lamp HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 278 of 1395

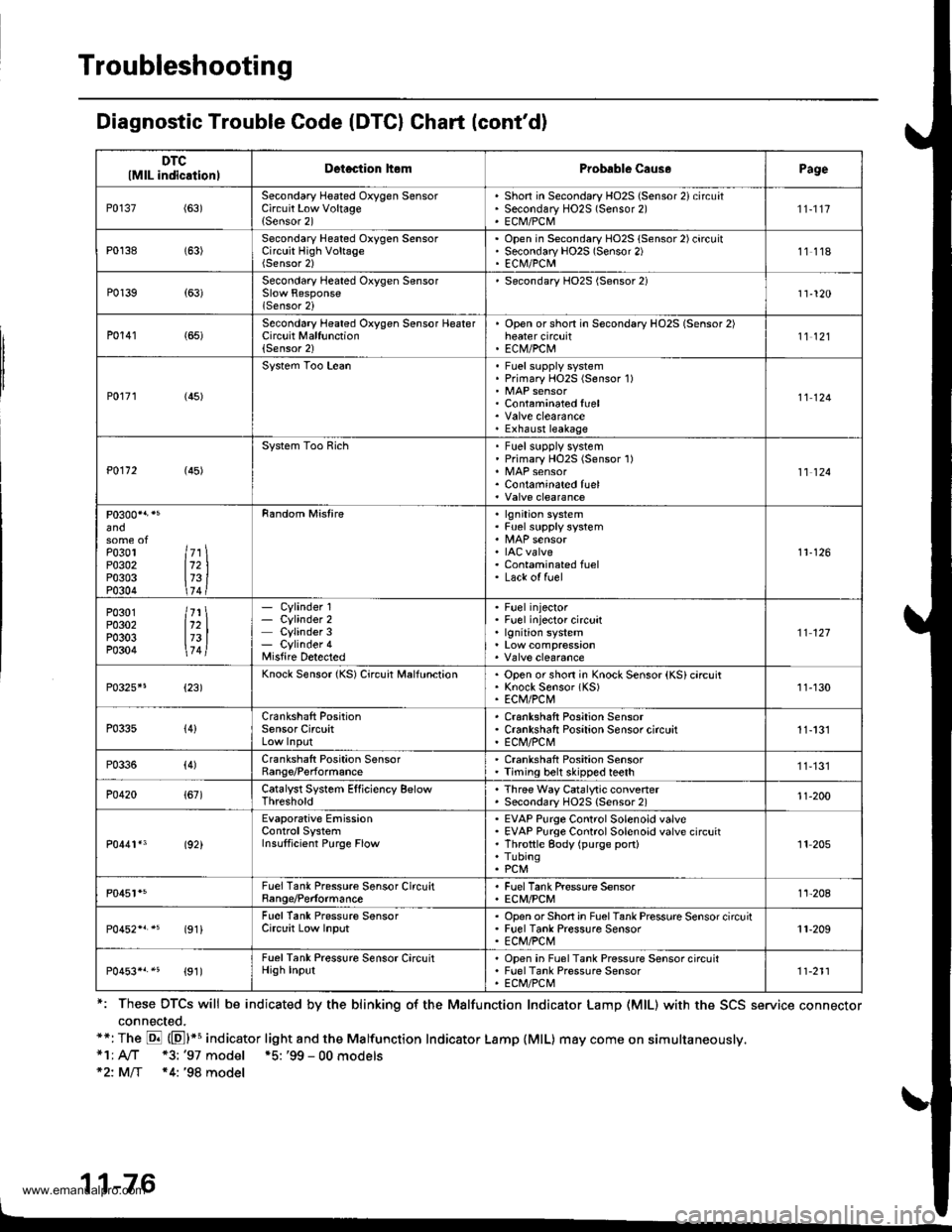

Troubleshooting

Diagnostic Trouble Code (DTCI Chart (cont'd)

*: These DTCS will be indicated by the blinking o{ the Malfunction Indicator Lamp (MlL) with the SCS service connector

connected.**: The E (El*s indicator light and the Malfunction Indicator Lamp {MlL) may come on simultaneously,*1; A/T *3: '97 model *5: '99 - 00 models*2: MlT *4: '98 model

11-76

DTClMlL indicationlDetection hemProbable Caus.Page

P0137(63)Secondary Heated Oxygen SensorCircuit Low Voltage{Sensor 2)

Shon in Secondary HO2S (Sensor 2) circuatSecondary HO2S (Sensor 2)ECM/PCM

'n-1t7

P0138 (63)Secondary Heated Oxygen SensorCircuit High VoltageOpen in Secondary HO2S (Sensor 2) circuitSecondary HO2S (Sensor 2)EC|\il/PCM11118

P0139{63)Secondary Heated Oxygen Sensor

lSensor 2i

Secondary HO2S (Sensor 2)11-120

P0141 (65)Second6ry Heated Oxygen Sensor HeaterCircuit Malfunction(Sensor 2)

Open orshon in Secondary HO2S (Sensor 2)heater circuitEC|V/PCtu11't2l

P0r71 (45)

System Too LeanFuel supply systemPrimary HOzS (Sensor 1)

Contaminated fuel

Exhaust leakage

11124

P0112 (45)

System Too RichFuel supplv systemPrimary HO2S (Sensor 1)

Contaminated fuel11 124

and

Po3ol ltr \P0302 112 |P0303 173 iP0304 \74 t

Random Mistirelgnition systemFuel supply system

IAC valveContaminated fuelLack of fuel

11-126

P0301 /71 \P0302 112 |P0303 173 |P0304 \7 4l

- Cylinder 1- Cylinder 2Cylinder 3- Cylinder 4Misfire Detected

Fuel injectorFuel injector circuitlgnition system't't 127

P0325*5{23)Knock Sensor {KS) Circuit MalfunctionOpen or shon in Knock Sensor (KS) circuitKnock Sensor (KS)ECM/PCt\411-130

P033s{4}Crankshaft PositionSensor CircuitCrankshaft Position SensorCrankshaft Positaon Sensor circuitE Cl\,l/PC l\,'!11-131

