HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 741 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Oil Seal Replacement

1. Remove the oil seal from the transmission housing.

OIL SEALReplace.

Remove the oil seal from the torque converter

housing.

OIL SEALReplace.TOROUE CONVERTERHOUSING

-.].

3. lnst HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Oil Seal Replacement

1. Remove the oil seal from the transmission housing.

OIL SEALReplace.

Remove the oil seal from the torque converter

housing.

OIL SEALReplace.TOROUE CONVERTERHOUSING

-.].

3. lnst](/img/13/5778/w960_5778-740.png)

Oil Seal Replacement

1. Remove the oil seal from the transmission housing.

OIL SEALReplace.

Remove the oil seal from the torque converter

housing.

OIL SEALReplace.TOROUE CONVERTERHOUSING

-.].

3. lnstall the oil seal in the transmission housing using

the special tools as shown.

DRIVER077a9 - 0010000

ATTACHMEMT079r? - slx[ax)

4.Install the oil seal in the torque converter housing

using the specialtools as shown.

14-225

www.emanualpro.com

Page 742 of 1395

Differential

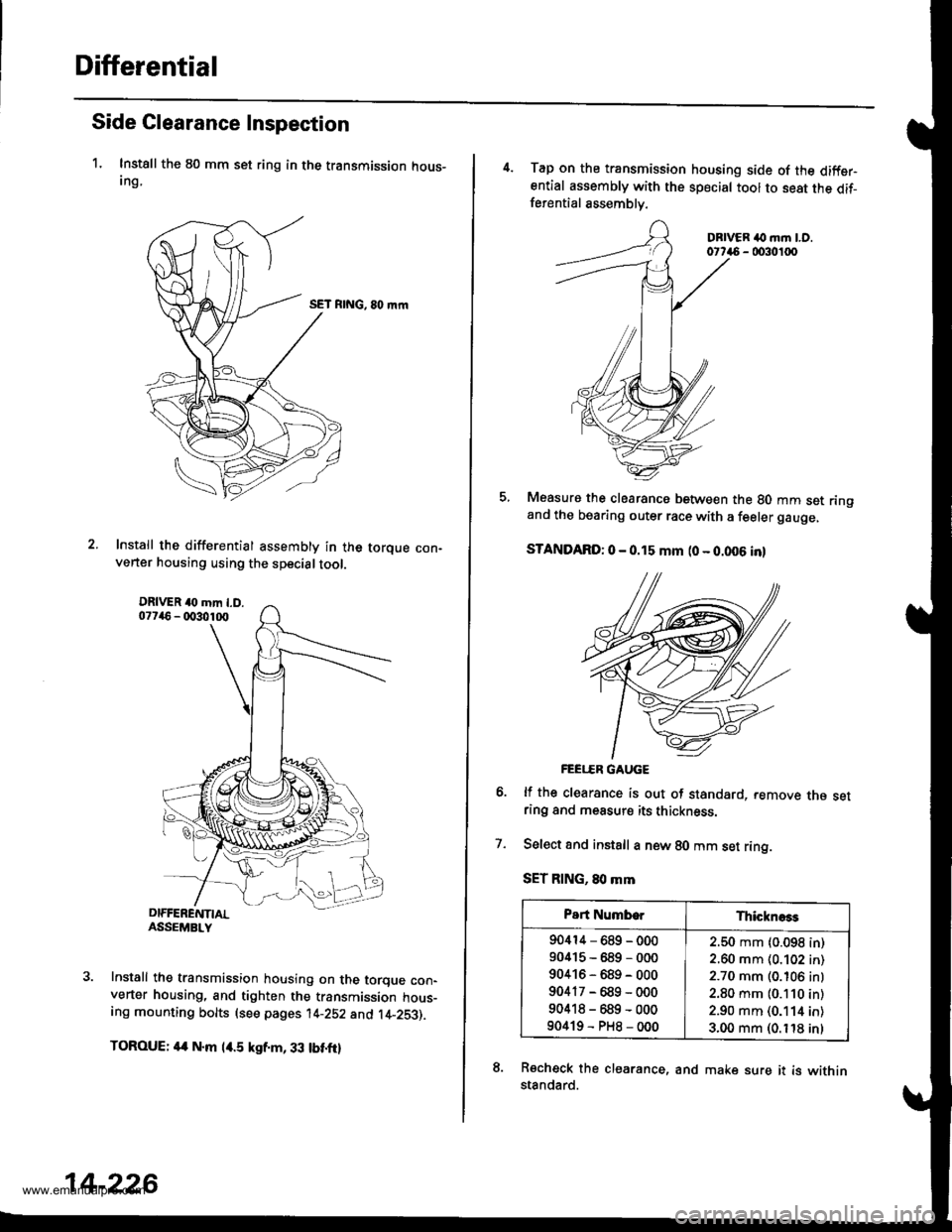

Side Clearance Inspection

1. Instsll the 80 mm set ring in the transmission hous-Ing,

SET RING, 80 mrn

Install the differential assembly in the torque con-verter housing using the specialtool.

Install the transmission housing on the torque con-verter housing, and tighten the transmission hous-ing mounting bolts (see pages 14-252 and t4-253).

TOROUE: 4a N.m l/r.5 kgf.m, 33 tbt.ftl

14-226

4. Tap on the transmission housing side of the diffsrential assembly with the special tool to seat the dif-ferential assemblv.

DBIVER ilo m.n LO.0t746 - 0030100

Measure the clearancs between the 80 mm set ringand the bearing outer race with a feeler gauge,

STANDARD: 0 - 0.15 mm (0 - 0.006 inl

FEEI..ER GAUGE

lf the clearance is out of standard, remove rne setring and measurs its thickness.

