relay HONDA CIVIC 2003 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 538 of 1139

EPS Indicator Circuit Troubleshooting

1.Turn the ignition switch ON (ll), start the engine,

and watch the EPS indicator.

Does the EPS indicator come on?

YES lf the EPS indicator comes on and goes off, it's

OK. lf the EPS indicator stays on or blinks. go to

step 12.

NO Go to step 2.

Turn the ignition switch OFF, then ON (ll) again,

and watch the brake system indicator,

Does the brake system indicator come on?

YES-Go to step 3.

NO Repair open in the indicator power source

circuit.l. Blown No. 10 (7.5A)fuse.

. Open in the wire between the No. 10 (7.5A) fuse

and gauge assembly.. Open circuit inside the under-dash fuse/relay box,. Faulty gauge assembly.

Turn the ignition switch OFF,

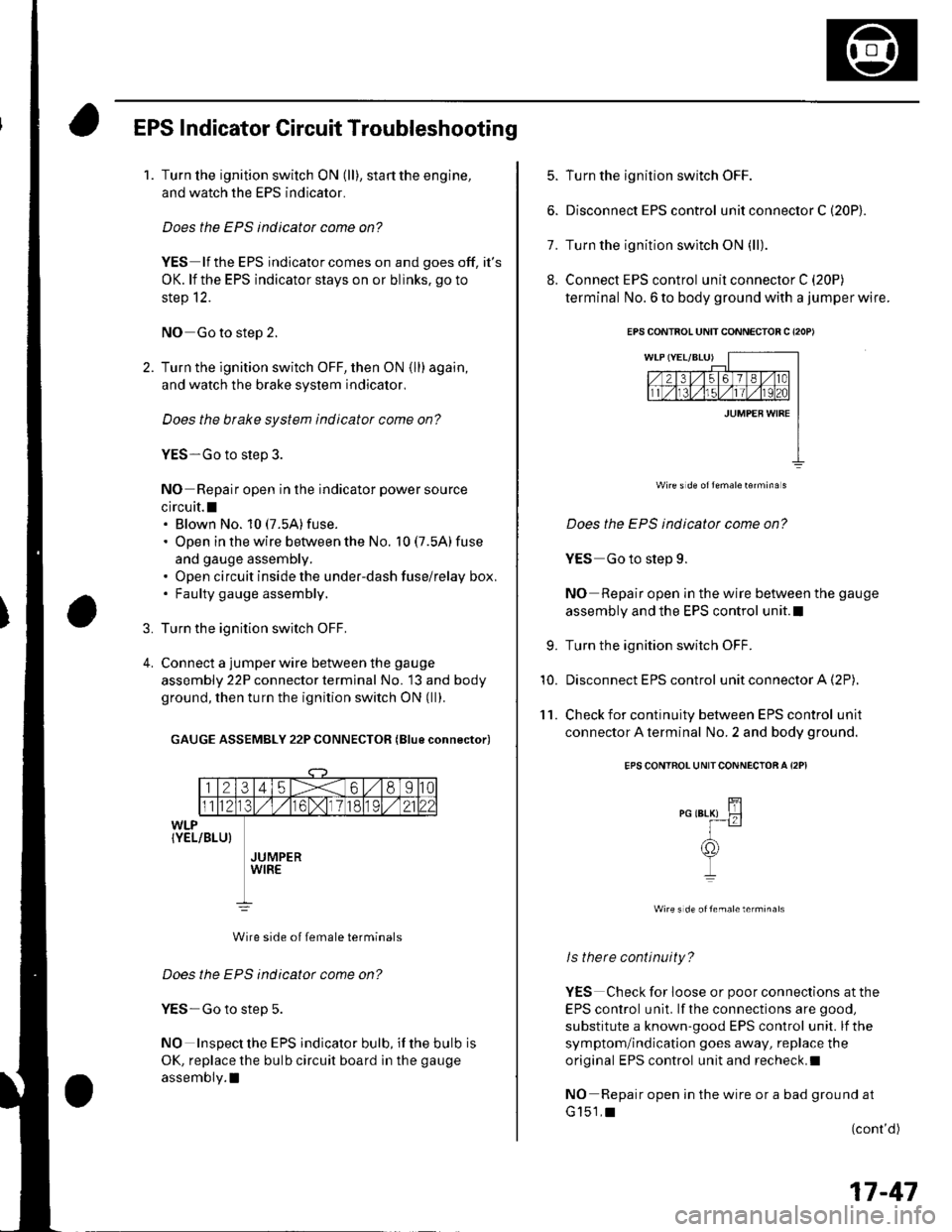

Connect a jumper wire between the gauge

assembly 22P connector terminal No. 13 and body

ground, then turn the ignition switch ON (ll).

GAUGE ASSEMBLY 22P CONNECTOR (Blue connector)

Wire side of female terminals

Does the EPS indicator come on?

YES-Go to step 5.

NO Inspect the EPS indicator bulb, if the bulb is

OK, replace the bulb circuit board in the gauge

assembly.l

3.

4.

5. Turn the ignition switch OFF.

6. Disconnect EPS control u n it connector C (20P).

7. Turn the ignition switch ON (ll).

8. Connect EPS control unit connector C (20P)

terminal No. 6 to body ground with a jumper wire.

Wire s d€ oflemale16rmina s

Does the EPS indicatot come on?

YES Go to step 9.

NO Repair open in the wire between the gauge

assembly and the EPS control unit.l

Turn the ignition switch OFF.

Disconnect EPS control unit connector A (2P),

Check for continuity between EPS control unit

connector A terminal No. 2 and body ground.

EPS CONTROL UNITCONNECTOA A I2PI

wire s de oftemale terminals

ls there continuity?

YES Check for loose or poor connections at the

EPS control unit. lf the connections are good,

substitute a known-good EPS control unit. lf the

symptom/indication goes away, replace the

original EPS control unit and recheck.I

NO Repair open in the wire or a bad ground at

G151,t(cont'd)

9.

10.

'l 1.

EPS CONTBOL UNIT CONNECTOB C {2OP)

17-47

Page 539 of 1139

EPS Components

I

12.

EPS Indicator Circuit Troubleshooting (cont'dl

Turn the ignition switch OFF.

Disconnect EPS control unit connector C (20P).

Turn the ignition switch ON (ll).

Does the EPS indicator come on?

