Back HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 920 of 1395

Rear Suspension

Hub Bearing Unit Replacement (cont'd)

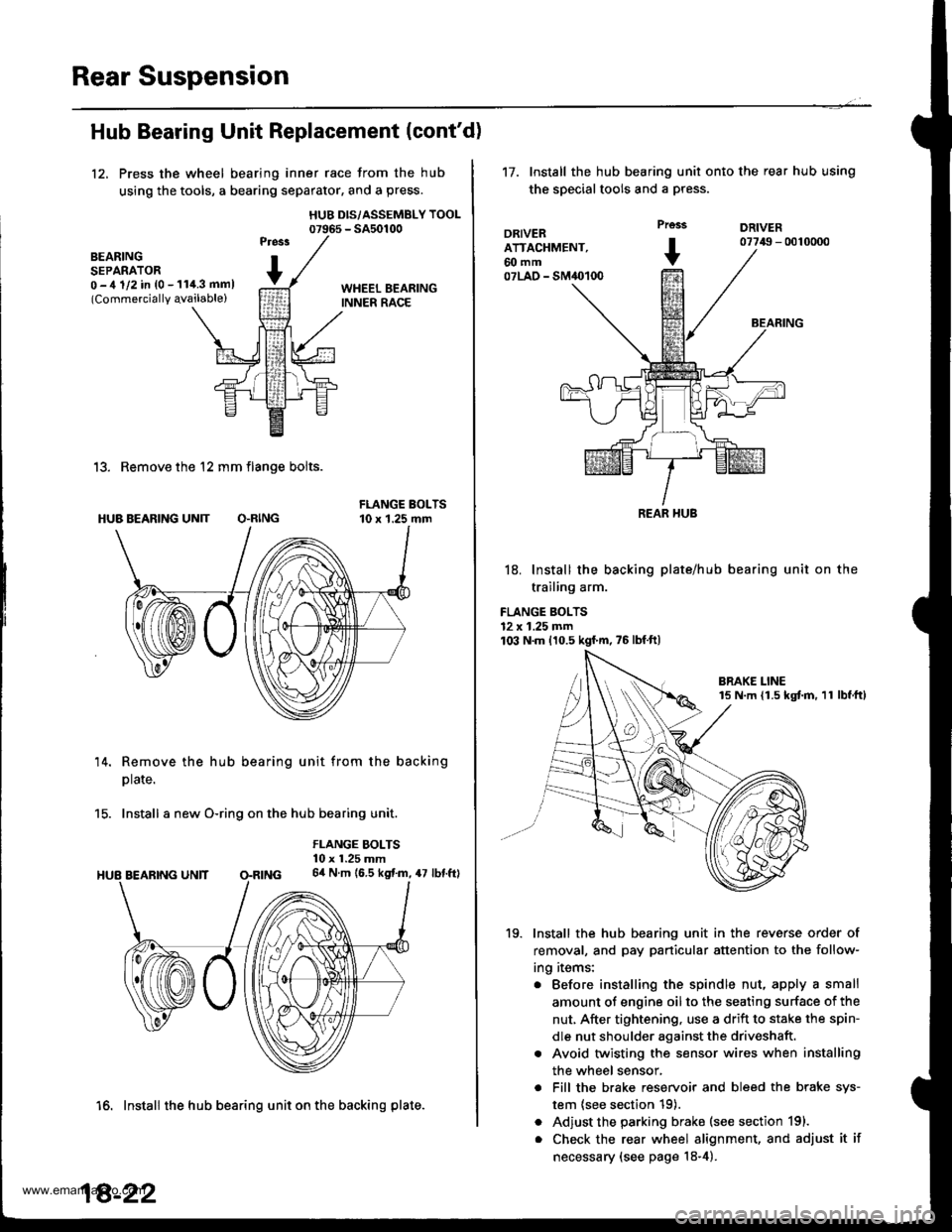

12, Press the wheel bearing inner race from the hub

using the tools, a bearing separator, and a press.

HUB DIS/ASSEMBLY TOOL07965 - SA50100

BEARINGSEPARATOR0 -,t 1/2 in {0 - 11i1.3 mml(Commercially qvailable)

13. Remove the 12 mm flange bolts.

HUB BEARING UN]T O.RING

14. Remove the hub bearing unit from the backing

plate.

15. Install a new O-ring on the hub bearing unit.

FLANGE BOLTS10 x 1.25 mm64 N.m (6.5 kgf.m, 47 lbf.ftl

16. Install the hub bearing unit on the backing plate.

18-22

't7.Install the hub bearing unit onto the rear hub using

the special tools and a press.

DRIVERATTACHMENT,60 mm07LAO - SM40100

Prcss

+

DRIVER07749 - 0010000

BEARING

18. Install the backing plate/hub

trailing arm.

FLANGE BOLTS12 x 1.25 mm103 N.m 110.5 kgf'm,75lbfft)

bearing unit on the

19. Install the hub bearing unit in the reverse order of

removal, and pay particular attention to the follow-

ing items:

. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface of the

nut, After tightening, use a drift to stake the spin-

dle nut shoulder against the driveshaft.

. Avoid twisting the sensor wires when installing

the wheel sensor,

. Fill the brake reservoir and bleed the brake sys-

tem {see section 19).

. Adjust the parking brake (see section 191.

. Check the rear wheel alignment, and adjust it if

necessary (see page 18-4).

