HONDA CIVIC 2003 7.G Workshop Manual

Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 551 of 1139

EPS Components

{Steering Gearbox Overhaul (cont'dl

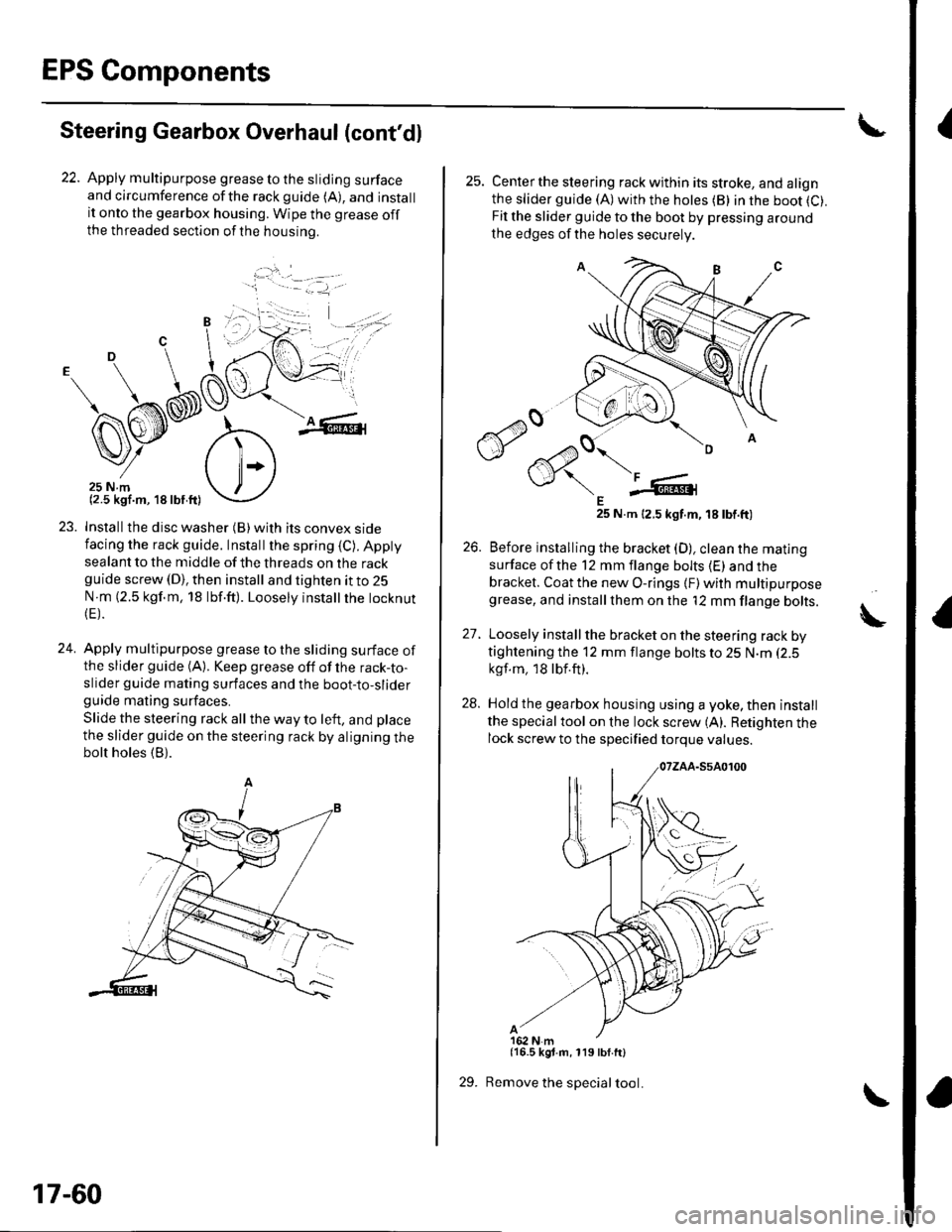

22. Apply multipurpose grease to the sliding surfaceand circumference ofthe rackguide (A), and installit onto the gearbox housing. Wipe the grease offthe threaded section ofthe housrno.

...'.

,. ,l

.j

23. Installthe disc washer (B)with its convex sidefacing the rack guide. Installthe spring (C). Appty

sealant to the middle of the threads on the rackguide screw (D), then install and tighten it to 25

N m (2.5 kgf.m, 18 lbf.ft). Loosely instatlrhe tocknut(E).

24. Apply multipurpose grease to the sliding surface ofthe slider guide (A). Keep grease off of the rack-to-slider guide mating surfaces and the boot-to-sliderguide mating surfaces.

Slide the steering rack all the way to left, and place

the slider guide on the steering rack by aligning thebolt holes (B).

'1 - .- =-1, -

17-60

29.

25. Centerthe steering rack within its stroke, and alignthe slider guide (A)with the hotes (B) in the boot (C).

Fit the slider guide to the boot by pressing around

the edges of the holes securely

E25 N.m 12.5 kgt.m, 18 tbt.ft)

26. Before installing the bracket (D), clean the mating

surface ofthe 12 mm flange bolts (E) and thebracket. Coat the new O-rings {F) with multipurposegrease, and installthem on the '12 mm flange bolts.

