relay HONDA CIVIC 2003 7.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 801 of 1139

Heating and Air Conditioning

Radiator and Condenser Fans

Common

(cont'dl

Circuit Troubleshooting

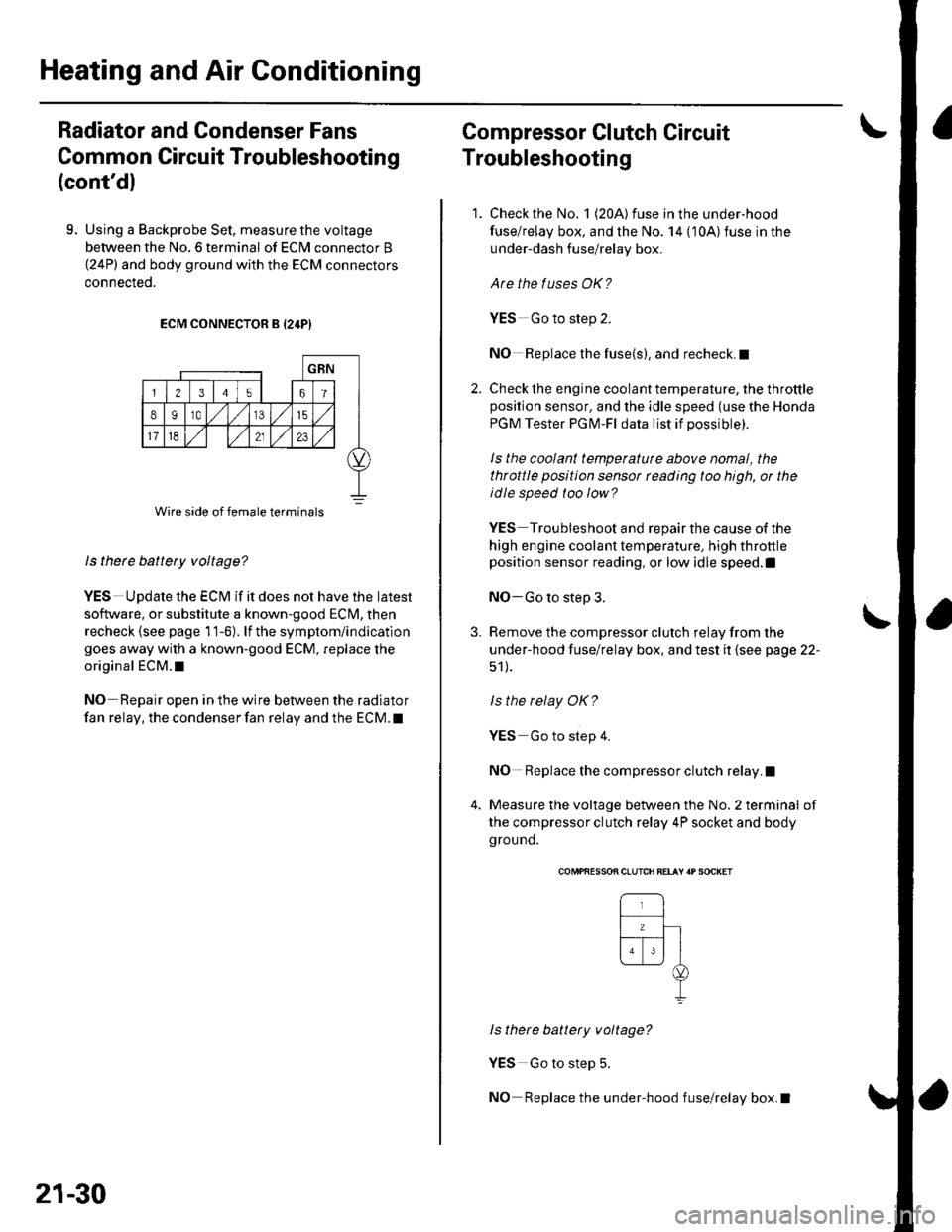

9. Using a Backprobe Set, measure the voltage

between the No. 6 terminal of ECN4 connector B

{24P) and body ground with the ECM connectors

connecteo.

ECM CONNECTOR B {24P}

ls there battery voltage?

YES UDdate the ECM if it does not have the latest

so{tware, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

NO Repair open in the wire between the radiator

fan relay, the condenser fan relay and the ECM. t

Wire side of female terminals

21-30

Compressor Clutch Circuit

Troubleshooting

1. Check the No. 1 (20A) fuse in the under-hood

fuse/relay box, and the No. 14 {10A)fuse in the

under-dash fuse/relay box.

Are the tuses OK?

YES Go to step 2.

NO Replace the fuse(s), and recheck.I

2. Check the engine coolant temperature, the throttleposition sensor, and the idle speed (use the Honda

PGM Tester PGM-Fl data list if possible).

ls the coolant temperaturc above nomal, the

throttle position sensor rcading too high, or the

idle speed too low?

YES Troubleshoot and repair the cause of the

high engine coolant temperature, high throttle

position sensor reading, or low idle speed.l

NO-Go to step 3.

3. Remove the compressor clutch relay from the

under-hood fuse/relay box, and test it (see page 22-

51 ).

ls the relay OK?

YES Go to step 4.

