Front HONDA CIVIC 2003 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 565 of 1139

Front Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster, camber, toe, and turning angle). Follow the

equipment manufacturer's instructions,

1. Center the steering wheel spokes.

2. Checkthetoe. lf it is not with in the specif ication, go

to step 3.

Front toe-in: 0 t 3 mm {0 t 0.12 in.)

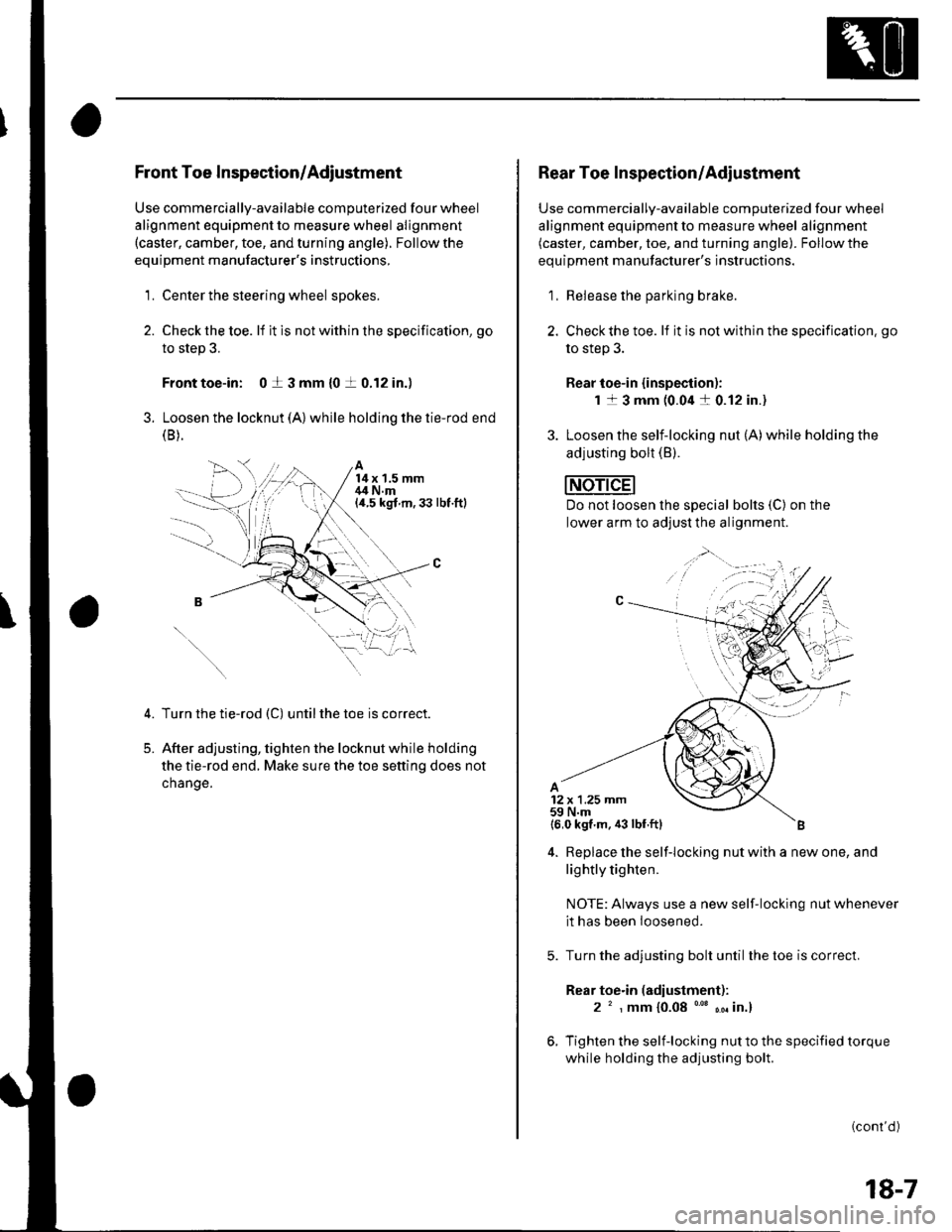

3. Loosen the locknut (A) while holding the tie-rod end(B ).

A14x 1.5 mm,14 N.m(a.5 kgt m,33 lbt.ftl

5.

Turn the tie-rod (C) untilthe toe is correct.

After adjusting, tighten the locknut while holding

the tie-rod end. Make sure the toe setting does not

change.

1,;

Rear Toe Inspection/Adiustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster, camber, toe, and turning angle). Follow the

equipment manufacturer's instructions.

1, Release the parking brake.

2. Checkthe toe. lf it is not within the specification. go

to step 3.

Rear toe-in {inspection):

1 1 3 mm (0.04 a 0.12 in.)

3. Loosen the self-locking nut (A)while holding the

adjusting bolt (B).

Do not loosen lhe special bolts (C) on the

lower arm to adjust the alignment.

4. Replace the self-locking nut with a new one, and

lightly tighten.

NOTE: Always use a new self-locking nut whenever

it has been loosened.

Turn the adjusting bolt until the toe is correct.

Rear toe.in (adiustment):

2 ' , mm {0.08 "' ,. in.}

Tighten the self-locking nut to the specified torque

while holding the adjusting bolt.

(cont'd )

18-7

Page 566 of 1139

Front and Rear Suspension

Wheel Alignment (cont'dl

Turning Angle Inspection

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster. camber, toe, and turning angle). Followthe

equiDment manufacturer's instructions.

1. Turn the steering wheel fullytotherightandleft

while applying the brake, and check the turning

angles of both front wheels, lf the turning angle is

not within the specification or the inward turning

angles differ between the right and left side, go to

steD 2.

