Indicator HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 127 of 1139

Gylinder Head

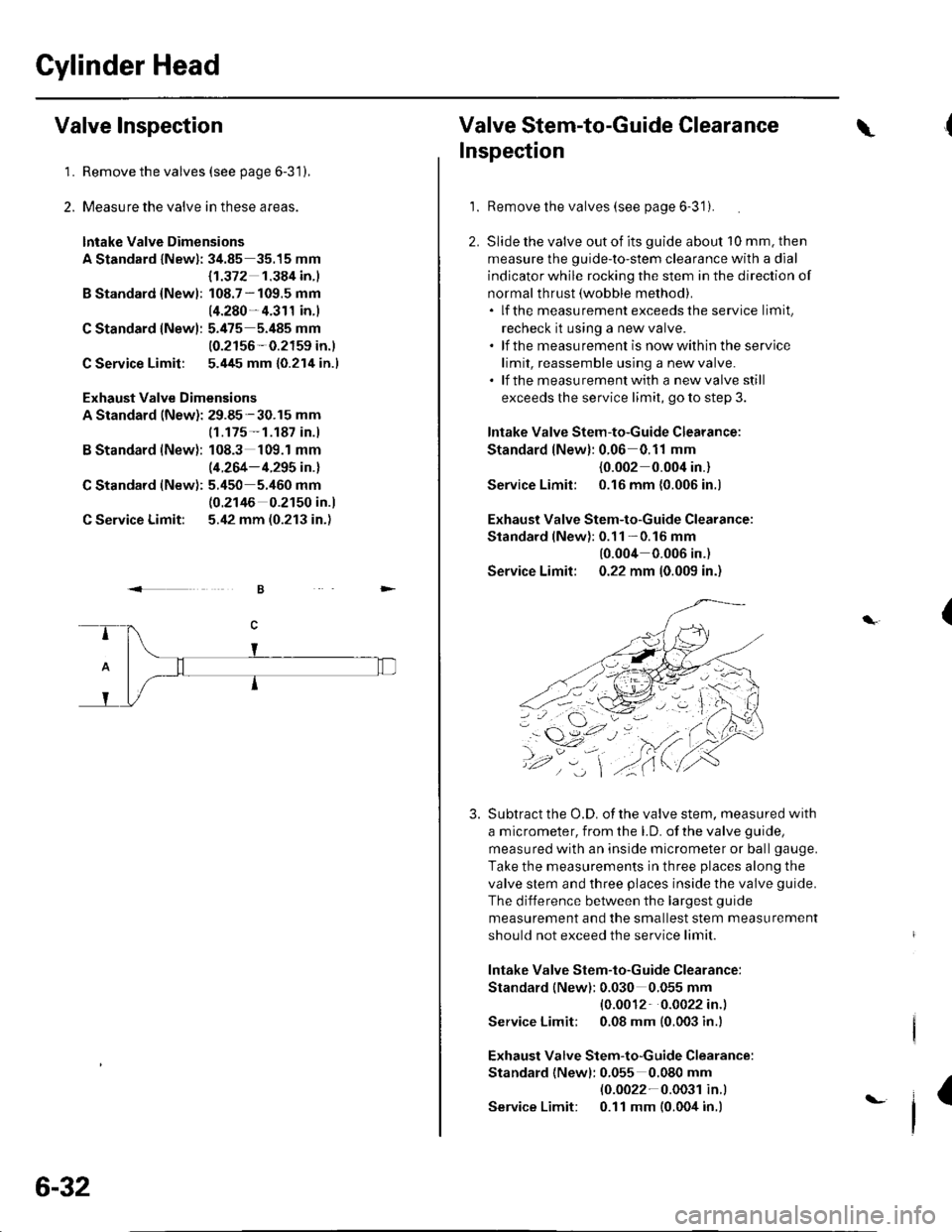

Valve Inspection

1.Remove the valves (see page 6-31),

Measure the valve in these areas.

lntake Valve Dimensions

A Standard lNewl: 34.85 35.15 mm

B Standard {Newl:

C Standard lNew):

C Service Limit:

B Standard (New):

C Standard (New):

C Service Limit:

Exhaust Valve Dimensions

A Standard (New): 29.85-30.15 mm

{1.372 1.384 in.l

108.7 - 109.5 mm

14.280- 4.311 in.)

5.475 5.485 mm

10.2156-0.2159 in.)

5.445 mm {0.214 in.l

(1.175- 1.187 in.)

108.3 109.1 mm

(4.264- 4.295 in.l

5.450 5.460 mm(0.2146 0.2150 in.)

5.42 mm (0.213 in.)

2.

.<

6-32

t-

Valve Stem-to-Guide Clearance\

Inspection

1.Remove the valves (see page 6-3'1).

Slide the valve out of its guide about 10 mm. then

measure the guide-to-stem clearance with a dial

indicator while rocking the stem in the direction of

normal thrust (wobble method).. lf the measurement exceedsthe service limit,

recheck it using a new valve.. lf the measurement is nowwithin the service

limit, reassemble using a new valve.. lf the measurementwith a newvalve still

exceeds the service limit, go to step 3.

lntake Valve Stem-to-Guide Clearance:

Standard lNew): 0.06 0.11 mm

{0.002 0.004 in.}

Service Limil: 0.16 mm {0.006 in.)

Exhaust Valve Stem-to-Guide Clearance:

Standard lNewl:0.11 -0.16 mm

10.004 0.006 in.)

Service Limit: 0.22 mm 10.009 in.)

Subtract the O.D. of the valve stem. measured with

a micrometer, from the LD. of the valve guide,

measured with an inside micrometer or ball gauge.

Take the measurements in three places along the

valve stem and three places inside the valve guide.

The difference between the largest guide

measurement and the smallest stem measurement

should not exceed the service limit

lntake Valve Stem-to-Guide Clearance:

Standard (New): 0.030 0.055 mm

{0.0012 0.0022 in.)

Service Limit; 0.08 mm (0.003 in.l

Exhaust Valve Stem-to-Guide Clearance:

Standard {Newl: 0.055 0.080 mm(0.0022-0.003r in.l

Service Limit: 0.11 mm (0.004 in.)

(

3.

4,.