Select and instsll a new 80 mm set ring.

SET RING, 80 mm

Recheck the clearance, and make sure it is withinstandard.

7.

Part NumborThicknoss

90414-689-000

90415-689-000

90416-689-000

90417-689-000

90418-689-000

90419-PH8-000

2.50 mm (0.098 in)

2.60 mm (0.102 in)

2.70 mm (0.106 inl

2.80 mm (0.110 in)

2.90 mm (0.114 in)

3.00 mm (0. t'18 inl

www.emanualpro.com

Page 743 of 1395

Transmission Housing Bearings

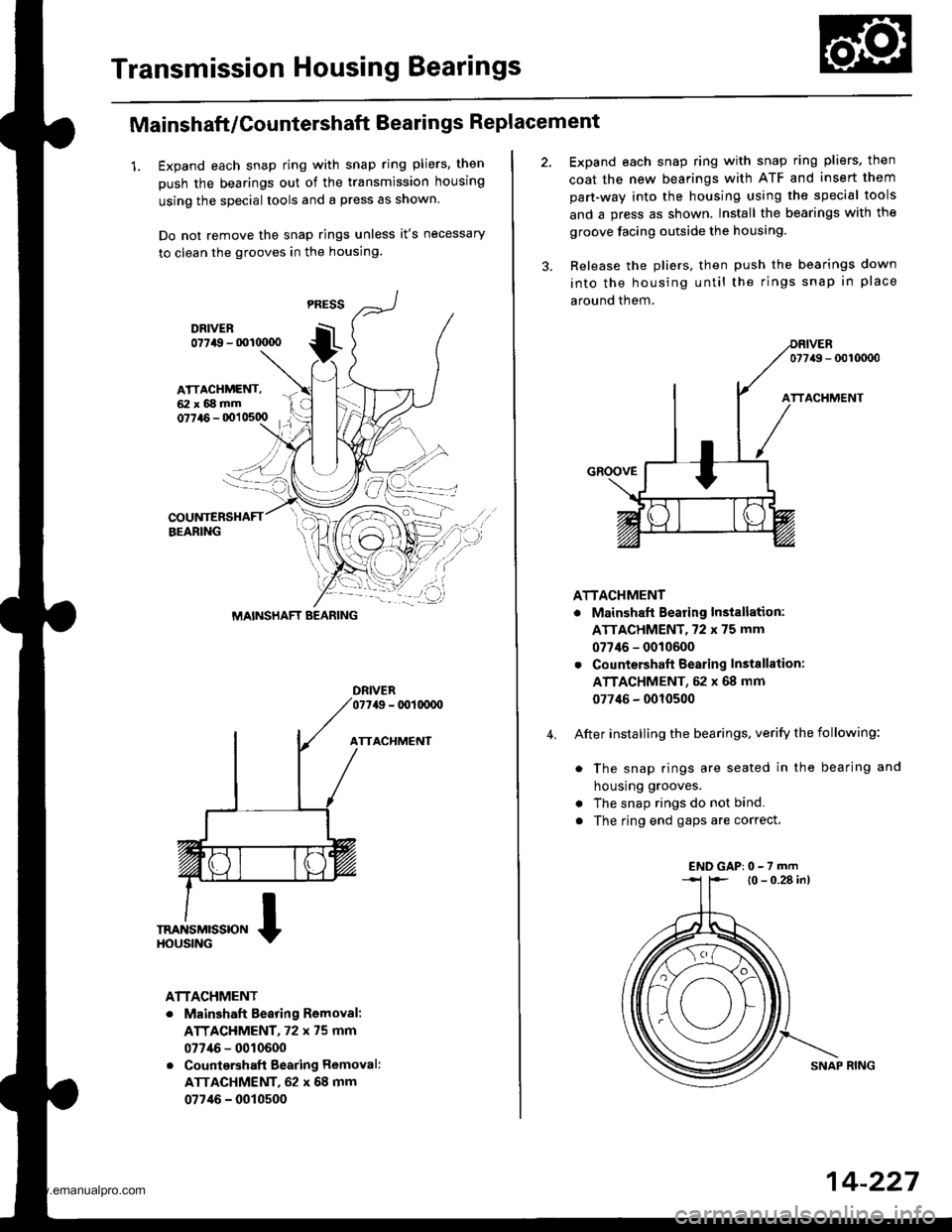

Mainshaft/Countershaft Bearings Replacement

1. Expand each snap ring with snap ring pliers, then

push the bearings out of the transmission housing

using the special tools and a press as shown.

Do not remove the snap rings unless it's necessary

to clean the grooves in the housing.

DFIVER077a9 - 001(xx)o

ATTACHMENT

ATTACHMENT

. Mainshaft Bearing Romoval:

ATTACHMENT, 72 x 75 mm

077/16 - 0010600

. Countqrshaft Bearing Removal:

ATTACHMENT, 62 x 68 mm

07746 - 0010500

MAINSHAFT BEARING

4.

Expand each snap ring with snap ring pliers, then

coat the new bearings with ATF and insert them

part-way into the housing using the special tools

and a press as shown. Install the bearings with the

groove facing outside the housing.

Release the pliers, then push the bearings down

into the housing until the rings snap in place

around them.

077/49 - 0010000

ATTACHMENT

. Mainshaft Bearing Installation:

ATTACHMENT,72 x 75 mm

07746 - 0010600

. Countershaft Bearing Instsllation:

ATTACHMENT, 52 x 68 mm

077'16 - 0010500

After installing the bearings, verify the following:

. The snap rings are seated in the bearing and

housrng grooves.

. The snap rings do not bind.