NO Replace the compressor clutch relay.I

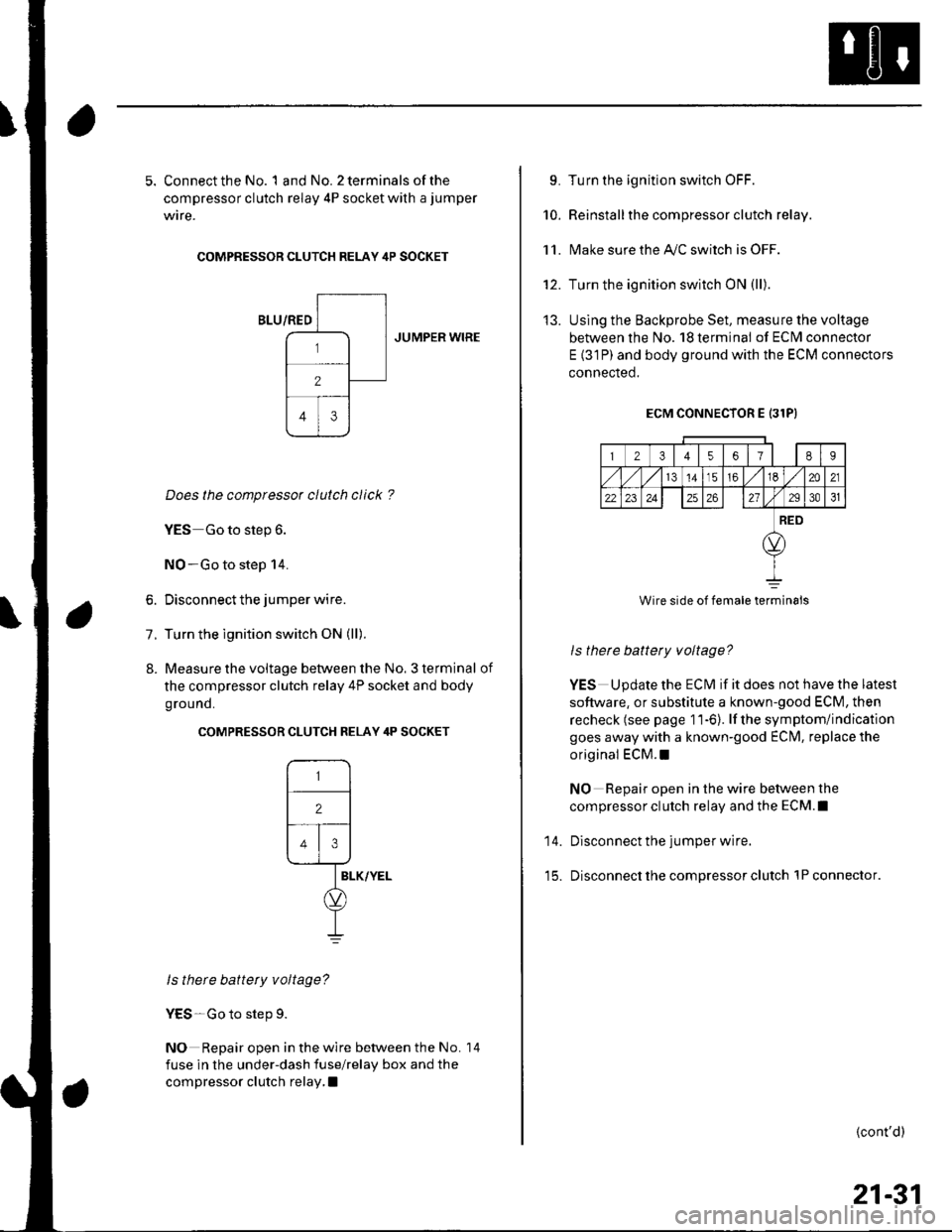

4. Measure the voltage between the No. 2 terminal of

the compressor clutch relay 4P socket and body

ground.

\

COMPfiESSON CLUTCH BELAY 'P SOCKET

ls there battery voltage?

YES Go to step 5.

NO Replace the under-hood fuse/relay box.I

Page 802 of 1139

5. Connect the No. 1 and No. 2 terminals of the

compressor clutch relay 4P socket with a jumper

wire.

COMPRESSOR CLUTCH RELAY 4P SOCKET

JUMPER WIRE

Does the compressor clutch click ?

YES Go to step 6.

NO-Go to step 14.

6. Disconnect the jumper wire.

7. Turn the ignition switch ON (ll).

8. Measure the voltage between the No. 3 terminal of

the compressor clutch relay 4P socket and body

ground.

COMPRESSOR CLUTCH RELAY 4P SOCKET

ls there battery voltage?

YES-Go to step 9.

NO Repair open in the wire between the No.

fuse in the under-dash fuse/relay box and the

compressor clutch relay, I

14

L Turn the ignition switch OFF.

10. Reinstallthe compressor clutch relay.

1 1. l\4ake sure the Ay'C switch is OFF.