P0336(4)Crankshaft Position SensorRange/PerformanceCrankshaft Position SensorTiming belt skipped teeth11,131

P0420{67)Catalyst System Efficiency BelowThresholdThree Way Catalytic convenerSecondary HO2S {Sensor 2)'t1-200

P0441*3 (92)

Evaporative EmissionControlSystemInsulficient Purge Flow

EVAP Purge Control Solenoid valveEVAP Purge Control Solenoid valve circuitThrottle gody (purge port)TubingPCM

'It 205

P0451*5FuelTank Pressure Sensor CircuitBange/PerformanceFuel Tank Pressure SensorECM/PCMt't-208

(91iFuel Tank Pressure SensorCirclit Low InputOpsn orShort in FuelTank Pressure Sensor circuitFuel Tank Pressure SensorECM/PCt\411-209

P0453*r.5 {91)FuelTank Pressure Sensor CircuitHigh InputOpen in Fuel Tank Pressure Sensor circuitFuel Tank Pressure SensorECt /PCt\.111-211

www.emanualpro.com

Page 279 of 1395

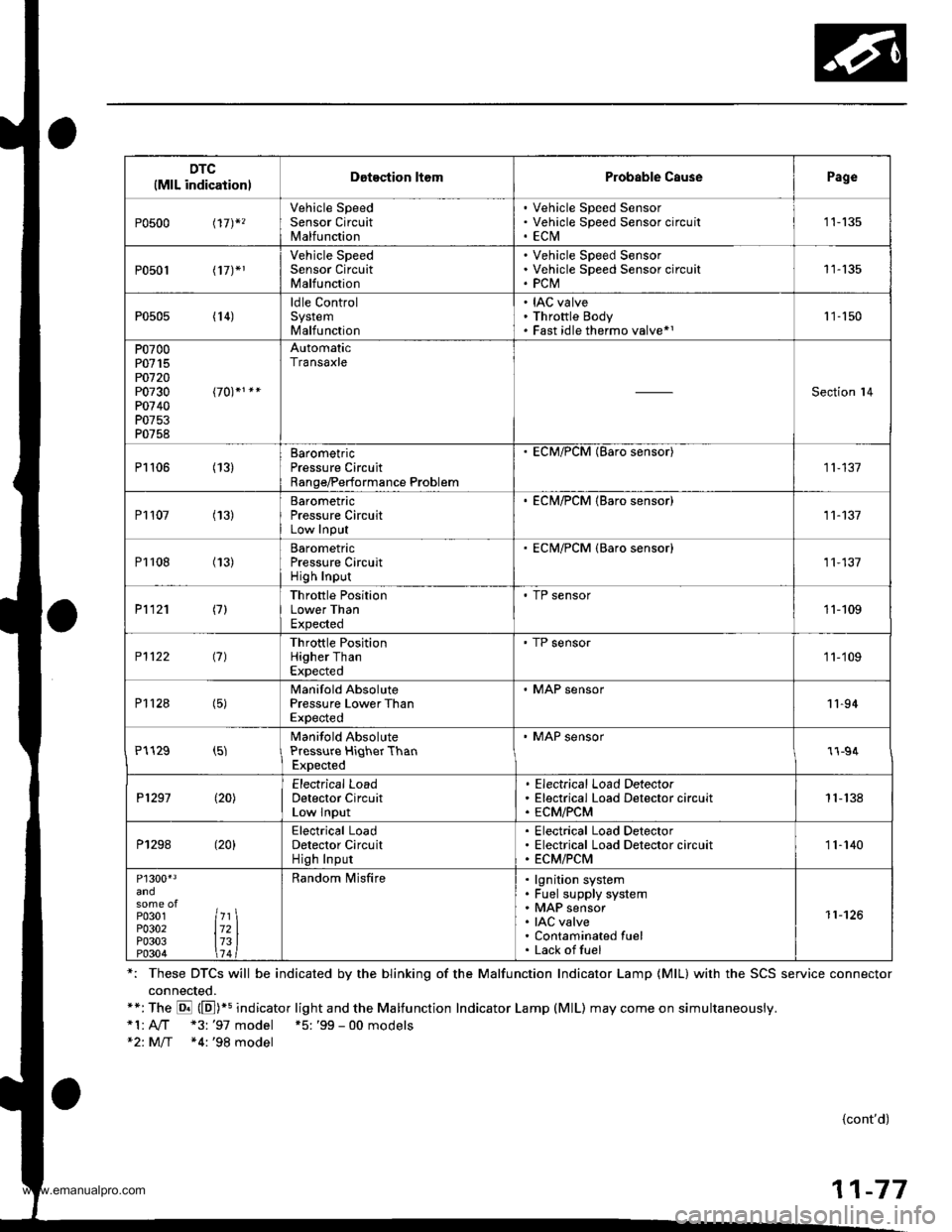

DTC(MlL indicationlDotection ltomProbable CausePage

P0500 t17)*,

Vehicle SpeedSensor CircuitMalfunction

Vehicle Speed SensorVehicle Speed Sensor circu itECtVI1 1-135

P0501 l17J*1

Vehicle SpeedSensor CircuitMalfunction

Vehicle Speed SensorVehicle Speed Sensor circuitPCM11-135

P0505 (14)ldle ControlSystemMalfunction

IAC valveThrottle BodyFast idle thermo valve*11 '�]- 150

P0700P0715PO720P0730P0740P0753P0758

AutomaticTransaxle

Section l4

P1106 (13)BarometricPressure CircuitRange/Performance Problem

ECM/PCM (Baro sensor)

