engine HONDA CIVIC 2002 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 136 of 1139

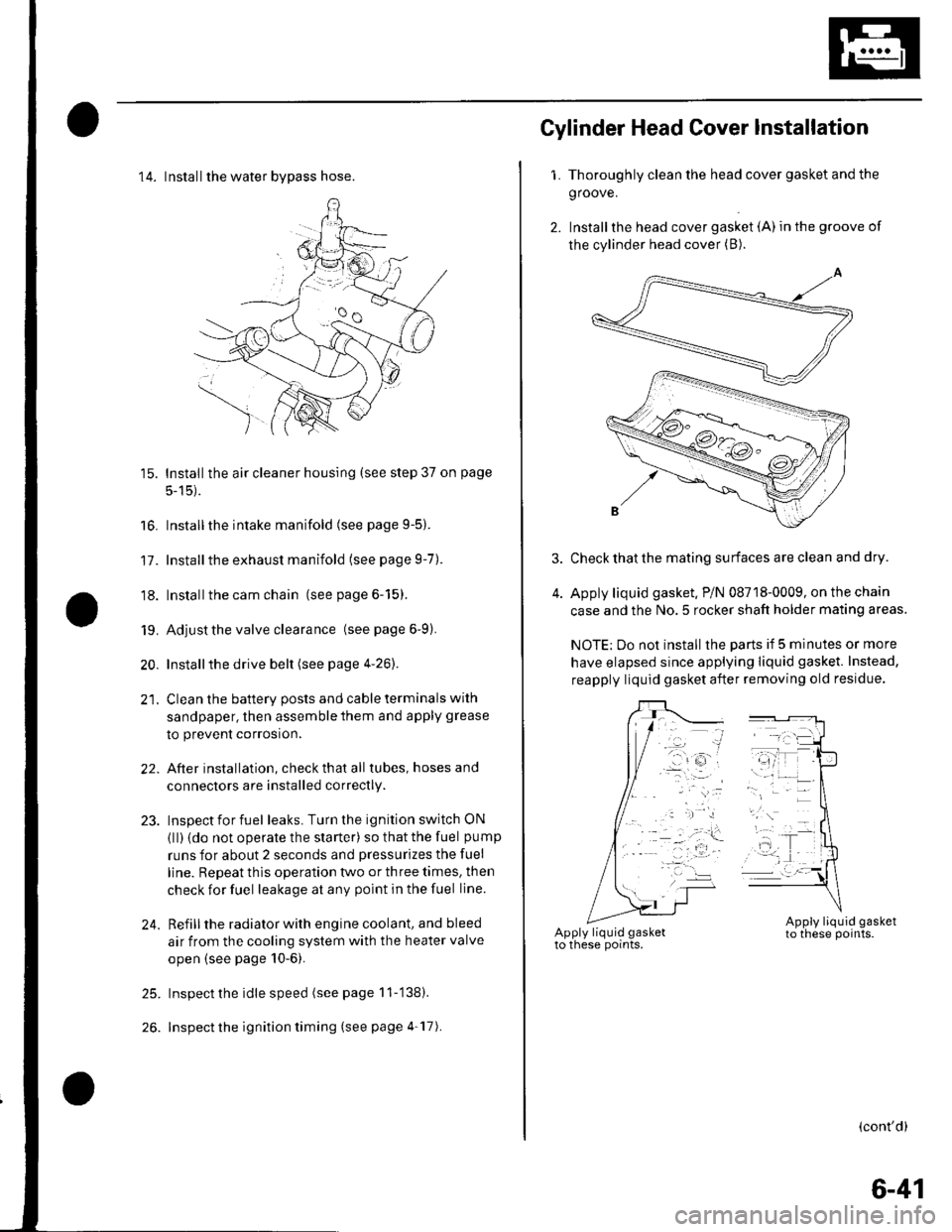

14. Installthe water bvpass hose.

15. Installthe air cleaner housing (see step 37 on page

5-15).

16. Installthe intake manifold (see page 9-5).

17. Installthe exhaust manifold (see page 9-7).

'18. Installthe cam chain (see page 6-15).

19. Adjust the valve clearance (seepage6-9).

20. Installthe drive belt (see page 4-26).

21. Clean the battery posts and cable terminals with

sandpaper, then assemble them and apply grease

to prevent corrosion.

22. After installation, checkthatall tubes, hosesand

connectors are installed correctly.

23. Inspectforfuel leaks. Turn the ignition switch ON

{ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat thls operation two or three times, then

check for fuel leakage at any point in the fuel line.

24. Refillthe radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

25. Inspect the idle speed (see page 11-'138).

26. Inspect the ignition timing (see page 4-17).

Gylinder Head Cover lnstallation

1. Thoroughly clean the head cover gasket and the

groove.

2. Installthe head cover gasket (A) in the groove of

the cylinder head cover (B).

Check that the mating surfaces are clean and dry.