. The ring end gaps are correct,

l0 - 0.28 in)

SNAP RING

ENDGAP:0-7rnm

14-227

www.emanualpro.com

Page 744 of 1395

Transmission Housing Bearings

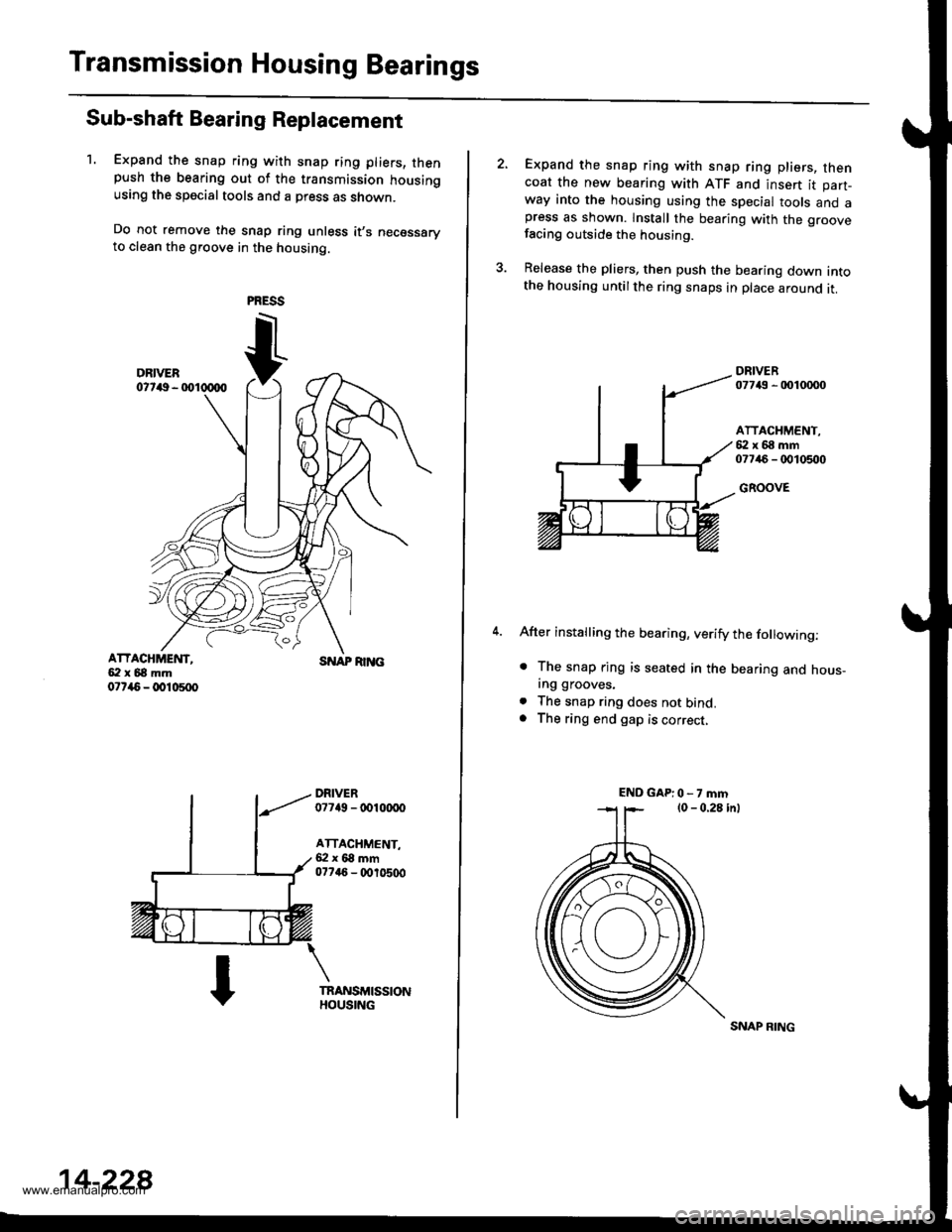

Sub-shaft Bearing Replacement

1. Expand the snap ring with snap ring pliers, thenpush the bearing out of the transmission housingusing the special tools and a press as shown.

Do not remove the snap ring unless it,s necessaryto clean the groove in the housing.

ATTACHMEI{T,5:l x 68 mm07r{5 - @10500

SNAP RI]TG

DRIVER07749 - tDl(xx)o

ATTACHMENT,6:l x 68 mm077a6 - (X,r0500

14-228

SNAP RING

Expand the snap ring with snap ring pliers, thencoat the new bearing with ATF and insert it part-way into the housing using the special tools and apress as shown. lnstall the bearing with the groovefacing outside the housing.

Release the pliers, then push the bearing down intothe housing untilthe ring snaps in place around it.

DRIVER07743 - 0010mo

ATTACHMENT,{i:l x 68 mm07746 - 0010500

GROOVE

After installing the bearing, verify the following:

. The snap rjng is seated in the bearing and hous_ing grooves.