11-137

P1107 (13)BarometricPressure CircuitLow InPut

. ECM/PCM {Baro sensor)11-137

P1108 (13)BarometricPressure CircuitHigh Inpur

ECM/PCM {Baro sensor)11,137

P1121 (7)Throttle PositionLower ThanExpected

. TP sensor11-109

P1122 (7)Throttle PositionHigher ThanExpected

' TP sensor1 1-'109

P112a (5)Manifold AbsolutePressure Lower ThanExpected

. MAP sensor11-94

P1129 (5)Manifold AbsolutePressure HiqherThanExpected

' MAP sensor1l-94

P1297 (20)Electrical LoadDetector CircuitLow Input

Electrical Load DetectorElectrical Load Detector circuitECM/PCM1 1- 138

P1298 (20)Electrical LoadDetector CircuitHigh Input

Electrical Load DetectorElectrical Load Detector circuitECM/PCM11-140

P1300'3

P0301P0302P0303P0304

7l721314

Random lvlisfirelgnition systemFuel supply systemMAP sensorIAC valveContaminated fuelLack offuel

11-126

*: These DTCS will be indicated by the blinking of the Malfunction Indicator Lamp {MlL} with the SCS service connector

connected.**:The E (E])+s indicator light and the Malfunction Indicator Lamp (MlL) may come on simultaneously.*1:A,./T "3: '97 model +5: '99 - 00 models*2: M/T *4:'98 model

{cont'd)

11-77

www.emanualpro.com

Page 280 of 1395

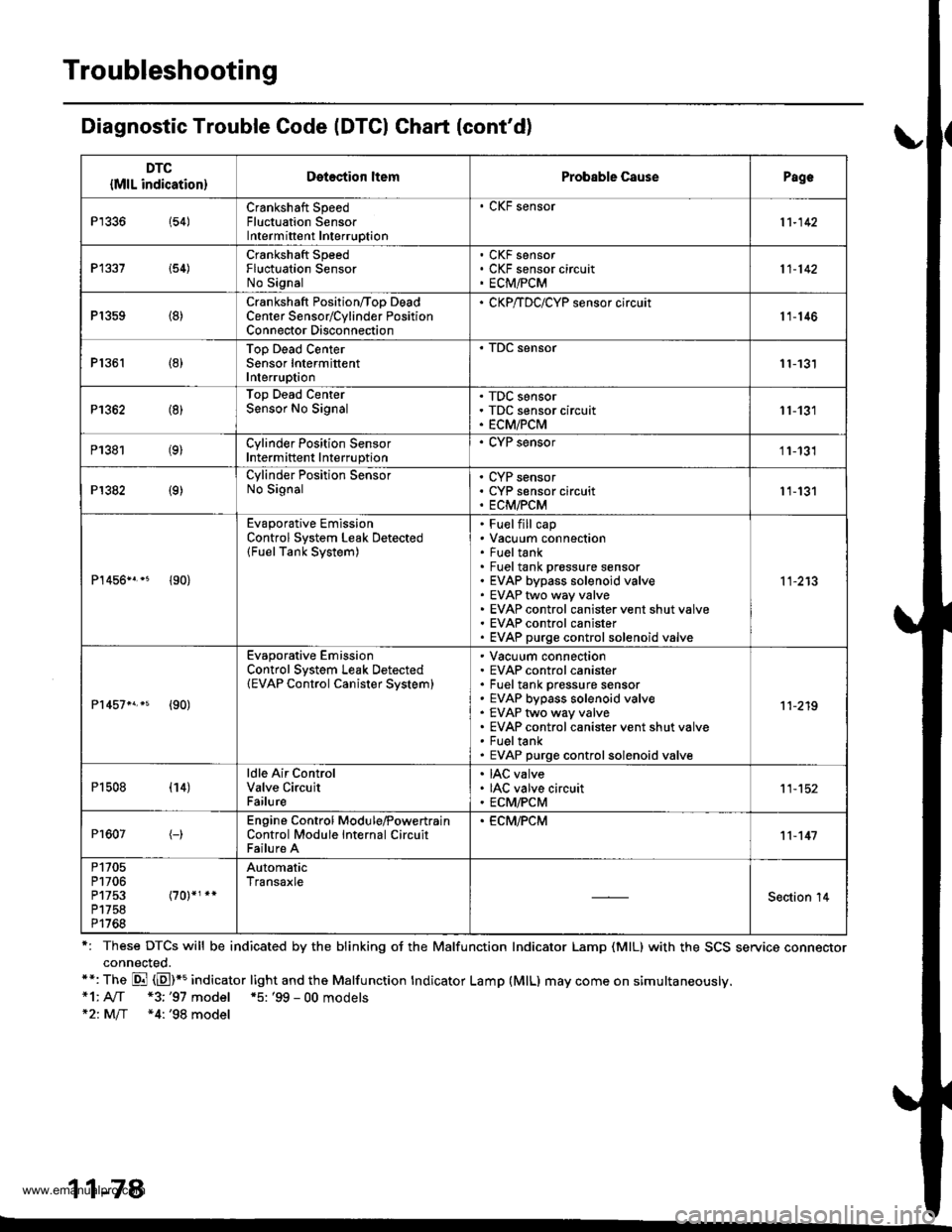

Troubleshooting

Diagnostic Trouble Code (DTCI Ghart (cont'd)

r: These DTCS will be indicated by the blinking oJ the Malfunction Indicator Lamp (MlL) with the SCS service connectorconnected.**: The Di (E)*5 indicator light and the Malfunction tndicator Lamp (MlL) may come on simultaneously.*1: A[f *3;'97 model *5: '99 - 00 models*21M/f *4: '98 model

11-78

DTC

{MlL indication}Detection ltemProbable CausePagc

P1336 154)Crankshaft SpeedFluctuation SensorIntermittent Interruption

. CKF sensor

11-142

P1337 i54)Crankshaft SpeedFluctuation SensorNo Signal

CKF sensorCKF sensor circuitECM,FCM11-142

P1359 (8)Crankshaft Position/Too DeadCenter Sensorrcylinder PositionConnector Disconnection

' CKP/TDC/CYP sensor circuit11-146

P1361 (8)Top Dead CenterSensor IntermittentInterruption11-131

P1362 (8)Top Dead CenterSensor No SignalTDC sensorTDC sensor circuitECM/PCM11-131