YES-Repair short to ground in the YEUBLU wire

between the gauge assembly and the EPS control

unit, or replace the bulb circuit board in the gauge

assembly.l

NO-Go to step 15.

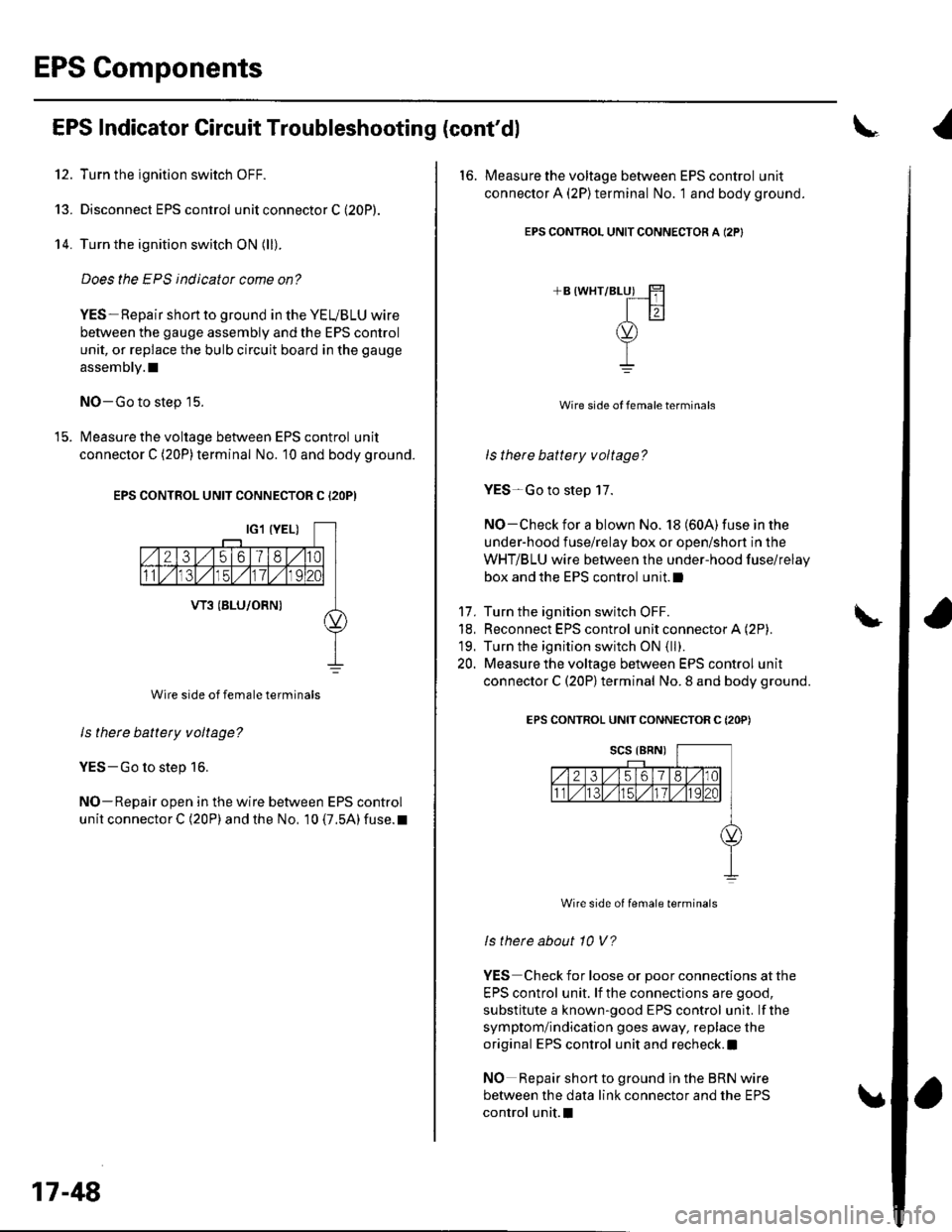

Measure the voltage between EPS control unit

connector C (20P)terminal No. 10 and body ground.

EPS CONTROL UNIT CONNECTOR C I2OP)

Wire side of female terminals

ls there battery voltage?

YES-Go to step 16.

NO-Repair open in the wire between EPS control

unit connector C (20P) and the No, 10 (7.5A) fuse. t

13.

14.

17-48

16. Measure the voltage between EPS control unit

connector A (2P)terminal No. '1 and body ground.

EPS CONTROL UNITCONNECTON A (2P}

+B (WHT/BLUI H

Itr

v-L

17.

18,

19.

20.

Wire side of female terminals

ls there battery voltage?

YES-Go to step 17.

NO-Check for a blown No. 18 (604) fuse in the

under-hood fuse/relay box or open/short in the

WHT/BLU wire between the under-hood fuse/relay

box and the EPS control unit.l

Turn the ignition switch OFF.

Reconnect EPS control unit connector A (2P).

Turn the ignition switch ON (ll).

Measure the voltage between EPS control unit

connector C (20P)terminal No. 8 and body ground.

EPS CONTROL UNIT CONNECTOR C (2OP)

Wire side of female terminals

ls therc about 10 V?

YES Check for loose or poor connections at the

EPS control unit. lf the connections are good,

substitute a known-good EPS control unit. lf the

symptom/indication goes away, replace the

original EPS control unit and recheck.l

NO Repair short to ground in the BRN wire

between the data link connector and the EPS

control unit.I

Page 545 of 1139

EPS Components

Steering Gearbox Removal {cont'd)