. The snap ring does not bind.. The ring end gap is correct,

ENDGAP:0-7mm

www.emanualpro.com

Page 745 of 1395

Torque Gonverter Housing Bearings

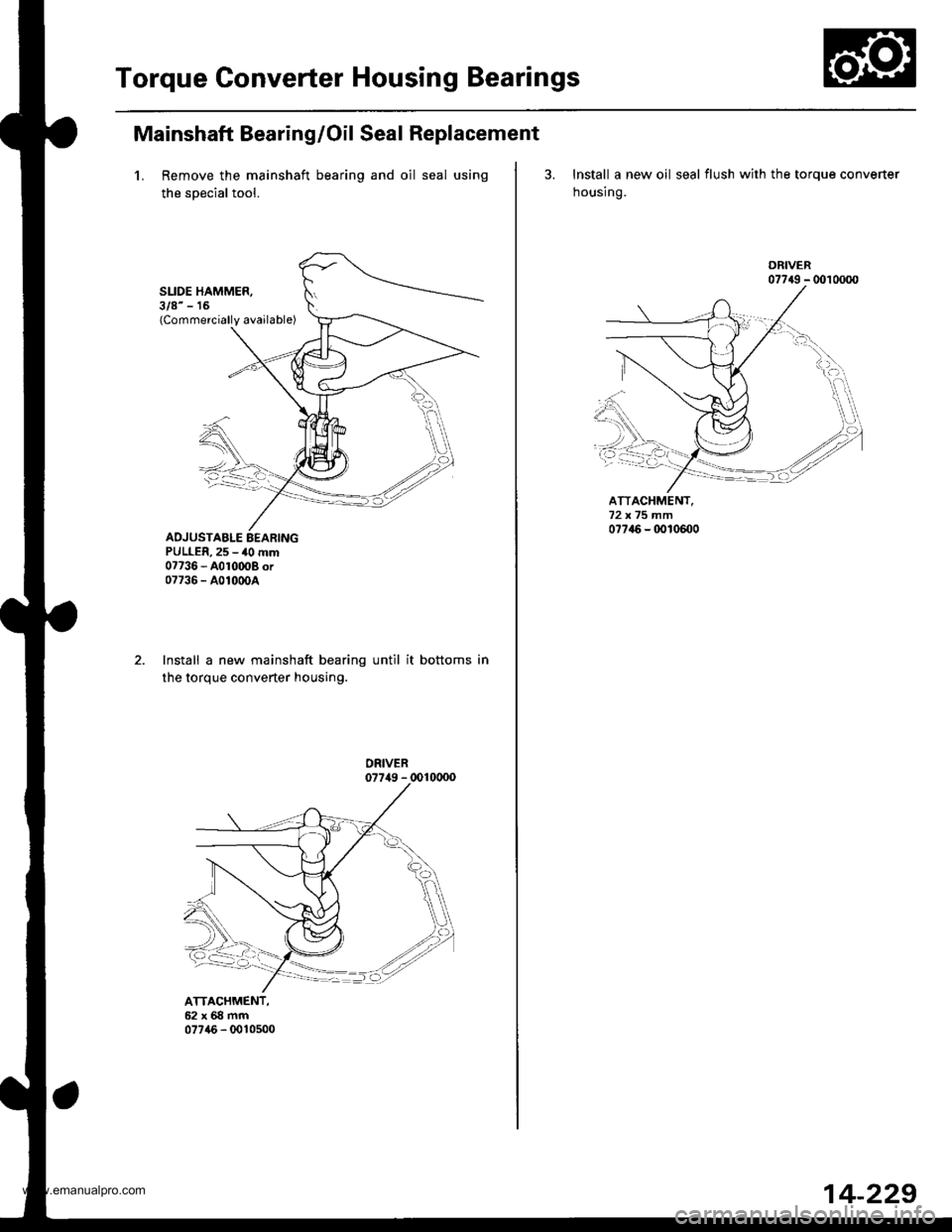

Mainshaft Bearing/Oil Seal Replacement

1. Remove the mainshaft bearing and oil seal using

the soecial tool.

SLIDE HAMMER,3/8" - 16(Commercially available)

ADJUSTABLE EEARINGPULLER,25 - 40 mm07736 - A010008 or07736 - A01000A

ATTACHMENT,62x68mm07746 - 0010500

Install a new mainshaft bearing until it bottoms in

the torque converter housing.

3. Install a new oil seal flush with the torque converter

housing.