P1381 (9)Cylinder Position SensorIntermittent Interruption

. CYP sensor11-131

P1382 (9)Cylinder Position SensorNo SignalCYP sensorCYP sensor circuitECM/PCM11-131

P1456n.* {90}

Evaporative EmissionControl System Leak Detected(FuelTank System)

Fuelfill capVacuum connectionFueltankFuel tank prossure sensorEVAP bypass solenoid valveEVAP two way valveEVAP control canister vent shut valveEVAP control canisterEVAP purge controlsolenoid valve

11-213

Pr457n.s {90)

Evaporative EmissionControl System Leak Detected(EVAP Control Canister Svstem)

Vacuum connectionEVAP control canisterFuel tank pressure sensorEVAP bypass solenoid valveEVAP two way valveEVAP control canister vent shut valveFueltankEVAP purge controlsolenoid valve

11-219

P1508 (14)ldle Air ControlValve CircuitFailure

IAC valveIAC valve circuitECM/PCM11-152

Pr607(-)Engine Control Module,PowertrainControl Module Internal CircuitFailure A

. ECM,FCM11-147

P1705P1706P1753P1758P1768

AutomaticTransaxle

Section '14

www.emanualpro.com

Page 281 of 1395

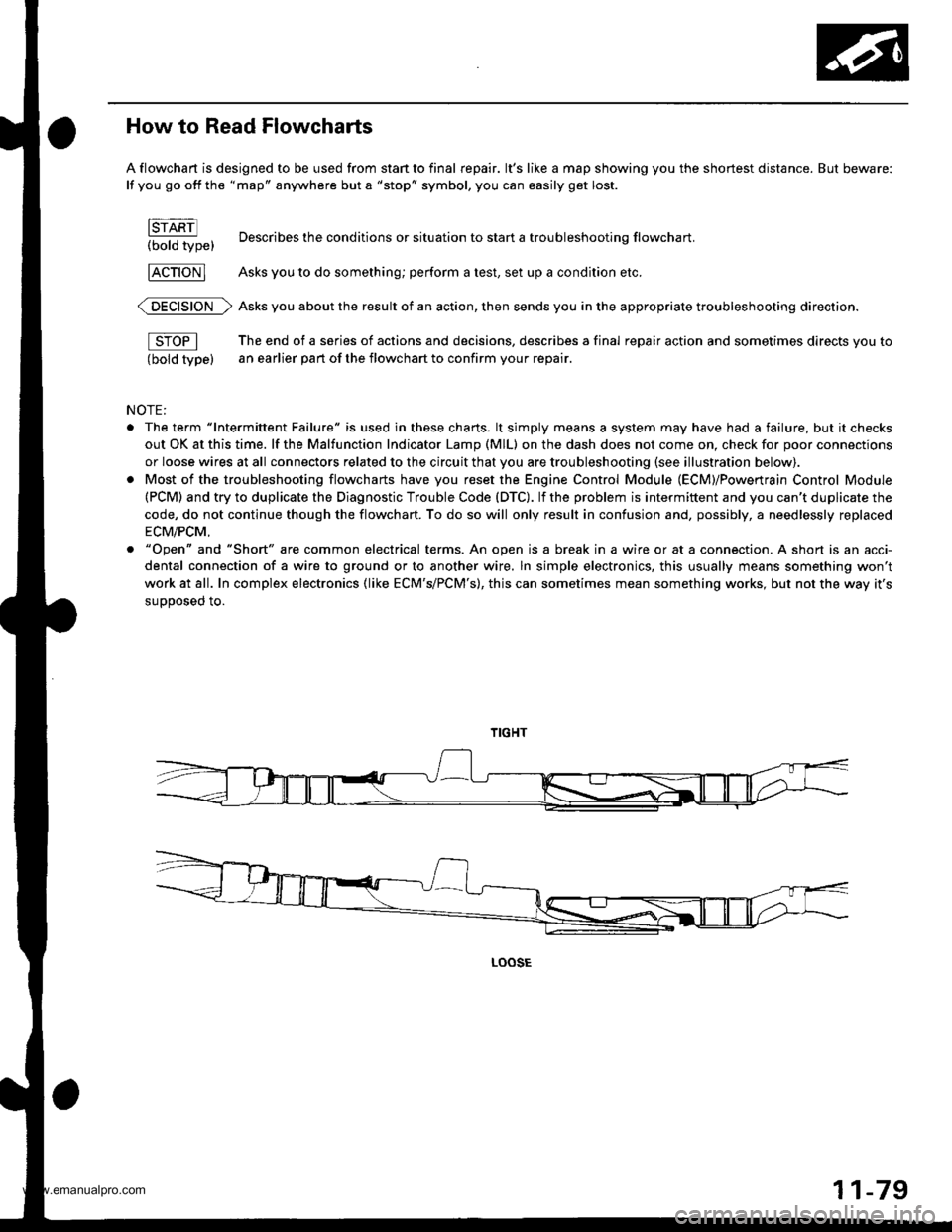

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. lt's like a map showing you the shortest distance. But beware:

lf you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

brARn

t.-OotO tw"t Describes the conditions or situation to start a troubleshooting flowchart.

FcTloNl Asks you to do something; perform a test, set up a condition etc.

@ Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

fS-OPl The end of a series of actions and decisions, describes a final repair action and sometimes directs you to

(bold type) an earlier part of the flowchart to confirm your repair.

NOTE:

. The term "lntermittent Failure" is used in these charts. lt simply means a system may have had a failure, but it checks

out OK at this time. lf the Malfunction Indicator Lamp (MlL) on the dash does not come on, check for poor connections

or loose wires at all connectors related to the circuit that you are troubleshooting (see illustration below).

. Most of the troubleshooting flowcharts have you reset the Engine Control Module (EcM)/Powertrain Control Module(PCM) and try to duplicate the Diagnostic Trouble Code (DTC). lf the problem is intermittent and you can't duplicate the

code, do not continue though the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced

ECM/PCM,

o "Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an acci-

dental connection of a wire to ground or to another wire. ln simple electronics, this usually means something won't

work at all. In complex electronics (like ECM'S/PCM'S), this can sometimes mean something works, but not the way it's

suooosed to.

