HONDA CIVIC 2003 7.G Workshop Manual

Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 331 of 1139

VTEC/VTC

DTC Troubleshooting (cont'd)

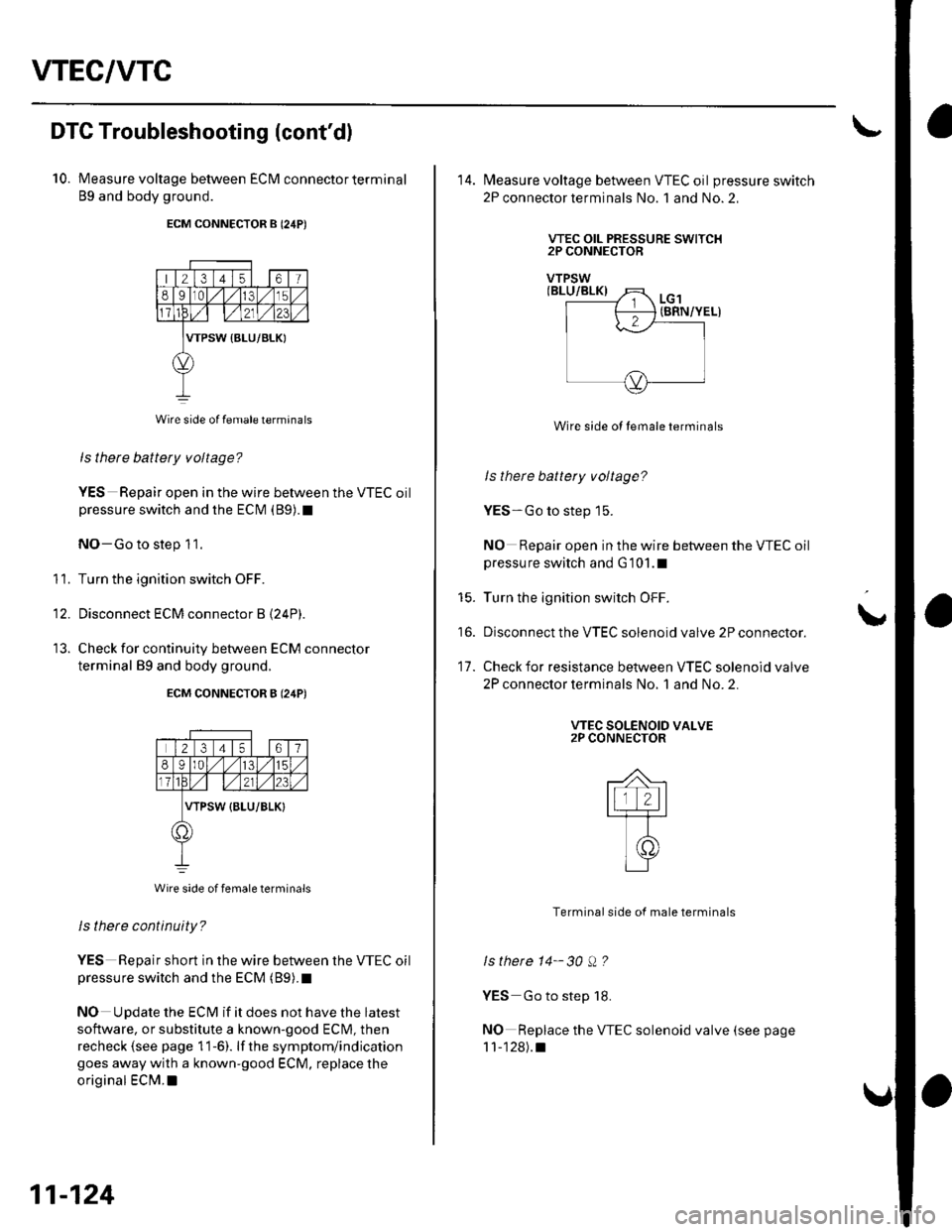

10. Measure voltage between ECM connectorterminal

89 and body ground.

ECM CONNECTOR B (24P)

213 415o1

8Iat/t/n315

WPSW {BLU/BLK}

Wire side of Iemale terminals

ls there battery voltage?

YES Repair open in the wire between the VTEC oilpressure switch and the ECM (89).t

NO-Go to step 11.

Turn the ignition switch OFF.

Disconnect ECM connector B {24P).

Check for continuity between ECM connector

terminal Bg and body ground.

ECM CONNECTOR B {24P)

2 3 41567

I9ol./ ./ 1315

VTPSW {BLU/BLK}

Wrre side of female terminals

ls there continuity?

YES Repair short in the wire between the VTEC oilpressure switch and the ECM (89).I

NO Update the ECM if it does not have the latest

software. or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECN4. !

11.

11-124

2P CONNECTOR

VTPSW(BLU/BLK)

