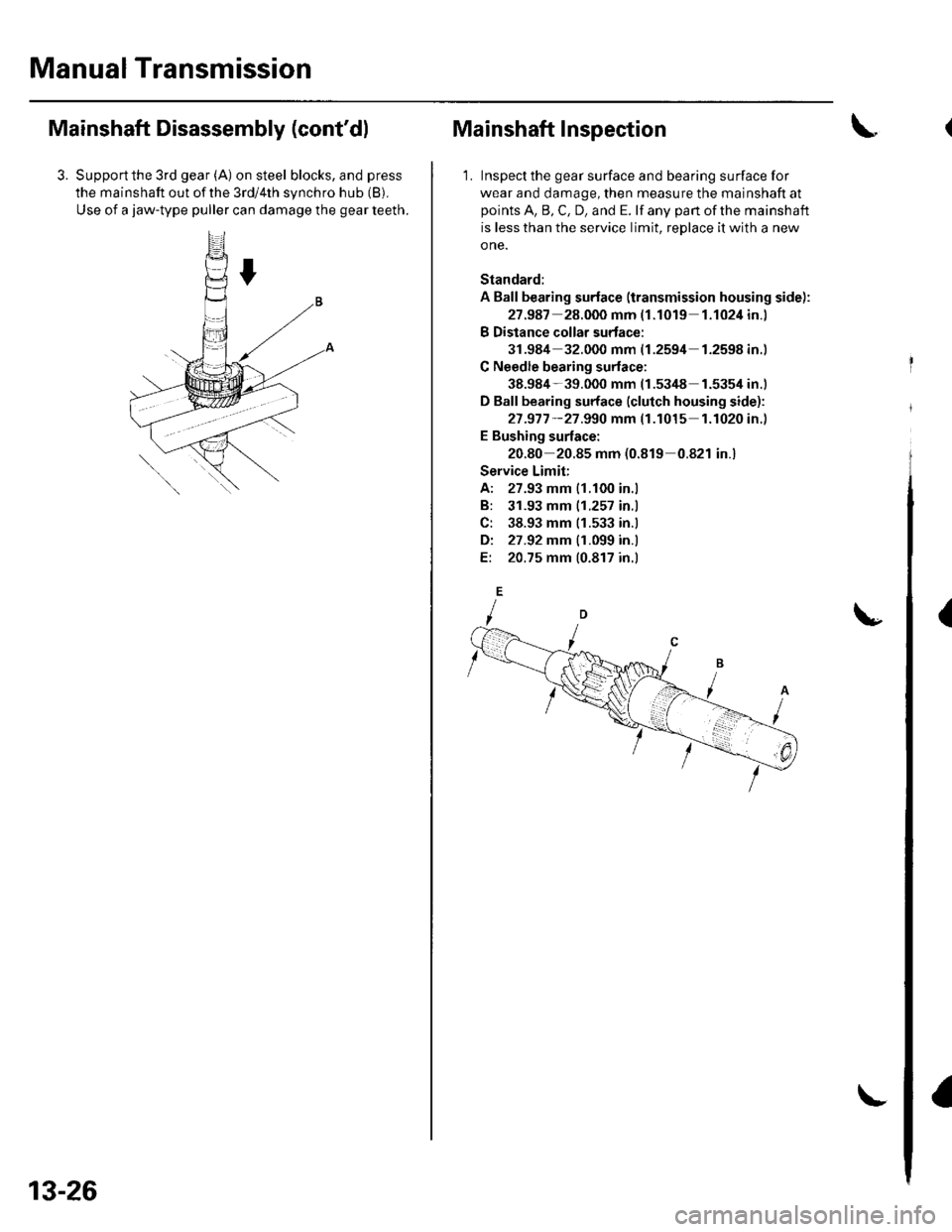

Mainshaft Disassembly (cont'dl

3. Supportthe 3rd gear (A) on steel blocks, and press

the mainshaft out of the 3rd/4th synchro hub (B).