LOOSE

11-79

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 375 of 1395

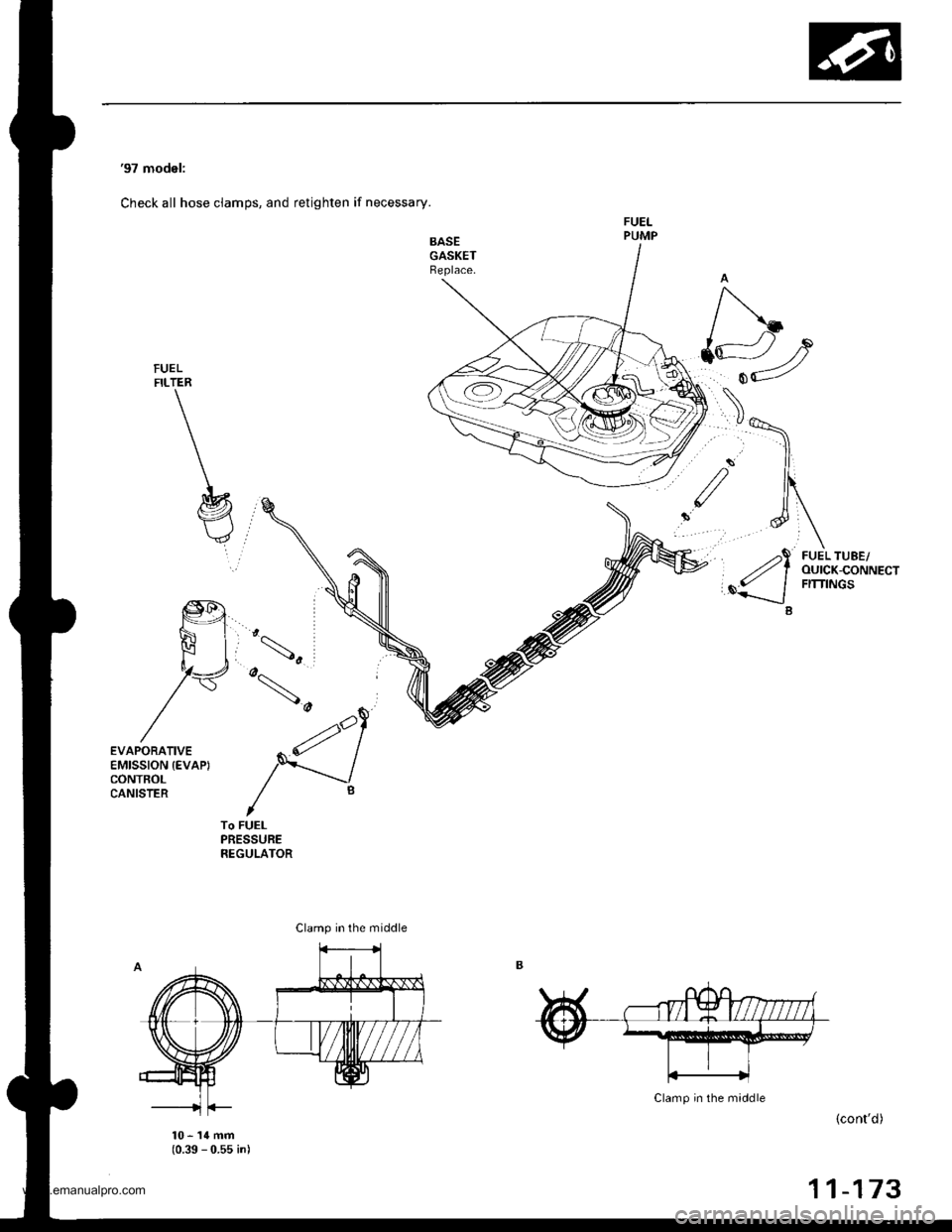

'97 model:

Check all hose clamps, and retighten if necessary.

FUELFILTER

/\

{"2

,"1<,, I___--tJ

B

FUEL TUBE/OUICK-CONNECTFITTINGS

EVAPORATIVEEMISSION {EVAP}CONTBOLCANISTER

'^s

,4\-') |Ift q'l I

/'------/

/B,To FUELPRESSUREREGULATOR

10-14mm(0.39 - 0.55 inl

(cont'd)