Turning angle:

lnward: 34'00'+ 2'

Outward: 28'00' {reference)

Check the toe. lf it is correct, but the turning angle

is not within the specification, check ior bent or

damaged suspension components,

18-8

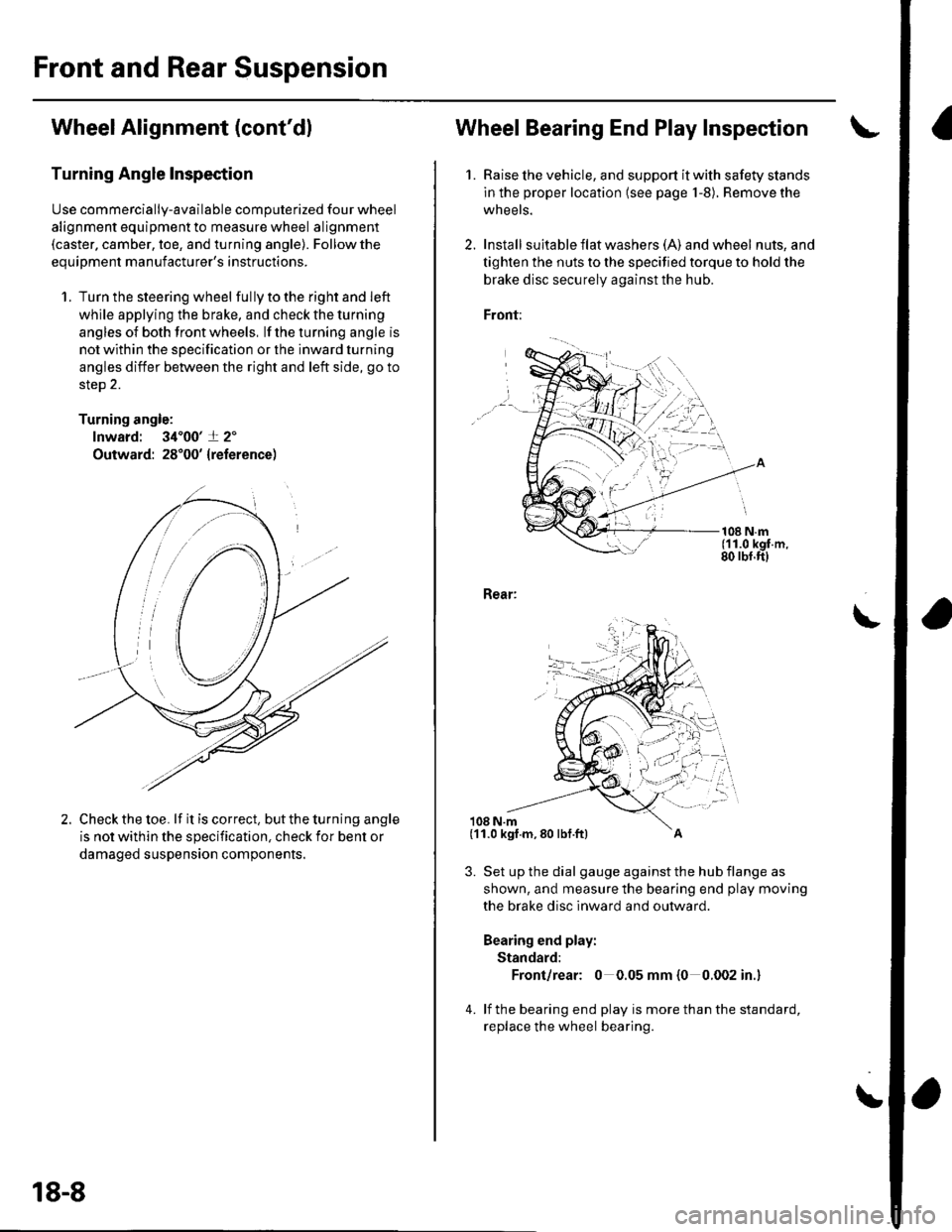

Wheel Bearing End Play Inspec'tion

1. Raise lhe vehicle, and support it with safety stands

in the proper location (see page 1-8). Remove the

wheels.

2. Install suita ble f lat washe rs (A) and wheel nuts, and

tighten the nuts to the specified torque to hold the

brake disc securely against the hub.

Front:

108 N.m(11.0 kgf.m,80 rbf.ft)

Rear:

108 N.m

3. Set up the dial gauge against the hub flange as

shown, and measure the bearing end play moving

the brake disc inward and outward.

Bearing end play:

Standard:

Front/rear: 0 0.05 mm {0 0.002 in.}

4. lf the bearing end play is more than the standard,

replace the wheel bearing.

\

(11.0 kgf.m,80 lbf.ft)

