HONDA CIVIC 2003 7.G Workshop Manual

Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 611 of 1139

Conventional Brake Components

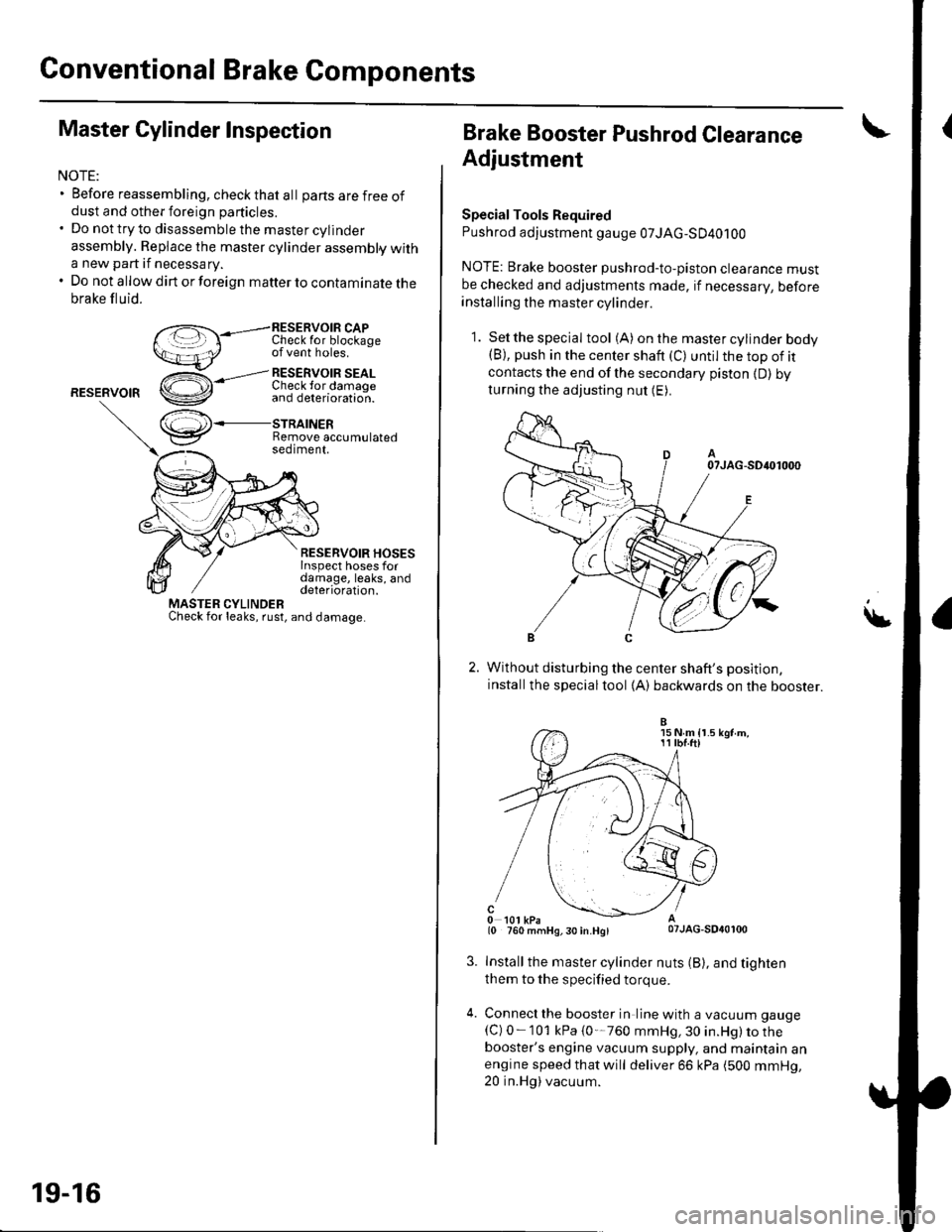

Master Cylinder Inspection

NOTE:. Before reassembling, check that al I parts are f ree ofdust and other foreign particles.. Do nottryto disassemblethe mastercylinder

assembly. Replace the master cylinder assembly witha new part if necessary.. Do not allow dirt or foreign matter to contaminate thebrake fluid.

RESERVOIB CAPI unecK Ior otocKageof vent holes.

RESERVOIR

,--l RESERvOIR SEALCheck lor damaoe

RESERVOIR HOSESInspect hoses fordamage, leaks, anddeterioration.

r',,.J\+

v

MASTER CYLINDERCheck for leaks, rust, and damage

and deterioration.

STRAINERRemove accumulatedseotment.