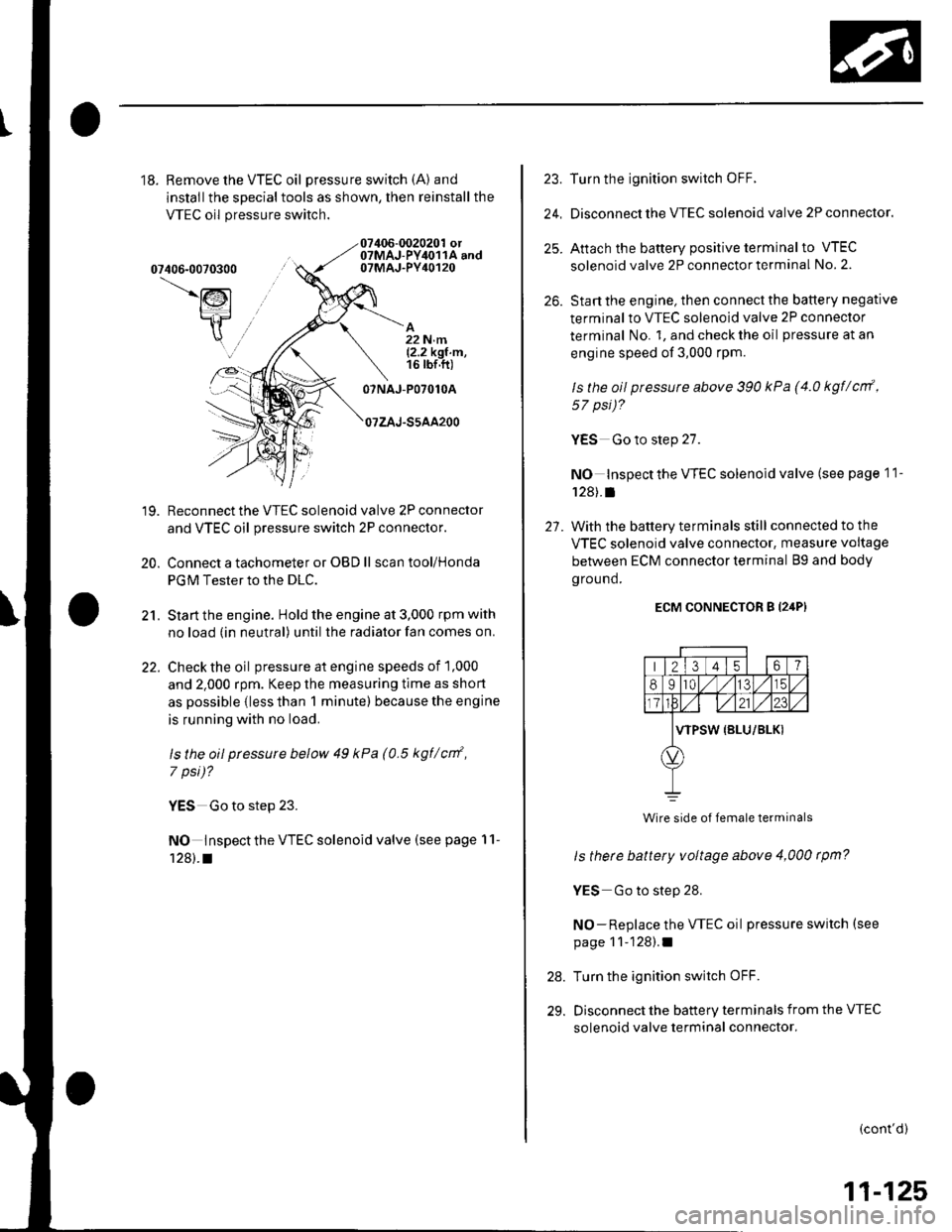

14. fMeasure voltage between VTEC oil pressure switch

2P connector terminals No. 1 and No. 2,

VTEC OIL PRESSURE SWITCH

(BRN/YELI

Wire side of Iemale terminals

ls there battery voltage?

YES-Go to step 15.

NO Repair open in the wire between the VTEC oil

pressure switch and G 101.1

Turn the ignition switch OFF.

Disconnect the VTEC solenoid valve 2P connector.

Check for resistance between VTEC solenoid valve

2P connector terminals No, 1 and No. 2.

VTEC SOLENOID VALVE2P CONNECTOR

Terminal side of male terminals

ls there 14- 30 Sl ?

YES Go to step 18.

NO Replace the VTEC solenoid valve (see page

11-128).t

to.

17.