I

Page 143 of 1139

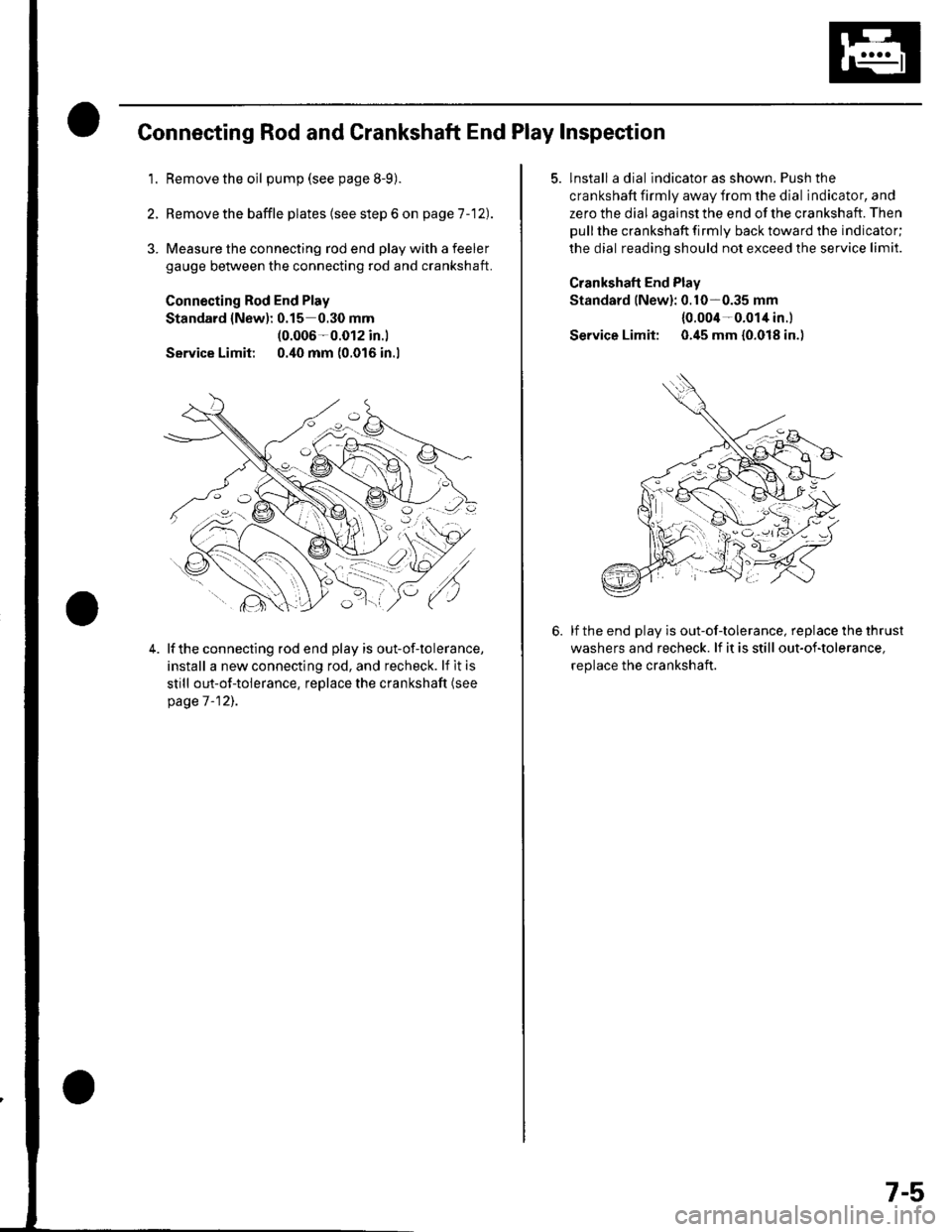

Connecting Rod and Crankshaft End Play Inspection

1.Remove the oil pump (see page 8-9).

Remove the baffle plates (see step 6 on page 1 -12).

3. Measure the connecting rod end play with a feeler

gauge between the connecting rod and crankshaft.

Connecting Rod End Play

Standard {New): 0.15 0.30 mm(0.006-0.012 in.l

Service Limit 0.40 mm (0.016 in.l

4.lf the connecting rod end play is out-of-tolerance,

install a new connecting rod, and recheck. lf it is

still out-of-tolerance, replace the crankshaft (see

page 7 -12],.

5. lnstall a dial indicator as shown. Push the

crankshaft firmly away from the dial indicator, and

zero the dial against the end of the crankshaft. Then

pull the crankshaft firmly back toward the indicator;

the dial reading should not exceed the service limit.

Crankshaft End Plav

Standard lNew): 0.10-0.35 mm

{0.004-0.014 in.l

Service Limit: 0.45 mm {0.018 in.)

lf the end play is out-of-tolerance, replace the thrust

washers and recheck. lf it is still out-of-tolerance,

replace the crankshaft.