ATTACHMENT,

07?46 - 0010m0

07749 - 0010000

14-229

www.emanualpro.com

Page 746 of 1395

Torque Gonverter Housing

BearingsGontrol Lever Assembly

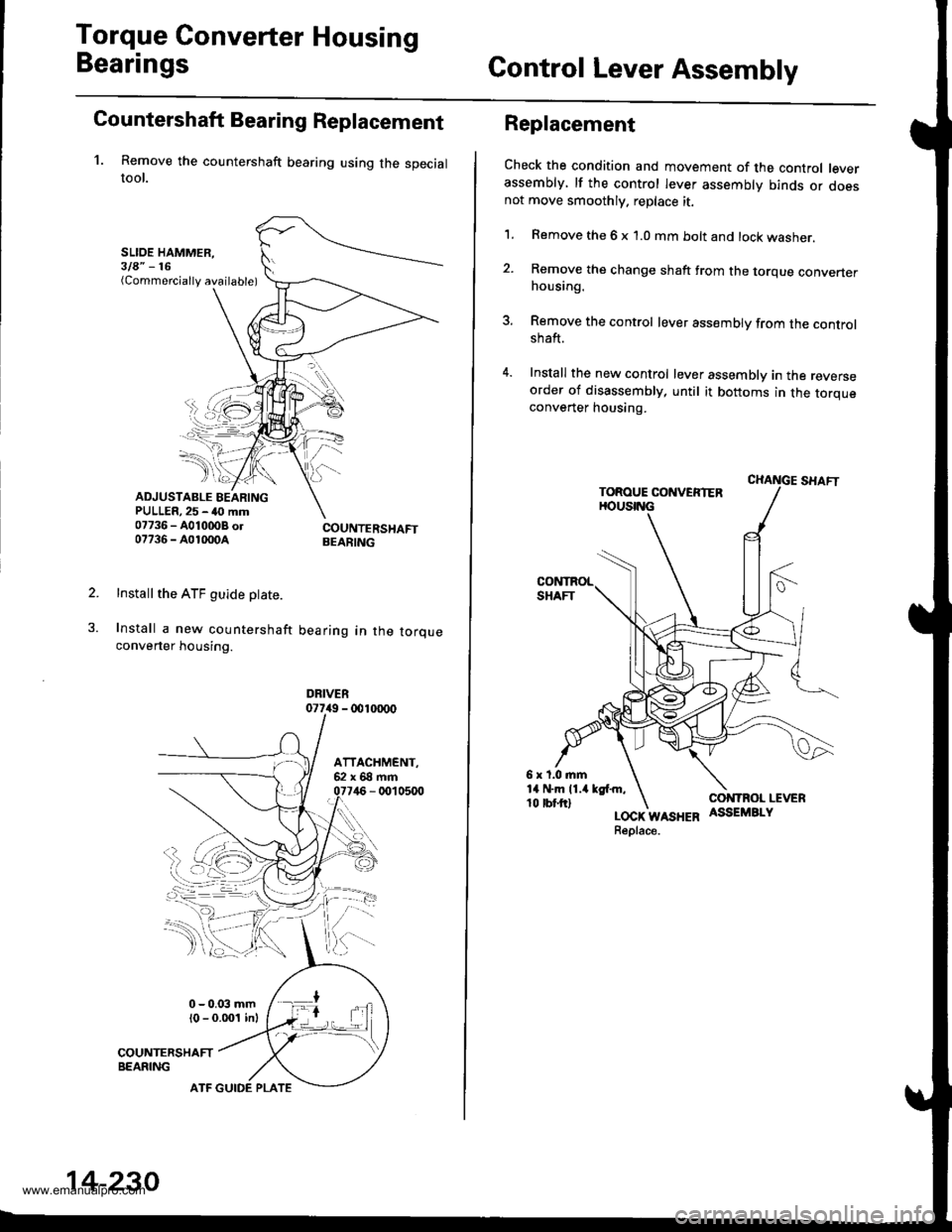

Countershaft Bearing Replacement

1. Remove the countershaft bearing using the specialtool.

SLIOE HAMMER,3la" -16(Commercially available)

ADJUSTABLE BEARINGPULLER,25 - 40 mm07736 - A0100OB ol07736 - A01m0A

Install the ATF guide ptate.

Install a new countershaft

converter housing.

COUNTERSHAFTBEARING

bearing in the torque

DRIVER077i19 - 001m00

14-230

ATF GUIDE PLATE

Replacement

Check the condition and movement of the control leverassembly, lf the control lever assembly binds or doesnot move smoothly. replace it.

1. Remove the 6 x 1.0 mm bolt and lock washer.

2. Remove the change shaft trom the torque converterhousing.

3. Remove the control lever assembly from the controlshaft.

4. Install the new control lever assembly in the reverseorder of disassembly, until it bottoms in the torqueconverter housing.

LOCK WASHERReplace.