Page 332 of 1139

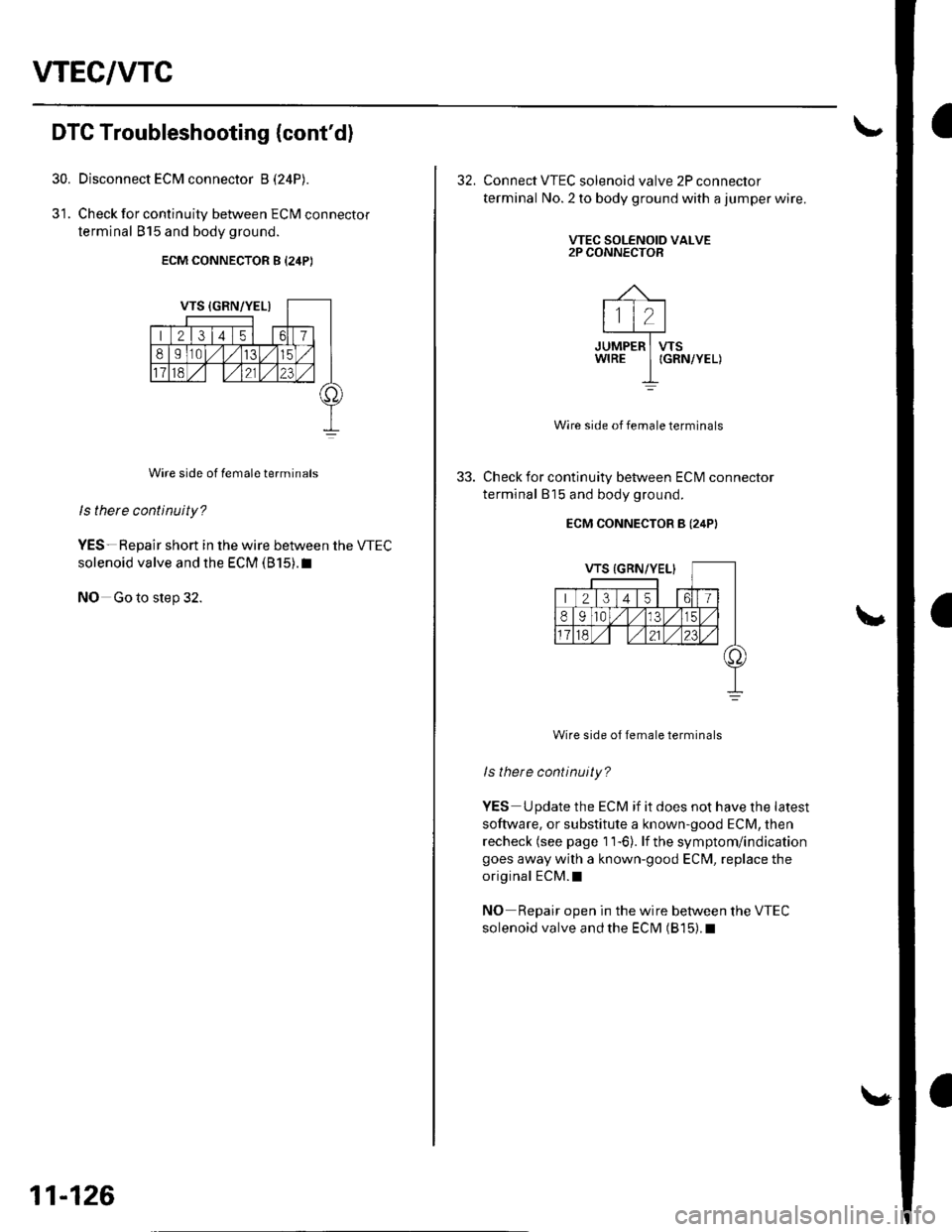

18.Remove the VTEC oil pressure switch (A) and

installthe specialtools as shown, then reinstall the

VTEC oil pressure switch.

07406-0070300

\lsl

t:={

R

07406-0020201 ot07MAJ-PY,lo11A and07MAJ-PY40120

A22 N.ml2.2kgt.m,16 rbf.ft)

19.

20.

21.

22.

07NAJ-P07010A

Reconnect the VTEC solenoid valve 2P connector

and VTEC oil pressure switch 2P connector.

Connect a tachometer or OBD ll scan tool/Honda

PGM Tester to the DLC.

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

Checkthe oil pressure at engine speeds of 1,000

and 2.000 rpm. Keep the measuring time as shon

as possible {less than 1 minute) because the engine

is running with no load.

ls the oil ptessure below 49 kPa (0.5 kgf/cnf,

7 psi)?

YES Go to step 23.

NO Inspect the VTEC solenoid valve (see page 11-'t28l.a

23.

24.

25.

26.

Turn the ignition switch OFF.

Disconnect the VTEC solenoid valve 2P connector.

Aftach the battery positive terminalto VTEC

solenoid valve 2P connector terminal No. 2.

Start the engine, then connect the battery negative

terminalto VTEC solenoid valve 2P connector

terminal No. 1, and check the oil pressure at an

engine speed of 3,000 rpm.

ls the oil pressure above 390 kPa (4.0 kgt/crtf ,

57 psi)?

YES Go to step 27.

NO Inspectthe VTEC solenoid valve (see page I1-

12Al.a

27. With the battery terminals still connectedtothe

VTEC solenoid valve connector, measure voltage

between ECM connector terminal 89 and bodv

oround.

ECM CONNECTOR B {24P)

ls there battery voltage above 4,000 tpm?

YES Go to step 28.

NO-Replace the VTEC oil pressure switch (see

page 11'128).1

Turn the ignition switch OFF.

Disconnect the battery terminals from the VTEC

solenoid valve terminal connector.

(cont'd)

28.

29.

Wire side of female terminals

11-125

Page 333 of 1139

WEC/VTC

30.

DTC Troubleshooting (cont'd)

Disconnect ECM connector B (24P)

Check for continuity between ECM connector

terminal 815 and body ground.

ECM CONNECTOR B {24P)

Wire side of female terminals

ls there continuity?

YES-Repair short in the wire between the VTEC

solenoid valve and the ECM (815).1

NO Go to step 32.

11-126

32. Connect VTEC solenoid valve 2P connector

terminal No. 2 to body ground with a jumper wire.

VTEC SOLENOID VALVL2P CONNECTOR

r-.'-r.---.1

t1t2l

+JUMPER I VtSWIRE I IGRN/YEL)

I

Wire side of female terminals

Check for continuity between ECM connector

terminal 815 and body ground.

ECM CONNECTOR B {24PI

Wire side of female terminals

ls thete continuity?