Apply liquid gasket. P/N 08718-0009, on the chain

case and the No.5 rocker shaft holder mating areas.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

6-41

Page 138 of 1139

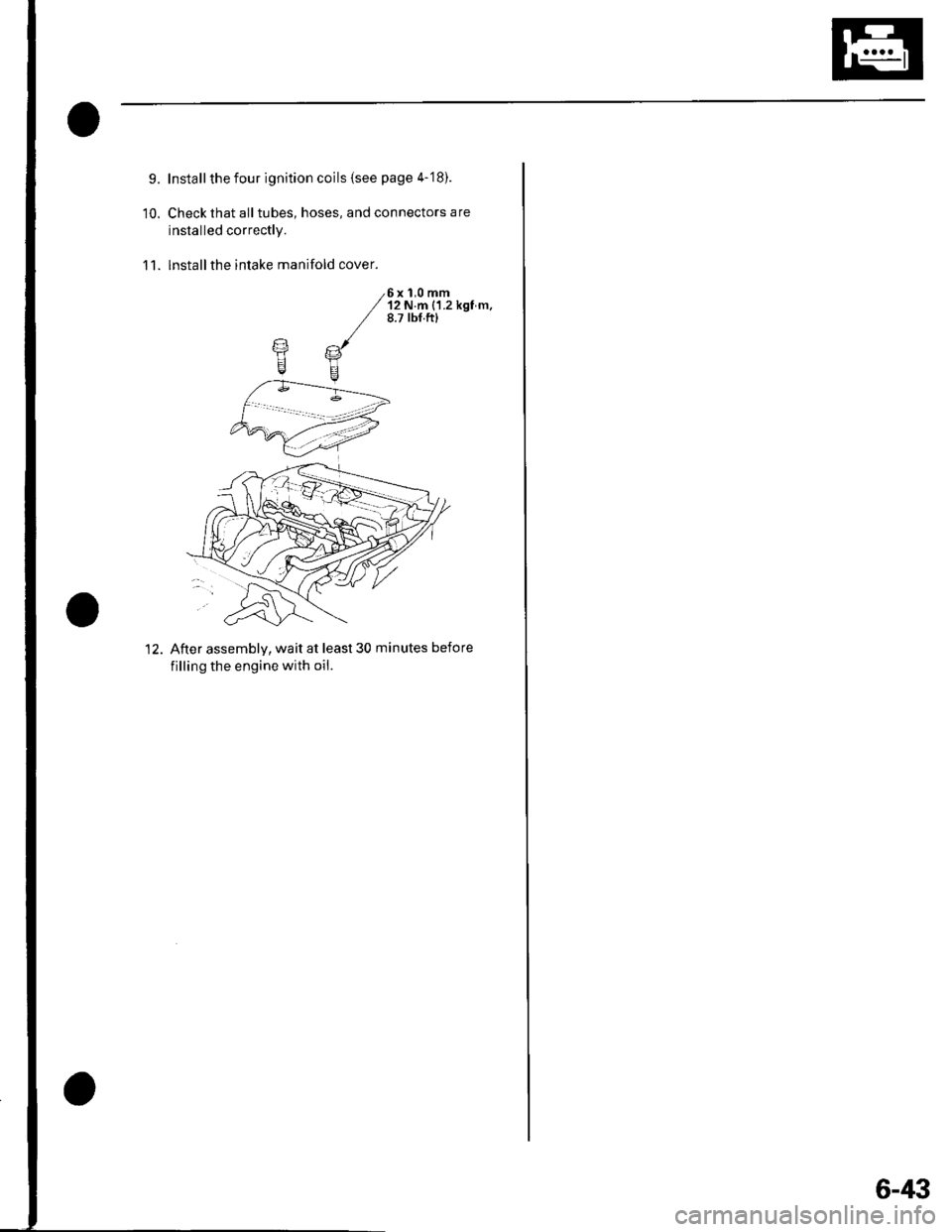

9.

10.

Install the four ignition coils (see page 4-'18).

Check that all tubes, hoses, and connectors are

installed correctly.

lnstallthe intake manifold cover.11.

6x 1,0 mm'12 N.m {1.2 kgf m.8.7 tbf.ftl

12. After assemblv, wait at least 30 minutes before

filling the engine with oil.