12. Turn the ignition switch ON {ll).

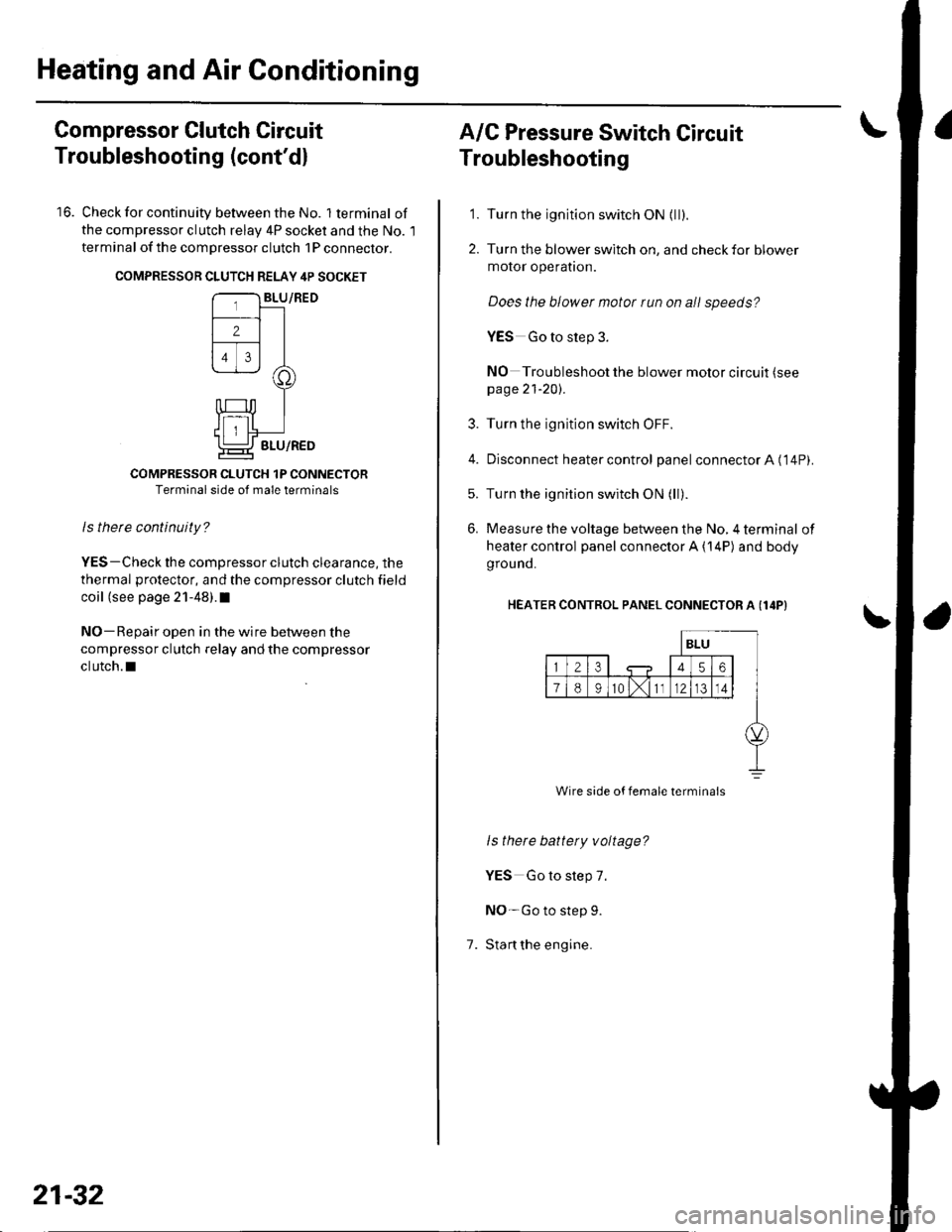

13. Uslng the Backprobe Set, measure the voltage

between the No. 18 termina! of ECI\4 connector

E {31P) and body ground with the ECM connectors

connected.

ECM CONNECTOR E 131P}

23t4561E9

141516m21

22232426272931

RED

Wire side of female terminals

ls there battery voltage?

YES Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECIM, replace the

original ECM.I

NO Repair open in the wire between the

compressor clutch relay and the ECM.I

14. Disconnect the jumper wire.

15. Disconnect the compressor clutch lPconnector.

{cont'd)

21-31

Page 803 of 1139

Heating and Air Conditioning

Compressor Clutch Circuit

Troubleshooting (cont'dl

16. Check for continuity between the No. lterminal of

the compressor clutch relav 4P socket and the No. l

terminal of the compressor clutch 1P conneclor.

COMPRESSON CLUTCH RELAY 4P SOCKET

COMPRESSOR CLUTCH 1P CONNECTORTerminal side of male terminals

ls therc continuity?

YES-Check the compressor clutch clearance, the

thermal protector, and the compressor clutch field

coil (see page 21-48).I

NO-Repair open in the wire between the

compressor clutch relay and the compressor

clutch.l

21-32

A/C Pressure Switch Circuit

Troubleshooting

'1. Turn the ignition switch ON {ll).

2. Turn the blower switch on, and check for blower

motor operatron.

Does the blower motor run on all speeds?

YES Go to step 3.

NO Troubleshoot the blower motor circuit (see

page 21-20).

3. Turn the ignition switch OFF.

4. Disconnect heater control panel connectorA ('14P).

5. Turn the ignition switch ON (ll).

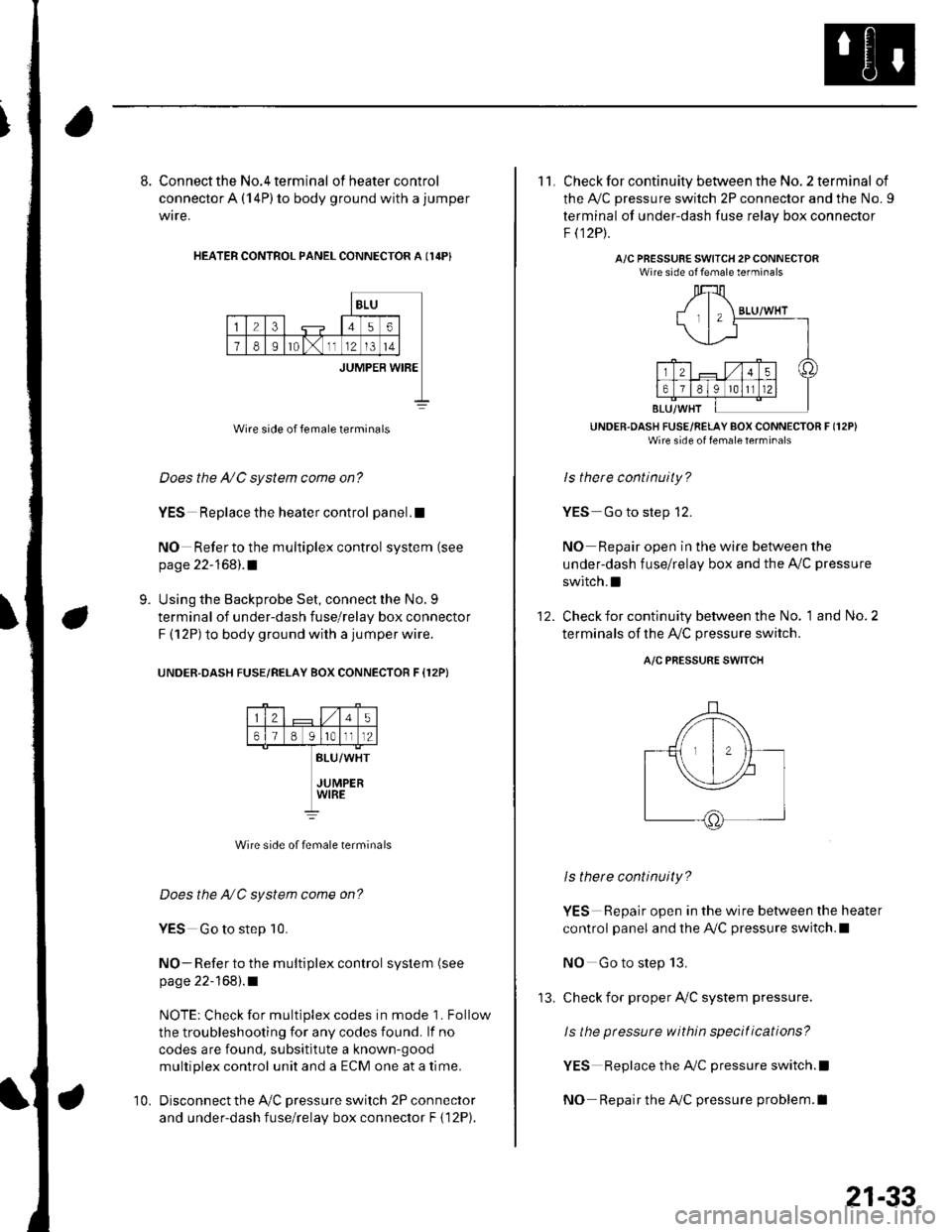

6. Measure the voltage between the No, 4 terminal of

heater control panel connector A {14P) and body

grou nd.