11-173

Clamp in the middle

www.emanualpro.com

Page 376 of 1395

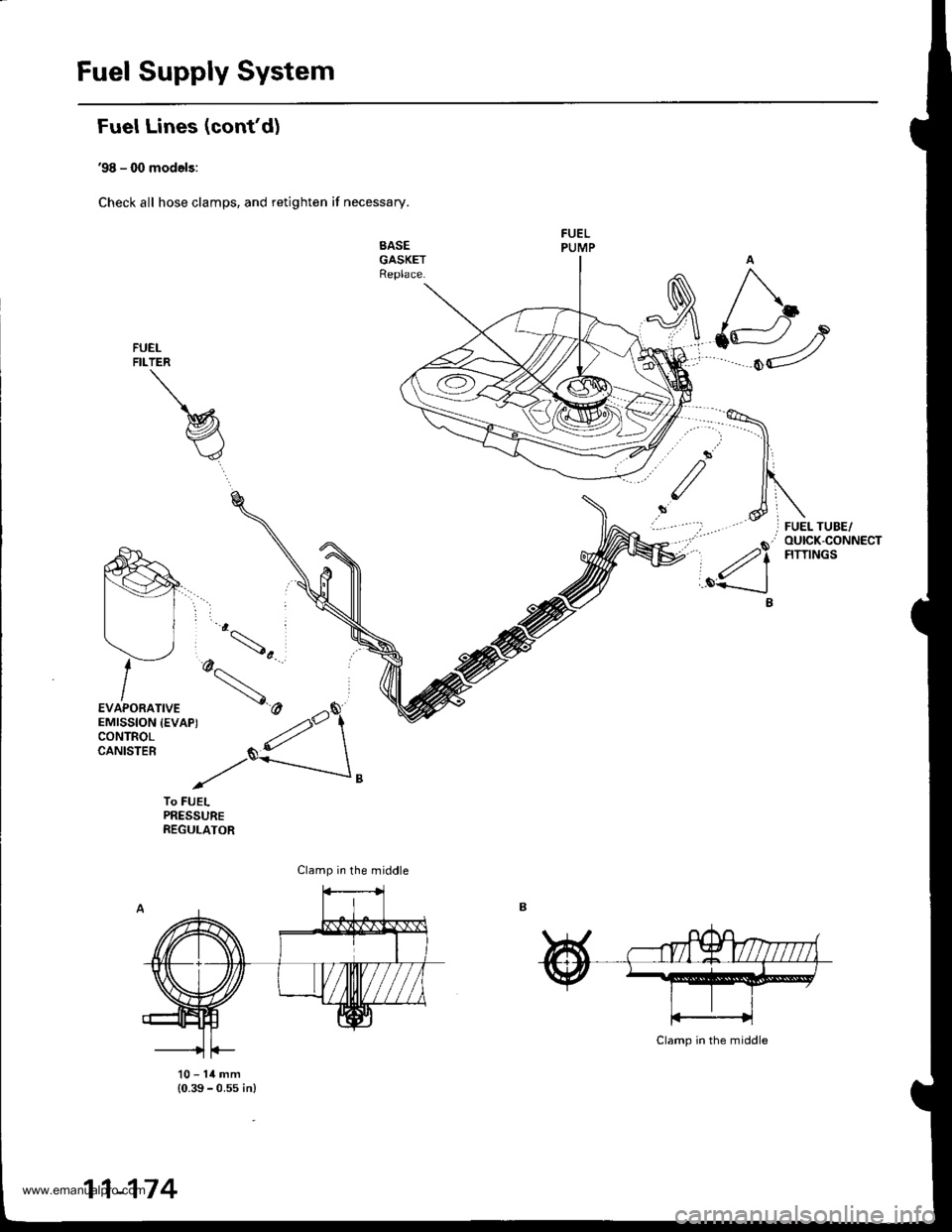

Fuel Supply System

Fuel Lines (confd)

'98 - (X) models:

Check all hose clamps, and retighten if necessary.

SASEGASKETReplace.

FUELFILTER

To FUELPRESSUREREGULATOR

10-14mm(0.39 - 0.ss in)

Clamp in the middle

11-174

www.emanualpro.com

Page 383 of 1395

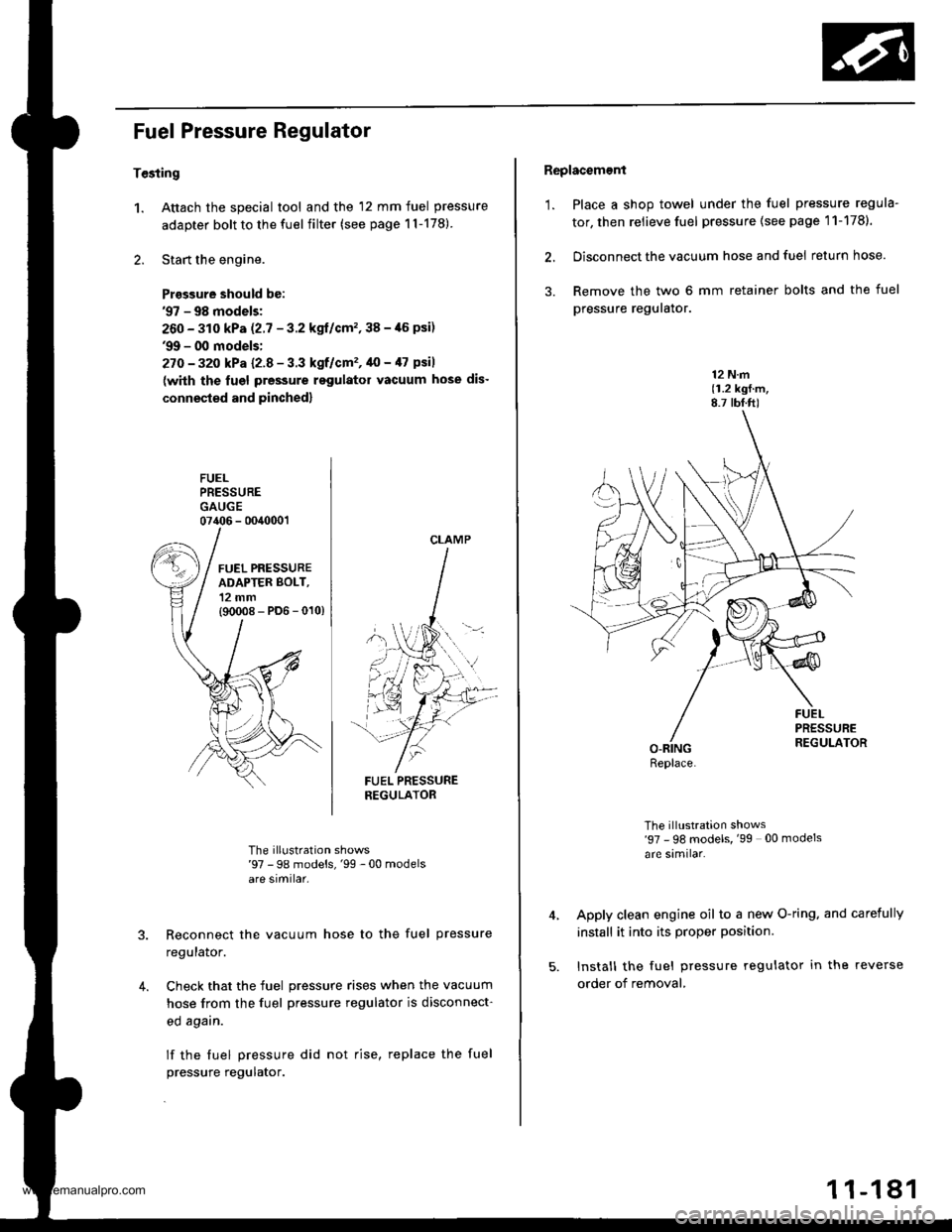

Fuel Pressure Regulator

Tesiing

1. Attach the special tool and the 12 mm fuel pressure

adapter bolt to the fuel filter (see page 1l-178)