27. Loosely install the bracket on the steering rack bytightening the 12 mm flange bolts to 25 N.m (2.5

kgf.m, 18lbf.ft).

28. Hold the gearbox housing using a yoke, then install

the specialtool on the lock screw (A). Retighten thelock screw to the specified torque values.

{16.5 kgt.m, 119 lbf.ft}

Remove the special tool.

A

Page 552 of 1139

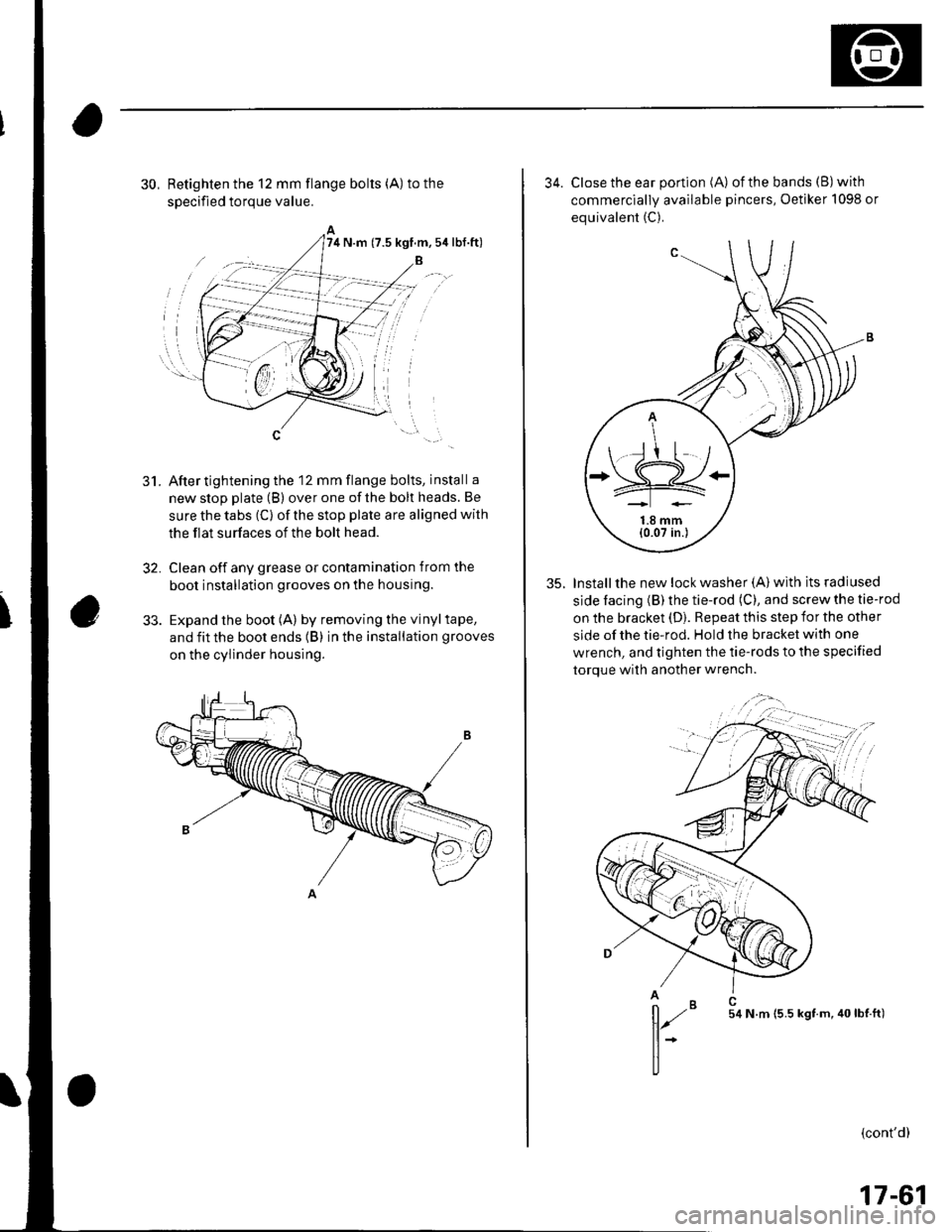

30, Retighten the 12 mm flange bolts (A) to the

soecified toroue value.

After tightening the 12 mm flange bolts, install a

new stop plate (B) over one of the bolt heads. Be

sure the tabs (C) of the stop plate are aligned with

the flat surfaces of the bolt head.

Clean off any grease or contamination from the

boot installation grooves on the housing.

Expand the boot (A) by removing the vinyltape,

and fit the boot ends (B) in the installation grooves

on the cylinder housing.

5t.

32,

74 N.m (7.5 kgf.m,5ir lbf.ft)

34. Close the ear portion (A) ofthe bands (B)with

commerciallv available pincers, Oetiker 1098 or

equivalent (C).

35. Installthe new lock washer (A) with its radiused

side facing (B) the tie-rod (C), and screw the tie-rod

on the bracket (D). Repeat this step for the other

side of the tie-rod. Hold the bracket with one

wrench, and tighten the tie-rods to the specified

torque with another wrench.