19-16

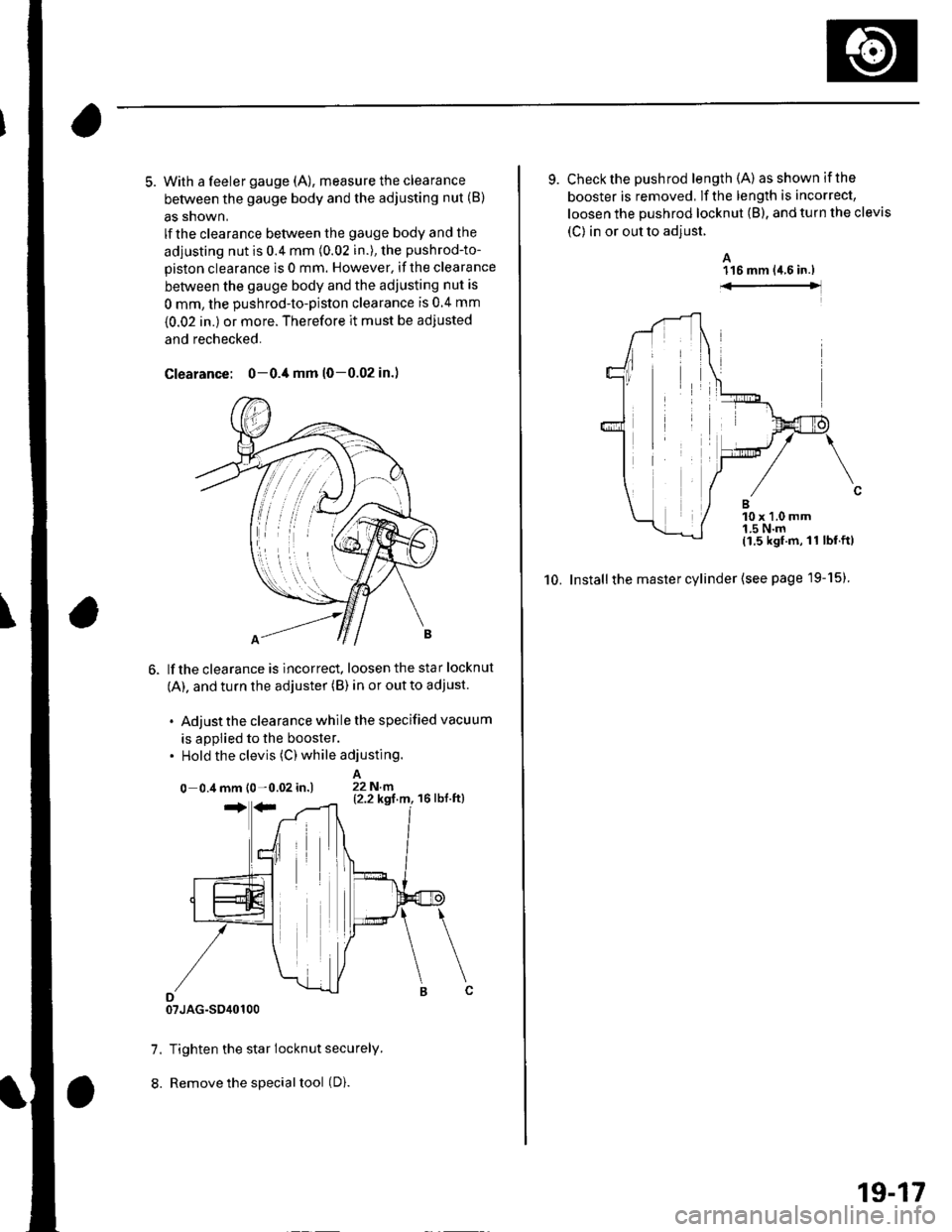

Brake Booster Pushrod Clearance

Adjustment

SpecialTools Required

Pushrod adjustment gauge 07JAG-SD40100

NOTE: Brake booster pushrod-to-piston clearance mustbe checked and adjustments made, if necessarV, beforeinstalling the master cylinder.

1. Setthespecial tool (A) onthe mastercylinder bodv(B), push in the center shaft (C) until the top of itcontacts the end of the secondary piston {D) byturning the adjusting nut (E).

Without disturbing the center shaft's position,

installthe specialtool (A) backwards on the booster.

Install the master cylinder nuts (B), and tighten

them to the specified torque.

Connecl the booster in line with a vacuum gauge

{C) 0-101 kPa {0'-760 mmHg, 30 in.Hg) to thebooster's engine vacuum supply, and maintain anengine speed that will deliver 66 kPa (500 mmHg,20 in.Hg) vacuum.

15 N m {r.511 tbf.ftl

Page 612 of 1139

5. With a feeler gauge (A), measure the clearance

between the gauge body and the adjusting nut (B)

as snown,

lf the clearance between the gauge body and the

adjusting nut is 0.4 mm (0.02 in.), the pushrod-to-

piston clearance is 0 mm. However. if the clearance

between the gauge body and the adjusting nut is

0 mm, the pushrod-to-piston clearance is 0 4 mm

{0.02 in.) or more. Therefore it must be adjusted

and rechecked.

Clearance: 0-0./t mm (0-0.02 in.)

lf the clearance is incorrect, loosen the star locknut

(A). and turn the adjuster (B) in or out to adjust.

. Adjust the clearance while the specified vacuum

is appiied to the booster.. Hold the clevis (C) while adjusting.

A0 0.4 mm l0 -0.02 in.) 22N.n

07JAG-SO40100

7. Tighten the star locknut securely.

8. Remove the special tool (D).

9. Check the pushrod length (A) asshownifthe

booster is removed, lf the length is incorrect,

loosen the pushrod locknut (B), and turn the clevis

(C) in or out to adjust.

A116 mm {4.6 in.)

10. Installthe master cylinder (see page l9-15)

10 x 1.0 mm1.5 N'm11.5 kgf.m,11 lbf.ftl

19-17

Page 613 of 1139

Gonventional Brake Components

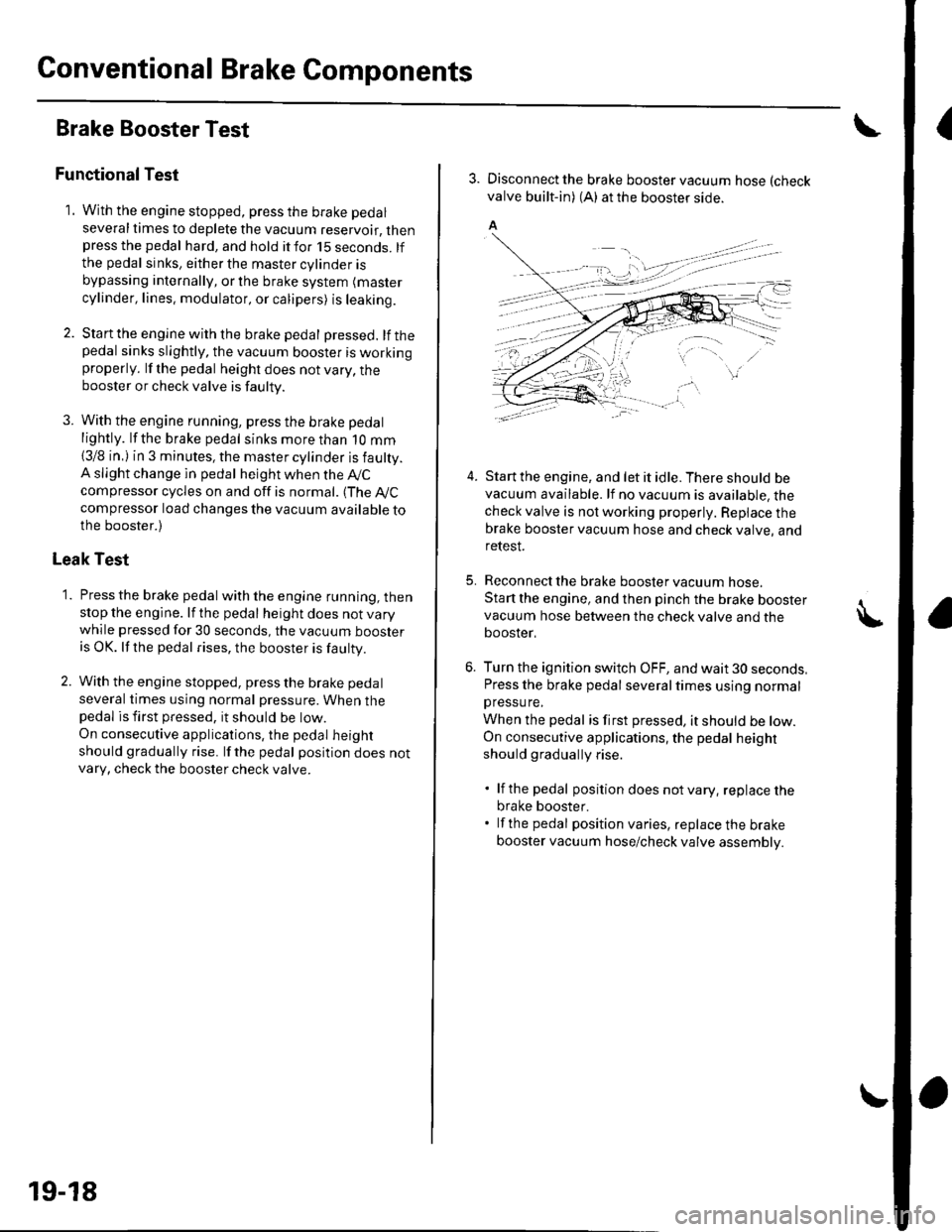

IBrake Booster Test

Functional Test

1. With the engine stopped, press the brake pedal

several times to deplete the vacuum reservoir, thenpress the pedal hard, and hold itfor 15 seconds. lfthe pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines. modulator, or calipers) is leaking.