Page 567 of 1139

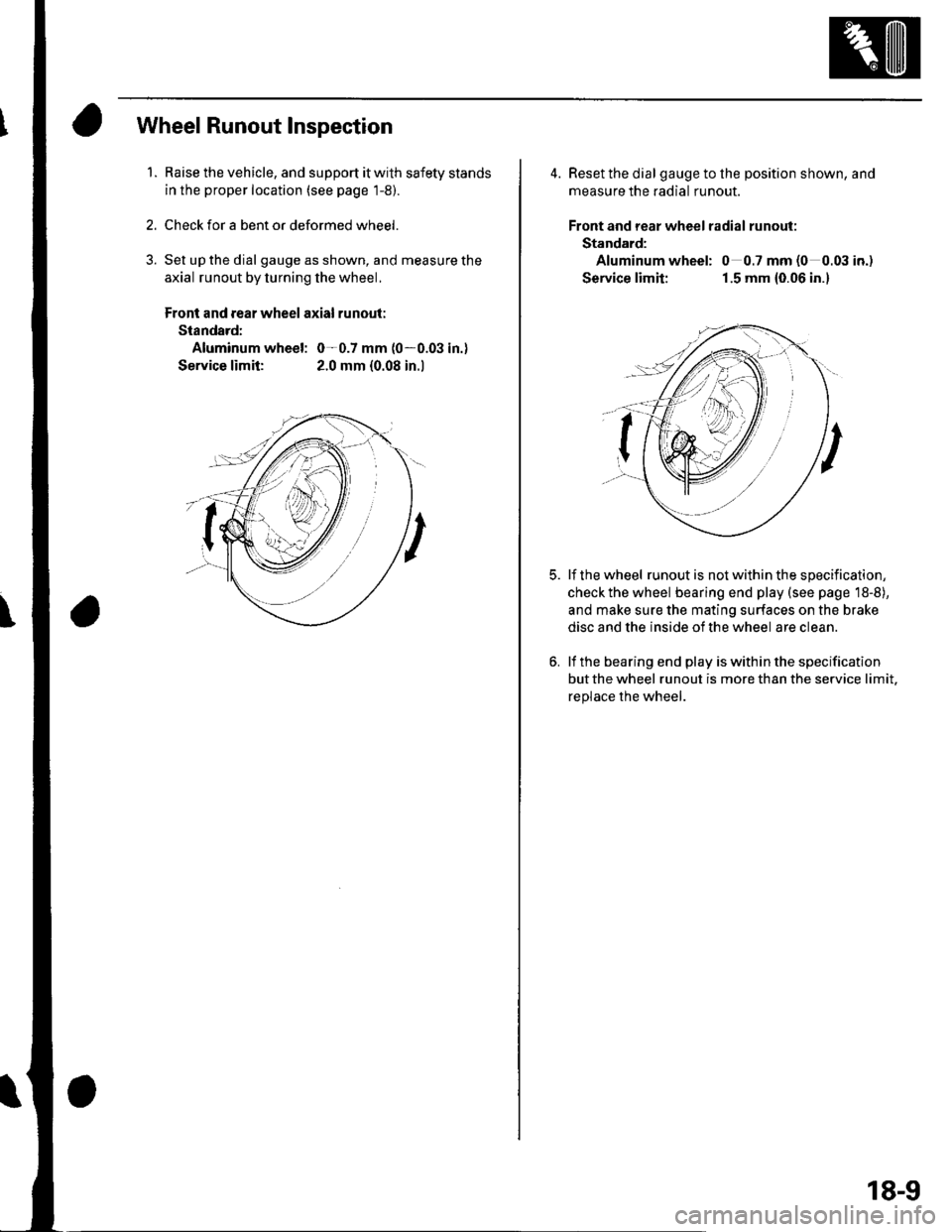

Wheel Runout Inspection

1.Raise the vehicle, and support it with safety stands

in the proper location (see page 1-5,.

Check for a bent or deformed wheel.

Set up the dial gauge as shown, and measure the

axial runout by turning the wheel.

Front and rear wheel axial runout:

Standard:

Aluminum wheel: 0-0.7 mm (0-0.03 in.)

Service limit: 2.0 mm {0.08 in.l

4. Reset the dial gaugetothe position shown, and

measure the radial runout.

Front and rear wheel radial runout:

Standard:

Aluminum wheel: 0 0.7 mm (0 0.03 io.)

Service limit: 1.5 mm {0.06 in.}

lf the wheel runout is not within the specification,

checkthe wheel bearing end play (see page 18-8),

and make sure the mating surfaces on the brake

disc and the inside of the wheel are clean.

lf the bearing end play is within the specification

but the wheel runout is more than the service limit.

replace the wheel.

18-9

Page 568 of 1139

Front and Rear Suspension

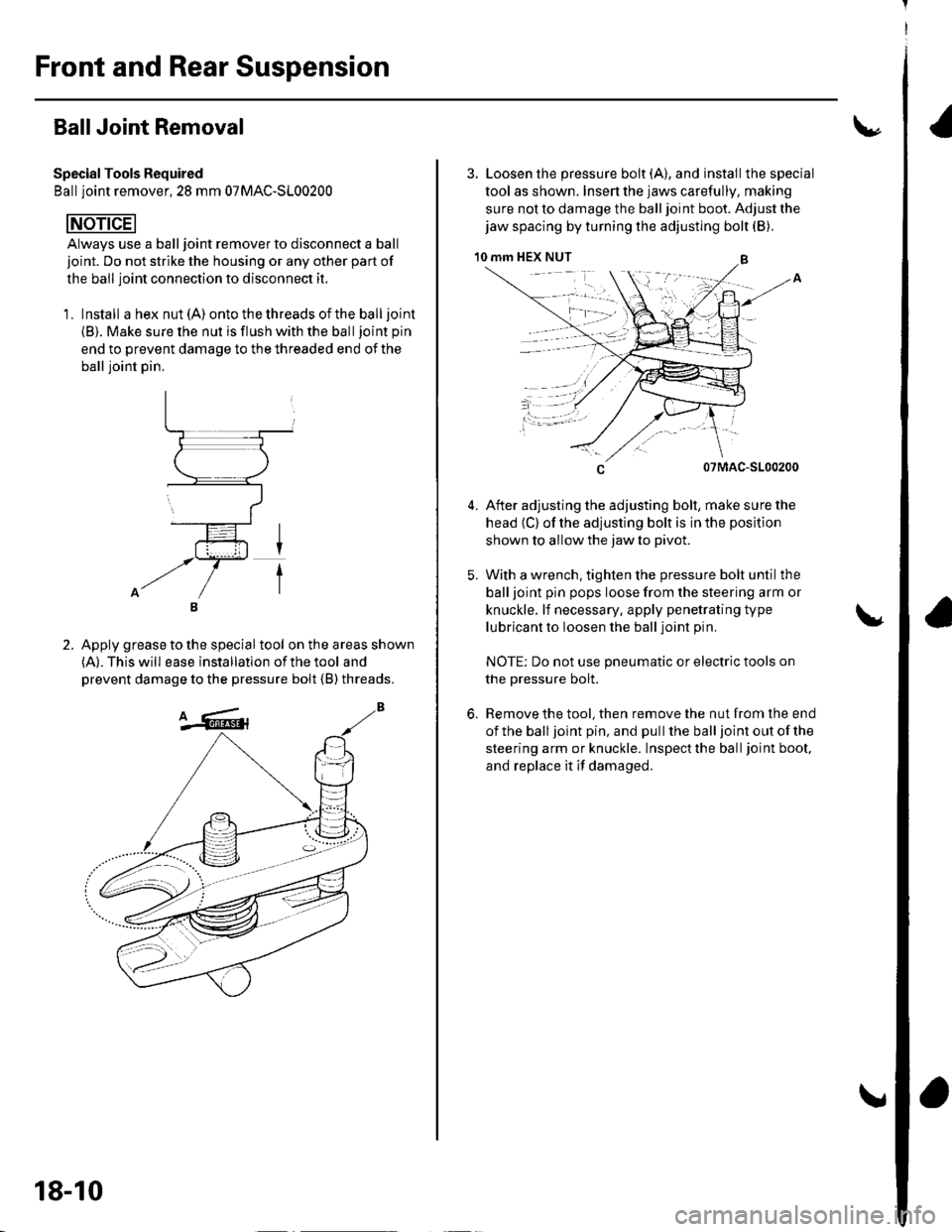

BallJoint Removal

Special Tools Required

Ball ioint remover.2S mm 07MAC-SL00200

Always use a ball joint remover to disconnect a ball

joint. Do not strike the housing or any other part of

the ball joint connection to disconnect it.