,,";=-...,.,

(cont'd)

*=,,',

17-61

Page 553 of 1139

EPS Components

Steering Gearbox Overhaul (cont'dl

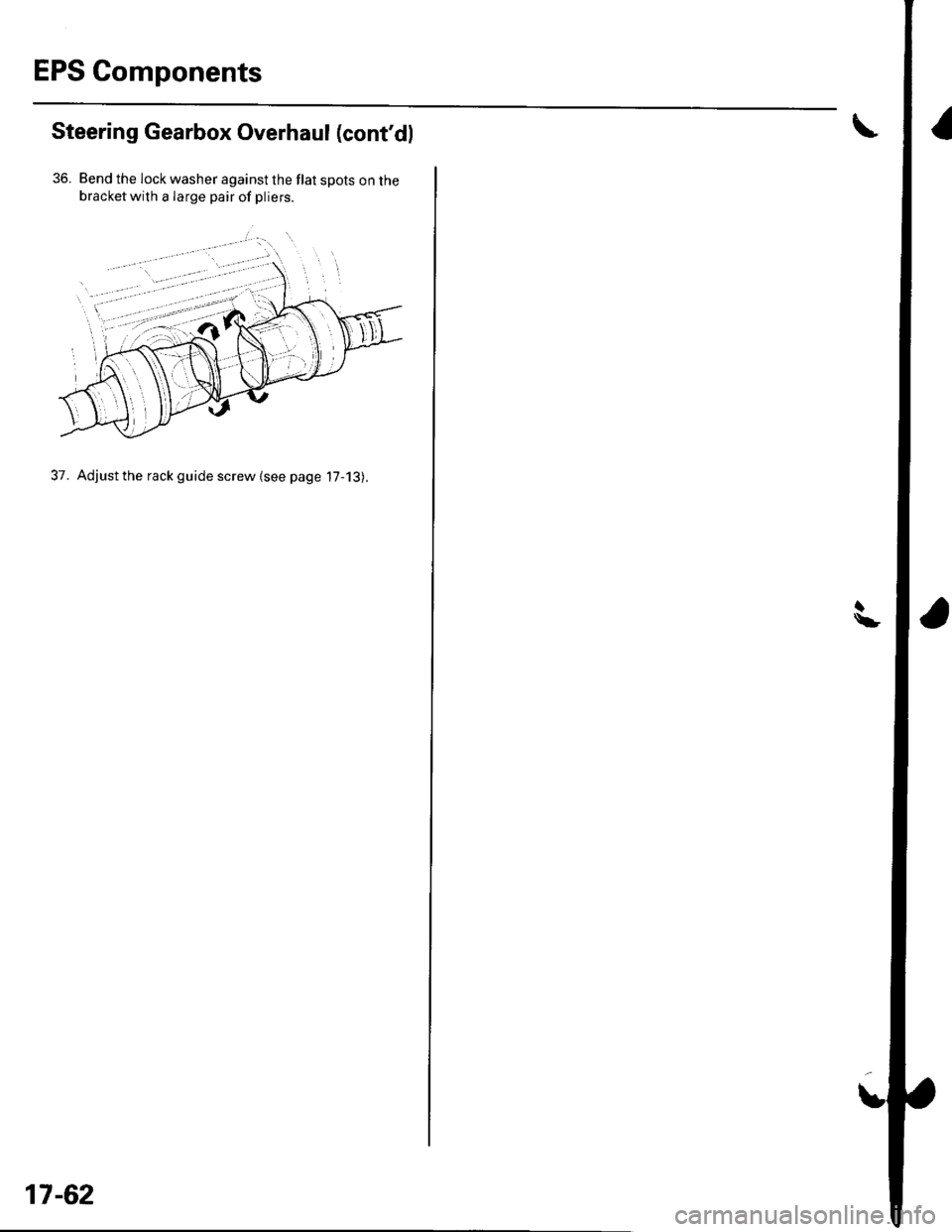

36. Bend the lock washer against the flat spots on thebracketwith a Iarge pair of pliers.

37. Adjust the rack guide screw {see page 17-13).

17-62

Page 554 of 1139

Steering Gearbox Installation

2.