HEATER CONTROL PANEL CONNECTOR A (I4P}

1.

ls there battety voltage?

YES Go to step 7.

NO-Go to step 9.

Stan the engine.

Wire side of female termina's

Page 804 of 1139

8. Connect the No.4 terminal ofheatercontrol

connector A (14P) to body ground with a jumper

wire,

HEATER CONTROL PANEL CONNECTOR A I14P}

BLU

23456

78Ir0lx1112l3t4

JUMPER WIBE

Wire side of female terminals

Does the A/C system come on?

YES Replace the heater control panel.!

NO Refer to the multiplex control system (see

page 22-168).1

Using the Backprobe Set, connect the No. 9

terminal of under-dash fuse/relay box connector

F (12P) to body ground with a jumper wire.

UNOER.DASH FUSE/RELAY BOX CONNECTOR F {12P}

9.

25

61B g lrotll2

BLU/WHT

JUMPERWIRE

Wire side of female terminals

Does the NC system come on?

YES Go to step 10.

NO- Refer to the multiplex control system (see

page 22-168).1

NOTE: Check for multiplex codes in mode '1. Follow

the troubleshooting {or any codes found. lf no

codes are found, subsititute a known-9ood

multiplex control unit and a ECM one at a time.

Disconnect the Ay'C pressure switch 2P connector

and under-dash fuse/relay box connector F { 12P).

10.

'13.

21-33

11. Check for continuity between the No. 2 terminal of

the A,/C pressure switch 2P connector and the No. 9

terminal of under-dash fuse relav box connector

F t12Pt.

A/C PRESSURE SWITCH 2PCONNECTORWire side of female terminals

UNDER.OASH FUSE/RELAY BOX CONNECTOR F (12P)

Wire side of fenale lerrrinal'

ls there continuity?

YES Go to step 12.

NO Repair open in the wire between the

under-dash fuse/relay box and the A,,/C pressure

switch.I

Check for continuity between the No. 1 and No. 2

terminals of the A,/C pressure switch.

12.

A/C PRESSURE SWITCH

ls there continuity?

YES Repair open in the wire between the heater

control panel and the A,/C pressure switch.l

NO Go to step 13.

check for proper Ay'C system pressure.

ls the pressure within specitications?

YES Replace the AilC pressure switch.l

NO Repair the AilC pressure problem.I

Page 805 of 1139

Heating and Air Conditioning

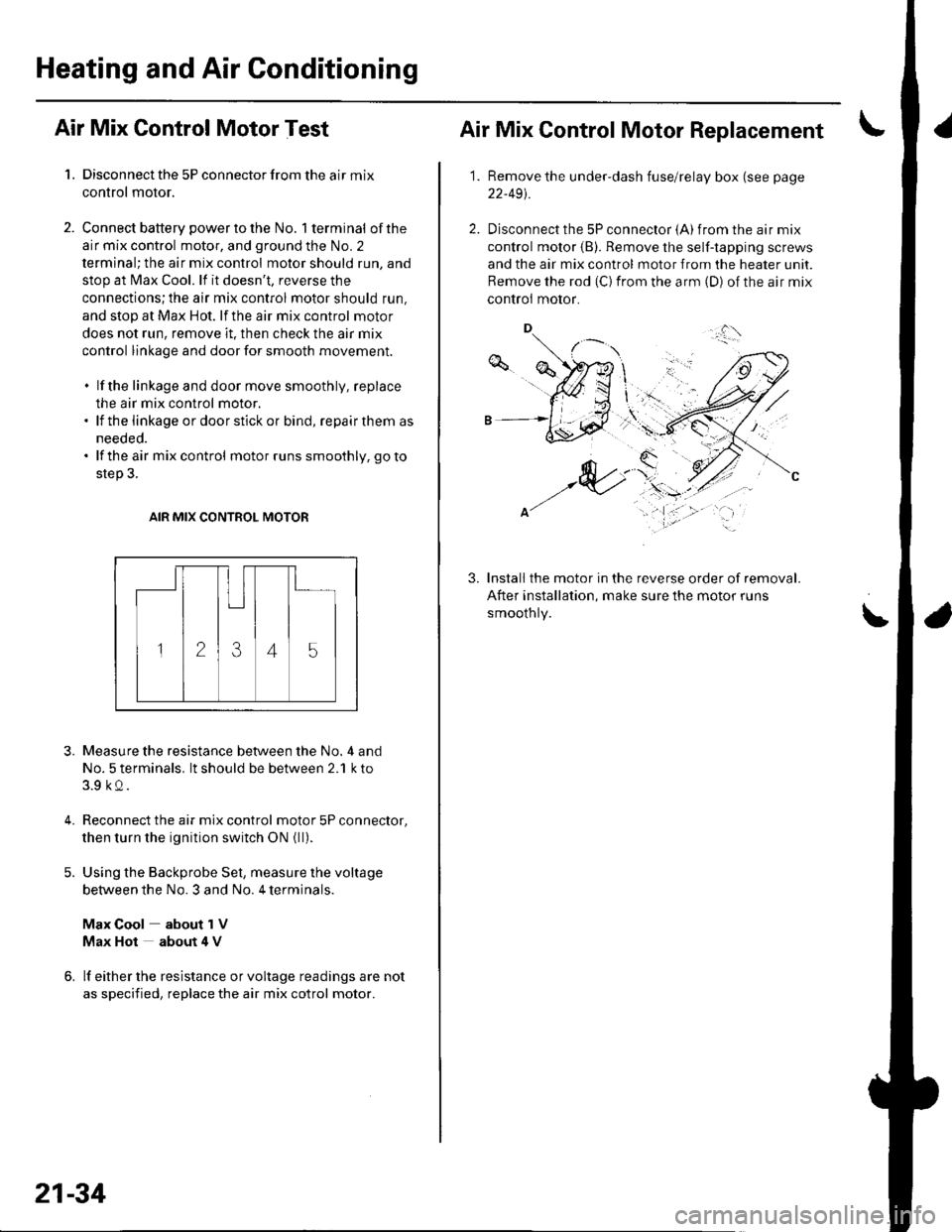

Air Mix Control Motor Test

1. Disconnect the 5P connector from the air mix

control motor.