6-43

Page 139 of 1139

Engine Mechanical

Engine Block

Soecial Tools ............. 7 -2

Comoonent Location Index ......................................... 7-3

Connecting Rod and Crankshaft End Play

InsDection .............. 7-5

Crankshaft Main Bearing Replacement ...................... 7-6

Connecting Rod Bearing Replacement ...................... 7-8

Oil Pan Removal ....................... .......... 7-11

Crankshaft and Piston Removal ........ 7-12

Crankshaft Inspection ........................ 7-14

Block and Piston Insoection ........................................ 7-15

Cyfinder Honing ............ .".................... 7 -'17

Piston, Pin and Connecting Rod Replacement .......... 7-18

Piston Ring Replacement ................... 7 -21

Piston lnstallation .................... ........... 7-23

Connecting Rod Bolt Inspection .......' 7 -24

Crankshaft lnstallation .....................'. 7-24

Oil Pan lnstallation .................. ........... 7 -27

Transmission End Crankshaft Seal

lnstallation-ln Car ................... ........' 7 -28

Page 140 of 1139

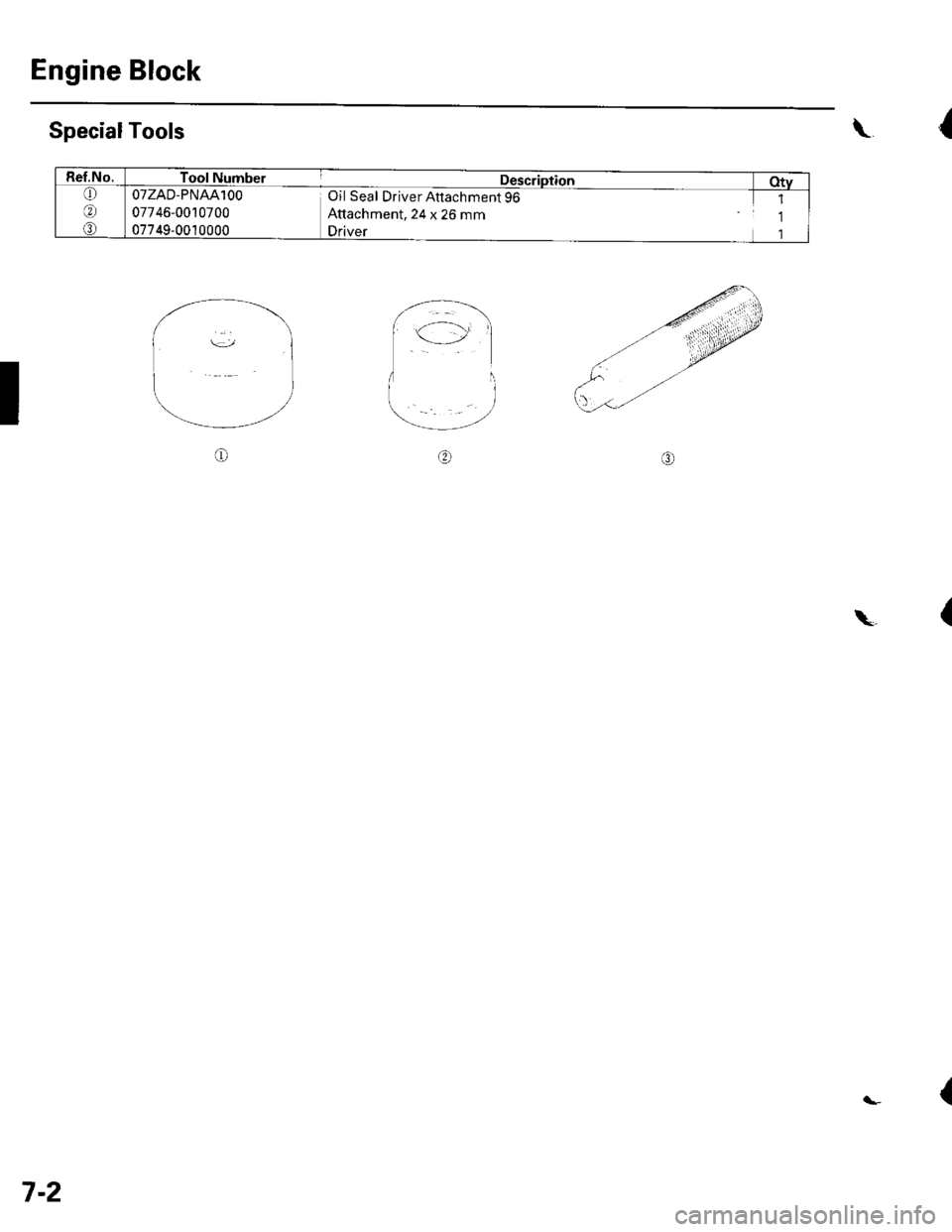