YES Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

NO Repair open in the wire between the VTEC

solenoid valve and the ECM (815).I

Page 334 of 1139

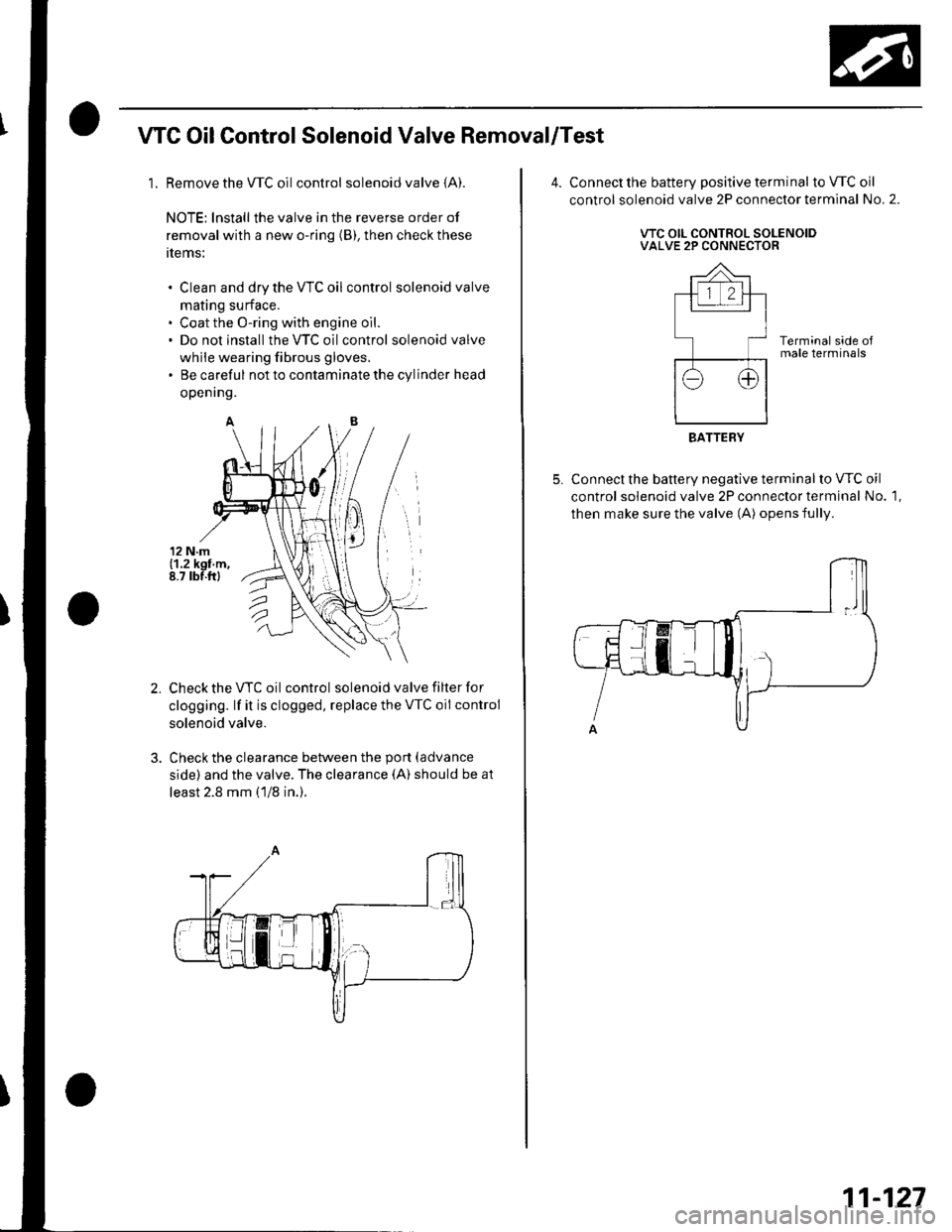

WC OilControl Solenoid Valve Removal/Test

1. Remove the WC oilcontrol solenoid valve (A).

NOTE: lnstall the valve in the reverse order of

removal with a new o-ring (B), then check these

tlems:

Clean and dry the VTC oil control solenoid valve

mating surface.

Coat the O-ring with engine oil.

Do not install the VTC oilcontrol solenoid valve

while wearing fibrous gloves,

Be careful not to contaminate the cylinder head

openrng.

Check the VTC oil control solenoid valve filter for

clogging. lf it is clogged, replace the VTC oil control

solenoid valve.

Check the clearance between the port (advance

side) and the valve. The clearance (A) should be at

least 2.8 mm (1/8 in.).

Connect the battery positive terminal to VTC oil

control solenoid valve 2P connector terminal No. 2.

VTC OIL CONTROL SOLENOIDVALVE 2P CONNECTOR

Terminal side oJmale terminals

Connect the battery negative terminal to VTC oil

control solenoid valve 2P connector terminal No. 1,

then make sure the valve (A) opens fully.

BATTERY

11-127

Page 335 of 1139

VTEC/WC

1.