7-5

Page 157 of 1139

v

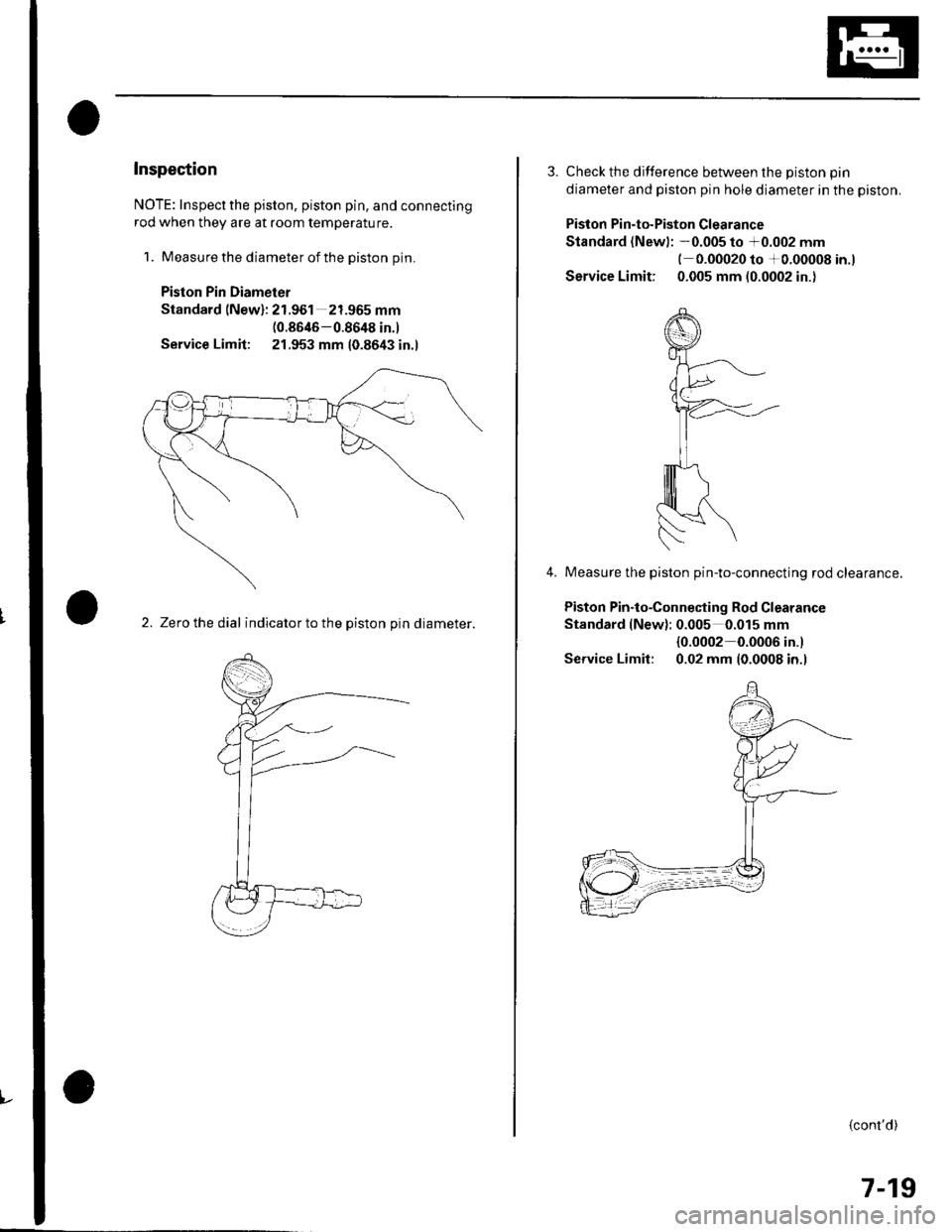

Inspection

NOTE: Inspect the piston, piston pin, and connecting

rod when they are at room temperature.

1. Measure the diameter of the piston pin.

Piston Pin Diameter

Standard (New): 21.961 21.965 mm(0.8646-0.8648 in.)

Service Limit: 21.953 mm 10.8643 in.l

2. Zerc the dial indicator to the piston pin diameter.

3. Check the difference between the Diston Din

diameter and piston pin hole diameter in the piston.

Piston Pin-to-Piston Clearance

Standard (Newl: -0.005 to +0.002 mm(-0.00020 to +0.00008 in.)

Service Limit: 0.005 mm (0.0002 in.)

Measure the piston pin-to-connecting rod clearance.

Piston Pin.to-Connecting Rod Clearance

Standard (New): 0.005 0.015 mm

{0.0002 0.0006 in.}

Service Limil: 0.02 mm (0.0008 in.l

4.

(cont'd)

7-19

Page 170 of 1139

Engine Lubrication

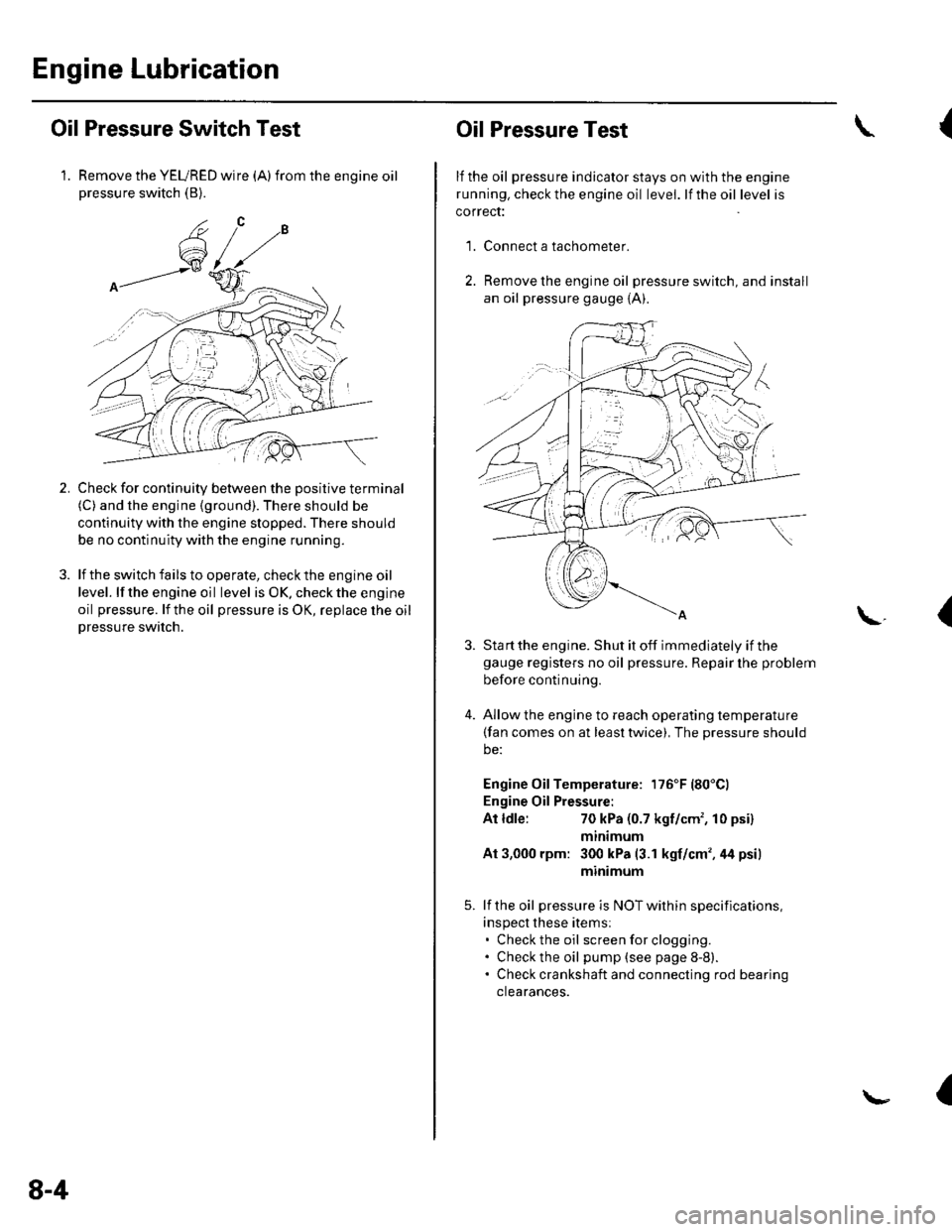

Oil Pressure Switch Test

1. Remove the YEURED wire (A)from the engine oilpressure switch (B).

Check for continuity between the positive terminal(C) and the engine (ground). There should be

continuity with the engine stopped. There should

be no continuity with the engine running.

lf the switch fails to operate, check the engine oil

level. lf the engine oil level is OK. check the engine

oil pressure. lf the oil pressure is OK, replace lhe oil

Dressure switch.