www.emanualpro.com

Page 747 of 1395

Reverse ldler GearPark Stop

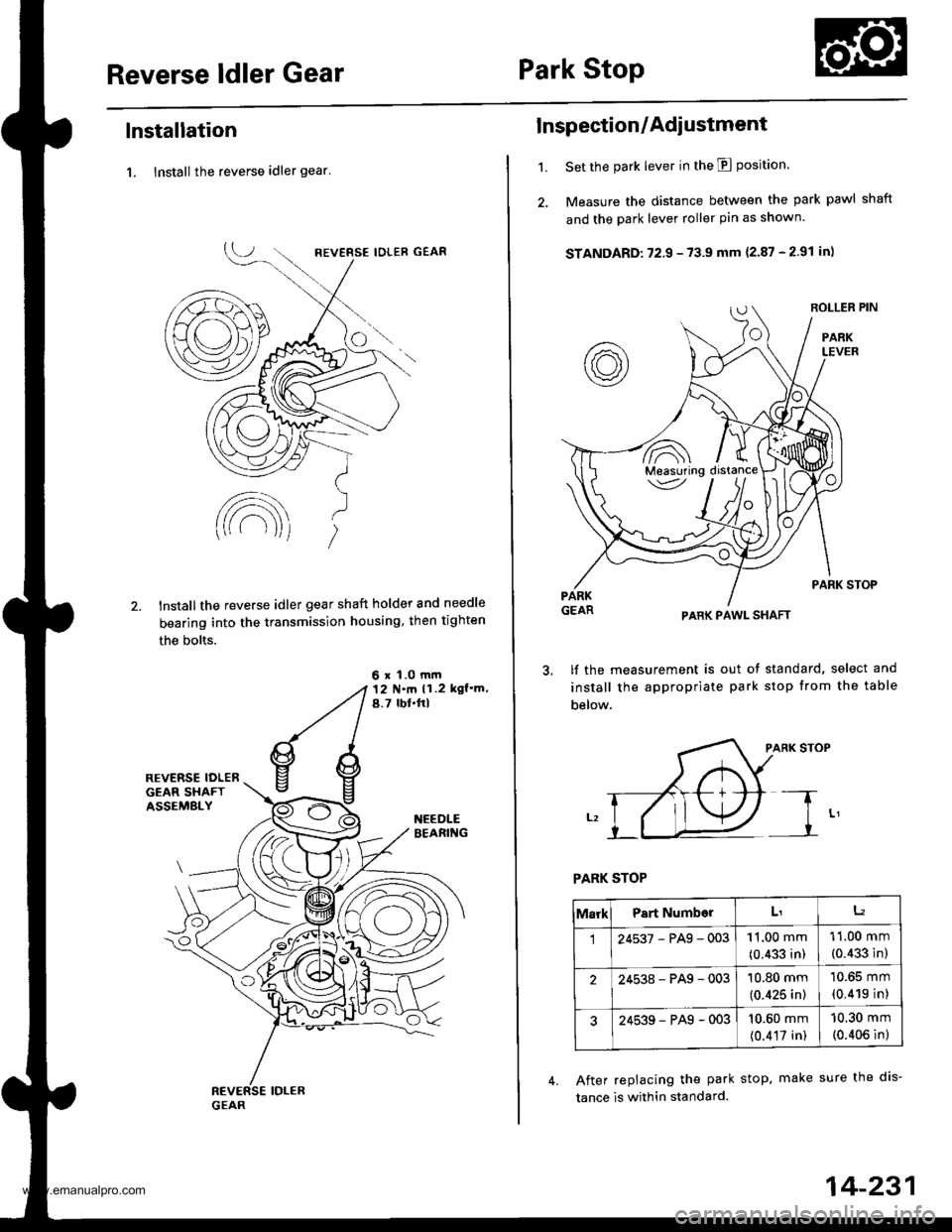

lnstallation

1. lnstall the reverse idler gear'

lnstallthe reverse idler gear shaft holder and needle

bearing into the transmission housing, then tighten

the bolts.

6 x 1.0 mm12 N.ft ll.2 kgl']n,a.7 rbl.frl

't.

Inspection/Adi ustment

Set the park lever in the E position.

Measure the distance between the park pawl shaft

and the park lever roller pin as shown.

STANDARD: 72.9 - 73.9 mm {2.87 - 2.91 in)

PARK STOP

PARK PAWL SHAFT

lf the measurement is out of standard, select and

install the appropriate park stop from the table

below.

PARK STOP

PARK STOP

After replacing the park stop. make sure the dis-

tance is within standard.

',.�A\

Measuring /

MarkPart NumberLtL2

124537-PAg-00311.00 mm

(0.433 in)

11.00 mm

(0.433 in)

24538-PAg-00310.80 mm

(0.425 in)

10.65 mm

(0.419 in)

24539-PAg-00310.60 mm

(0.417 in)

10.30 mm

(0.406 in)

14-231

www.emanualpro.com

Page 748 of 1395

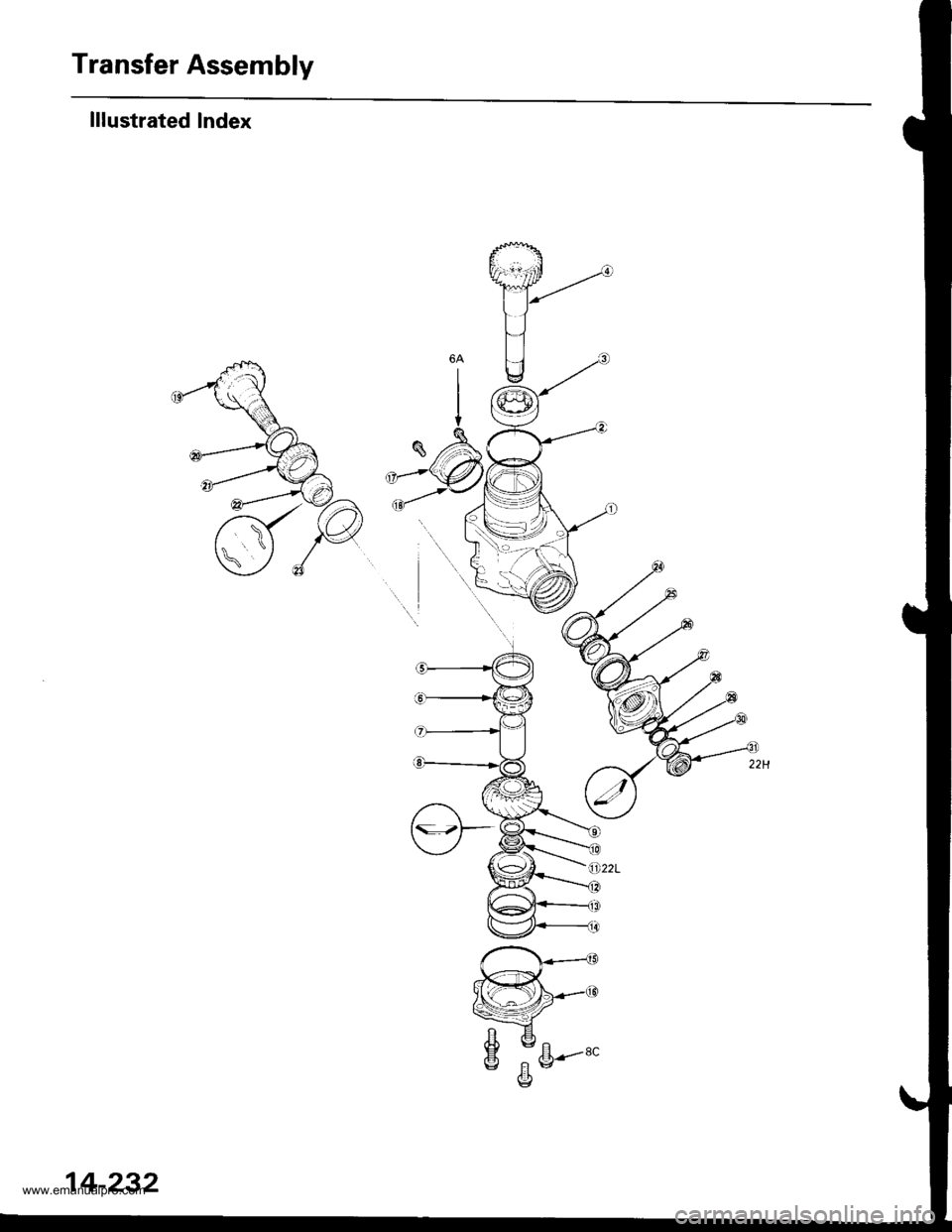

Transfer Assembly

lllustrated Index

www.emanualpro.com

Page 749 of 1395

O TRANSFER HOUSING

O o-RING Replace.