2. Start the engine with the brake pedal pressed. lf thepedal sinks slightly, the vacuum booster is workingproperly. lf the pedal height does not vary, thebooster or check valve is faulty.

3. With the engine running, press the brake pedal

lightly. lfthe brake pedal sinks more than 1O mm

{3/8 in, ) in 3 minutes, the master cylinder is faulty.A slight change in pedal height when the Ay'C

compressor cycles on and off is normal. (The A,/C

compressor load changes the vacuum available tothe booster.)

Leak Test

1. Press the brake pedal with the engine running, thenstop the engine. lf the pedal height does not vary

while pressed for 30 seconds, the vacuum boosteris OK. lf the pedal rises, the booster is faulty.

2. With the engine stopped, press the brake pedal

several times using normal pressure. When thepedal is first pressed, it should oe row.

On consecutive applications, the pedal height

should gradually rise. lfthe pedal position does notvarv, check the booster check valve.

19-18

3. Disconnect the brake booster vacuum hose (check

valve built-in) (A) at the booster side.

5.

4.Start the engine, and let it idle. There should bevacuum available. lf no vacuum is available, thecheck valve is not working properly. Repiace thebrake booster vacuum hose and check valve, andrelesI.

Reconnect the brake booster vacuum nose.

Start the engine, and then pinch the brake boostervacuum hose between the check valve and thebooster,

Turn the ignition switch OFF, and wait 30 seconds,Press the brake pedal several times using normalpressu re,

When the pedal is first pressed, it should be low.On consecutive applications, the pedal height

should gradually rise.

. lf the pedal position does notvary, replacethe

brake booster.. lf the pedal position varies, replace the brake

booster vacuum hose/check valve assembly.

Page 614 of 1139

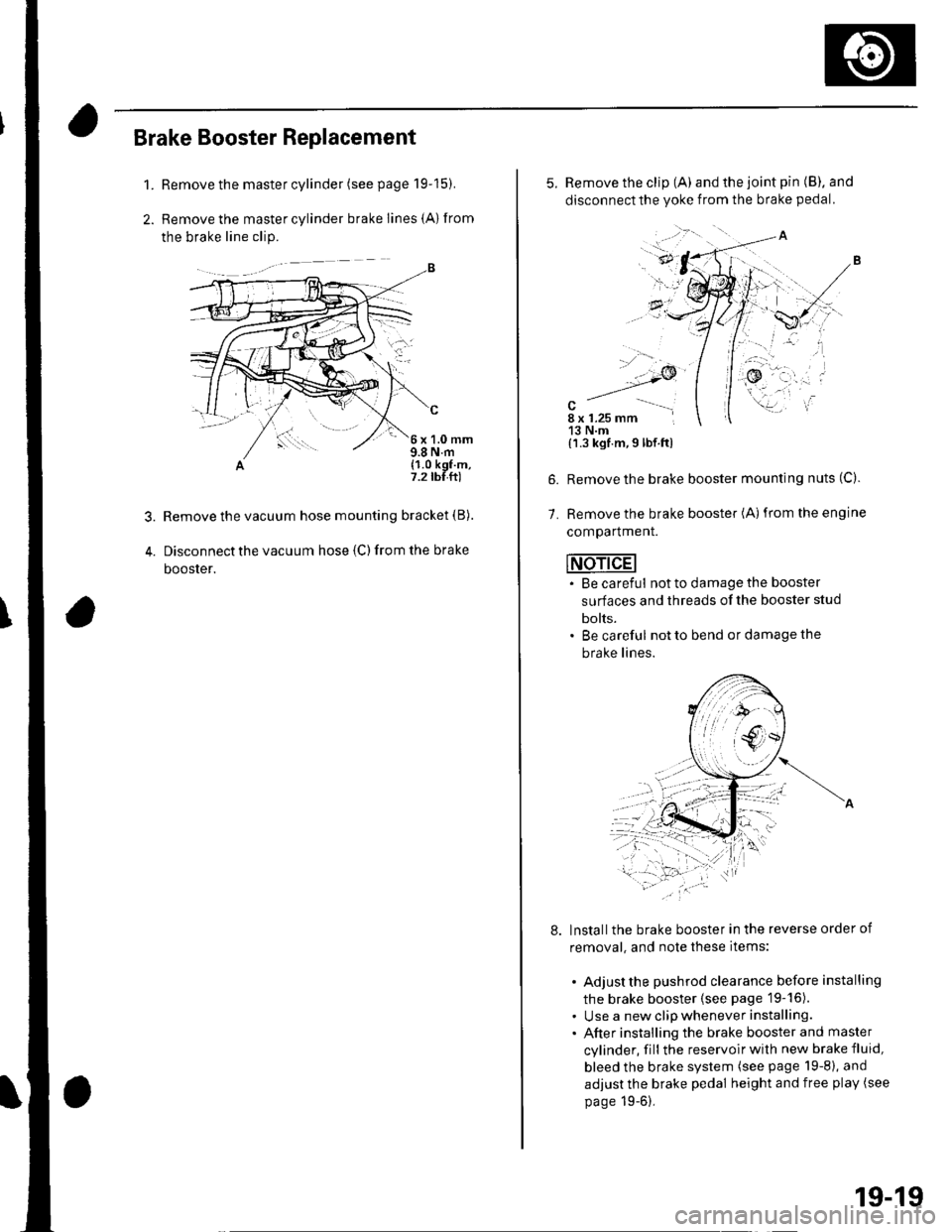

Brake Booster Replacement

1.Remove the master cylinder (see page 19-15).

Remove the master cylinder brake lines {A) from

the brake line clip.

c

6x1.0mm9.8 N.m(1.0 kgf.m,7.2 tbf.ft)

Remove the vacuum hose mounting bracket (B).

Disconnect the vacuum hose {C) from the brake

booster.

'-/

.,.,....

alu

i '..