2.

8-4

Oil Pressure Test

lf the oil pressure indicator stays on with the engine

running. check the engine oil level. lf the oil level is

correct:

Connect a tachometer.

Remove the engine oil pressure switch, and install

an oil pressure gauge {A).

{

'1.

\.(

4.

Sta rt the engine. Shut it off immediately if thegauge registers no oil pressure. Repair lhe problem

before continuing.

Allow the engine to reach operating temperature(fan comes on at least twice), The pressure should

be:

Engine Oil Temperature: 176'F (80'Cl

Engine Oil Pressure:

At ldle:70 kPa (0.7 kgf/cm', 10 psi)

mtntmum

At 3,000 rpm: 300 kPa (3.1 kgf/cm',44 psi)

minimum

lf the oil pressure is NOT within specifications,

inspect these items:. Check the oil screenforclogging.. Check the oil pump (see page 8-8).. Check crankshaft and connecting rod bearing

clearances.

I

Page 177 of 1139

1.

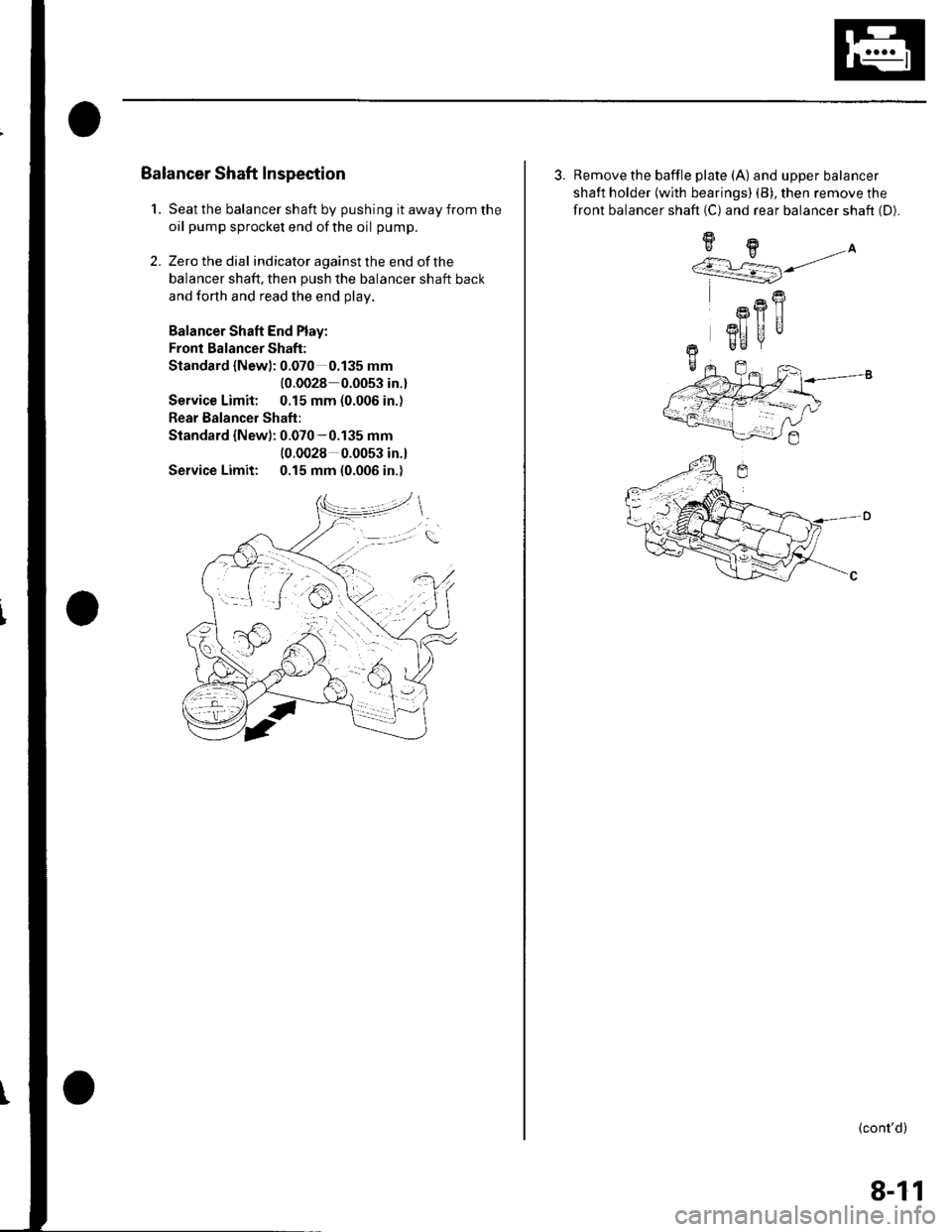

Balancer Shaft Inspection

Seat the balancer shaft by pushing it away from the

oil pump sprocket end ofthe oil pump.

Zero the dial indicator against the end of the

balancer shaft, then push the balancer shaft back

and forth and read the end olav.

Balancer Shaft End Play:

Fronl Balancer Shaft:

Standard {Newl: 0.070 0.135 mm

{0.0028 0.0053 in.}

Service Limit: 0.15 mm (0.006 in.)

Rear Balancer Shaft:

Standard {New): 0.070-0.135 mm(0.0028 0.0053 in.l

Service Limit: 0.15 mm (0.006 in.)

2.