O TRANSFER HOUSING ROLLER BEARING

@ TRANSFER SHAFT

O TAPERED ROLLER BEARING OUTER RACE

@ TAPERED ROLLER BEARING

O TRANSFER SHAFT COLLAR

@ THRUST SHIM, 25 mm Selective part

€) TRANSFER DRtvE GEAR (HYPoID GEAR}

@ coNtcAL SPRtNG WASHER Reptace,

@ TRANSFER SHAFT LOCKNUT,22 x 1.25 mm Left-hand rhreads, replace.

(D TAPERED ROLLER EEARING

@ TAPERED ROLLER EEARING OUTER RACE(} THRUST SHIM, 68 mm Selective part

@ O-RING Replace.

@ TRANSFER coVER A

(} TRANSFER COVER B

@ o-RING Replace.

(9 TRANSFER DRIVEN GEAR SHAFT (HYPOID GEAR)

@ THRUST SHIM, 35 mm Selective part

@ TAPERED ROLLER BEARING

@ TRANSFER SPACER Reptace.

@ TAPERED RoLLER BEARTNG OUTER RACE

@ TAPERED ROLLER BEARING OUTER RACE

@ TAPERED BOLLER BEARTNG

@ olL SEAL Replace.

@ COMPANION FLANGE

@ o-RING Replace.

@ BACK-UP RING

@ coNtcAL SPRtNG WASHER Reptace.

@ TRANSFER DRIVEN GEAR SHAFT LOCKNUT,22 x 1.25 mm Replace.

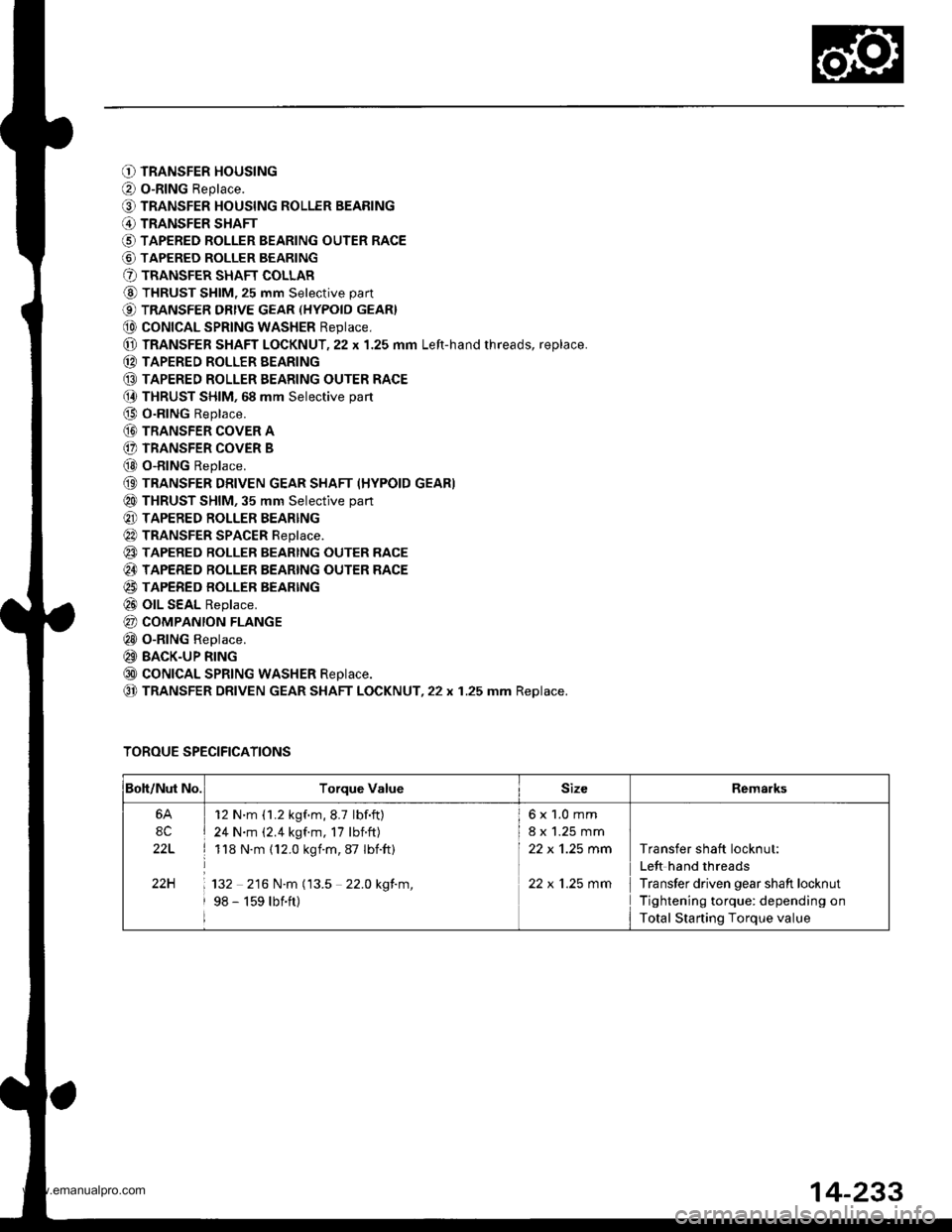

TOROUE SPECIFICATIONS

Boh/Nut No.Torque ValueSizeRemarks

6A

8C

22L

22H

12 N'm (1.2 kgf.m,8.7 lbf.ft)

24 N.m (2.4 kgf.m, 17 lbnft)

118 N.m (12.0 kgim,87 Ibift)

132 216 N.m (13.5 22.0 kgf.m,

98 - 159 lbift)