5. Remove the clip (A) and the joint pin (B). and

disconnectthe yoke from the brake pedal.

7.

{'l.3 kgf.m,9 lbf.ftl

Remove the brake booster mounting nuts (C).

Remove the brake booster (A)from the engine

comparlmenr.

INdAdEI. Be careful not to damage the booster

surfaces and threads of the booster stud

bolts.. Be careful not to bend or damage the

brake lines.

lnstallthe brake booster in the reverse order of

removal, and note these items:

. Adjust the pushrod clearance before installing

the brake booster (see page 19-16).. Use a new clip whenever installing.. After installing the brake booster and master

cylinder, fill the reservoir with new brake fluid,

bleed the brake system (see page 19-8), and

adjust the brake pedal height and free play (see

page 19-6),

19-19

Page 615 of 1139

Conventional Brake Components

Rear Brake Pads Inspection and Replacement

Frequent inhalation of brake pad dust, regardless ofmaterial composition, could be hazardous to your

hea hh.. Avoid breathing dust particles.. Never use an air hose or brush to clean brake

assemblies, Use an OSHA-approved vacuum

cleaner.

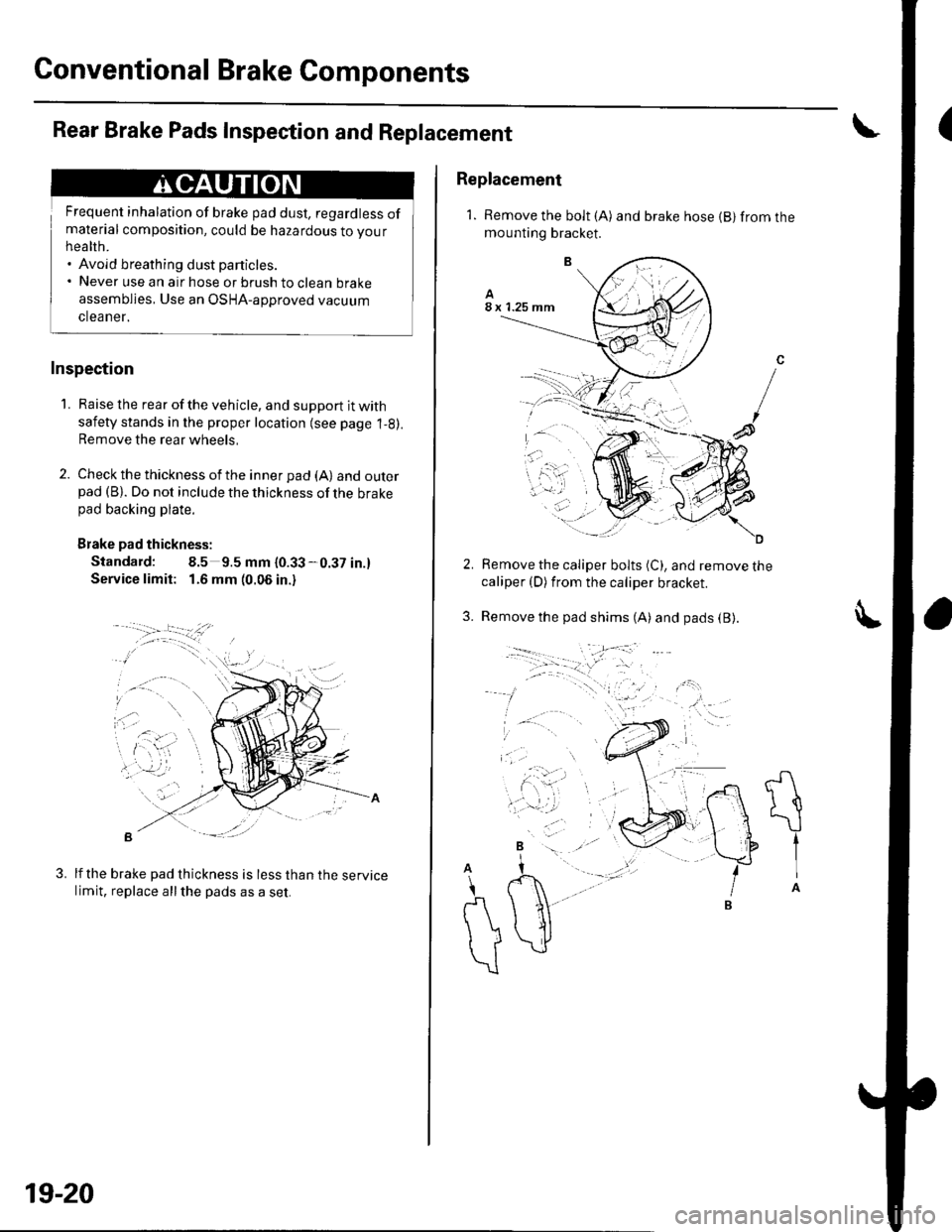

Inspection

'1. Raise the rear of the vehicle, and support jt with

safety stands in the proper location (see page 1-8).Remove the rear wheels,

2. Check the thickness of the inner pad (A) andouterpad (B). Do not include the thickness of the brakepad backing plate.

Brake pad thickness:

Standard: 8.5 9.5 mm {0.33-0.37 in.}

Service limit: 1.6 mm (0.06 in.)

B -::--

lf the brake pad thickness is less than the servicelimit, replace allthe pads as a set.

3.

19-20

Replacement

1. Remove the bolt (A) and brake hose {B} from themounting bracket.

Remove the caliper bolts (C), and remove thecaliper (D) from the caliper bracket.

Remove the pad shims (A) and pads (B).3.

A

t{

\

tIA

A

\

r\

))