'1, Install a hex nut (A) ontothethreadsoftheballjoint

{B). Make sure the nut is flush with the balljoint pin

end to prevent damage to the threaded end of the

ball ioint oin.

Apply grease to the special tool on the areas shown(A). This will ease installation of the tool and

prevent damage to the pressure bolt {B) threads.

2.

18-10

3. Loosen the pressure bolt (A), and installthe special

tool as shown. Insen the jaws carefully, making

sure not to damage the ball joint boot. Adjust the

jaw spacing by turning the adjusting bolt (B).

10 mm HEX NUT

5.

07MAC-S100200

After adjusting the adjusting bolt, make sure the

head (C) of the adjusting bolt is in the position

shown to allow the jaw to pivot.

With a wrench, tighten the pressure bolt until the

ball ioint pin pops loose from the steering arm or

knuckle. lf necessary. apply penetrating type

lubricant to loosen the ball joint pin

NOTE: Do not use pneumatic or electric tools on

the pressure bolt.

Remove the tool, then remove the nut from the end

ofthe balljoint pin, and pullthe balljoint out ofthe

steering arm or knuckle. Inspectthe balljoint boot,

and replace it if damaged.

6.

Page 569 of 1139

Front Suspension

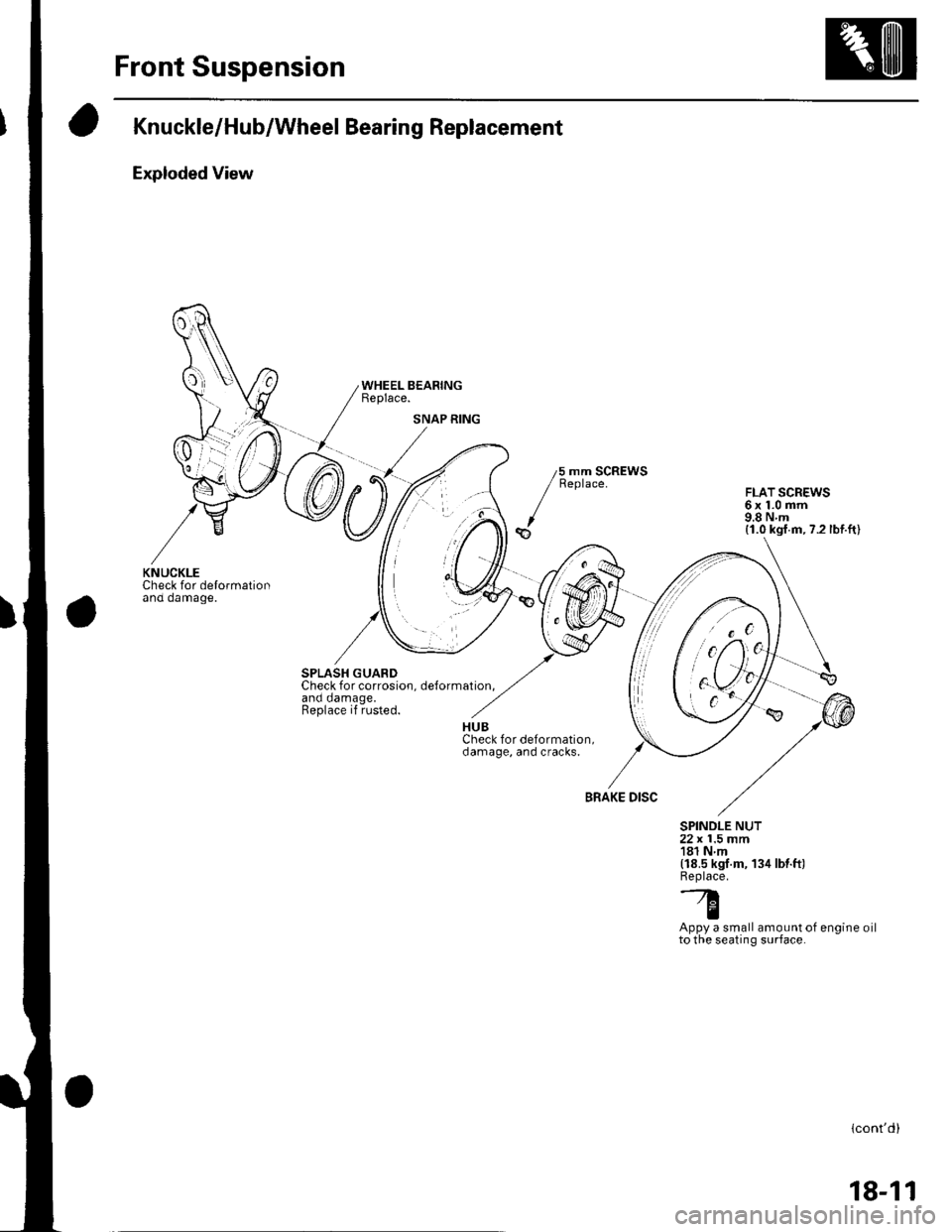

Knuckle/Hub/Wheel Bearing Replacement

Exploded View

Check for delormationano oamage.

SPLASH GUARDCheck for corrosion. delormation.and damage.Replace if rusted.

WHEEL BEARINGReplace.