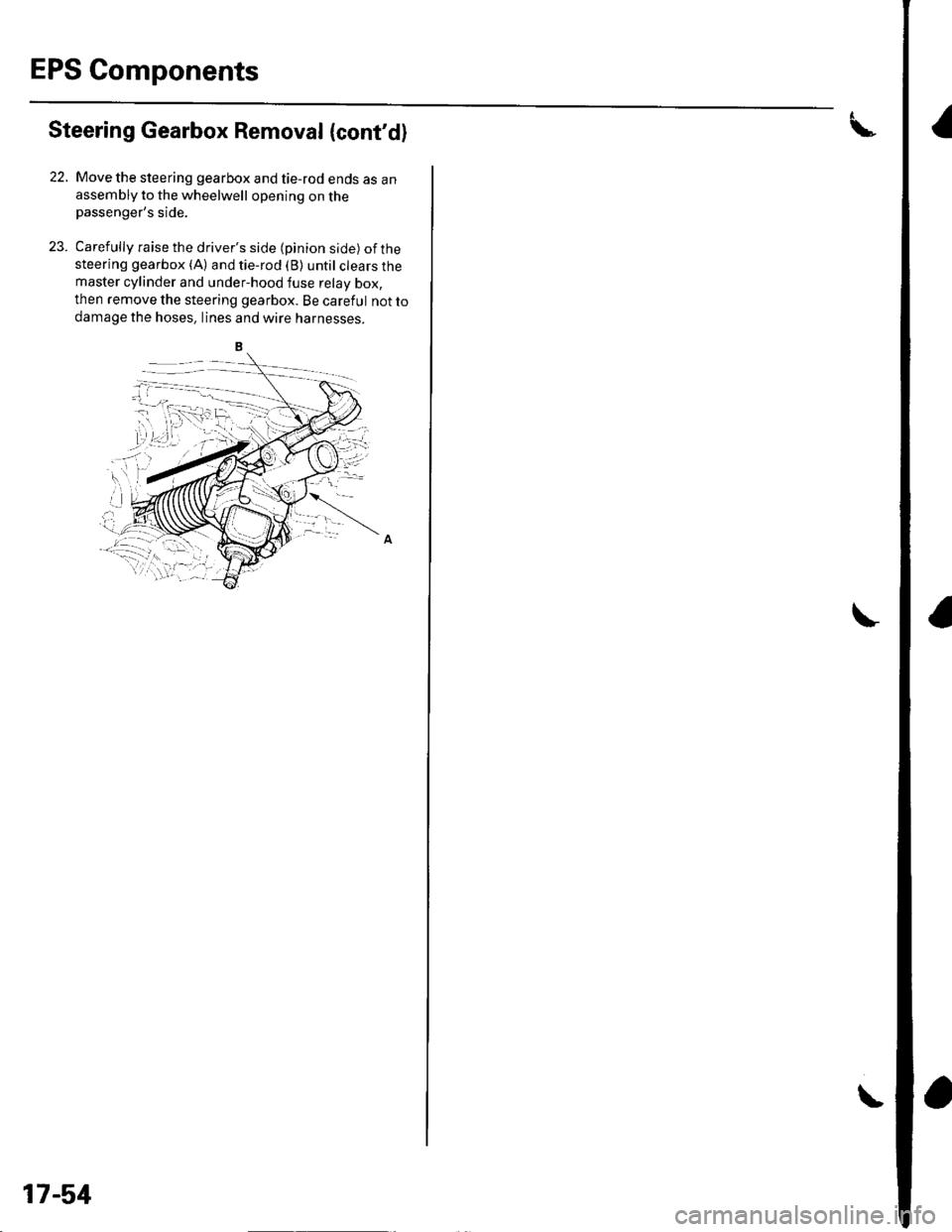

22. Move the steering gearbox and tie-rod ends as anassembly to the wheelwell opening on thepassenger's side.

23. Carefully raise the driver's side (pinion side) ofthesteering gearbox (A) and tie-rod (B) until clears themaster cylinder and under-hood fuse relay box,

then remove the steering gearbox. Be careful not to

damage the hoses, lines and wtre narnesses.

17-51

Page 624 of 1139

ABS Gomponents

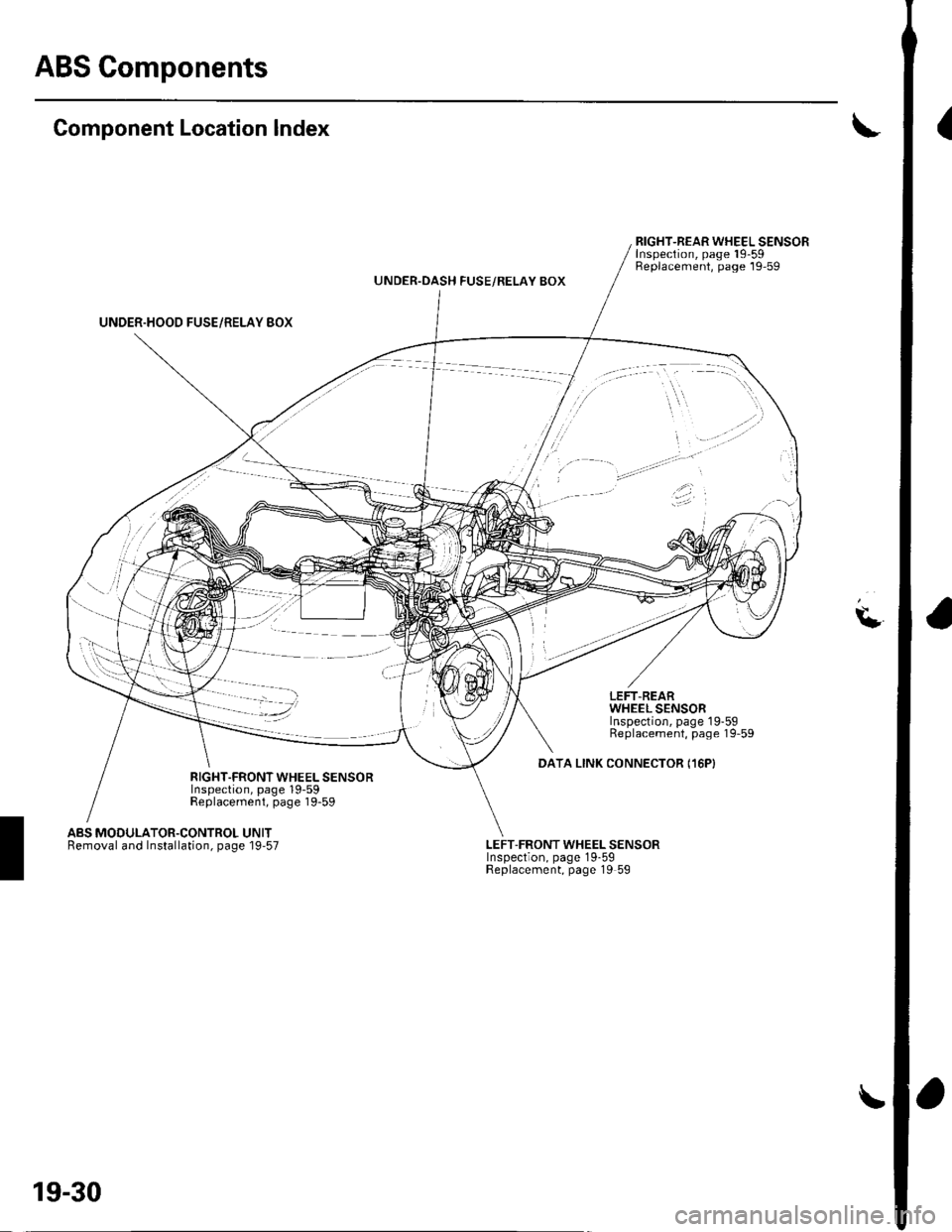

(Component Location Index

UNDER.HOOD FUSE/RELAY BOX

RIGHT-REAR WHEEL SENSORInspection, page 19-59Replacement, page 19-59UNDER.OASH FUSE/RELAY BOX