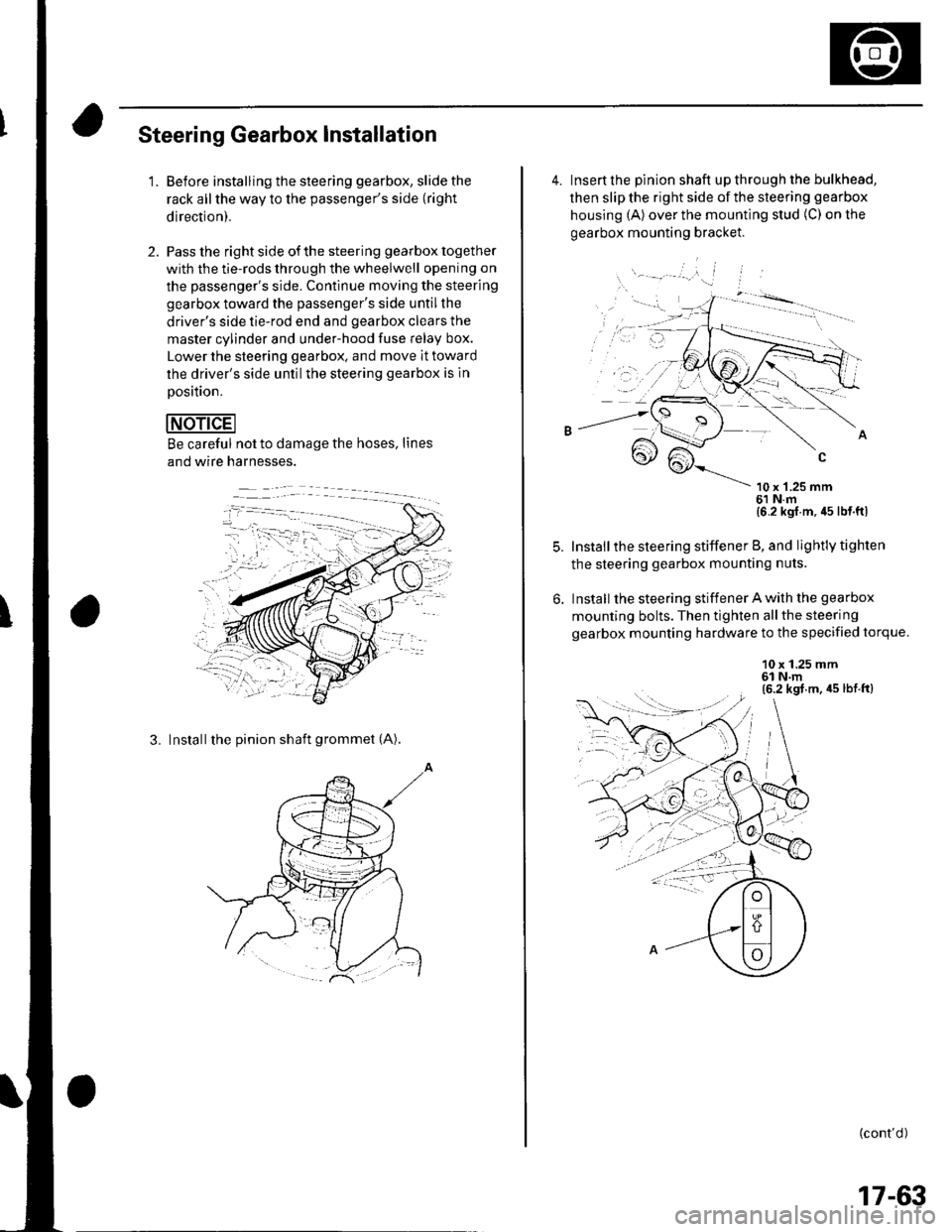

'1.Before installing the steering gearbox, slide the

rack all the way to the passenger's side (right

direction).

Pass the right side of the steering gearbox together

with the tie-rods through the wheelwell opening on

the passenger's side. Continue moving the steering

gearbox toward the passenger's side untilthe

driver's side tie-rod end and gearbox clears the

master cylinder and under-hood fuse Ielay box.

Lower the steering gearbox. and move it toward

the driver's side untilthe steering gearbox is ln

Dosition.

Be careful not to damage the hoses, lines

and wire harnesses.

3. Installthe pinion shaft grommet (A).

4. Insert the pinion shaft up through the bulkhead,

then slip the right side of the steering gearbox

housing (A) over the mounting stud (C) on the

gearbox mounting bracket.

\- --' '.'', i

10 x '1.25 mm61 N.m{6 2 kgl m, 45 lb{ ftl

Install the steering stiffener B, and lightly tighten

the steering gearbox mounting nuts.

Install the steering stiffener A with the gearbox

mounting bolts. Then tighten allthe steering

gearbox mounting hardware to the specified torque.

10 x 1.25 mm6l N.m(6.2 kgt.m, 45 lbt.ft)

: --.-{..

(cont'd )

:-1....

17-63

Page 555 of 1139

EPS Components

Steering Gearbox Installation (cont'd)