REAR HUB

www.emanualpro.com

Page 929 of 1395

Brake Pedal

Pedal Hoight

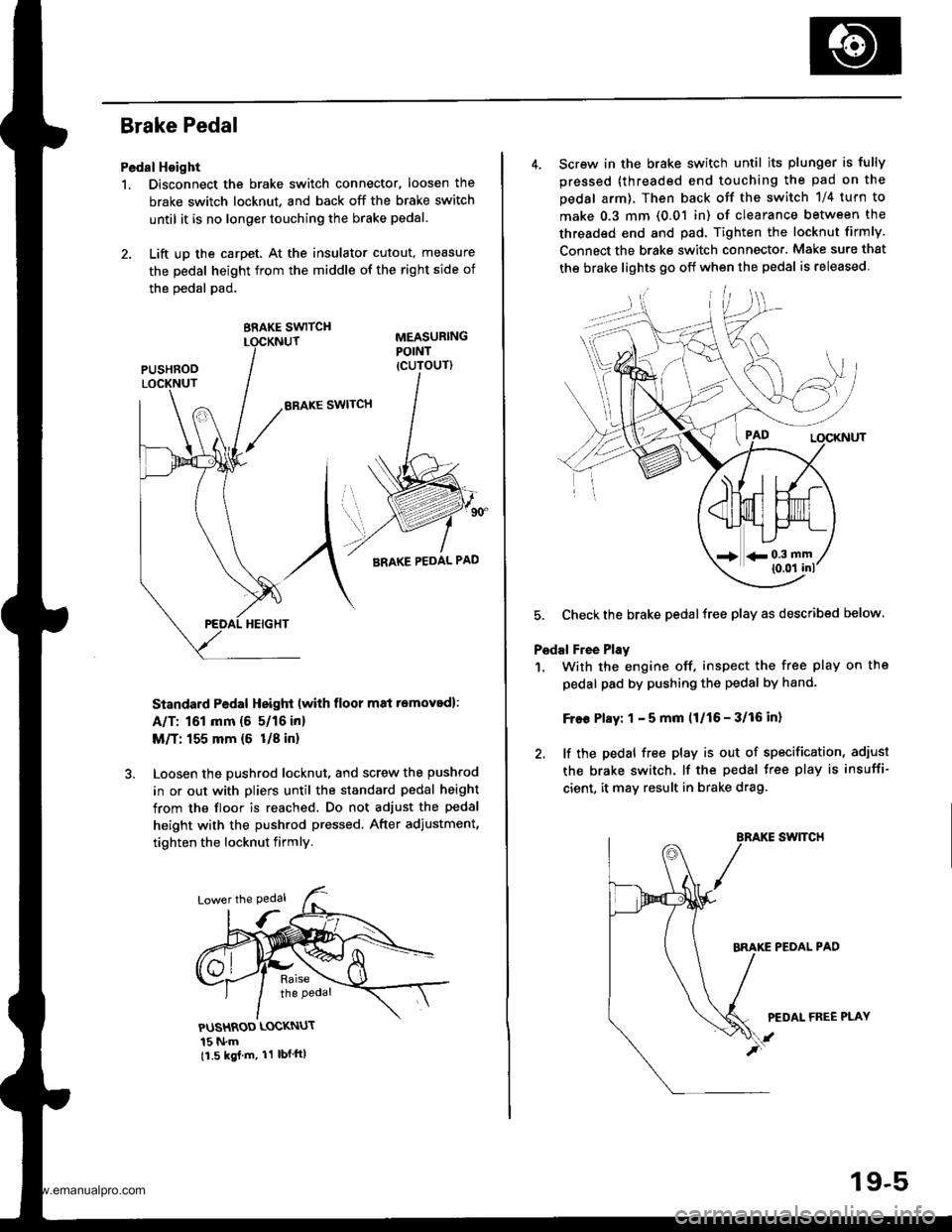

1. Disconnect the brake switch connector, loosen the

brake switch locknut, and back off the brake switch

until it is no longer touching the brake pedal.

2. Lift up the carpet, At the insulator cutout, measure

the pedal height from the middle of the right side of

the oedal pad.

BRAKE SWITCH

ERAKE SWITCH

Standard Pedal Height (with floor m8i removed):

A/T: 161 mm (5 5/16 in)

M/T: 155 mm {6 U8 in}

Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. Do not adjust the pedal

height with the pushrod pressed. After adiustment,

tighten the locknut firmly.

PUSHROD LOCKNUT

15 N.m11.5 kgj m, 11 lbf ftl

4. Screw in the brake switch until its plunger is fully

pressed (threaded end touching the pad on the

pedal arm), Then back otf the switch 1/4 turn to

make 0.3 mm (0.01 in) of clearance between the

threaded end and pad. Tighten the locknut firmly.

Connect the brake switch connecto.. Make sure that

the brake lights 90 off when the pedal is released

5. Checkthe brake pedalfree play as described below

Pedal Free Play

1. With the engine off. inspect the free play on the

pedal pad by pushing the pedal by hand-

Free Play: 1 - 5 mm (1/16 - 3/16 in)

2. lf the pedal free play is out of specification, adiust

the brake switch. lf the pedal free play is insuffi-

cient, it may result in brake drag.

swtTcH

PEOAL PAD

PEDAL FREE PLAY

19-5

www.emanualpro.com

Page 933 of 1395

Front Brake Pads

Inspection and Replacement

1.