\L

LEFT.REARWHEEL SENSORInspection, page 19-59Replacement, page 19-59

DATA LINK CONNECTOR I16PIRIGHT.FRONT WHEEL SENSORInspection, page 19-59Replacement, page 19-59

ABS MODULATOR.CONTROL UNITRemoval and Installation, page 19'57LEFT-FRONT WHEEL SENSORInspection, page 19-59Replacement, page 19 59

19-30

Page 638 of 1139

ABS Components

q,

CONNECTOR A {12P)BRAKE PEDAL POSITIONSWITCH 4P CONNECTOR

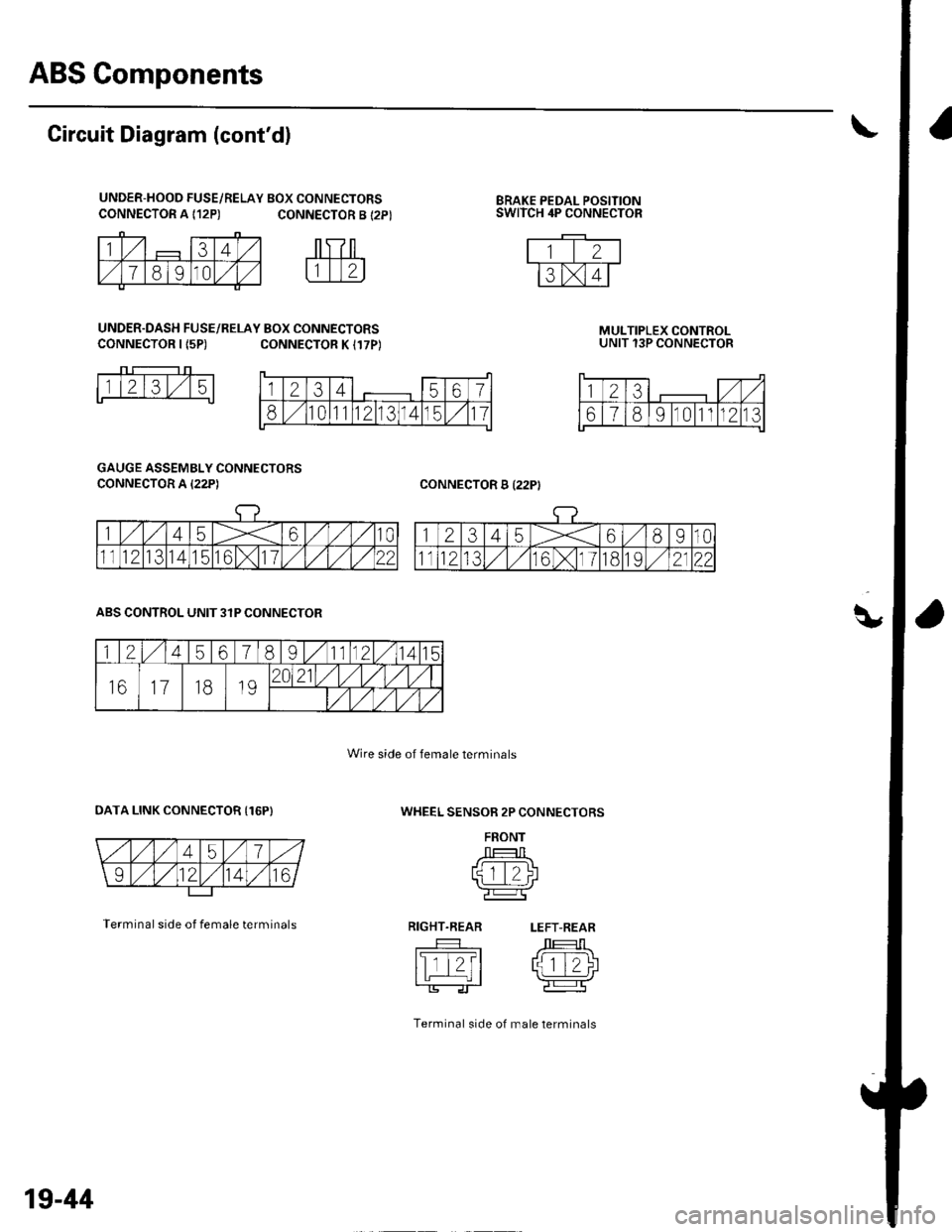

Circuit Diagram (cont'd)

UNDER-HOOD FUSE/RELAY BOX CONNECTORSCONNECTOR A {12P) CONNECTOR B {2P}

UNDER.DASH FUSE/RELAY BOX CONNECTORSCONNECTOR I {5P)CONNECTOR K I17P)MULTIPLEX CONTROLUNIT 13P CONNECTOR

CONNECTOR B I22PI

1l2l3l,/15

GAUGE ASSEMBLY CONNECTORS

CONNECTOR A I22P)

WHEEL SENSOR 2P CONNECTORS

FRONT

J --T:-l Ltqtt/)l'l L_.:-:J r\-r-----Tr'e:l

RIGHT.REAR LEFT-REAR

tslTt?t /J 1T-1\I tL | rlziJ

Terminal side of male lerminals

ABS CONTROL UNIT 3IP CONNECTOR

OATA LINK CONNECTOR {16P)