6x1.0mm

8 x 1.25 mm

22 x 'l.25 mm

22 x 1.25 mm

Transfer shaft locknut:

Left hand threads

Transfer driven gear shaft locknut

Tightening torque: depending on

Total Starting Torque value

14-233

www.emanualpro.com

Page 750 of 1395

Transfer Assembly

Inspection

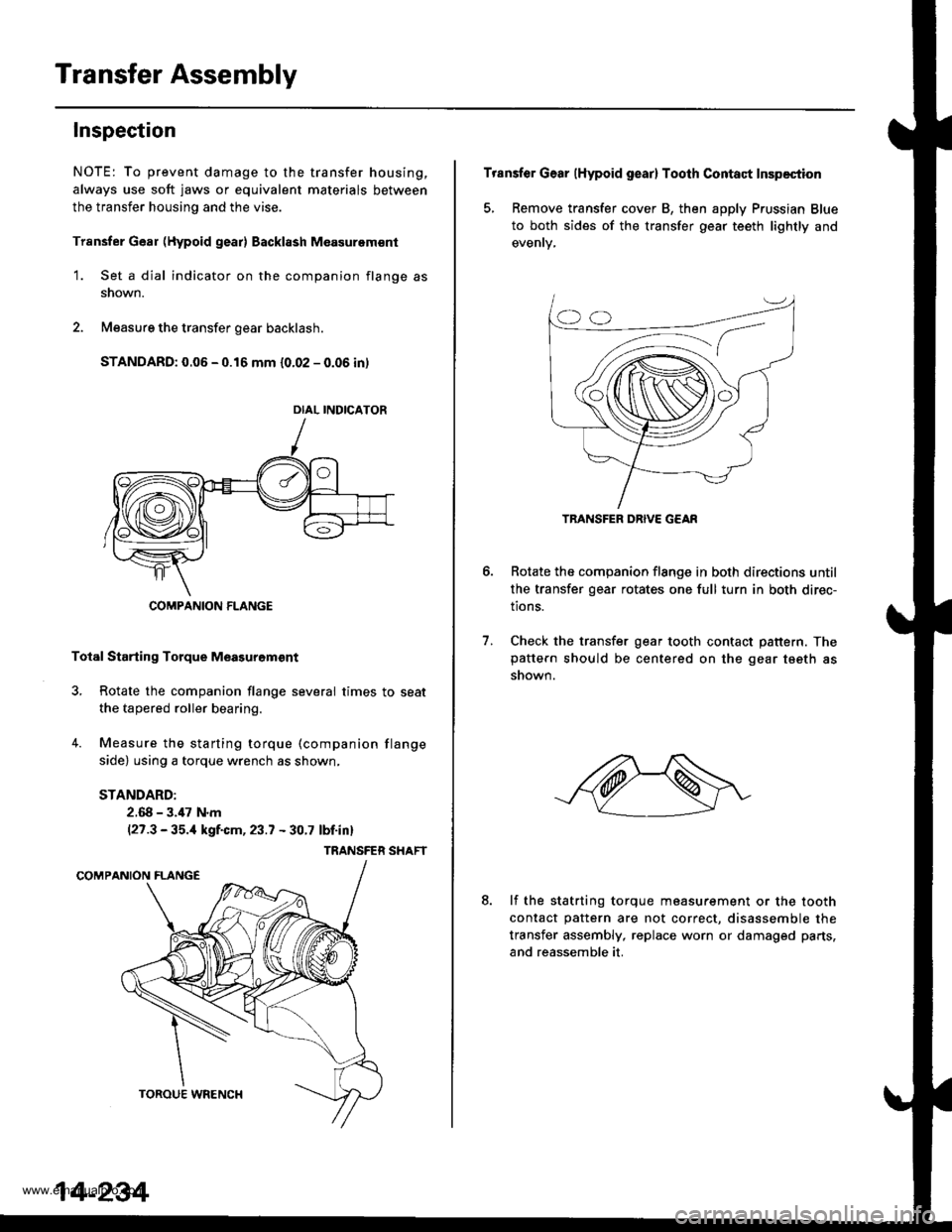

NOTE: To prevent damage to the transfer housing,

always use soft jaws or equivalent materials between

the transfer housing and the vise.

Trsnsfer Gear (Hypoid gear) Backl8sh M€asurem€nt

1. Set a dial indicator on the companion flange as

snown.

2. Measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm {0.02 - 0.06 in)

Total Starting Torque Meagurgm€nt

3, Rotate the companion flange several times to seat

the tapered roller bearing.

4. Measure the starting torque (companion flange

side) using a torque wrench as shown,

STANDARD:

2.68 - 3.,17 N.m(27.3 - 35.,1 kgf.cm, 23.7 - 30.7 lbf.inl

TRANSFER SHAFT

DIAL INDICATOR

COMPANION FLANGE

14-234

Transfer Gear (Hypoid gear) Tooth Contact Inspection

5, Remove transfer cover B, then apply Prussian Blue

to both sides of the transfer gear teeth lightly and

Rotate the companion flange in both directions until

the transfer gear rotates one full turn in both direc-

tions.

Check the transfer gear tooth contact pattern. Thepattern should be centered on the gear tseth as

snown.

6.

7.

8.lf the statrting torque measurement or the tooth

contact pattern are not correct, disassemble the

transfer assembly, replace worn or damaged parts,

and reassemble it.

TRANSFER DRIVE G€AR

www.emanualpro.com