\

Page 616 of 1139

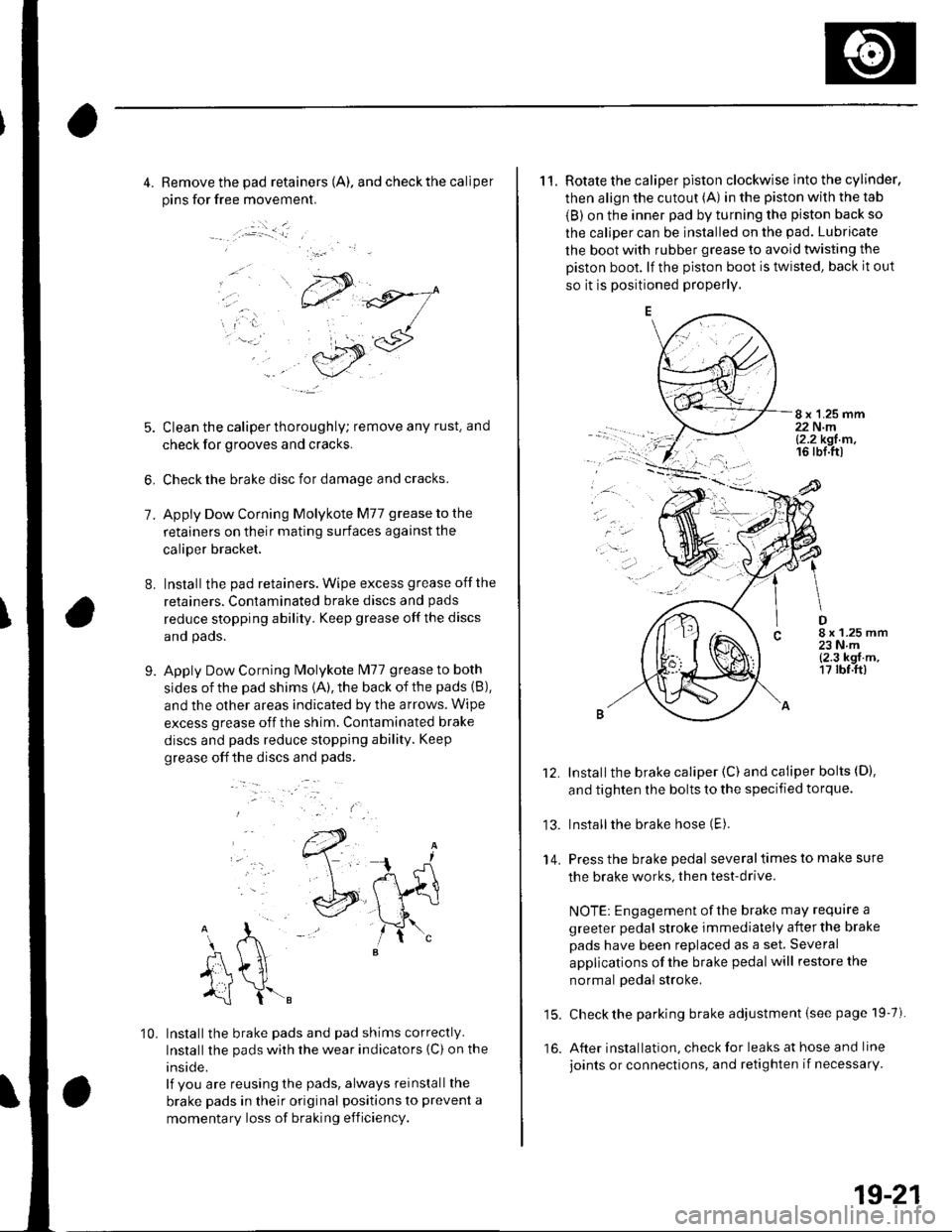

4. Remove the pad retainers (A). and check the caliper

pins for free movement.

:.i _ _l

7.

8.

5. Clean the caliper thoroughly; remove any rust. and

check for grooves and cracks.

6, Check the brake disc for damage and cracks.

Apply Dow Corning Molykote M77 grease to the

retainers on their mating surfaces against the

caliper bracket,

Installthe pad retainers. Wipe excess grease offthe

retainers. Contaminated brake discs and pads

reduce stopping ability. Keep grease off the discs

and pads.

Apply Dow Corning Molykote lvl77 grease to both

sides of the pad shims {A), the back of the pads (B),

and the other areas indicated by the arrows. Wipe

excess grease off the shim. Contaminated brake

discs and pads reduce stopping ability. Keep

grease off the discs and pads.

9.

..-.

10. Installthe brake pads and pad shims correctly.

Installthe pads wirh the wear indicators {C) on the

inside.

lf you are reusing the pads, always reinstall the

brake pads in their original positions to prevent a

momentary loss of braking efficiency.

11. Rotate the caliper piston clockwise into the cylinder,

then align the cutout (A) in the piston with the tab

{B) on the inner pad by turning the piston back so

the caliper can be installed on the pad. Lubricate

the boot with rubber grease to avoid twisting the

Diston boot. lf the piston boot is twisted, back it out

so it is positioned properly.

8 x 1.25 mm22 N.ml2.2 kgt m,16 rbl.ttl

.ar

D8 x 1.25 mm23Nm{2.3 kgf.m,17 rbf.ft)

13.

14.

Installthe brake caliper (C) and caliper bolts (D).

and tighten the bolts to the specified torque.

Installthe brake hose (E).

Press the brake pedal several times to make sure

the brake works, then test-drive.

NOTE: Engagement of the brake may require a

greeter pedal stroke immediately after the brake

pads have been replaced as a set. Several

applications of the brake pedal will restore the

normal pedal stroke,

15. Check the parking brake adjustment {see page 19-7).

16. After installation, check for leaks at hose and line

joints or connections, and retighten if necessarY.