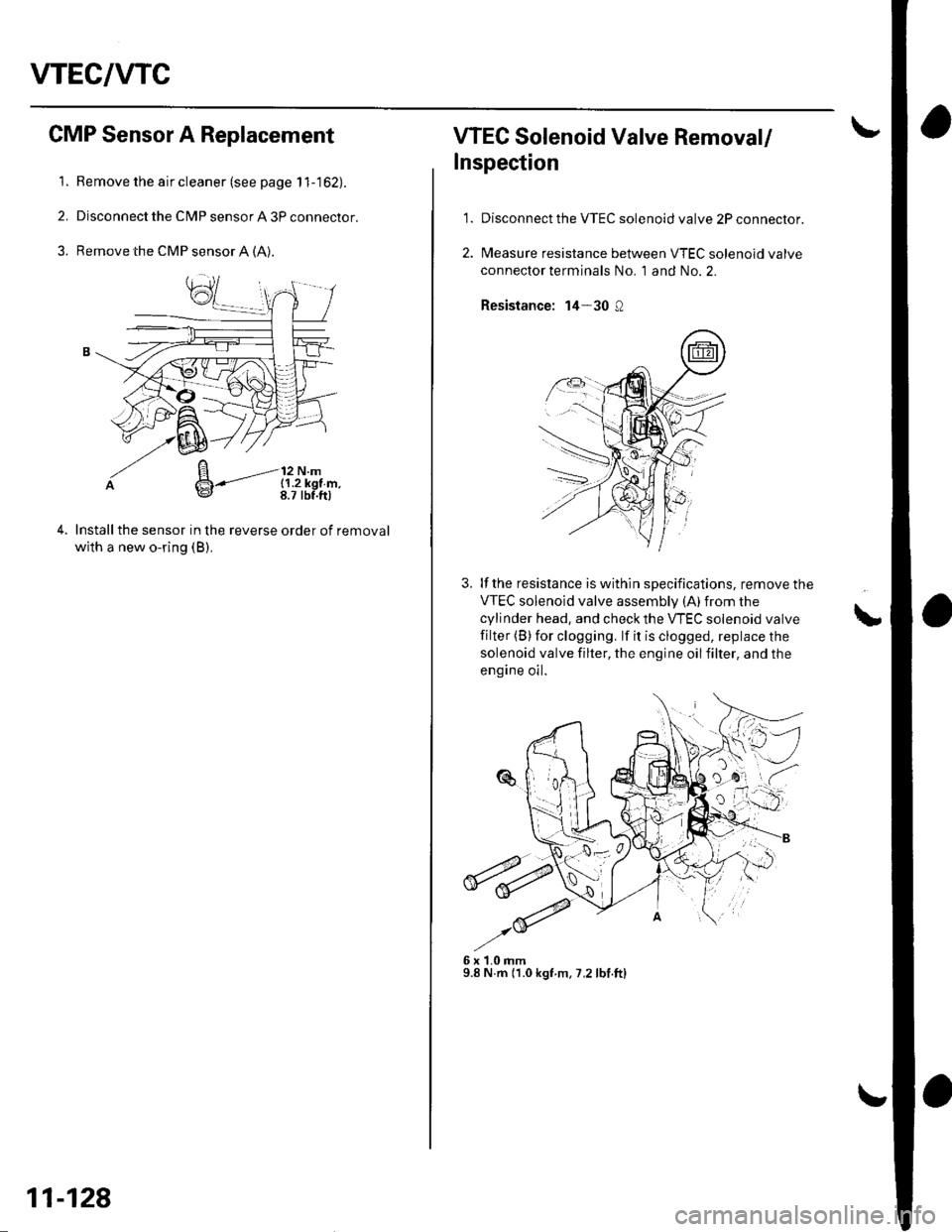

CMP Sensor A Replacement

Remove the air cleaner (see page 1 1-162).

Disconnect the CMP sensor A 3P connector.

Remove the CMP sensor A (A).

Installthe sensor in the reverse order of removal

with a new o-ring (B).

B-'-----'-l:,",14*

11-128

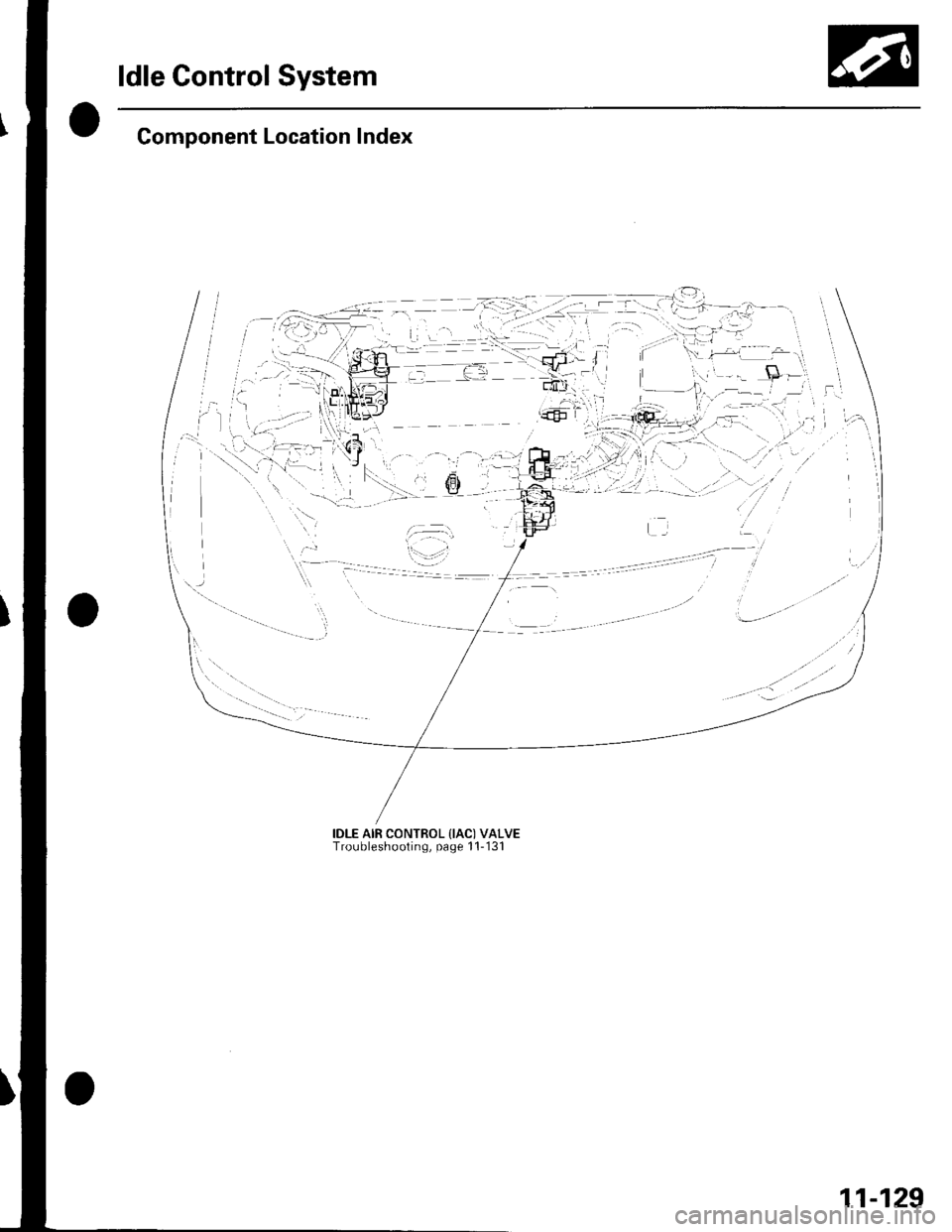

WEC Solenoid Valve Removal/

Inspection

1.Disconnect the VTEC solenoid valve 2P connector.