5 mm SCREWSReplace.FLAT SCREWS6x1.0mm9.8Nm(1.0 kgf.m,7.2 lbf.ft)

BRAKE DISC

SPINDLE NUT22 x 1.5 mm181 Nm(18.5 kgf.m, 134 lbt.ft)Replace.'--7.l'tq

IAppy a small amount of engine oilto the seating surface.

lcont'd)

SNAP RING

KNUCKLE

18-11

Page 570 of 1139

Front Suspension

Knuckle/Hub/Wheel Bearing Replacement {cont'dl

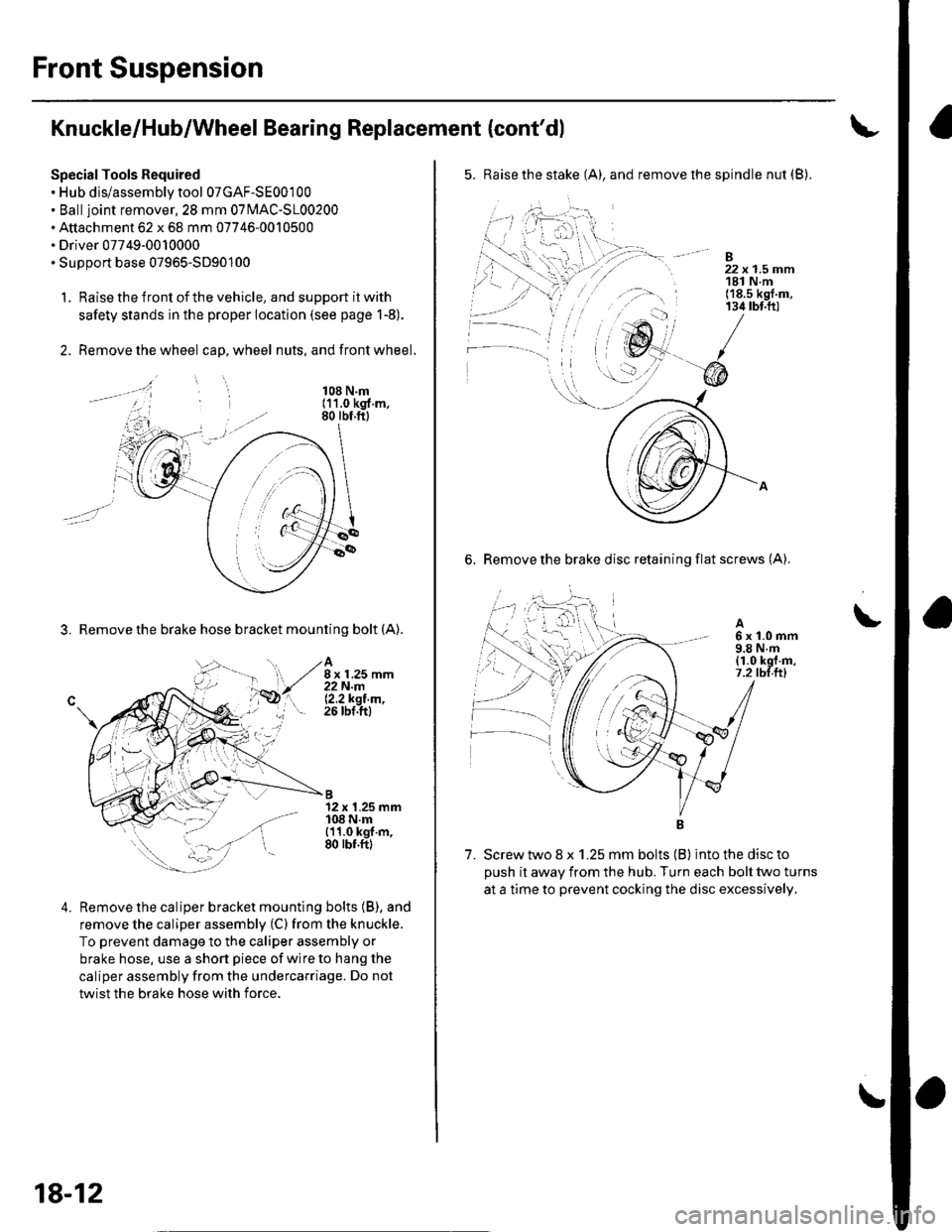

Special Tools Required. Hub dis/assembly tool 07GAF-SE00100. Balljoint remover,2S mm 0TlvlAC-S100200. Attachment 62 x 68 mm 07746-0010500. Driver 07749-0010000. SuDDort base 07965-5D90'100

1. Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

2. Remove the wheel cap, wheel nuts, and front wheel.

3. Remove the brake hose bracket mounting bolt (A).

108 N.m(11.0 kgf m,80 rbf.ftl

A8 x 1.25 mm22N.m12.2ksl.m,26 tbf.ftl

B12 x 1.25 mm108 N.m{11.0 kgf.m,80 rbf.ftl

4.Remove the caliper bracket mounting bolts (B), and

remove the caliper assembly (C) from the knuckle.

To prevent damage to the caliper assembly or

brake hose, use a short piece of wire to hang the

caliper assembly from the undercarriage. Do not

twist the brake hose with force.

18-12

5. Raise the stake (A), and remove the spindle nut (B).

-B

' 22x1.5mm, 181 N.m('18.s kgf.m,134 tbt.ft)

6. Remove the brake disc retaining flat screws (A).

A6x1.0mm9.8 N.m{1.0 kgt.m,7.2 tbl.ttl

7. Screw two 8 x 1.25 mm bolts (B) into the disc to

oush it awav from the hub. Turn each bolt two turns

at a time to prevent cocking the disc excessively,

\

\

Page 572 of 1139

Front Suspension

Knuckle/Hub/Wheel Bearing Replacement (cont'd)