Engine Block

SpecialTools

I

{\

Ref.No.Tool Number

OTZAD-PNAAlOO

07746-0010700

07749,0010000

Description

Oil Seal Driver Attachment 96

Attachment, 24 x 26 mm

Driver

Oty

6

@

1

1

1

o

{\

{

7-2

Page 142 of 1139

Engine Block

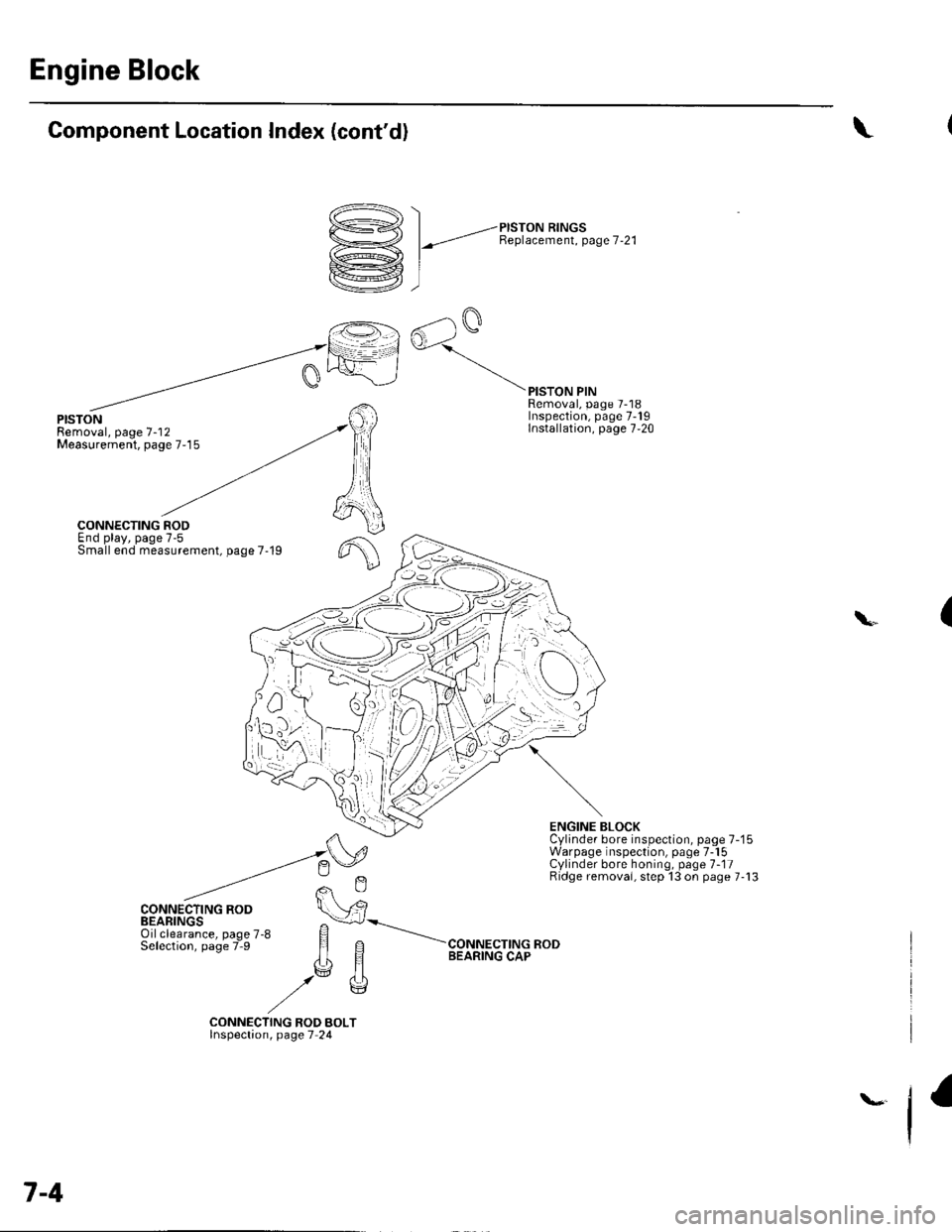

Component Location Index (cont'd)

/^., \

D->< | _,-ersroru nrrucs

Y1 l-"t Benlacement. Page 7-21

rkrej, I

ffil

rG AalQ

[=l^oJ

\

PISTONRemoval, page 7-'12Measurement, page 7-15

PISTON PINRemoval, page 7-18Inspection, page 7-19Installation, page 7,20

f,

6

CONNECTING RODEnd play, page 7-5Small end measurement, page 7-19

CONNECTING ROD

ENGINE BLOCKCylinder bore inspection, page 7-'15Warpage inspection, page 7-15Cylinder bore honing, page 1-11Ridge removai, step 13 on page 7-13

(\

CONNECTING ROD BOLTlnspectaon, page 7 24

7-4

Page 144 of 1139

Engine Block

Crankshaft Main Bearing Replacement

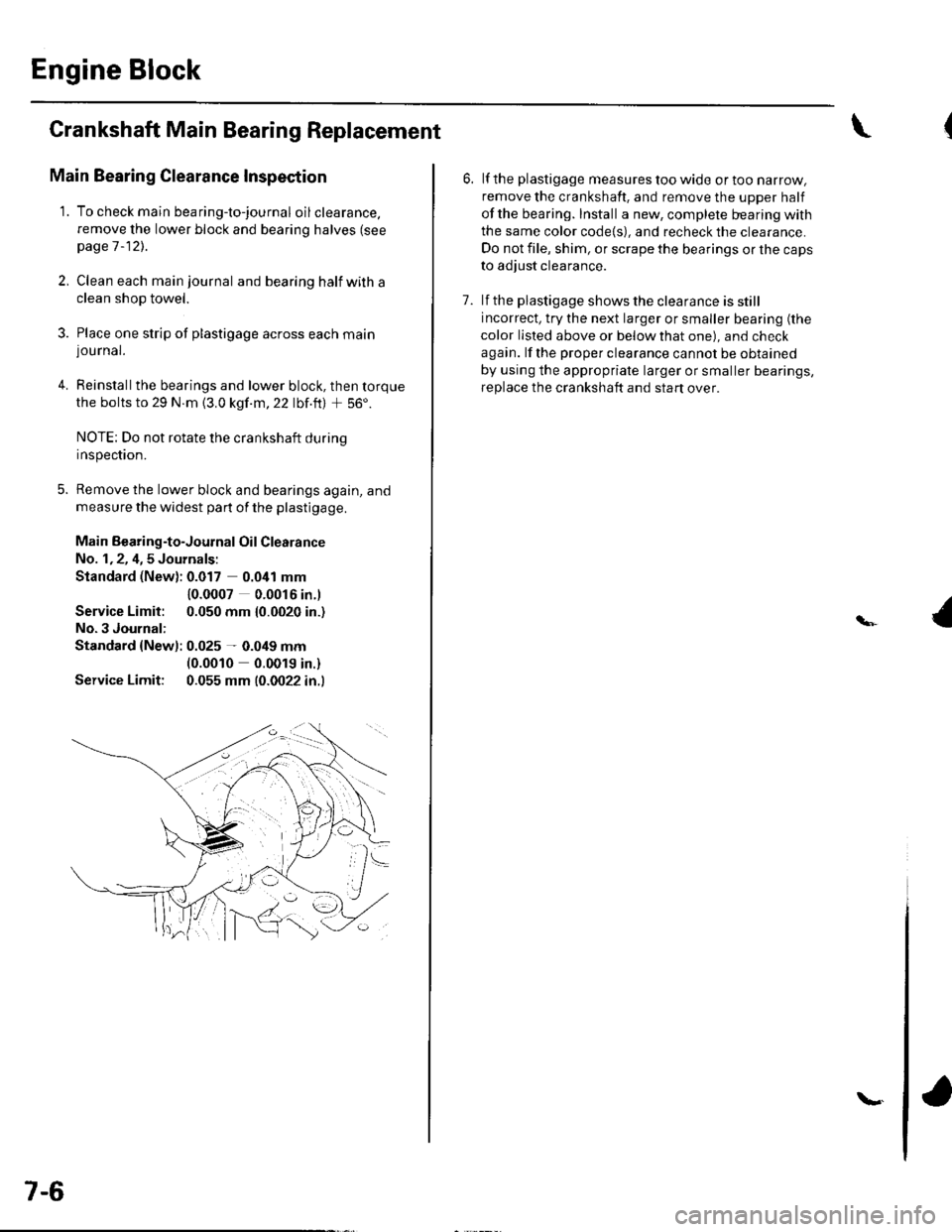

Main Bearing Clearance Inspection

1. To check main bea ring-to-jou rna I oil clearance.

remove the lower block and bearing halves (see

page 1 -12)..