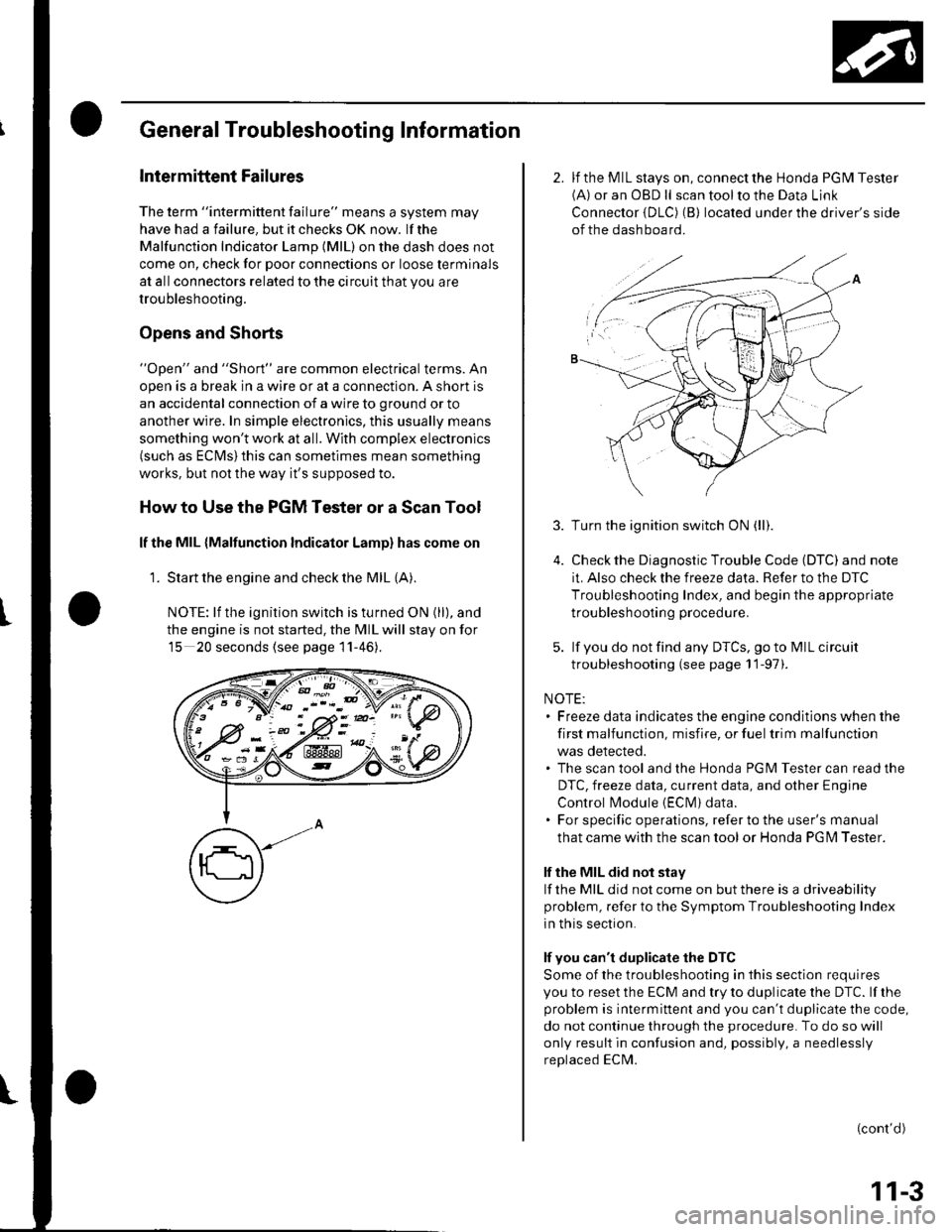

3. Remove the baffle plate (A) and upper balancer

shaft holder {with bearings) (B), then remove the

front balancer shaft (C) and rear balancer shaft (D).

9H.A''/.r L=] j/

R

Rfl|]

3I] UUr Be

+-

(cont'd)

8-11

Page 210 of 1139

General Troubleshooting Information

Intermittent Failures

The term "intermittent failure" means a svstem mav

have had a failure. but it checks OK now. lf the

Malfunction Indicator Lamp (MlL) on the dash does not

come on, check for Door connections or loose terminals

at all connectors related to the circuit that Vou are

troubleshooting.

Opens and Shorts

"Ooen" and "Short" are common electrical terms. An

open is a break in a wire or at a connection. A short is

an accidental connection of a wire to ground or to

another wire. In simple electronics, this usually means

something won't work at all. With complex electronics(such as ECMs)this can sometimes mean something

works, but not the way it's supposed to.