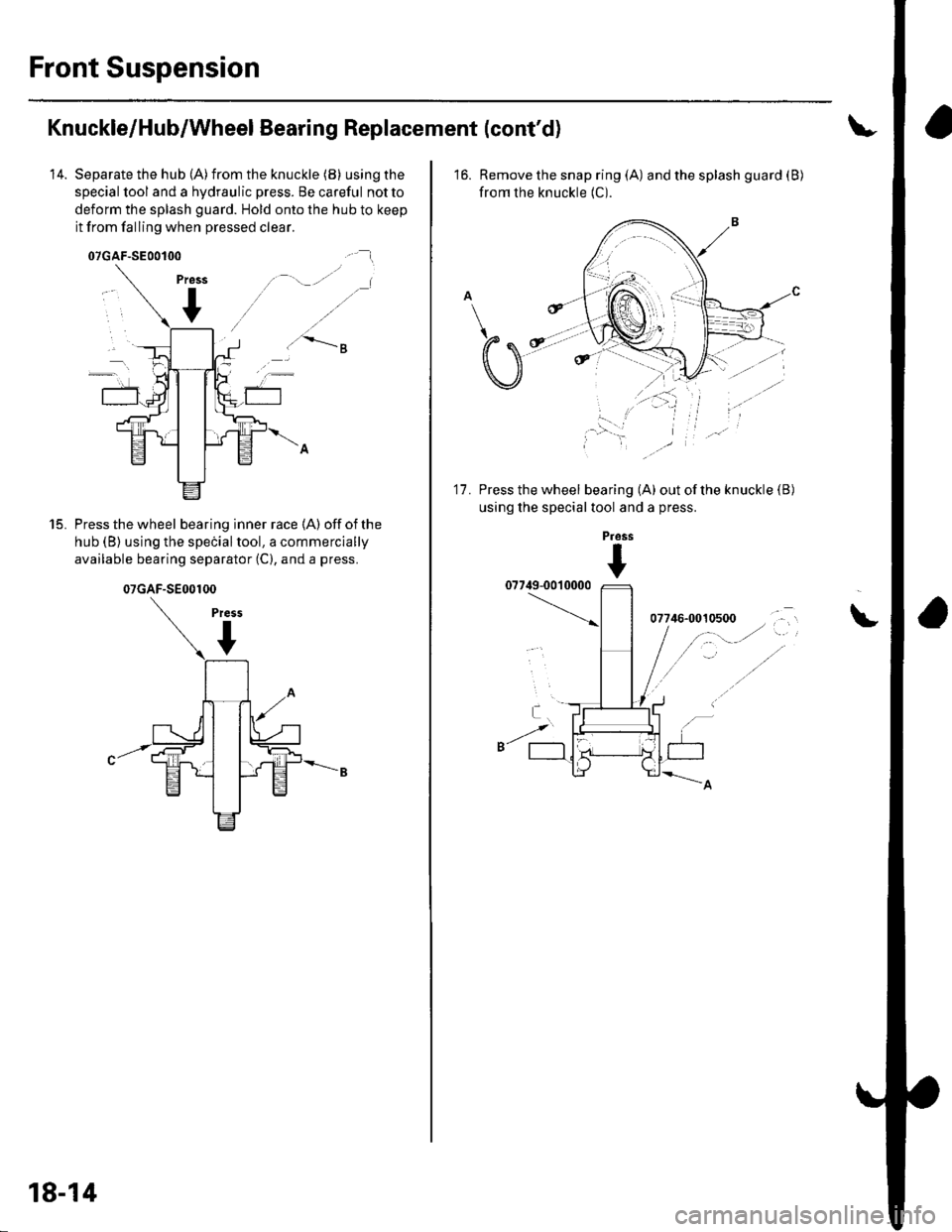

14. Separate the hub (A)from the knuckle (B) using the

special tool and a hydraulic press. Be careful notto

deform the splash guard. Hold onto the hub to keep

it from falling when pressed clear.

./ .-''- .|

a'\s

Press the wheel bearing inner race (A) off of the

hub (B) using the speiialtool, a commercially

available bearing separator (C), and a press.

15.

07GAF-SE00100

Press

07GAF-SE00100

18-14

16. Remove the snap ring (A) and the splash guard (B)

from the knuckle (C).

Press the wheel bearing (A) out of the knuckle (B

using the special tool and a press.

11.

Pross

+

\

Page 573 of 1139

18.

19.