2. Connect battery powertothe No. l terminal ofthe

air mix control motor, and ground the No. 2

terminal; the air mix control motor should run, and

stop at Max Cool. lf it doesn't, reverse the

connections;the air mix control motor should run,

and stop at Max Hot. lf the air mix control motor

does not run, remove it. then check the air mix

control linkage and door for smooth movement.

. lf the linkage and door move smoothly, replace

the air mix control motor.. lf the linkage ordoorstickor bind, repairthem as

needed.. lf the air mix control motor runs smoothly, go to

step 3.

AIR MIX CONTROL MOTOR

3.

4.

Measure the resistance between the No. 4 and

No. 5 terminals. lt should be between 2.1 k to

3.9 kQ.

Reconnect the air mix control motor 5P connector,

then turn the ignition switch ON {ll).

Using the Backprobe Set, measure the voltage

between the No. 3 and No. 4 terminals.

Max Cool about 1V

Max Hot about 4 V

lf either the resistance or voltage readings are not

as specified, replace the air mix cotrol motor.

21-34

Air Mix Control Motor Replacement

1.Remove the under-dash fuse/relay box (see page

22-491.

Disconnect the 5P connector {A) from the air mix

control motor (B). Remove the self-tapping screws

and the air mix control motor from the heater unit.

Remove the rod (C) from the arm (D) of the air mix

controi motor.

Install the motor in the reverse order of removal.

After installation, make sure the motor runs

smoothly.

3.

\'

,.,:l'

Page 806 of 1139

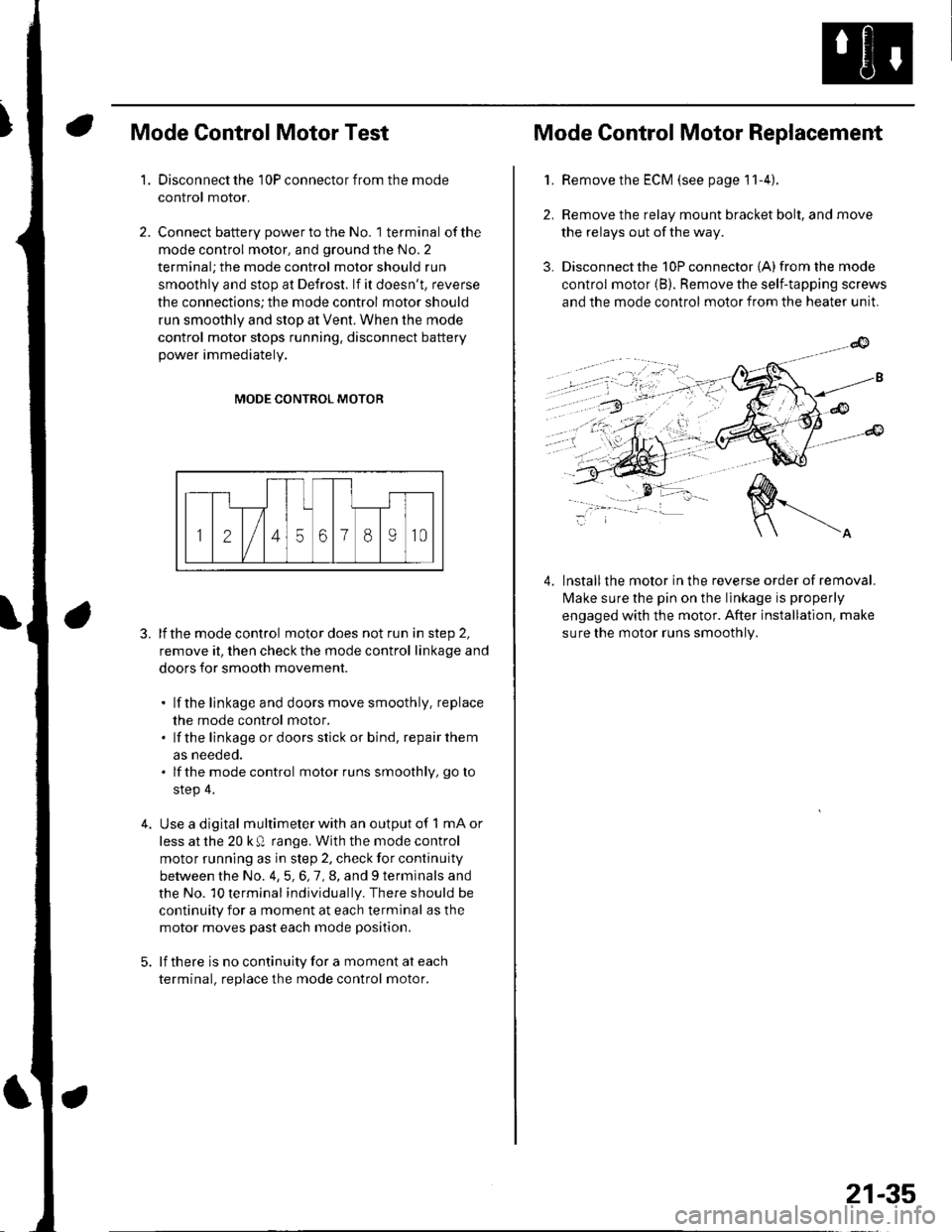

Mode Control Motor Test

Disconnect the 10P connector from the mode

control motor.

Connect battery power to the No. 1 terminal of the

mode control motor, and ground the No. 2

terminal; the mode control motor should run

smoothly and stop at Defrost. lf it doesn't, reverse

the connections; the mode control motor should

run smoothly and stop at Vent. When the mode

control motor stops running, disconnect battery

power immediately.

'1.

4.

MODE CONTROL MOTOR

3. lfthe mode control motor does not run in step 2,

remove it, then check the mode control linkage and

doors for smooth movement.

. lf the linkage and doors move smoothly. replace

the mode control motor.. lf the linkage ordoorsstick or bind, repairthem

as neeoeo.. lfthe mode control motor runs smoothly, go to

step 4.

Use a digital multimeter with an output of 1 mA or

less at the 20 k Q range. With the mode control

motor running as in step 2, check for continuity

between the No. 4,5,6,7,8, and 9 terminals and

the No. 10 terminal individually. There should be

continuity for a moment at each terminal as the

motor moves past each mode position.

lf there is no continuity for a moment at each

terminal. replace the mode control motor.