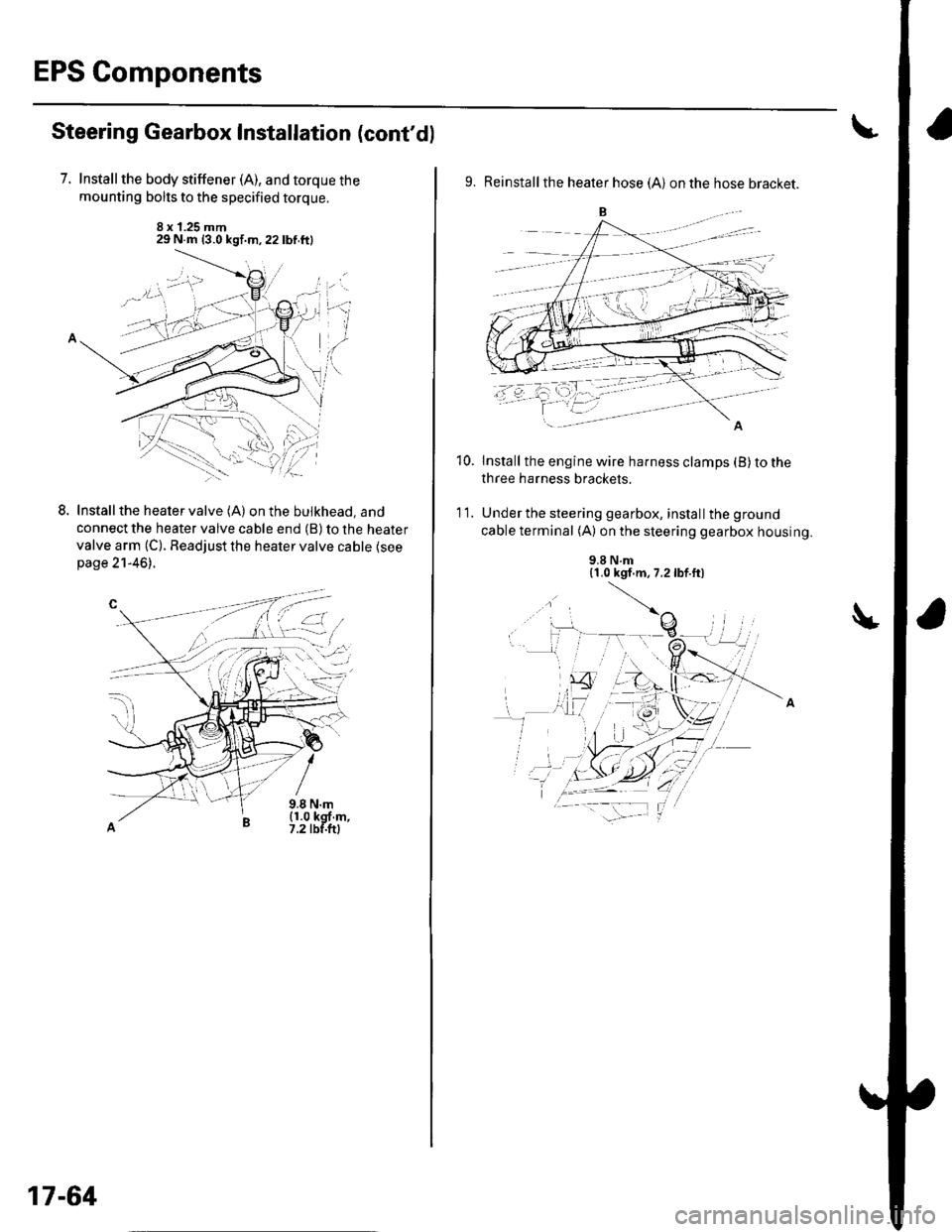

7. Installthe body stiffener (A), and torque the

mounting bolts to the specified torque.

8 x 1.25 mm29 N.m {3.0 kgf.m,22lbf.ftl

LInstall the heater valve (A) on the bulkhead, and

connect the heater valve cable end (B) to the heater

valve arm (C). Readjust the heater valve cable {seepage 21-46).

9.8 N.m(1.0 kgf m,7.2 tbf.ftl

L-t ,:.i.t'

17-64

9. Reinstall the heater hose (A) on the hose bracket.

Install the engine wire harness clamps (B) to the

three harness brackets.

Under the steering gearbox, install the ground

cable terminal (A) on the steering gearbox housing.

10.

'I t.