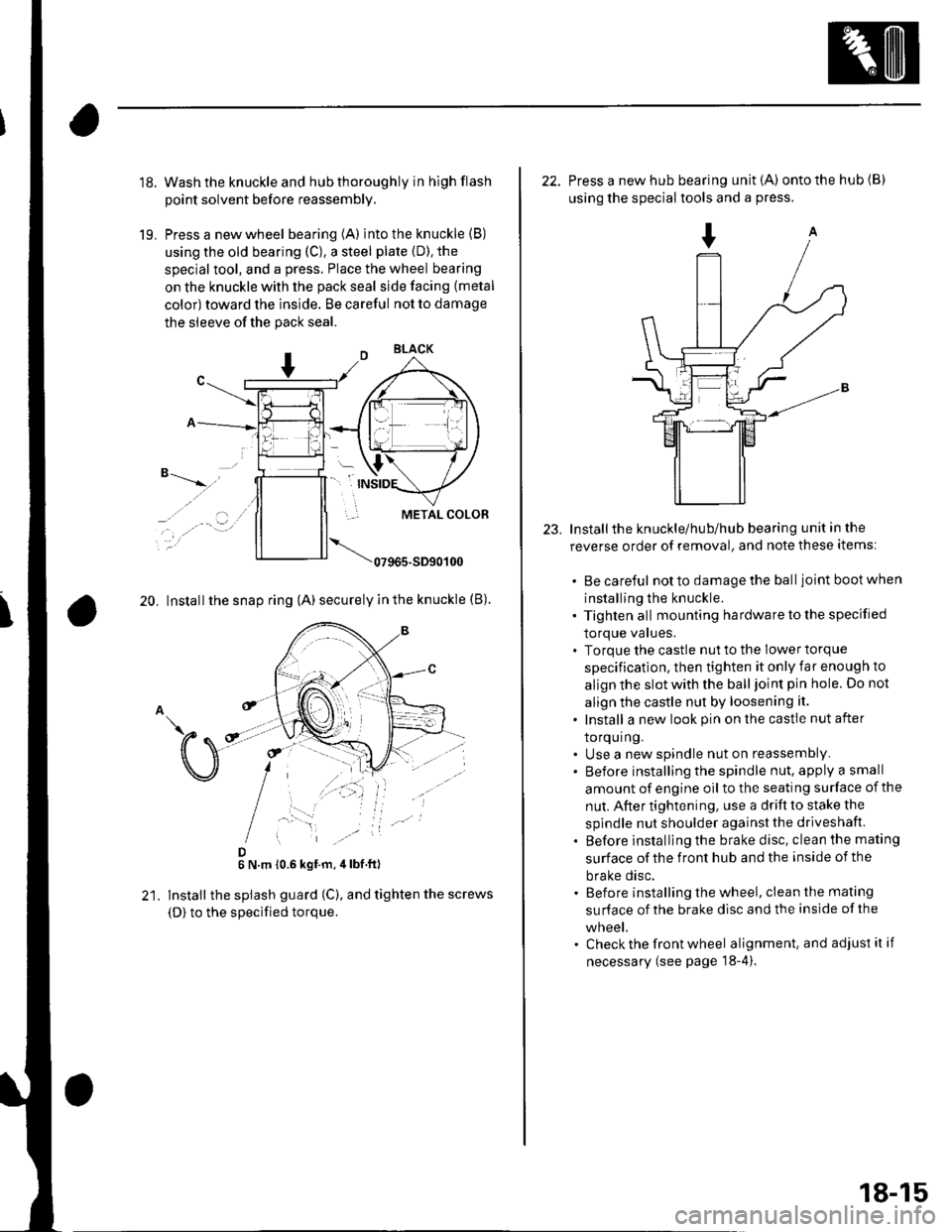

Wash the knuckle and hub thoroughly in hlgh flash

point solvent before reassembly.

Press a new wheel bearing (A) into the knuckle (B)

using the old bearing (C), a steel plate {D). the

special tool, and a press. Place the wheel bearing

on the knuckle with the pack seal side facing (metal

color) toward the inside. Be careful not to damage

the sleeve of the pack seal.

"-t-_"*,,''

_, .' . . a-�.) ../

..-.

20. Install the snap ring (A) securely in the knuckle (B).

D6 N.m 10.6 kgf.m,4lbf ft)

lnstall the splash guard (C), and tighten the screws

(D) to the specified torque.

23.

22. Press a new hub bearing unit {A) ontothehub(B)

using the special tools and a press.

Installthe knuckle/hub/hub bearing unit in the

reverse order of removal, and note these items:

. Be careful notto damagethe balljoint bootwhen

installing the knuckle.. Tighten all mounting hardware to the specified

lOrque values.. Torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the ball joint pin hole. Do not

align the castle nut by loosening it.

. Install a new look pin on the castle nut after

torquing.. Use a new spindle nut on reassembly.. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface of the

nut. After tightening, use a drift to stake the

spindle nut shoulder against the driveshaft.

. Before installlng the brake disc, clean the mating

surface of the front hub and the inside of the

brake disc.. Before installing the wheel, clean the mating

su rface of the brake disc and the inside of the

wneet.. Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

18-15

Page 574 of 1139

Front Suspension

Ball Joint Boot Replacement

Special Tools Required

Front hub dis/assembly tool 07965-5450500

1. Remove the boot.

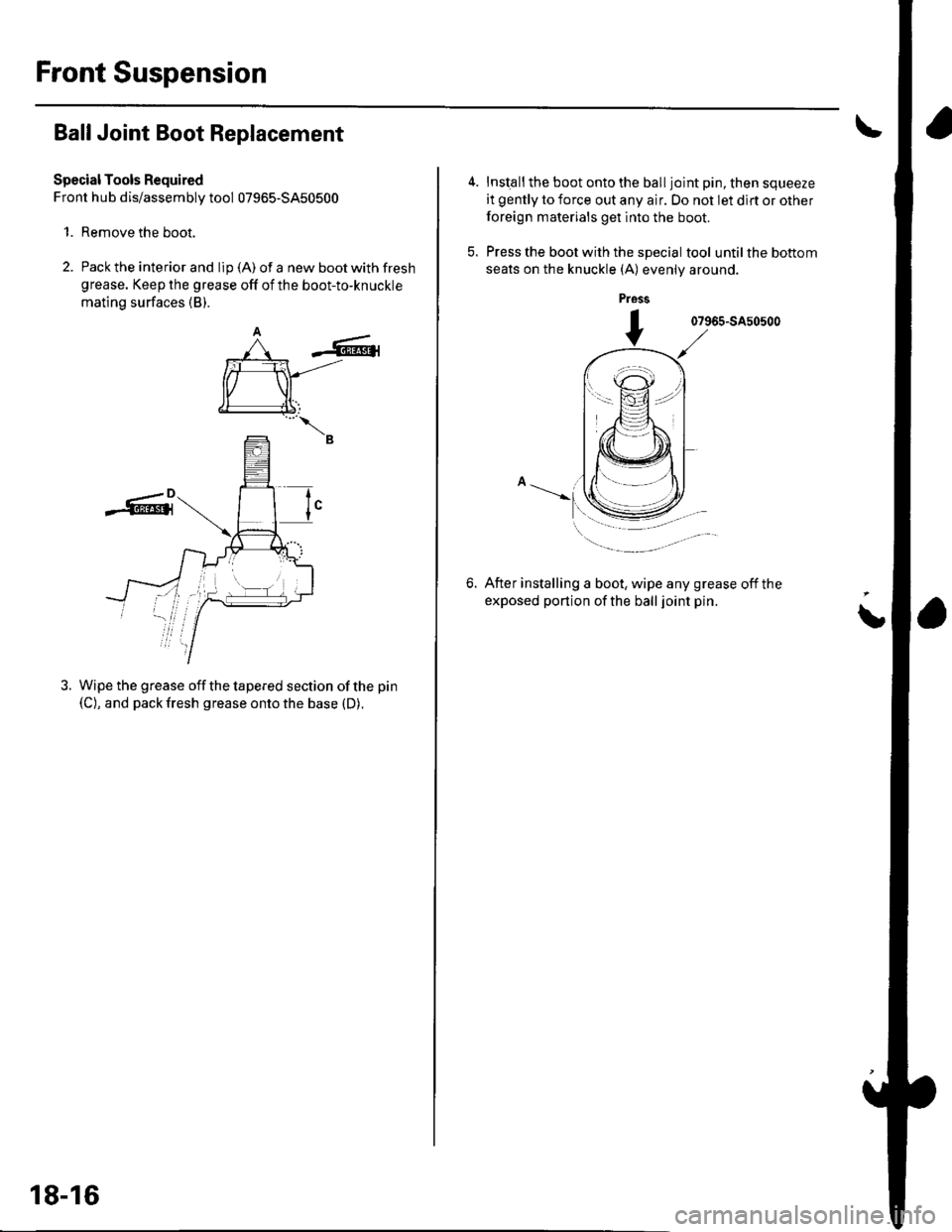

2. Pack the interior and lip (A) of a new boot with fresh

grease. Keep the grease off of the boot-to-knuckle

mating surfaces (B).