Mode Control Motor Replacement

2.

3.

1.Remove the ECM (see page 11-4).

Remove the relay mount bracket bolt, and move

the relays out of the way.

Disconnect the 10P connector {A) from the mode

control motor (B). Remove the self-tapping screws

and the mode control motor from the heater unit.

lnstallthe motor in the reverse order of removal.

lvlake sure the pin on the linkage is properly

engaged with the motor. After installation. make

sure the motor runs smoothly.

4.

21-35

Page 807 of 1139

Heating and Air Conditioning

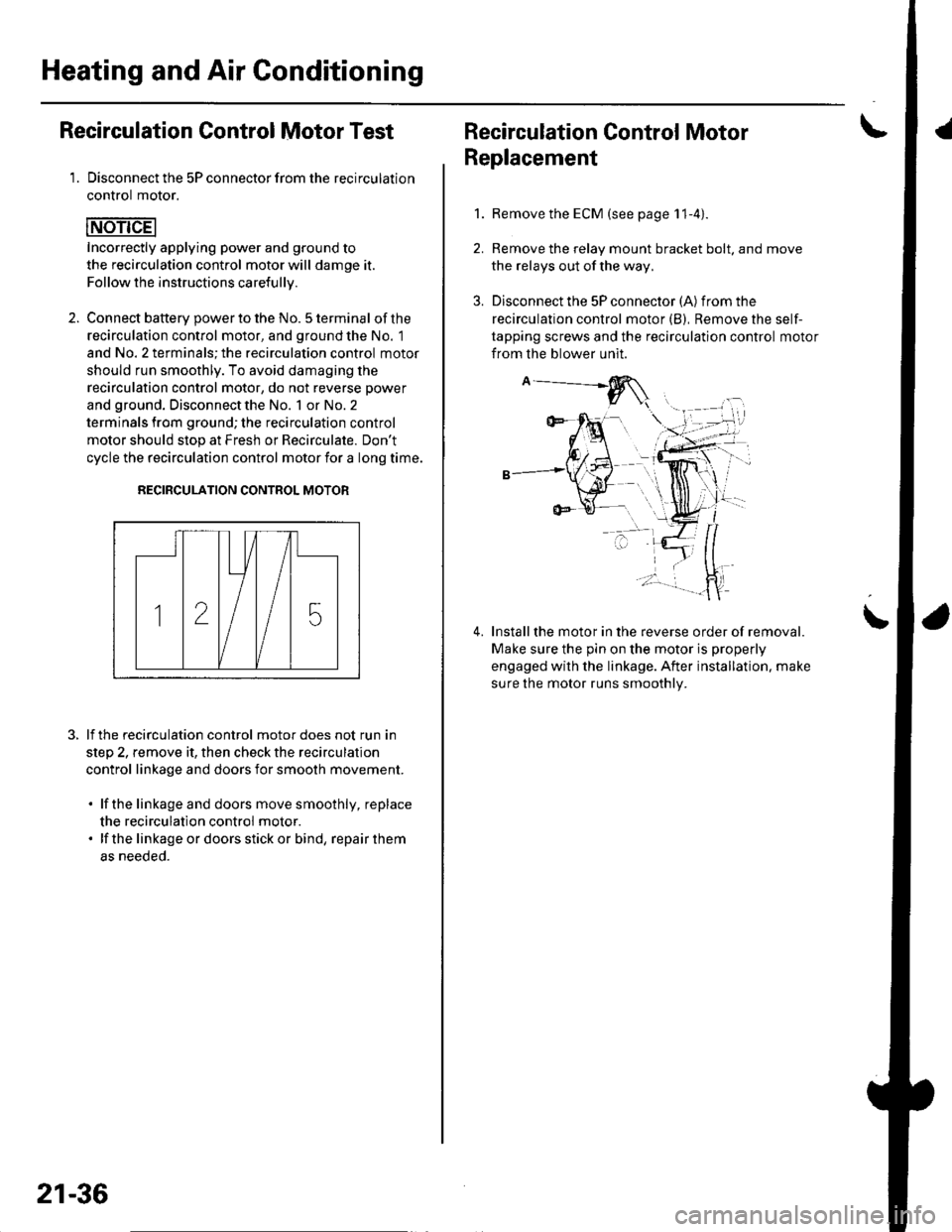

Recirculation Control Motor Test

1. Disconnect the 5P connector from the recirculation

control motor.

Incorrectly applying power and ground to

the recirculation control motor will damge it.

Follow the instructions carefullv.

2. Connect batterv oower to the No. 5 terminal ofthe

recirculation control motor, and ground the No. 1

and No. 2 terminals; the recirculation control motor

should run smoothly. To avoid damaging the

recirculation control motor, do not reverse power

and ground. Disconnect the No. 1 or No. 2

terminals from ground; the recirculation control

motor should stop at Fresh or Recirculate. Don't

cycle the recirculation control motor {or a long time.

RECIRCULATION CONTROL MOTOR

lf the recirculation control motor does not run in

step 2, remove it, then check the recirculation

control linkage and doors for smooth movement.

. lfthe linkage and doors move smoothly, replace

the recirculation control motor.. lf the linkageordoorsstickor bind, repairthem

as neeoeo.

21-36

Recirculation Control MotorI

Replacement

1.Remove the ECM (see page 11-4).

Remove the relay mount bracket bolt. and move

the relays out of the way,

Disconnect the 5P connector (A) from the

recirculation control motor (B), Remove the self-

tapping screws and the recirculation control motor

from the blower unit.

Installthe motor in the reverse order of removal.

Make sure the pin on the motor is properly

engaged with the linkage. After installation. make

sure the motor runs smoothly.

\

Page 808 of 1139

Evaporator Temperature Sensor

Replacement

1.Remove the driver's dashboard lower cover (see

page 20-59) and the under cover (see page 20-60).

Remove the under-dash fuse/relay box (see page

22-491.

Disconnect the 2P connector (A) from the

evaporator temperature sensor (B), then remove

the connector clip (C). Remove the self-tapping

screw, and carefully pull out the evaporator

temperature.