Measure resistance between VTEC solenoid valve

connector terminals No. 1 and No. 2.

Resistance: 14-30 Q

3. lf the resistance is within specifications, remove the

VTEC solenoid valve assemblv (A)from the

cylinder head, and check the VTEC solenoid valve

filter (B)for clogging. lf it is clogged, replace the

solenoid valve filter, the engine oilfilter, and the

engine oil.

6x1.0mm9.8 N.m (1.0 kgf.m, 7,2 lbf.ftl

L

Page 336 of 1139

ldle Gontrol System

Component Location Index

TE'

IDLE AIR CONTROL {IAC) VALVETroubleshooting, page 1 1-'131

11-129

Page 337 of 1139

ldle Control System

DTC Troubleshooting

DTC P0505: ldle Control System Malfunction

NOTE: lf DTC P1519 is stored atthe same time as DTC

P0505, troubleshoot DTC P1519 first, then recheck for

DTC P0505.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle,

2. Checkthe engine speed at idle with no,load

conditions: headlights, blower fan, rear defogger,

radiator fan, and air conditioner off.

Is the engine running at 750t50 rpm?

YES - Intermittent failure, system is OK at this

trme.I

NO lf the idle speed is less than 700 rpm, go to

step 3; if it's 800 rpm or higher, go to step 4.

3. Disconnect the idle air control {lAC) valve3P

connector.

Does the engine speed increase or fluctuate?

YES- Check the idle speed {see page 1 1-138). lf the

idle will not adjust properly, clean the passage in

the throttle body, and then adjust the idle. I

NO- Replace the IAC valve.I

4. Turn the ignition switch OFF.

5. Remove the intake air duct from the throttle body.

6. Start the engine, and let it idle.

11-130

(

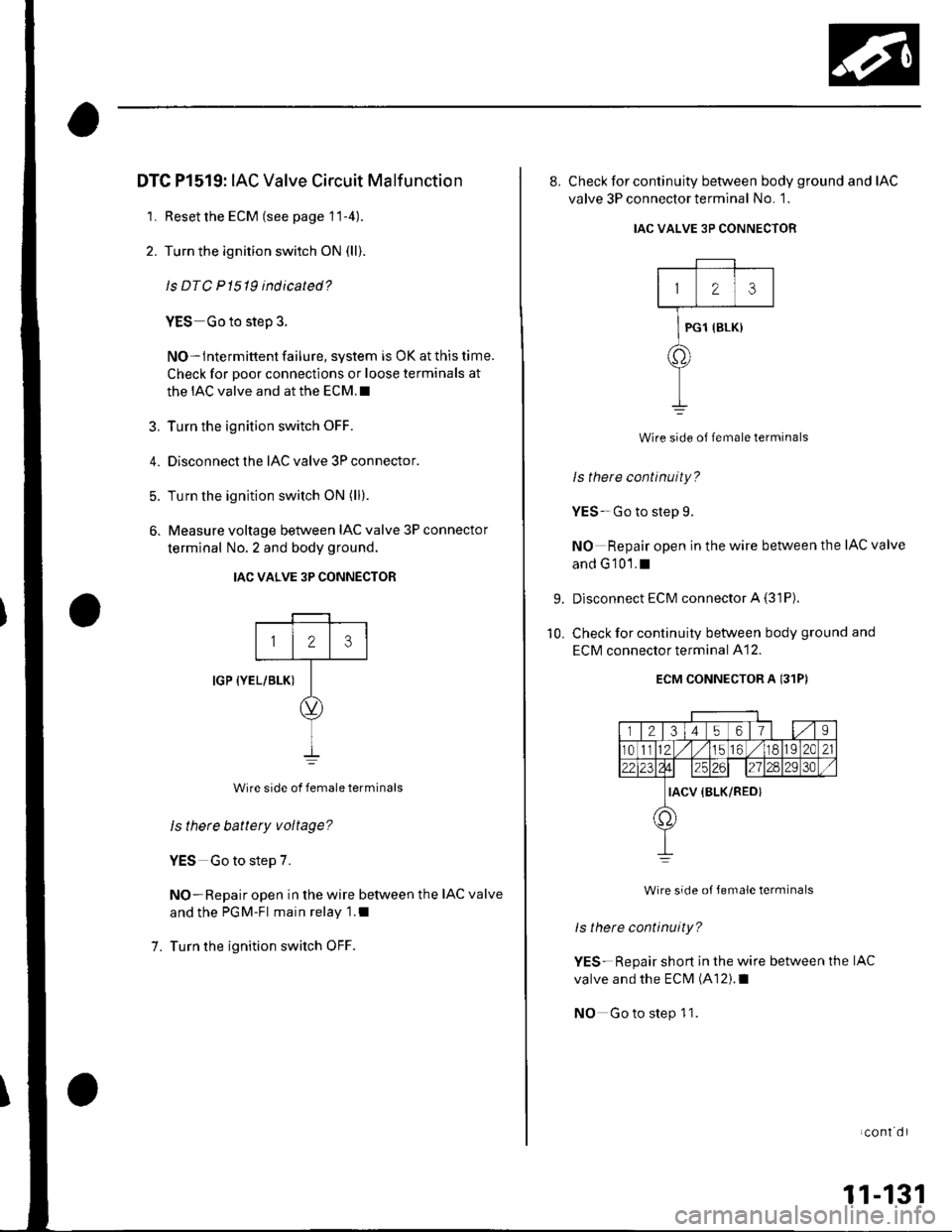

7. Put your fingers on the lower pon (A) inthethrottle

oooy.