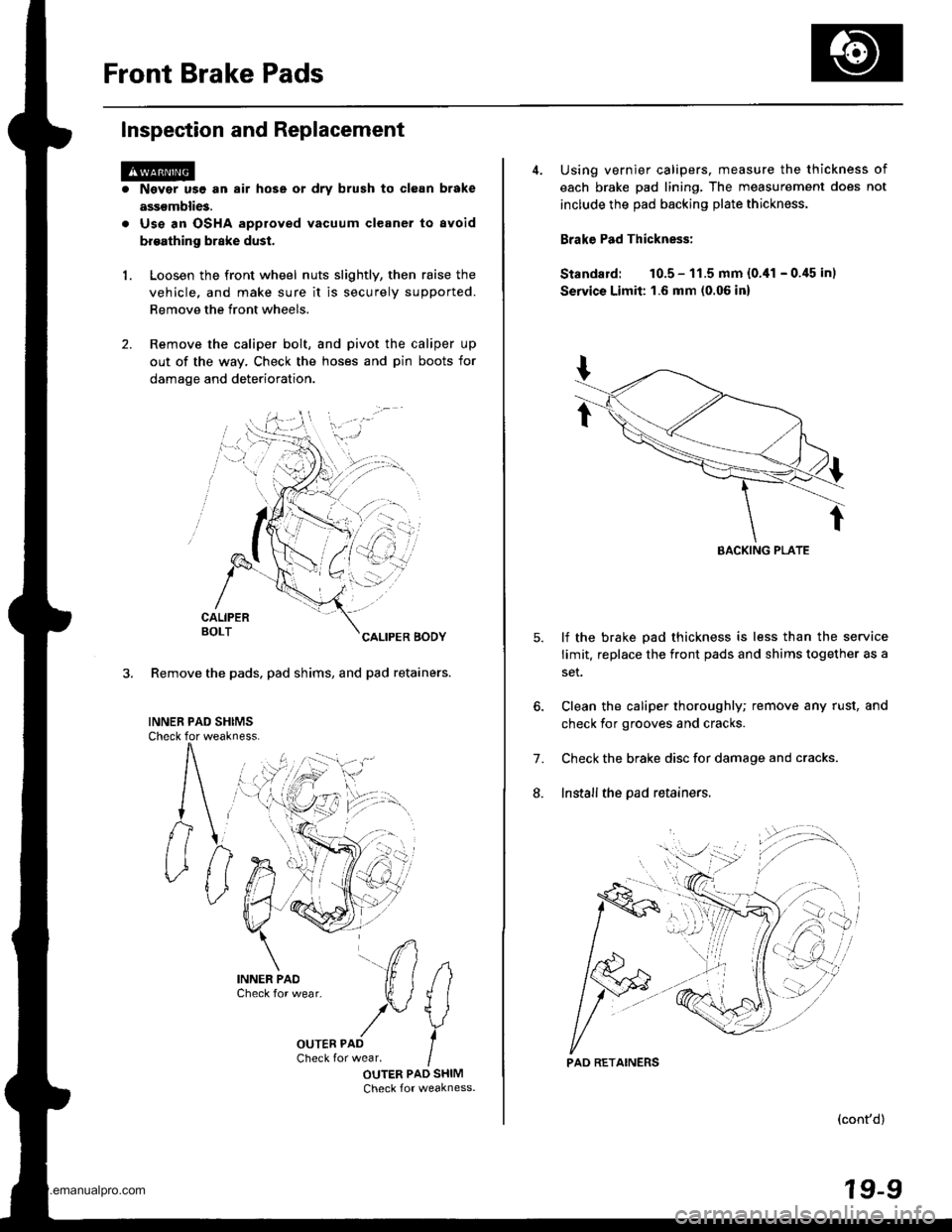

Nsvgr u9e an air hose or dry brush to clean brake

assemblies.

Use an OSHA approved vacuum cleaner to avoid

broathing brake dust.

Loosen the front wheel nuts slightly, then raise the

vehicle, and make sure it is securely supported.

Remove the front wheels.

Remove the caliper bolt, and pivot the caliper up

out of the way. Check the hoses and pin boots for

damage and deterioration.

CALIPERBOLTCALIPER BODY

3. Remove the pads, pad shims, and pad retainers.

INNEB PAD SHIMSCheck for weakness.

#

IOUTER PAD SHIMCheck for weakness.

i)n.

4. Using vernier calipers, measure the thickness of

each brake pad lining. The measurement does not

include the pad backing plate thickness.

Brake Pad Thickness:

Standard: 10.5 - 11.5 mm {0.,11 - 0.45 in)

Servics Limit: 1.6 mm (0.06 in)

lf the brake pad thickness is less than the service

limit. replace the front pads and shims together as a

set.

Clean the caliper thoroughly; remove any rust, and

check for grooves and cracks.

Check the brake disc for damage and cracks.

Install the pad retainers.

7.

L

(cont'd)