4. Install the sensor in the reverse order of removal,

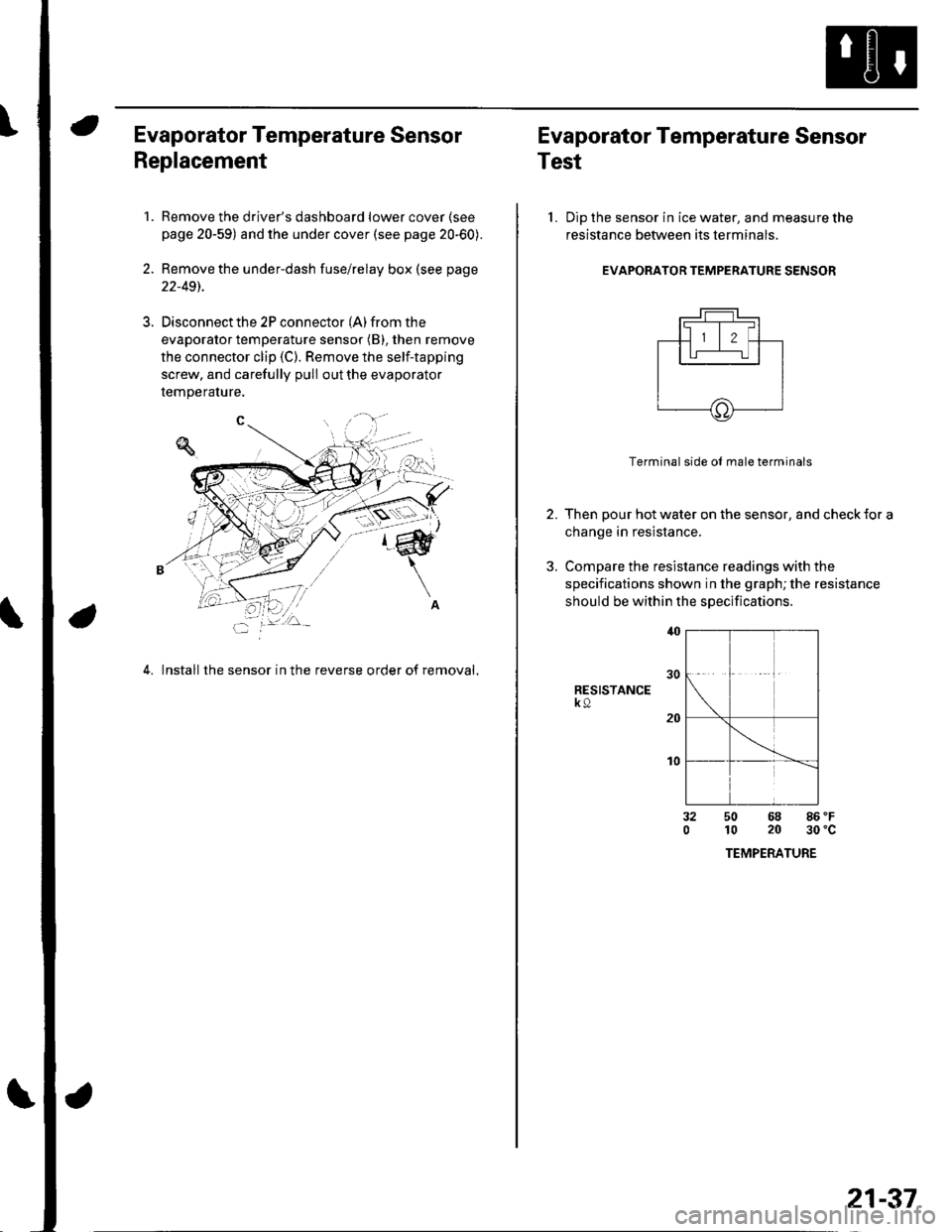

Evaporator Temperature Sensor

Test

l. Dip the sensor in ice water, and measure the

resistance between its terminals

EVAPORATOR TEMPERATURE SENSOR

2.

3.

Terminal side ol male terminals

Then pour hot water on the sensor, and check {or a

change in resistance.