How to Use the PGM Tester or a Scan Tool

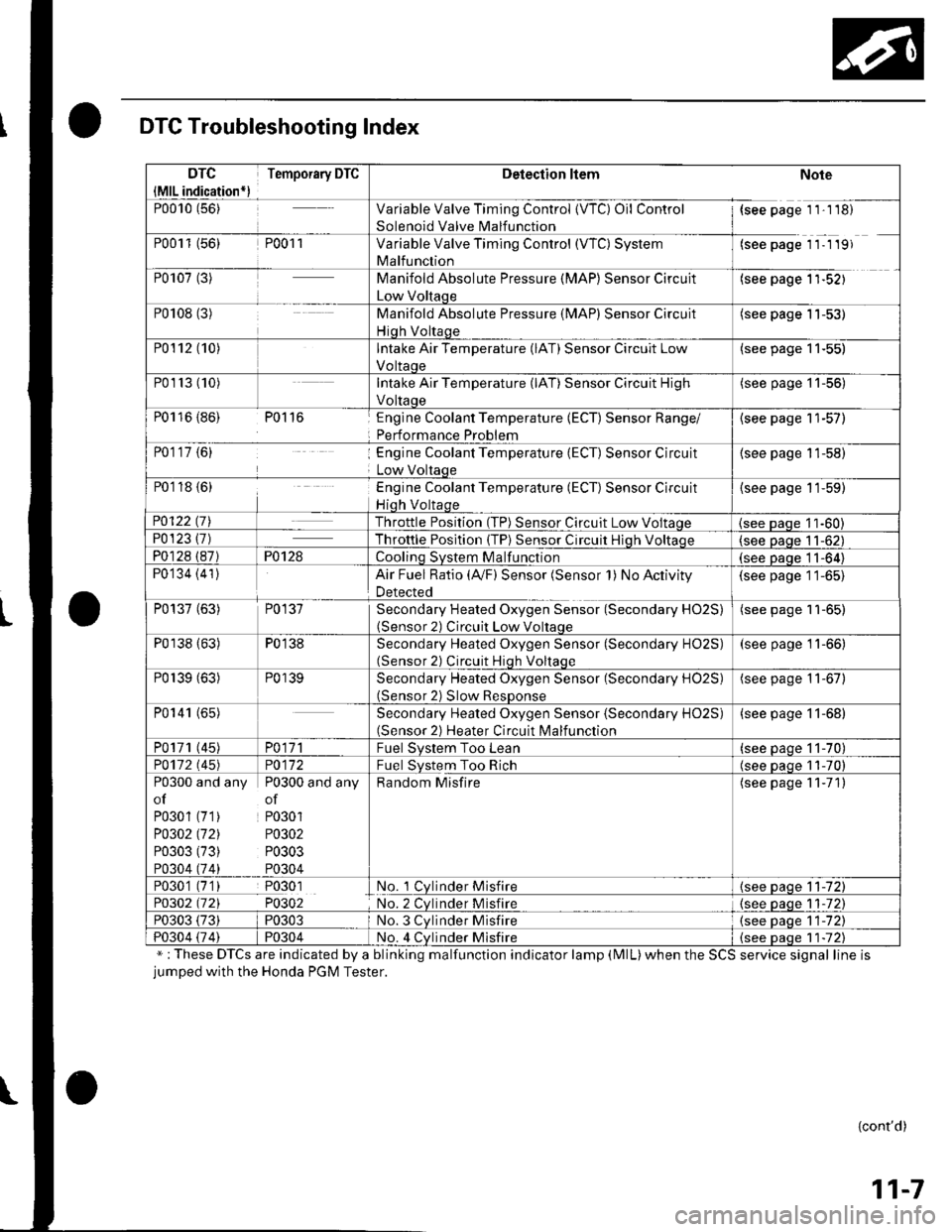

lf the MIL {Malfunction Indicator Lamp} has come on

'1. Start the engine and check the MIL {A).

NOTE: lf the ignition switch is turned ON (ll), and

the engine is not started, the MIL will stay on for

15 20 seconds (see page 11-46).

K-> ;"PN/.- -::: - -d V-: !

w:ix&K#

2. lf the MIL stays on, connect the Honda PGM Tester(A) or an OBD ll scan tool to the Data Link

Connector {DLC) (B) located under the driver's side

of the dashboard.

3.

5.

Turn the ignition switch ON (ll).

Check the Diagnostic Trouble Code (DTC) and note

it. Also check the freeze data. Refer to the DTC

Troubleshooting Index, and begin the appropriate

troubleshooting procedure.

lf you do not find any DTCS, go to MIL circuit

troubleshooting (see page 11-97).

NOTE:. Freeze data indicates the engine conditions when the

first malfunction, misfire, or fuel trim malfunction

was detected.. The scan tool and the Honda PGM Tester can read the

DTC, freeze data, current data, and other Engine

Control l\4odule {EClvl) data.. For specific operations, refer to the user's manual

that came with the scan tool or Honda PG l\4 Tester.

lf the MIL did not stay

lf the MIL did not come on but there is a driveability

problem, refer to the Symptom Troubleshooting Index

in this section.

lf you can't duplicate the DTC

Some of the troubleshooting in this section requires

you to reset the ECM and try to duplicate the DTC. lf rhe

problem is intermittent and you can't duplicate the code,

do not continue through the procedure. To do so will

only result in confusion and, possibly, a needlessly

replaced ECM.

(cont'd)

11-3

Page 214 of 1139

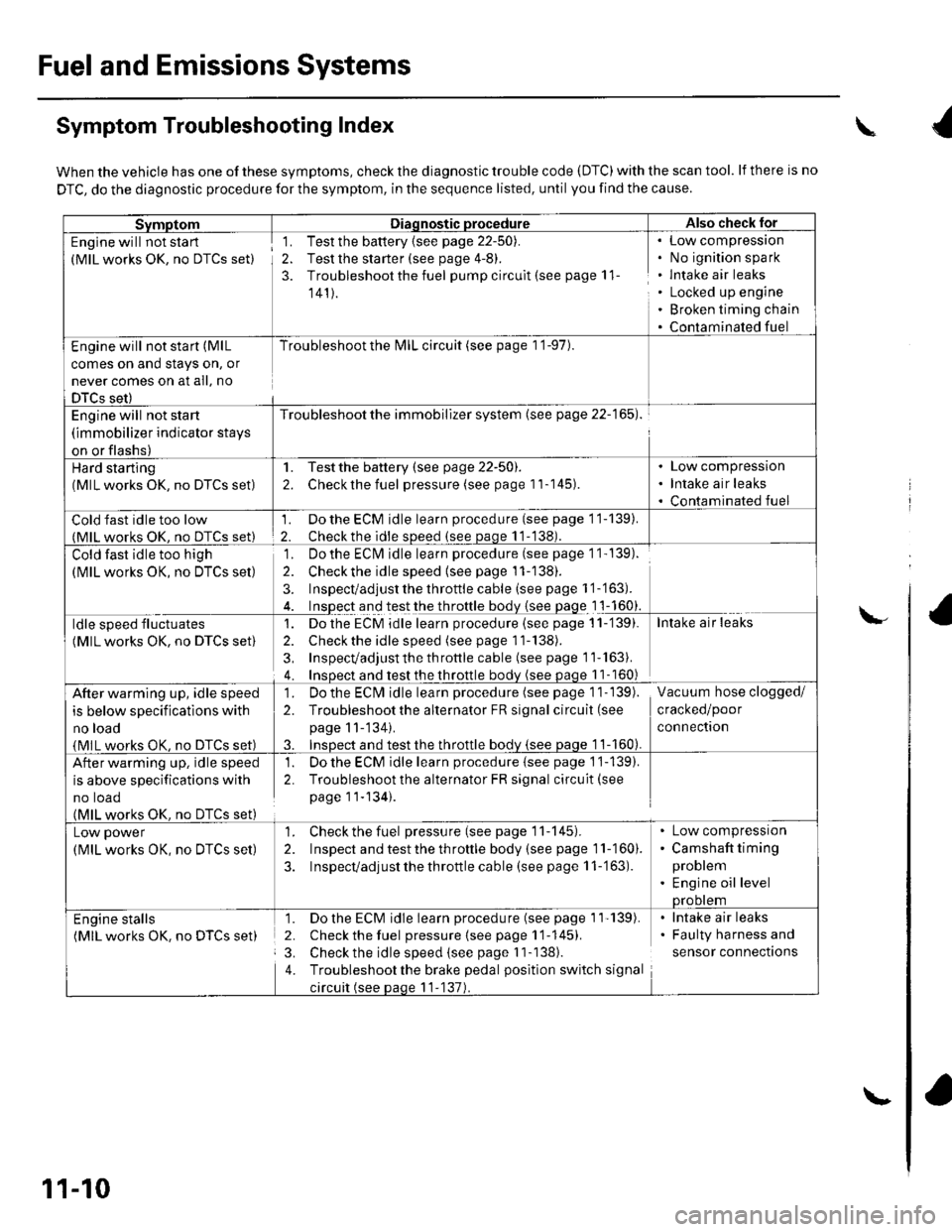

DTC Troubleshooting Index

";These DTCs are indicated by a blinking malfunction indicator lamp (MlL)when the SCS service signal line isjumped with the Honda PGM Tester.