19-9

EACKING PLATE

'.'..i

PAD RETAINERS

www.emanualpro.com

Page 934 of 1395

Front Brake Pads

Inspection and Replacement (cont'dl

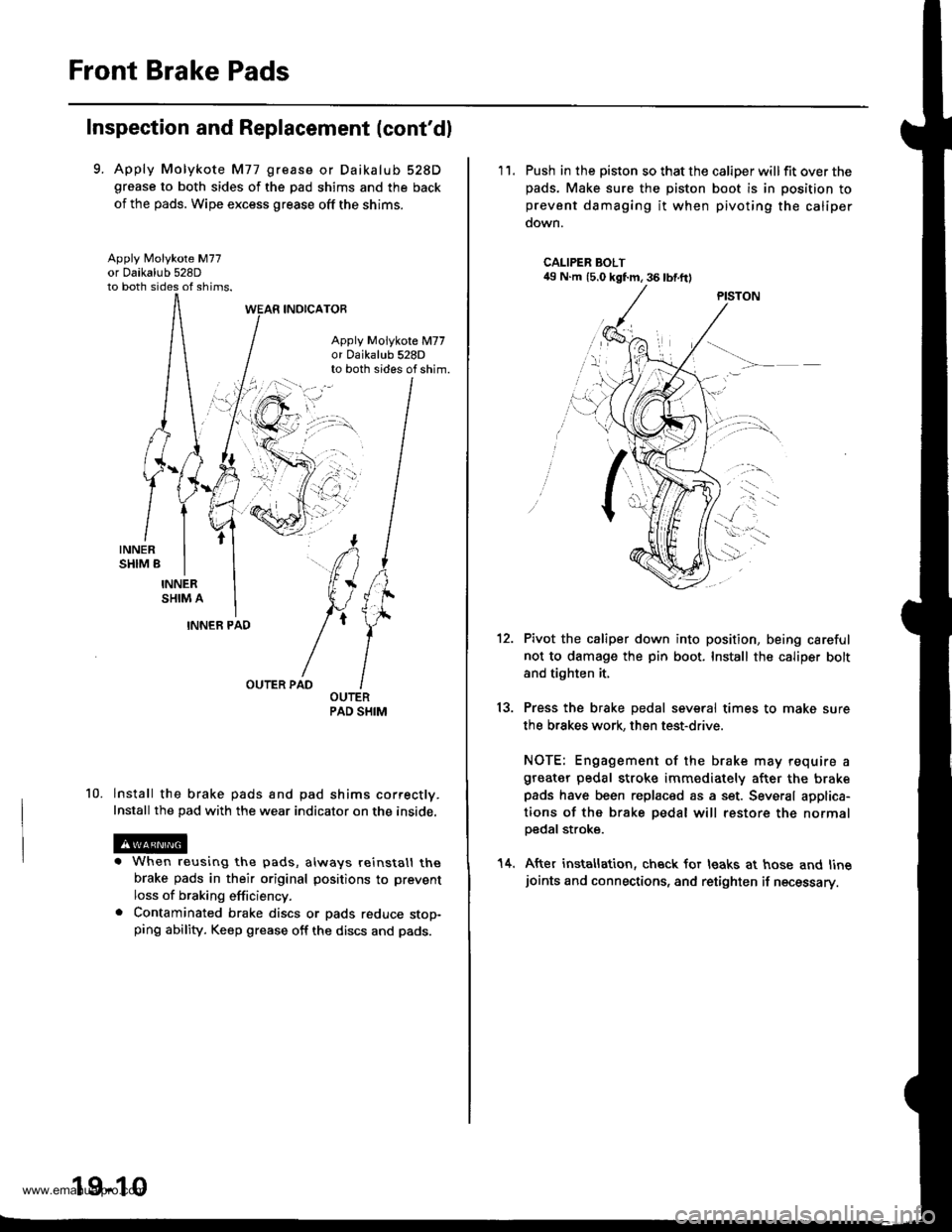

9. Apply Molykote M77 grease or Daikalub 528Dgrease to both sides of the pad shims and the back

of the pads. Wipe excess grease off the shims.

Apply Molykote M77

to both sides of shims.

INOICATOR

Apply Molykote M77or 0aikalub 528Dto both sides of shim.

10.

INNER PAD

OUTER PAD

lnstall the brake pads and pad shims correctly.

Install the pad with the wear indicator on the inside.

. When reusing the pads, always reinstall thebrake pads in their original positions to prevent

loss of braking efficiency.. Contaminated brake discs or pads reduce stop-ping ability. Keep grease off the discs and pads.

19-10

'11. Push in the piston so that the caliper willfit over thepads. Make sure the piston boot is in position toprevent damaging it when pivoting the caliper

down.

CALIPER BOLT49 N.m (5.0 kgf.m, 36 lbf.ftl

13.

Pivot the caliper down into position, being careful

not to damage the pin boot. Install the caliper bolt

and tighten it,

Press the brake pedal several times to make sure

the brakes work, then test-drive.

NOTE: Engagement of the brake may require agreater pedal stroke immediately after the brakepads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normalpedal stroke.

After installation, check for leaks at hose and linejoints and connections, and retighten if necessary.

14.

www.emanualpro.com

Page 939 of 1395

6.

7.

8.