Compare the resistance readings with the

specifications shown in the graph; the resistance

should be within the specifications

RESISTANCEk9

t0

32050 68 86 'F

10 20 30'c

TEMPERATURE

21-37

Page 811 of 1139

Heating and Air Gonditioning

Blower Unit Removal and Installation {cont'd}

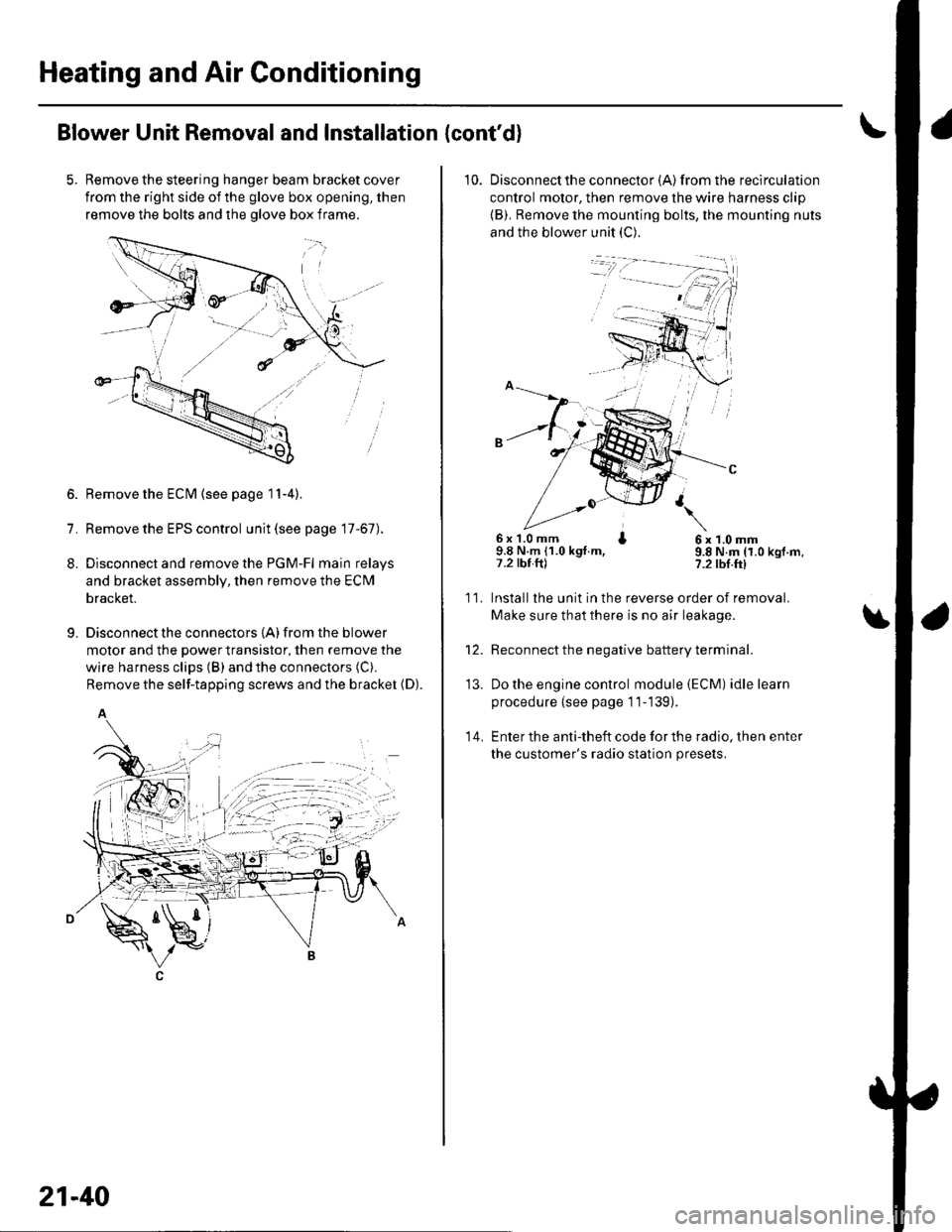

Remove the steering hanger beam bracket cover

from the right side of the glove box opening, then

remove the bolts and the olove box frame.

1.

8.

9.

Remove the ECM (see page 11-4).

Remove the EPS control unit (see page 17-67).

Disconnect and remove the PGM-Fl main relays

and bracket assembly, then remove the ECM

bracket.

Disconnect the connectors {A) from the blower

motor and the power transistor, then remove the

wire harness clips (B) and the connectors (C).

Remove the self-tapping screws and the bracket (D).

A

21-40

10. Disconnectthe connector {A) from the recirculation

control motor, then remove the wire harness clip

{B). Remove the mounting bolts, the mounting nuts

and the blower unit (C).

6x 1.0 mm I9.8 N.m (1.0 kgt.m,7.2 tbt.ftl

6x1.0mm9.8 N.m (1.0 kgf.m,?.2 tbf.ft)

11.

14.

Installlhe unit in the reverse order of removal.

Make sure that there is no air leakage.

Reconnect the negative battery terminal.

Do the engine control module (ECM) idle learn

procedure {see page 11-139).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

\

'13.

Page 831 of 1139

\Body Electrical

Body ElectricalSpecialToolsGeneral Troubleshooting tntorrnaiion.'......

Relay and Control Unit Locations .....

Connectors and Harnesses

Fuse/Relay Boxes ...............................

Power Distribution .............................

Ground Distribution ...........................

Under-dash Fuse/Relay Box ..............

Battery ..............

Relays ................

*lgnition Switch ..............

*Gauges

Component Location Index .......................Self-diagnostic Procedure ..........................Circuit DiagramGauge Bulb Replacement ..........................Gauge Assembly ReplacementCoolant Temperature

Gauge Troubleshooting .... ....................Vehicle Speed Signal CircuitTroubleshootingVSS Replacement

Exterior LightsComponent Location Index .......................Circuit DiagramDaytime Running Lights ControiUnit Input Test (Canada) ........................Headlight Ad,ustment .................. .. .....Headlighr Replacement ..............................Combination Light SwitchTest/ReplacementBulb ReplacementTaillight Replacement ..........................High Mount Brake Light Replacement ......License Plate Light Replacement ..............Side Marker Light Replacement ................Brake Pedal Position Switch Test ..............Side Turn Signal Light Replacement ........

Turn Signal/HazardFlasher SystemComponent Location Index .......................Circuit DiagramTurn Signal/Hazard Relay lnputTest ........Hazard Warning Switch Test

22,3

22-7

22-13

22-44

22-46

22-4A

22-49

22-50

22-51

22-53

22-5422-5622-5422 6322-64

22-64

22-6522 61

22-6822--71

22-7 622-7422-79

22-AO22-4122-8222-4222-4322-4322-4422-84

22-8�522 A622-8722-88

22-10422-105

22-10622-107

Entry Lights control systemComponent Location Index ....................... 22-89Circuit Diagram ......... 22 90lgnition Key Switch Test .....................,...... 22-9'llgnition Key Light Test ............................... 22-91Control Unit Input Test ..........,.................... 22 92

Interior LightsComponent Location Index ....................... 22-94Circuit Diagram ......... 22-95Ceiling LighVSpotlightsTesVReplacement ................................... 22-96Rear Ceiling Light TesVReplacem ent ........ 22-96Cargo Area Light Test/Replacem ent ......... 22-97Hatch Latch Switch Test ..,..,....................... 22-97

*Audio SystemComponent Location Index ....................... 22-98Circuit Diagram ......... 22,99Audio Unit Removal/lnstallation ............... 22-1OOAudio Unit Connector Replacement ......... 22-101Speaker Replacement ................................ 22-102Roof Antenna Rep1acement ....................-.. 22-103

Rear Window DefoggerComponent Location Index ...........Circuit Diasram .. ....... .. ..... ....... ...:::::.::.::.Function TestDefogger Wire Repair .................................Noise Condenser CapacityTest ................

MoonroofComponent Location Index ....................... 22-1OBCircuit Diagram ......... 22-109Moonroof Control Unit Input Test ............. 22-'l10Switch TesVReplacement ........,.....,........... 22-1 12Motor Test ................. 22-112Limit Swilch Test ...... 22-'l'13Auto-stop Switch Test ................................ 22-1 13

Power MirrorsComponent Location Index ....................... 22-114Circuit Diagram ......... 22-115Function Test ............. 22-116Power Mirror Switch Test .......................... 22-ll7Power Mirror Actuator Test ....................... 22-117Power Mirror Actuator Replacement ........ 22-11A

* HornsComponent Location Index ....................... 22-120Circuit Diagram ......... 22-121Horn TesVReplacement ...........................-. 22-122Horn Switch Test .,.... 22-122

\