{cont'd)

11-7

DTC

{MlL indication*)

Temporary DTCDetection ltemNote

P0010 (56)Variable Valve Timing Control {VTC) Oil Control

Solenoid Valve Malfunction

{see page 1 1'1 18)

P0011 (56)P001 1Variable Valve Timing Control (WC) System

Malfunction

(see page 11- 1 19)

P0107 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Low Voltaqe

(see page 1'l-521

P0108 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Hiqh Voltaqe

(see page 11-53)

P0112 (10)Intake Air Temperature (lAT) Sensor Circuit Low

Voltaoe

(see page 11-55)

P01r3 (10)Intake Air Temperature (lAT) Sensor Circuit High

Voltaoe

(see page '11-56)

P0116 {86) P0116Englne Coolant Temperature (ECT) Sensor Range/

Performance Problem

{see page 11-57)

P0117 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Low Voltaqe

(see page 11-58)

P0118 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Hiqh Voltaqe

{see page 11-59)

P0122 t7\Throttle Position (TP) Sensor Circuit Low Voltaqe(see Daqe 11-60)P0123 {7)Throttle Posltion (TP) Sensor Circuit Hiqh Voltaoe(see paqe 11-62)

P0128 (87)P0128Coolinq SVStem Malfunction(see Daqe 11-64)

P0134 (41)Air Fuel Ratio (Ay'F) Sensor (Sensor 1) No Activity

Detected

(see page 11-65)

P0137 (63)P0137Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Low Voltaqe

(see page 11-65)

P0138 (63)P0138Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Hiqh Voltaqe

(see page 11-66)

P0139 (63)P0139Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Slow ResDonse

(see page 11-67)

P0141 (65)Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Heater Circuit Malfunction

(see page 11-68)

P0171 (45)PO\11Fuel Svstem Too Lean(see paqe 11-70)

PO112 l'45)PO\l2Fuel System Too Rich(see oaoe 11-70)

P0300 and any P0300 and any

of of

P0301 (71) P0301

PO302 (721 P0302

P0303 (73) P0303

P0304 (74) P0304

Random Misfire(see page 11-71)

P0301 (7'1) P0301No. 1 Cylnder Misfire{see page 11-72)

P0302 (721 P0302No. 2 Cvlnder Misfire{see paqe 1 1-72)

P0303 (73)P0303No. 3 Cvlnder Misfire(see oaqe 11-72)

P0304 {74)P0304No. 4 Cvlnder Misfire{see Daqe 1 1-72)

Page 217 of 1139

Fuel and Emissions Systems

Symptom Troubleshooting Index

When the vehicle has one of these symptoms, check the diagnostic trouble code (DTC) with the scan tool. lf there is no

DTC, do the diagnostic procedure for the symptom, in the sequence listed, until you find the cause.

SvmotomDiaqnostic procedureAlso check lor

Engine will not sta rt

(MlL works OK, no DTCS set)

1. Test the battery {see page 22-50).

2. Test the starter (see page 4-8).

3. Troubleshoot the fuel pump circult (see page 11

141).

Low compressron

No ignition spark

lntake air leaks

Locked up engine

Broken timing chain

Contaminated fuel

Engine will not start (MlL

comes on and stays on, or

never comes on at all, no

DTCS set)

Troubleshoot the l\4lL circuit (see page 1 '1-97).

Engine will not start

(immobilizer indicator stays

on or flashs)

Troubleshoot the immobilizer system (see page 22-165).

Hard starting(MlL works OK, no DTCS set)

1. Testthe battery (see page 22-50).

2. Checkthe fuel pressure (see page 11-145).

Low compression

Intake air leaks

Contaminated fuel

Cold fast idle too low(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 11-139).

2. Checkthe idle sDeed (see paqe 11-138).

Cold fast idle too high

(MlL works OK, no DTCS set)

Do the ECI\4 idle learn procedure (see page 1 1- 139).

Checkthe idle speed {see page 11-138).

Inspect/adjust the throttle cable (see page 1 '1-'163).

Inspect and test the throttle body {see page 1 1-160}.

']�

2.

3.

ldle speed fluctuates

(MlL works OK, no DTCS set)

1. Dothe ECM idle learn procedure (see page 11-'139).

2. Check the idle speed (see page 11-138).

3, Inspecvadjust th e throttle cable (see page 11''163).

4. Insoect and test the throttle bodv (see paqe 11- 160)

Intake air leaks

After warming up, idle speed

is below specifications with

no load

{MlL works OK, no DTCS set)

1. Do the ECIVI idle learn procedure (see page 1 1- 139).

2. Troubleshootthe alternator FR signal circuit (see

page 11-'134).

3. InsDect and test the throttle bodv {see paqe 1 1-160).

Vacuum hose clogged/

cracked/poor

connectron

After warming up, idle speed

is above specifications with

no toao(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure {see page 1'j-139).

2. Troubleshoot the alternator FR signal circuit(see

page 11-134).

Low power

(MlL works OK, no DTCS set)

1. Check the fuel pressure(seepagell-145).

2. Inspect and test the th roftle body (see page 11-160).

3. Inspecvadjust the throttle cable (see page 11-'163).

Low compressron

Camshaft timing

problem

Engine oil levelprootem

Engine stalls(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 1'l'139).

2. Check the fuel pressure{seepagell-145).

3. Check the idle speed (see page I 1-138).

4. Troubleshootthe brake pedal position switch signal

circuit (see paqe 11-137).

lntake air leaks

Faulty harness and

sensor connections

\

\-

11-10

\-

Page 219 of 1139

Fuel and Emissions Systems

System Descriptions

Electronic Control System

The functions of the fuel and emlssion control systems are managed by the engine control module (ECM).

Fail-safe Function

When an abnormality occurs in the signal from a sensor, the ECI\4 ignores that signal and assumes a pre-programmed

value for that sensor that allows the enqine to continue to run.

Back-up Function

When an abnormality occurs in the ECM, the injectors are controlled by a back-up circuit independent of the system to

permit minimal driving.