9.8 N.m{1.0 kgf.m, 7.2lbf.ft)

Page 556 of 1139

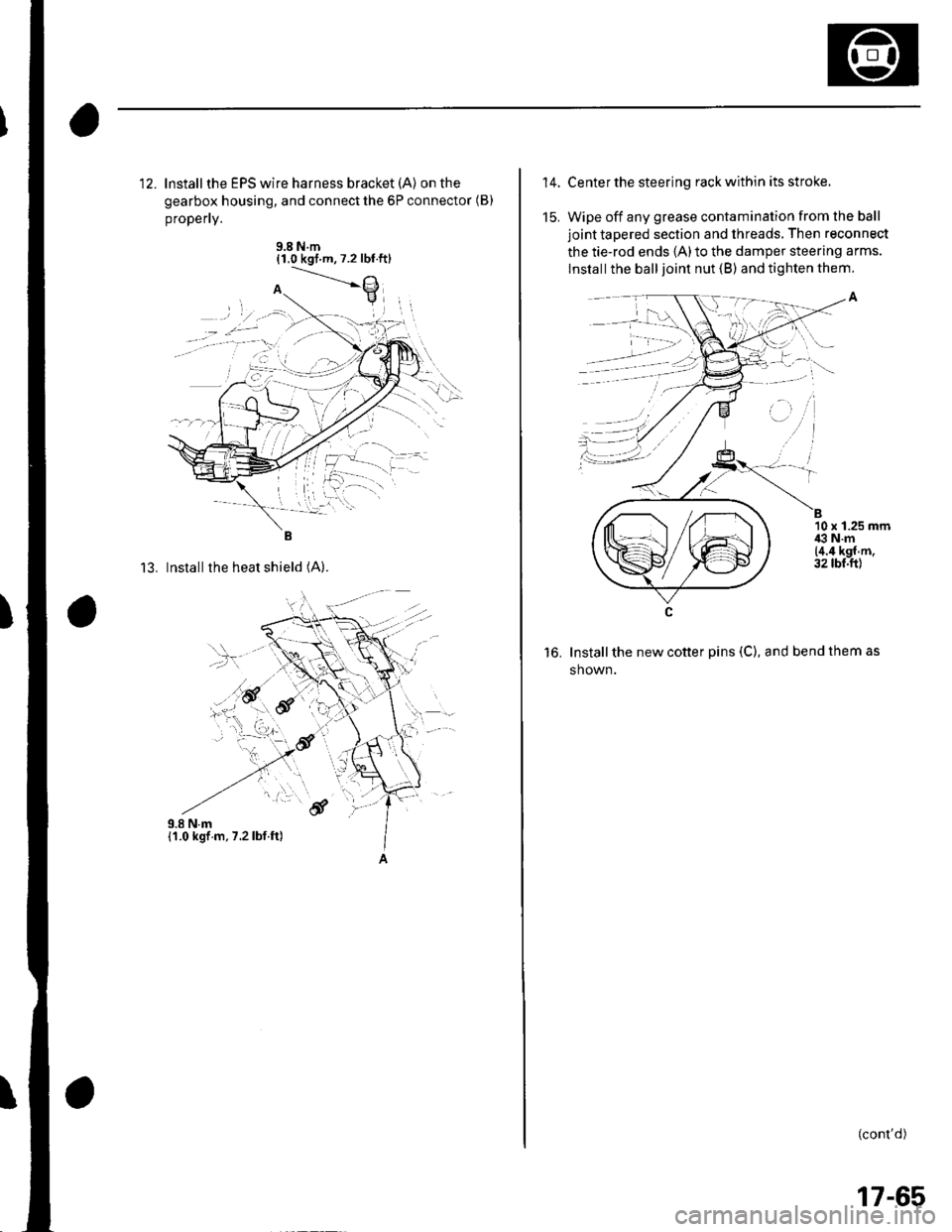

12. lnstallthe EPS wire harness bracket (A) on the

gearbox housing, and connect the 6P connector (B)

propefly.

9.8 N.m{1.0 kgt m,7.2 lbt.ftl

13. Installthe heat shield (A).

,.!,..''6f

14.

15.

Center the steering rack within its stroke.

Wipe off any grease contamination from lhe ball

joint tapered section and threads. Then reconnect

the tie-rod ends 1A)to the damper steering arms.

lnstall the ball joint nut (B) and tighten them.

Install the new cotter pins (C), and bend them as

shown.

(cont'd)

B10 x 1.25 mmi€ N.m{4.4 kgf.m.32 tbt.ftl

to.

, -', ''l

:1)