2, Clean each main journal and bearing half witha

clean shop towel.

3. Place one strip of plastigage across each main

lou rnal.

4. Reinstallthe bearings and lower block, then torque

the bolts to 29 N.m {3.0 kgf.m,22 lbf.ft) + 56'.

NOTE: Do not rotate the crankshaft during

Inspeclton.

5. Remove the lower block and bearings again, and

measure the widest part of the plastigage.

Main Bearing-to-Journal Oil Clearance

No. 1,2, 4,5 Journals:

Standard (New): 0.017 0.041 mm

Service Limit:

No.3 Journal:

10.0007 0.0016 in.l

0.050 mm {0.0020 in.)

Standard {Newl: 0.025 - 0.049 mm(0.0010 0.0019 in.)

Service Limit: 0.055 mm (0.0022 in.l

7-6

\.

6. lf the plastigage measures too wide or too narrow,

remove the crankshaft. and remove the upper half

ofthe bearing. Install a new, complete bearing with

the same color code{s), and recheck the clearance.

Do not file, shim, or scrape the bearings or the caps

to adjust clearance.

7. lf the plastigage shows the clearance is still

incorrect, try the next larger or smaller bearing (the

color listed above or below that one), and check

again. lf the proper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

Page 146 of 1139

Engine Block

Crankshaft Main Bearing

Replacement (cont'd)

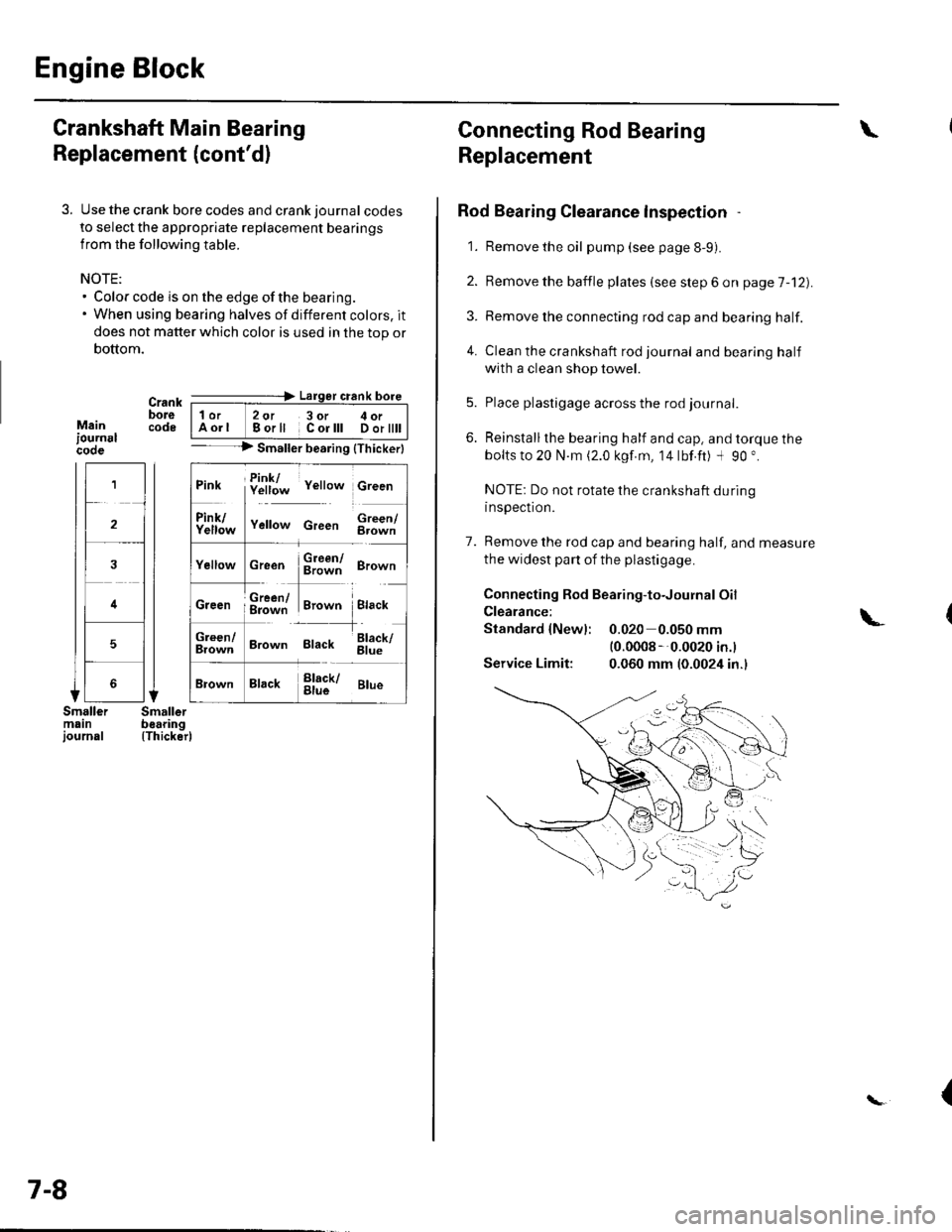

3. Use the crank bore codes and crank journal codes

to select the appropriate replacement bearings

from the following table.