Use of a jaw-type puller can damage the gear teeth.

13-26

Mainshaft Inspection

1. Inspect the gear surface and bearing surface for

wear and damage, then measure the mainshaft at

points A, B, C, D, and E. lf any part of the mainshaft

is less than the service limit, reDlace it with a new

o ne.

Standard:

A Ball bearing surface (transmission housing side):

27.987 28.000 mm (1.1019 1.1024in.)

B Distance collar surtace:

31.984 32.000 mm {1.2594 1.2598in.)

C Needle bearing surlace:

38.984-39.000 mm (1.53/t8 1.5354 in.)

D Ball bearing surface (clutch housing side):

27 .977 -27 .990 mm (1.1015 1.1020in.)

E Bushing surface:

20.80 20.85 mm (0.819 0.821 in.)

Service Limit;

A: 27.93 mm 11.100 in.l

B: 31.93 mm |.1.257 in.l

C: 38.93 mm 11.533 in.l

Di 27.92 mm {1.099 in.l

E: 20.75 mm 10.817 in.l

{

Page 442 of 1139

Manual Transmission

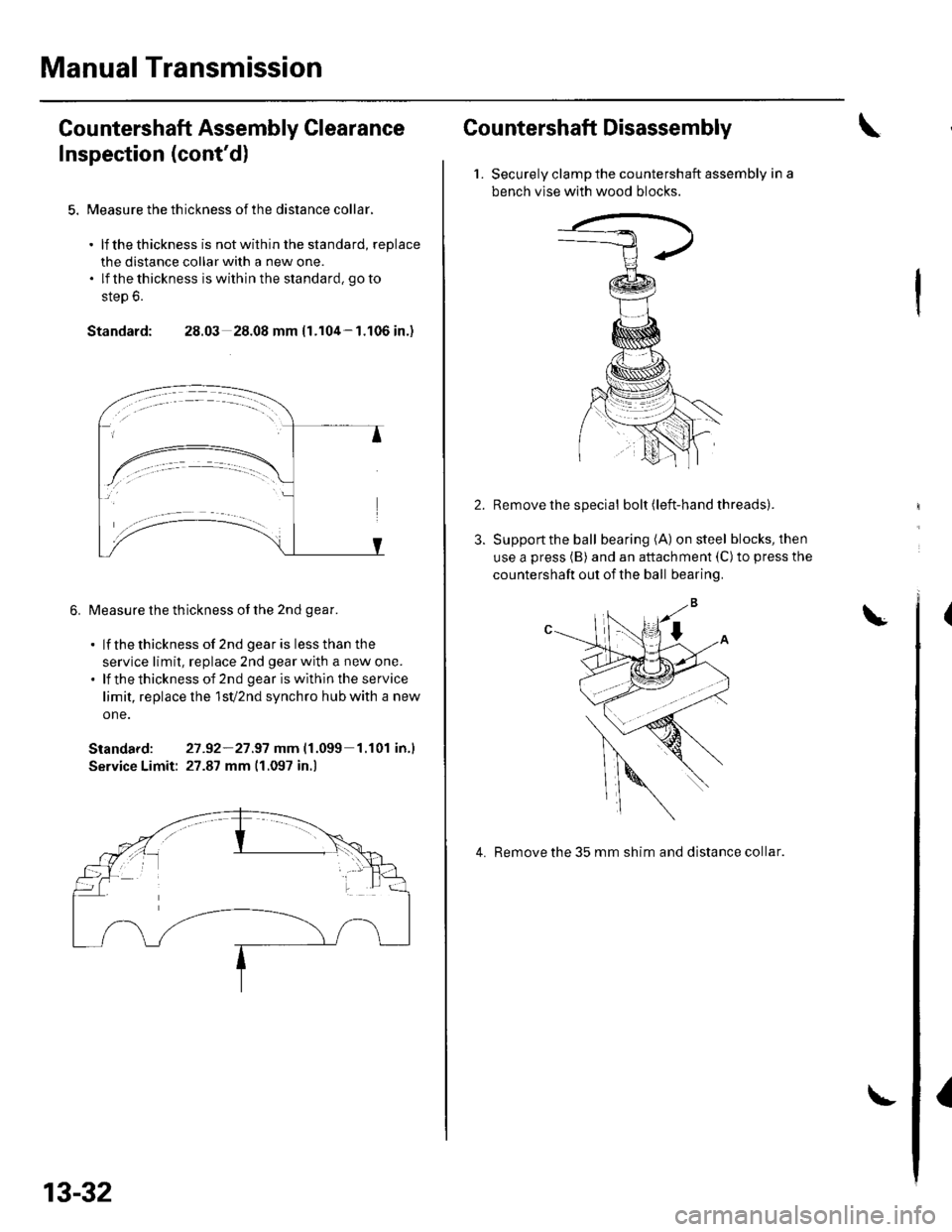

Countershaft Assembly Clearance

Inspection (cont'd)

5. Measure the th ickness of the distance collar.

. lf thethickness is notwithin the standard, replace

the distance collar with a new one.. lf thethickness iswithinthe standard, goto

step 6.

Standard: 28.03 28.08 mm {1.104-1.106 in.)

6. Measure the thickness of the 2nd qear.

. lf thethickness of 2nd gearis lessthan the

service limit, replace 2nd gear with a new one.. lf thethicknessof 2nd geariswithintheservice

limit, replace lhe 1sV2nd synchro hub with a new

one.

Standard: 27 -92-21.97 mm|.1.099 1.r01 in.l

Service Limit: 27.87 mm 11.097 in.)

13-32

Countershaft Disassembly

1.Securely clamp the countershaft assembly in a

bench vlse with wood blocks.

Remove the special bolt (left-hand threads).

Support the ball bearing (A) on steel blocks, then

use a press (B) and an attachment (C)to press the

countershaft out of the ball bearing.