19-21

Page 617 of 1139

Conventional Brake Components

Rear Brake Disc Inspection

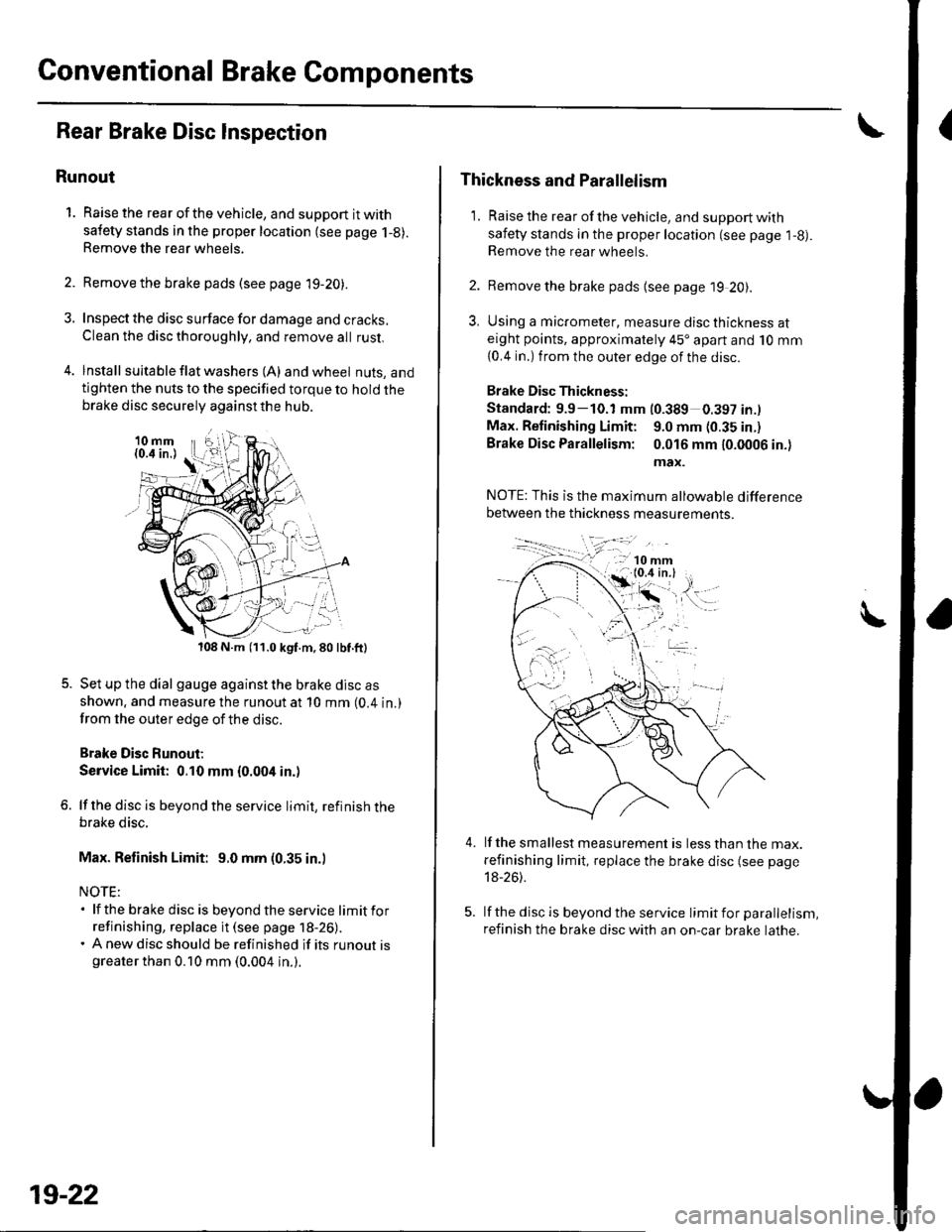

Runout

1. Raise the rear of the vehicle, and support it with

safety stands in the proper location (see page 1-8).Remove the rear wheels,

2. Remove the brake pads (see page 19-20).

3. Inspect the disc surface for damage and cracks.

Clean the disc thoroughly, and remove all rust,

4. lnstall suita ble f lat washers (A) and wheel nuts, andtighten the nuts to the specified torque to hold thebrake disc securely against the hub.

108 N.m (11.0 kgf.m,80lbf.ft)

Set up the dial gauge against the brake disc as

shown. and measure the runout at 10 mm (0.4 in.)

from the outer edge of the disc.

Brake Disc Runout;

Service Limit: 0.10 mm {0.004 in.)

lf the disc is beyond the service limit, refinish thebrake disc.

Max. Refinish Limit: 9.0 mm (0.35 in.)

NOTE:. lf the brake disc is beyondtheservice limitfor

refinishing, replace it (see page 18-26).. A new disc should be refinished if its runout isgreater than 0.10 mm (0.004 in.).

19-22

Thickness and Parallelism

1. Raise the rear of the vehicle, and support with

safety stands in the proper location (see page l-g).Remove the rear wheels.

2. Remove the brake pads {see page 19 20).

3, Using a micrometer, measure disc thickness ateight points, approximately 45'apart and 10 mm

{0.4 in.) from the outer edge of the disc.

Brake Disc Thickness:

Standard: 9.9-10.1 mm (0.389 0.397 in.l

Max. Retinishing Limit: 9.0 mm (0.35 in.)

Brake Disc Parallelism: 0.016 mm 10.0006 in.)

max.

4.lf the smallest measurement is less than the max.

refinishing limit, replace the brake disc (see page

18-26).

lf the disc is beyond the service limit for parallelism,

refinish the brake disc with an on-car brake lathe.

Page 618 of 1139

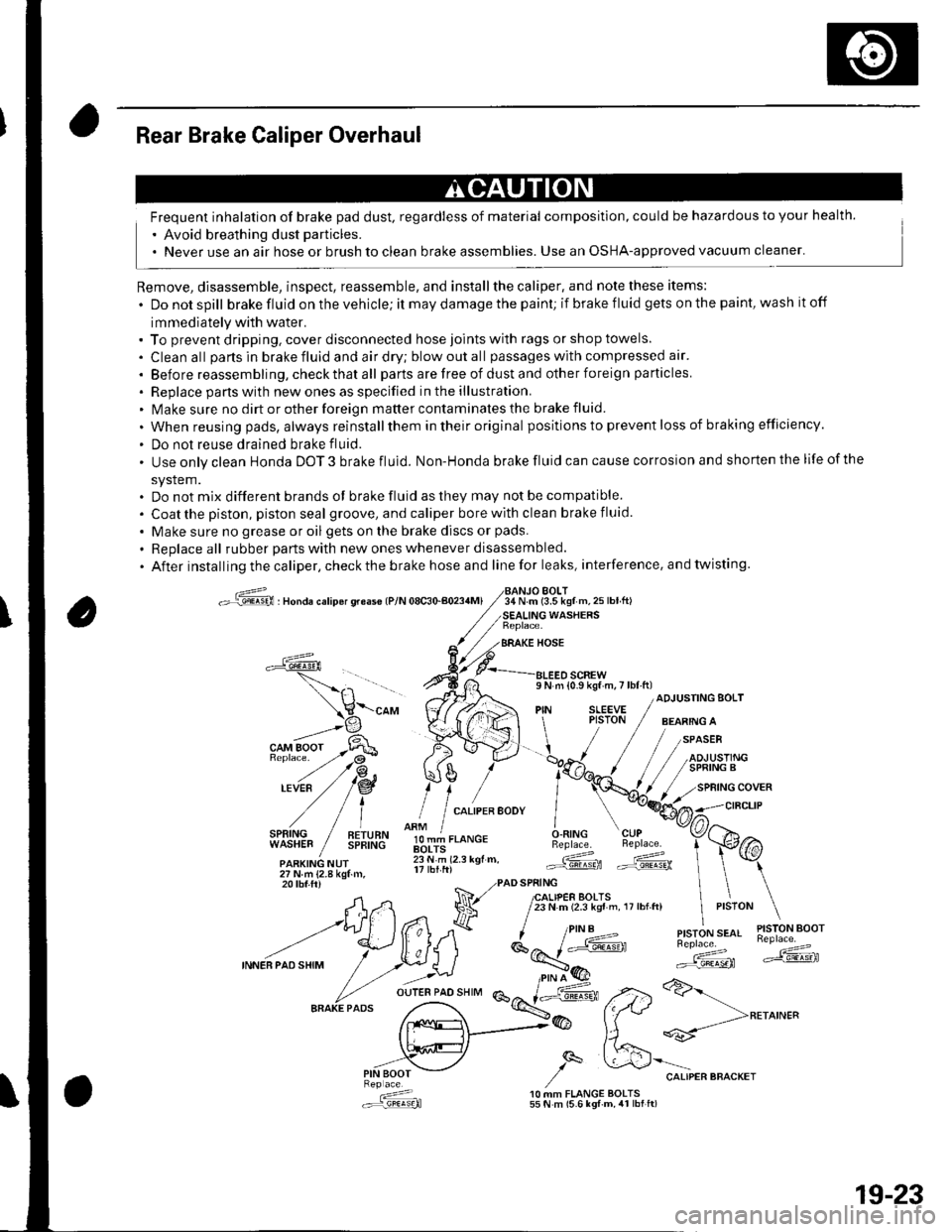

Rear Brake Caliper Overhaul

Frequent inhalation of brake pad dust, regardless of material composition, could be hazardous to your health.