NOTE:. Color code is on the edge of the bearing.. When using bearing halves of different colors. it

does not matter which color is used in the top or

bottom.

Mainiournslcooe

Crank ---=-> Lalger crank bore

bore | 1or 2ot 3or c oi__-lcode IAorl Borll Corlll Dortttt I-- --> Smaller bearing {Thickerl

(Thicker)

1

2

4

5

Pink f!1f;* v"rro* c,""n

ll

f111f;,," v"no* c,""" $;;fl

cr""n $ffi ero-n

ffi#Tr,.*" i.,""*Creen ; g=jiff;i Brown Black

;;lT]*

'---l-'o"*,

Brown Black 6il;

Brack !l;kr ar*

7-8

Connecting Rod Bearing

Replacement

Rod Bearing Clearance lnspection

1. Remove the oil pump (see page 8-9).

2. Bemove the baffle plates (see step 6 on page 7-12).

3. Remove the connecting rod cap and bearing half.

4. Clean the crankshaft rod journal andbearinghalf

with a clean shop towel.

5. Place plastigage across the rod journal.

6. Reinstallthe bearing half and cap, and torque the

bolts to 20 N.m (2.0 kgf.m, 14lbf.ft) -l 90 ".

NOTE: Do not rotate the crankshaft during

inspection.

7. Remove the rod cap and bearing half, and measure

the widest part of the plastigage.

Connecting Rod Bearing-to-Journal Oil

Clearance:

Standard {Newl: 0.020 0.050 mm(0.0008 --0.0020 in.l

Service Limit: 0.060 mm (0.0024 in.)

\

\-

{

Page 147 of 1139

8.

9.

lf the plastigage measures too wide or too narrow,

remove the upper half of the bearing, install a new,

complete bearing with the same color code(s), and

recheck the clearance. Do not file. shim, or scrape

the bearings or the caps to adjust clearance.

lf the plastigage shows the clearance is still

incorrect, try the next larger or smaller bearing (the

color listed above or below that one), and check

clearance agaln. lf the proper clearance cannot be

obtained by using the appropriate larger or smaller

bearing, replace the crankshaft and stan over.