Terminal side of female terminals

Wire side of female terminals

1234567

810111213141511

123,/ ,/

67891011n213

1245678I11121415

161118192021/1,/1,/vl,/l

/t,/t/t,/t/

19-44

Page 643 of 1139

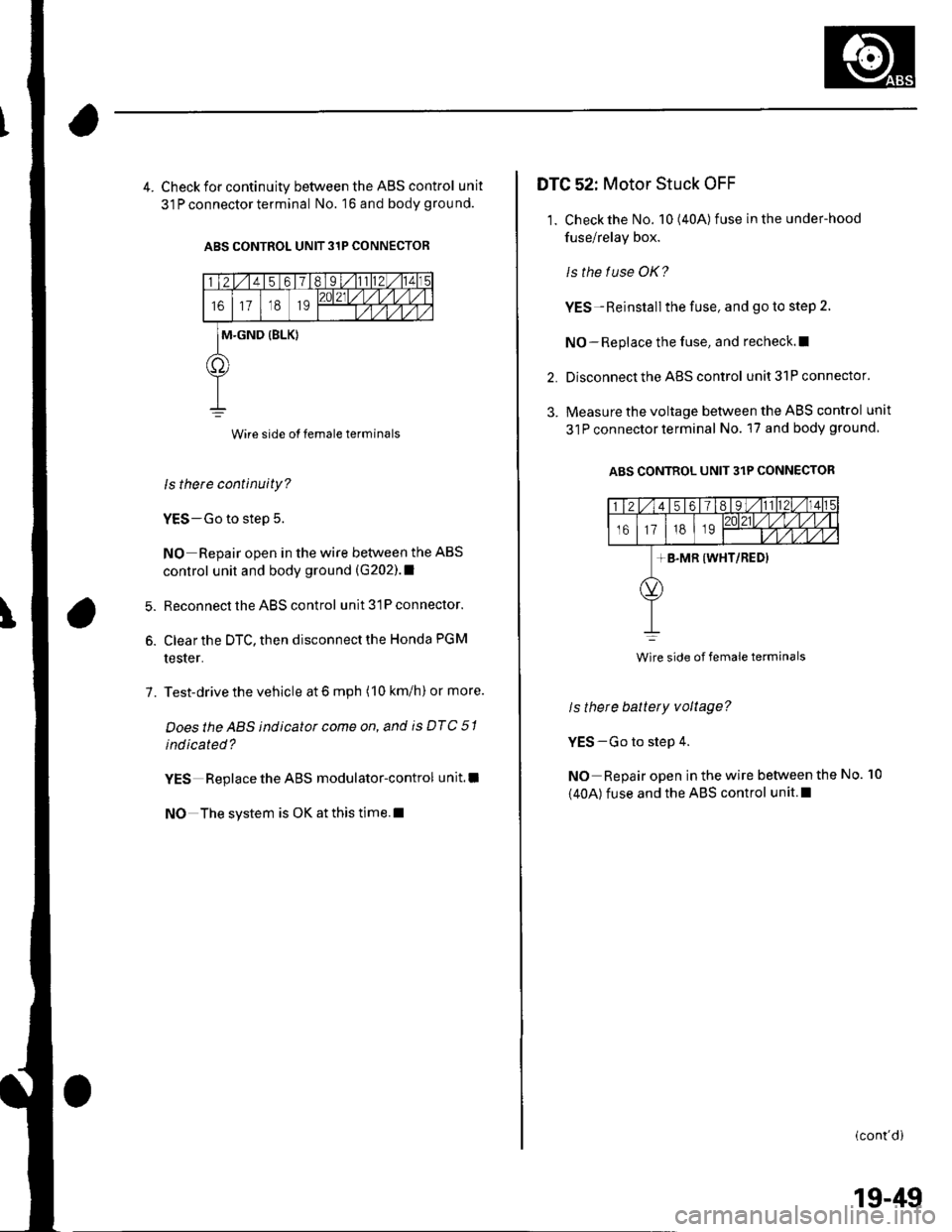

4. Check for continuity between the ABS control unit

31 P connector terminal No. 16 and body grou nd.

ABS CONTROL UNIT 31P CONNECTOR

Wire side of female terminals

ls there continuity?

YES-Go to step 5.

NO Repair open in the wire between the ABS

control unit and body ground (G202).1

Reconnect the ABS control unit 31P connector.

Clear the DTC, then disconnect the Honda PGM

tester.

Test-drive the vehicle at 6 mph (10 km/h) or more.

Doesthe ABS indicator come on, and is DTC 51

indicated?

YES Replace the ABS modulator-control unit.l

NO The system is OK at this time.l

6.

7.

DTG 52: Motor Stuck OFF

1. Check the No. 10(40A) fuse in the under-hood

fuse/relay box.

ls the f use OK?

YES-Reinstall the fuse, and go to step 2.

NO-Replace the fuse, and recheck.l|

Disconnect the ABS control unit 31P connector.

Measure the voltage between the ABS control unit

31P connector terminal No. 17 and body ground

ABS CONTROL UNIT 31P CONNECTOR

2.

3.

ls there battery voltage?

YES-Go to step 4.