4. Remove the 35 mm shim and distance collar.

I

Page 443 of 1139

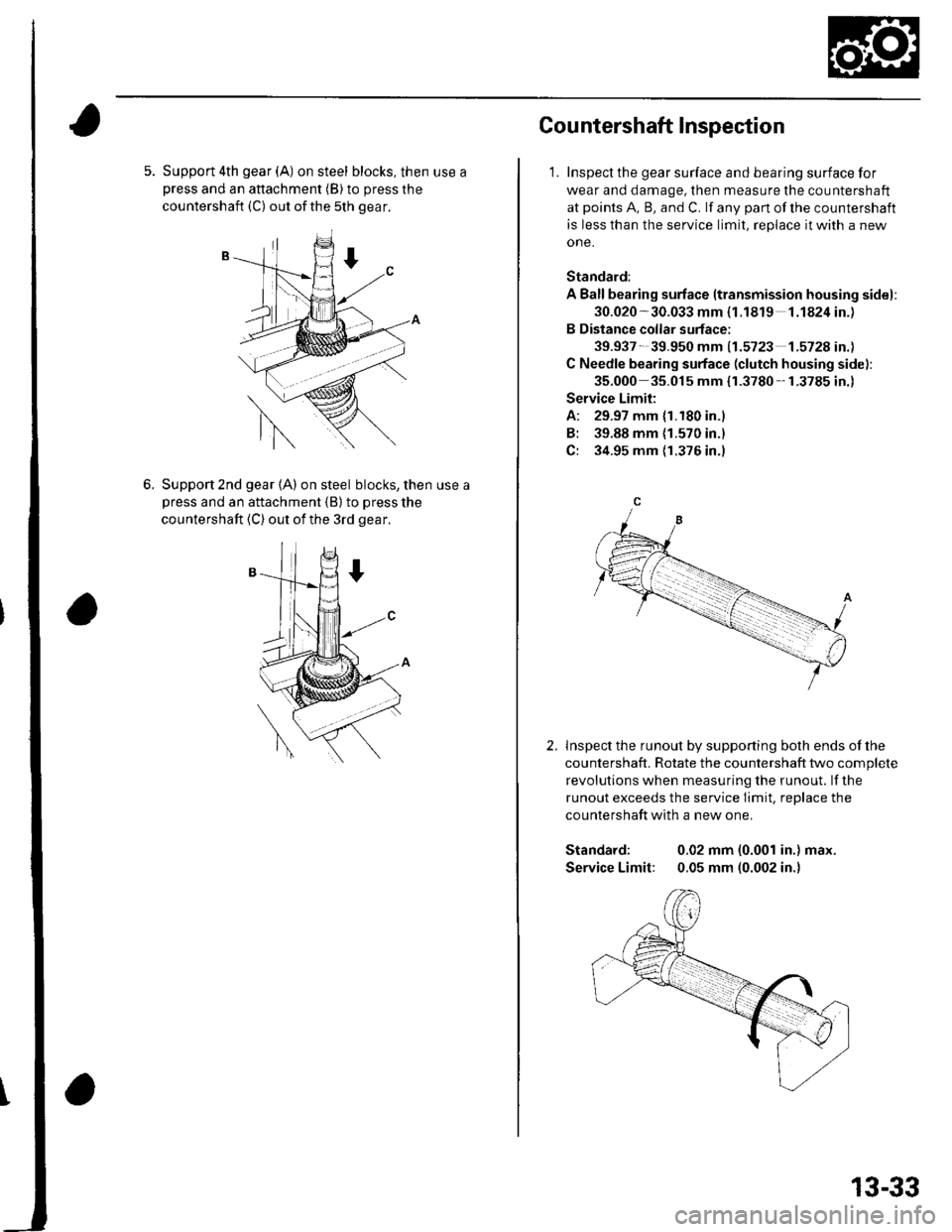

5. Support 4th gear (A) on steel blocks, then use apress and an attachment (B) to press the

countershaft (C) out ofthe 5th gear.

6.Support 2nd gear (A) on steel blocks, then use a

Dress and an attachment {B} to press the

countershaft (C) out of the 3rd gear.

Cou ntershaft lnspection

1. Inspect the gear surface and bearing surface for

wear and damage, then measure the countershaft

at points A, B, and C. lf any part of the countershaft

is less than the service limit, replace it with a new

one.

Standard:

A Ballbearing surface ltransmission housing sidel:

30.020 -30.033 mm {1.1819 1.1824in.)

B Distance collar surface;

39.937- 39.950 mm 11.5723 1.572A in.l

C Needle bearing surface (clutch housing side):

35.000 35.015 mm {r.3780-1.3785 in.)

Service Limit:

A: 29.97 mm {1.180 in.)

B: 39.88 mm {1.570 in.l

C: 34.95 mm {1.376 in.)

lnspect the runout by supporting both ends of lhe

countershaft. Rotate the countershaft two complete

revolutions when measuring the runout. lf the

runout exceeds the service Iimit, replace the

countershaft with a new one.

Standard: 0.02 mm (0.001 in.) max.

Service Limit: 0.05 mm (0.002 in.)

2.

13-33

Page 446 of 1139

Manual Transmission

10.