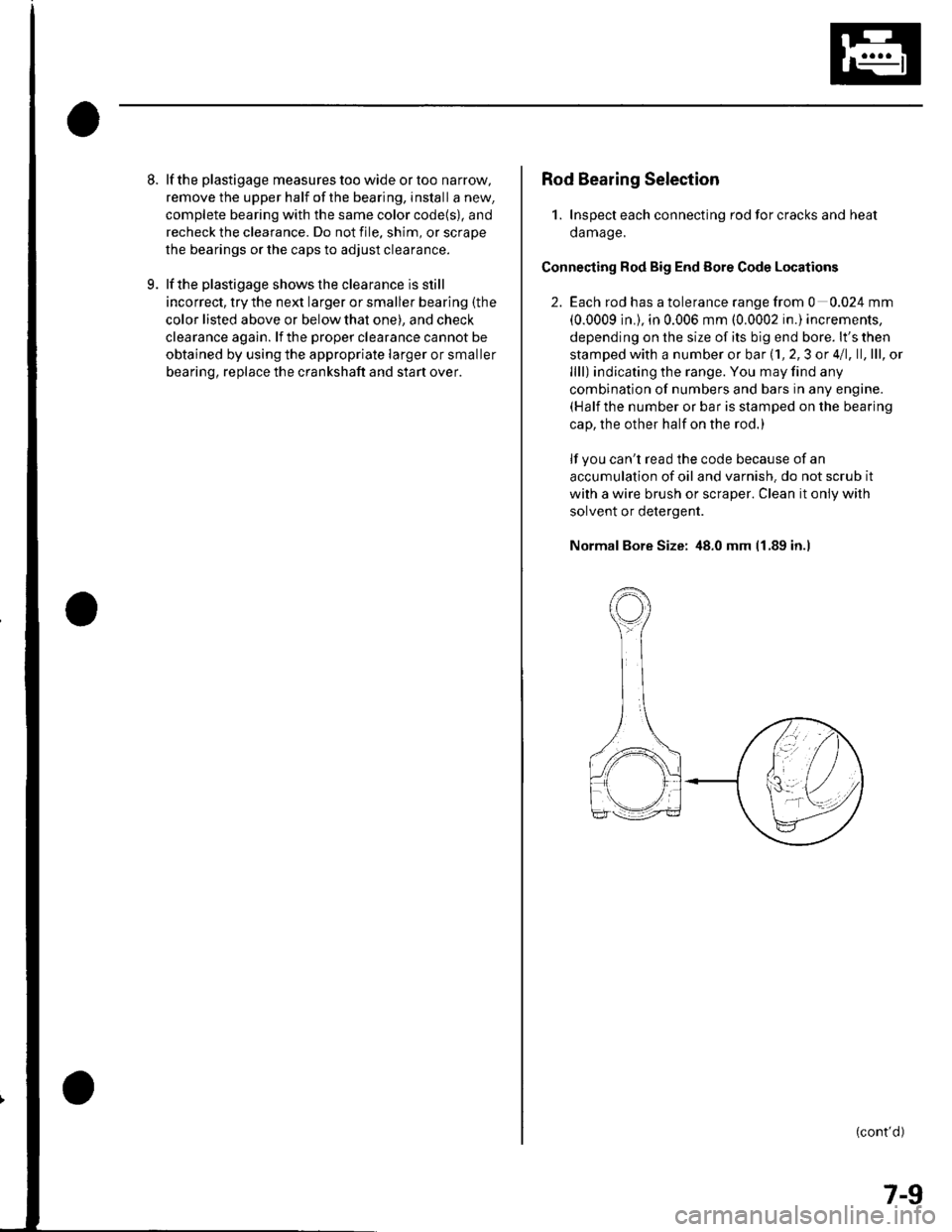

Rod Bearing Selection

1. Inspect each connecting rod for cracks and heat

damage.

Connecting Rod Big End Eore Code Locations

2. Each rod has a tolerance range from 0 0.024 mm

(0.0009 in.), in 0.006 mm (0.0002 in.) increments,

depending on the size of its big end bore. lt's then

stamped with a number or bar (1, 2,3 or 4/1, ll,lll, ol

llll) indicating the range. You may find any

combination of numbers and bars in any engine.(Half the number or bar is stamped on the bearing

cap, the other half on the rod.)

lf you can't read the code because of an

accumulation of oil and varnish. do not scrub it

with a wire brush or scraper. Clean it only with

solvent or detergent.

Normal Bore Size: 48.0 mm 11.89 in.l

(cont'd)

7-9

Page 148 of 1139

Engine Block

Connecting Rod Bearing Replacement (cont'dl

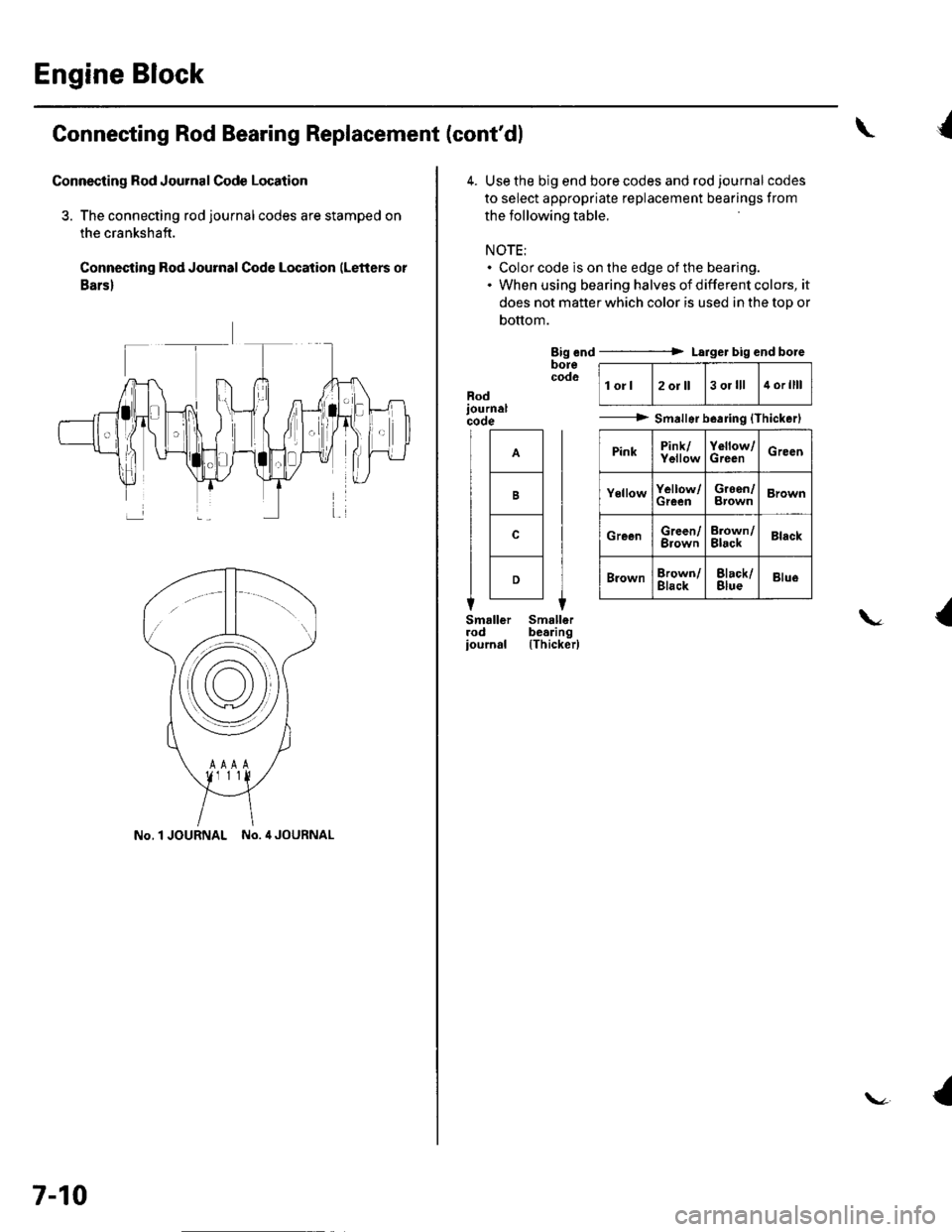

Connecting Rod Journal Code Location

3. The connecting rod journalcodes are stamped on

the crankshaft.