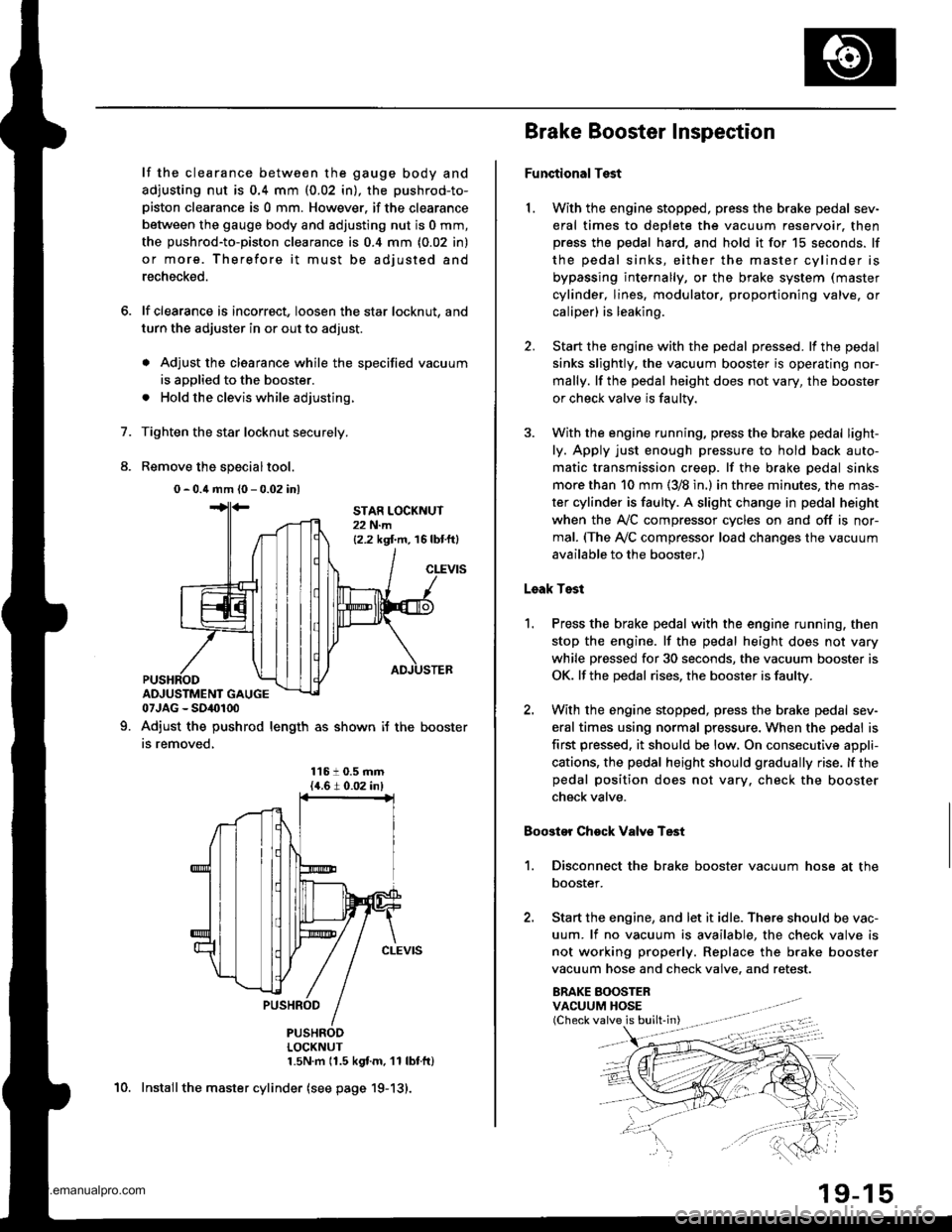

lf the clearance between the gauge body and

adjusting nut is 0.4 mm (0.02 in), the pushrod-to-

piston clearance is 0 mm. However. if the clearance

between the gauge body and adjusting nut is 0 mm,

the pushrod-to-piston clearance is 0.4 mm (0.02 in)

or more. Therefore it must be adjusted and

recheck€d.

lf clearance is incorrect, loosen the star locknut, and

turn the adjuster in or out to adjust.

. Adjust the clearance while the specified vacuum

is applied to the booster.

. Hold the clevis while adjusting.

Tighten the star locknut securely.

Remove the special tool.

0 - 0.4 mm (0 - 0.02 inl

Adjust the pushrod length as shown if the

is removed,

booster

11610.5 mm{4.6 t 0.02 inl

PUSHRODLOCKNUT1.5N.m 11.5 kgf.m. '11 lbtfl)

Install the master cylinder (see page 19-13).

9.

STAR LOCKNUT22 N.m12.2 kgt m. 16 lbtftl

10.

(Check valve is built-in)

Brake Booster Inspection

FunctionalTest

1. With the engine stopped, press the brake pedal sev-

eral times to deplete the vacuum reservoir. thenpress the pedal hard, and hold it for 15 seconds. lf

the pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines, modulator, proportioning valve. or

caliper) is leaking.

2. Start the engine with the pedal pressed. lf the pedal

sinks slightly. the vacuum booster is operating nor-

mally. lf the pedal height does not vary, the booster

or check valve is faultv.

3. With the engine running, press the brake pedal light-

ly. Apply just enough pressure to hold back auto-

matic transmission creep. lf the brake pedal sinks

more than 10 mm (3/8 in.) in three minutes, the mas-

ter cylinder is faulty. A slight change in pedal height

when the Ay'C compressor cycles on and off is nor-

mal. (The Ay'C compressor load changes the vacuum

available to the booster.)

Leak Test

1.Press the brake pedal with the engine running, then

stop the engine. lf the pedal height does not vary

while pressed for 30 seconds, the vacuum booster is

OK. lf the pedal rises, the booster is faulty.

With the engine stopped, press the brake pedal sev-

eral times using normal pressure. When the pedal is

first pressed. it should be low, On consecutive appli-

cations, the pedal height should gradually rise. lf thepedal position does not vary. check the booster

check valve.

Boostor Chock Valve Test

1. Disconnect the brake booster vacuum hose at the

booster.

2. Start the engine, and let it idle. There should be vac-

uum. lf no vacuum is available, the check valve is

not working properly. Replace the brake booster

vacuum hose and check valve. and retest.