NO Repair open in the wire between the

(40A) fuse and the ABS control unit.l

No. 10

(cont'di

Wire side of female terminals

19-49

Page 645 of 1139

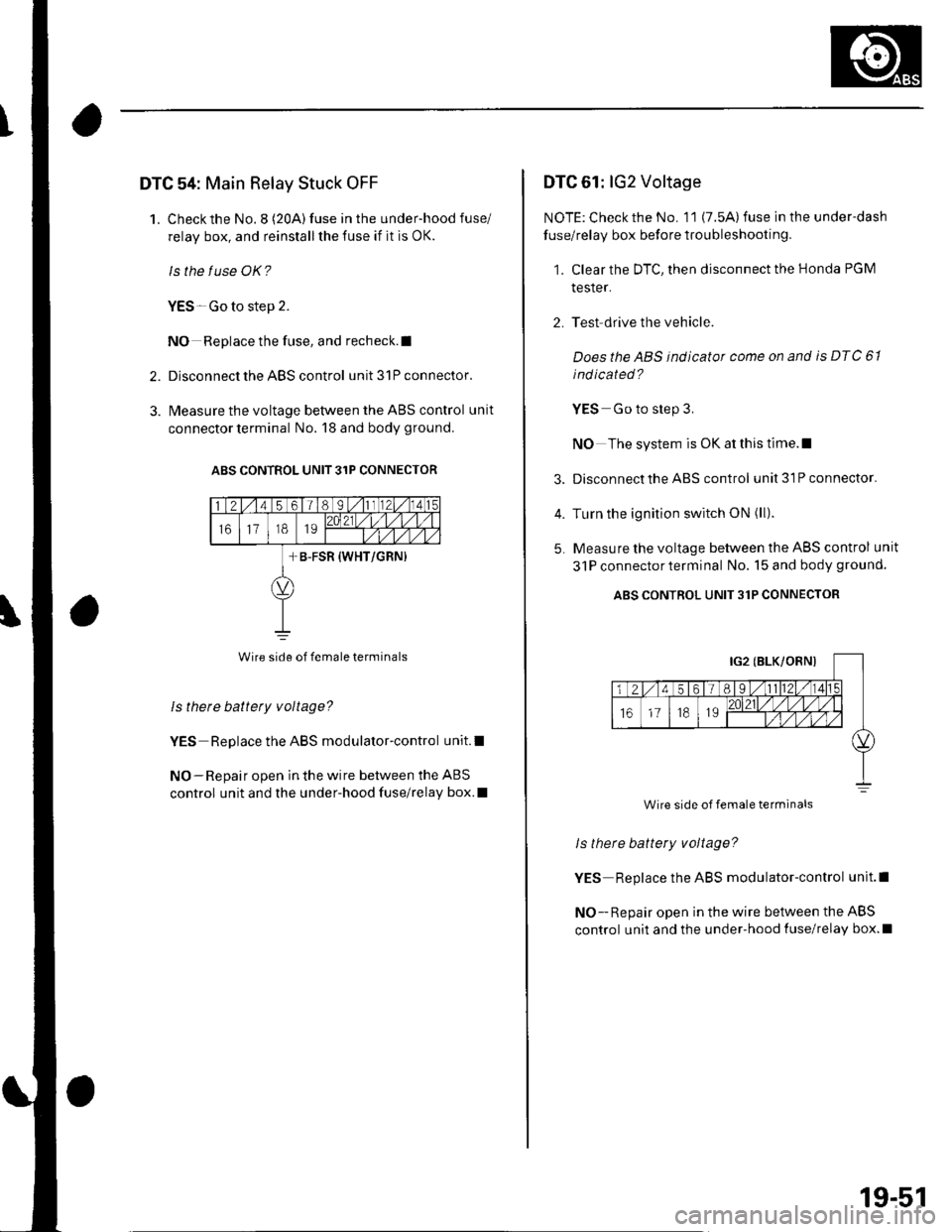

DTC 54: Main Relay Stuck OFF

1. Checkthe No.8 (20A) fuse in the under-hood fuse/

relay box, and reinstallthe fuse if it is OK.

ls the f use OK?

YES-Go to step 2.

NO Replace the fuse, and recheck.l

2. Disconnect the ABS control unit 31P connector.

3. l\4easure the voltage between the ABS control unit

connector terminal No. 18 and body ground.

ABS CONTROL UNIT 31P CONNECIOR

Wire side of female terminals

Is there battety voltage?

YES Replace the ABS modulator-control unit.l

NO-Repair open in the wire between the ABS

control unit and the under-hood fuse/relay box.I

DTC 61: lG2 Voltage

NOTE: Check the No. 11 (7.5A) fuse in the under-dash

fuse/relay box before troubleshooting.

1. Clear the DTC, then disconnect the Honda PGM

tesler.

2. Test drive the vehicle.

Doesthe ABS indicator come on and is DTC 61

ind icated ?

YES Go to step 3.

NO The system is OK at this time.l

3. Disconnect the ABS control unit3lPconnector.

4. Turn the ignition switch ON (ll).

5. Measure the voltage between the ABS control unit

31P connectorterminal No. 15 and body ground.

ABS CONTROL UNIT 31P CONNECTOR

ls there battery voltage?