Does the engine stall?

YES Checkthe idle speed (see page 11-138). lfit's

out of specification, replace the IAC valve.l

NO With the throttle valve completely closed,

check for vacuum leaks, and repair as necessary.l

Page 338 of 1139

DTC Pl519: IAC Valve Circuit Malf unction

1. Resetthe ECM (see page 11-4).

2. Turn the ignition switch ON (ll)

ls DTC P 1519 indicated?

YES Go to step 3.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the IAC valve and at the ECM.I

3. Turn the ignition switch OFF.

4. Disconnect the IAC valve 3P connector.

5. Turn the ignition switch ON (ll).

6. Measure voltage betlveen IAC valve 3P connector

terminal No. 2 and body ground.

IAC VALVE 3P CONNECTOR

IGP {YEL/BLK)

Wire side of female terminals

ls there battery voltage?

YES Go to step 7.

NO-Repair open in the wire between the IAC valve

and the PGM-Fl main relay 1.1

Turn the ignition switch OFF.

123

7.

8, Check for continuity between body ground and IAC

valve 3P connector terminal No. 1.

IAC VALVE 3P CONNECTOR

123

PG1 {BLK}

a.

Wire side of lemale terminals

Is there continuity?

YES-Go to step 9.

NO Repair open in the wire between the IAC valve

and G'101.1

Disconnect ECM connector A (31P)

Check for continuity between body ground and

ECM connector terminal A12.

ECM CONNECTOR A 131P)

r l2l3l4 5617s

r01l12 .// 1156 ./118192C21

da25126l27ln2930

IACV {BLK/RED}

1,)

Wire side oJ Jemale terminals

ls there continuity?

YES-Repair short in the wire between the IAC

valve and the ECM (A12).1

NO Go to step 1 1.

9.

10.

LCOnI Ol

11-131

Page 339 of 1139

ldle Control System

(DTC Troubleshooting (cont'd)

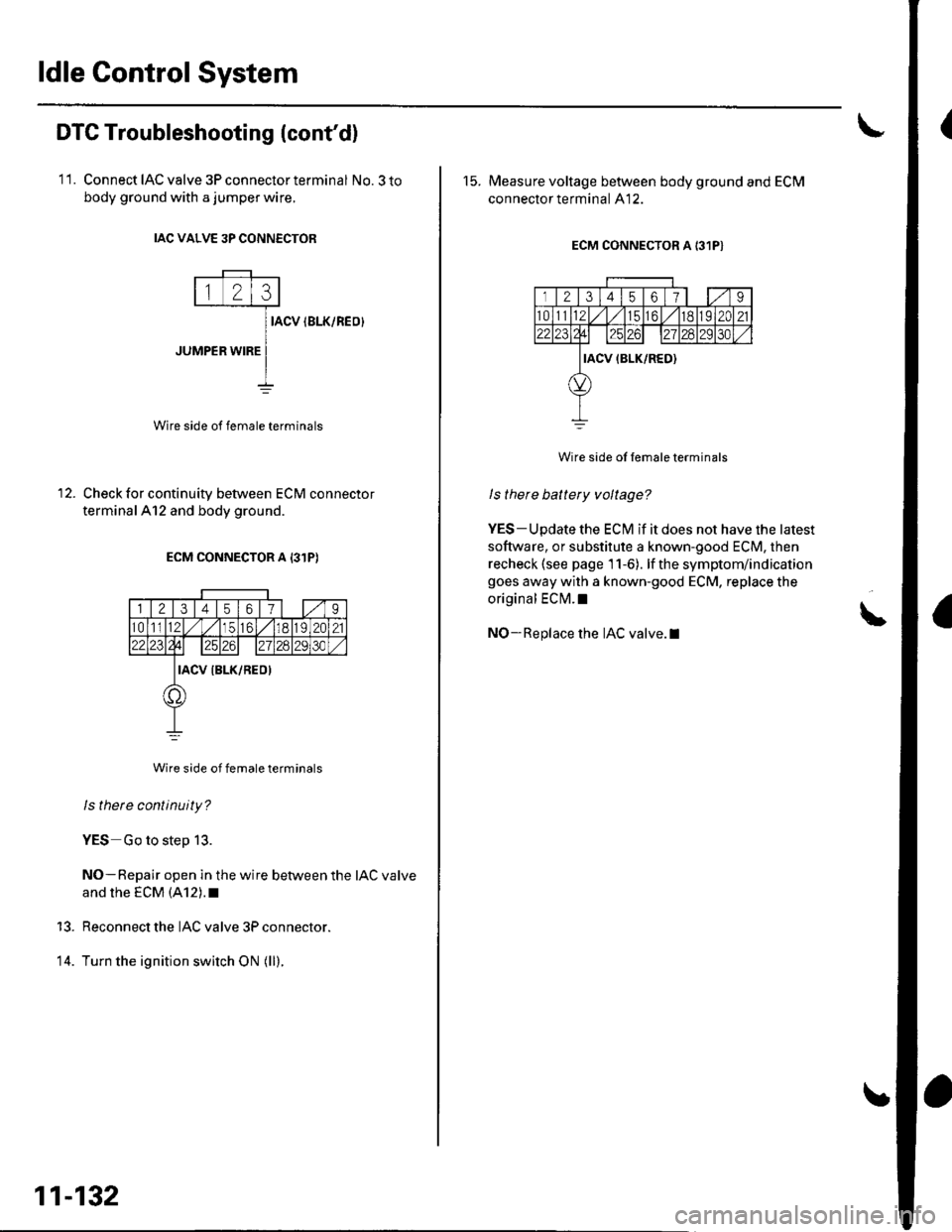

11. Connect IAC valve 3P connector terminal No.3 to

body ground with a jumper wire.