17-65

Page 557 of 1139

EPS Components

4

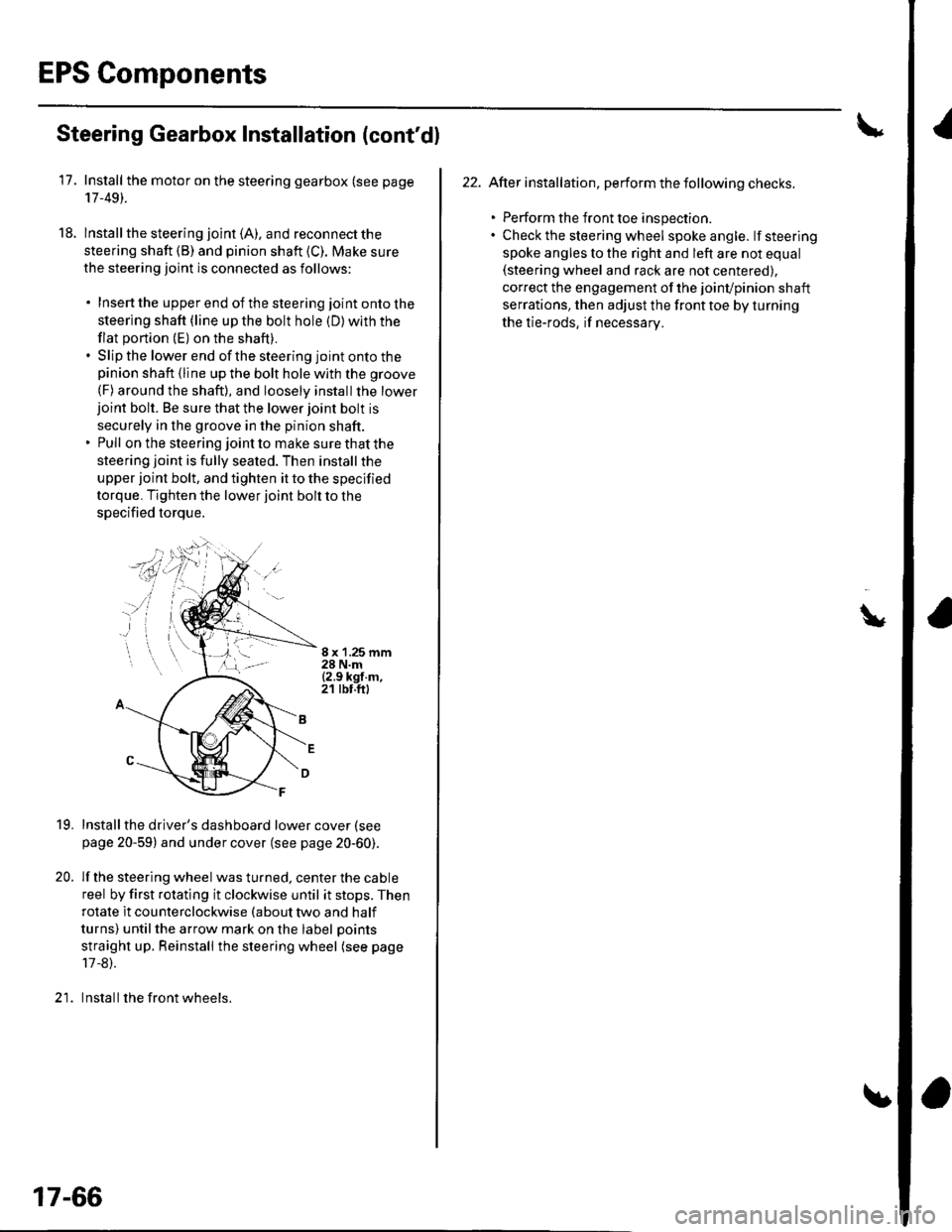

17.

18.

Steering Gearbox Installation (cont'dl

Install the motor on the steering gearbox (see page

17-49).

lnstall the steering joint (A). and reconnect the

steering shaft (B) and pinion shaft (C). Make sure

the steering joint is connected as follows:

. Insertthe upperend of thesteering jointontothe

steering shaft (line up the bolt hole (D) with the

flat portion (E) on the shaft).. Slip the lower end of the steering joint onto thepinion shaft (line up the bolt hole with the groove

(F) around the shaft), and loosely installthe lowerjoint bolt. Be sure that the lower joint bolt is

securely in the groove in the pinion shaft.. Pull on the steering joint to make sure that the

steering joint is fully seated. Then install the

upper joint bolt, and tighten it to the specified

torque. Tighten the lower joint bolt to the

specified torque.

8 x '1.25 mm28 N.m{2.9 kgf.m,21 tbt.ft)

19.

20.

Installthe driver's dashboard lower cover (see

page 20-59) and under cover (see page 20-60).

lf the steering wheel was turned, center the cable

reel by first rotating it clockwise until it stops. Then

rotate it counterclockwise (about two and half

turns) untilthe arrow mark on the label points

straight up. Reinstall the steering wheel (see page

17 -8).

Install the front wheels.)1

17-66

22. After installation, perform the following checks.

. Perform the front toe inspection.. Check the steering wheel spokeangle. lfsteering

spoke angles to the right and left are not equal(steering wheel and rack are not centered),

correct the engagement of the joinvpinion shaft

serrations, then adjust the front toe by turning

the tie-rods, if necessarv.