YES Replace the ABS modulator-control unit.l

NO - Repair open in the wire between the ABS

control unit and the under-hood {use/relay box.l

Wire side of female terminals

19-51

Page 647 of 1139

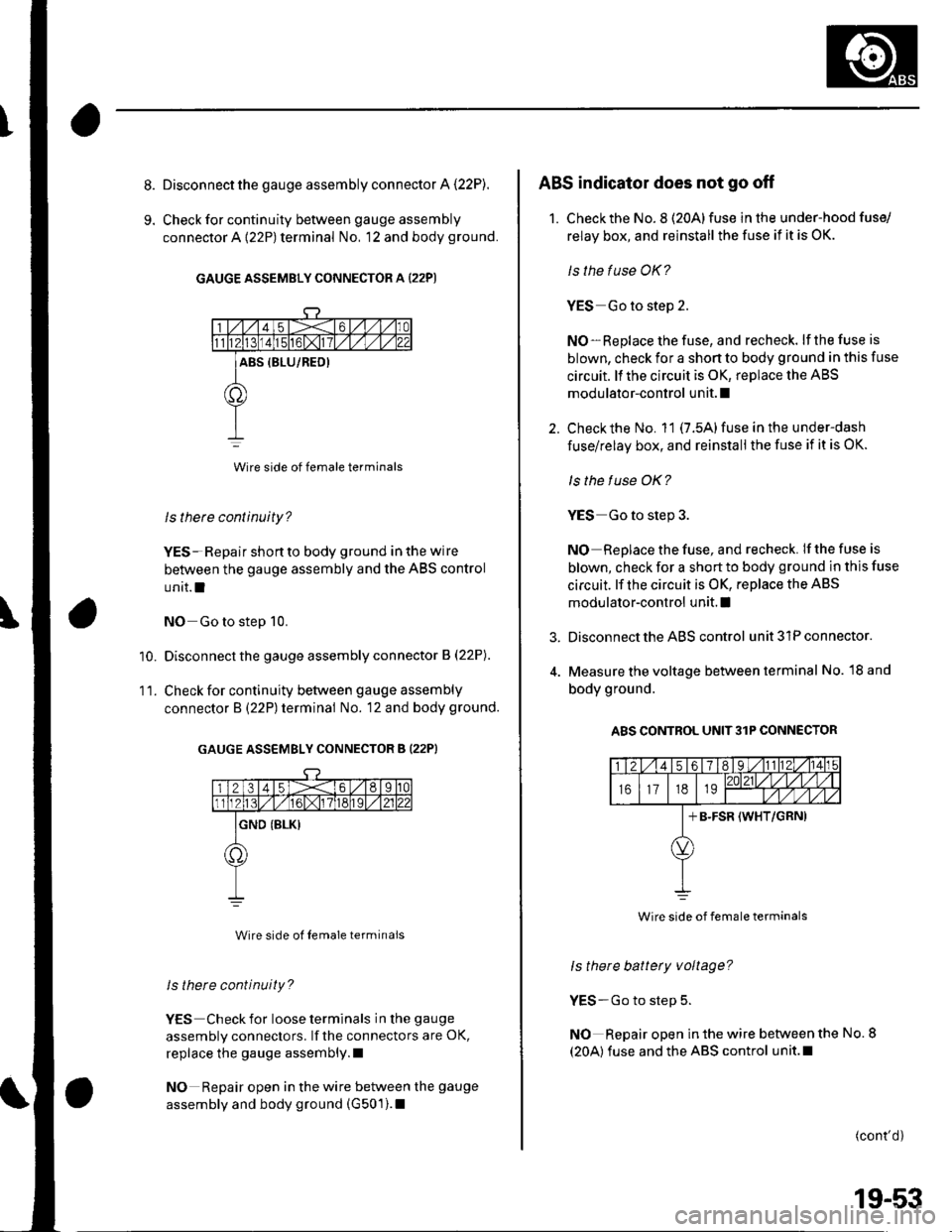

8.

9.

Disconnect the gauge assembly connector A (22P).

Check for continuity between gauge assembly

connector A {22P) terminal No, 12 and body ground.

GAUGE ASSEMBLY CONNECTOR A (22P)

Wire side of female terminals

ls there continuity?

YES- Repair shon to body ground in the wire

between the gauge assembly and the ABS control

unit.l

NO Go to step 10.

Disconnect the gauge assembly connector B (22P).

Check for continuity between gauge assembly

connector B (22P) terminal No. 12 and body ground.

GAUGE ASSEMBLY CONNECTOR B (22PI

Wire side ol Iemale terminals

ls there continuity?

YES Check for loose terminals in the gauge

assembly connectors. lf the connectors are OK,

replace the gauge assembly.l

NO Repair open in the wire between the gauge

assembly and body ground (G501).1

'10.

11.

3.

ABS indicator does not go off

1. Checkthe No. 8 (20Alfuse in the under-hood fuse/

relay box, and reinstall the fuse if it is OK.

ls the fuse OK?

YES Go to step 2.

NO-Replace the fuse, and recheck. lf the fuse is

blown, check for a shon to body ground in this fuse

circuit. ll the circuit is OK, replace the ABS

modulator-control unit. I

Check the No. 11 (7.5A) fuse in the under-dash

fuse/relay box, and reinstall the fuse if it is OK.

ls the f use OK?

YES Go to step 3.

NO Replace the fuse, and recheck. If the fuse is

blown, check for a short to body ground in this fuse

circuit. lf the circuit is OK, replace the ABS

modulator-control unit. I

Disconnect the ABS control unit 31P connector.

Measure the voltage between terminal No. l8 and

body ground.

A8S CONTROL UNIT3lP CONNECTOR

ls there battery voltage?

YES-Go to step 5.

NO Repair open in the wire between the No. 8

(20A) fuse and the ABS control unit.l

(cont'd)

Wire side of female terminals

19-53

Page 690 of 1139

Moonroof

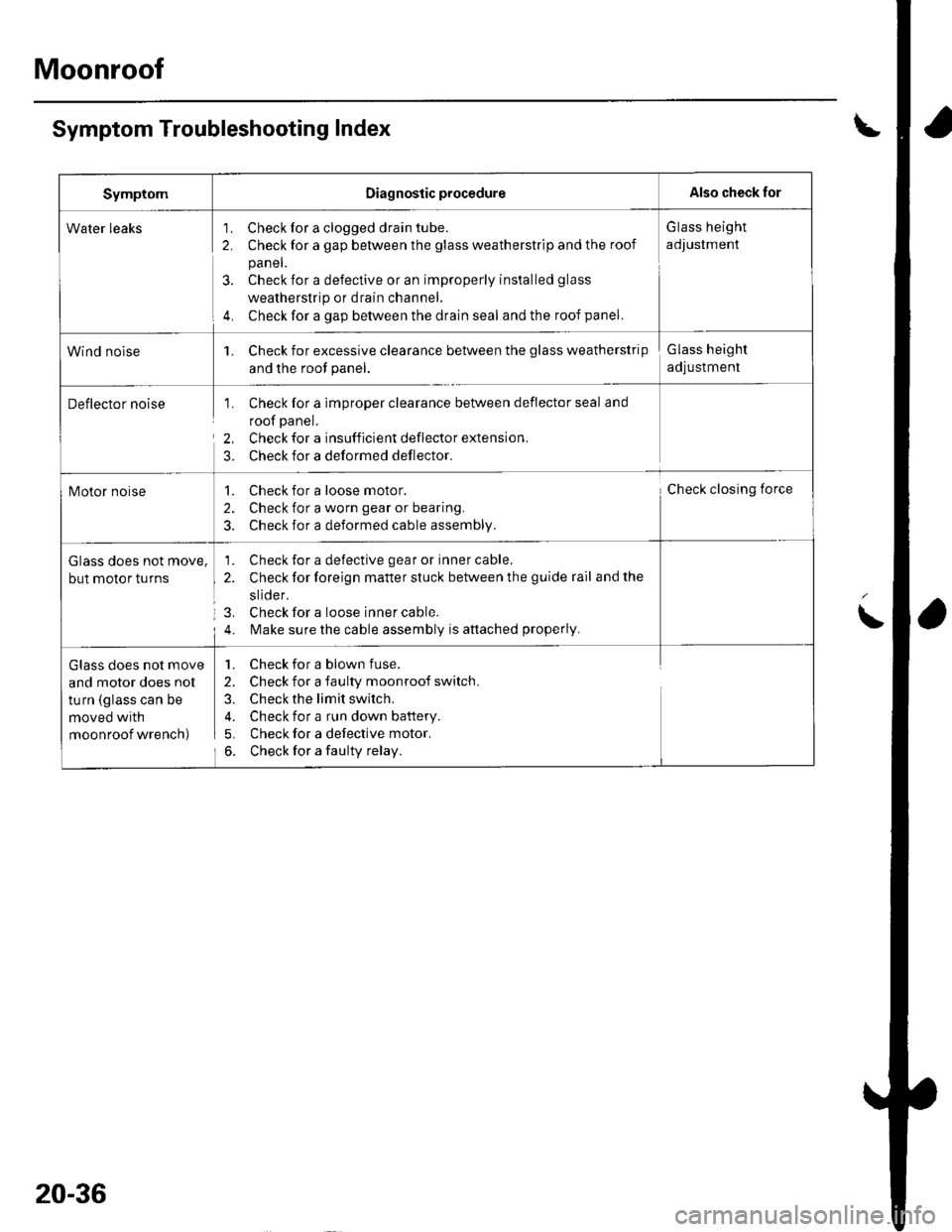

Symptom Troubleshooting Index

SymptomDiagnostic procedureAlso check for

Water leaks'1. Check for a clogged drain tube.