Countershaft Reassembly (cont'dl

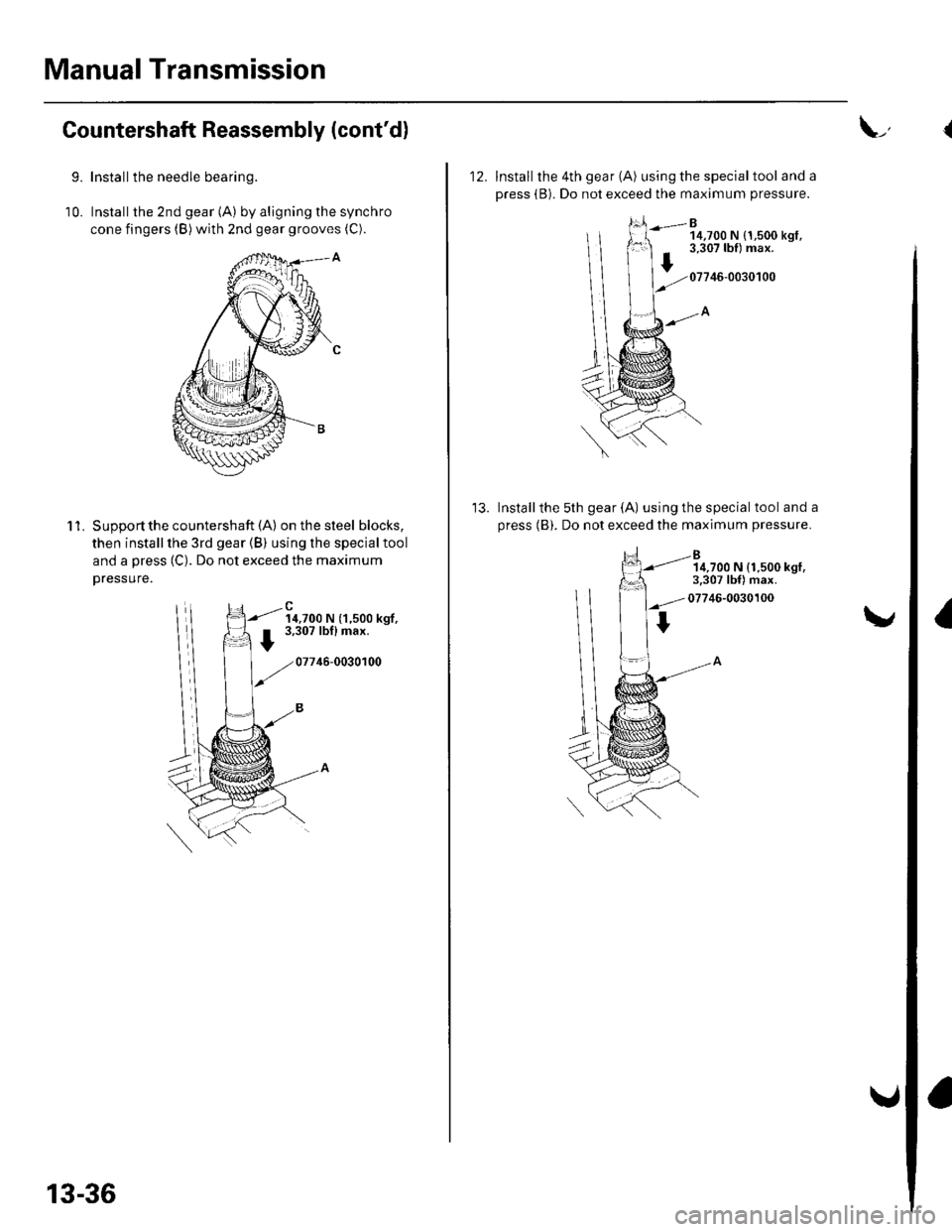

9.Install the needle bearing.

Installthe 2nd gear (A) by aligning the synchro

cone fingers (B) with znd gear grooves (C).

'l 1.Supoort the countershaft (A) on the steel blocks,

then install the 3rd gear (B) using the special tool

and a press (C). Do not exceed the maximum

Dressure.

14,700 N (1,500 kgf,3,307 lbflmax.

07746-0030100

13-36

L,

12. Install the 4th gear (A) using the specialtool and a

press (B). Do not exceed the maximum pressure.

B14,700 N {1,500 kgt,3,307 lbf) max.

07746-0030100

Installthe 5th gear (A) using the special tool and a

press (B). Do not exceed the maximum pressure.

14,700 N (1.500 kgl,3.307 lbf) max.

07746-0030100

I