2. Start the engine.

Prasgure should be:'97 - 98 models;

260 - 310 kPa (2.7 - 3.2 kgl/cm'�,38 -,16 psi)'9!t - 00 models:

27O - 32o kPa l2-8 - 3.3 kgf/cm'�, 40 - /l7 psil

(with the lugl pressure rsgulator vacuum hose dis-

connested and pinched)

FUELPRESSUREGAUGE07406 - 0040001

FUEL PRESSURENEGULATOR

The illustration shows'97 - 98 models,'99 -00 modelsare similar.

Reconnect the vacuum hose to the fuel pressure

regulalor.

Check that the fuel pressure rises when the vacuum

hose from the fuel pressure regulator is disconnect-

ed agarn.

lf the fuel pressure did not rise, replace the fuel

pressure regulator.

4.

CLAMP

Replacement

'1. Place a shop towel under the fuel pressure regula-

tor, then relieve fuel pressure (see page 11-1781.

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts and the fuel

pressure reguralor.

12 N.m(1.2 kgf.m,8.7 tbf.ft)

The illustration shows'97 - 98 models, '99 00 models

are similar.

Apply clean engine oil to a new O-ring. and carefully

install it into its proper position.

Install the fuel pressure regulator in the reverse

order of removal,

Replace.

1 1-181

www.emanualpro.com

Page 384 of 1395

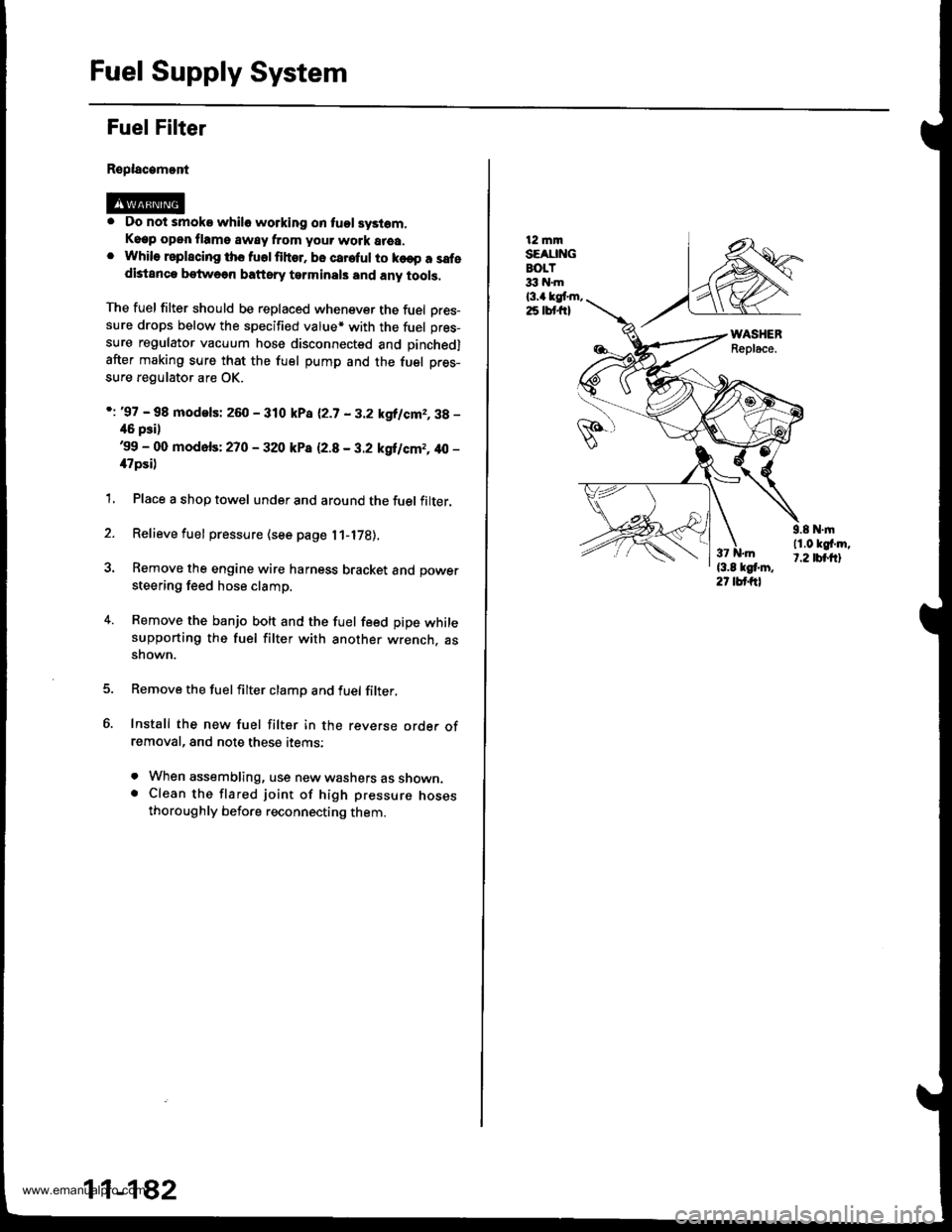

Fuel Supply System

Fuel Filter

Replacamont

. Do not smoke whilo working on tuol syslom,Keep open flame away from your work area.. While rsplscing ths fuolfihor. bo careful to ko€p a safedistanca betweon baftsry tarminals and any tools,

The fuel filter should be replaced whenever the fuel Dres-sure drops below the specified value* with the fuel pres-

sure regulator vacuum hose disconnected and pinchedl

after making sure that the fuel pump and the fuel pres-

sure regulator are OK.

i: '97 - 98 modelsi 260 - 310 kPa 12.7 - 3.2 kgllcm2,3g -

46 psil'99 - 00 mod6fs: 270 - 320 kP8 12.8 - 3.2 kgilcm2, 40 -

il7psi)

1, Place a shop towel under and around the fuel filter.