\

Page 558 of 1139

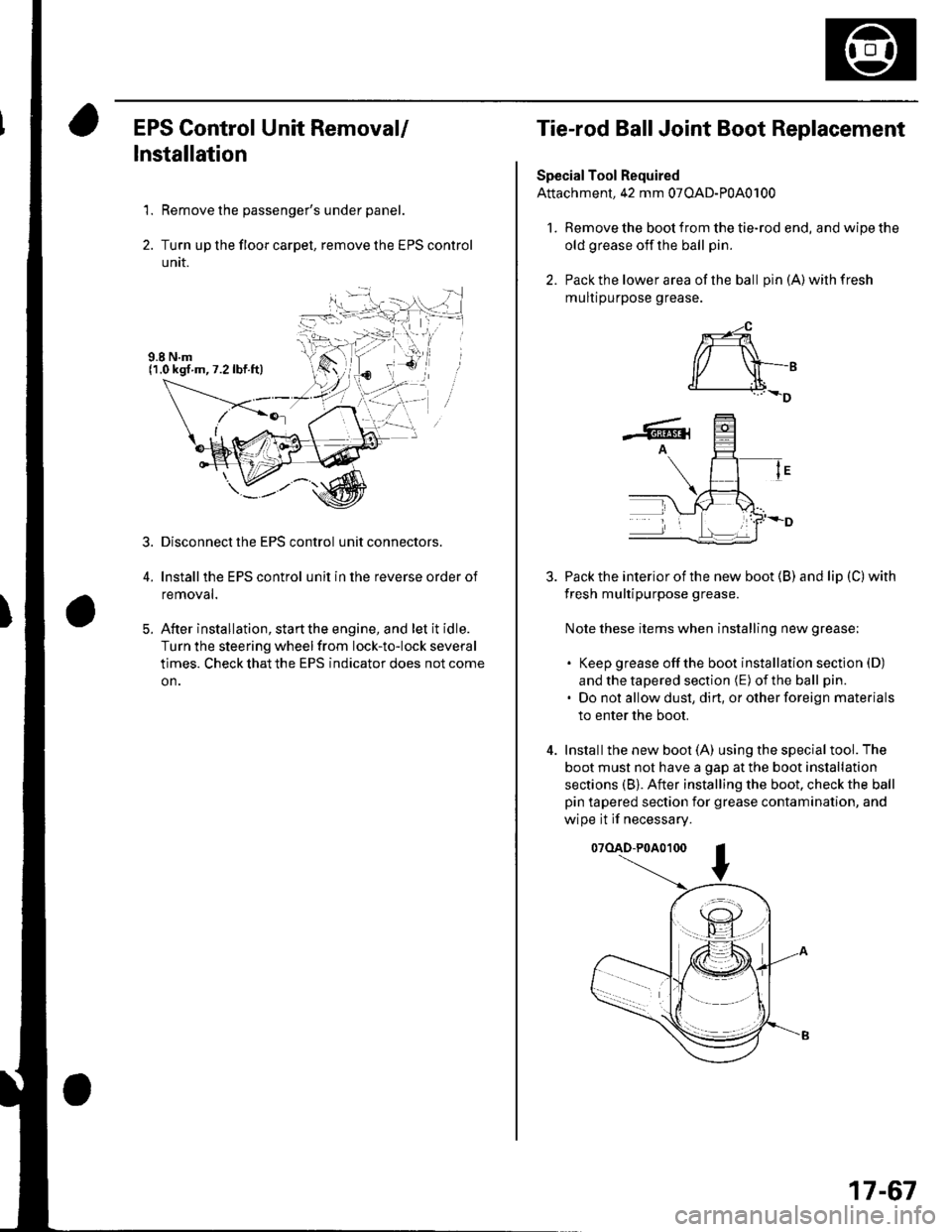

EPS Control Unit Removal/

Installation

1. Remove the passenger's under panel.

2. Turn up the floor carpel, remove lhe EPS control

untr.

Disconnect the EPS control unit connectors.

lnstallthe EPS control unit in the reverse order of

removal.

After installation, start the engine, and let it idle.

Turn the steering wheelfrom lock-to-lock several

times. Check that the EPS indicator does not come

on.

3.

E

Tie-rod Ball Joint Boot Replacement

Special Tool Required

Attachment, 42 mm 07OAD-P0A0100

l. Remove the boot from the tie-rod end, and wipe the

old grease off the ball pin.

2. Pack the lower area of the ball pin(A)wilhfresh

mulr purpose grease.

3. Pack the interior of the new boot (B) and lip (C) with

fresh multipurpose grease.

Note these items when installing new grease;

. Keep grease offthe boot installation section (D)

and the tapered section (E) of the ball pin.

. Do not allow dust, dirt, or other foreign materials

to enter the boot.

4. Installthe new boot (A) using the specialtool. The

boot must not have a gap at the boot installation

sections (B). After installing the boot. check the ball

pin tapered section for grease contamination, and

wipe it if necessary.

07(lAD-P0A0100

*-4

r/ \-,d______i.l+_D

-6rA

17-67

Page 559 of 1139

Suspension

Front and Rear Suspension

SpecialTools ............. 18-2

Component Location Index ......................................... 18-3

Wheel Alignment ..................... ........... 18-4

Wheel Bearing End Play Inspection ............................ 18-8

Wheel Runout Inspection .................. 18-9

Ball Joint Removal ... 18-10

Front Suspension

Kn uckle/H u bAVheel Bearing Replacement

Ball Joint Boot Reolacement ..................

Stabilizer Bar Rep|acement ....................

Stabilizer Link Removal/lnstallation

LowerArm Removal/lnstallation ...............

Damper/Spring Replacement

Rear Suspension

Hub Bearing Unit Replacement .....................

Knuckle Reolacement

Stabilizer Bar Replacement ....................

Stabilizer Link Removal/lnstallation ..........................

Upper Arm Removal/lnstallation ...............

Trailing Arm Removal/lnstallation

Damper/Spring Replacement

18-1 1

18-16

18-17

18-18

18-19

18-20

18-26

18-28

18-30

18-31

18-32

18-33

18-34

Page 560 of 1139

![HONDA CIVIC 2003 7.G Workshop Manual Front and Rear Suspension

SpecialTools

o

[]

o

o

a6,l@

I

Ref.No.Tool NumberDescriptionotv

o

@

o

G)

07GAF-SE00100

07MAC-S100200

07746-0010500

07749-0010000

07965-SA50500

07965-SD90100

Hub Dis/Assembly T HONDA CIVIC 2003 7.G Workshop Manual Front and Rear Suspension

SpecialTools

o

[]

o

o

a6,l@

I

Ref.No.Tool NumberDescriptionotv

o

@

o

G)

07GAF-SE00100

07MAC-S100200

07746-0010500

07749-0010000

07965-SA50500

07965-SD90100

Hub Dis/Assembly T](/img/13/5744/w960_5744-559.png)

Front and Rear Suspension

SpecialTools

o

[]

o

o

a6,l@

I

Ref.No.Tool NumberDescriptionotv

o

@

o

G)

07GAF-SE00100

07MAC-S100200

07746-0010500

07749-0010000

07965-SA50500

07965-SD90100

Hub Dis/Assembly Tool

Ball Joint Remover, 28 mm

Attachment, 62 x 68 mm

Driver

Front Hub Dis/Assembly Tool

Support Base

18-2