ERAKE BOOSTERVACUUM HOSE

www.emanualpro.com

Page 940 of 1395

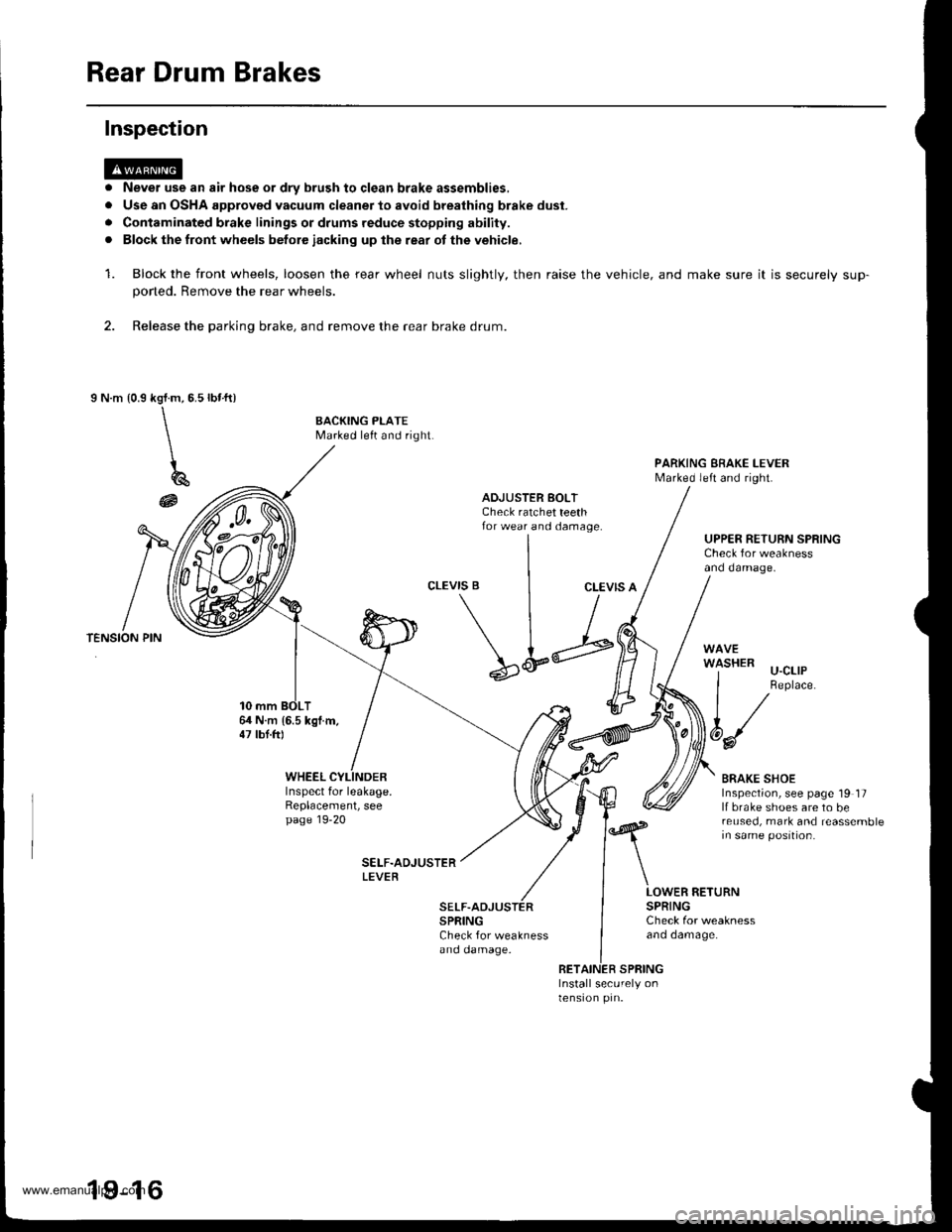

Rear Drum Brakes

Never use an air hose or dry brush to clgan brake assemblies,

Use an OSHA approved vacuum cleaner to avoid breathing brake dust.

Contaminated brake linings or drums reduce stopping ability.

Block the front wheels betore iacking up lhe rear ot the vehicle,

Block the front wheels, loosen the rear wheel nuts slightly, then raise the

poned. Remove the rear wheels.

2. Release the parking brake, and remove the rear brake drum.

I N.m {0.9rbr.ft)kgl.m,5.5

\\

\

196

@

Inspection

a

a

rl

a

1.vehicle, and make sure it is securely sup-

BACKING PLATEMarked left and right.

PARKING EBAKE I-EVERMarked left and right.

ADJUSTER BOLTCheck ratchet teethfor wear and damage.UPPER RETURN SPRINGCheck for weaknessand damage.

CLEVIS BCLEVIS A

64 N.m 16.5 kgl.m,47 lbt.ftl

\L;

SPRINGCheck for weaknessano oamage.

'l-'-' u-cllP

I Replace.

t/

6d/

BRAKE SHOEInspection, see page 19 17lf brake shoes are to bereused, mark and reassemblein same position.

WHEELInspect for leakage.Replacement, seepage 19-20

LOWER RETURNSPRINGCheck for weaknessano oamage.

RETAINER SPRINGInstall securely onlensron prn.

19-16

www.emanualpro.com

Page 943 of 1395

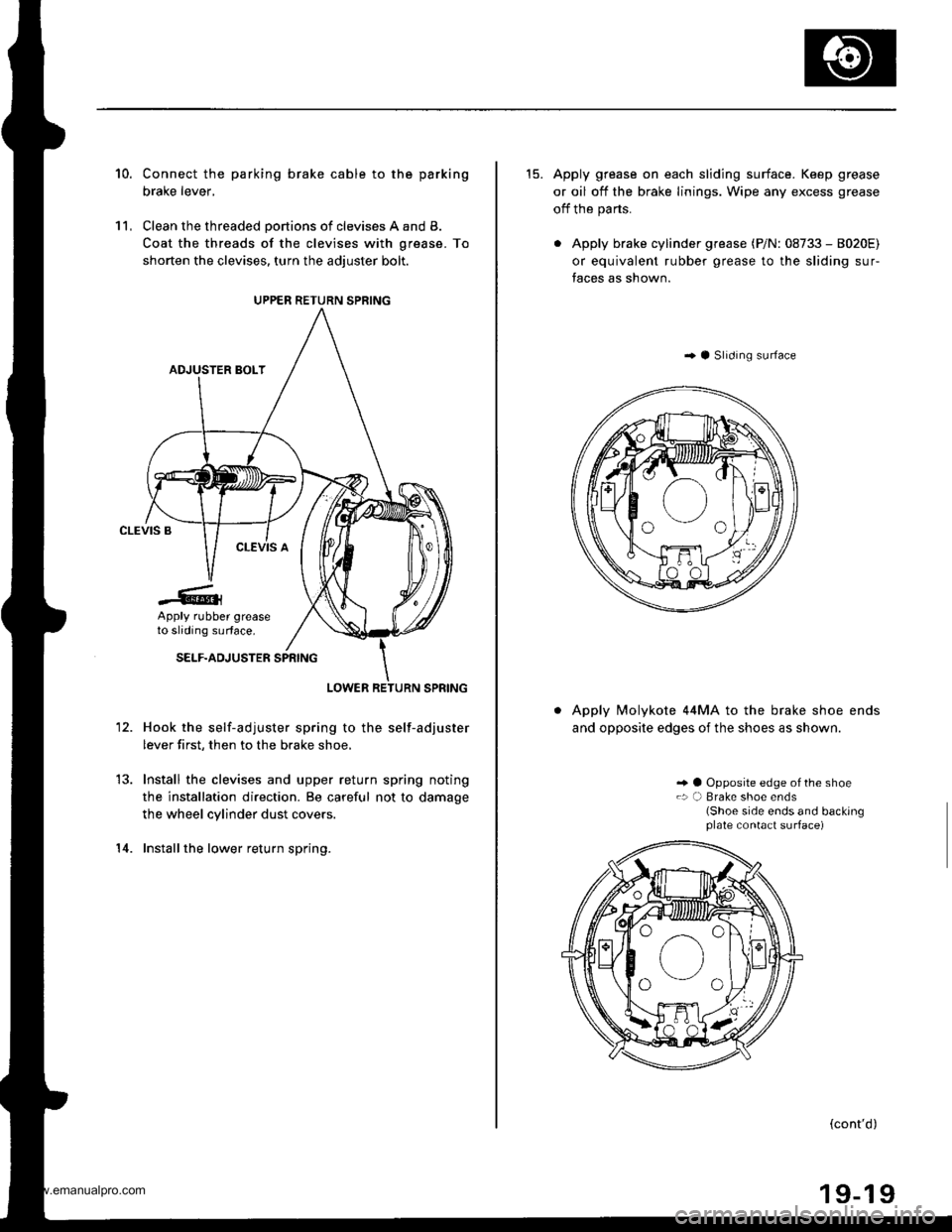

10.