2. Check for a gap between the glass weatherstrip and the roof

panel.

3. Check for a defective or an improperly installed glass

weatherstrip or drain channel.

4. Check for a gap between the drain seal and the roof panel.

G lass height

adJustment

Wind nolse1. Check for excessive clearance between the glass weatherstrip

and the root panel.

Glass height

adjustment

Deflector noise1. Check for a imDrooer clearance between deflector seal and

roof panel.

2, Check for a insufficient deflector extension.

3. Check for a deformed deflector.

Motor noise1. Check for a loose motor.

2. Check for a worn gear or bearing.

3. Check for a deformed cable assembly.

Check closing force

Glass does not move,

but motor turns

1. Check for a defective gear or inner cable.

2. Check for foreign matter stuck between the guide rail and the

slide r.

3. Check for a loose inner cable.

4. l\,4ake sure the cable assembly is attached properly.

Glass does not move

and motor does nol

turn (glass can be

moved with

moonroof wrench)

1. Check for a blown fuse.

2. Check for a faulty moonroof switch.

3. Check the limit switch.

4. Check for a run down battery.

5. Check for a defective motor.

6. Check for a faulty relay.

20-36

Page 696 of 1139

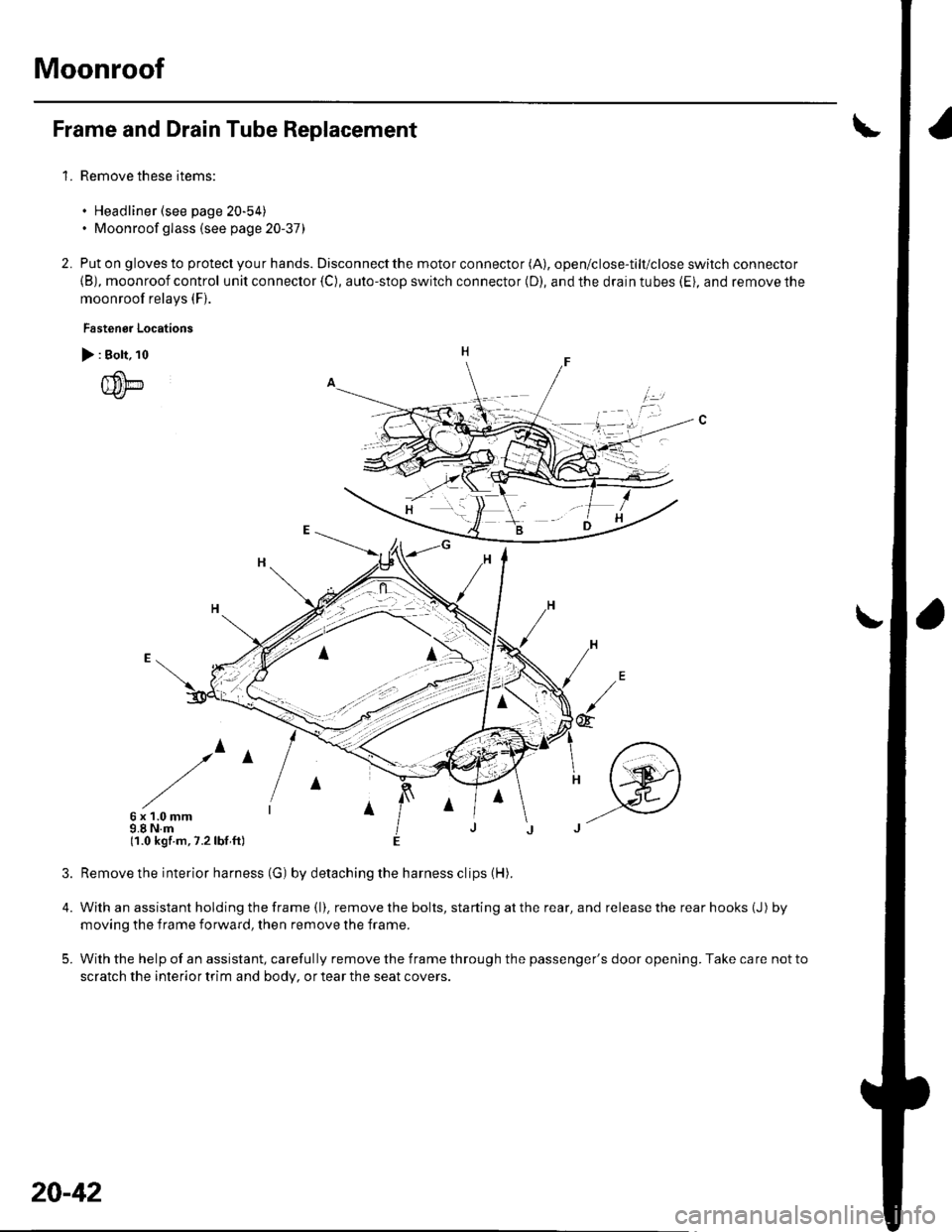

Moonroof

1.

Frame and Drain Tube Replacement

Remove these items:

. Headliner (see page 20-54). Moonroof glass (see page 20-37)

Put on gloves to protect you r hands. Disconnect the motor connector (A), open/close-tilt/close switch connector

{B), moonroof control unit connector {C), auto-stop switch connector (D), and the drain tubes (Ei, and remove the

moonroof relays (F).

Fastenor Locations

> : Bolt, 10

{um

/^

6x1.0mm9.8 N.m(1.0 kgf.m,7.2lbf ft)

4.

5.

2.

irl

@

Remove the interior harness (G) by detaching the harness clips (H).

With an assistant holding the frame (l). remove the bolts, starting at the rear, and release the rear hooks (J) by

moving the f rame forward, then remove the frame.

With the help of an assistant, carefully remove the frame through the passenger's door opening. Take care not to

scratch the interior trim and body, or tear the seat covers.

20-42