Self-diagnosis

When an abnormality occurs in the signal from a sensor, the ECM supplies ground for the malfunction indicator lamp

{MlL) and stores the diagnostic trouble code {DTC) in erasable memory. When the ignition is first turned on, the EClvl

supplies ground to the l\4lL for 15 to 20 seconds to check the M lL bulb condition.

Two Driving Cycle Detection Method

To prevent false indications, the "two driving cycle detection method" is used for some self-diagnostic functions.

When an abnormality occurs, the ECM stores it in its memory. When the same abnormality recurs afterthe ignition

switch is turned OFF and ON (ll) again, the ECM turns on the MlL.

\

11-12

\.

\{

Page 230 of 1139

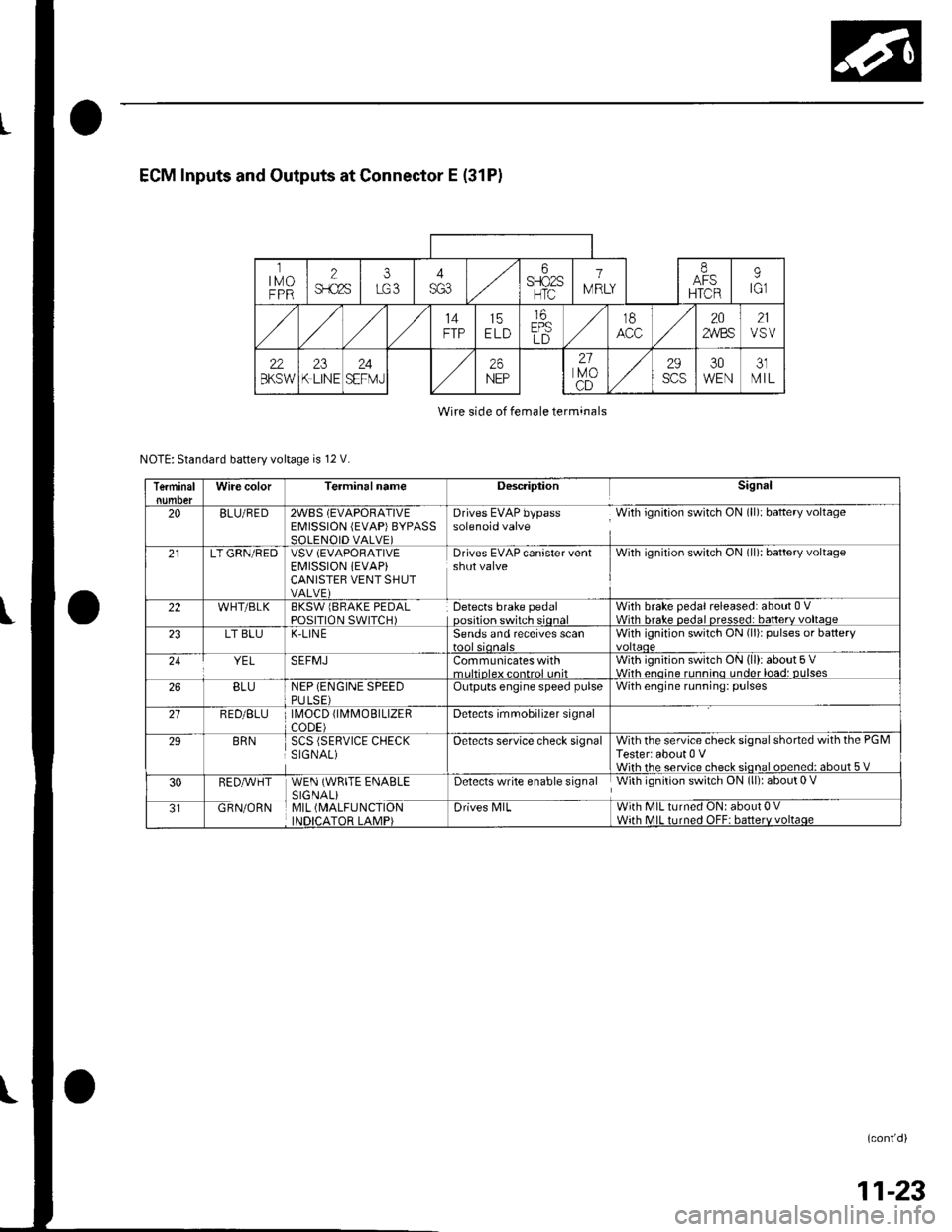

ECM Inputs and Outputs at Connector E (31P)

ltMoFPR

2$.c2s

i6SFIO2SHTC

1

IV RLY

IAFSHTCR

9tGl

14FTP15ELD

16EPSLD

t8202,4/BS21VSV

22BKSW23K LINE24SEFMJ26NEP

21lvoCD

29scs30WEN31MIL

Wire side of female terminals

NOTE: Standard battery voltage is 12 V.

TerminalWire colorTerminalnameDescriptionSignal

20BLU/RED2WBS (EVAPORATIVEEMISSION (EVAP)BYPASSSOLENOID VALVE)

Drives EVAP bypass With ignition switch ON (ll): baftery voltagesolenoid valve

21LT GRN/REDVSV (EVAPORATIVE

EI\4ISSION iEVAP)CANISTEB VENT SHUTVALVE)

Drives EVAP canister ventshut valveWith ignilion switch ON (ll): battery voltage

22WHT/BLKBKSW lBRAKE PEDALPOSITION SWITCH)Detects brake pedaloosition switch sionalWith brake pedal released: about 0 VWith hrake nedal nresse.l: batterv voltaoe23LT BLUK-LIN ESends and receives scanWith ignition switch ON (li)r pulses or battery

YELSEFMJCommunicates withmrltinleY eontrol unitWith ignition switch ON (ll): about 5 VWith enoine runnino under load: DUlses26BLUNEP (ENGINE SPEEDPULSE)Outputs engine speed pulseWith engine running: pulses

21RED/BLU \40CD fl\4MOBTLTZERCODE)Detects imrnobilizer signal

29BRNSCS (SERVICE CHECKSIGNAL)Oetects service check signalWith the service check signal shorted with the PGMTester: about 0 VWiih rhe service check sional ooened: about 5 V

30RED,A/VHTWEN (WRITE ENABLESIGNALiDetects write enable signal With ignition switch ON (ll): about 0 V

GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP)Drives N4lLWith MIL turned ON: about 0 VWith MIL turned OFF: batterv voltaqe

(cont'd)

11-23