11,

Connect the parking brake cable to the parking

brake lever,

Clean the threaded portions of clevises A and B.

Coat the threads of the clevises with grease. To

shorten the clevises, turn the adiuster bolt.

Hook the self-adjuster spring to the self-adjuster

lever first, then to the brake shoe,

Install the clevises and upper return spring noting

the installation direction. Be careful not to damage

the wheel cylinder dust covers.

Installthe lower return spring.

12.

14.

UPPER RETURN SPRING

Apply rubber greaseto sliding surface.

15. Apply grease on each sliding surface. Keep grease

or oil off the brake linings. Wipe any excess grease

off the parts.

. Apply brake cylinder grease (P/N: 08733 - 8020E)

or equivalent rubber grease to the sliding sur-

faces as shown.

..4 Slrdrng surface

Apply Molykote 44MA to the brake shoe ends

and opposite edges of the shoes as shown.

.. a Opposite edge of the shoe.: a) Brake shoe ends(Shoe side ends and backingplate contact surface)

(cont'd)

www.emanualpro.com

Page 944 of 1395

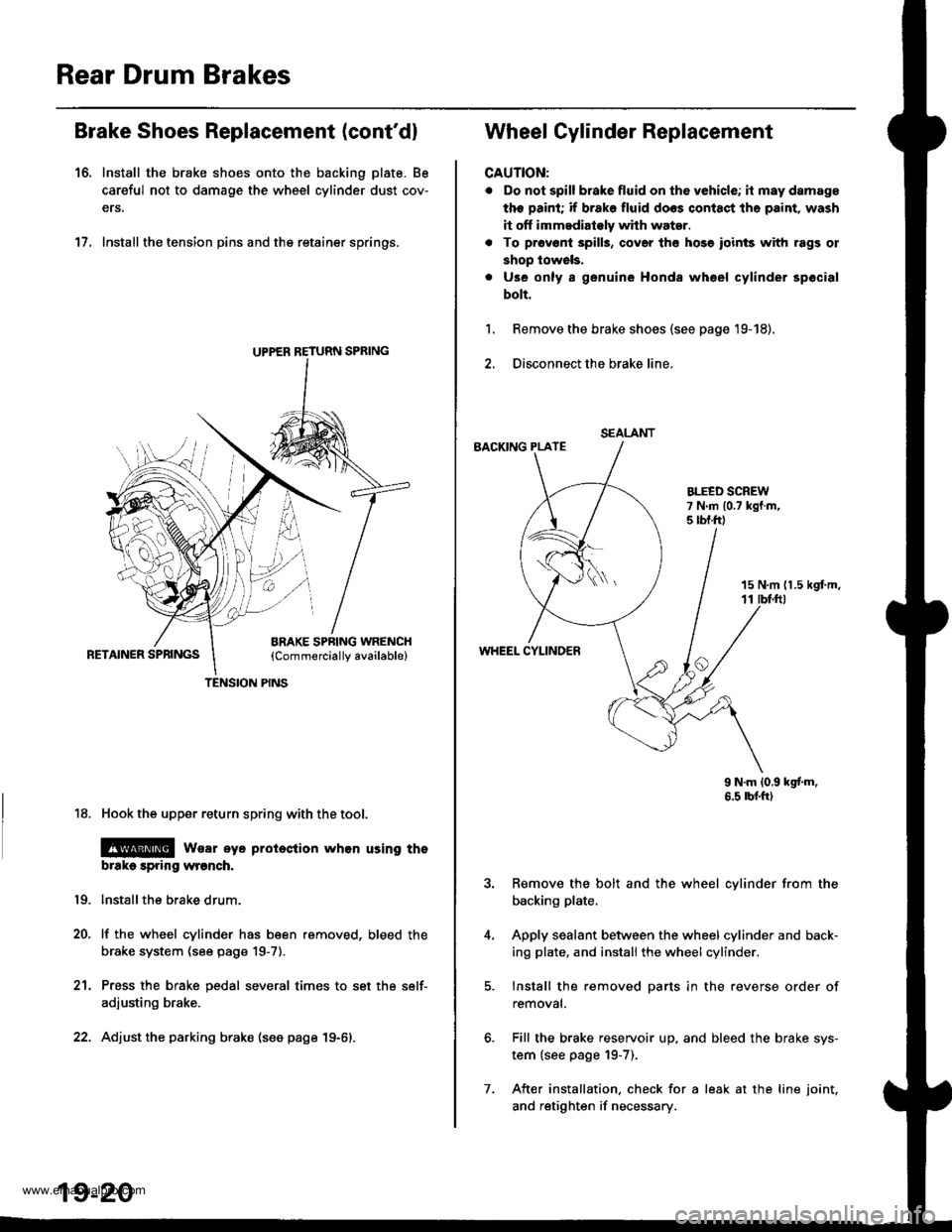

Rear Drum Brakes

Brake Shoes Replacement (cont'd)

16. Install the brake shoes onto the backing plate. Be

careful not to damage the wheel cylinder dust cov-

ers.