' Avoid breathing dust particles.

. Never use an air hose or brush to clean brake assemblies. Use an OSHA-approved vacuum cleaner'

Remove, disassemble, inspect, reassemble, and installthe caliper, and note these items:

. Donotspill brake fluid on the vehicle; it may damage the paint; if brake f luid gets on the paint, wash it off

immediately with water.. To prevent dripping. cover disconnected hose joints with rags or shop towels.

. Cleanall partsinbrakefluidandairdry;blowoutall passageswith compressed air'

. Before reassembling, check that all parts are free of dust and other foreign particles

. Replace pans with new ones as specified in the illustration.. Make sure no dirt or other foreign matter contaminates the brake fluid.

. When reusing pads, always reinstallthem in their original positions to prevent loss of b ra king efficie ncy.

. Do not reuse drained brake fluid.

. Use only clean Honda DOT 3 brake fluid. Non-Honda brake fluid can cause corrosion and shorten the life of the

system.. Do not mix different brands ot brake fluid as they may not be compatible.

. Coatthe piston, piston seal groove, and caliper bore with clean brake fluid.

. Make sure no grease or oil gets on the brake discs or pads.

. Replaceall rubber parts with new ones whenever disassembled.

. After installing the caliper, check the brake hose and line for leaks, interference. and twisting.

oG , nonau."rip6r qreas€ lP/N 08c30-aoa4Ml34 N.m (3.5 kgf m,25lbtft)BOLT

WASHERS

BRAKE HOSE

a

l,i,,'IltE" / !!;,ff

olT-J,.o"c.O.RING CUPBeplace. Beplace.

.ARKING NUr lii.'i rz.r rgr.. Gd ffi27Nm{2.8kgtm,

\-"o, V((rA ",1 ;[.,.JF /;;;;---

t H\a \l / t,i*t'*"

?,,.t/*"^.,,.:,"", /"V4#

ADJUSTING BOLT

,/

27Nm{2.8kgf.m,20 tbf.ftr PAD SPRING

A,n Na 7lfl,lif,loffi ',,0,n, ,,:,o" \

--t)(*ff l^7k ''"'t!1'ry#'

INNEBPA'SHIM

/ .r.:._U i*E'( ":;*" *dF ,.2>a>-

fr.x{_>@ fftt **-->**^'"

,,.-"iV ,/q &'"o.,"."""o"^.,

: 10 MM FLANGE BOLTS.:r=,9!q!q}l 55 N m (5.6 lgf-m, 4r lbt ft)

19-23

Page 619 of 1139

Conventional Brake Components

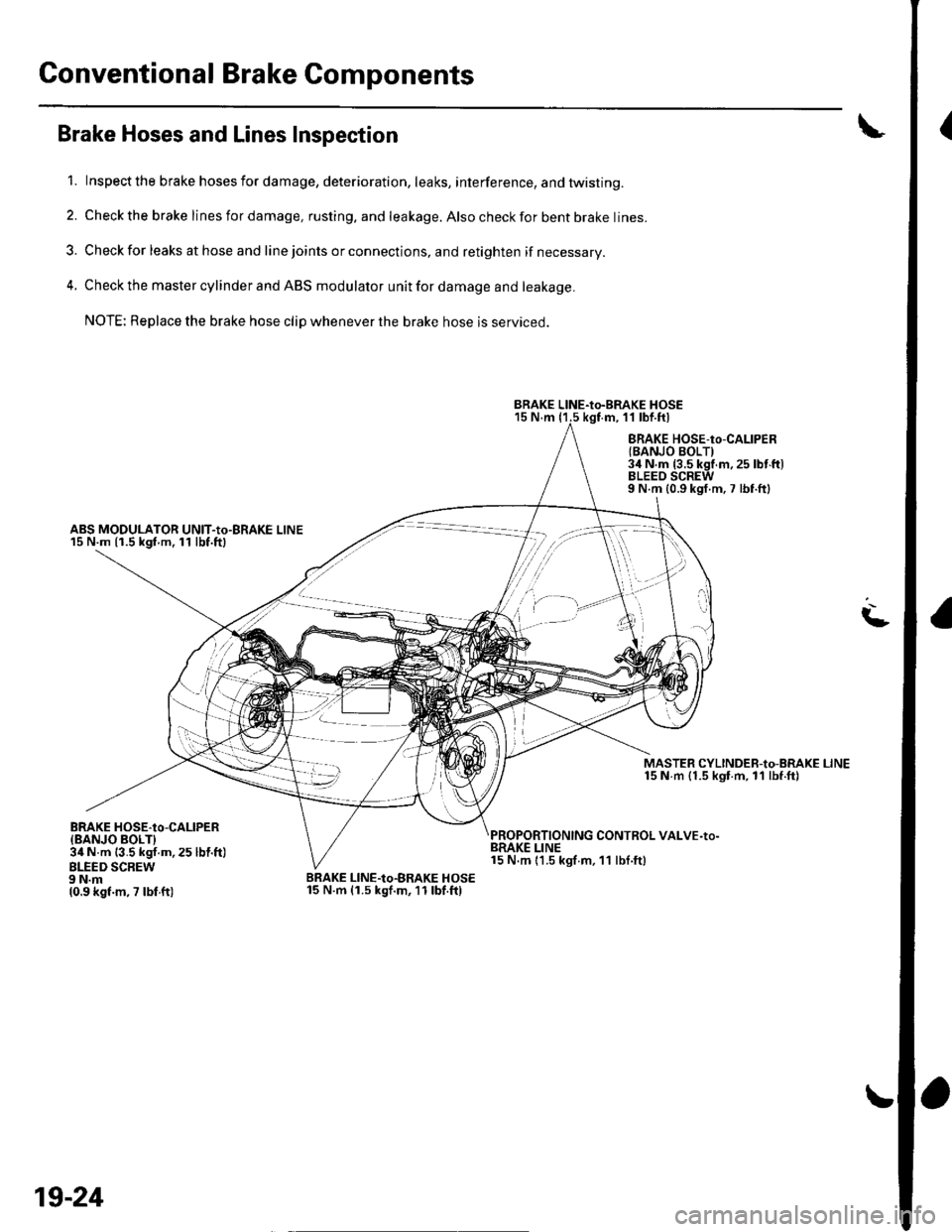

{Brake Hoses and Lines Inspection

1. Inspect the brake hosesfordamage, deterioration, leaks, interference, andtwisting.

2. Check the brake lines for damage, rusting. and leakage. Also check for bent brake lines.

3. Check for leaks at hose and line joints or connections, and retighten if necessary.

4. Check the master cylinder and ABS modulator unit for damage and leakage.

NOTE: Replace the brake hose clip whenever the brake hose is serviced.