2. Relieve fuel pressure (see page l1-l7B).

3. Remove the engine wire harness bracket and power

steering feed hose clamp.

4. Remove the banjo bolt and the fuel feed pipe whilesupporting the fuel filter with another wrench. assnown.

Remove the fuelfilter clamp and fuel filter,

Install the new fuel filter in the reverse orde. ofremoval, and note these items:

. When assembling, use new washers as shown.. Clean the flared joint of high pressure nosesthoroughly before reconnecting them.

11-182

12 mmSEAUNGBOLT33 hl.m

l3.a kgt m,25 lbt frl

9.8 N.|n11.0 kgf'm,t.2 tbt.ftl

www.emanualpro.com

Page 393 of 1395

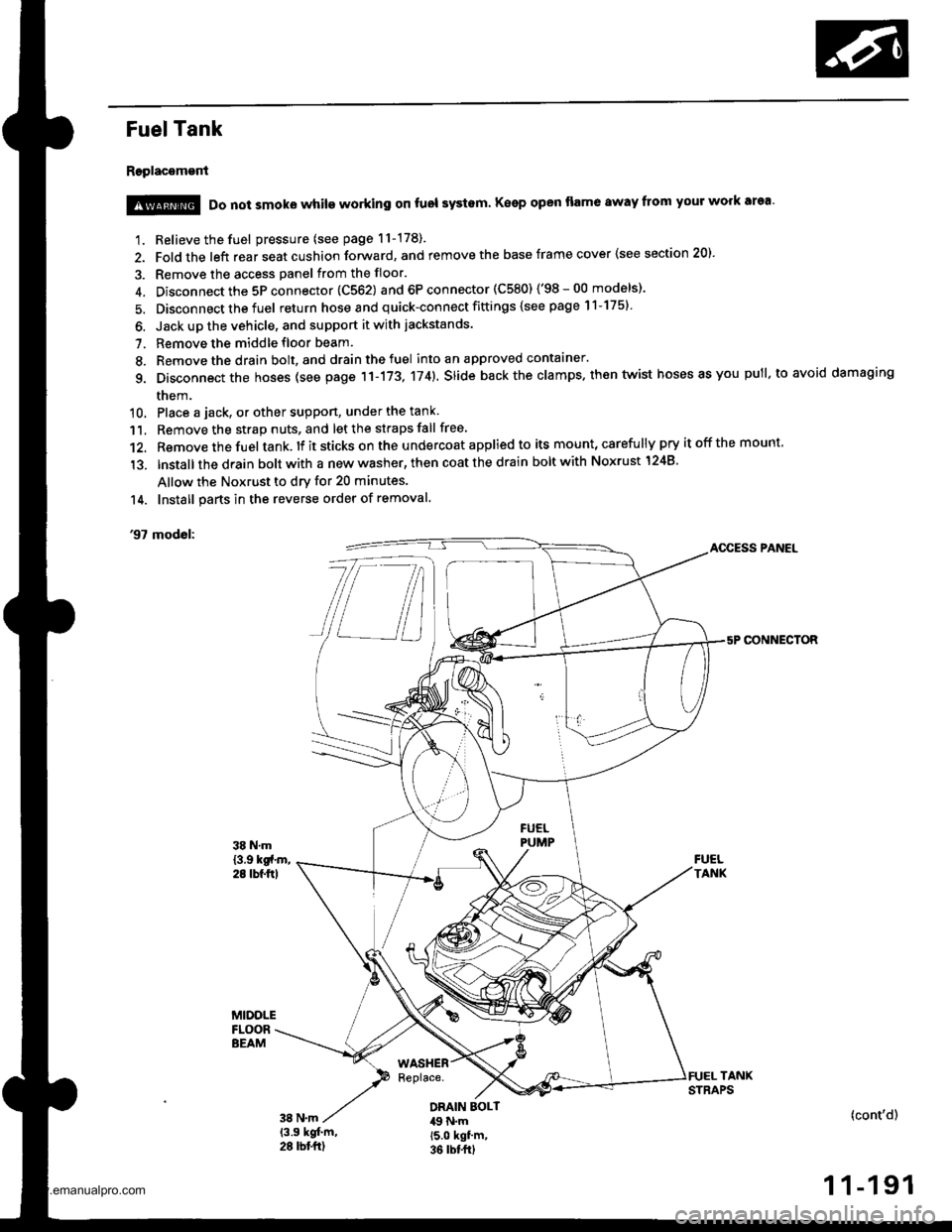

Fuel Tank

Replacement

1. Relieve the fuel pressure (see page 11-178).

2. Fold the left rear seat cushion forward, and remove the base frame cover {see section 20).

3. Remove the access panel from the floor.

4. Disconnect the 5P connector 1C562) and 6P connector (C580) ('98-00 models)'

5. Disconnect the fuel return hose and quick-connect fittings {see page 11-175}

6. Jack up the vehicle, and support it with jackstands.

7. Remove the middle floor beam.

8. Remove the drain bolt, and drain the fuel into an approved contaaner.

g. Disconnect the hoses (see page 11-173, 174). slide back the clamps. then twist hoses as you pull, to avoid damaging

them.

10. Place a jack, or other suppon, under the tank

11. Remove the strap nuts, and let the straps fall free

12. Remove the fuel tank. lf it sticks on the u ndercoat applied to its mount, carefu lly pry it off the mount,

'13. lnstallthe drain bolt with a new washer, then coat the drain bolt with Noxrust 1248'

Allow the Noxrust to dry for 20 minutes.

14. Install parts in the reverse order of removal.

'97 modol:AOCESS PANEL

CONNECTOR

@ Do not smoke while working on fuol systam Keep open flame away from your work area'

DRAIN EOLT49 N.m15.0 kgf'm,36 rbt frl

(cont'd)

1 1-191

www.emanualpro.com