17. Install the tension pins and the retainer springs.

18. Hook the upper return spring with the tool.

@ wsar eye proieclion whon using tho

brtko spring wronch.

lnstallthe brake drum.

lf the wheel cylinder has been removed, bleed the

brake system (see page 19-7).

Press the brake pedal several times to set the self-

adjusting brake.

Adjust the parking brako (see page 19-6).

19.

20.

21.

UPPER RETURN SPRING

TENSION PINS

19-20

7.

SEALANT

Wheel Cylinder Replacement

CAUTION:

. Do not spill brake fluid on th6 vehicle; it may damage

the paint; if brako fluid doos contact tho paint, wash

it off immedialely whh water.

. To pr6v6ni 3pills, cov6r th6 hose ioinls with rags ol

shop lowels,

. Use only a genuine Honda whoel cylinder spocial

bolt.

Remove the brake shoes {see page '19-18).

Disconnect the brake line,

BACKING PLATE

1.

15 N,m 11.5 kgt m,11 tbf.ftl

WHEEL CYLINDER

9 N.m 10,9 kgf'm.6.5 rbtft)

Remove the bolt and the wheel cylinder from the

backing plate.

Apply sealant between the wheel cylinder and back-

ing plate, and install the wheel cylinder.

Install the removed parts in the reverse order of

removal.

Fill the brake reservoir up. and bleed the brake sys-

tem {see page 19-7).

After installation. check for a leak at the line joint.

and retighten if necessary.

www.emanualpro.com

Page 947 of 1395

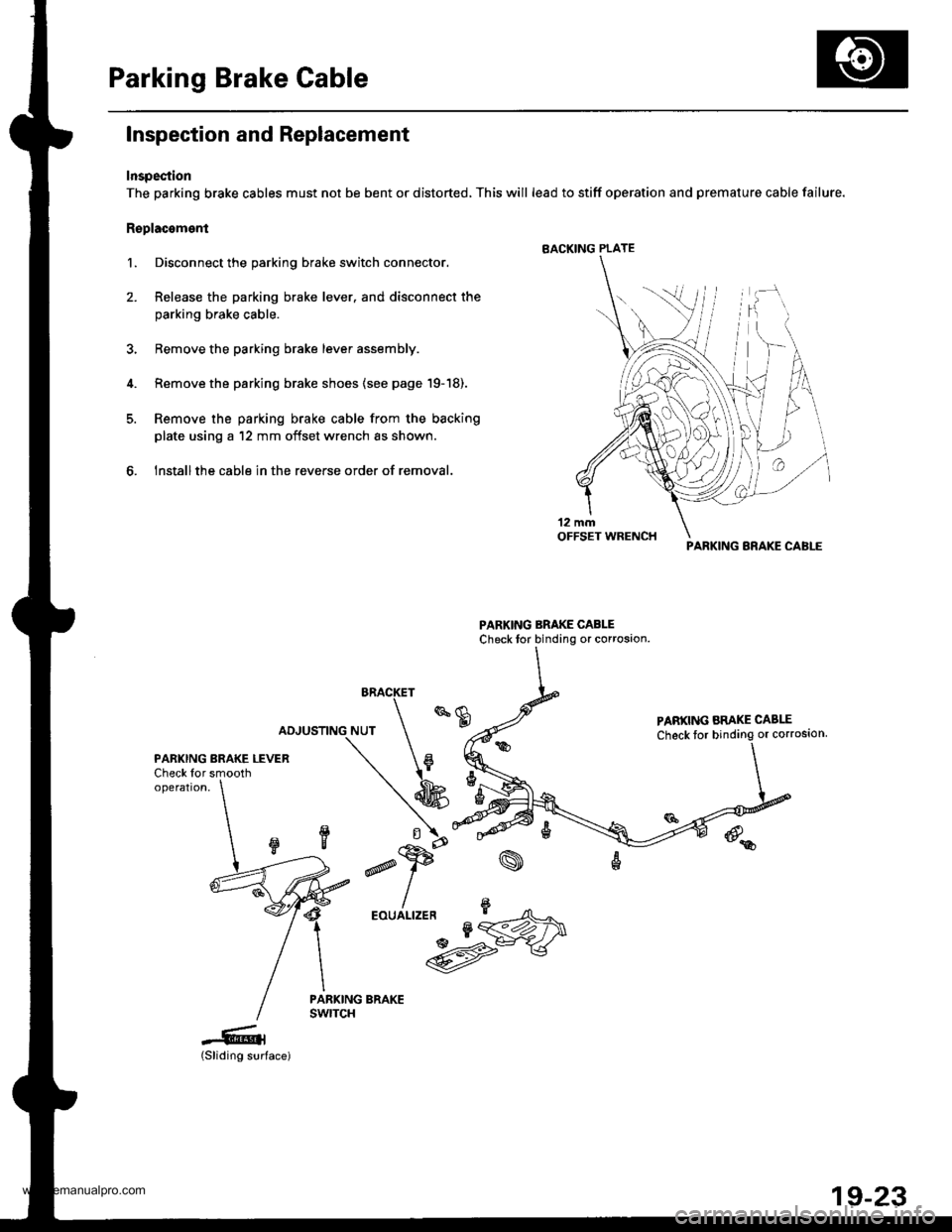

Parking Brake Cable

Inspection and Replacement

Inspection

The parking brake cables must not be bent or distorted, This will lead to stiff operation and premature cable failure.

Replacoment

l. Disconnect the parking brake switch connector.

2. Release the parking brake lever. and disconnect the

parking brake cable.

3, Bemove the parking brake lever assembly.

4. Remove the parking brake shoes {see page '19-18).

5. Remove the parking brake cable from the backing

plate using a '12 mm offset wrench as shown.

6. Installthe cable in the reverse order of removal.

BRACKET

PABKING ARAKE CABLE

Check toror corroston,

PARKING BRAKE LEVERCheck for smoothoperation,

d

,"u/n*UM

-6l(Sliding surface)

PARKING BRAKE CABI-E

19-23

www.emanualpro.com

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com