15 N.m (1.5 kgf.m, 11 lbf.ftl

ABS MODULATOR UNIT-Io-BRAKE LINE15 N.m {1.5 kgf m.11 lbf.ftl

BRAKE HOSE-to-CALIPERlBANJO BOLTI3il N.m {3.5 kgf.m.25 lbt'ft)BLEEO SCREW9 N.m {0.9 kgf.m,7 lbf.ftl

MASTER CYLINDEB-to-BRAKE LINE15 N m {1.5 kgt.m, ll lbf.ft)

CONTROL VALVE-to-

L

BRAKE HOSE.tO-CALIPER{BANJO BOLTI34 N.m {3.5 kgf.m, 25 lbl.ft)BLEED SCBEW9 N.m10.9 kgf.m, 7 lbf ft)

BRAKE LINE15 N.m 11.5 kgf m, 11 lbf.ft)

BRAKE LINE-Io-BRAKE HOSE15 N.m (1.5 kgf.m,11lbf.ftl

BRAKE LINE-to-BRAKE HOSE

t''/,i'i'

,/ ,l

t t,.. -)

19-24

Page 620 of 1139

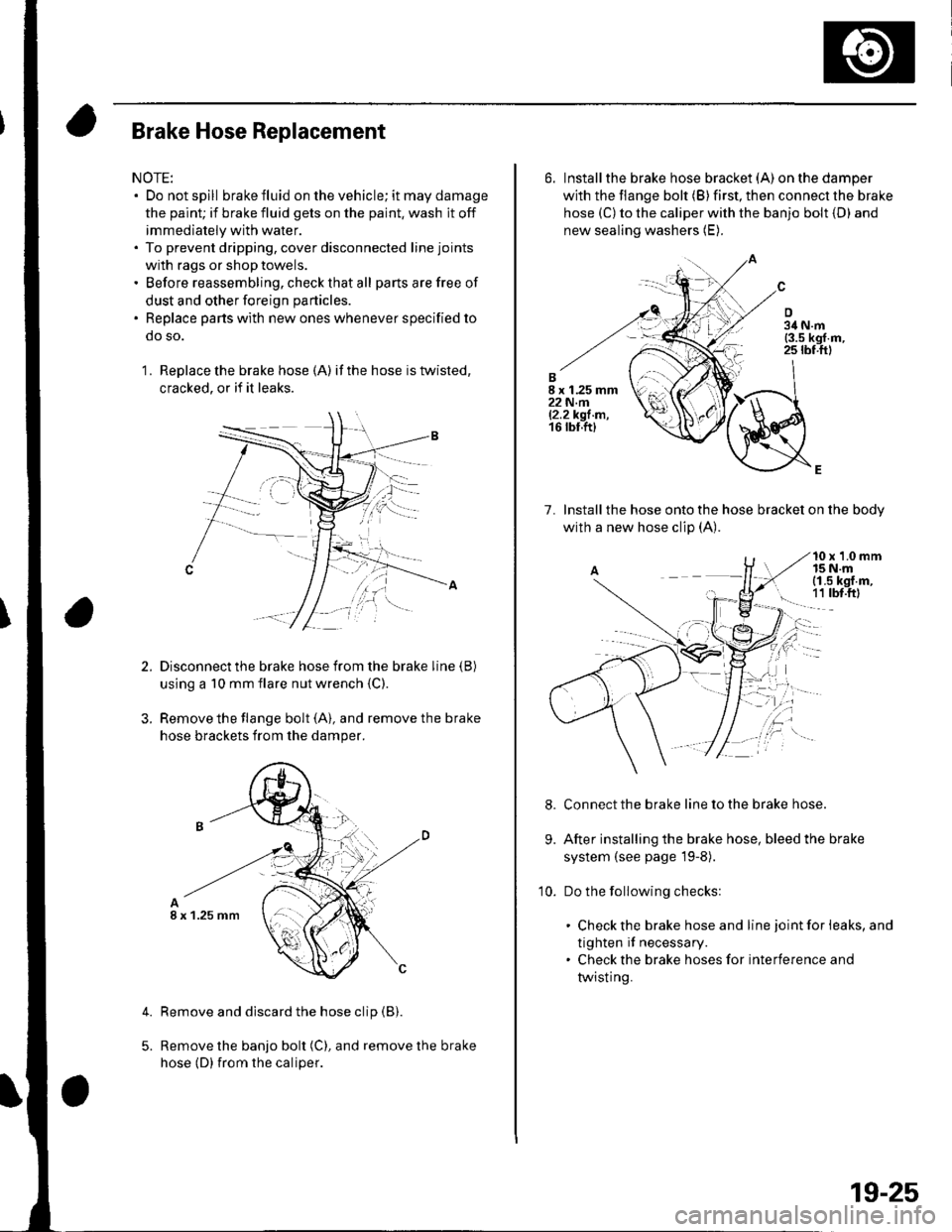

Brake Hose Replacement

NOTE:. Do not spill brake fluid on the vehicle; it may damage

the paint; if brake fluid gets on the paint, wash it off

immediately with water.. To prevent dripping, cover disconnected line joints

with rags or shop towels.. Before reassembling, check that all parts are free of

dust and other foreign particles.

. Replace parts with new ones whenever specified to

do so.

1 . Replace the brake hose (A) if the hose is twisted,

cracked, or if it leaks.

Disconnect the brake hose from the brake line (B)

using a 10 mm flare nut wrench {C)

Remove the flange bolt (A), and remove the brake

hose brackets from the damper.

Remove and discard the hose clip (B).

Remove the banjo bolt (C), and remove the brake

hose (D) {rom the caliper.

4.

I x 1.25 mm

6. Installthe brake hose bracket (A)on the damper

with the flange bolt (B) first, then connect the brake

hose (C) to the caliper with the banjo bolt {D) and

new sealing washers (E).

7. lnstallthe hose onto the hose bracket on the bodv

with a new hose clip (A).

10 x 1.0 mm15 N.mi (1.5 kgf.m,

! 1t tbt.ftl

Connect the brake line to the brake hose.

After installing the brake hose, bleed the brake

system (see page l9-8).

Do the following checks:

. Check the brake hose and line joint for leaks, and

tighten if necessary.. Check the brake hoses for interference and

twisting.

9.

10.

19-25