-6r

rffi

€l

--B

Wipe the grease off the tapered section of the pin

(C), and pack fresh grease onto the base (D).

tI

18-16

Inst€ll the boot onto the ball joint pin, then squeeze

it gently to force out any air. Do not let dlrt or other

foreign materials get into the boot.

Press the boot with the special tool until the bottom

seats on the knuckle (A) evenly around.

pross

07965-SA50500

6.After installing a boot, wipe any grease off the

exposed portion of the ball joint pin.

i

Page 575 of 1139

Stabilizer Bar Replacement

1.Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

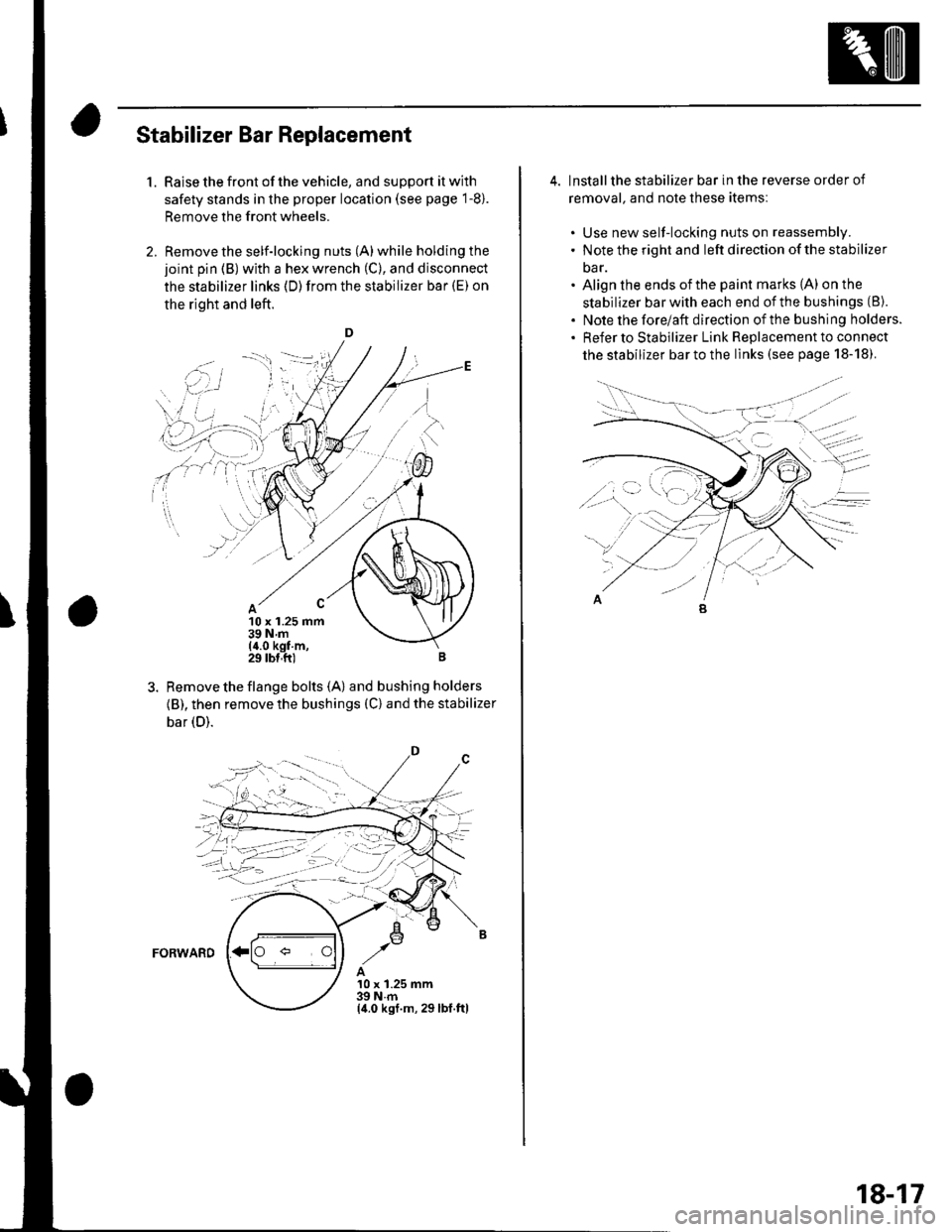

Remove the self-locking nuts (A) while holding the

joint pin (B) with a hex wrench (C), and disconnect

the stabilizer links (D)from the stabilizer bar (E) on

the right and left.

D

10 x 1.25 mm39Nm(4.0 kgf m,29 tbl,ft)

Remove the flange bolts {A) and bushing holders

{B), then remove the bushings (C) and the stabilizer

bar (D).

FORWARD

A10 x 1.25 mm39Nm(4.0 ksf.m, 29lbl.ftl

,.'i i

''i]

. i.',.:-l I

\' ,r' ,' i :..r'j-- r-'1 _: i'

i-ii::;i

;4-llt,-'j--;

4. lnstallthe stabilizer bar in the reverse order of

removal. and note these itemsl

. Use new self-locking nuts on reassembly.. Note the right and left direction of the stabilizer

oar.. Align the ends ofthe paint marks (A) on the

stabilizer bar with each end of the bushings (8).

. Note the forelaft direction ofthe bushing holders.. Refer to stabilizer Link Replacement to connect

the stabilizer bar to the links (see page 18-18).

18-17