Connecting Rod Journal Code Location (Letters or

Bars)

No.l JOURNAL No. 4 JOURNAL

7-10

\{

4. Use the big end bore codes and rod journalcodes

to select appropriate replacement bearings from

the following table.

NOTE:. Color code is on the edge of the bearing.. When using bearing halves of different colors, it

does not matter which color is used in the top or

bottom.

Big end ----------> Larger big end boreborecodolorl2oJll3 ol lll4 orllll

---------> Smallsrb.aring {Thickerl

PinkPink/YellowYollow/GrecnGreen

YellowYellow/GreenGreen/BrownBrown

GreenGreen/BrownErown/BlackBlack

BrownBrown/BlackBlack/BlueBlue

Rod

B

c

D

{\

(Thicker)

{

Page 149 of 1139

1.

OilPan Removal

Drain the engine oil (see page 8-5).

lf the engine is still in the vehicle, remove the

subframe.

-1 Attach the chain hoist to the engine (see step

35 on page 5-6).-2 Disconnectthe suspension lower arm balljoints (see step 3 on page 18-19).-3 Remove the rear mounl mounting bolts (see

step 39 on page 5-7).-4 Remove the front mount mounting bolt (see

step 40 on page 5-7).-5 Use a marker to make alignment marks on the

reference lines that align with the centers of

the rear subframe mounting bolts. Remove the

front subframe (see step 43 on page 5-8).

Remove the bolts/nuts securing the oil pan.

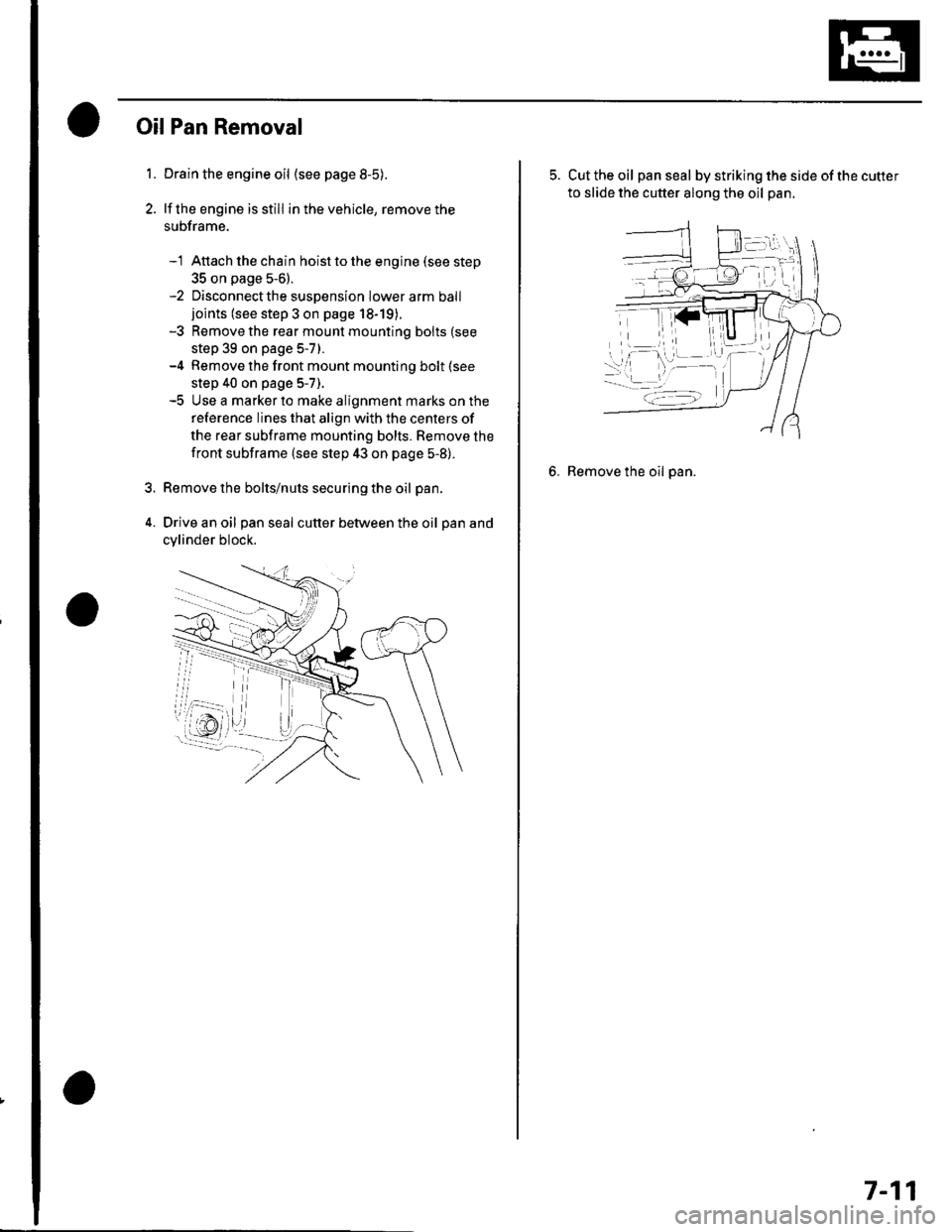

Drive an oil pan seal cutter between the oil pan and

cylinder block.

5. Cut the oil panseal bystrikingthesideofthecutter

to slide the cutter along the oil pan.

6. Remove the oil pan.

7-11