IAC VALVE 3P CONN€CTOR

IACV IBLK/REO}

JUMPER WIRE

Wire side of female terminals

Check for continuity between ECM connector

terminalAl2 and body ground.

ECM CONNECTOR A 131P)

Wire side of female terminals

ls there continuity?

YES Go to step 13.

NO-Repair open in the wire between the IAC valve

and rhe EcM (A12).r

Reconnect the IAC valve 3P connector.

Turn the ignition switch ON (ll).

13.

14.

11-132

15. Measure voltage between body ground and ECM

connector terminal A12.

ECM CONNECTOR A 131P}

rl2l31456179

t01tl12l,/l/tc6,/ 1182C2122231?4l| 12.zil2830

IACV IBLK/RED)

Wire side ol female terminals

I s there battery voltage?

YES-Update the ECI\4 if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECI\4.1

NO-Replace the IAC valve.I!

Page 340 of 1139

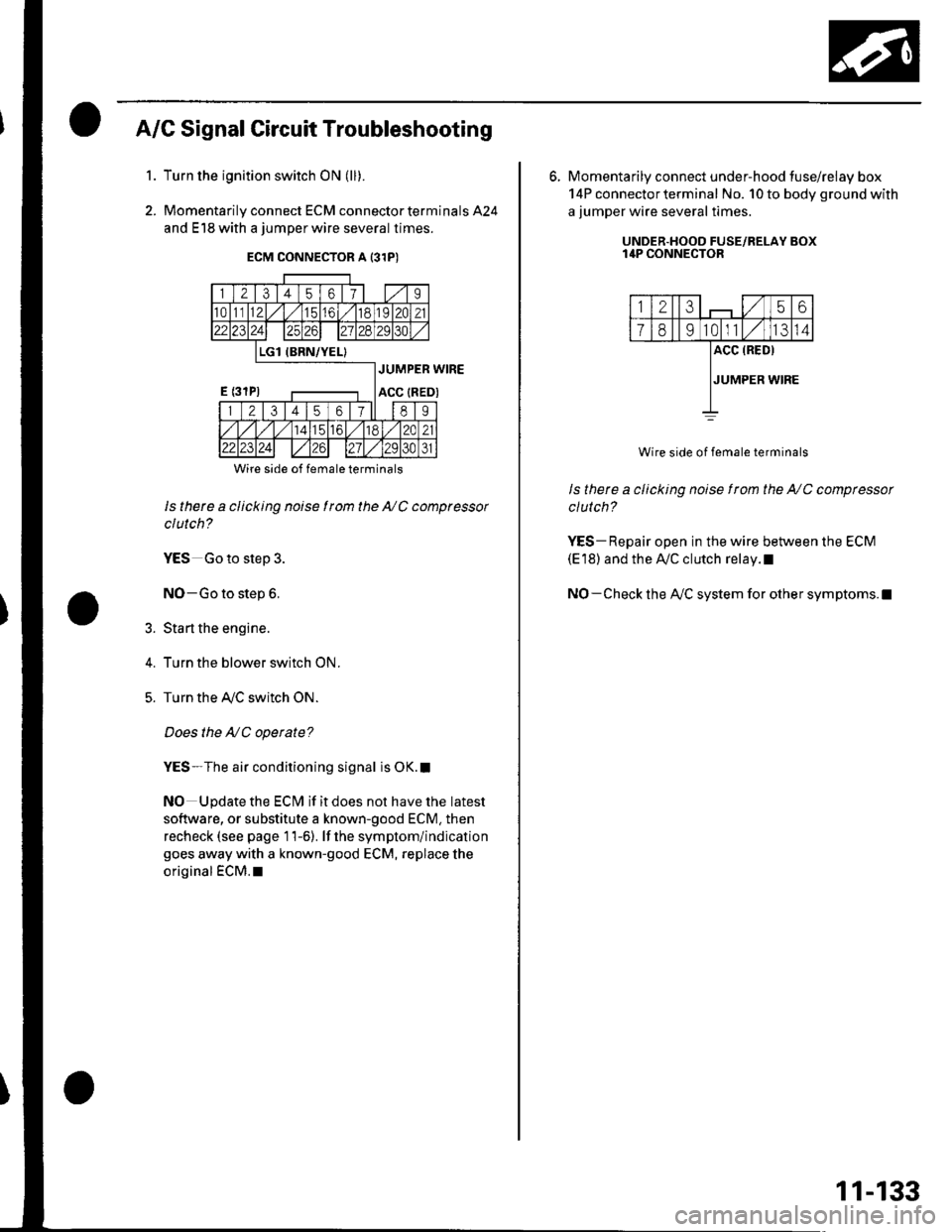

A/G Signal Circuit Troubleshooting

Turn the ignition switch ON (ll).

Momentarily connect ECM connector terminals 424

and E18 with a jumper wire several times.

1.

2.

5.

Wire side of female terminals

ls there a clicking noise I rom the NC compressor

clutch?

YES Go to step 3.

NO-Go to step 6.

Sta rt the engine.

Turn the blower switch ON.

Turn the Ay'C switch ON.

Does the NC operate?

YES-The air conditioning signal is OK.I

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM. then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original €CM.l

6. Momentarily connect under-hood tuse/relay box

14P connector terminal No. 10 to body ground with

a jumper wire several times.

UNDER.HOOD FUSE/RELAY BOXI4P CONNECTOR

12356

1891011IJ14

ACC (RED)

JUMPER WIRE

Wire side of female terminals

ls there a clicking noise f rom the NC compressor

clutch?

YES- Repair open in the wire between the ECM(E'18) and the Ay'C clutch relay.l

NO- Check the A/C system for other symptoms.l

11-133